ISO/IEC 80079-20-2:2016

(Main)Explosive atmospheres — Part 20-2: Material characteristics — Combustible dusts test methods

Explosive atmospheres — Part 20-2: Material characteristics — Combustible dusts test methods

ISO/IEC 80079-20-2:2016 is published as a dual logo standard and describes the test methods for the identification of combustible dust and combustible dust layers in order to permit classification of areas where such materials exist for the purpose of the proper selection and installation of electrical and mechanical equipment for use in the presence of combustible dust. The standard atmospheric conditions for determination of characteristics of combustible dusts are: - temperature -20 °C to 60 °C, - pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar) and - air with normal oxygen content, typically 21 % v/v. The test methods defined do not apply to: - recognized explosives, propellants (e.g. gunpowder, dynamite), or substances or mixtures of substances which may, under some circumstances, behave in a similar manner or - dusts of explosives and propellants that do not require atmospheric oxygen for combustion, or to pyrophoric substances. This first edition cancels and replaces the first edition of IEC 61241-2-1 published in 1994, the first edition of IEC 61241-2-2 published in 1993 and the first edition of IEC 61241-2-3 published in 1994, combining the requirements into a single document, and is considered to constitute a technical revision. Significant changes with respect to IEC 61241-2-1:1994, IEC 61241-2-2:1993 and IEC 61241-2-3:1994 can be found in the foreword of the document. Keywords: combustible dust

Atmosphères explosives — Partie 20-2: Caractéristiques des produits — Méthodes d’essai des poussières combustibles

General Information

- Status

- Published

- Publication Date

- 24-Feb-2016

- Technical Committee

- ISO/TMBG - Technical Management Board - groups

- Drafting Committee

- ISO/TMBG - Technical Management Board - groups

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 25-Jun-2025

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 06-Jun-2022

Overview

ISO/IEC 80079-20-2:2016 - Explosive atmospheres - Part 20-2: Material characteristics - Combustible dusts test methods is a dual-logo ISO/IEC standard that defines laboratory test methods to identify and characterise combustible dust and combustible dust layers. The results support classification of hazardous areas and the proper selection and installation of electrical and mechanical equipment for environments where combustible dusts may be present. The standard applies under standard atmospheric conditions (temperature −20 °C to 60 °C, pressure 80–110 kPa and air with normal oxygen content ≈21 % v/v) and excludes recognized explosives, propellants and pyrophoric materials.

Key topics and requirements

- Scope and exclusions: Defines what materials and situations are covered (combustible dusts) and what are excluded (explosives, propellants, oxygen-independent fuels, pyrophoric substances).

- Sample handling: Requirements for receipt, characterisation, preparation and conditioning of dust samples prior to testing.

- Test conditions: Specifies the atmospheric and equipment conditions for reproducible results.

- Identification tests: Visual inspection and particle size distribution to determine whether a material can form a combustible dust or combustible flying.

- Ignition/reactivity test methods:

- Modified Hartmann tube (vertical tube) for ignition sensitivity.

- 20‑litre sphere dispersion tests for dust cloud ignition (with informative Annex E).

- Godbert‑Greenwald (GG) and BAM ovens for minimum ignition temperature (MIT) of dust clouds (Annex B, F).

- MIT of dust layers using heated surface tests.

- Minimum Ignition Energy (MIE)/Minimum Ignition Energy of dust/air mixtures with high-voltage spark systems (examples in Annex C).

- Powder resistivity measurement methods relevant to electrostatic ignition hazards.

- Reporting: Prescribed test report content and recording of results for use in risk assessments.

- Normative/Informative annexes: Apparatus designs and example data (e.g., Annex D - modified Hartmann tube, Annex H - 1 m vessel).

Applications and who should use it

- Process safety and explosion protection engineers performing dust hazard analyses and area classification.

- Testing laboratories that perform combustible dust characterisation and certification.

- Equipment manufacturers selecting or certifying electrical/mechanical equipment for dusty environments.

- Plant designers, safety managers, insurers and regulators requiring objective data for mitigation measures and compliance.

- Use cases include chemical, food, metallurgy, pharmaceuticals, wood processing and other industries where dust formation and accumulation present explosion risks.

Related standards

- Part of the ISO/IEC 80079 series on explosive atmospheres. This edition combines and replaces earlier IEC 61241-2 series documents (1993–1994). For full compliance and installation guidance, consult other parts of the 80079 series and national regulations.

