EN ISO 23779:2025

(Main)Shot blasting machinery - Safety and environmental requirements (ISO 23779:2024)

Shot blasting machinery - Safety and environmental requirements (ISO 23779:2024)

This document specifies safety and environmental requirements for shot blasting machinery.

Shot blasting machinery includes:

— wheel blasting machinery;

— air blasting machinery for dry and wet blasting;

— combined wheel and air blasting machinery.

NOTE Annex A illustrates examples of shot blasting machinery.

This document is applicable to:

— all significant hazards, hazardous situations and hazardous events relevant to shot blasting machinery, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse;

— measures for minimization of environmental impact and energy usage of shot blasting machinery.

Interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope of this document are:

— mechanical and electrical interface to external workpiece transport system;

— connector to electrical energy supply;

— connector to fresh air supply ducting;

— connector to exhaust air ducting;

— connector to pressurized air supply;

— connector to water supply;

— connector to waste water system;

— interface for safe exchange of control signals;

— connector for fresh air supply for respiratory protection device (in blast rooms).

NOTE Annex C gives an illustration of interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope of this document.

The specific significant risks related to mobile and movable shot blasting machinery (e.g. shot blasting machines designed for operation at changing locations) are not dealt with in this document.

This document does not apply to:

— high pressure water jet machinery;

— dry-ice blasting machinery.

This document does not apply to shot blasting machines manufactured before the date of its publication as an ISO standard.

NOTE The requirements specified in this document can serve as a guideline for a risk assessment of shot blasting machines manufactured before the date of its publication as an ISO standard.

Strahlanlagen - Sicherheits- und Umweltanforderungen (ISO 23779:2024)

Dieses Dokument legt Sicherheits- und Umweltschutzanforderungen für Strahlanlagen fest.

Strahlanlagen umfassen:

Schleuderrad-Strahlanlagen;

Druckluftstrahlanlagen für Trocken- und Nassstrahlen;

kombinierte Schleuderrad- und Druckluftstrahlanlagen.

ANMERKUNG 1 Anhang A zeigt Beispiele für Strahlanlagen.

Dieses Dokument ist anwendbar für:

alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die für Strahlanlagen relevant sind, wenn sie bestimmungsgemäß und unter den vom Hersteller vorgesehenen Bedingungen verwendet werden, einschließlich des vernünftigerweise vorhersehbaren Missbrauchs;

Maßnahmen zur Minimierung der Umweltauswirkungen und des Energieverbrauchs von Strahlanlagen.

Schnittstellen zwischen Strahlanlagen und anderen Ausrüstungen, die beim Strahlen verwendet werden, aber nicht in den Anwendungsbereich dieses Dokumentes fallen, sind:

Mechanische und elektrische Schnittstelle zum externen Werkstücktransportsystem,

Anschluss an die elektrische Energieversorgung,

Anschluss an die Frischluftversorgungsleitung,

Anschluss an die Abluftleitung,

Anschluss an die Druckluftversorgung,

Anschluss an die Wasserversorgung,

Anschluss an das Abwassersystem,

Schnittstelle für den sicheren Austausch von Steuersignalen,

Anschluss für Frischluftzufuhr für fremdbelüftete Atemschutzgeräte (in Freistrahlräumen).

ANMERKUNG 2 Anhang C zeigt die Schnittstellen zwischen Strahlanlagen und anderen Ausrüstungen, die beim Strahlen verwendet werden, aber nicht in den Anwendungsbereich dieses Dokuments fallen.

Die spezifischen signifikanten Risiken im Zusammenhang mit mobilen und beweglichen Strahlanlagen (z. B. Strahlanlagen, die für den Betrieb an wechselnden Standorten ausgelegt sind) werden in diesem Dokument nicht behandelt.

Diese Norm ist nicht anwendbar für

Hochdruckwasserstrahlmaschinen;

Trockeneisstrahlanlagen.

Dieses Dokument ist nicht anwendbar auf Strahlanlagen, die vor dem Datum ihrer Veröffentlichung als ISO-Norm hergestellt wurden.

ANMERKUNG 3 Die in diesem Dokument festgelegten Anforderungen können als Leitfaden für eine Risikobeurteilung von Strahlanlagen dienen, die vor dem Datum der Veröffentlichung dieser Norm als ISO-Norm hergestellt wurden.

Équipements de grenaillage - Exigences de sécurité et d'environnement (ISO 23779:2024)

Le présent document spécifie les exigences de sécurité et d'environnement des équipements de grenaillage.

Les équipements de grenaillage couvrent:

— les équipements de grenaillage à turbine;

— les équipements de grenaillage à air comprimé pour le grenaillage sec ou humide;

— les équipements de grenaillage combinés à turbine et air comprimé.

NOTE L'Annexe A illustre les exemples d'équipements de grenaillage.

Le présent document s'applique:

— à tous les phénomènes dangereux, situations dangereuses et évènements dangereux significatifs qui sont pertinents pour les équipements de grenaillage, lorsqu’ils sont utilisés normalement et dans les conditions prévues par le fabricant, y compris le mauvais usage raisonnablement prévisible;

— aux mesures pour minimiser l’impact environnemental et la consommation d’énergie des équipements de grenaillage.

