ISO 23555-2:2022

(Main)Gas pressure safety and control devices for use in gas transmission, distribution and installations for inlet pressures up to and including 10 MPa — Part 2: Gas pressure regulator

Gas pressure safety and control devices for use in gas transmission, distribution and installations for inlet pressures up to and including 10 MPa — Part 2: Gas pressure regulator

This document specifies safety, constructional, performance, testing and documentation requirements for gas pressure regulators for use in gas transmission and distribution installations (hereafter referred to as regulators). This document is applicable to regulators with operating pressures greater than 500 kPa and up to and including 10 MPa (100 bar) and nominal diameters up to DN 400 for use with fuel gases as natural gas, manufactured gas, biomethane or liquefied petroleum gas (LPG). This document is applicable to: — test methods which are intended for product type test, routine tests and product surveillance tests; — regulators which use the pipeline gas as a source of control energy unassisted by any external power source; — regulators integrating on the same body a second regulator, used as monitor, complying with the requirements in this document; — regulators integrating a safety shut off device (SSD) according to ISO 23555-3; — regulators incorporating a creep (venting) relief device and/or a vent limiter complying with the requirements in this document. This document does not apply to: — regulators upstream from/on/in domestic gas‑consuming appliances which are installed downstream of domestic gas meters; — regulators designed to be incorporated into pressure control systems used in service lines (pipework from the main pipework in a gas infrastructure to the point of delivery of the gas) with declared volumetric flow rate ≤ 200 m3/h at normal conditions and declared inlet pressure ≤ 500 kPa (5 bar); — industrial process control valves, such as IEC 60534 (all parts); — regulators used in aggressive/sour gas environments (gas environments containing water and H2S are considered sour) or severely corrosive conditions; — regulators in service conditions with renewables (e.g. H2NG with hydrogen more than 10 %) and/or waste gases (e.g. biogas etc.), if additional information is not provided (e. g. contaminant, liquid, etc.).

Titre manque — Partie 2: Titre manque

General Information

- Status

- Published

- Publication Date

- 10-Jan-2022

- Technical Committee

- ISO/TC 161 - Controls and protective devices for gas and/or oil

- Drafting Committee

- ISO/TC 161/WG 5 - High pressure controls

- Current Stage

- 6060 - International Standard published

- Start Date

- 11-Jan-2022

- Due Date

- 04-Nov-2020

- Completion Date

- 11-Jan-2022

Relations

- Effective Date

- 09-Feb-2026

Overview - ISO 23555-2:2022 (Gas pressure regulator)

ISO 23555-2:2022 defines safety, constructional, performance, testing and documentation requirements for gas pressure regulators used in gas transmission and distribution systems. It applies to regulators with inlet pressures > 500 kPa and up to 10 MPa (100 bar) and nominal diameters up to DN 400, intended for fuel gases such as natural gas, manufactured gas, biomethane and LPG. The standard covers product type tests, routine and surveillance tests, and regulators that use pipeline gas as control energy (no external power). It also applies to devices integrating a monitor regulator, a safety shut‑off device (SSD) per ISO 23555‑3, and creep (venting) relief devices and vent limiters.

Key topics and technical requirements

- Scope & limits: Operating pressure and size limits, permitted gas types, and explicit exclusions (see below).

- Design and materials: Requirements for metallic and elastomeric parts, diaphragms, welding and strength of pressure-containing parts.

- Performance & testing: Test rig requirements, type/routine/surveillance tests, shell strength, internal/external tightness, antistatic characteristics, sound emission, control classification, fail‑safe behaviour (fail‑open / fail‑close).

- Functional features: Requirements for monitor regulators, integrated SSDs, creep (token) relief devices and high‑pressure vent limiters.

- Documentation & marking: Type test and batch documentation, routine test records, marking and packaging requirements.

- Annexes: Normative and informative annexes provide materials lists, elastomer guidance, vent limiter and creep device definitions, compliance evaluation, inspection certificate and test templates, dynamic force calculations and order specification guidance.

Important exclusions noted by the standard:

- Regulators for domestic appliances downstream of domestic meters.

- Service‑line regulators with declared flow ≤ 200 m3/h and inlet ≤ 500 kPa.

- Industrial process control valves (referenced IEC 60534).

- Use in aggressive/sour gas or severely corrosive environments, and in renewable/waste gas mixes with H2 >10% unless additional data is provided.

Applications - who uses ISO 23555-2

- Manufacturers of gas pressure regulators for high‑pressure transmission and distribution networks.

- Gas network operators / utilities specifying compliant equipment for mains and transmission.

- Testing and certification bodies carrying out type, routine and surveillance tests.

- System designers, procurement and maintenance teams ensuring safe selection, installation and documentation of regulators.

- Supports compliance, safety assurance, product specification and interoperability for high‑pressure gas infrastructure.

Related standards

- ISO 23555 series (other parts, e.g., ISO 23555‑3 for SSD integration).