For authoritative test procedures and instrument designs, obtain the full ISO/IEC 80079-20-2:2016 publication from an authorized distributor.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

ISO/IEC 80079-20-2:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Explosive atmospheres — Part 20-2: Material characteristics — Combustible dusts test methods". This standard covers: ISO/IEC 80079-20-2:2016 is published as a dual logo standard and describes the test methods for the identification of combustible dust and combustible dust layers in order to permit classification of areas where such materials exist for the purpose of the proper selection and installation of electrical and mechanical equipment for use in the presence of combustible dust. The standard atmospheric conditions for determination of characteristics of combustible dusts are: - temperature -20 °C to 60 °C, - pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar) and - air with normal oxygen content, typically 21 % v/v. The test methods defined do not apply to: - recognized explosives, propellants (e.g. gunpowder, dynamite), or substances or mixtures of substances which may, under some circumstances, behave in a similar manner or - dusts of explosives and propellants that do not require atmospheric oxygen for combustion, or to pyrophoric substances. This first edition cancels and replaces the first edition of IEC 61241-2-1 published in 1994, the first edition of IEC 61241-2-2 published in 1993 and the first edition of IEC 61241-2-3 published in 1994, combining the requirements into a single document, and is considered to constitute a technical revision. Significant changes with respect to IEC 61241-2-1:1994, IEC 61241-2-2:1993 and IEC 61241-2-3:1994 can be found in the foreword of the document. Keywords: combustible dust

ISO/IEC 80079-20-2:2016 is published as a dual logo standard and describes the test methods for the identification of combustible dust and combustible dust layers in order to permit classification of areas where such materials exist for the purpose of the proper selection and installation of electrical and mechanical equipment for use in the presence of combustible dust. The standard atmospheric conditions for determination of characteristics of combustible dusts are: - temperature -20 °C to 60 °C, - pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar) and - air with normal oxygen content, typically 21 % v/v. The test methods defined do not apply to: - recognized explosives, propellants (e.g. gunpowder, dynamite), or substances or mixtures of substances which may, under some circumstances, behave in a similar manner or - dusts of explosives and propellants that do not require atmospheric oxygen for combustion, or to pyrophoric substances. This first edition cancels and replaces the first edition of IEC 61241-2-1 published in 1994, the first edition of IEC 61241-2-2 published in 1993 and the first edition of IEC 61241-2-3 published in 1994, combining the requirements into a single document, and is considered to constitute a technical revision. Significant changes with respect to IEC 61241-2-1:1994, IEC 61241-2-2:1993 and IEC 61241-2-3:1994 can be found in the foreword of the document. Keywords: combustible dust

ISO/IEC 80079-20-2:2016 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 80079-20-2:2016 has the following relationships with other standards: It is inter standard links to EN ISO/IEC 80079-20-2:2016, ISO 16106:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/IEC 80079-20-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

ISO/IEC 80079-20-2

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 20-2: Material characteristics – Combustible dusts test methods

Atmosphères explosives –

Partie 20-2: Caractéristiques des produits – Méthodes d’essai des poussières

combustibles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about

ISO/IEC copyright or have an enquiry about obtaining additional rights to this publication, please contact the address

below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'ISO/IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication,

utilisez les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

ISO/IEC 80079-20-2

Edition 1.0 2016-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 20-2: Material characteristics – Combustible dusts test methods

Atmosphères explosives –

Partie 20-2: Caractéristiques des produits – Méthodes d’essai des poussières

combustibles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.230; 29.260.20 ISBN 978-2-8322-3179-1

