ISO 28219:2017

(Main)Packaging — Labelling and direct product marking with linear bar code and two-dimensional symbols

Packaging — Labelling and direct product marking with linear bar code and two-dimensional symbols

ISO 28219:2017 - defines minimum requirements for identifying items, - provides guidelines for item marking with machine-readable symbols, - covers both labels and direct marking of items, - includes testing procedures for label adhesive characteristics and mark durability, - provides guidance for the formatting on the label of data presented in linear bar code, two-dimensional symbol or human-readable form, - is intended for applications which include, but are not limited to, support of systems that automate the control of items during the processes of: - production, - inventory, - distribution, - field service, - point of sale, - point of care, - repair, and - is intended to include, but it is not limited to, multiple industries including: - automotive, - aerospace, - chemical, - consumer items, - electronics, - health care, - marine, - rail, - telecommunications. The location and application method of the marking are not defined (these will be reviewed and agreed upon by suppliers and manufacturers and their trading partners before implementing ISO 28219:2017). ISO 28219:2017 does not supersede or replace any applicable safety or regulatory marking or labelling requirements. ISO 28219:2017 is meant to satisfy the minimum item marking requirements of numerous applications and industry groups and as such its applicability is to a wide range of industries, each of which may have specific implementation guidelines for it. ISO 28219:2017 is to be applied in addition to any other mandated labelling direct-marking requirements. The labelling and direct marking requirement of ISO 28219:2017 and other standards can be combined into one label or marking area or appear as separate labels or marking areas. ISO 28219:2017 uses the terms "part marking" and "item marking" interchangeably. Unless otherwise stated, ISO 28219:2017 will use the term "item marking" to describe both the labelling and direct part marking (DPM) of an item, where DPM includes, but is not limited to, altering (e.g. dot peen, laser etch, chemical etch), as well as additive type processes (e.g. ink jet, vacuum deposition). The purpose of ISO 28219:2017 is to establish the machine-readable (linear, two-dimensional, and composite symbols) and human-readable content for direct marking and labelling of items, parts, and components. ISO 28219:2017 provides a means for items, parts and components to be marked, and read in either fixtured or hand-held scanning environments at any manufacturer's facility and then read by customers purchasing items for subsequent manufacturing operations or for final end use. Intended applications include, but are not limited to, supply chain applications, e.g. inventory, distribution, manufacturing, quality control, acquisition, transportation, supply, repair, and disposal. The figures are illustrative and not necessarily to scale or to the quality requirements specified in ISO 28219:2017.

Emballage — Étiquetage et marquage direct sur le produit avec un code à barres et des symboles bidimensionnels

General Information

- Status

- Published

- Publication Date

- 25-Sep-2017

- Technical Committee

- ISO/TC 122 - Packaging

- Drafting Committee

- ISO/TC 122/WG 12 - Supply chain applications of logistics technology

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 13-Sep-2023

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Oct-2013

Overview

ISO 28219:2017 - Packaging - Labelling and direct product marking with linear bar code and two-dimensional symbols - defines minimum requirements and practical guidance for marking items with machine-readable and human‑readable identifiers. The standard covers both labels and direct part marking (DPM) (e.g., dot peen, laser etch, chemical etch, ink‑jet, vacuum deposition) and includes requirements for data formatting, mark durability, and label adhesive characteristics. ISO 28219:2017 is intended to enable reliable automatic identification across manufacturing and supply‑chain processes while not replacing any mandated safety or regulatory markings.

Key topics and technical requirements

- Item identification: Rules for unique item identification and lot/batch identification to support traceability.

- Data format and syntax: Guidance on structuring data in linear bar codes, two‑dimensional symbols (Data Matrix, QR Code, PDF417) and human‑readable form; includes mandatory and optional data fields and use of standard syntaxes.

- Symbol and print quality: Requirements and recommendations for symbologies, composite symbols, and expected print/read quality for reliable scanning in handheld or fixtured environments.

- Label adhesive & mark durability testing: Procedures and guidance for evaluating adhesive performance and direct mark durability to ensure long‑term readability.

- Layout and human‑readable interpretation: Best practices for label layout, titles for linear bar codes, and placement of human-readable text alongside machine-readable marks.

- DPM considerations: Defines DPM inclusively (altering or additive processes) and emphasizes that marking location/methods are agreed between trading partners prior to implementation.

- Interoperability focus: Ensures marks can be read at manufacturers’ facilities and by customers for subsequent manufacturing, distribution, or end use.

Applications and who uses it

ISO 28219:2017 supports automation and traceability in:

- Production, inventory, distribution, repair, field service

- Point of sale and point of care (healthcare)

- Quality control, acquisition, transport, disposal

Primary users:

- Packaging and labeling engineers

- Supply chain and logistics managers

- Manufacturing and quality assurance teams

- Medical device, automotive, aerospace, electronics and telecommunications manufacturers

- Label suppliers, DPM equipment vendors and system integrators

Related standards

ISO 28219 references and complements multiple AIDC standards, for example:

- ISO/IEC 15434 (data syntax), ISO/IEC 15416 / 15415 (print quality)

- ISO/IEC 15417, 16022, 18004 (Code 128, Data Matrix, QR Code)

- ISO/IEC 24723 (GS1 Composite) Use ISO 28219 in conjunction with industry‑specific regulations and any mandated safety or regulatory marking requirements.