- IEC 60534 (industrial process control valves) - explicitly excluded from ISO 23555‑2 scope.

Keywords: ISO 23555-2:2022, gas pressure regulator, gas transmission and distribution, 10 MPa, safety testing, vent limiter, creep relief, monitor regulator.

Buy Documents

ISO 23555-2:2022 - Gas pressure safety and control devices for use in gas transmission, distribution and installations for inlet pressures up to and including 10 MPa — Part 2: Gas pressure regulator Released:1/11/2022

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

ISO 23555-2:2022 is a standard published by the International Organization for Standardization (ISO). Its full title is "Gas pressure safety and control devices for use in gas transmission, distribution and installations for inlet pressures up to and including 10 MPa — Part 2: Gas pressure regulator". This standard covers: This document specifies safety, constructional, performance, testing and documentation requirements for gas pressure regulators for use in gas transmission and distribution installations (hereafter referred to as regulators). This document is applicable to regulators with operating pressures greater than 500 kPa and up to and including 10 MPa (100 bar) and nominal diameters up to DN 400 for use with fuel gases as natural gas, manufactured gas, biomethane or liquefied petroleum gas (LPG). This document is applicable to: — test methods which are intended for product type test, routine tests and product surveillance tests; — regulators which use the pipeline gas as a source of control energy unassisted by any external power source; — regulators integrating on the same body a second regulator, used as monitor, complying with the requirements in this document; — regulators integrating a safety shut off device (SSD) according to ISO 23555-3; — regulators incorporating a creep (venting) relief device and/or a vent limiter complying with the requirements in this document. This document does not apply to: — regulators upstream from/on/in domestic gas‑consuming appliances which are installed downstream of domestic gas meters; — regulators designed to be incorporated into pressure control systems used in service lines (pipework from the main pipework in a gas infrastructure to the point of delivery of the gas) with declared volumetric flow rate ≤ 200 m3/h at normal conditions and declared inlet pressure ≤ 500 kPa (5 bar); — industrial process control valves, such as IEC 60534 (all parts); — regulators used in aggressive/sour gas environments (gas environments containing water and H2S are considered sour) or severely corrosive conditions; — regulators in service conditions with renewables (e.g. H2NG with hydrogen more than 10 %) and/or waste gases (e.g. biogas etc.), if additional information is not provided (e. g. contaminant, liquid, etc.).

This document specifies safety, constructional, performance, testing and documentation requirements for gas pressure regulators for use in gas transmission and distribution installations (hereafter referred to as regulators). This document is applicable to regulators with operating pressures greater than 500 kPa and up to and including 10 MPa (100 bar) and nominal diameters up to DN 400 for use with fuel gases as natural gas, manufactured gas, biomethane or liquefied petroleum gas (LPG). This document is applicable to: — test methods which are intended for product type test, routine tests and product surveillance tests; — regulators which use the pipeline gas as a source of control energy unassisted by any external power source; — regulators integrating on the same body a second regulator, used as monitor, complying with the requirements in this document; — regulators integrating a safety shut off device (SSD) according to ISO 23555-3; — regulators incorporating a creep (venting) relief device and/or a vent limiter complying with the requirements in this document. This document does not apply to: — regulators upstream from/on/in domestic gas‑consuming appliances which are installed downstream of domestic gas meters; — regulators designed to be incorporated into pressure control systems used in service lines (pipework from the main pipework in a gas infrastructure to the point of delivery of the gas) with declared volumetric flow rate ≤ 200 m3/h at normal conditions and declared inlet pressure ≤ 500 kPa (5 bar); — industrial process control valves, such as IEC 60534 (all parts); — regulators used in aggressive/sour gas environments (gas environments containing water and H2S are considered sour) or severely corrosive conditions; — regulators in service conditions with renewables (e.g. H2NG with hydrogen more than 10 %) and/or waste gases (e.g. biogas etc.), if additional information is not provided (e. g. contaminant, liquid, etc.).

ISO 23555-2:2022 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators; 27.060.20 - Gas fuel burners; 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 23555-2:2022 has the following relationships with other standards: It is inter standard links to EN ISO 13577-2:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 23555-2:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23555-2

First edition

2022-01

Gas pressure safety and control

devices for use in gas transmission,

distribution and installations for

inlet pressures up to and including 10

MPa —

Part 2:

