ISO 80079-36:2016

(Main)Explosive atmospheres — Part 36: Non-electrical equipment for explosive atmospheres — Basic method and requirements

Explosive atmospheres — Part 36: Non-electrical equipment for explosive atmospheres — Basic method and requirements

ISO 80079-36:2016 specifies the basic method and requirements for design, construction, testing and marking of non-electrical Ex equipment, Ex Components, protective systems, devices and assemblies of these products that have their own potential ignition sources and are intended for use in explosive atmospheres. Hand tools and manually operated equipment without energy storage are excluded from the scope of this standard. This standard does not address the safety of static autonomous process equipment when it is not part of equipment referred to in this standard. This standard does not specify requirements for safety, other than those directly related to the risk of ignition which may then lead to an explosion. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that equipment can be operated are: - temperature -20 °C to 60 °C; - pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and - air with normal oxygen content, typically 21 % v/v. Such atmospheres can also exist inside the equipment. In addition, the external atmosphere can be drawn inside the equipment by natural breathing produced as a result of fluctuations in the equipment's internal operating pressure, and/or temperature. This part of ISO/IEC 80079 specifies the requirements for the design and construction of equipment, intended for explosive atmospheres in conformity with all Equipment Protection Levels (EPLs) of Group I, II and III. This standard supplements and modifies the general requirements of IEC 60079-0, as shown in Table 1 in the Scope of the document. Keywords: mechanical explosion protected equipment

Atmosphères explosives — Partie 36: Appareils non électriques destinés à être utilisés en atmosphères explosives — Méthodologie et exigences

L'ISO 80079-36:2016 spécifie la méthodologie et les exigences de base pour la conception, la construction, les essais et le marquage des appareils Ex non électriques, des composants Ex, des systèmes de protection, des dispositifs et des assemblages de ces produits qui comportent leurs propres sources potentielles d'inflammation et qui sont destinés à être utilisés en atmosphères explosives. Les outils à main et les appareils à fonctionnement manuel sans stockage d'énergie sont exclus du domaine d'application de la présente norme. La présente norme ne traite pas de la sécurité des appareils de procédés autonomes statiques s'ils ne font pas partie des appareils auxquels la présente norme fait référence. La présente norme ne spécifie pas les exigences de sécurité autres que les exigences directement liées au risque d'inflammation pouvant entraîner une explosion. Les conditions atmosphériques normalisées (relatives aux caractéristiques d'explosion de l'atmosphère), selon lesquelles il peut être assumé que les appareils peuvent fonctionner sont les suivantes: - température de - 20 °C à 60 °C; - pression de 80 kPa (0,8 bar) à 110 kPa (1,1 bar); et - air avec teneur normale en oxygène, typiquement de 21 % v/v. De telles atmosphères peuvent également exister à l'intérieur de l'appareil. En outre, l'atmosphère externe peut être aspirée à l'intérieur de l'appareil par la respiration naturelle produite en raison des variations de pression de fonctionnement interne de l'appareil et/ou de la température. La présente partie de l'ISO/IEC 80079 définit les exigences relatives à la conception et à la construction des appareils destinés à être utilisés en atmosphères explosives en conformité avec tous les niveaux de protection de l'appareil (EPL) des Groupes I, II et III. Cette norme complète et modifie les exigences générales de l'IEC 60079-0 comme indiqué dans le Tableau 1 dans l'avant-propos du document. Mots clés: appareils mécaniques protégés contre l'explosion

General Information

- Status

- Published

- Publication Date

- 08-Mar-2016

- Technical Committee

- ISO/TMBG - Technical Management Board - groups

- Drafting Committee

- ISO/TMBG - Technical Management Board - groups

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 09-May-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Referred By

EN ISO 23779:2025 - Shot blasting machinery - Safety and environmental requirements (ISO 23779:2024) - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 12-Feb-2026

Overview

ISO 80079-36:2016 - Explosive atmospheres - Part 36: Non-electrical equipment for explosive atmospheres - Basic method and requirements - defines the basic method and requirements for the design, construction, testing and marking of non-electrical Ex equipment, Ex Components, protective systems, devices and assemblies that have their own potential ignition sources and are intended for use in explosive atmospheres. It covers all Equipment Protection Levels (EPLs) for Groups I, II and III and supplements/modifies the general requirements of IEC 60079-0. Hand tools and manually operated equipment without energy storage are excluded. The standard applies under standard atmospheric conditions (−20 °C to 60 °C; 80 kPa to 110 kPa; air ~21% v/v O2).