Keywords: ISO 28219:2017, packaging, labelling, direct product marking, DPM, linear bar code, two‑dimensional symbols, item identification, traceability, mark durability, adhesive testing, supply chain.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

BRCGS (Brand Reputation Compliance Global Standards)

Global food safety and quality standards owner.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO 28219:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Packaging — Labelling and direct product marking with linear bar code and two-dimensional symbols". This standard covers: ISO 28219:2017 - defines minimum requirements for identifying items, - provides guidelines for item marking with machine-readable symbols, - covers both labels and direct marking of items, - includes testing procedures for label adhesive characteristics and mark durability, - provides guidance for the formatting on the label of data presented in linear bar code, two-dimensional symbol or human-readable form, - is intended for applications which include, but are not limited to, support of systems that automate the control of items during the processes of: - production, - inventory, - distribution, - field service, - point of sale, - point of care, - repair, and - is intended to include, but it is not limited to, multiple industries including: - automotive, - aerospace, - chemical, - consumer items, - electronics, - health care, - marine, - rail, - telecommunications. The location and application method of the marking are not defined (these will be reviewed and agreed upon by suppliers and manufacturers and their trading partners before implementing ISO 28219:2017). ISO 28219:2017 does not supersede or replace any applicable safety or regulatory marking or labelling requirements. ISO 28219:2017 is meant to satisfy the minimum item marking requirements of numerous applications and industry groups and as such its applicability is to a wide range of industries, each of which may have specific implementation guidelines for it. ISO 28219:2017 is to be applied in addition to any other mandated labelling direct-marking requirements. The labelling and direct marking requirement of ISO 28219:2017 and other standards can be combined into one label or marking area or appear as separate labels or marking areas. ISO 28219:2017 uses the terms "part marking" and "item marking" interchangeably. Unless otherwise stated, ISO 28219:2017 will use the term "item marking" to describe both the labelling and direct part marking (DPM) of an item, where DPM includes, but is not limited to, altering (e.g. dot peen, laser etch, chemical etch), as well as additive type processes (e.g. ink jet, vacuum deposition). The purpose of ISO 28219:2017 is to establish the machine-readable (linear, two-dimensional, and composite symbols) and human-readable content for direct marking and labelling of items, parts, and components. ISO 28219:2017 provides a means for items, parts and components to be marked, and read in either fixtured or hand-held scanning environments at any manufacturer's facility and then read by customers purchasing items for subsequent manufacturing operations or for final end use. Intended applications include, but are not limited to, supply chain applications, e.g. inventory, distribution, manufacturing, quality control, acquisition, transportation, supply, repair, and disposal. The figures are illustrative and not necessarily to scale or to the quality requirements specified in ISO 28219:2017.

ISO 28219:2017 - defines minimum requirements for identifying items, - provides guidelines for item marking with machine-readable symbols, - covers both labels and direct marking of items, - includes testing procedures for label adhesive characteristics and mark durability, - provides guidance for the formatting on the label of data presented in linear bar code, two-dimensional symbol or human-readable form, - is intended for applications which include, but are not limited to, support of systems that automate the control of items during the processes of: - production, - inventory, - distribution, - field service, - point of sale, - point of care, - repair, and - is intended to include, but it is not limited to, multiple industries including: - automotive, - aerospace, - chemical, - consumer items, - electronics, - health care, - marine, - rail, - telecommunications. The location and application method of the marking are not defined (these will be reviewed and agreed upon by suppliers and manufacturers and their trading partners before implementing ISO 28219:2017). ISO 28219:2017 does not supersede or replace any applicable safety or regulatory marking or labelling requirements. ISO 28219:2017 is meant to satisfy the minimum item marking requirements of numerous applications and industry groups and as such its applicability is to a wide range of industries, each of which may have specific implementation guidelines for it. ISO 28219:2017 is to be applied in addition to any other mandated labelling direct-marking requirements. The labelling and direct marking requirement of ISO 28219:2017 and other standards can be combined into one label or marking area or appear as separate labels or marking areas. ISO 28219:2017 uses the terms "part marking" and "item marking" interchangeably. Unless otherwise stated, ISO 28219:2017 will use the term "item marking" to describe both the labelling and direct part marking (DPM) of an item, where DPM includes, but is not limited to, altering (e.g. dot peen, laser etch, chemical etch), as well as additive type processes (e.g. ink jet, vacuum deposition). The purpose of ISO 28219:2017 is to establish the machine-readable (linear, two-dimensional, and composite symbols) and human-readable content for direct marking and labelling of items, parts, and components. ISO 28219:2017 provides a means for items, parts and components to be marked, and read in either fixtured or hand-held scanning environments at any manufacturer's facility and then read by customers purchasing items for subsequent manufacturing operations or for final end use. Intended applications include, but are not limited to, supply chain applications, e.g. inventory, distribution, manufacturing, quality control, acquisition, transportation, supply, repair, and disposal. The figures are illustrative and not necessarily to scale or to the quality requirements specified in ISO 28219:2017.