Gas pressure regulator

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

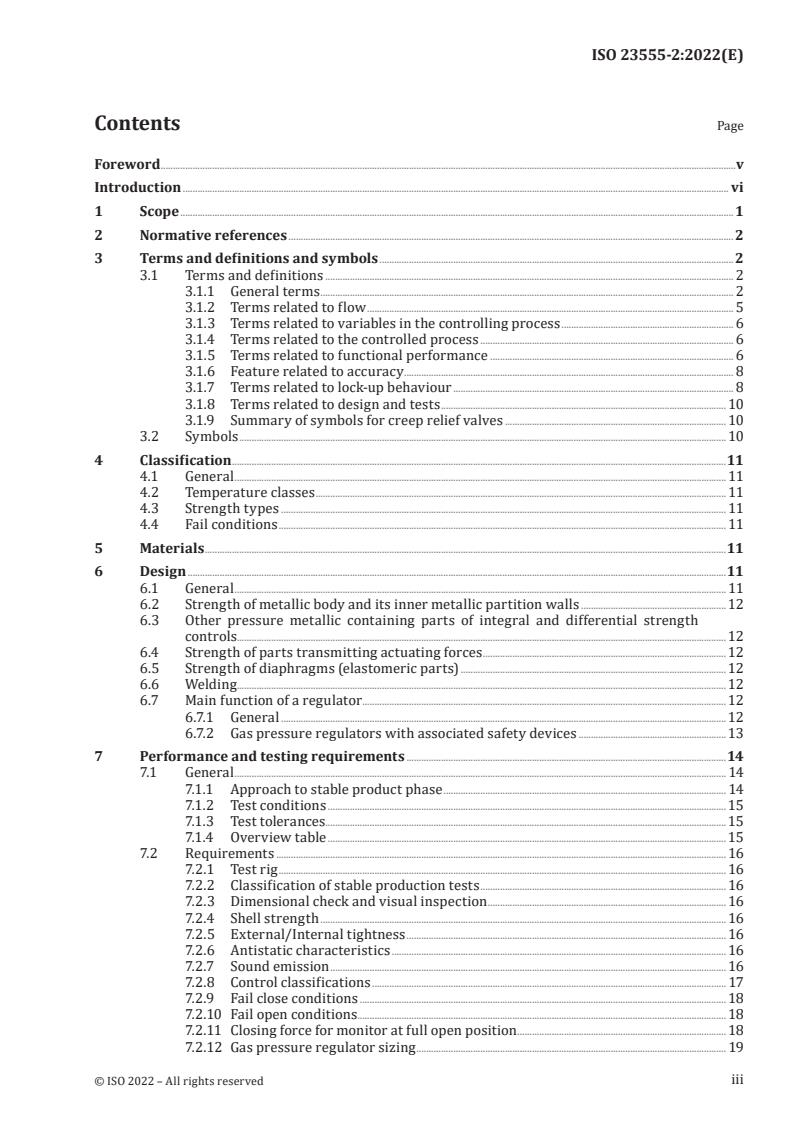

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions and symbols .2

3.1 Terms and definitions . 2

3.1.1 General terms . 2

3.1.2 Terms related to flow . 5

3.1.3 Terms related to variables in the controlling process . 6

3.1.4 Terms related to the controlled process . 6

3.1.5 Terms related to functional performance . 6

3.1.6 Feature related to accuracy . 8

3.1.7 Terms related to lock-up behaviour . 8

3.1.8 Terms related to design and tests . 10

3.1.9 Summary of symbols for creep relief valves . 10

3.2 Symbols . 10

4 Classification .11

4.1 General . 11

4.2 Temperature classes . 11

4.3 Strength types . 11

4.4 Fail conditions . 11

5 Materials .11

6 Design .11

6.1 General . 11

6.2 Strength of metallic body and its inner metallic partition walls .12

6.3 Other pressure metallic containing parts of integral and differential strength

controls.12

6.4 Strength of parts transmitting actuating forces .12

6.5 Strength of diaphragms (elastomeric parts) .12

6.6 Welding . .12

6.7 Main function of a regulator . 12

6.7.1 General .12

6.7.2 Gas pressure regulators with associated safety devices .13

7 Performance and testing requirements .14

7.1 General . 14

7.1.1 Approach to stable product phase . 14

7.1.2 Test conditions . 15

7.1.3 Test tolerances . . .15

7.1.4 Overview table . 15

7.2 Requirements . 16

7.2.1 Test rig . 16

7.2.2 Classification of stable production tests . 16

7.2.3 Dimensional check and visual inspection . 16

7.2.4 Shell strength . 16

7.2.5 External/Internal tightness . 16

7.2.6 Antistatic characteristics . 16

7.2.7 Sound emission . 16

7.2.8 Control classifications . 17

7.2.9 Fail close conditions . 18

7.2.10 Fail open conditions. 18

7.2.11 Closing force for monitor at full open position . 18

7.2.12 Gas pressure regulator sizing . 19

iii

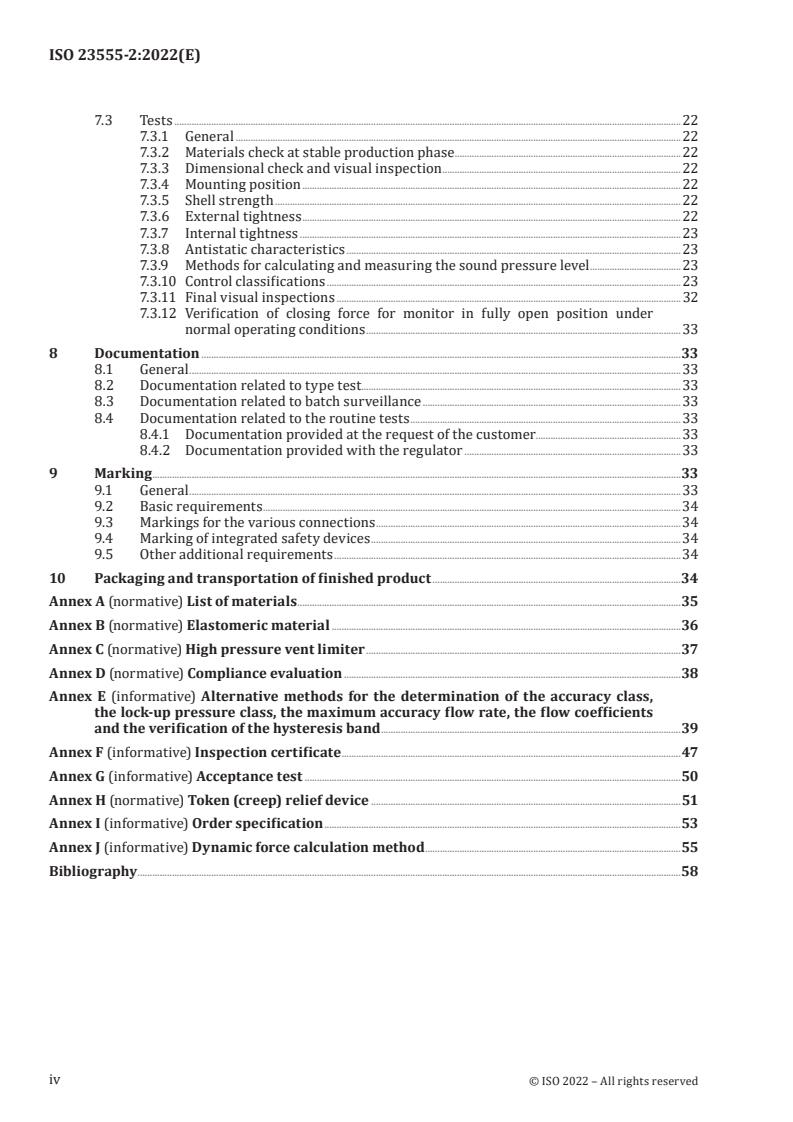

7.3 Tests .22

7.3.1 General .22

7.3.2 Materials check at stable production phase. 22

7.3.3 Dimensional check and visual inspection . 22

7.3.4 Mounting position . 22

7.3.5 Shell strength . 22

7.3.6 External tightness . 22

7.3.7 Internal tightness .23

7.3.8 Antistatic characteristics . 23

7.3.9 Methods for calculating and measuring the sound pressure level .23

7.3.10 Control classifications .23

7.3.11 Final visual inspections . 32

7.3.12 Verification of closing force for monitor in fully open position under

normal operating conditions . 33

8 Documentation .33

8.1 General . 33

8.2 Documentation related to type test. 33