Key topics and technical requirements

- Ignition hazard assessment: formal procedures to identify ignition hazards, evaluate malfunctions and determine required protection measures and EPLs.

- Assessment of ignition sources and control means: evaluation of hot surfaces, flames/hot gases, mechanically generated sparks and friction, electrical and stray-current sources, static electricity, adiabatic compression, shock waves and exothermic reactions.

- Dust and material considerations: guidance on dust deposits, flame arrester integrity, and material selection for non-metallic parts.

- Verification and tests: hot surface ignition tests, mechanical impact and drop tests, thermal endurance, resistance to chemical substances, surface resistance tests and other tests for non-metallic components.

- Documentation, marking and instructions: technical documentation requirements, conformity evidence, marking rules (including examples and requirements for small equipment) and user instructions.

- Annexes: methodologies for confirming EPLs and worked examples / explanations of the ignition hazard assessment procedure.

Practical applications

ISO 80079-36 is essential when developing or certifying mechanical explosion protected equipment and other non-electrical devices intended for potentially explosive atmospheres. Use cases include:

- Design and verification of mechanical components and assemblies that may generate ignition sources (moving parts, hot surfaces, pressure systems).

- Preparation of conformity documentation and marking for equipment placed on market in hazardous locations.

- Establishing test programs and acceptance criteria for non-electrical Ex Components and protective systems.

Who should use this standard

- Design and mechanical engineers working on equipment for petrochemical, mining, pharmaceutical, grain handling and similar industries.

- Manufacturers of non-electrical Ex equipment and Ex Components.

- Certification and conformity assessment bodies, safety engineers, maintenance teams and regulatory authorities responsible for hazardous-area safety.

Related standards

- IEC 60079-0 (general requirements for equipment for explosive atmospheres) - ISO 80079-36 supplements and modifies its general requirements.

- ISO 80079 series (other parts addressing electrical and non-electrical Ex equipment).

Keywords: mechanical explosion protected equipment, non-electrical Ex equipment, ignition hazard assessment, Equipment Protection Levels, explosive atmospheres.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

ISO 80079-36:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Explosive atmospheres — Part 36: Non-electrical equipment for explosive atmospheres — Basic method and requirements". This standard covers: ISO 80079-36:2016 specifies the basic method and requirements for design, construction, testing and marking of non-electrical Ex equipment, Ex Components, protective systems, devices and assemblies of these products that have their own potential ignition sources and are intended for use in explosive atmospheres. Hand tools and manually operated equipment without energy storage are excluded from the scope of this standard. This standard does not address the safety of static autonomous process equipment when it is not part of equipment referred to in this standard. This standard does not specify requirements for safety, other than those directly related to the risk of ignition which may then lead to an explosion. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that equipment can be operated are: - temperature -20 °C to 60 °C; - pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and - air with normal oxygen content, typically 21 % v/v. Such atmospheres can also exist inside the equipment. In addition, the external atmosphere can be drawn inside the equipment by natural breathing produced as a result of fluctuations in the equipment's internal operating pressure, and/or temperature. This part of ISO/IEC 80079 specifies the requirements for the design and construction of equipment, intended for explosive atmospheres in conformity with all Equipment Protection Levels (EPLs) of Group I, II and III. This standard supplements and modifies the general requirements of IEC 60079-0, as shown in Table 1 in the Scope of the document. Keywords: mechanical explosion protected equipment

ISO 80079-36:2016 specifies the basic method and requirements for design, construction, testing and marking of non-electrical Ex equipment, Ex Components, protective systems, devices and assemblies of these products that have their own potential ignition sources and are intended for use in explosive atmospheres. Hand tools and manually operated equipment without energy storage are excluded from the scope of this standard. This standard does not address the safety of static autonomous process equipment when it is not part of equipment referred to in this standard. This standard does not specify requirements for safety, other than those directly related to the risk of ignition which may then lead to an explosion. The standard atmospheric conditions (relating to the explosion characteristics of the atmosphere) under which it may be assumed that equipment can be operated are: - temperature -20 °C to 60 °C; - pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and - air with normal oxygen content, typically 21 % v/v. Such atmospheres can also exist inside the equipment. In addition, the external atmosphere can be drawn inside the equipment by natural breathing produced as a result of fluctuations in the equipment's internal operating pressure, and/or temperature. This part of ISO/IEC 80079 specifies the requirements for the design and construction of equipment, intended for explosive atmospheres in conformity with all Equipment Protection Levels (EPLs) of Group I, II and III. This standard supplements and modifies the general requirements of IEC 60079-0, as shown in Table 1 in the Scope of the document. Keywords: mechanical explosion protected equipment