ISO 28219:2017 is classified under the following ICS (International Classification for Standards) categories: 35.040 - Information coding; 35.040.50 - Automatic identification and data capture techniques; 55.020 - Packaging and distribution of goods in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 28219:2017 has the following relationships with other standards: It is inter standard links to ISO 28219:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 28219:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 28219

Second edition

2017-09

Packaging — Labelling and direct

product marking with linear bar code

and two-dimensional symbols

Emballage — Étiquetage et marquage direct sur le produit avec un

code à barres et des symboles bidimensionnels

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

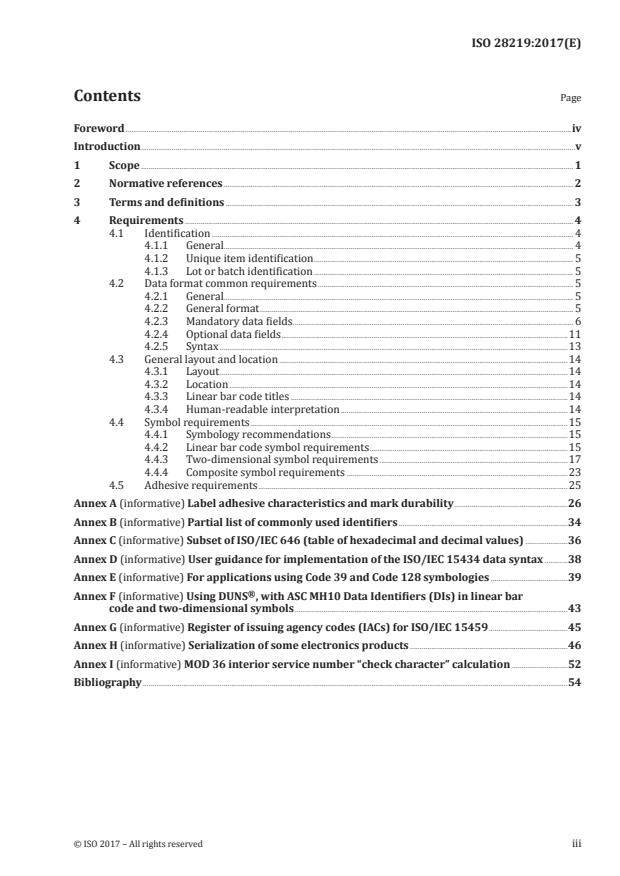

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Requirements . 4

4.1 Identification . 4

4.1.1 General. 4

4.1.2 Unique item identification . 5

4.1.3 Lot or batch identification . 5

4.2 Data format common requirements . 5

4.2.1 General. 5

4.2.2 General format . 5

4.2.3 Mandatory data fields . 6

4.2.4 Optional data fields .11

4.2.5 Syntax .13

4.3 General layout and location .14

4.3.1 Layout .14

4.3.2 Location .14

4.3.3 Linear bar code titles .14

4.3.4 Human-readable interpretation .14

4.4 Symbol requirements .15

4.4.1 Symbology recommendations .15

4.4.2 Linear bar code symbol requirements .15

4.4.3 Two-dimensional symbol requirements .17

4.4.4 Composite symbol requirements .23

4.5 Adhesive requirements .25

Annex A (informative) Label adhesive characteristics and mark durability .26

Annex B (informative) Partial list of commonly used identifiers .34

Annex C (informative) Subset of ISO/IEC 646 (table of hexadecimal and decimal values) .36

Annex D (informative) User guidance for implementation of the ISO/IEC 15434 data syntax .38

Annex E (informative) For applications using Code 39 and Code 128 symbologies .39 ®

Annex F (informative) Using DUNS , with ASC MH10 Data Identifiers (DIs) in linear bar

code and two-dimensional symbols .43

Annex G (informative) Register of issuing agency codes (IACs) for ISO/IEC 15459 .45

Annex H (informative) Serialization of some electronics products .46

Annex I (informative) MOD 36 interior service number “check character” calculation .52

Bibliography .54

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 122, Packaging.

This second edition cancels and replaces the first edition (ISO 28219:2009), which has been technically

revised.

iv © ISO 2017 – All rights reserved

Introduction

Today, global industries widely use machine-readable markings on products for inventory control,

quality control, and product life cycle management. Common technologies, data structures,

conformance, and applications standards are necessary to enable all trading partners to use such

markings internally and throughout the supply chain.

A number of different product labelling and marking standards exist, each designed to meet the

requirements of the specific industry sector. For effective and economic use within and between

industry sectors, one common multi-industry standard is a necessity.

A standard linear bar code or two-dimensional symbol marked on a product or part will facilitate the

automation of inventory control, quality control, and product life cycle management. The linear bar code

or two-dimensional symbol information on the product can be used as a key to access the appropriate

database that contains detailed information about the product, including information transmitted via

EDI. In addition, a product mark can contain other information as agreed between the trading partners.

