ISO 5667-10:2020

(Main)Water quality — Sampling — Part 10: Guidance on sampling of waste water

Water quality — Sampling — Part 10: Guidance on sampling of waste water

This document contains details on the sampling of domestic and industrial waste water, i.e. the design of sampling programmes and techniques for the collection of samples. It covers waste water in all its forms, i.e. industrial waste water, radioactive waste water, cooling water, raw and treated domestic waste water. It deals with various sampling techniques used and the rules to be applied so as to ensure the samples are representative. Sampling of accidental spillages is not included, although the methods described in certain cases may also be applicable to spillages.

Qualité de l'eau — Échantillonnage — Partie 10: Lignes directrices pour l'échantillonnage des eaux résiduaires

Kakovost vode - Vzorčenje - 10. del: Navodilo za vzorčenje odpadne vode

General Information

- Status

- Published

- Publication Date

- 05-Nov-2020

- Technical Committee

- ISO/TC 147/SC 6 - Sampling (general methods)

- Drafting Committee

- ISO/TC 147/SC 6/WG 14 - Waste waters

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 22-Apr-2023

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Mar-2016

Overview - ISO 5667-10:2020 (Water quality - Guidance on sampling of waste water)

ISO 5667-10:2020 provides guidance for the sampling of domestic and industrial waste water to ensure representative, reliable water quality data. The standard addresses the design of sampling programmes and practical techniques for collecting samples from all forms of waste water - including industrial effluents, radioactive liquid effluents, cooling water, and raw or treated domestic waste water. Sampling of accidental spillages is excluded, though some methods can be applicable.

Key technical topics and requirements

The standard covers the full sampling workflow and emphasizes representativeness, traceability and safety. Major technical topics include:

- Design of sampling programmes - objectives, selection of sampling points and representativeness criteria.

- Sampling frequency and timing - guidance on scheduling and number of samples to capture variability.

- Sampling locations - procedures for sewers, channels, manholes, treatment plants, industrial sites and cooling systems.

- Main sampling strategies - comparison of spot (grab) sampling and composite sampling (automatic and manual), including event-triggered sampling.

- Sampling equipment - requirements and options for automatic samplers, peristaltic/vacuum pumps, manual samplers, tank sampling and ballasted collectors.

- Sample handling - homogenization, distribution into laboratory bottles, preservation, packaging, transport, storage temperature and time considerations.

- Quality assurance and control - contamination avoidance, identification, records, and quality control of sampling devices.

- Reporting and documentation - analytical reports and sampling protocols to support interpretation and legal defensibility.

- Safety - personnel and equipment safety measures for waste water sampling.

- Informative annexes provide examples, cleaning protocols, field forms and equipment compatibility tables.

Practical applications and who uses it

ISO 5667-10 is used where reliable waste water monitoring is required:

- Municipal and industrial environmental monitoring programs

- Waste water treatment plant operators and process engineers

- Environmental consultants and field sampling teams

- Regulatory agencies enforcing discharge permits and compliance

- Laboratories receiving samples for chemical, microbiological or radiological analysis

Benefits include improved data comparability, defensible compliance evidence, and reduced sampling bias.

Related standards

ISO 5667-10 is part of the ISO 5667 series. Relevant companion standards include:

- ISO 5667-1 (design of sampling programmes)

- ISO 5667-3 (preservation and handling)

- ISO 5667-14 (QA/QC)

- ISO 19458 (microbiological sampling)

Referencing these ensures complete coverage of water quality sampling, sample preservation, and quality assurance best practices.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO 5667-10:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Water quality — Sampling — Part 10: Guidance on sampling of waste water". This standard covers: This document contains details on the sampling of domestic and industrial waste water, i.e. the design of sampling programmes and techniques for the collection of samples. It covers waste water in all its forms, i.e. industrial waste water, radioactive waste water, cooling water, raw and treated domestic waste water. It deals with various sampling techniques used and the rules to be applied so as to ensure the samples are representative. Sampling of accidental spillages is not included, although the methods described in certain cases may also be applicable to spillages.

This document contains details on the sampling of domestic and industrial waste water, i.e. the design of sampling programmes and techniques for the collection of samples. It covers waste water in all its forms, i.e. industrial waste water, radioactive waste water, cooling water, raw and treated domestic waste water. It deals with various sampling techniques used and the rules to be applied so as to ensure the samples are representative. Sampling of accidental spillages is not included, although the methods described in certain cases may also be applicable to spillages.