ISO 80079-36:2016 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 80079-36:2016 has the following relationships with other standards: It is inter standard links to EN ISO 22734-1:2025, EN ISO 21789:2022, EN ISO/IEC 80079-38:2016, EN ISO 16321-1:2022, EN ISO/ASTM 52938-1:2025, EN ISO 12643-1:2023, EN ISO 23779:2025, EN ISO 20321:2020, EN ISO 80079-37:2016, EN ISO 80079-36:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 80079-36:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

ISO 80079-36

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 36: Non-electrical equipment for explosive atmospheres – Basic method

and requirements

Atmosphères explosives –

Partie 36: Appareils non électriques destinés à être utilisés en atmosphères

explosives – Méthodologie et exigences

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in

any form or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet,

without prior written permission. Permission can be requested from either ISO at the address below or ISO’s member

body in the country of the requester.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie,

l’affichage sur l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent

être adressées à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

ISO 80079-36

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 36: Non-electrical equipment for explosive atmospheres – Basic method

and requirements

Atmosphères explosives –

Partie 36: Appareils non électriques destinés à être utilisés en atmosphères

explosives – Méthodologie et exigences

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.230; 29.260.20 ISBN 978-2-8322-3202-6

– 2 – ISO 80079-36:2016 ISO 2016

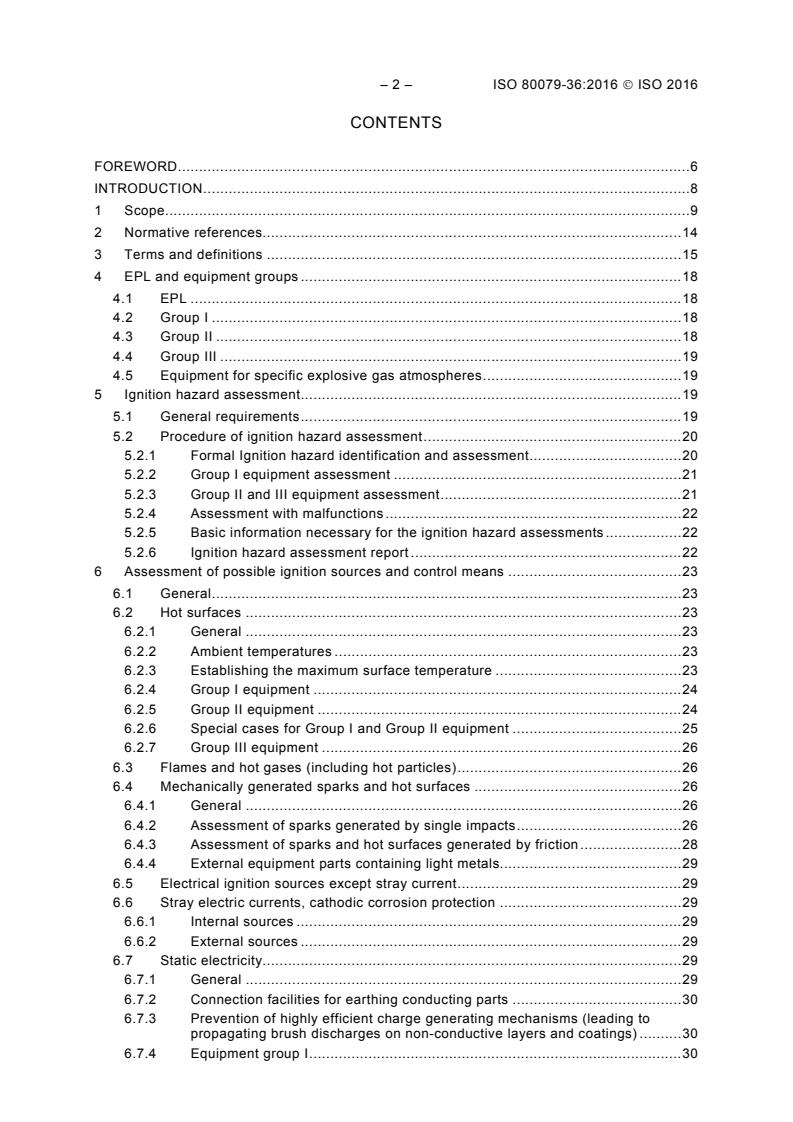

CONTENTS

FOREWORD . 6

INTRODUCTION . 8

1 Scope . 9

2 Normative references. 14

3 Terms and definitions . 15

4 EPL and equipment groups . 18

4.1 EPL . 18

4.2 Group I . 18

4.3 Group II . 18

4.4 Group III . 19

4.5 Equipment for specific explosive gas atmospheres . 19

5 Ignition hazard assessment . 19

5.1 General requirements . 19

5.2 Procedure of ignition hazard assessment . 20

5.2.1 Formal Ignition hazard identification and assessment . 20

5.2.2 Group I equipment assessment . 21

5.2.3 Group II and III equipment assessment . 21

5.2.4 Assessment with malfunctions . 22

5.2.5 Basic information necessary for the ignition hazard assessments . 22

5.2.6 Ignition hazard assessment report . 22

6 Assessment of possible ignition sources and control means . 23

6.1 General . 23

6.2 Hot surfaces . 23

6.2.1 General . 23

6.2.2 Ambient temperatures . 23

6.2.3 Establishing the maximum surface temperature . 23

6.2.4 Group I equipment . 24

6.2.5 Group II equipment . 24

6.2.6 Special cases for Group I and Group II equipment . 25

6.2.7 Group III equipment . 26

6.3 Flames and hot gases (including hot particles) . 26

6.4 Mechanically generated sparks and hot surfaces . 26

6.4.1 General . 26

