ISO 80079-37:2016

(Main)Explosive atmospheres — Part 37: Non-electrical equipment for explosive atmospheres — Non-electrical type of protection constructional safety ''c'', control of ignition sources ''b'', liquid immersion ''k''

Explosive atmospheres — Part 37: Non-electrical equipment for explosive atmospheres — Non-electrical type of protection constructional safety ''c'', control of ignition sources ''b'', liquid immersion ''k''

ISO 80079-37:2016 specifies the requirements for the design and construction of non-electrical equipment, intended for use in explosive atmospheres, protected by the types of protection constructional safety "c", control of ignition source "b" and liquid immersion "k". This part of ISO/IEC 80079 supplements and modifies the requirements in ISO 80079-36. Where a requirement of this standard conflicts with the requirement of ISO 80079-36 the requirement of this standard takes precedence. Types of protection "c", "k" and "b" are not applicable for Group I, EPL Ma without additional protective precautions. The types of ignition protection described in the standard can be used either on their own or in combination with each other to meet the requirements for equipment of Group I, Group II, and Group III depending on the ignition hazard assessment in ISO 80079-36. Keywords: constructional safety "c", control of ignition source "b" and liquid immersion "k"

Atmosphères explosives — Partie 37: Appareils non électriques destinés à être utilisés en atmosphères explosives — Mode de protection non électrique par sécurité de construction "c", par contrôle de la source d'inflammation "b", par immersion dans un liquide "k"

L'ISO 80079-37:2016 spécifie les exigences relatives à la conception et à la construction d'un appareil non électrique, destiné à être utilisé dans les atmosphères explosives et protégés par les modes de protection par sécurité de construction "c", par contrôle de la source d'inflammation "b", par immersion dans un liquide "k". La présente partie de l'ISO/IEC 80079 complète et modifie les exigences de l'ISO 80079-36. Lorsqu'une exigence de cette norme s'oppose à une exigence de l'IEC 80079-36, l'exigence de cette norme prime. Les types de protections "c", "k" et "b" ne s'appliquent pas pour le Groupe I, EPL Ma sans l'ajout d'autres précautions de protection. Les modes de protection contre l'inflammation décrits dans la norme peuvent être utilisés indépendamment ou en combinaison les uns avec les autres pour satisfaire aux exigences relatives aux appareils du Groupe I, du Groupe II et du Groupe III, en fonction de l'évaluation du danger d'inflammation dans l'ISO 80079-36. Mots clés: sécurité de construction "c", par contrôle de la source d'inflammation "b", par immersion dans un liquide "k"

General Information

- Status

- Published

- Publication Date

- 08-Mar-2016

- Technical Committee

- ISO/TMBG - Technical Management Board - groups

- Drafting Committee

- ISO/TMBG - Technical Management Board - groups

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 09-May-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 12-Feb-2026

- Consolidates

ISO 185:2005 - Grey cast irons — Classification - Effective Date

- 06-Jun-2022

Overview

ISO 80079-37:2016 - "Explosive atmospheres - Part 37: Non‑electrical equipment for explosive atmospheres - Non‑electrical type of protection constructional safety 'c', control of ignition sources 'b', liquid immersion 'k'" - specifies design and construction requirements for non‑electrical equipment intended for use in potentially explosive atmospheres. This part supplements and modifies ISO 80079-36 and takes precedence where requirements conflict. The standard defines how the types of protection constructional safety "c", control of ignition source "b", and liquid immersion "k" (used singly or in combination) are applied to equipment for Group I, II and III atmospheres depending on the ignition hazard assessment.

Key Topics and Technical Requirements

ISO 80079-37 addresses practical engineering and safety topics relevant to mechanical equipment used in explosive atmospheres, including:

- Design and construction requirements for types of protection c, b, and k

- Ingress protection and sealing arrangements for moving parts (gaskets, stuffing boxes, bellows, lubricated/unlubricated seals)

- Lubricants, coolants and protective liquids (selection and compatibility)

- Moving parts and bearings: clearances, lubrication, vibration and wear considerations

- Power transmission: gear drives, belt drives, chain drives, couplings, clutches and braking systems

- Electrostatic mitigation and earthing/bonding requirements for conveyor belts and similar equipment

- Type tests and test procedures for each protection type, including functional and overpressure tests for liquid‑immersed enclosures

- Documentation and marking requirements for equipment, safety devices and ignition prevention systems

- Informative and normative annexes covering test methods, sealing examples and methodology for assigning ignition protection types

These elements combine to control ignition sources from mechanical, thermal, electrostatic and other origins.