ISO 5667-10:2020 is classified under the following ICS (International Classification for Standards) categories: 13.060.30 - Sewage water. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 5667-10:2020 has the following relationships with other standards: It is inter standard links to EN ISO 13162:2021, EN ISO 13163:2022, EN ISO 20042:2021, EN ISO 21676:2021, EN ISO 20595:2022, EN ISO 20596-2:2022, EN ISO 10703:2021, EN ISO 23695:2025, EN ISO 23697-1:2025, EN ISO 23697-2:2025, EN ISO 23696-2:2025, EN ISO 23548:2025, EN ISO 23696-1:2025, ISO 5667-10:1992. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 5667-10:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2021

Nadomešča:

SIST ISO 5667-10:1996

Kakovost vode - Vzorčenje - 10. del: Navodilo za vzorčenje odpadne vode

Water quality - Sampling - Part 10: Guidance on sampling of waste waters

Qualité de l'eau - Échantillonnage - Partie 10: Guide pour l'échantillonnage des eaux

résiduaires

Ta slovenski standard je istoveten z: ISO 5667-10:2020

ICS:

13.060.30 Odpadna voda Sewage water

13.060.45 Preiskava vode na splošno Examination of water in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 5667-10

Second edition

2020-11

Water quality — Sampling —

Part 10:

Guidance on sampling of waste water

Qualité de l'eau — Échantillonnage —

Partie 10: Lignes directrices pour l'échantillonnage des eaux

résiduaires

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

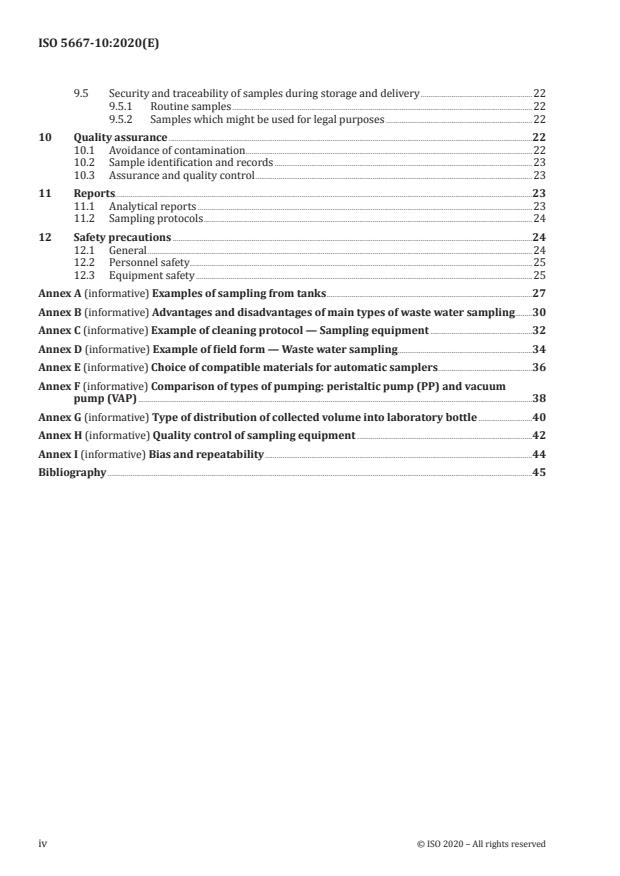

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 General aspects . 3

4.1 Design of sampling programme . 3

4.2 Sampling point selection - Representativeness . 3

4.3 Frequency and time of sampling . 4

4.3.1 Number of samples . 4

4.3.2 Sampling time for effluent stream . 4

5 Sampling at specific locations. 5

5.1 Sampling from sewers, channels and manholes . 6

5.2 Sampling from waste water treatments plants . 6

5.3 Sampling from industrial sites . 7

5.4 Sampling from cooling systems . 7

6 Main types of waste water sampling . 8

6.1 Spot sampling . 8

6.2 Composite sampling . 8

7 Waste water sampling . 9

7.1 General aspects . 9

7.1.1 Preparation of the sampling campaign . 9

7.1.2 Arrival on site . 9

7.2 Composite sampling for waste water quality monitoring .10

7.2.1 General.10

7.2.2 Automatic composite sampling .10

7.2.3 Manual composite sampling .13

7.2.4 Manual sample reconstitution .13

7.3 Spot sampling in an effluent stream .14

7.3.1 General.14

7.3.2 Direct sampling .15

7.3.3 Indirect sampling .15

7.3.4 Automatic, remote start or event-triggered sampling.16

7.4 Spot sampling of tanks — planned discharges .16

8 Sampling equipment .17

8.1 General .17

8.2 Automatic sampler .17

8.3 Manual sampling equipment .18

8.3.1 General.18

8.3.2 Ballasted sample collector .18

8.3.3 Bucket, vertical water sampler .18

8.4 Tank sampling equipment .19

8.4.1 Mixing .19

8.4.2 Sampling equipment . . .19

9 Homogenization, preservation, transport and storage of samples .19

9.1 Homogenization of collected volume .19

9.2 Distribution of collected volume into laboratory bottles .20

9.3 Preservation and packaging of samples .21

9.4 Transportation and reception .21

9.4.1 General.21

9.4.2 Time .21

9.4.3 Temperature .21

9.5 Security and traceability of samples during storage and delivery .22

9.5.1 Routine samples .22

9.5.2 Samples which might be used for legal purposes .22

10 Quality assurance .22

10.1 Avoidance of contamination .22

10.2 Sample identification and records .23

10.3 Assurance and quality control .23

11 Reports.23

11.1 Analytical reports .23

11.2 Sampling protocols .24

12 Safety precautions .24

12.1 General .24

12.2 Personnel safety .25

12.3 Equipment safety .25

Annex A (informative) Examples of sampling from tanks .27

Annex B (informative) Advantages and disadvantages of main types of waste water sampling .30