6.4.2 Assessment of sparks generated by single impacts . 26

6.4.3 Assessment of sparks and hot surfaces generated by friction . 28

6.4.4 External equipment parts containing light metals. 29

6.5 Electrical ignition sources except stray current . 29

6.6 Stray electric currents, cathodic corrosion protection . 29

6.6.1 Internal sources . 29

6.6.2 External sources . 29

6.7 Static electricity. 29

6.7.1 General . 29

6.7.2 Connection facilities for earthing conducting parts . 30

6.7.3 Prevention of highly efficient charge generating mechanisms (leading to

propagating brush discharges on non-conductive layers and coatings) . 30

6.7.4 Equipment group I . 30

6.7.5 Equipment group II . 31

6.7.6 Equipment group III . 31

6.8 Adiabatic compression and shock waves . 32

6.9 Exothermic reactions, including self-ignition of dusts . 32

7 Additional considerations . 32

7.1 Dust deposits and other material in the gap of moving parts . 32

7.2 Dust deposits and other material in the flame arresters incorporated in the

equipment . 33

7.3 Opening times of enclosures . 33

7.4 Non-metallic enclosures and non-metallic parts of the equipment . 33

7.4.1 General . 33

7.4.2 Specification of the materials . 33

7.4.3 Thermal endurance . 33

7.5 Removable parts . 33

7.6 Materials used for cementing . 33

7.7 Light transmitting parts . 34

7.8 Stored energy . 34

8 Verification and tests . 34

8.1 General . 34

8.2 Determination of the maximum surface temperature . 34

8.2.1 General . 34

8.2.2 Hot Surface Ignition Test . 36

8.3 Mechanical tests . 37

8.3.1 Test for resistance to impact . 37

8.3.2 Drop test . 37

8.3.3 Required results . 37

8.4 Additional tests of non-metallic parts of the equipment relevant for explosion

protection . 37

8.4.1 Test temperatures . 37

8.4.2 Tests for Group I equipment . 37

8.4.3 Tests for Group II and III equipment . 38

8.4.4 Thermal endurance to heat . 38

8.4.5 Thermal endurance to cold . 39

8.4.6 Resistance to chemical substances for Group I equipment . 39

8.4.7 Mechanical resistance tests . 39

8.4.8 Surface resistance test of non-conductive parts of the equipment

relevant for explosion prevention and protection . 39

8.4.9 Thermal shock test . 39

9 Documentation . 39

9.1 Technical documentation . 39

9.2 Conformity with the documentation . 40

9.3 Certificate . 40

9.4 Responsibility for marking . 40

10 Instructions. 40

11 Marking . 41

11.1 Location . 41

11.2 General . 41

11.3 Warning markings . 42

11.4 Marking on very small equipment . 43

– 4 – ISO 80079-36:2016 ISO 2016

11.5 Examples of marking . 43

Annex A (informative) Methodology for confirming the EPL . 44

A.1 Methodology for confirming the EPL of Group I . 44

A.1.1 EPL Ma . 44

A.1.2 EPL Mb . 44

A.2 Methodology for confirming the EPL of Group II and III . 44

A.2.1 EPL Ga and Da . 44

A.2.2 EPL Gb and Db . 44

A.2.3 EPL Gc and Dc . 44

Annex B (informative) Explanation of the ignition hazard assessment procedure . 45