Practical Applications

This standard is essential where mechanical non‑electrical equipment operates in hazardous locations. Typical applications include:

- Pumps, gearboxes and seals in petrochemical and chemical plants

- Conveyors, elevators and processing equipment in grain handling, food and bulk solids industries

- Rotating machinery, clutches and brakes used in mining or offshore facilities

- Any non‑electrical mechanical assemblies where ignition prevention or liquid immersion protection is required

Implementing ISO 80079-37 helps reduce ignition risk, supports compliance with regulatory frameworks, and guides selection of materials, seals, lubricants and protective liquids.

Who Should Use This Standard

- Mechanical designers and equipment manufacturers

- Safety and plant engineers in oil & gas, chemical, mining, grain and pharmaceutical sectors

- Certification bodies and compliance officers assessing equipment for hazardous areas

- Maintenance engineers responsible for repair, lubrication and sealing systems

Related Standards

- ISO 80079-36 (general requirements and ignition hazard assessment) - supplements and is supplemented by ISO 80079-37

- Other parts of the ISO/IEC 80079 series on explosive atmospheres and protection methods

Keywords: ISO 80079-37:2016, explosive atmospheres, non-electrical equipment, constructional safety "c", control of ignition source "b", liquid immersion "k", ignition protection, hazardous areas.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

ISO 80079-37:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Explosive atmospheres — Part 37: Non-electrical equipment for explosive atmospheres — Non-electrical type of protection constructional safety ''c'', control of ignition sources ''b'', liquid immersion ''k''". This standard covers: ISO 80079-37:2016 specifies the requirements for the design and construction of non-electrical equipment, intended for use in explosive atmospheres, protected by the types of protection constructional safety "c", control of ignition source "b" and liquid immersion "k". This part of ISO/IEC 80079 supplements and modifies the requirements in ISO 80079-36. Where a requirement of this standard conflicts with the requirement of ISO 80079-36 the requirement of this standard takes precedence. Types of protection "c", "k" and "b" are not applicable for Group I, EPL Ma without additional protective precautions. The types of ignition protection described in the standard can be used either on their own or in combination with each other to meet the requirements for equipment of Group I, Group II, and Group III depending on the ignition hazard assessment in ISO 80079-36. Keywords: constructional safety "c", control of ignition source "b" and liquid immersion "k"

ISO 80079-37:2016 specifies the requirements for the design and construction of non-electrical equipment, intended for use in explosive atmospheres, protected by the types of protection constructional safety "c", control of ignition source "b" and liquid immersion "k". This part of ISO/IEC 80079 supplements and modifies the requirements in ISO 80079-36. Where a requirement of this standard conflicts with the requirement of ISO 80079-36 the requirement of this standard takes precedence. Types of protection "c", "k" and "b" are not applicable for Group I, EPL Ma without additional protective precautions. The types of ignition protection described in the standard can be used either on their own or in combination with each other to meet the requirements for equipment of Group I, Group II, and Group III depending on the ignition hazard assessment in ISO 80079-36. Keywords: constructional safety "c", control of ignition source "b" and liquid immersion "k"

ISO 80079-37:2016 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 80079-37:2016 has the following relationships with other standards: It is inter standard links to EN ISO 22734-1:2025, EN ISO 80079-36:2016, EN ISO/IEC 80079-38:2016, EN ISO 20321:2020, EN ISO 21789:2022, EN ISO 12643-1:2023, EN ISO 80079-37:2016, ISO 185:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 80079-37:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

ISO 80079-37

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 37: Non-electrical equipment for explosive atmospheres – Non electrical

type of protection constructional safety “c”, control of ignition source “b”, liquid

immersion “k”