– 2 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

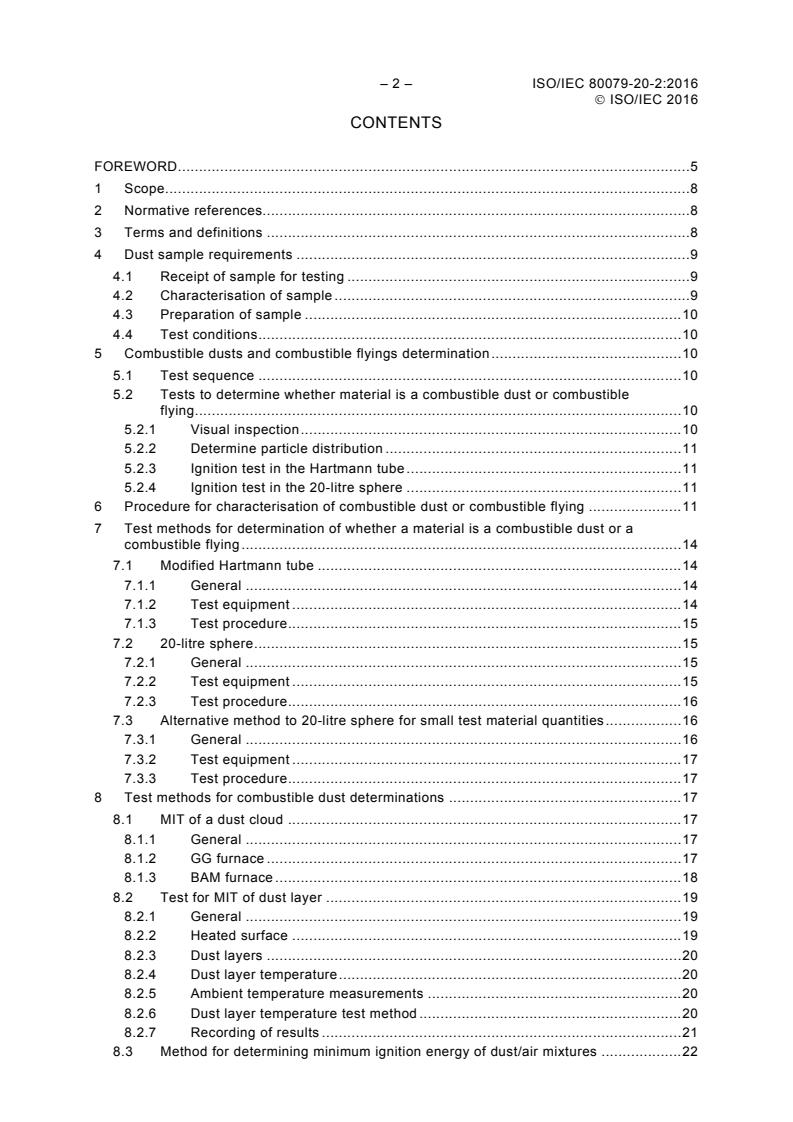

CONTENTS

FOREWORD . 5

1 Scope . 8

2 Normative references. 8

3 Terms and definitions . 8

4 Dust sample requirements . 9

4.1 Receipt of sample for testing . 9

4.2 Characterisation of sample . 9

4.3 Preparation of sample . 10

4.4 Test conditions . 10

5 Combustible dusts and combustible flyings determination . 10

5.1 Test sequence . 10

5.2 Tests to determine whether material is a combustible dust or combustible

flying . 10

5.2.1 Visual inspection . 10

5.2.2 Determine particle distribution . 11

5.2.3 Ignition test in the Hartmann tube . 11

5.2.4 Ignition test in the 20-litre sphere . 11

6 Procedure for characterisation of combustible dust or combustible flying . 11

7 Test methods for determination of whether a material is a combustible dust or a

combustible flying . 14

7.1 Modified Hartmann tube . 14

7.1.1 General . 14

7.1.2 Test equipment . 14

7.1.3 Test procedure . 15

7.2 20-litre sphere . 15

7.2.1 General . 15

7.2.2 Test equipment . 15

7.2.3 Test procedure . 16

7.3 Alternative method to 20-litre sphere for small test material quantities . 16

7.3.1 General . 16

7.3.2 Test equipment . 17

7.3.3 Test procedure . 17

8 Test methods for combustible dust determinations . 17

8.1 MIT of a dust cloud . 17

8.1.1 General . 17

8.1.2 GG furnace . 17

8.1.3 BAM furnace . 18

8.2 Test for MIT of dust layer . 19

8.2.1 General . 19

8.2.2 Heated surface . 19

8.2.3 Dust layers . 20

8.2.4 Dust layer temperature . 20

8.2.5 Ambient temperature measurements . 20

8.2.6 Dust layer temperature test method . 20

8.2.7 Recording of results . 21

8.3 Method for determining minimum ignition energy of dust/air mixtures . 22

ISO/IEC 2016

8.3.1 General . 22

8.3.2 Test equipment . 22

8.3.3 Test procedure . 23

8.3.4 Calibration for determination of minimum ignition energies (MIE) by

electrically generated high-voltage d.c. sparks . 24

8.3.5 Recording of test results . 24

8.4 Test on resistivity . 24

8.4.1 General . 24

8.4.2 Test equipment . 25

8.4.3 Test procedure . 25

8.4.4 Recording of test results . 26

9 Test report. 26

Annex A (normative) Measurement of temperature distribution on the surface of the