Les interfaces entre les équipements de grenaillage et d’autres équipements utilisées dans le cadre du grenaillage mais ne faisant pas partie du domaine d’application du présent document sont:

— interface mécanique et electrique vers le système de transport de pièces extérieur;

— connecteur pour l'alimentation électrique;

— connecteur pour la conduite d’alimentation en air neuf;

— connecteur pour la conduite d’air extrait;

— connecteur pour l'alimentation en air sous pression;

— connecteur pour l'alimentation en eau;

— connecteur pour le système d’eaux usées;

— interface pour l'échange sécurisé de signaux de commande;

— connecteur pour l’alimentation en air neuf pour le dispositif de protection respiratoire (dans les cabines de grenaille).

NOTE L'Annexe C illustre les interfaces entre les équipements de grenaillage et d'autres équipements utilisées dans le cadre du grenaillage mais ne faisant pas partie du domaine d’application du présent document.

Les risques significatifs spécifiques relatifs aux équipements de grenaillage mobiles et déplaçables (par exemple, équipements de grenaillage conçus pour un fonctionnement dans différents lieux) ne sont pas traités dans le présent document.

Le présent document ne s’applique pas aux:

— machines à jet d'eau haute pression;

— machines de projection de glace sèche.

Le présent document ne s’applique pas aux équipements de grenaillage fabriqués avant la date de sa publication en tant que norme ISO.

NOTE Les exigences spécifiées dans le présent document peuvent servir de lignes directrices pour une appréciation du risque des équipements de grenaillage fabriqués avant la date de sa publication en tant que norme ISO.

Stroji za peskanje - Varnostne in okoljske zahteve (ISO 23779:2024)

Ta dokument določa varnostne in okoljske zahteve za stroje za peskanje.

Stroji za peskanje vključujejo:

– stroje za turbinsko peskanje;

– stroje za peskanje pod tlakom za suho in mokro peskanje;

– kombinirane stroje za turbinsko peskanje in peskanje pod tlakom.

OPOMBA: V dodatku A so navedeni primeri strojev za peskanje.

Ta dokument se uporablja za:

– vse večje nevarnosti, nevarne situacije in dogodke v zvezi s stroji za peskanje, kadar se uporabljajo v skladu s svojim namenom ter pod pogoji, ki jih je predvidel proizvajalec, vključno z razumno predvideno nepravilno uporabo;

– ukrepe za zmanjšanje vpliva na okolje in porabe energije strojev za peskanje.

Vmesniki med stroji za peskanje in drugo opremo, ki se uporablja pri peskanju, vendar ni zajeta v tem dokumentu, so:

– mehanski in električni vmesnik do zunanjega sistema za transport obdelovancev;

– priključek za napajanje z električno energijo;

– priključek za dovod svežega zraka;

– priključek za odvod izstopnega zraka;

– priključek za dovod zraka pod tlakom;

– priključek za dovod vode;

– priključek za sistem za odpadno vodo;

– vmesnik za varno izmenjavo krmilnih signalov;

– priključek za dovod svežega zraka v opremo za varovanje dihal (v območjih peskanja).

OPOMBA: V dodatku C so navedeni vmesniki med stroji za peskanje in drugo opremo, ki se uporablja pri peskanju, vendar ni zajeta v tem dokumentu.

Ta dokument ne obravnava posebnih večjih tveganj, povezanih z mobilnimi in premičnimi stroji za peskanje (npr. stroji za peskanje, ki so zasnovani za delovanje na spreminjajočih se lokacijah).

Ta dokument se ne uporablja za:

– stroje za visokotlačne vodne curke;

– opremo za peskanje s suhim ledom.

Ta dokument se ne uporablja za stroje za peskanje, ki so bili izdelani, preden je bil objavljen kot standard ISO.

OPOMBA: Zahteve v tem dokumentu se lahko uporabljajo kot vodilo za oceno tveganja strojev za peskanje, izdelanih pred datumom njegove objave kot standarda ISO.

General Information

- Status

- Published

- Publication Date

- 11-Feb-2025

- Technical Committee

- CEN/TC 202 - Foundry machinery

- Drafting Committee

- CEN/TC 202/WG 4 - Blasting

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 12-Feb-2025

- Completion Date

- 12-Feb-2025

Relations

- Replaces

EN 1248:2001+A1:2009 - Foundry machinery - Safety requirements for abrasive blasting equipment - Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

EN ISO 23779:2025 (ISO 23779:2024) specifies safety and environmental requirements for shot blasting machinery used in foundry and metalworking environments. The standard covers wheel blasting, air blasting (dry and wet) and combined wheel/air systems, and addresses hazards, environmental impact and energy usage throughout the machine life cycle. It includes informative illustrations (Annex A), an interfaces overview (Annex C) and a normative noise test code (Annex B). EN ISO 23779:2025 also aligns with the EU Machinery Directive (see Annex ZA).

Key topics and technical requirements

- Scope and applicability

- Applies to significant hazards, hazardous situations and events during intended use and reasonably foreseeable misuse.

- Excludes high-pressure water jet and dry-ice blasting machinery; does not retroactively apply to machines manufactured before publication (can guide risk assessment).

- Risk reduction and safety measures

- Guards and doors, interlocks and fixed guarding for operator protection.

- Control systems and safety-related control functions including start/stop selection and failure modes.

- Emergency stop requirements and safe integration with external equipment.