Atmosphères explosives –

Partie 37: Appareils non électriques destinés à être utilisés en atmosphères

explosives – Mode de protection non électrique par sécurité de construction "c",

par contrôle de la source d'inflammation "b", par immersion dans un liquide "k"

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in

any form or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet,

without prior written permission. Permission can be requested from either ISO at the address below or ISO’s member

body in the country of the requester.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie,

l’affichage sur l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent

être adressées à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

ISO 80079-37

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 37: Non-electrical equipment for explosive atmospheres – Non electrical

type of protection constructional safety “c”, control of ignition source “b”, liquid

immersion “k”

Atmosphères explosives –

Partie 37: Appareils non électriques destinés à être utilisés en atmosphères

explosives – Mode de protection non électrique par sécurité de construction "c",

par contrôle de la source d'inflammation "b", par immersion dans un liquide "k"

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.230; 29.260.20 ISBN 978-2-8322-3181-4

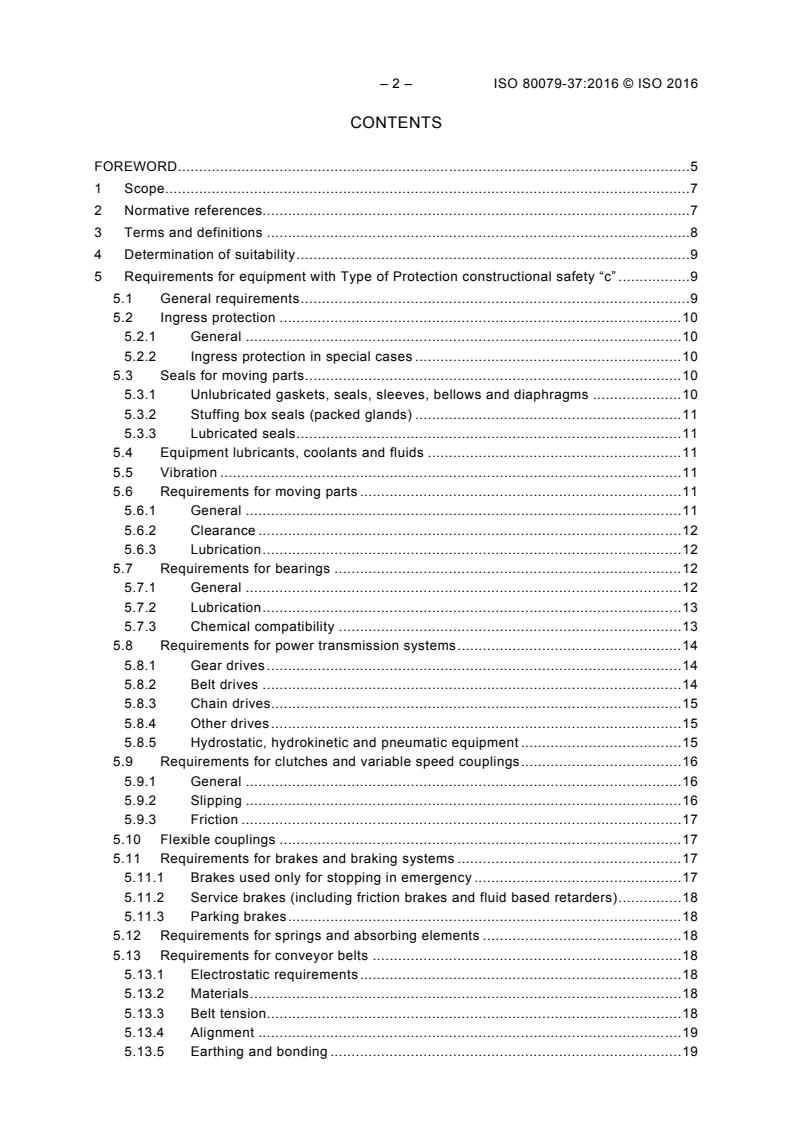

– 2 – ISO 80079-37:2016 © ISO 2016

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 8

4 Determination of suitability . 9

5 Requirements for equipment with Type of Protection constructional safety “c” . 9

5.1 General requirements . 9

5.2 Ingress protection . 10

5.2.1 General . 10

5.2.2 Ingress protection in special cases . 10

5.3 Seals for moving parts . 10

5.3.1 Unlubricated gaskets, seals, sleeves, bellows and diaphragms . 10

5.3.2 Stuffing box seals (packed glands) . 11

5.3.3 Lubricated seals . 11

5.4 Equipment lubricants, coolants and fluids . 11

5.5 Vibration . 11

5.6 Requirements for moving parts . 11

5.6.1 General . 11

5.6.2 Clearance . 12

5.6.3 Lubrication . 12

5.7 Requirements for bearings . 12

5.7.1 General . 12

5.7.2 Lubrication . 13

5.7.3 Chemical compatibility . 13

5.8 Requirements for power transmission systems . 14

5.8.1 Gear drives . 14

5.8.2 Belt drives . 14

5.8.3 Chain drives. 15

5.8.4 Other drives . 15

5.8.5 Hydrostatic, hydrokinetic and pneumatic equipment . 15

5.9 Requirements for clutches and variable speed couplings . 16

5.9.1 General . 16

5.9.2 Slipping . 16

5.9.3 Friction . 17

5.10 Flexible couplings . 17

5.11 Requirements for brakes and braking systems . 17

5.11.1 Brakes used only for stopping in emergency . 17

5.11.2 Service brakes (including friction brakes and fluid based retarders) . 18

5.11.3 Parking brakes . 18

5.12 Requirements for springs and absorbing elements . 18

5.13 Requirements for conveyor belts . 18

5.13.1 Electrostatic requirements . 18

5.13.2 Materials . 18