Annex C (informative) Example of cleaning protocol — Sampling equipment .32

Annex D (informative) Example of field form — Waste water sampling .34

Annex E (informative) Choice of compatible materials for automatic samplers .36

Annex F (informative) Comparison of types of pumping: peristaltic pump (PP) and vacuum

pump (VAP) .38

Annex G (informative) Type of distribution of collected volume into laboratory bottle .40

Annex H (informative) Quality control of sampling equipment .42

Annex I (informative) Bias and repeatability .44

Bibliography .45

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 147, Water quality, SC 6, Sampling (general

methods).

This second edition cancels and replaces the first edition (ISO 5667-10:1992), which has been technically

revised. The main changes compared to the previous edition are as follows:

— integration of radioactive liquid effluent sampling and its specificities;

— integration of qualified spot sampling.

A list of all parts in the ISO 5667 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

INTERNATIONAL STANDARD ISO 5667-10:2020(E)

Water quality — Sampling —

Part 10:

Guidance on sampling of waste water

1 Scope

This document contains details on the sampling of domestic and industrial waste water, i.e. the design

of sampling programmes and techniques for the collection of samples. It covers waste water in all its

forms, i.e. industrial waste water, radioactive waste water, cooling water, raw and treated domestic

waste water.

It deals with various sampling techniques used and the rules to be applied so as to ensure the samples

are representative.

Sampling of accidental spillages is not included, although the methods described in certain cases may

also be applicable to spillages.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5667-1, Water quality — Sampling — Part 1: Guidance on the design of sampling programmes and

sampling techniques

ISO 5667-3, Water quality — Sampling — Part 3: Preservation and handling of water samples

ISO 5667-7, Water quality — Sampling — Part 7: Guidance on sampling of water and steam in boiler plants

ISO 5667-14, Water quality — Sampling — Part 14: Guidance on quality assurance and quality control of

environmental water sampling and handling

ISO 5667-16, Water quality — Sampling — Part 16: Guidance on biotesting of samples

ISO 6107 (all parts), Water quality — Vocabulary

ISO 19458, Water quality — Sampling for microbiological analysis

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 6107 (all parts) and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

composite sample

two or more samples or sub-samples, mixed together in appropriately known proportions (either

discretely or continuously), from which the average value of a desired characteristic may be obtained

Note 1 to entry: The number of samples or sub samples are usually based on time, flow measurements, area or

depth profile sampling.

EXAMPLE Composite sample can be made in different ways:

— constant volume variable time sampling (C.V.V.T): flow proportional sampling based on collecting equal

volumes of sample at frequencies proportional to flow.

— constant time variable volume sampling (C.T.V.V): flow proportional sampling based on collecting samples at

fixed time intervals but where the volume of sample is varied in proportion to the flow.

— constant time constant volume sampling (C.T.C.V): equal volumes of sample or sub-sample collected at equal

increments of time.

3.2

sampling point

precise position within a sampling location from which samples are taken

3.3

spot sample

discrete sample taken randomly (with regard to time and/or location) from a body of water, usually

taken manually, but may be taken by automatic sampling equipment or by event-triggered automatic

samplers

3.4

qualified spot sample

special form of a composite sample (3.1), consisting of at least five spot samples, taken and mixed within

a maximum period of two hours and at an interval of not less than two minutes

3.5

radioactive liquid effluent

water or waste water that contains radioactive substances, resulting from a process and that can be

recycled, treated and/or discharged to the environment

Note 1 to entry: The activity concentration of the radioactive liquid effluent is usually measured before being

discharged in the environment to verify that it is lower than the authorized levels in order to comply with

national regulation.

3.6

supernatant

solid or liquid phase present on the surface of an effluent

3.7

planned discharge

discharge subject to prior agreement further to a consultation between several parties based on

knowing certain predefined parameters and referring to limit values (regulatory or otherwise)

Note 1 to entry: These parameters may, for example, be physical, chemical and radiological measurements, the

estimated discharge volume, the discharge period or the maximum discharge flow rate.

3.8

permanent discharge

direct discharge into a channel or collector or water body, which is not subject to a specific prior

agreement, but which shall conform with limit values

2 © ISO 2020 – All rights reserved

3.9

tank

hollow object, very variable in size, used to hold liquids

Note 1 to entry: Covers the usual names such as tank, chamber and pool. The content of this tank is intended for

direct and indirect liquid discharge to the environment or to a specific treatment.