8.3 Documentation related to batch surveillance . 33

8.4 Documentation related to the routine tests . 33

8.4.1 Documentation provided at the request of the customer . 33

8.4.2 Documentation provided with the regulator . 33

9 Marking . .33

9.1 General . 33

9.2 Basic requirements .34

9.3 Markings for the various connections .34

9.4 Marking of integrated safety devices .34

9.5 Other additional requirements .34

10 Packaging and transportation of finished product .34

Annex A (normative) List of materials .35

Annex B (normative) Elastomeric material .36

Annex C (normative) High pressure vent limiter .37

Annex D (normative) Compliance evaluation .38

Annex E (informative) Alternative methods for the determination of the accuracy class,

the lock-up pressure class, the maximum accuracy flow rate, the flow coefficients

and the verification of the hysteresis band .39

Annex F (informative) Inspection certificate .47

Annex G (informative) Acceptance test .50

Annex H (normative) Token (creep) relief device .51

Annex I (informative) Order specification .53

Annex J (informative) Dynamic force calculation method .55

Bibliography .58

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 161, Controls and protective devices for

gas and/or oil.

A list of all parts in the ISO 23555 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

This document is designed to be used in combination with ISO 23555-1. This document together with

ISO 23555-1 establishes the complete standard as it applies to the specific control covered by the

ISO 23555 series.

Where needed, this document adapts ISO 23555-1 by stating in the corresponding clause:

— “with the following modification”;

— “with the following addition”;

— “is replaced by the following”; or

— “is not applicable”.

In order to identify specific requirements that are particular to this document but not already covered

by ISO 23555-1, this document can contain clauses or subclauses that are additional to the structure

of ISO 23555-1. These subclauses are indicated by the introductory sentence: “Subclause (or Annex)

specific to this document.”.

vi

INTERNATIONAL STANDARD ISO 23555-2:2022(E)

Gas pressure safety and control devices for use in gas

transmission, distribution and installations for inlet

pressures up to and including 10 MPa —

Part 2:

Gas pressure regulator

1 Scope

This document specifies safety, constructional, performance, testing and documentation requirements

for gas pressure regulators for use in gas transmission and distribution installations (hereafter

referred to as regulators).