- Electrical equipment and connectors for power, fresh/exhaust air, pressurized air, water and wastewater.

- Process-specific requirements

- Wheel blaster and air blaster design safety measures.

- Blasting chamber safety, access, and maintenance considerations.

- Shot media transport and recovery systems to prevent ejection and spillage.

- Hazard classes and special topics

- Wear-related hazards, static electricity control, noise reduction and measurement (Annex B), and management of hazardous substances and emissions.

- Environmental and energy aspects

- Measures for energy efficiency, reduction of environmental impact across acquisition, production, use and end-of-life.

- Documentation and verification

- Verification procedures, marking, and comprehensive instruction handbook requirements for installation, operation and maintenance.

Applications and who uses this standard

- Manufacturers and designers of shot blasting machinery to ensure compliant machine design and safety features.

- Plant managers, safety engineers and maintenance teams for safe installation, operation, servicing and risk assessments.

- Compliance officers and notified bodies for conformity assessment with the Machinery Directive.

- Integrators connecting blasting machines to conveyors, ducting, power supplies and respiratory air systems.

- Useful for improving noise control, energy efficiency, waste minimization and environmental compliance in blasting operations.

Related standards and references

- ISO 23779 links to machine safety and noise standards and is intended for harmonised use with EU Directive 2006/42/EC (Machinery Directive). Annex B provides the noise test code used for measurement and declaration.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Sponsored listings

Frequently Asked Questions

EN ISO 23779:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shot blasting machinery - Safety and environmental requirements (ISO 23779:2024)". This standard covers: This document specifies safety and environmental requirements for shot blasting machinery. Shot blasting machinery includes: — wheel blasting machinery; — air blasting machinery for dry and wet blasting; — combined wheel and air blasting machinery. NOTE Annex A illustrates examples of shot blasting machinery. This document is applicable to: — all significant hazards, hazardous situations and hazardous events relevant to shot blasting machinery, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse; — measures for minimization of environmental impact and energy usage of shot blasting machinery. Interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope of this document are: — mechanical and electrical interface to external workpiece transport system; — connector to electrical energy supply; — connector to fresh air supply ducting; — connector to exhaust air ducting; — connector to pressurized air supply; — connector to water supply; — connector to waste water system; — interface for safe exchange of control signals; — connector for fresh air supply for respiratory protection device (in blast rooms). NOTE Annex C gives an illustration of interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope of this document. The specific significant risks related to mobile and movable shot blasting machinery (e.g. shot blasting machines designed for operation at changing locations) are not dealt with in this document. This document does not apply to: — high pressure water jet machinery; — dry-ice blasting machinery. This document does not apply to shot blasting machines manufactured before the date of its publication as an ISO standard. NOTE The requirements specified in this document can serve as a guideline for a risk assessment of shot blasting machines manufactured before the date of its publication as an ISO standard.

This document specifies safety and environmental requirements for shot blasting machinery. Shot blasting machinery includes: — wheel blasting machinery; — air blasting machinery for dry and wet blasting; — combined wheel and air blasting machinery. NOTE Annex A illustrates examples of shot blasting machinery. This document is applicable to: — all significant hazards, hazardous situations and hazardous events relevant to shot blasting machinery, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse; — measures for minimization of environmental impact and energy usage of shot blasting machinery. Interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope of this document are: — mechanical and electrical interface to external workpiece transport system; — connector to electrical energy supply; — connector to fresh air supply ducting; — connector to exhaust air ducting; — connector to pressurized air supply; — connector to water supply; — connector to waste water system; — interface for safe exchange of control signals; — connector for fresh air supply for respiratory protection device (in blast rooms). NOTE Annex C gives an illustration of interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope of this document. The specific significant risks related to mobile and movable shot blasting machinery (e.g. shot blasting machines designed for operation at changing locations) are not dealt with in this document. This document does not apply to: — high pressure water jet machinery; — dry-ice blasting machinery. This document does not apply to shot blasting machines manufactured before the date of its publication as an ISO standard. NOTE The requirements specified in this document can serve as a guideline for a risk assessment of shot blasting machines manufactured before the date of its publication as an ISO standard.

EN ISO 23779:2025 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 23779:2025 has the following relationships with other standards: It is inter standard links to EN 1248:2001+A1:2009, ISO 11201:2010, ISO 3746:2010, ISO 11204:2010, ISO 14122-3:2016, ISO 4413:2010, ISO 80079-36:2016, ISO 14122-2:2016, ISO 12100:2010, ISO 13857:2019, ISO 3864-1:2011, ISO 11202:2010, ISO 3744:2010, ISO 4414:2010, ISO 14119:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 23779:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN ISO 23779:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2025

Stroji za peskanje - Varnostne in okoljske zahteve (ISO 23779:2024)

Shot blasting machinery - safety and environmental requirements (ISO 23779:2024)

Strahlanlagen - Sicherheits- und Umweltanforderungen (ISO 23779:2024)

Équipements de grenaillage - Prescriptions de sécurité et de l'environnement (ISO

23779:2024)

Ta slovenski standard je istoveten z: EN ISO 23779:2025

ICS:

13.110 Varnost strojev Safety of machinery

77.180 Oprema za metalurško Equipment for the

industrijo metallurgical industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN ISO 23779

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2025

EUROPÄISCHE NORM

ICS 77.180; 13.110 Supersedes EN 1248:2001+A1:2009

English Version

Shot blasting machinery - Safety and environmental

requirements (ISO 23779:2024)

Équipements de grenaillage - Exigences de sécurité et Strahlanlagen - Sicherheits- und Umweltanforderungen

d'environnement (ISO 23779:2024) (ISO 23779:2024)

This European Standard was approved by CEN on 3 October 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 23779:2025 E

worldwide for CEN national Members.