5.13.3 Belt tension . 18

5.13.4 Alignment . 19

5.13.5 Earthing and bonding . 19

6 Requirements for equipment with Type of Protection control of ignition source “b” . 19

6.1 General . 19

6.2 Determination of the control parameters . 19

6.2.1 General . 19

6.2.2 Determination of the safety critical values . 20

6.3 Ignition prevention system design and settings . 20

6.3.1 Determining the performance requirements or operating characteristics . 20

6.3.2 Instructions . 20

6.3.3 System lockout . 20

6.3.4 Operator intervention . 21

6.4 Ignition protection of sensors and actuators . 21

6.5 Ignition protection types . 21

6.5.1 Ignition protection type b1 . 21

6.5.2 Ignition protection type b2 . 21

6.5.3 Application of ignition protection types . 22

6.5.4 Requirements for ignition protection types . 23

6.5.5 Programmable electronic devices . 23

7 Requirements for equipment with Type of Protection liquid immersion “k”. 23

7.1 Determination of the maximum / minimum criteria . 23

7.2 Protective liquid . 24

7.3 Equipment construction . 24

7.3.1 General . 24

7.3.2 Working angle . 24

7.3.3 Measures to ensure effectiveness of liquid . 24

7.3.4 Accidental loosening . 25

7.3.5 Level monitoring . 25

7.3.6 Loss of liquid . 25

7.3.7 Open equipment . 26

8 Type tests . 26

8.1 Type tests for equipment with Type of Protection constructional safety “c” . 26

8.2 Type tests for equipment with Type of Protection control of ignition source

“b” . 26

8.2.1 Determination of control parameters . 26

8.2.2 Function and accuracy check of the ignition protection system . 26

8.3 Type tests for equipment with Type of Protection liquid immersion “k” . 26

8.3.1 General . 26

8.3.2 Increased pressure test on enclosed equipment having a sealed

enclosure that contains static, or flowing protective liquid . 26

8.3.3 Overpressure test on enclosed equipment having a vented enclosure . 26

9 Documentation . 26

9.1 Documentation for equipment with Type of Protection constructional safety

“c” . 26

9.2 Documentation for equipment with Type of Protection control of ignition

sources “”b” . 27

9.3 Documentation for equipment with Type of Protection liquid immersion “k” . 27

10 Marking . 28

10.1 General . 28

10.2 Safety devices . 28

– 4 – ISO 80079-37:2016 © ISO 2016

Annex A (informative) Approach and application: equipment with Type of

Protection “c” . 29

A.1 General remarks regarding ignition hazard assessment . 29

A.2 Stuffing box seal (see Table A.2) . 29

A.3 Slide ring seal . 31

A.4 Radial seal . 36

A.5 Belt drives . 40

Annex B (normative) Test requirements . 42

B.1 "Dry run" type test for lubricated sealing arrangements . 42

B.2 Type test for determining the maximum engaging time of clutch assembly . 42

B.2.1 Apparatus . 42

B.2.2 Procedure . 43

Annex C (informative) Methodology: equipment with Type of Protection “b” . 44

Annex D (informative) Approach to assign the required ignition protection type used