B.1 Overview. 45

B.1.1 General . 45

B.1.2 Reporting with the help of a table . 45

B.2 Assessment Procedure . 45

B.3 Assessment Steps . 46

B.3.1 Identification of Ignition Hazards . 46

B.3.2 Determination of measures . 47

B.3.3 Concluding ignition hazard estimation and categorisation . 48

B.3.4 Determination of the EPL . 48

Annex C (informative) Examples of ignition hazard assessment . 49

C.1 General remarks . 49

C.2 Examples for common cases demonstrating the use of the scheme . 49

C.3 Example of an ignition hazard assessment for a pump . 56

C.4 Example of an ignition hazard assessment for an agitator . 60

Annex D (normative) Charging tests with non-conductive materials . 71

D.1 General . 71

D.2 Principle of the test . 71

D.3 Samples and apparatus . 72

D.4 Procedure . 72

D.4.1 Conditioning . 72

D.4.2 Determination of the most efficient charging method . 72

Annex E (informative) Consideration of misuse which can reasonably be anticipated

during ignition hazard assessment procedure . 76

E.1 General . 76

E.2 Identification and analysis of the ignition hazards . 76

E.3 First assessment of the ignition hazards . 76

E.4 Determination of safety measures . 76

E.5 Final assessment of the ignition hazards . 77

Annex F (informative) Development of different types of incendive electrostatic

discharges . 78

Annex G (normative) Protection concepts of types of protection "d", "p" and "t"

acceptable for non-electrical equipment . 79

Annex H (informative) Volume dependence of auto-ignition temperature . 80

Annex I (informative) Relationship between Equipment protection levels (EPLs) and

zones . 82

Bibliography . 83

Figure 1 – Relationship between ignition source definitions . 20

Figure D.1 – Rubbing with a pure polyamide cloth . 74

Figure D.2 – Discharging the charged surface of the test piece with a probe connected

to earth via a 0,1 µF capacitor . 74

Figure D.3 – Charging by the influence of a DC high voltage power . 75

Figure F.1 – Different types of incendive electrostatic discharges . 78

Figure H.1 – Volume dependence of auto-ignition temperature . 81

Table 1 – Applicability of specific clauses of IEC 60079-0 . 10

Table 2 – Classification of maximum surface temperatures for Group II equipment . 24

Table 3 – Assessment for temperature classification for small surface areas . 25

Table 4 – Single impact energy limits for EPL Ga . 28

Table 5 – Single impact energy limits for EPL Gb . 28

Table 6 – Single impact energy limits for EPL Gc . 28

Table 7 – Single impact energy limits for EPL Da, Db and Dc . 28

Table 8 – Permitted maximum projected areas for non-conductive parts of equipment

liable to become electrostatically charged . 31

Table 9 – Thermal endurance test . 38

Table 10 – Ambient temperature marking . 42

Table 11 – Text of warning markings . 42

Table B.1 –Table showing recommended documentation of an example of initial

assessment of equipment related ignition sources . 46

Table B.2 – Example for reporting of the identification of ignition hazards (step 1) and

the first assessment (step 2) . 47

Table B.3 – Example for reporting of the determination of protective measures (step 3)

and the concluding estimation and categorisation (step 4) . 48

Table C.1 – List of examples . 49

Table C.2 – Common cases demonstrating the use of the scheme – Electrostatic

discharge . 50

Table C.3 – Common cases demonstrating the use of the scheme – Hot surface . 52

Table C.4 – Common cases demonstrating the use of the scheme – Mechanical spark . 54

Table C.5 – Ignition hazard assessment report for a pump . 57

Table C.6 – Ignition hazard assessment report for an agitator . 61

Table H.1 – AITs of combustibles taken from IEC 60079-20-1 as contained in Figure H.1. . 80

Table I.1 – Relationship between Equipment protection levels (EPLs) and zones . 82

– 6 – ISO 80079-36:2016 ISO 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 36: Non-electrical equipment for explosive atmospheres –

Basic method and requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 80079-36 has been prepared by IEC sub-committee 31M: Non-

electrical equipment and protective systems for explosive atmospheres, of IEC 31: Equipment

for explosive atmospheres.