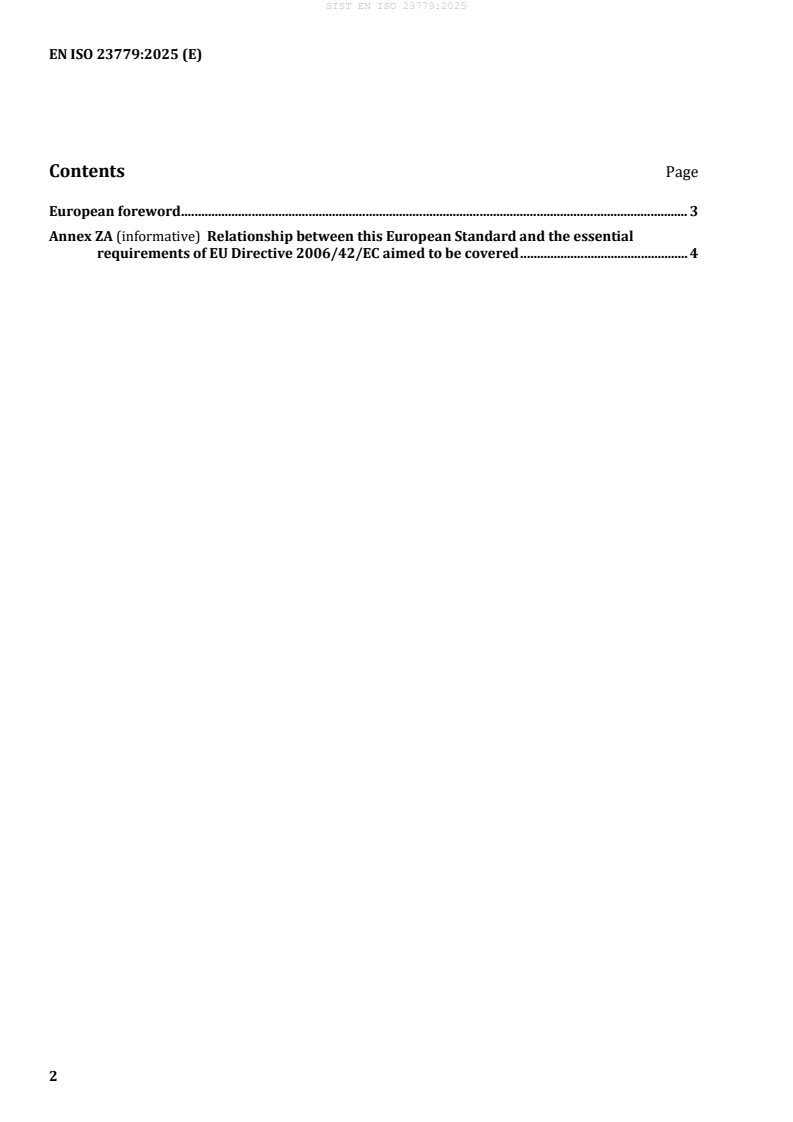

Contents Page

European foreword . 3

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2006/42/EC aimed to be covered . 4

European foreword

This document (EN ISO 23779:2025) has been prepared by Technical Committee ISO/TC 306 "Foundry

machinery" in collaboration with Technical Committee CEN/TC 202 “Foundry machinery” the

secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2025, and conflicting national standards shall

be withdrawn at the latest by August 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1248:2001+A1:2009.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards

body/national committee. A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

Endorsement notice

The text of ISO 23779:2024 has been approved by CEN as EN ISO 23779:2025 without any modification.

Annex ZA

(informative)

Relationship between this European Standard and the essential

requirements of EU Directive 2006/42/EC aimed to be covered

This European Standard has been prepared under a Commission’s standardization request „M/396

Mandate to CEN and CENELEC for Standardisation in the field of machinery“ to provide one voluntary

means of conforming to essential requirements of Directive 2006/42/EC of the European Parliament

and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast).

Once this standard is cited in the Official Journal of the European Union under that Directive,

compliance with the normative clauses of this standard given in Table ZA.1 confers, within the limits of

the scope of this standard, a presumption of conformity with the corresponding essential requirements

of that Directive and associated EFTA regulations.