This document is applicable to regulators with operating pressures greater than 500 kPa and up to and

including 10 MPa (100 bar) and nominal diameters up to DN 400 for use with fuel gases as natural gas,

manufactured gas, biomethane or liquefied petroleum gas (LPG).

This document is applicable to:

— test methods which are intended for product type test, routine tests and product surveillance tests;

— regulators which use the pipeline gas as a source of control energy unassisted by any external

power source;

— regulators integrating on the same body a second regulator, used as monitor, complying with the

requirements in this document;

— regulators integrating a safety shut off device (SSD) according to ISO 23555-3;

— regulators incorporating a creep (venting) relief device and/or a vent limiter complying with the

requirements in this document.

This document does not apply to:

— regulators upstream from/on/in domestic gas-consuming appliances which are installed

downstream of domestic gas meters;

— regulators designed to be incorporated into pressure control systems used in service lines (pipework

from the main pipework in a gas infrastructure to the point of delivery of the gas) with declared

volumetric flow rate ≤ 200 m /h at normal conditions and declared inlet pressure ≤ 500 kPa (5 bar);

— industrial process control valves, such as IEC 60534 (all parts);

— regulators used in aggressive/sour gas environments (gas environments containing water and H2S

are considered sour) or severely corrosive conditions;

— regulators in service conditions with renewables (e.g. H2NG with hydrogen more than 10 %) and/

or waste gases (e.g. biogas etc.), if additional information is not provided (e. g. contaminant, liquid,

etc.).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 23555-1:2022, Gas pressure safety and control devices for use in gas transmission, distribution and

installations for inlet pressures up to and including 10 MPa — Part 1: General requirements

IEC 60534-1:2005, Industrial-process control valves — Part 1: Control valve terminology and general

considerations

IEC 60534-2-3, Industrial-process control valves — Part 2-3: Flow capacity — Test procedures

IEC 60534-4, Industrial-process control valves — Part 4: Inspection and routine testing

3 Terms and definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 23555-1 and the following

apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1.1 General terms

3.1.1.1

gas pressure regulator

device whose function is to maintain the value of the controlled variable (3.1.3.1) within its tolerance

field irrespective of disturbance variables

3.1.1.2

direct acting gas pressure regulator

regulator in which the net force required to move the control member is supplied directly by the

controlled variable

Note 1 to entry: See example in Figure 1.

a) Direct acting regulator - type integral b) Direct acting regulator - type differential

strength strength

Key

1 + 2 = Controller

1 setting element 6 sensing line

2 pressure detecting element 7 regulator body

3 breather/exhaust line 8 valve seats

4 actuator 9 seat ring

5 casing of actuator 10 control member

Figure 1 — Examples of a direct acting regulator

3.1.1.3

pilot-controlled gas pressure regulator

regulator in which the net force required to move the control member is supplied by a pilot

Note 1 to entry: See example in Figures 2 and 3.

Key

1 auxiliary device 6 regulator body

2 pilot 7 valve seats

3 actuator 8 seat ring

4 casing of actuator 9 control member

5 sensing/process line 10 motorization chamber

Figure 2 — Example of a pilot-controlled regulator

Key

1 auxiliary device 6 sensing/process lines

2 pilot 7 regulator body

3 throttle 8 valve seat

4 control member 9 motorization chamber

5 casing of control member

Figure 3 — Example of a pilot-controlled regulator with a diaphragm as control member

3.1.1.4

monitor

second regulator installed in series with an active regulator, normally upstream, which has the task

of maintaining the controlled variable within allowable limits in the event of its value exceeds pre-

established values (e.g. in the event of opening of the active regulator due to a failure, etc.)

3.1.1.5

fail close regulator

regulator whose control member automatically tends to close or close when failures occur

Note 1 to entry: This definition is based on typical control failure modes.

3.1.1.6

fail open regulator

regulator whose control member automatically tends to open or open when failures occur

Note 1 to entry: This definition is based on typical control failure modes.

3.1.1.7

regulator size

nominal size DN of the inlet connection

Note 1 to entry: The preferred DN values are specified in ISO 6708.

3.1.1.8

series of regulators

regulators with the same design concept but differing only in size

3.1.2 Terms related to flow

3.1.2.1

flow coefficient in critical conditions

Cg

characteristic value for the flow capacity of regulator in critical conditions

Note 1 to entry: Flow coefficient Cg is a non-SI regulator coefficient.

Note 2 to entry: Numerically, Cg is represented as the number of normal cubic feet per hour of air flowing through

a regulator in critical conditions with inlet absolute pressure 1 psia and with a reference inlet temperature t

ur

1) 3

= 15 °C . The numerical value in SI units is equal to the number of m /h of air flowing through a regulator in

critical conditions with inlet absolute pressure 243 kPa (2,43 bar) and inlet temperature of 15 °C.