The text of this standard is based on the following documents of the IEC:

FDIS Report on voting

31M/103/FDIS 31M/109/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table. In ISO, the standard has been approved by 15 P members

out of 22 having cast a vote.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

"A list of all parts in the IEC 60079 series, under the general title Explosive atmospheres, as

well as the International Standard 80079 series, can be found on the IEC website."

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 8 – ISO 80079-36:2016 ISO 2016

INTRODUCTION

This part of ISO/IEC 80079 addresses for the first time basic requirements and protection

concepts for mechanical explosion protected equipment on an international level. Up to now,

with some exceptions, only the design, manufacture, installation and operation of electrical

equipment in explosive atmospheres have been addressed in ISO and IEC standards.

Examples of non-electrical equipment are: couplings, pumps, gearboxes, brakes, hydraulic

and pneumatic motors and any combination of devices to realise a machine, fan, engine,

compressor, assemblies, etc.

Although many but not all of such machines use an explosion protected electric motor for

motive power the measures needed to reduce the risk of ignition in mechanical equipment as

part of the machine may be different to those applied to electrical equipment.

Whereas electrical equipment working within design parameters often contains effective

ignition sources such as sparking parts, this is not necessarily true for mechanical equipment

which is designed to operate without break-down between predetermined maintenance

operations.

Generally there are two mechanical ignition scenarios that need to be considered. These are,

ignition resulting from a failure in the machine such as a bearing over-heating or ignition

created by the normal functioning of the machine such as a hot brake surface.

Experience has shown that it is essential to perform a comprehensive ignition hazard

assessment on the complete mechanical equipment to identify all potential ignition sources

and determine if they can become effective ignition sources during the expected lifetime of

the mechanical equipment. Once these ignition risks are understood and documented it is

then possible to assign protective measures, depending on the required Equipment Protection

Level (EPL), to minimise the probability that these ignition sources will become effective.

This standard addresses mechanical equipment and assemblies intended for the generation,

transfer, storage, measurement, control and conversion of energy and/or the processing of

material and which are capable of causing an explosion through their own potential sources of

ignition.

Potential ignition sources are not limited to those created by the equipment but include any

ignition sources created by the operation of the equipment; for example hot surfaces when

pumping hot fluids or electrostatic charging when handling plastics.

If the only source of ignition of an item comes from the external process such items are not

considered to have their own source of ignition, and they are not in the scope of this part of

ISO/IEC 80079.

NOTE Examples are items made from plastics (polymers) like plastic pipes and containers that can become

charged due to an external process (and not by the operation of the equipment), or items that can become hot due

to an external process (like a pipe). These are not considered to be “non-electrical equipment" on their own. If on

the other hand such items are incorporated into non-electrical equipment, and could become an ignition source by

the intended operation of the equipment, they need to be assessed together with the equipment under

consideration (for example a plastic pipe as part of a petrol dispenser could become charged due to the operation

of this dispenser).

EXPLOSIVE ATMOSPHERES –

Part 36: Non-electrical equipment for explosive atmospheres –

Basic method and requirements

1 Scope

This part of ISO/IEC 80079 specifies the basic method and requirements for design,

construction, testing and marking of non-electrical Ex equipment, Ex Components, protective

systems, devices and assemblies of these products that have their own potential ignition

sources and are intended for use in explosive atmospheres.

Hand tools and manually operated equipment without energy storage are excluded from the

scope of this standard. This standard does not address the safety of static autonomous

process equipment when it is not part of equipment referred to in this standard.

NOTE 1 Static autonomous process equipment includes items such as tanks, vessels, fixed pipework and hand

operated valves which do not have their own source of energy that could create a potential ignition source during

operation.

This standard does not specify requirements for safety, other than those directly related to the

risk of ignition which may then lead to an explosion. The standard atmospheric conditions

(relating to the explosion characteristics of the atmosphere) under which it may be assumed

that equipment can be operated are:

• temperature -20 °C to +60 °C;

• pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar); and

• air with normal oxygen content, typically 21 % v/v.

Such atmospheres can also exist inside the equipment. In addition, the external atmosphere

can be drawn inside the equipment by natural breathing produced as a result of fluctuations in

the equipment’s internal operating pressure, and/or temperature.