hot plate . 27

Annex B (informative) Godbert-Greenwald oven (GG) . 28

Annex C (informative) Examples of spark-generating systems . 29

C.1 General . 29

C.2 Triggering by auxiliary spark using three-electrode system . 30

C.3 Triggering by electrode movement . 31

C.4 Triggering by voltage increase (trickle-charging circuit) . 32

C.5 Triggering by auxiliary spark, using normal two-electrode system – Trigger

transformer in discharge circuit . 33

Annex D (normative) Vertical tube (modified Hartmann tube) apparatus . 34

Annex E (informative) 20-litre sphere . 35

Annex F (informative) BAM oven . 37

Annex G (informative) Data for dust explosion characteristics . 38

Annex H (informative) 1 m vessel . 39

H.1 Test principle . 39

H.2 Test apparatus . 39

H.3 Test conditions . 43

H.4 Test procedure . 43

Bibliography . 45

Figure 1 – Protocol for characterisation of combustible dust or combustible flying . 12

Figure 2 – Tests to define ability to form explosive dust atmosphere (combustible

dust/combustible flyings) . 13

Figure 3 – Tests to characterise combustible dust or combustible flying . 14

Figure 4 – Modified Hartmann tube . 23

Figure 5 – Measuring cell for powder resistivity . 25

Figure A.1 – Typical surface temperature distribution (method A) . 27

Figure B.1 – Vertical cross-section through the Godbert-Greenwald oven . 28

Figure C.1 – Circuit – Triggering by high-voltage relay, using a two-electrode system . 29

Figure C.2 – Apparatus for determining the minimum ignition energies of dust

(schematic) – Triggering by auxiliary spark using three-electrode system . 30

Figure C.3 – Apparatus for determining the minimum ignition energies of dust

(schematic) – Triggering by electrode movement . 31

Figure C.4 – Apparatus for determining the minimum ignition energies of dust

(schematic) – Triggering by voltage increase . 32

– 4 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

Figure C.5 – Apparatus for determining the minimum ignition energies for dust

(schematic) – Trigger transformer in discharge circuit . 33

Figure D.1 – Vertical tube apparatus (modified Hartmann tube) . 34

Figure E.1 – Test equipment 20-litre sphere (schematic) . 35

Figure E.2 – Cross-sectional view of rebound nozzle . 36

Figure E.3 – Plan view of rebound nozzle . 36

Figure E.4 – Cross-sectional view of dispersion cup . 36

Figure F.1 – Cross-sectional arrangement of BAM oven . 37

Figure H.1 – 1 m vessel (schematic) . 40

Figure H.2 – Location of the 6 mm holes in the semicircular dust dispenser . 41

Figure H.3 – Rebound nozzle . 42

Figure H.4 – Dispersion cup . 43

Table 1 – Example of ignition test report . 21

ISO/IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 20-2: Material characteristics –

Combustible dusts test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard ISO/IEC 80079-20-2 has been prepared by subcommittee 31M: Non-

electrical equipment and protective systems for explosive atmospheres, of IEC 31: Equipment

for explosive atmospheres.

It is published as a double logo standard.

This first edition cancels and replaces the first edition of IEC 61241-2-1 published in 1994, the

first edition of IEC 61241-2-2 published in 1993 and the first edition of IEC 61241-2-3

published in 1994, combining the requirements into a single document, and is considered to

constitute a technical revision.

– 6 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

The text of this standard is based on the following documents:

FDIS Report on voting

31M/102/FDIS 31M/108/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table. In ISO, the standard has been approved by 15 P-members

out of 21 having cast a vote.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

"A list of all parts in the IEC 60079 series, under the general title Explosive atmospheres, as

well as the International Standard 80079 series, can be found on the IEC website."