Table ZA.1 — Correspondence between this European Standard and Annex I of Directive

2006/42/EC

The relevant Essential Requirement of Directive Clause(s)/ subclause(s) Remarks/Notes

of this EN

1.1.2 (a) 5, 8

1.1.2 (c) 5, 8

1.1.2 (d) 5, 8

1.1.2 (e) 5, 8

1.1.3 Materials and products 5.7, 5.8, 5.11, 5.15

1.1.7 Operating positions not covered

1.2.1 Safety and reliability of control systems 5.5, 5.6

1.2.3 Starting 5.5, 5.8

1.2.4.3 Emergency Stop 5.4, 5.8

1.2.4.4 Assembly of machinery 5.5, 5.16

1.2.5 Selection of control or operating modes 5.5, 5.8

1.2.6 Failure of the power supply 5.5, 5.10

1.3.3 Risks due to falling or ejected objects 5.6, 5.7, 5.8, 5.9

1.3.4 Risks due to surfaces, edges or angles not covered

1.3.7 Risks related to moving parts 5.8, 5.9, 5.11

1.3.8.1 Moving transmission parts 5.6

1.3.8.2 Moving parts involved in the process 5.8, 5.9, 5.11

1.3.9 Risks of uncontrolled movements 5.7, 5.10

1.4.2.1 Fixed guards 5.2, 5.8, 5.9

1.4.2.2 Interlocking movable guards 5.2, 5.8, 5.9

1.5.1 Electricity supply 5.3

The relevant Essential Requirement of Directive Clause(s)/ subclause(s) Remarks/Notes

of this EN

1.5.2 Static electricity 5.13

1.5.3 Energy supply other than electricity 5.7

1.5.6 Fire 5.15

1.5.7 Explosion 5.15

1.5.8 Noise 5.14, Annex B

1.5.13 Emissions of hazardous materials and substances Not covered

1.5.14 Risk of being trapped in a machine 5.8

1.5.15 Risk of slipping, tripping or falling 5.8

1.6.1 Machinery maintenance 5.8

1.6.2 Access to operating positions and servicing points 5.8

1.7.1 Information and warnings on the machinery 5.8

1.7.1.1 Information and information devices 5.1

1.7.1.2 Warning devices 5.1, 5.8

1.7.2 Warning of residual risks 5.8, 5.11, 5.12, 5.15

1.7.3 Marking of machinery 8.3

1.7.4 Instructions 8.1

1.7.4.1 General principles for the drafting of instructions 8.1

1.7.4.2 Contents of the instructions 5.6, 5.7, 5.8, 5.11, 5.12, 5.13,

5.15, 8.1, 8.2.1, 8.2.2, 8.2.3,

Annex B

1.7.4.3 Sales literature not covered

WARNING 1 Presumption of conformity stays valid only as long as a reference to this European

Standard is maintained in the list published in the Official Journal of the European Union. Users of this

standard should consult frequently the latest list published in the Official Journal of the European

Union.

WARNING 2 Other Union legislation may be applicable to the product(s) falling within the scope of

this standard.

International

Standard

ISO 23779

First edition

Shot blasting machinery — Safety

2024-10

and environmental requirements

Équipements de grenaillage — Exigences de sécurité et

d'environnement

Reference number

ISO 23779:2024(en) © ISO 2024

ISO 23779:2024(en)

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

ISO 23779:2024(en)

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Significant hazards, environmental impact and energy usage . 4

4.1 General .4

4.2 Significant hazards .4

4.3 Environmental impact and energy usage .5

5 Safety requirements, protective measures, risk reduction measures . 5

5.1 General .5

5.2 Guards and doors .5

5.3 Electrical equipment .5

5.4 Emergency stop .5

5.5 Control systems .5

5.6 Wheel blaster .6

5.7 Air blaster .7

5.8 Blasting chamber .8

5.9 Shot blasting media transport and recovery system .11

5.10 Power and driving devices . 12

5.11 Loading and unloading systems for workpieces . 12

5.12 Wear related hazards . 13

5.13 Static electricity.14

5.14 Noise .14

5.14.1 Measures for reducing noise at source at the design stage .14

5.14.2 Noise emission measurement and declaration . 15

5.15 Substances . 15

5.16 Integration with external equipment .17

6 Energy-efficiency and reduction of environmental impact .18

6.1 General .18

6.2 Acquisition .18

6.3 Production .18

6.4 Use .18

6.4.1 Input .18

6.4.2 Output .19

6.5 End of life .19

7 Verification of the safety requirements and/or measures . 19

8 Information for use .20

8.1 General . 20

8.2 Instruction handbook. 20

8.2.1 Information related to installation . 20

8.2.2 Information related to operation. 20

8.2.3 Information related to maintenance . 20

8.3 Marking .21

Annex A (informative) Figures of shot blasting machinery .22

Annex B (normative) Noise test code .25

Annex C (informative) Interfaces of shot blasting machinery to ancillary machinery .30

Bibliography .31

iii

ISO 23779:2024(en)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 306, Foundry machinery, in collaboration with

the European Committee for Standardization (CEN) Technical Committee CEN/TC 202, Foundry machinery,

in accordance with the Agreement on technical cooperation between ISO and CEN (Vienna Agreement).

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

ISO 23779:2024(en)

Introduction

This document is a type C standard as stated in ISO 12100:2010 and also deals with aspects of environmental

impact and energy efficiency.

The design, the construction and the actual operation of shot blasting machinery affects aspects of safety,

energy usage and environmental impact. It is essential to minimize energy usage and environmental impact

while achieving the safety requirements given in this document.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events are

covered are indicated in the scope of this document. When provisions of this type C standard are different

from those which are stated in type A or B standards, the provisions of this type C standard take precedence

over the provisions of the other standards, for machines that have been designed and built according to the

provisions of this type C standard.

Where for clarity an example of a preventative measure is given in the text, this should not be considered as

the only possible solution. Other solutions can be used as far as they fulfil correctly the criteria expressed in

the requirement.