NOTE 2 Although the standard atmospheric conditions above give a temperature range for the atmosphere of -

20 °C to +60 °C, the normal ambient temperature range for the equipment is -20 °C to +40 °C, unless otherwise

specified and marked. It is considered that -20 °C to +40 °C is appropriate for most equipment and that to

manufacture all equipment to be suitable for a standard atmosphere upper ambient temperature of +60 °C would

place unnecessary design constraints.

NOTE 3 The requirements of this standard can also be helpful for the design, construction, testing and marking of

equipment intended for use in atmospheres outside the validity range stated above. In this case however, the

ignition hazard assessment, ignition protection provided, additional testing (if necessary), manufacturer’s technical

documentation and instructions to the user, clearly demonstrate and indicate the equipment’s suitability for the

conditions it may encounter. It is also recognized that changes in temperature and pressure can have a significant

influence on characteristics of the explosive atmosphere, such as ignitability.

This part of ISO/IEC 80079 specifies the requirements for the design and construction of

equipment, intended for explosive atmospheres in conformity with all Equipment Protection

Levels (EPLs) of Group I, II and III.

NOTE 4 It is not unusual for equipment designed and constructed in accordance with this standard for a particular

EPL to be used in areas requiring an EPL with a higher level of safety by including the application of additional

measures. Such measures include for example inerting, suppression, venting or containment or for example by

dilution, drainage, monitoring and shut-down. Such measures are outside the scope of this standard.

This standard supplements and modifies the general requirements of IEC 60079-0, as shown

in Table 1. Where a requirement of this standard conflicts with a requirement of IEC 60079-0,

as far as applicable for non-electrical equipment, the requirement of this standard takes

precedence.

– 10 – ISO 80079-36:2016 ISO 2016

This standard is supplemented or modified by the following standards concerning specific

types of protection:

– ISO 80079-37, Explosive atmospheres – Part 37: Non-electrical equipment for explosive

atmospheres – Non-electrical type of protection constructional safety "c", control of

ignition source "b", liquid immersion "k"

– IEC 60079-1, Explosive atmospheres – Part 1: Equipment protection by flameproof

enclosures "d"

– IEC 60079-2, Explosive atmospheres – Part 2: Equipment protection by pressurized

enclosures "p"

– IEC 60079-31, Explosive atmospheres – Part 31: Equipment dust ignition protection by

enclosure "t"

The nature and ignition sources of non-electrical equipment shall be considered when

applying types of protection "d", "p", or "t" on non-electrical equipment (see Annex G).

Table 1 – Applicability of specific clauses of IEC 60079-0 (1 of 5)

Clause of IEC 60079-0 IEC 60079-0 application to

Ed 6.0 Clause / Sub-Clause Title ISO 80079-36 ISO 80079-37

(2011) (Normative)

(Inf.)

"c" "b" "k"

4 Equipment grouping Modified (see Clause (*) (*) (*)

4)

4.1 Group I Applies (*) (*) (*)

4.2 Group II Applies (*) (*) (*)

4.3 Group III Modified (see 4.4) (*) (*) (*)

4.4 Equipment for a particular explosive Applies (*) (*) (*)

atmosphere

5 Temperatures Modified (see 6.2 and (*) (*) (*)

Table 2)

5.1 Environmental influences Applies (*) (*) (*)

5.1.1 Ambient temperature Applies (*) (*) (*)

to be read as non-

electrical equipment

5.1.2 External source of heating or cooling Applies (*) (*) (*)

to be read as non-

electrical equipment

5.2 Service temperature Applies (*) (*) (*)

to be read as non-

electrical equipment

5.3.1 Determination of maximum surface Modified (see 6.2.3) (*) (*) (*)

temperature non-electrical

5.3.2.1 Group I electrical equipment Modified (see 6.2.4) (*) (*) (*)

non-electrical

5.3.2.2 Group II electrical equipment Modified (see 6.2.5) (*) (*) (*)

non-electrical

5.3.2.3 Group III electrical equipment Modified (see 6.2.7) (*) (*) (*)

non-electrical

Table 1 (2 of 5)

Clause of IEC 60079-0 IEC 60079-0 application to

Ed 6.0 Clause / Sub-Clause Title ISO 80079-36 ISO 80079-37

(2011) (Normative)

(Inf.)