for equipment to achieve different EPL . 45

D.1 For EPL Gc and Dc . 45

D.2 For EPL Gb and Db . 45

D.3 For EPL Mb . 45

D.4 For EPL Ga and Da . 46

Annex E (informative) Information on functional safety concept . 47

E.1 ISO 13849-1 . 47

E.2 IEC 61508-1 . 47

E.3 IEC 62061 . 47

E.4 Reliability according to functional safety standards . 47

Bibliography . 49

Figure C.1 – Flow diagram of the procedures described in this document . 44

Table 1 – Minimum ignition protection types required when Ex “b” is selected to

achieve the intended EPL for Group II and III equipment. 22

Table 2 – Minimum ignition protection types required when Ex “b” is selected to

achieve the intended EPL for Group I equipment . 23

Table A.1 – List of examples for some of the thought processes and principles used . 29

Table A.2 – Stuffing box seal . 30

Table A.3 – Slide ring seal . 32

Table A.4 – Radial seal . 37

Table A.5 – Belt drives . 41

Table E.1 – Application of ignition protection type . 48

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHÈRES –

Part 37: Non-electrical equipment for explosive atmospheres –

Non electrical type of protection constructional safety “c”,

control of ignition source “b”, liquid immersion “k”

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 80079-37 has been prepared by IEC sub-committee 31M: Non-

electrical equipment and protective systems for explosive atmospheres, of IEC 31: Equipment

for explosive atmospheres.

The text of this standard is based on the following documents of the IEC:

FDIS Report on voting

31M/104/FDIS 31M/110/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table. In ISO, the standard has been approved by 15 P members

out of 20 having cast a vote.

– 6 – ISO 80079-37:2016 © ISO 2016

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

"A list of all parts in the IEC 60079 series, under the general title Explosive atmospheres, as

well as the International Standard 80079 series, can be found on the IEC website."

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

.

EXPLOSIVE ATMOSPHERES –

Part 37: Non-electrical equipment for explosive atmospheres –

Non electrical type of protection constructional safety “c”,

control of ignition source “b”, liquid immersion “k”

1 Scope

This part of ISO/IEC 80079 specifies the requirements for the design and construction of non-

electrical equipment, intended for use in explosive atmospheres, protected by the types of

protection constructional safety “c”, control of ignition source “b” and liquid immersion “k”.

This part of ISO/IEC 80079 supplements and modifies the requirements in ISO 80079-36.

Where a requirement of this standard conflicts with the requirement of ISO 80079-36 the

requirement of this standard takes precedence.

Types of Protection “c”, “k” and “b” are not applicable for Group I, EPL Ma without additional

protective precautions.

The types of ignition protection described in the standard can be used either on their own or

in combination with each other to meet the requirements for equipment of Group I, Group II,

and Group III depending on the ignition hazard assessment in ISO 80079-36.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60079-0, Explosive atmospheres – Part 0: Equipment – General requirements

IEC TS 60079-32-1, Explosive atmospheres – Part 32-1: Electrostatic hazards, Guidance

IEC 60529, Degrees of protection provided by enclosures (IP Code)

ISO 281, Rolling bearings – Dynamic load ratings and rating life

ISO 1813, Belt drives – V-ribbed belts, joined V-belts and V-belts including wide section belts

and hexagonal belts – Electrical conductivity of antistatic belts: Characteristics and methods

of test

ISO 9563, Belt drives – Electrical conductivity of antistatic endless synchronous belts –

Characteristics and test method

ISO 4413, Hydraulic fluid power – General rules and safety requirements for systems and

their components

ISO 4414, Pneumatic fluid power – General rules and safety requirements for systems and

their components

ISO 19353, Safety of machinery – Fire prevention and protection

– 8 – ISO 80079-37:2016 © ISO 2016

ISO 80079-36: 2016, Explosive atmospheres – Non-electrical equipment for explosive

atmospheres – Part 1: Basic method and requirements

EN 13237, Potentially explosive atmospheres – Terms and definitions for equipment and

protective systems intended for use in potentially explosive atmospheres

EN 13501-1, Fire classification of construction products and building elements – Part 1:

Classification using data from reaction to fire tests

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 80079-36,

IEC 60079-0 and the following apply.