3.10

event-trigged sampling

sampling which is triggered because a pre-determined criterion has been met (e.g. rainfall, change in

electrical conductivity, pH or the introduction of a polluting substance), when samples should be taken

manually or by automatic equipment

4 General aspects

4.1 Design of sampling programme

Sampling is usually the first step in carrying out an investigation and largely determines the quality

of the whole investigation. It is therefore recommended that a detailed sampling strategy be drawn

up, often based upon a preliminary investigation in which an assessment has identified the important

aspects. Both the purpose and the ambient situation determine the way in which the sampling is carried

out. General aspects for sampling programme design can be found in ISO 5667-1.

4.2 Sampling point selection - Representativeness

The sampling point selection should be representative of the waste stream to be examined. In some

waste waters this representativeness may be difficult to obtain because of the spatial and temporal

heterogeneity of the water body. It is necessary to carry out the sampling in the sections where the flow

is well mixed and homogeneous.

The term “representativeness” encompasses two notions depending on the type of environment to be

sampled:

— representativeness in a flow (canal, sewer, manhole, pressurised pipes, etc.);

— representativeness in a storage (tank, lagoons, basins, etc.).

These two notions should be treated in different ways, but the goal remains to obtain a representative

sample of the water body.

Sampling points may be clearly identified (by regulatory text) or not, in which case a preliminary

investigation is recommended. This is generally the case for the selection of sewer sampling locations.

By studying drawings of the sewer system initially, possible locations can be identified. Subsequently, a

site inspection should be conducted to ensure that the locations of the sewers and the path of the waste

stream corresponds to the drawings, and to make sure that the selected location is representative for

the sampling purpose. The tracer studies may be a helpful tool.

Each sampling point should be documented. It is important to gather, for example, the following

information: identification, location of the site, photos, geographical coordinates, site location, type of

flow (open, closed), access conditions and sampling technique.

If necessary, specifically describe and label the sampling site. Select the site so that representative

samples can be obtained and the waste water flow (with the exception of fixed sampling equipment) is

clearly visible from the sampling site.

The following facilities should be available for the for the sampling sites involving a fixed automatic

sampling device:

— access for motor vehicles to the immediate vicinity of the sampling site;

— flat working surfaces at appropriate height above the sampling point for the set-up of sampling

devices;

— adequate lighting and power connection;

— water connection to clean the equipment after sampling;

— adequate safety precautions (e.g. grids, railings, fall arresting devices); and

— flow meters in the case of a flow-dependent sampling.

If the hydraulic conditions do not ensure the representativeness of the sample (absence of flow, reduced

activity, abnormal load rise), this unusual situation should be noted on the sampling report and the

client and the analytical laboratory should be informed.

4.3 Frequency and time of sampling

4.3.1 Number of samples

Analyses should be based on samples taken at regular intervals during a certain period (composite

or spot). The decision on the required number of samples taken during each period should be decided

[1] [2]

based on statistical techniques (see ISO 2602, ISO 3534 (all parts) and ISO 5667-1). But the number

of samples to be taken may often be decided by the regulatory body or pollution control authorities.

4.3.2 Sampling time for effluent stream

The objective of a sampling programme often dictates when and how a sample is collected and is often

determined by legislation or directives. Generally, when sampling sewages and effluents, it is normal to

make allowances for the following sources of variation in quality:

a) diurnal variations (i.e. within-day variability);

b) variations between days of the week;

c) variations between weeks and months;

d) variations between seasons;

e) variations due to storm water episodes; and

f) trends.

If there is little or no diurnal variation, or day-to-day variations, then the particular time of day or day

of the week for sampling is relatively unimportant.

If the identification of the nature and magnitude of peak load are important, sampling should be

restricted to those periods of the day, week or month when peak loads are known to occur.

Relating the times of sampling to the particular process being monitored may be very important when

considering industrial effluent discharges that are either seasonal or operated on a batch basis. In

either case, the discharge will not be continuous, and the sampling programme will need to take this

fact into account.

Sampling for the detection of trends needs careful planning. For example, when detecting trends on a

month-to-month basis, it can be appropriate to always sample on the same day of the week, in order

that any diurnal and daily variations are eliminated from the overall variability of data, thus allowing

trends to be more efficiently detected.

When the number of samples has been decided upon according to 4.3.1, the sampling times should be

determined. The samples should normally be taken at fixed intervals during the whole control period.

The sampling period may be one year, a number of months or weeks, or even shorter periods of time.

4 © ISO 2020 – All rights reserved

If the sampling period covers one year, the days of sampling may be determined using a formula. An

example of this is:

Formula (1) for a number of samples (n), larger than about 25 and from Formula (2) for a number of

samples less than about 25.