Note 3 to entry: IEC 60534-2-1:2011, Clause 7 and Appendix B deals with this flow coefficient.

3.1.2.2

flow coefficient in normal conditions

KG

characteristic value for the flow capacity of a regulator in normal conditions

Note 1 to entry: The flow coefficient is equal to the volumetric flow rate at normal conditions through the

regulator under the following reference conditions:

— reference natural gas at normal conditions with the relative density d = 0,64 (density ρ = 0,827 5 kg/m );

r r

— fully opened control member (mechanical stop);

— reference inlet temperature of t = 15 °C;

ur

— reference absolute gas inlet pressure p = 200 kPa (2 bar);

ur

— reference absolute gas outlet pressure p = 100 kPa (1 bar).

dr

Note 2 to entry: The KG value is specified in (m /h)/bar.

1) The definition of this flow coefficient is based on IEC 60534-1.

3.1.3 Terms related to variables in the controlling process

3.1.3.1

controlled variable

variable which is monitored by the controlling process

Note 1 to entry: In this document, only the outlet pressure, p , is considered as the controlled variable.

d

3.1.3.2

disturbance variable

variable acting from outside on the controlling process

Note 1 to entry: In the case of regulators with outlet pressure as the controlled variable, the disturbance variables

are essentially:

— changes in the inlet pressure;

— changes in the volumetric flow rate.

3.1.3.3

reference inlet temperature

t

ur

temperature at the inlet of control in the assessment of its functional performance

Note 1 to entry: This document considers as reference temperature 15 °C.

Note 2 to entry: The use of reference inlet temperature is necessary to obtain homogeneous set of test results

when comparing the functional performances of different type of control.

3.1.4 Terms related to the controlled process

3.1.4.1

set point

p

ds

nominal value of the controlled variable under specified conditions

Note 1 to entry: The set point is not directly measurable but determined as shown in Figure 6.

3.1.4.2

set range

W

d

whole range of set points which can be obtained from a regulator by adjustment and/or the replacement

of some components (i.e. replacement of the valve seat or setting element, e.g. spring)

3.1.4.3

specific set range

W

ds

whole range of set points which can be obtained from a regulator by adjustment and with no replacement

of its components

3.1.4.4

regulation change

difference between the actual value of the controlled variable and the set point expressed as a

percentage of the set point

3.1.5 Terms related to functional performance

3.1.5.1

stable

condition where the controlled variable settles to a stable value after a disturbance has occurred

3.1.5.2

performance curve

graphic representation of the controlled variable as a function of the volumetric flow rate

Note 1 to entry: This curve is determined by increasing and then decreasing the volumetric flow rate with

constant inlet pressure and set point (see Figure 4).

3.1.5.3

hysteresis band

difference between the two values of outlet pressure for a given volumetric flow rate

Note 1 to entry: See Figure 4.

Key

⊗ start setting 1 max hysteresis band

⨉ measured values 2 hysteresis band

Figure 4 — Performance curve (p constant, p constant)

ds u

3.1.5.4

family

set of the performance curves for each value of inlet pressure determined for

a given set point

Note 1 to entry: See Figure 5.

Figure 5 — Family of performance curves (p constant)

ds

3.1.6 Feature related to accuracy

3.1.6.1

accuracy

maximum absolute value of regulation change under specified operating range

3.1.6.2

accuracy class

AC

maximum permissible value of the accuracy under specified operating range

3.1.6.3

inlet pressure range

b

pu

range of the inlet pressure for which the regulator ensures a given accuracy class

Note 1 to entry: The inlet pressure range is characterized by its limit values p and p .

umax umin

3.1.6.4

maximum accuracy flow rate

lowest value of the maximum volumetric flow rate up to which, for a given set point and within the

ambient temperature range specified, a given accuracy class is ensured:

— at the lowest inlet pressure (see Figure 6) Q ;

n,max,pumin

— at the highest inlet pressure (see Figure 6) Q ;

n,max,pumax

— at an intermediate inlet pressure between p and p (see Figure 6) Q

umax umin n,max,pu

Figure 6 — Family of performance curves indicating maximum accuracy flow rates and

minimum flow rates (p constant, stable conditions)

ds

3.1.7 Terms related to lock-up behaviour

3.1.7.1

lock-up time

t

f

time taken for the control member to move from an open position to the closed position

3.1.7.2

lock-up pressure

p

f

pressure that occurs at the measuring point of the controlled variable when the control member is in

the closed position

Note 1 to entry: The lock-up pressure corresponds to the outlet pressure at the volumetric flow rate Q = 0 in the

performance curve (see Figure 4). It results when the time taken for a change in volumetric flow rate from Q to

zero is greater than the lock- up time of the regulator.