3.1

constructional safety “c”

ignition protection where constructional measures are applied so as to protect against the

possibility of ignition from hot surfaces, sparks and adiabatic compression generated by

moving parts

3.2

mechanically generated sparks

sparks produced by mechanical impact or friction burning particles, as well as showers of

particles, produced by impact or friction between two solid materials

3.3

control of ignition source “b”

ignition protection where mechanical or electrical devices are used in conjunction with non-

electrical equipment to manually or automatically reduce the likelihood of a potential ignition

source from becoming an effective ignition source

Note 1 to entry: This might for example be a level sensor used to indicate loss of oil, a temperature sensor to

indicate a hot bearing or a speed sensor to indicate over-speed.

3.3.1

automatic control measure

action taken without manual intervention, to reduce the likelihood of a potential ignition source

from becoming an effective ignition source

3.3.2

manual control measure

action taken by a person as a result of a warning, indication, or alarm, to reduce the likelihood

of a potential ignition source from becoming an effective ignition source

3.3.3

ignition prevention devices/systems

arrangement that converts signals from one or more sensors into an action, or indication, to

reduce the likelihood of a potential ignition source from becoming an effective ignition source

____________

To be published.

3.3.4

safety devices

devices intended for use inside or outside explosive atmospheres but required for or

contributing to the safe functioning of equipment and protective systems with respect to the

risks of explosion

3.4

liquid immersion “k”

type of protection where potential ignition sources are made ineffective or separated from the

explosive atmosphere by either totally immersing them in a protective liquid, or by partially

immersing and continuously coating their active surfaces with a protective liquid in such a way

that an explosive atmosphere which may be above the liquid, or outside the equipment

enclosure, cannot be ignited

3.4.1

protective liquid

a liquid which prevents the explosive atmosphere from making direct contact with potential

ignition sources and thereby ensures the explosive atmosphere cannot be ignited

3.4.2

equipment with a sealed enclosure

totally enclosed equipment that limits the ingress of an external atmosphere during the

expansion and contraction of the internally contained protective liquid during use in service

Note 1 to entry: Such equipment includes any pipework associated with it and often contains an overpressure

relief device.

3.4.3

equipment with a vented enclosure

enclosed equipment that allows the ingress and egress of an external atmosphere through a

breathing device or constricted opening during the expansion and contraction of the internally

contained protective fluid during normal operation

Note 1 to entry: Such equipment includes any pipework associated with it.

3.4.4

open equipment

equipment that is immersed, or has its components immersed, in a protective liquid that is

open to the external atmosphere

Note 1 to entry: For example, an open top vessel with immersed moving components. Such equipment includes

any pipework associated with it.

4 Determination of suitability

Before a decision is made to protect equipment or parts of equipment for use as an assembly,

including interconnecting parts, by the measures described in this standard, it shall have been

subjected to the ignition hazard assessment in accordance with ISO 80079-36.

5 Requirements for equipment with Type of Protection constructional safety

“c”

5.1 General requirements

Equipment designed and constructed according to the applicable safety requirements of the

relevant industrial standards is intended to be capable of functioning in conformity with the

operational parameters established by the manufacturer, including any mechanical and

thermal stresses that they are intended to be subjected to.

– 10 – ISO 80079-37:2016 © ISO 2016

This also applies to interconnecting parts of equipment including joints (e.g. cemented,

soldered, or welded joints).

NOTE This is accomplished by using one or more of the following documents:

• International standards or Technical Specifications

• FDIS of International standards or Technical Specifications

• National Standards or Technical Specifications

• Technical specifications or Test Reports issued by an Ex accredited Test Laboratory

• Technical specifications of industrial associations.