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

ISO/IEC 2016

Significant changes with respect to IEC 61241-2-1:1994, IEC 61241-2-2:1993 and

IEC 61241-2-3:1994

Type

Explanation of the significance of the Clause Minor and Extension Major technical

changes editorial changes changes

Normative references 2 X

Terms and Definitions 3 X

Dust sample Requirements 4 X

Combustible Dust Determination 5 X

Procedure for Characterisation of combustible 6 X

dust or combustible flying

Test methods for determination of a 7 X

combustible dust or a combustible flying

MIT of a dust cloud 8.1 X

MIT of a dust layer 8.2 X

MIE of a dust/air mixture 8.3 X

Tests on resistivity 8.4 X

Measurement of temperature distribution on Annex X

the surface of the hot plate A

Godbert-Greenwald oven Annex X

B

Examples of spark-generating systems Annex X

C

Vertical tube apparatus Annex X

D

20-litre sphere Annex X

E

BAM oven Annex F X

Data for dust explosion characteristics Annex X

G

1m vessel Annex X

H

– 8 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

EXPLOSIVE ATMOSPHERES –

Part 20-2: Material characteristics –

Combustible dusts test methods

1 Scope

This part of ISO/IEC 80079 describes the test methods for the identification of combustible

dust and combustible dust layers in order to permit classification of areas where such

materials exist for the purpose of the proper selection and installation of electrical and

mechanical equipment for use in the presence of combustible dust.

The standard atmospheric conditions for determination of characteristics of combustible dusts

are:

• temperature –20 °C to +60 °C,

• pressure 80 kPa (0,8 bar) to 110 kPa (1,1 bar) and

• air with normal oxygen content, typically 21 % v/v.

The test methods defined do not apply to:

• recognized explosives, propellants (e.g. gunpowder, dynamite), or substances or mixtures

of substances which may, under some circumstances, behave in a similar manner or

• dusts of explosives and propellants that do not require atmospheric oxygen for

combustion, or to pyrophoric substances.

2 Normative references

None.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

combustible dust

finely divided solid particles, 500 µm or less in nominal size, which may form explosive

mixtures with air at standard atmospheric pressure and temperatures

Note 1 to entry: This includes dust and grit as defined in ISO 4225.

Note 2 to entry: The term 'solid particles' is intended to address particles in the solid phase but does not preclude

a hollow particle.

3.1.1

conductive dust

combustible metal dusts and other combustible dusts with electrical resistivity equal to or less

than 1 × 10 Ω⋅m

Note 1 to entry: Metal dust is treated as conductive dust because it is assumed that surface oxidation cannot be

depended upon to always ensure electrical resistivity greater than 1 × 10 Ω⋅m

ISO/IEC 2016

3.1.2

non-conductive dust

combustible dust with electrical resistivity greater than 1 × 10 Ω⋅m

3.2

combustible flyings

solid particles, including fibres, where one dimension is greater than 500 µm in nominal size,

which may form an explosive mixture with air at standard atmospheric pressure and

temperature

Note 1 to entry: The ratio of length to width is 3 or more.

Note 2 to entry: Examples of flyings include carbon fibre, rayon, cotton (including cotton linters and cotton waste),

sisal, jute, hemp, cocoa fibre, oakum and baled waste kapok.

3.3

explosive dust atmosphere

mixture with air, under atmospheric conditions, of combustible substances in the form of dust,

fibres, or flyings which, after ignition, permits self-sustaining propagation

3.4

minimum ignition temperature of a dust layer

lowest temperature of a hot surface at which ignition occurs in a dust layer under specified

test conditions

3.5

minimum ignition temperature of a dust cloud

lowest temperature of a hot surface on which the most ignitable mixture of the dust with air is

ignited under specified test conditions

3.6

minimum ignition energy (of a combustible dust/air mixture)

lowest electrical energy stored in a capacitor which upon discharge is sufficient to effect

ignition of the most sensitive dust/air mixture under specified test conditions

4 Dust sample requirements

4.1 Receipt of sample for testing

A material safety data sheet or equivalent with the sample.

The test material shall be provided in suitable packaging, labelled according to relevant

guidelines labelled according to relevant guidelines, and appropriate transportation.

NOTE It is usual to provide a quantity of at least 0,5 kg for testing. If sample preparation is required this may be

insufficient. If only a smaller volume of material is available then the full range of testing may not be possible.

4.2 Characterisation of sample

The sample shall be representative of the material as it appears in the entire process

operated.

NOTE Many unit operations such as extract systems will separate dust into finer fractions than seen in the main

processing equipment and this is accounted for when taking the sample.

If the sample is not representative of the material as found in the process then sample

preparation shall be carried out to apply the worst case conditions.