3.1.7.3

lock-up pressure class

SG

maximum permissible positive difference between the actual lock-up pressure and the set point

expressed as a percentage of the set point [see Formula (1)]:

pp−

fds

SG = •100 (1)

p

ds

Note 1 to entry: For better understanding of ()pp− , see Figure 6.

fds

max

3.1.7.4

minimum flow rate

largest value of the minimum volumetric flow rate down to which, for a given set point and within the

ambient temperature range specified, stable conditions are obtained:

— at the lowest inlet pressure (see Figure 6) Q ;

nmin,pumin

— at the highest inlet pressure (see Figure 6) Q ;

nmin,pumax

— at an intermediate inlet pressure between p and p (see Figure 6) Q .

umax umin nmin,pu

Note 1 to entry: Stable conditions are given in 7.2.8.3.

3.1.7.5

lock-up pressure zone

zone between the volumetric flow rate Q = 0 and the minimum flow rate Q for each corresponding

n nmin,pu

inlet pressure and set point (see Figure 7)

3.1.7.6

class of lock-up pressure zone

SZ

maximum permissible lock-up pressure zone for specified:

— inlet pressure p ;

u

— set point p ;

ds

which is expressed as the percentage of Q to Q [see Formula (2)]:

nmin,pu nmax,pu

Q

nminpu

SZ = •100 (2)

Q

nmaxpu

3.1.7.7

computational fluid dynamics

CFD

set of numerical methods and algorithms to solve and analyse problems that involve fluid flows

Key

1 lock-up pressure zone SZ

Figure 7 — Performance curve indicating lock-up pressure zone (stable condition)

3.1.8 Terms related to design and tests

3.1.8.1

closing force

F

S

force acting on control member of the monitor in full open position in normal operating conditions to

bring it to its control position after activation of the monitor itself

3.1.9 Summary of symbols for creep relief valves

3.1.9.1

opening pressure

p

do

pressure at which the first internal leak occurs

3.1.9.2

closing pressure

p

df

falling pressure at which the relief valve is pressure tight after re-seating

3.2 Symbols

Shall be according to ISO 23555-1:2022, 3.2 with the following addition:

The following prospect summarizes the symbols and relevant descriptions and unit considered in this

chapter and/or used in this document. The symbols are listed in alphabetic order.

Symbol Term Subclause Unit

AC Accuracy class 3.1.6.2 %

b Inlet pressure range 3.1.6.3 kPA

pu

Cg Flow coefficient in critical conditions 3.1.2.1 See definition

F Closing force 3.1.8.1 N

S

KG Flow coefficient in normal conditions 3.1.2.2 See definition

p Closing pressure 3.1.9.2 kPA

df

p Opening pressure 3.1.9.1 kPA

do

Symbol Term Subclause Unit

p Reference absolute outlet pressure 3.1.2.2 kPA abs

dr

p Set point 3.1.4.1 kPA

ds

p Lock-up pressure 3.1.7.2 kPA

f

p Reference absolute inlet pressure 3.1.2.2 kPA abs

ur

Q Minimum flow rate at inlet pressure p m /h at normal conditions

nmin,pu u

Q Minimum flow rate at inlet pressure p 3.1.7.4 m /h at normal conditions

nmin,pumax umax

Q Minimum flow rate at inlet pressure p m /h at normal conditions

nmin,pumin umin

SG Lock-up pressure class 3.1.7.3 %

SZ Class of lock-up pressure zone 3.1.7.6 %

t Lock-up time 3.1.7.1 s

f

t Reference inlet temperature for KG 3.1.2.1 °C

ur

W Set range 3.1.4.2 kPA

d

W Specific set range 3.1.4.3 kPA

ds

4 Classification

4.1 General

Shall be according to ISO 23555-1:2022, 4.1 with the following addition.

— Fail condition.

4.2 Temperature classes

Shall be according to ISO 23555-1:2022, 4.2.

4.3 Strength types

Shall be according to ISO 23555-1:2022, 4.2.

4.4 Fail conditions

Subclause specific to this document.

This document considers the following fail conditions.

— Fail close condition: the control member shall tend to close or close.

— Fail open conditions: the control member shall tend to open or open.

5 Materials

Shall be according to ISO 23555-1:2022, Clause 5.

6 Design

6.1 General

Shall be according to ISO 23555-1:2022, 6.1.

6.2 Strength of metallic body and its inner metallic partition walls

Shall be according to ISO 23555-1:2022, 6.2.

6.3 Other pressure metallic containing parts of integral and differential strength

controls

Shall be according to ISO 23555-1:2022, 6.3.

6.4 Strength of parts transmitting actuating forces

Shall be according to ISO 23555-1:2022, 6.4.

6.5 Strength of diaphragms (elastomeric parts)

Shall be according to ISO 23555-1:2022, 6.5.

6.6 Welding

Shall be according to ISO 23555-1:2022, 6.6.

6.7 Main function of a regulator

6.7.1 General

Subclause specific to this document.

The main function of a regulator is to maintain the value of the controlled variable within its tolerance

field irrespective of the disturbance variables.

Regulators shall not have any continuous discharge of gas into the atmosphere. However, temporary

discharges from auxiliary devices can occur.