This document does not supersede or replace any applicable safety or regulatory marking or labelling

requirements. This document is meant to satisfy the minimum product package requirements of

numerous applications and industry groups. As such, its applicability is to a wide range of industries,

each of which can have specific implementation guidelines for this document. This document is intended

to be applied in addition to any other mandated labelling requirements.

This document supersedes and replaces ANS MH10.8.7.

This document supersedes and replaces CEA-802.

This document supersedes and replaces CEA-621-A.

INTERNATIONAL STANDARD ISO 28219:2017(E)

Packaging — Labelling and direct product marking with

linear bar code and two-dimensional symbols

1 Scope

This document

— defines minimum requirements for identifying items,

— provides guidelines for item marking with machine-readable symbols,

— covers both labels and direct marking of items,

— includes testing procedures for label adhesive characteristics and mark durability,

— provides guidance for the formatting on the label of data presented in linear bar code, two-

dimensional symbol or human-readable form,

— is intended for applications which include, but are not limited to, support of systems that automate

the control of items during the processes of:

— production,

— inventory,

— distribution,

— field service,

— point of sale,

— point of care,

— repair, and

— is intended to include, but it is not limited to, multiple industries including:

— automotive,

— aerospace,

— chemical,

— consumer items,

— electronics,

— health care,

— marine,

— rail,

— telecommunications.

The location and application method of the marking are not defined (these will be reviewed and agreed

upon by suppliers and manufacturers and their trading partners before implementing this document).

This document does not supersede or replace any applicable safety or regulatory marking or labelling

requirements. This document is meant to satisfy the minimum item marking requirements of numerous

applications and industry groups and as such its applicability is to a wide range of industries, each of

which may have specific implementation guidelines for it. This document is to be applied in addition to

any other mandated labelling direct-marking requirements.

The labelling and direct marking requirement of this document and other standards can be combined

into one label or marking area or appear as separate labels or marking areas.

This document uses the terms “part marking” and “item marking” interchangeably. Unless otherwise

stated, this document will use the term “item marking” to describe both the labelling and direct part

marking (DPM) of an item, where DPM includes, but is not limited to, altering (e.g. dot peen, laser etch,

chemical etch), as well as additive type processes (e.g. ink jet, vacuum deposition).

The purpose of this document is to establish the machine-readable (linear, two-dimensional, and

composite symbols) and human-readable content for direct marking and labelling of items, parts, and

components.

This document provides a means for items, parts and components to be marked, and read in either

fixtured or hand-held scanning environments at any manufacturer’s facility and then read by customers

purchasing items for subsequent manufacturing operations or for final end use. Intended applications

include, but are not limited to, supply chain applications, e.g. inventory, distribution, manufacturing,

quality control, acquisition, transportation, supply, repair, and disposal.

The figures are illustrative and not necessarily to scale or to the quality requirements specified in this

document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 21067, Packaging — Vocabulary

ISO/IEC 646, Information technology — ISO 7-bit coded character set for information interchange

ISO 3166-1, Codes for the representation of names of countries and their subdivisions — Part 1: Country codes

ISO/IEC 15415, Information technology — Automatic identification and data capture techniques — Bar

code symbol print quality test specification — Two-dimensional symbols

ISO/IEC 15416, Automatic identification and data capture techniques — Bar code print quality test

specification — Linear symbols

ISO/IEC 15417, Information technology — Automatic identification and data capture techniques — Code

128 bar code symbology specification

ISO/IEC 15434, Information technology — Automatic identification and data capture techniques — Syntax

for high-capacity ADC media

ISO/IEC 15438, Information technology — Automatic identification and data capture techniques — PDF417

bar code symbology specification

ISO/IEC 15459-2, Information technology — Automatic identification and data capture techniques —

Unique identification — Part 2: Registration procedures

ISO/IEC 16022, Information technology — Automatic identification and data capture techniques — Data

Matrix bar code symbology specification

2 © ISO 2017 – All rights reserved

ISO/IEC 16388, Information technology — Automatic identification and data capture techniques — Code

39 bar code symbology specification

ISO/IEC 18004, Information technology — Automatic identification and data capture techniques — QR

Code bar code symbology specification

ISO/IEC 19762, Information technology — Automatic identification and data capture (AIDC) techniques —

Harmonized vocabulary

ISO/IEC 24723, Information technology — Automatic identification and data capture techniques — GS1

Composite bar code symbology specification

ISO/IEC 24728, Information technology — Automatic identification and data capture techniques —

MicroPDF417 bar code symbology specification

ANS ATIS-0300213, American National Standard for Telecommunication — Coded Identification of

Equipment Entities of the North American Telecommunications System for Information Exchange

ANS MH10.8.2, Data Application Identifier Standard

1)

Dun & Bradstreet (D&B), DUNS® Number

GS1, General Specifications

NAMSA, ACodP-1(D), Chapter 2, Subsection 242-243, (NCAGE)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 19762 and ISO 21067 and

the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

cell

smallest element of a two-dimensional matrix symbol

3.2

2)

TM

CLEI code

coding structure maintained by Telcordia d.b.a. iconectiv that identifies communications equipment

and describes product type, features, source document and associated drawings and vintages per

ANS ATIS-0300213

3.3

components

parts (bare printed circuit board, integrated circuits, capacitor, diodes, switch, valve, spring, bearing,

bracket, bolt, etc.) of a first level/modular assembly (3.6)

3.4

data element separator

specified character used to delimit discrete fields of data

1) DUNS® Number is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by ISO of this product.