At least the following information about the sample shall be provided:

– 10 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

– minimum particle size,

– median particle size,

– maximum particle size,

– particle distribution,

– moisture content, and

– method of determination (e.g. optical methods or sieving).

If the applicant cannot provide usable data then this shall be determined separately.

4.3 Preparation of sample

If it is not possible to test the sample as received, or if the sample is no longer representative

of the process material then it may be necessary to condition or alter the sample for testing.

This may include

– grinding/sieving,

– drying and

– humidifying.

Any apparent changes noted in the properties of the dust during preparation of the sample, for

example, by sieving or owing to temperature or humidity conditions, shall be stated in the test

report.

NOTE 1 Sample preparation such as grinding and sieving, or drying can alter the material characteristics. Where

finer fractions are present in a facility it is appropriate to take fractions of less than 63 µm to give the most easily

ignitable mixtures. When the sample is a mixture of substances, the sample preparation can result in a change to

the sample’s composition.

NOTE 2 The presence of solvents can become altered in the sample preparation process.

4.4 Test conditions

+10

The tests shall be carried out at standard atmospheric temperature of 20 °C and standard

−10

atmospheric pressure of 80 kPa to 110 kPa (0,8 bar to 1,1 bar) unless otherwise specified.

5 Combustible dusts and combustible flyings determination

5.1 Test sequence

The sequence followed for the determination of the material properties of combustible dust

and combustible flyings is given in 5.2, Clause 6 and Figure 1, Figure 2 and Figure 3.

NOTE 1 Refer also to the information referenced in Annex G.

NOTE 2 Testing in the Hartman tube is a screening method. The test procedure can be directly started with the

20 litre sphere or the GG Oven.

5.2 Tests to determine whether material is a combustible dust or combustible flying

5.2.1 Visual inspection

Make a visual inspection of the test material (by microscope if necessary) to determine

whether the material consists of combustible flyings:

• If the material consists of combustible flyings with dust then continue the test procedure in

a Hartmann tube (see 5.2.3) to determine whether the combination of the two is

combustible dust.

• If the material consists only of combustible flyings then continue the test procedure in a

Hartmann tube (see 5.2.3) to determine whether it is combustible flyings.

ISO/IEC 2016

5.2.2 Determine particle distribution

For material which does not contain combustible flyings check the particle size distribution:

• If there are no particles less than 500 µm in size then the material is not a combustible

dust.

• If there are any particles less than 500 µm in size then continue the test procedure in a

Hartmann tube to determine whether it is a combustible dust.

5.2.3 Ignition test in the Hartmann tube

5.2.3.1 Test in a Hartmann tube with a spark (see 7.1):

1) If ignition occurs, the material is a combustible dust or a combustible flying (proceed to the

procedure for characterisation of combustible dust or combustible flying (see Clause 6)).

2) If no ignition occurs:

a) proceed to a Hartmann tube with a hot coil ignition source (see 7.1);

b) it can be assumed that the minimum ignition energy is greater than 1 J and the test

material is hard to ignite.

5.2.3.2 Test in a Hartmann tube with a hot coil ignition source (see 7.1):

1) If ignition occurs, the material is a combustible dust or a combustible flying, (proceed to

the procedure for the characterisation of combustible dust or combustible flying (see

Clause 6).

2) If no ignition occurs:

a) proceed to the test in the 20-litre sphere (see 7.2);

b) it can be assumed that the minimum ignition energy is greater than 10 J.

5.2.4 Ignition test in the 20-litre sphere

Test in the 20-litre sphere (see 7.2):

• If ignition occurs the material is a combustible dust or a combustible flying (proceed to

procedure for characterisation of combustible dust or combustible flying (see Clause 6)).

• If no ignition occurs then the material is not a combustible dust or a combustible flying and

the testing procedure is completed.

NOTE Although the material does not form explosive mixtures with air, it can still ignite as a combustible dust

layer.

If there is insufficient material available for testing in a 20-litre sphere then testing in the

Godbert-Greenwald (GG) oven at 1 000 °C is an acceptable alternative (see 7.3):

• If no ignition occurs at 1 000 °C then the material is not a combustible dust or a

combustible flying.

• If there is an ignition at 1 000 °C then the material should be subject to further verification

in the 20-litre sphere before declaring it combustible or non-combustible.