This document assumes that the shot blasting machinery is operated and maintained by trained personnel.

v

International Standard ISO 23779:2024(en)

Shot blasting machinery — Safety and environmental

requirements

1 Scope

This document specifies safety and environmental requirements for shot blasting machinery.

Shot blasting machinery includes:

— wheel blasting machinery;

— air blasting machinery for dry and wet blasting;

— combined wheel and air blasting machinery.

NOTE Annex A illustrates examples of shot blasting machinery.

This document is applicable to:

— all significant hazards, hazardous situations and hazardous events relevant to shot blasting machinery,

when used as intended and under the conditions foreseen by the manufacturer, including reasonably

foreseeable misuse;

— measures for minimization of environmental impact and energy usage of shot blasting machinery.

Interfaces between shot blasting machinery and other equipment used in shot blasting but not in the scope

of this document are:

— mechanical and electrical interface to external workpiece transport system;

— connector to electrical energy supply;

— connector to fresh air supply ducting;

— connector to exhaust air ducting;

— connector to pressurized air supply;

— connector to water supply;

— connector to waste water system;

— interface for safe exchange of control signals;

— connector for fresh air supply for respiratory protection device (in blast rooms).

NOTE Annex C gives an illustration of interfaces between shot blasting machinery and other equipment used in

shot blasting but not in the scope of this document.

The specific significant risks related to mobile and movable shot blasting machinery (e.g. shot blasting

machines designed for operation at changing locations) are not dealt with in this document.

This document does not apply to:

— high pressure water jet machinery;

— dry-ice blasting machinery.

ISO 23779:2024(en)

This document does not apply to shot blasting machines manufactured before the date of its publication as

an ISO standard.

NOTE The requirements specified in this document can serve as a guideline for a risk assessment of shot blasting

machines manufactured before the date of its publication as an ISO standard.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 3743-1:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using

sound pressure — Engineering methods for small movable sources in reverberant fields — Part 1: Comparison

method for a hard-walled test room

ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using

sound pressure — Engineering methods for an essentially free field over a reflecting plane

ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise sources using

sound pressure — Survey method using an enveloping measurement surface over a reflecting plane

ISO 3864-1:2011, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety

signs and safety markings

ISO 4413:2010, Hydraulic fluid power — General rules and safety requirements for systems and their components

ISO 4414:2010, Pneumatic fluid power — General rules and safety requirements for systems and their

components

ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment

ISO 7000:2019, Graphical symbols for use on equipment — Registered symbols

ISO 7731:2003, Ergonomics — Danger signals for public and work areas — Auditory danger signals

ISO 10218-2:2011, Robots and robotic devices — Safety requirements for industrial robots — Part 2: Robot

systems and integration

ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound

pressure levels at a work station and at other specified positions in an essentially free field over a reflecting

plane with negligible environmental corrections

ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate environmental

corrections

ISO 11204:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission sound

pressure levels at a work station and at other specified positions applying accurate environmental corrections

ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk reduction

ISO 13849-1:2023, Safety of machinery — Safety-related parts of control systems — Part 1: General principles

for design

ISO 13850:2015, Safety of machinery — Emergency stop function — Principles for design

ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by upper and

lower limbs

ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for design and

selection

ISO 23779:2024(en)

ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and construction of fixed

and movable guards

ISO 14122-2:2016, Safety of machinery — Permanent means of access to machinery — Part 2: Working platforms

and walkways

ISO 14122-3:2016, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs, stepladders

and guard-rails

ISO 80079-36:2016, Explosive atmospheres — Part 36: Non-electrical equipment for explosive atmospheres —

Basic method and requirements

IEC 60204-1:2016, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

IEC 60079-0:2017, Explosive atmospheres — Part 0: Equipment — General requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 12100:2010 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

external workpiece transport system

system that transports the workpiece to or from the shot blasting machine

3.2

internal workpiece transport system

system that transports the workpiece within the shot blasting machine

3.3

wheel blaster

device which accelerates the shot blasting media by a rotating wheel with blades

3.4

air blaster

assembly consisting of a nozzle and connected hose(s) or tube(s), which accelerates the shot blasting media

by pressurized air

3.5

accessible blasting chamber

blasting chamber which, by designated use, is designed to be entered by personnel

3.6

workspace

workplace for the operator as specified by the manufacturer of the shot blasting machine

3.7

interior workspace

workspace inside of a shot blasting machine

3.8

screw conveyor

device that uses a rotating helical blade to move shot blasting media, horizontally or at a slight incline

3.9

belt conveyor

endless belt between two, or more, pulleys to move shot blasting media or products, horizontally or incline

ISO 23779:2024(en)

3.10

vibrating conveyor

device that transports shot blasting media or products by vibration and gravity

3.11

scraper conveyor

device to transport bulk shot blasting media over a plane with the help of scrapers

3.12

hopper

container for storing shot blasting media or for providing or replenishing shot blasting media for the shot

blasting process

3.13

bucket elevator

continuous conveyor that uses a series of bucket shaped hoppers uniformly fixed on the endless circular

traction component to vertically lift shot blasting media

3.14

hopper discharge conveyor

mechanical device, screw conveyor, belt conveyor or other suitable transport system, to feed shot blasting

media from the hopper to the shot blasting machine

3.15

switch valve

electrical, pneumatical or magnetical operated device for closing or opening the shot blasting media flow to

the shot blasting process

3.16

magnetic separator

system, mostly operating with partial magnetic drums, where a ferromagnetic- and non-ferromagnetic

mixture is separated to obtain reusable shot blasting media for the shot blasting process

3.17

cleaning system

device to separate small particles from shot blasting media, to obtain a required grain size distribution,

mostly combined with a sieve for separating large particles

4 Significant hazards, environmental impact and energy usage

4.1 General

The variety of machinery could not be covered in all details in a standard. To deal with this fact, an individual

risk assessment of the machinery in question shall be carried out considering the safety requirements of

this document.