Formula (1) indicates the day number during which sampling should take place.

365 365×2 365×3 365×n

A++,,A A+ ,.,A+ (1)

n n n n

where

n is the number of samples;

A 365

is a random number in the interval between − and 0.

n

Formula (2) indicates the week number during which the sampling should take place. The day of each

week should be determined so that samples are taken on every weekday.

52 52×2523× 52×n

B++,,B B+ ,.,B+ (2)

n n n n

where

n is the number of samples;

B 52

is a random number in the interval between − and 0.

n

Similar formulae can be used for other periods, for example, one month, three months, six months, etc.

The period chosen should cover any seasonal variations.

After determining the intervals and the day or week number, it should be ensured that the sampling

does not lead to any risk of systematic error, for example by always taking samples on one day, or by

systematically omitting weekdays.

5 Sampling at specific locations

The concentration profiles of dissolved substances and suspended solids measured in an effluent are

often heterogeneous because they depend on the hydraulic conditions and transport conditions of the

solid phase in the body of water. Observations are:

— A vertical gradient of concentration, due to the flow velocities or the shear stresses near the bottom

are low;

— A very dense layer at the interface between the deposit of the bottom and the water circulating in

the structure;

— An increase of the concentration near the walls;

— An increase of the concentration near the surface of the flow due to the presence of floating matter.

It is therefore necessary to define carefully the positioning of the sample taken within the body of water.

To take a sample theoretically representative of the average concentration of the measured section, it

is advisable to place the sampling point about halfway up the water column and at a sufficient distance

from the walls and deposits to avoid measurement bias.

5.1 Sampling from sewers, channels and manholes

A location should be chosen where the effluent has a high turbulent flow to ensure good mixing. Often

accessibility, lack of site security, or power unavailability may preclude the use of the best sites.

Since effluent channels are generally designed to cope with both effluent and storm-water discharge

conditions and/or for higher flows than those actually occurring, laminar flow may often occur. In the

absence of a location with turbulent flow conditions at permanent sampling location, such conditions

should be induced by restricting the flow, for example with a baffle or weir. The restriction should

be made in such a way that sedimentation upstream of the restriction does not occur (e.g. foresee

enlargement of the downstream effluent channel compared to the upstream channel, to avoid any

pressure increase of the effluent downstream).

The sampling intake point should always be located downstream from the restriction and, as a general

rule, it should be located at least three times the pipe diameter, or width of the channel, downstream of

the restriction. The inlet of the sampling probe should preferably face the direction of flow but may face

downstream if too many blockages result.

The exact location of the sampling point should be evaluated with respect to variations in water

level, types and concentrations of the determinands, etc. The sampling point should be at a minimum

distance from the bottom and walls to avoid sample contamination by deposits or the biofilms that

develop. Generally, a sampling point between one third and one half of the effluent water depth below

the surface of the water may be recommended.

Whenever practicable, permanent sampling locations should be established, care being taken to ensure

reproducible sampling conditions.

Before proceeding with the sampling of industrial discharges and if the information is accessible, the

conditions inside the plant (e.g. processes and production rates) should be noted and recorded along

with any potential hazards.

5.2 Sampling from waste water treatments plants

When choosing sampling locations for waste water treatment plants, it is again important to refer to

the objective of the data collection programme, of which the sampling is a part.

Typical objectives are:

— control of the performance of the entire treatment plant: samples should be collected at the main

inlet and main outlet points;

— control of the operation of individual processing units, or groups of units: samples should be

collected at the inlet and outlet of the units in question.

When sampling at the waste water treatments plants, the importance, the relevance of any bypass

flow should be evaluated, and sampling of such flows may also be needed for the sampling to be

representative for the overall effluent.

When sampling at the inlets of plants, the objective of the sampling programme should be carefully

considered. In some situations, there may be a need to sample raw sewage in the mixture with

recirculated processing liquid (e.g. in the assessment of primary sedimentation tank loadings and

efficiency). In other cases, it may be necessary to exclude the effect of these liquids (e.g. when collecting

data designed to assess domestic/industrial loadings to a plant or to assist in industrial effluent

control).

Representative sampling is often facilitated by using locations downstream of a measuring flume or

weir (see also 5.1).

When sampling effluents from processes employing more than one individual treatment unit (e.g.

several sedimentation tanks), care should be exercised in ensuring that the sample is representative of

6 © ISO 2020 – All rights reserved

the overall effluent stream rather than any one specific treatment unit (unless that unit forms the basis

of a specific study).

Frequent reviews of a plant's sampling locations need to be made to ensure that any relevant changes

in the operation of unit processes are considered when sampling. For example, the percolating filter

operation may be changed from a "single-pass" operation to a "recirculation" or "alternating-double

filtration" operation. Treatment plant operation may involve changes in the manner in which feed

or return liquors are introduced to the plant (e.g. return of sewage from storm tanks, changes in the

position at which processing liquors are returned to the treatment plant).