6 Procedure for characterisation of combustible dust or combustible flying

The following is the procedure for the characterisation of combustible dust or combustible

flying:

– test for dust cloud minimum ignition temperature (MIT) (see Clause 8):

a) GG oven (see 8.1.2) or

b) BAM oven (see 8.1.3)

– test for dust layer MIT (see 8.2);

– 12 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

– test for minimum ignition energy (MIE) of dust cloud (see 8.3);

– test for resistivity of bulk dust (see 8.4).

IEC

Figure 1 – Protocol for characterisation of combustible dust or combustible flying

ISO/IEC 2016

IEC

Figure 2 – Tests to define ability to form explosive dust atmosphere

(combustible dust/combustible flyings)

– 14 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

IEC

Figure 3 – Tests to characterise combustible dust or combustible flying

7 Test methods for determination of whether a material is a combustible dust

or a combustible flying

7.1 Modified Hartmann tube

7.1.1 General

Dust is dispersed in a tube to form a dust cloud, and ignition trials are attempted with two

different ignition sources.

7.1.2 Test equipment

The test equipment consists of a vertical tube closed at the bottom with a dispersion cup

(volume approximately 1,2 l, internal diameter (70 ± 5) mm).

As ignition sources

ISO/IEC 2016

– a continuous induction spark (electrode gap of approximately 4 mm, with a transformer

rated approximately 15 kV, and approximately 0,2 kVA),

– a glowing coil (wire diameter approximately 1,2 mm, wire length approximately 470 mm,

coil diameter approximately 11 mm and wire temperature at least 1 000 °C)

The vertical separation between the bottom of the dispersion cup and the ignition source is

approximately 100 mm.

A detailed description of suitable equipment can be found in Annex D.

7.1.3 Test procedure

The test sample is deposited in the dispersion cup and dispersed with a blast of air (50 cm ,

700 kPa to 800 kPa gauge). The dust concentration is varied over a wide range from 250 g/m

3 3 3 3 3 3

to 1500 g/m (typically 250 g/m , 500 g/m , 750 g/m , 1 000 g/m and 1 500 g/m ) and the

behaviour is visually observed. The different quantities are each tested once, but repeated

dispersions are made for at least 3 attempts.

If a flame propagates from the ignition source, the test material is a combustible dust or

combustible flying.

If no ignitions are observed with the spark ignition source, then the coil ignition source is

used. Testing may be stopped immediately after an ignition is observed.

If it is unclear, whether ignition has been observed then the 20-litre sphere test shall be used.

NOTE 1 In the case of high density materials such as metals higher concentrations (e.g. up to 2 500 g/m ) are

used.

NOTE 2 Deposits on the coil can result in localised smouldering or burning, which is not considered as ignition.

7.2 20-litre sphere

7.2.1 General

Dust is dispersed in a pressure resistant closed apparatus (20-litre sphere) to form a dust

cloud under standard conditions of pressure and temperature. Ignition trials are attempted

with pyrotechnic igniters.

As an alternative method, the 1 m vessel can be used (see Annex H).

7.2.2 Test equipment

The standard test apparatus to determine dust cloud combustibility is a spherical explosion

pressure resistant vessel of 20 litres.

The main components of the test apparatus are:

• spherical explosion vessel;

• dust dispersion system (rebound nozzle);

• ignition source (2 × 1 000 J pyrotechnical igniters);

• control unit;

• pressure measuring system with two sensors (± 10 kPa);

• dispersion overpressure p = (2 000 ± 100) kPa;

z

• initial temperature T = (20 +/- 5) °C (water cooling).

i

A detailed description of suitable equipment can be found in Annex E.

– 16 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

NOTE 1 For flyings and very coarse materials other nozzles are typically used (see Annex E).

NOTE 2 The particle size of friable materials can be affected by the dispersing system.

7.2.3 Test procedure

Explosion tests with defined dust/air mixtures shall be carried out according to the following

procedure. The test material is dispersed in the explosion vessel by an air blast such that a

homogeneous dust cloud is created. Prior to the air blast the explosion vessel is evacuated to

a level such that immediately after dispersion the internal pressure of the vessel shall be

equal to standard atmospheric pressure.

3 3

The dust concentration is varied over a wide range from 250 g/m to 1 500 g/m (typically

3 3 3 3 3

250 g/m , 500 g/m , 750 g/m , 1 000 g/m and 1 500 g/m ) and the pressure increase is

measured. The different concentrations shall each be tested at least once.