5.2 Ingress protection

5.2.1 General

The degree of ingress protection (IP) as specified in IEC 60529 provided by the outer

enclosures of equipment depends upon its intended duty and the type of environment it is

designed to be used in. An appropriate rating shall be determined as part of the ignition

hazard assessment (see Clause 4) and, if relevant for ignition protection, shall be able to

provide that degree of protection.

NOTE IP degrees of protection according to IEC 60529 are not intended to provide protection against the ingress

of an explosive gas atmosphere.

5.2.2 Ingress protection in special cases

The following points specify the minimum IP rating for enclosures used in the circumstances

described.

a) In the case of equipment intended for use in explosive gas atmospheres, where entry of

foreign objects can cause ignition, but entry of dust is harmless, the required degree of

protection against the entry of foreign objects shall be determined in the ignition hazard

assessment and shall be at least IP20.

b) In the case of equipment intended for use in explosive gas atmospheres, where the entry

of dusts or liquids could cause a malfunction leading to an ignition source, the degree of

protection shall be at least IP5X for dust and IPX4 for liquids.

c) In the case of equipment intended for use in explosive dust atmospheres, where ingress of

dust can result in an ignition source or fire, the degree of protection shall be IP6X.

d) In the case of equipment intended for use in explosive dust atmospheres, where ingress of

dust, foreign objects and liquids are not likely to cause an ignition, no specific degree of

protection is necessary for the purpose of ignition protection.

NOTE An enclosure is often employed for other safety reasons, e.g. IP2X to prevent parts of the body coming into

contact with rotating parts.

5.3 Seals for moving parts

5.3.1 Unlubricated gaskets, seals, sleeves, bellows and diaphragms

Un-lubricated gaskets, seals, sleeves, bellows and diaphragms shall not become an effective

ignition source, e.g. if there is a risk of mechanically generated sparks and hot surfaces which

can become an effective ignition source. Light metals shall not be used for these parts in this

case (see ISO 80079-36).

Non-metallic materials shall be resistant to distortion and degradation which would reduce the

effectiveness of explosion protection within the specified lifetime of operation.

5.3.2 Stuffing box seals (packed glands)

Stuffing box seals (packed glands) shall only be used when instructions are provided by the

manufacturer to limit the maximum surface temperature during operation of the gland;

alternatively an automatic means shall be provided.

5.3.3 Lubricated seals

Seals which normally require the presence of a lubricant which can be replenished to reduce

the likelihood of hot surfaces occurring at their interface with equipment parts shall be

designed to ensure the sufficient presence of lubricant or shall be protected by one of the

following means:

• provision of an effective means to monitor the continued presence of the lubricant; or

• provision of a temperature detection device to warn of increasing temperatures; or

• design of the equipment to be capable of completing the ‘dry run’ type test, as described

in Annex B, without exceeding the maximum surface temperature of the equipment and

without suffering damage which would reduce the effectiveness of its ignition protection.

Monitoring shall be either continuous or by required appropriate inspection and examination.

Where the level of lubricant cannot be easily monitored (e.g. seal containing grease) the

relevant information shall be given in the instructions.

The instructions shall include details relating to the correct lubrication, monitoring and

maintenance of such seals.

5.4 Equipment lubricants, coolants and fluids

Lubricants and coolants, which are required for the protection against incendive hot surfaces

or mechanically generated sparks (see Clause 7) shall have an auto-ignition temperature (see

IEC 60079-20-1) at least 50 K above the maximum surface temperature of the equipment

where the liquid is being used.

NOTE IEC 60079-20-1 is under revision and is expected to be published as ISO/IEC 80079-20-1.

Any fluid which can be released shall not result in an effective ignition source, e.g. due to high

temperature or electrostatic charging.

5.5 Vibration

Effective ignition sources, hot surfaces or mechanically generated sparks or loss of

protection, caused by vibration shall be avoided. Vibration can arise from the equipment itself

or from the place where it is mounted.

The manufacturer shall prepare any necessary installation, operation and maintenance

instructions. In particular, the instructions shall specify the correct operating speed range of

the equipment in order to avoid excessive vibration.