Whenever sampling waste waters, great care should be exercised to overcome or minimize the

substantial heterogeneity caused by suspended solids that are often present. Similarly, thermal

stratification of separate industrial effluent streams may be found when sampling effluents or

discharges from industrial processes, and measures have to be taken to promote the mixing of such

streams before sampling.

5.3 Sampling from industrial sites

Sampling liquid effluents involves sampling a certain representative amount before and/or after they

are transferred to discharge channels or collectors.

The sampling method depends on the type of discharge or transfer taking place. The following should

therefore be distinguished:

— planned discharges, which require a preceding inspection before the discharge takes place. These

may be, for example, discharges from facilities’ liquid effluent tanks prior to their transfer to general

collectors or buffer pools before being discharged into the environment (refer to 7.4);

— permanent discharges, which concern effluents that are continuously discharged. They are

monitored based on sequential or continuous sampling of the discharged effluent. These may be, for

example, discharges from an effluent collector at the outlet of a nuclear site or a rainwater collector,

prior to discharge into the environment.

As such, the kind of sampling and the creation of representative samples shall be adapted to suit the

type of discharge and its potential heterogeneity (e.g. the presence of suspended matter or any density

or thermal stratification).

For this, and to guarantee the representative nature, the samples shall be produced:

— ensuring sampling only takes place after obtaining suitable effluent homogeneity;

— ensuring there is no change to the nature of the effluent or cross-contamination; and

— taking account of the volumes of the tanks, the flow rates and the flow conditions in the lines, to

enable quantification of the discharges from the facility in question (see Annex A, Figure A.1 for an

example of tank sampling).

Sampling may be performed based on several configurations, depending on the facilities:

— in a tank prior to its discharge (see Annex A, Figures A.1 and A.3);

— in a continuous or discontinuous flow in a line or a discharge channel (see Annex A, Figure A.1).

5.4 Sampling from cooling systems

The selection of sampling points in industrial cooling processes using water as a coolant depends on the

cooling water system to be tested.

In continuous-flow cooling systems, fresh water (ground water, bank filtrate, surface water) or saline

water are used in one or repeated flow. The sampling points are located both in front and behind the

aggregates, which shall be cooled.

During cooling via primary and/or secondary circuit, two cooling circuits are coupled to one another,

wherein a closed secondary circuit is re-cooled with a primary circuit. The primary circuit can

consist of a continuous cooling system, an open or closed recooling plant or a refrigerating plant (e.g.

brine cooling). The sampling site should be on the return side and on a well through-flow site of the

circulatory system.

In many cases, the cooling water is precooled in an open system by evaporation cooling, whereby water

losses due to evaporation, spraying and desludging (desalination) will be replaced by fresh water. In the

closed recooling process, the cooling water flows through pipes, which are cooled from outside by air or

water. The methods of open and closed recooling can be combined. The sampling site is located on the

return side of the circulatory system.

Representative sampling locations throughout the system shall be defined for periodic microbiological/

hygiene checks. Microbiological sampling guidance is given in ISO 19458. The sample is preferably

taken from the circulating water between the running pump at the spraying/trickling stage. A sampling

facility (sampling tap allowing disinfection, preferably by flaming, and draining) is to be provided at

this location. Allow the water to drain for at least 30 s before sampling. Sampling shall be performed in

such a manner that results are not distorted by biocide dosage. The sampling location shall be upstream

of the point of biocide dosage.

If sampling is not possible at this location, the sample can be taken from the sprayed water or by bail

[3]

sampling from the circulating-water basin .

Special cooling processes are usually used when the medium to be cooled is very hot (e.g. waste heaters,

heat pumps) or when very low flow temperatures are required (e.g. brine cooling). For special cooling

processes in the high temperature range (temperature > 100 °C), ISO 5667-7 shall apply.

6 Main types of waste water sampling

6.1 Spot sampling

In the case of spot sampling (refer Annex B), it is possible to implement:

a) direct sampling in the waste water body:

1) directly by using laboratory bottles;

2) using a ballasted sample collector equipped with laboratory bottles;

3) using an automatic sampler.

b) indirect sampling in the waste water body:

1) using a sampling rod equipped with a collection container;

2) using a bucket or other equipment.

NOTE Spot samples are usually taken manually, but may be taken by automatic sampling equipment or by

event-triggered automatic samplers.

6.2 Composite sampling

Composite sampling consists of several discrete samples. It can be done automatically or manually

(refer Annex B).

For automatic composite sampling, there are several types of composite sample (see ISO 5667-1). It is

possible to implement:

— constant volume variable time sampling (C.V.V.T)

— constant time variable volume sampling (C.T.V.V)

8 © ISO 2020 – All rights reserved

— constant time constant volume sampling (C.T.C.V)

For manual composite sampling, this approach is equivalent to sampling with fixed time, fixed flow and

fixed volume.