The required amount of the dust is placed in the dust container. The bulk volume of the dust

shall not exceed ¾ of the dust container allowing proper pressurization. The amount of the

dust in the dust container has to be completely dispersed into the 20-litre-sphere. The

container is then pressurized to an overpressure of 2 000 kPa.

Before starting the test procedure the temperature inside the vessel shall be measured and

recorded.

After dispersion of dust the pressure in the 20-litre sphere shall be at atmospheric pressure.

The actual pressure in the 20-litre sphere at the moment of ignition (initial pressure p ) shall

i

be measured and recorded.

The delay between the initiation of the dust dispersion and the activation of the ignition source

) shall be 60 +/- 5 ms. The pressure is recorded as a function of time. From

(ignition delay t

v

the pressure/time curve the explosion pressure p is determined by taking the arithmetic

ex

mean of the maximum values measured by the pressure sensors (see Annex E).

If the difference in the pressures measured by the different pressure sensors is more than

10 kPa of the mean, the accuracy of the sensors shall be checked and the measurements

repeated.

An ignition of the dust (dust explosion) shall be considered to have taken place, if an

overpressure is detected which is equal to or greater than the overpressure created by the

ignition source alone in air plus 30 kPa.

If an ignition occurs, then the test material is a combustible dust or combustible flying, and

testing may be stopped.

If no ignition occurs for all concentrations it is not a combustible dust or combustible flying.

In the case of high density materials such as metals, higher concentrations (e.g. up to

2 500 g/m ) are permitted to be used.

After each test, the explosion vessel shall be cleaned.

7.3 Alternative method to 20-litre sphere for small test material quantities

7.3.1 General

Small quantities of dust are blown through a heated vertical tube (GG oven) at a temperature

of 1 000 °C and ignition is detected by visual inspection.

ISO/IEC 2016

7.3.2 Test equipment

The main components of the test apparatus are

• a furnace capable of achieving a wall temperature of 1 000 °C,

• a dust dispersion system including an air reservoir of 500 ml and

• a temperature control unit.

A detailed description of suitable equipment can be found in Annex B.

7.3.3 Test procedure

The test material is dispersed in the furnace by an air blast.

The dust quantity is varied from 0,3 g to 0,5 g.

The dust is dispersed with air at pressures varying between 10 kPa and 50 kPa.

If a burst of flame is seen below the end of the furnace tube the test material is a combustible

dust or a combustible flying.

If a burst of flame is not seen below the end of the furnace tube the test material is not a

combustible dust or combustible flying.

In case of uncertainties in the detection of flames the test material shall be considered to be a

combustible dust or combustible flying. The ultimate determination shall be from a 20-litre

sphere test as described in 7.2.

NOTE In the case of high density materials such as metals, higher quantities (e.g. up to 5,0 g) are typically used.

8 Test methods for combustible dust determinations

8.1 MIT of a dust cloud

8.1.1 General

There are two methods for measuring the MIT of the dust cloud outlined below, the GG

furnace in 8.1.2 or the BAM furnace in 8.1.3.

8.1.2 GG furnace

8.1.2.1 General

Small quantities of dust are blown vertically downward through a heated furnace and ignition

is detected by visual inspection.

8.1.2.2 Test equipment

The main components of the test apparatus are as shown in 7.3.1.

8.1.2.3 Test procedure

The test material is dispersed in the furnace by an air blast.

The dust quantity is varied over a wide range from 0,05 g to 0,5 g (typically 0,1 g, 0,2 g and

0,3 g). The dust is dispersed with air at pressures varying between 10 and 50 kPa (typically

10 kPa, 20 kPa, 30 kPa and 50 kPa).

– 18 – ISO/IEC 80079-20-2:2016

ISO/IEC 2016

In the absence of preliminary information the first test should be performed at a furnace wall

temperature of 500 °C, with a quantity of 0,3 g and an air pressure of 30 kPa.

If no ignition is observed at this temperature the temperature should be increased in steps of

50 K until 600 °C is reached.

Once ignition is obtained, vary the mass of test material and the dispersion pressure of the air

until the most vigorous ignition is apparent. Then using the same mass and dispersion

pressure carry out further tests with the temperature reduced in steps of 20 K until no ignition

is obtained after 10 attempts. If ignition still occurs at 300 °C reduce the temperature in steps

of 10 K.

When no ignition is obtained using this temperature redu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...