Significant hazards identified in the individual risk assessment but not dealt with in this document shall be

avoided or reduced by applying the principles of ISO 12100:2010.

Safety requirements described in different clauses of this document shall be considered together if they are

referring to the same hazard zone.

4.2 Significant hazards

Clause 5 gives requirements to prevent or minimise all hazards, hazardous situations and events identified

by risk assessment as significant for this type of machinery.

See ISO 12100:2010 for measures against hazards that are relevant but not significant for this machine type.

NOTE ISO 12100:2010 contains information for the procedure of risk assessment.

ISO 23779:2024(en)

4.3 Environmental impact and energy usage

Clause 6 contains measures for minimization of:

— environmental impact and

— energy usage.

5 Safety requirements, protective measures, risk reduction measures

5.1 General

Shot blasting machinery shall comply with the safety requirements and/or protective measures against the

significant hazards given in Clause 5.

Warning devices and safety signs shall be in accordance with ISO 3864-1:2011, ISO 7000:2019 or

ISO 7731:2003.

5.2 Guards and doors

All potential accesses to hazardous areas shall be secured by guards in accordance with ISO 13857:2019,

ISO 14120:2015 and ISO 14119:2013. If access to a work area is limited by interlocking movable guards (e.g.

doors), these shall be secured by the safety-related control system according to the performance level given

in Table 1.

5.3 Electrical equipment

Electrical equipment of shot blasting machinery shall comply with IEC 60204-1:2016.

5.4 Emergency stop

Emergency stop devices shall comply with ISO 13850:2015.

5.5 Control systems

Safety related control systems shall be designed according to ISO 13849-1:2023. This applies also for input

and processing of safety related parameters (e.g. operating parameters).

Table 1 — Required performance level (PLr) for control systems of shot blasting machinery

Safety function Clause PLr

Guard locking of access points of wheel blasters by interlock- 5.2 d

ing movable guards associated with an interlocking device 5.6, Table 2, row 1

interlocked with the hazardous movement and a guard locking 5.6, Table 3, row 1

device

Guard locking of access points of wheel blasters by fixed guards 5.2 c

associated with an interlocking device interlocked with the 5.6, Table 2, row 1

hazardous movement 5.6, Table 3, row 1

Guard locking of access to the blasting chamber of wheel blast- 5.2 d

ing machines without additional safety measures 5.6, Table 2, row 2

5.6, Table 3, row 1

Guard locking of access to the blasting chamber of wheel blast- 5.2 c

ing machines with additional safety measures 5.6, Table 2, row 2

5.6, Table 3, row 1

Maximum overrun time of hold-to-run nozzle control device 5.7, Table 4, row 4 d

ISO 23779:2024(en)

TTabablele 1 1 ((ccoonnttiinnueuedd))

Safety function Clause PLr

Interlocking of means of access with the shot blasting process 5.2 c

and hazardous movement of parts, for blasting chambers with- 5.8, Table 5, row 2, sub-row 1

out interior workspace

If access is possible before the shot blasting process has

stopped, interlocking with guard locking is required

Interlocking of means of access with the shot blasting process 5.2 c

and hazardous movement of parts, for blasting chambers with 5.8, Table 5, row 2, sub-row 2

interior workspace

Interlocking to prevent start up of the shot blasting process 5.8, Table 5, row 3 c

Interlocking between wheel drive and air blaster 5.8, Table 5, row 3 c

Interlocking with guard locking with hazardous movement of 5.8, Table 7, row 1 c

parts 5.8, Table 7, row 2

Access to hazardous moving parts of the shot blasting media 5.9, Table 9, row 1 c

transport and recovery system

Avoid uncontrolled movement of machine parts 5.10, Table 10, row 1 c

Avoid uncontrolled movement of machine parts due to loss or 5.10, Table 10, row 2 c

reactivation of electric, pneumatic or hydraulic energy supply

Interlocking with external equipment 5.16 Individual risk

assessment

5.6 Wheel blaster

See Table 2 for significant hazards or hazardous situations concerning shearing and crushing, cutting and

severing, the related safety requirements and/or measures and the requirements for verification of these

measures.

Table 2 — Wheel blaster – Shearing and crushing, cutting and severing

Significant hazard Hazardous situation Safety requirements Verification

Shearing Access to shear traps Access points to internal rotating parts of Visual inspection

between fixed and wheel blasters shall be guarded either by Functional test

Crushing

internal rotating parts

Cutting — fixed guards associated with an

of the wheel blaster.

interlocking device interlocked with the

Severing

hazardous movement

or

— interlocking movable guards associated

with an interlocking device interlocked

with the hazardous movement and a

guard locking device.