7 Waste water sampling

7.1 General aspects

The client should clearly define the purpose of the sampling so that the sampling operative implements

the appropriate sampling strategies.

7.1.1 Preparation of the sampling campaign

Controlled sampling is conditioned by good preparation of the sampling campaign and knowledge of

the activity of the establishment, type and mode of operation.

Sampling operative should take all necessary steps to ensure that the coordinates and the feasibility

of the operations requested are established beforehand. The use of a GPS and the exploitation of the

photos and/or plans made available or the observations collected during the preliminary investigation

make it possible to avoid any localization errors.

The sampling operative shall have at their disposal in their vehicles the procedures relating to sampling

operations and measurements, as well as the notices specific to in-situ measurement apparatus (pH

meter, conductivity, etc.).

All equipment (in-situ measurement apparatus, sampling equipment, refrigerated device) should have

been checked. Use dedicated equipment for waste water sampling.

Laboratory bottles should be selected and prepared according to the type of analysis requested and

respecting the packaging and preservation conditions prescribed by the laboratory.

Recordings of sampling operations (field form, label, other) should be prepared and possibly pre-filled.

Ensure the safety conditions (see Clause 12) before any intervention.

7.1.2 Arrival on site

It is important to confirm on site, the location of the points where the sampling operation will be carried

out. In case of pollution identification, consider the extent of pollution.

If possible, the sample should be taken out below the surface of the water in order not to collect floating

materials or fluids which cannot be representatively sampled. Avoid manipulations (such as transfer,

shaking) of the samples to a minimum, as this may cause changes. The sample volume depends on

the study programme and extent of analysis and can vary within wide limits from a few millilitres to

many litres.

As a rule, f

...

INTERNATIONAL ISO

STANDARD 5667-10

Second edition

2020-11

Water quality — Sampling —

Part 10:

Guidance on sampling of waste water

Qualité de l'eau — Échantillonnage —

Partie 10: Lignes directrices pour l'échantillonnage des eaux

résiduaires

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 General aspects . 3

4.1 Design of sampling programme . 3

4.2 Sampling point selection - Representativeness . 3

4.3 Frequency and time of sampling . 4

4.3.1 Number of samples . 4

4.3.2 Sampling time for effluent stream . 4

5 Sampling at specific locations. 5

5.1 Sampling from sewers, channels and manholes . 6

5.2 Sampling from waste water treatments plants . 6

5.3 Sampling from industrial sites . 7

5.4 Sampling from cooling systems . 7

6 Main types of waste water sampling . 8

6.1 Spot sampling . 8

6.2 Composite sampling . 8

7 Waste water sampling . 9

7.1 General aspects . 9

7.1.1 Preparation of the sampling campaign . 9

7.1.2 Arrival on site . 9

7.2 Composite sampling for waste water quality monitoring .10

7.2.1 General.10

7.2.2 Automatic composite sampling .10

7.2.3 Manual composite sampling .13

7.2.4 Manual sample reconstitution .13

7.3 Spot sampling in an effluent stream .14

7.3.1 General.14

7.3.2 Direct sampling .15

7.3.3 Indirect sampling .15

7.3.4 Automatic, remote start or event-triggered sampling.16

7.4 Spot sampling of tanks — planned discharges .16

8 Sampling equipment .17

8.1 General .17

8.2 Automatic sampler .17

8.3 Manual sampling equipment .18

8.3.1 General.18

8.3.2 Ballasted sample collector .18

8.3.3 Bucket, vertical water sampler .18

8.4 Tank sampling equipment .19

8.4.1 Mixing .19

8.4.2 Sampling equipment . . .19

9 Homogenization, preservation, transport and storage of samples .19

9.1 Homogenization of collected volume .19

9.2 Distribution of collected volume into laboratory bottles .20

9.3 Preservation and packaging of samples .21

9.4 Transportation and reception .21

9.4.1 General.21

9.4.2 Time .21

9.4.3 Temperature .21

9.5 Security and traceability of samples during storage and delivery .22

9.5.1 Routine samples .22

9.5.2 Samples which might be used for legal purposes .22

10 Quality assurance .22

10.1 Avoidance of contamination .22

10.2 Sample identification and records .23

10.3 Assurance and quality control .23

11 Reports.23

11.1 Analytical reports .23

11.2 Sampling protocols .24

12 Safety precautions .24

12.1 General .24

12.2 Personnel safety .25

12.3 Equipment safety .25

Annex A (informative) Examples of sampling from tanks .27

Annex B (informative) Advantages and disadvantages of main types of waste water sampling .30

Annex C (informative) Example of cleaning protocol — Sampling equipment .32

Annex D (informative) Example of field form — Waste water sampling .34

Annex E (informative) Choice of compatible materials for automatic samplers .36

Annex F (informative) Comparison of types of pumping: peristaltic pump (PP) and vacuum

pump (VAP) .38

Annex G (informative) Type of distribution of collected volume into laboratory bottle .40

Annex H (informative) Quality control of sampling equipment .42

Annex I (informative) Bias and repeatability .44

Bibliography .45

iv © ISO 2020 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 147, Water quality, SC 6, Sampling (general

methods).