"c" "b" "k"

5.3.3 Small component temperature for Modified (see 6.2.6) (*) (*) (*)

Group I and Group II electrical non-electrical

equipment

6. Requirements for all electrical Applies (*) (*) (*)

equipment to be read as non-

electrical equipment

6.1 General Applies (*) (*) (*)

to be read as non-

electrical equipment

6.2 Mechanical strength of equipment Applies (*) (*) (*)

6.3 Opening times Modified (see 7.3) (*) (*) (*)

6.4 Circulating currents in enclosures Applies (*) (*) (*)

(e.g. of large electrical machines)

6.5 Gasket retention Applies (*) (*) (*)

6.6 Electromagnetic and ultrasonic Excluded - - -

energy radiating equipment

7 Non-metallic enclosures and non- Applies (*) (*) (*)

metallic parts of enclosures

7.1 General Applies (*) (*) (*)

7.1.1 Applicability Applies (*) (*) (*)

7.1.2 Specification of materials Applies (*) (*) (*)

7.2 Thermal endurance Applies (*) (*) (*)

7.3 Resistance to light Applies (*) (*) (*)

7.4 Electrostatic charges on external Modified (see 6.7.4, (*) (*) (*)

non-metallic materials 6.7.5 and 6.7.6)

7.5 Accessible metal parts Applies (*) (*) (*)

8 Metallic enclosures and metallic Modified (see 6.4.2.1 (*) (*) (*)

parts of enclosures Footnote 1) and ref. to

ISO 6507-1

8.1 Material composition Modified (see 6.4.2.1 (*) (*) (*)

Footnote 1) and ref. to

ISO 6507-1

8.2 Group I Modified (see 6.4.2.1 (*) (*) (*)

Footnote 1) and ref. to

ISO 6507-1

8.3 Group II Modified (see 6.4.2.1 (*) (*) (*)

Footnote 1) and ref. to

ISO 6507-1

– 12 – ISO 80079-36:2016 ISO 2016

Table 1 (3 of 5)

Clause of IEC 60079-0 IEC 60079-0 application to

Ed 6.0 Clause / Sub-Clause Title ISO 80079-36 ISO 80079-37

(2011) (Normative)

(Inf.)

"c" "b" "k"

8.4 Group III Modified (see 6.4.2.1 (*) (*) (*)

Footnote 1) and ref. to

ISO 6507-1

9 Fasteners Excluded - - -

10 Interlocking devices Excluded - - -

11 Bushings Excluded - - -

12 Materials used for cementing Applies (see 7.6) (*) (*) (*)

13 Ex Components Applies (*) (*) (*)

14 Connection facilities and termination Excluded - - -

compartments

15 Connection facilities for earthing or Excluded - - -

bonding conductors

16 Entries into enclosures Excluded - - -

17 Supplementary requirements for Excluded - - -

rotating machines

18 Supplementary requirements for Excluded - - -

switchgear

19 Supplementary requirements for Excluded - - -

fuses

20 Supplementary requirements for Excluded - - -

plugs, socket outlets and connectors

21 Supplementary requirements for Excluded - - -

luminaires

22 Supplementary requirements for Excluded - - -

caplights and handlights

23 Equipment incorporating cells and Excluded - - -

batteries

24 Documentation Modified (see 9) (*) (*) (*)

25 Compliance of prototype or sample Applies (*) (*) (*)

with documents

26 Type Tests Modified (see 8) (*) (*) (*)

26.1 General Applies (*) (*) (*)

26.2 Test configuration Applies (*) (*) (*)

to be read as non-

electrical equipment

26.3 Tests in explosive test mixtures Applies (*) (*) (*)

Table 1 (4 of 5)

Clause of IEC 60079-0 IEC 60079-0 application to

Ed 6.0 Clause / Sub-Clause Title ISO 80079-36 ISO 80079-37

(2011) (Normative)

(Inf.)

"c" "b" "k"

26.4.1 Order of tests Excluded - - -

26.4.2 Resistance to impact Applies (see 8.3.1) (*) (*) (*)

26.4.3 Drop test Applies (see 8.3.2) (*) (*) (*)

26.4.4 Acceptance criteria Applies (see 8.3.3 (*) (*) (*)

26.4.5 Degree of protection (IP) by Applies (*) (*) (*)

enclosure

26.5.1.1 General Applies (*) (*) (*)

26.5.1.2 Service temperature Applies (*) (*) (*)

26.5.1.3 Maximum surface temperature Modified (see 8.2) (*) (*) (*)

26.5.2 Thermal shock test Applies (*) (*) (*)

26.5.3 Small component ignition test Excluded - - -

(Group I and Group II)

26.6 Torque test for bushings Excluded -

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...