See Table 1 for safety related controls.

The shot blasting media supply opening of Visual inspection

wheel blasters shall be guarded by fixed

guards.

Access from the inside Unauthorized access to process openings See 5.8, Table 5

of the blasting chamber of wheel blasters shall be prevented by

to shear traps between guarding with guard locking of the blasting

fixed and internal ro- chamber access (see 5.8, Table 5).

tating parts of a wheel

Additional safety measures (e.g. key locking

blaster.

the access) can reduce the PLr of the guard

locking.

See Table 1 for safety related controls.

ISO 23779:2024(en)

See Table 3 for significant hazards or hazardous situations concerning impact of accelerated shot blasting

media and parts, the related safety requirements and/or measures and the requirements for verification of

these measures.

Table 3 — Wheel blaster – Impact of accelerated shot blasting media and parts

Significant hazard Hazardous situation Safety requirements Verification

Friction or abrasion Exposure to ejected See Table 2 See Table 2

shot blasting media.

Puncture

Information on maintenance and inspection Documentation

of wheel blasters shall be given in the infor-

mation for use, see Clause 8.

Impact Exposure to ejected The housing of the wheel blaster shall with- Documentation

parts in case of wheel stand the impact of accelerated parts that

Stabbing or Punc-

blaster breakdown. can occur in the event of the collapse of the

ture

blast wheel.

Information on maintenance and inspection Documentation

of wheel blasters shall be given in the infor-

mation for use, see Clause 8.

See Table 14 for noise sources, the related noise reduction measures and the requirements for verification of

these measures.

5.7 Air blaster

See Table 4 for significant hazards or hazardous situations concerning impact of accelerated shot blasting

media and parts, the related safety requirements and/or measures and the requirements for verification of

these measures.

Table 4 — Air blaster – Impact of accelerated shot blasting media and parts

Significant hazard Hazardous situation Safety requirements Verification

Friction or abrasion Exposure to ejected The construction of the air blaster shall Visual inspection

shot blasting media, minimize wear by accelerated shot blasting Documentation

Puncture

parts and fluids in case media.

Injection

of breakdown, wear

The air blaster shall withstand the pressure Documentation

and malfunction of an

generated by the shot blasting process. Its

air blaster or an air

pressurized components (e.g. tubing, hoses,

blasting machine.

vessel, couplings, valves, nozzle) shall be

designed according to ISO 4413:2010 and ISO

4414:2010.

Information on maintenance and inspection Documentation

of air blasters shall be given in the informa-

tion for use, see Clause 8.

Impact For manual air blasters: The air blaster shall be equipped with a hold- Functional test

to-run nozzle control device which, upon

Friction or abrasion

— uncontrolled

release within 3 seconds, reduces the kinetic

Puncture movement of the

energy of the:

nozzle and hose

Injection

— the shot blasting media and

— the pressurized air

and/or

ISO 23779:2024(en)

TTabablele 4 4 ((ccoonnttiinnueuedd))

Significant hazard Hazardous situation Safety requirements Verification

— release of shot to assure:

blasting media.

— no hazardous movement of the hose;

— no hazardous ejection of shot blasting

media.

This can be achieved by e.g.:

— depressurization of the shot blasting

media supply system;

— a shutter in the supply to the nozzle.

For long hoses additional measures (e.g. pres-

sure release valve) may be required.

See Table 1 for safety related controls.

See Table 14 for noise sources, the related noise reduction measures and the requirements for verification of

these measures.

5.8 Blasting chamber

See Table 5 for significant hazards or hazardous situations concerning impact of accelerated shot blasting

media and parts, the related safety requirements and/or measures and the requirements for verification of

these measures.

Table 5 — Blasting chamber – Impact of accelerated shot blasting media and parts

Significant hazard Hazardous situation Safety requirements Verification

Friction or abrasion Exposure to accelerat- The construction of the blasting chamber Documentation

ed shot blasting media shall prevent the exposure to hazardous Functional test

Puncture

and parts in the work- accelerated shot blasting media and parts

Impact

space outside of the in the workspace outside of the blasting

blasting chamber. chamber.

Information on maintenance and inspection Documentation

shall be given in the information for use, see

Clause 8.

Friction or abrasion Exposure to accelerat- Access to blasting chambers without interior Visual inspection

ed shot blasting media workspace shall be prevented by design.

Puncture Documentation

and moving parts in

Impact

Means of access shall be interlocked with Functional test

blasting chambers

the shot blasting process and hazardous

without interior work-

movement of parts. Opening of means of ac-

space.

cess shall stop the shot blasting process and

hazardous movement of parts.

If access is possible before the shot blasting

process has stopped, interlocking with guard

locking is required.

It shall not be possible to initiate the shot

blasting process and hazardous movement

of parts, until the means of access are closed.

The shot blasting process shall not re-start

automatically upon closure of the means of

access.

The interlocking device shall comply with

ISO 14119:2013.

Robots shall be integrated according to ISO

10218-2:2011.

See Table 1 for safety related controls.

ISO 23779:2024(en)

TTabablele 5 5 ((ccoonnttiinnueuedd))

Significant hazard Hazardous situation Safety requirements Verification

Workpiece inlet and outlet openings shall Visual inspection

be secured against unauthorized access by

Measurement

measures to prevent easy access of persons

through work

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...