TM

2) CLEI coder is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by ISO of this product.

3.5

3)

DUNS® Number

nine-digit number, issued by D&B, assigned to each business location in the D&B database, having a

unique, separate, and distinct operation for the purpose of identifying them

3.6

first level

modular assembly

manufactured item (3.8) (populated printed circuit board, hydraulic pump, starter, dashboard

assembly, door assembly, etc.) made up of components (3.3)

3.7

Global Trade Item Number

GTIN

GS1 identification key used to identify trade items

Note 1 to entry: The key comprises a GS1 Company Prefix, an item reference and a check digit.

3.8

item

product

first level or higher assembly that is sold in a complete end-usable configuration

3.9

label

adhesive backed media capable of being marked with information in machine-readable and/or human-

readable form

Note 1 to entry: Both labels and direct marking methods are referred to in this document under the term “label”.

3.10

manufacturer

actual producer or fabricator of an item (3.8), not necessarily the supplier (3.11) in a transaction

3.11

supplier

party that produces, provides, or furnishes an item (3.8) or service

3.12

traceability identification

string of characters assigned to identify or trace an entity or a unique group of entities (e.g. lot, batch,

item (3.8), revision/version or serial number)

4 Requirements

4.1 Identification

4.1.1 General

Enterprises may choose to assign uniqueness to items at the individual, group, or product level.

Individual uniqueness requires serialization or one-of-a-kind production, see 4.1.2 and 4.2.3.3. A lot or

batch number captures group uniqueness, see 4.1.3 and 4.2.3.3. A product code is an example of item

uniqueness, see 4.2.3.4.

3) DUNS® Number is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by ISO of this product.

4 © ISO 2017 – All rights reserved

4.1.2 Unique item identification

Items may be assigned a unique item identification code to each instance of the item, i.e. serialization.

Serial numbers shall be unique either within an enterprise ID or within enterprise ID + part number.

When using unique identification, the encoded symbol shall contain only one enterprise identifier,

serial number and/or original part number to avoid confusion and ensure uniqueness.

4.1.3 Lot or batch identification

Items can have group uniqueness applied by an enterprise. Some items are assigned group identification,

e.g. lot or batch number.

4.2 Data format common requirements

4.2.1 General

Those implementing this document should refer to the guidelines for their particular industries. For a

partial list of industry guidelines, see the Bibliography.

4.2.2 General format

4.2.2.1 Overview

Labels will accommodate both mandatory and optional data fields. The maximum length of each

discrete data field shall be 25 data characters unless otherwise specified. This character count is

exclusive of overhead characters.

See Annex H for information on serialization of some electronic products.

All data elements encoded in a machine-readable medium shall be preceded by the appropriate Data

Identifier (DI) as defined in ANS MH10.8.2 Data Identifier, or the appropriate Application Identifier (AI)

defined in the GS1 General Specifications. The exceptions to this rule are the UPC-A, UPC-E, EAN-8, and

EAN-13 symbologies.

The choice between DIs and GS1 AIs, for any user, will normally be determined in the applicable industry

convention being followed.

Other industries developing item identification conventions should consider business practices,

information requirements and systems capabilities of the trading partners in choosing between DIs

and GS1 AIs. See Annex B for a list of commonly used DIs and the equivalent AIs.

The character set shall be upper case alphabetic characters (A to Z), numeric digits (0 to 9), and

the five characters [dash (–), period (.), space ( ), solidus (/) and plus sign (+)], as permitted within

the applicable identifier standard, ANSI MH10.8.2 or the GS1 General Specification. Further, the

recommended field separators, record separators, segment terminators and compliance indicator

contained in ISO/IEC 15434 are part of the allowable character set. A table of these characters and their

hexadecimal and decimal equivalent is given in Annex C. The actual character set employed conforming

to this document shall be the character set permitted by the data field and not the symbology. It is

recommended that the resultant data stream from scanning a 2D symbol follow the syntax described

in ISO/IEC 15434. See Annex D for guidance on the implementation of the ISO/IEC 15434 data syntax.

4.2.2.2 Data identifiers (DIs)

The descriptions in the DI list are general in nature and are used in industrial and international

applications. Specific application guidelines provide the detailed definition used among trading

partners.

The full list of registered DIs and the full specification for their use are found in the American National

Standard MH10.8.2.

DIs may be used with any alphanumeric data carrier and are designed to ensure cross-industry

commonality of Data Identifiers used in automatic identification technologies.

DIs have a format of one alphabetic character alone or one alphabetic character prefixed by one, two or

three numeric characters.

4.2.2.3 GS1 Application Identifiers (AIs)

The definitions of the GS1 AIs are supported by application guidelines. The GS1 AIs, and associated

guidelines, have been designed for international and multi-sector trading purposes.

The GS1 item identification system and related encoding standard are complemented by the GS1

maintained AIs. This document comprises two principal elements, which are the key to any encoding

system: the data content and the data carrier.