5.6 Requirements for moving parts

5.6.1 General

The ignition hazard assessment (see ISO 80079-36) shall identify those moving parts which

could lead to the occurrence of unsafe vibration or impact or friction. Such parts shall be

constructed in such a way so that they are unlikely to become an effective ignition source

during the specified lifetime of operation of the equipment, taking the EPL into consideration

in combination with the instructions.

Where the melting point of the material used in the construction of moving parts is below the

maximum surface temperature of the equipment, or is not capable of causing incendive hot

– 12 – ISO 80079-37:2016 © ISO 2016

surfaces or mechanical sparks, additional protective measures are not normally necessary

(e.g. the provision of a low melting point sacrificial wear plate; the use of a plastic fan inside a

metal housing, or a metallic fan with sacrificial non-sparking low melting point fan blade-tips).

5.6.2 Clearance

Clearances between un-lubricated moving parts and fixed parts shall be designed such that

likelihood of frictional contact, able to produce an effective ignition source in the form of hot

surfaces or mechanically generated sparks, is appropriate to the intended EPL.

5.6.3 Lubrication

For moving parts needing lubrication to avoid excessive temperatures or mechanically

generated sparks, effective lubrication shall be ensured, e.g. by:

• an oil splash lubricator, or

• a constant oil feed by means of a reservoir, pump and perhaps an oil cooler, or

• an automatic greasing system, or

• an adequate maintenance procedure to provide for routine greasing or oil level verification

by manual or visual means.

If the above measures do not achieve the required EPL of the equipment additional measures

to monitor adequate lubrication shall be applied, e.g. level, flow, pressure or temperature

sensors which operates an alarm or switch function before a critical lubricant condition is

reached, see Clause 6.

Where equipment is designed to process liquids and the presence of the process liquid is

essential for the purpose of lubrication, cooling, quenching, or ignition protection, or when the

safe operation of the equipment (e.g. of a pump) requires special priming considerations, this

shall be stated in the instructions.

5.7 Requirements for bearings

5.7.1 General

Bearings are basically divided into three types, sliding plane motion, sliding rotary motion and

rolling element. When assessing bearings, as part of the ignition hazard assessment required

by ISO 80079-36, at least the following shall be taken into account:

a) the bearing’s suitability for the equipment’s intended duty e.g. speed, temperature, loading

and variations of speed and loading;

b) the bearing’s basic rated life as described in ISO 281 for rolling element bearings (see

also Note 1);

c) the proper fit of the bearings in their housing and on the shaft (tolerances, roundness and

surface quality), taking into consideration the vertical and axial loads on the bearing with

respect to shaft and housing;

d) the correct alignment of the bearings;

e) the axial and radial loading of the bearings caused by thermal expansion of the shaft and

the housing under the most severe operating conditions;

f) protection of the bearing from ingress of water and solids, if necessary to avoid premature

failure;

g) protection of the bearing from electrical currents, including stray circulating currents

(which can cause, for example, incendive sparking, or spark erosion leading to premature

failure, at the point of contact between the ball and ball race of a ball bearing);

h) the provision of adequate lubrication, according to the lubricating regime necessary for the

type of bearing (e.g. for sliding bearings, boundary lubrication, mixed film, or full film

hydrodynamic lubrication are the most commonly used regimes);

i) Maintenance checks at recommended intervals (e.g. vibration, temperature);

j) replacement after unacceptable wear or at the end of its recommended life, whichever

comes first;

k) protection of the bearing from vibration, especially at standstill;

l) the use of low reliability non-metallic bearing cages in industrial applications.

m) Where a special initial running in period is necessary that could lead to an effective

ignition source, information shall be given in the instructions.

NOTE 1 At the present time, no suitable experimental test exists to demonstrate that a given type of bearing has

a low risk of becoming an ignition source in service. Ball and roller bearing manufacturers do, however, quote a

basic rated life corresponding to a probability of mechanical failure occurring during operation (e.g. failure by

deformation of an element, or fatigue flaking or spalling occurring on one of its elements). This basic rating can be

used in the ignition hazard assessment in an attempt to determine the risk of bearing malfunction that might lead to

the production

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...