Regulators shall be so designed that the external tightness and internal sealing meet the requirements

of 7.2.4 and 7.2.5. If in the event of failure of the regulator (e.g. failure of a diaphragm) leakage to

atmosphere is possible, the breather shall be provided with a threaded connection of at least DN 10

to enable an exhaust line to be connected. This connection may be used for a specific device (e.g. a

dumping device). For proper operation of the regulator, any exhaust line shall be designed in such a way

to prevent the ingress of foreign materials.

Pressure bearing parts including measuring and test points, which may be dismantled for servicing,

adjustment or conversion shall be made pressure tight by mechanical means (e.g. metal to metal joints,

o-rings, gaskets, etc.). Jointing compounds, such as liquids and pastes, shall not be used.

Jointing compounds, however, may be used for permanent assemblies and shall remain effective under

normal operating conditions.

Pressure bearing parts not intended to be dismantled during servicing, adjustment or conversion shall

be sealed by means which show evidence of interference or tampering (e.g. lacquer).

When external protrusions or other external parts need special care to cover the hazards during

transport and handling, the manual shall include the provisions to cover these risks.

The motorization energy in a pilot-controlled regulator shall be provided by the gas upstream of the

regulator.

For regulators used as stand-by monitor, it shall be possible to check whether the control member is in

fully open or in controlling position by a visual inspection.

6.7.2 Gas pressure regulators with associated safety devices

6.7.2.1 Gas pressure regulators with integrated safety devices

Additional integrated (same body) safety devices, i.e. gas safety shut-off devices (SSD) and/or a monitor

shall be functionally independent from the regulator.

This requirement is met if:

a) the function of the regulator is not affected in the event of the failure and/or loss of functionality of

one or more of the following safety shut-off device/monitor components:

— closure / control member;

— seat ring;

— actuator;

— casing of actuator;

— controller;

— pilot (in case of pilot-controlled monitor type);

— sensing and process lines;

b) the function of the safety shut-off device/monitor is not affected in the event of the failure and/or

loss of functionality of one or more of the following regulator components:

— control member;

— seat ring;

— actuator;

— casing of actuator;

— controller;

— pilot (in case of pilot-controlled regulator type);

— sensing and process lines.

When the regulator incorporates more than one safety devices (e.g. a monitor and an SSD or two SSDs),

the functional independence shall be met by each device from the other ones in similar way as detailed

in this subclause.

When the integrated safety device is a slam-shut device or a cut-off device or a monitor, the motorization

energy for the regulator, when it is a pilot-controlled type, shall be provided by the gas downstream of

the safety device.

6.7.2.2 Gas pressure regulators with in-line monitor

The system includes a regulator with the function of active regulator and a second (in series) regulator

with the function of monitor. The monitor shall be installed normally upstream of the active regulator

and both equipment shall control the pressure at the same location.

The associated in-line monitor shall be functionally independent from the active regulator.

This requirement is met if:

a) the function of the active regulator is not affected in the event of the failure and/or loss of

functionality of one or more of the following monitor components:

— pilot (in case of pilot-controlled monitor type);

— sensing and process lines; and

b) the function of the monitor is not affected in the event of the failure and/or loss of functionality of

one or more of the following active regulator components:

— pilot (in case of pilot-controlled regulator type);

— sensing and process lines.

The motorization energy for active regulator in case of pilot-controlled type shall be taken downstream

of the monitor.

For monitor in fully open position in normal operating conditions, it is necessary to adopt appropriate

design measures to avoid the possible effect of static friction (break away friction) at the first movement

between movable and fixed parts.

6.7.2.3 Gas pressure regulator with in-line safety shut off device

The system includes a regulator with the function of active regulator and an in-line SSD (in series).

The SSD shall be installed directly upstream of active regulator and both devices shall control the

pressure at the same location.

The associated in-line SSD shall be functionally independent from the active regulator.

The requirement is met if:

a) the function of active regulator is not affected in the event of the failure and/or loss of functionality

of one or more of the following SSD components:

— controller;

— sensing and process lines; and

b) the function of SSD is not affected in the event of the failure and/or loss of functionality of one or

more of the following active regulator components:

— pilot (in case of pilot-controlled regulator type);

— sensing and process lines.

The motorization energy for active regulator, in case of pilot-controlled type, shall be taken downstream

of the SSD.

7 Performance and testing requirements

7.1 General

7.1.1 Approach to stable product phase

Shall be according to ISO 23555-1:2022, 7.1.1.

7.1.2 Test conditions

Shall be according to ISO 23555-1:2022, 7.1.2.

7.1.3 Test tolerances

Shall be according to ISO 23555-1:2022, 7.1.3.

7.1.4 Overview table

Shall be according to ISO 23555-1:2022, 7.1.4 with the replacement of Table 11 by Table 1:

Table 1 — Summary of test methods and requirements

Test schedule Requirement Test method

T M S Clause Title Clause

Constructional tests

A A A 6.1 Dim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...