The use of GS1 AIs is subject to the rules established by GS1.

GS1 AIs identify generic and simple data fields for use in cross-sector and international supply chain

applications. The GS1 General Specifications provide rules for the definition, format and structure of

the data fields.

Each GS1 AI consists of two, three or four characters.

4.2.2.4 Organization inclusion in coding

It is recommended that data structures used to identify items or the traceability of items include

identification of the organization providing the coding, as well as the specific coding structure.

In the GS1 General Specifications, this coding structure is the GS1 Company Prefix portion of the global

trade item number (GTIN).

When telecommunications companies use the CLEI Code, the coding structure is specified in ANS ATIS-

0300213. The CLEI Code is always 10 characters and the structure is as follows: a basic code (four

alphanumeric characters) representing the technology or equipment type and consisting of a family

code (two alphanumeric characters), sub-family code (two alphanumeric characters), a features

code (three alphanumeric characters) to represent attributes of the equipment, reference code (one

alphanumeric character) to represent the manufacturer of the equipment within the basic code and

a complemental code (two alphanumeric characters) to identify vintage or version of the equipment.

When using DIs, this coding structure uses the issuing agency code (IAC) established in ISO/IEC 15459-

2 and the company identification number (CIN) assigned by the issuing agency.

See Annex G for information about the register of issuing agency codes (IACs) for ISO/IEC 15459.

4.2.3 Mandatory data fields

4.2.3.1 General

Mandatory data fields are given in Table 1.

6 © ISO 2017 – All rights reserved

Table 1 — Item identification code type

Item identification type Mandatory fields

1. Commodity Item identification code (example nails)

2. Non-traceable Enterprise identification code

Item identification code

3. Group traceability Enterprise identification code

Item identification code

Unique lot or batch traceability code

4. Unique serialization within item Enterprise identification code

identification code

Item identification code

Unique individual item identification code

5. Unique serialization within enterprise Enterprise identification code

Unique item traceability code within enterprise

identification code

The enterprise identification code and item identification code may be combined in a single data field,

see 4.2.3.4.

4.2.3.2 Enterprise identification code

The enterprise identification code shall use formats contained in Table 2 and Table 3. The use of

more than one enterprise identification code preceded by DI 20V is permitted on an item. The choice

of enterprise identification code(s) should be mutually agreed upon between trading partners. The

appropriate DI shall precede the enterprise identification when separate data fields are used to identify

the supplier and the item identification.

Table 2 — Data Identifiers used for enterprise identification

Data characteristics

Data Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

18V Combined IAC/CIN an3+an1.3+an3.13 Combined IAC/CIN

12V DUNS® Number an3+n9 Entity (manufacturer) identification

Identifying assigned by Dun and Bradstreet

Manufacturer

17V US Department of an3+an5 Company identification assigned by the US

Defence (DoD) CAGE Department of Defence

Code/NAMSA NCAGE

20V Company an3+an1.3+an3.13+“+”+an3 Combined IAC/CIN and Party Qualifier

identification Code (EDIFACT DE 3035)

21V Supplier an3 +an.25 Combined IAC/CIN followed by an

identification internally assigned entity identification

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data except for “+” in 20V.

Table 3 — Application Identifiers used for enterprise identification

Data characteristics

Application Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

N/A Part number n12 UPC-A Symbology (combination of supplier

(supplier/item) and item identification)

UPC-A (GTIN-12)

N/A Part number n13 EAN-13 Symbology (combination of

(supplier/item) supplier and item identification)

EAN-13 (GTIN-13)

01 Part number n2+n14 GS1–128, GS1 Data Bar Expanded and GS1

(supplier/item and Data Matrix (combination of indicator digit,

quantity) GTIN-14 supplier and item identification)

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data.

4.2.3.3 Group and item traceability identification

The traceability identification is assigned by the manufacturer or supplier. The DIs or AIs given

in Table 4 and Table 5 represent a partial list of the ASC MH10 Data Identifiers and GS1 Application

Identifiers that may be applicable to traceability identification.

The maximum length of a single traceability identification data field should not exceed 35 characters,

which excludes the associated DI or AI. The traceability identification data field shall not exceed 50

characters.

Table 4 — Data Identifiers used for traceability identification

Data characteristics

Data Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

S Serial number an1+an.20 Serial number or code assigned by the

supplier to an entity for its lifetime

18S Serial number an3+an.20 Serial number or code assigned by the

within CAGE Code CAGE Code that is unique within CAGE Code

20S Customer assigned an3+an.20 Serial number or code assigned by the

serial number customer to an entity for its lifetime

22S Cellular Mobile an3+an.25 Electronic Serial Number (ESN) for Cellular

Telephone (CMT) Mobile Telephones or the Mobile

Electronic Serial Equipment Identifier (MEID) or the

Number International Mobile Station Equipment

Identity (IMEI)

a

The characters before the first “+” symbol describe the format of the DI. Note that the “+” symbols are not encoded in

the data.

20S may be used by industries that are serializing items that were not serialized by the manufacturer at time of

manufacturing.

Asset identifiers shall not be used for any other purpose and shall remain unique for a period well beyond the lifetime of

relevant records. If a company assigns asset identifiers to trade items supplied to its customers, the company shall ensure

that the asset identifiers are never reused.

The length specified in the table may be shorter than the length specified in the reference standard; however, that is the

maximum length specified in this document.

NOTE 1 The variable lengths for the IAC/CIN combined lengths are defined by ISO 15459.

NOTE 2 See ESN Assignment Guidelines and Procedures and MOBILE EQUIPMENT IDENTIFIER (MEID) GHA (Global

Hexadecimal Administrator) Assignment Guidelines and Procedures for additional information on ESN and MEID.

8 © ISO 2017 – All rights reserved

Table 4 (continued)

Data characteristics

Data Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

25S Serial number an3 +IAC/CIN+an.20 Combined IAC/CIN and the serial number

assigned by the supplier

+$+ Serial number an3+an…18 HIBC Serial Number associated with HIBC

Lot/batch number (+$) option

1T Lot/batch number an2+an.20 Lot/Batch Number defined by the

manufacturer

25T Lot/batch number an3 +IAC/CIN+an.20 Combined IAC/CIN and enterprise

identification and lot or batch number

assigned by the supplier

+$ Lot/batch number a2+an.18 Options of concatenated lot or batch

combinations with item data are

specified with ANSI/HIBC 2

a

The characters before the first “+” symbol describe the format of the DI. Note that the “+” symbols are not encoded in

the data.

20S may be used by industries that are serializing items that were not serialized by the manufacturer at time of

manufacturing.

Asset identifiers shall not be used for any other purpose and shall remain unique for a period well beyond the lifetime of

relevant records. If a company assigns asset identifiers to trade items supplied to its customers, the company shall ensure

that the asset identifiers are never reused.

The length specified in the table may be shorter than the length specified in the reference standard; however, that is the

maximum length specified in this document.

NOTE 1 The variable lengths for the IAC/CIN combined lengths are defined by ISO 15459.

NOTE 2 See ESN Assignment Guidelines and Procedures and MOBILE EQUIPMENT IDENTIFIER (MEID) GHA (Global

Hexadecimal Administrator) Assignment Guidelines and Procedures for additional information on ESN and MEID.

Table 5 — Application Identifiers used for traceability identification

Data characteristics

Application Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

10 Batch/lot number n2+an.20 Traceability identification defined by the

manufacturer

b

11 Production date n2+n6 Production date (YYMMDD)

21 Serial number n2+an.20 Serial number or code assigned by the

supplier to an trade item for its lifetime

a

The characters before the first “+” symbol describe the format of the AI. Note that the “+” symbols are not encoded in

the data.

b

Production date code construction using GS1 Application Identifiers use a two-digit designation for year.

Asset identifiers shall not be used for any other purpose and shall remain unique for a period well beyond the lifetime of

relevant records. If a company assigns asset identifiers to trade items supplied to its customers, the company shall ensure

that the asset identifiers are never reused.

The length specified in the table may be shorter than the length specified in the reference standard; however, that is the

maximum length specified in this document.

Table 5 (continued)

Data characteristics

Application Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

414 Global location n3+n13 Global location number (GLN) to be

number processed according to the particular

application requirements

8003 Global returnable n4+n14+an.16 Global returnable asset identifier (GRAI)

asset identifier

8004 Global individual n4+an.30 Global individual asset identifier (GIAI)

asset identifier

a

The characters before the first “+” symbol describe the format of the AI. Note that the “+” symbols are not encoded in

the data.

b

Production date code construction using GS1 Application Identifiers use a two-digit designation for year.

Asset identifiers shall not be used for any other purpose and shall remain unique for a period well beyond the lifetime of

relevant records. If a company assigns asset identifiers to trade items supplied to its customers, the company shall ensure

that the asset identifiers are never reused.

The length specified in the table may be shorter than the length specified in the reference standard; however, that is the

maximum length specified in this document.

4.2.3.4 Item identification

The identity for individual products and product packages shall not contain more than 50 characters.

For efficient use within various AIDC data carrier systems, it is recommended that the number of

characters to be coded by one line linear bar code should not exceed 20 characters and number of

characters should be kept as short as possible regardless of the permissible maximum of 50 characters.

This maximum excludes the associated DI or AI. Item identification codes may be concatenated with the

enterprise identification to produce a unique item identification. See Tables 2 to 5 for IAC/CIN.

The item identification code (e.g. supplier or customer part number) shall be designated as mutually

agreed upon between the supplier or manufacturer and customer. The supplier’s part number is the

recommended item identification code.

An item identification code may be concatenated with the company prefix to produce a unique item

identification code. GTIN-12 and GTIN-13 formats are fixed length numeric examples of company prefix

codes concatenated with item identification codes to provide worldwide item identification uniqueness.

See Table 7.

Likewise, variable length examples of fixed length enterprise identification codes concatenated with

variable length alphanumeric item identification codes to provide worldwide item identification

uniqueness may be provided with DIs such as “9P” and “17P”. See Table 6.

Table 6 — Data Identifiers used for item identifier

Data characteristics

Data Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

P Part number an1+an.20 Customer assigned part number

1P Part number an2+an.20 Supplier assigned part number

8P Part number an2+n14 GS1 GTIN-14

9P Part number an2+n9+an.16 Combined DUNS-9 supplier identification

and item code assigned by the supplier

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data.

10 © ISO 2017 – All rights reserved

Table 6 (continued)

Data characteristics

Data Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

TM

11P Part number an3+an10 CLEI code for telecommunications

equipment

17P Part number an3+ an8.27 Combined GS1 company prefix and item code

assigned by the supplier

25P Product number an3+IAC/CIN+an.20 Combined IAC/CIN and item code assigned

by the supplier

+ Product number a1+an.19 HIBCC

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data.

Table 7 — GS1 item identifiers

Data characteristics

Application Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

N/A Part number (supplier/ n12 UPC-A/UPC-E Symbology (combination of

item) UPC-A/UPC-E supplier and item identification)

(GTIN-12)

N/A Part number (supplier/ n13 EAN-13 Symbology (combination of

item) supplier and item identification)

EAN-13 (GTIN-13)

01 Part number (supplier/ n2+n14 GS1–128, GS1 Data Bar Expanded and GS1

item and quantity) Data Matrix (combination of indicator digit,

(GTIN-14) supplier, and item identification)

241 Part number n3+an.30 Customer assigned part number

8001 Roll products n4+n14 Roll products - width, length, core

diameter, direction and splices

8006 Identification of the n4+n14+n2+n2 GS1 Identification of a fixed measure trade

components of a trade item (GTIN) packed in separate parcels.

item

8018 Global service relation n4+n18 GS1 identification number of a service

number (GSRN) relation (GSRN) to be assigned by the

service provider

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data.

NOTE While GS1 permits AI “241” to be a maximum of 30 characters, the customer assigned part number should be

limited to no more than 25 characters.

4.2.4 Optional data fields

Specific applications and trading partner agreements may require additional data fields. See Table 8

and Table 9 for examples.

When using DIs or AIs to encode country of origin, it shall be in one of the formats shown in Table 8 or

Table 9.

Table 8 — Data Identifiers for optional data

Data characteristics

Data Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

4L Country of origin an2+an2 The two-character country code as

defined by ISO 3166-1. The country of

origin is defined as the manufacturing

country wherein the product obtained its

present identity as a part, subassembly, or

finished product.

6D Defined date an2+n8+an3 ISO format YYYYMMDD immediately

followed by an ANSI X12.3 Data Element

Number 374 Qualifier providing a code

specifying type of date (e.g. ship date,

manufacture date)

11D Week an3+n6 Format YYYYWW

12D Date an3+n8 Format YYYYMMDD

14D Expiration date an3+n8 Expiration date (YYYYMMDD)

16D Production date an3+n8 Production date (YYYYMMDD)

30P First level additional an3+an…20 First level (supplier assigned) item

item identification identification (item ID), which is different

than or in addition to Item ID provided by

“1P”

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data.

Table 9 — Application Identifiers for optional data

Data characteristics

Application Type followed by the

Data field Description

Identifier number of characters

a

(e.g. a#, n#, an#)

422 Country of origin n3+n3 The three-digit country code as defined by

ISO 3166-1. The country of origin is defined

as the manufacturing country wherein the

product obtained its present identity as a

part, subassembly, or finished product.

423 Country of initial n3+n.15 ISO country codes stating the countries

processing (with ISO of initial processing of a trade item. The

country code) n.15 code may be 3, 6, 9, 12, 15 characters

long depending on number of processing

countries.

424 Country of processing n3+n3 ISO country code stating the country of

(with ISO country processing of a trade item

code)

425 Country of n3+n3 ISO country code stating the country of

disassembly (with ISO disassembly of a trade item

country code)

426 Country covering full n3+n3 ISO country code stating the (single)

process chain (with country of full processing of a trade item

ISO country code)

17 Expiration date n2+n8

11 Production date n2+n8

a

The characters before the first “+” symbol describe the format of the DI or AI. Note that the “+” symbols are not encoded

in the data.

12 © ISO 2017 – All rights reserved

4.2.5 Syntax

4.2.5.1 Linear bar code symbol data field syntax

Data encoded in the EAN/UPC symbology includes no identifiers. A Data Identifier, as per ANS MH10.8.2,

shall precede data encoded in the Code 39 symbology, as described in ISO/IEC 16388. Data encoded

in GS1-128 symbology shall be formatted as defined in GS1 General Specification preceded by an

Application Identifier. Data encoded in Code 128, as described in ISO/IEC 15417, not using GS1

Application Identifiers shall be preceded by a Data Identifier per ANS MH10.8.2. Data encoded in UPC-A

symbology shall be in accordance with GS1 General Specification.

4.2.5.2 Concatenation of multiple data fields

When concatenating data in a linear bar code symbol, the total length should be limited to 32 data

characters, including the associated DIs and AIs and concatenation characters but not including

symbology overhead characters. If the length exceeds the 32-character maximum message length, two-

dimensional symbols should be used.

a) When concatenating data in a linear bar code message, the appropriate data element separator shall

be used in accorda

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...