This second edition cancels and replaces the first edition (ISO 5667-10:1992), which has been technically

revised. The main changes compared to the previous edition are as follows:

— integration of radioactive liquid effluent sampling and its specificities;

— integration of qualified spot sampling.

A list of all parts in the ISO 5667 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

INTERNATIONAL STANDARD ISO 5667-10:2020(E)

Water quality — Sampling —

Part 10:

Guidance on sampling of waste water

1 Scope

This document contains details on the sampling of domestic and industrial waste water, i.e. the design

of sampling programmes and techniques for the collection of samples. It covers waste water in all its

forms, i.e. industrial waste water, radioactive waste water, cooling water, raw and treated domestic

waste water.

It deals with various sampling techniques used and the rules to be applied so as to ensure the samples

are representative.

Sampling of accidental spillages is not included, although the methods described in certain cases may

also be applicable to spillages.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5667-1, Water quality — Sampling — Part 1: Guidance on the design of sampling programmes and

sampling techniques

ISO 5667-3, Water quality — Sampling — Part 3: Preservation and handling of water samples

ISO 5667-7, Water quality — Sampling — Part 7: Guidance on sampling of water and steam in boiler plants

ISO 5667-14, Water quality — Sampling — Part 14: Guidance on quality assurance and quality control of

environmental water sampling and handling

ISO 5667-16, Water quality — Sampling — Part 16: Guidance on biotesting of samples

ISO 6107 (all parts), Water quality — Vocabulary

ISO 19458, Water quality — Sampling for microbiological analysis

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 6107 (all parts) and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

composite sample

two or more samples or sub-samples, mixed together in appropriately known proportions (either

discretely or continuously), from which the average value of a desired characteristic may be obtained

Note 1 to entry: The number of samples or sub samples are usually based on time, flow measurements, area or

depth profile sampling.

EXAMPLE Composite sample can be made in different ways:

— constant volume variable time sampling (C.V.V.T): flow proportional sampling based on collecting equal

volumes of sample at frequencies proportional to flow.

— constant time variable volume sampling (C.T.V.V): flow proportional sampling based on collecting samples at

fixed time intervals but where the volume of sample is varied in proportion to the flow.

— constant time constant volume sampling (C.T.C.V): equal volumes of sample or sub-sample collected at equal

increments of time.

3.2

sampling point

precise position within a sampling location from which samples are taken

3.3

spot sample

discrete sample taken randomly (with regard to time and/or location) from a body of water, usually

taken manually, but may be taken by automatic sampling equipment or by event-triggered automatic

samplers

3.4

qualified spot sample

special form of a composite sample (3.1), consisting of at least five spot samples, taken and mixed within

a maximum period of two hours and at an interval of not less than two minutes

3.5

radioactive liquid effluent

water or waste water that contains radioactive substances, resulting from a process and that can be

recycled, treated and/or discharged to the environment

Note 1 to entry: The activity concentration of the radioactive liquid effluent is usually measured before being

discharged in the environment to verify that it is lower than the authorized levels in order to comply with

national regulation.

3.6

supernatant

solid or liquid phase present on the surface of an effluent

3.7

planned discharge

discharge subject to prior agreement further to a consultation between several parties based on

knowing certain predefined parameters and referring to limit values (regulatory or otherwise)

Note 1 to entry: These parameters may, for example, be physical, chemical and radiological measurements, the

estimated discharge volume, the discharge period or the maximum discharge flow rate.

3.8

permanent discharge

direct discharge into a channel or collector or water body, which is not subject to a specific prior

agreement, but which shall conform with limit values

2 © ISO 2020 – All rights reserved

3.9

tank

hollow object, very variable in size, used to hold liquids

Note 1 to entry: Covers the usual names such as tank, chamber and pool. The content of this tank is intended for

direct and indirect liquid discharge to the environment or to a specific treatment.

3.10

event-trigged sampling

sampling which is triggered because a pre-determined criterion has been met (e.g. rainfall, change in

electrical conductivity, pH or the introduction of a polluting substance), when samples should be taken

manually or by automatic equipment

4 General aspects

4.1 Design of sampling programme

Sampling is usually the first step in carrying out an investigation and largely determines the quality

of the whole investigation. It is therefore recommended that a detailed sampling strategy be drawn

up, often based upon a preliminary investigation in which an assessment has identified the important

aspects. Both the purpose and the ambient situation determine the way in which the sampling is carried

out. General aspects for sampling programme design can be found in ISO 5667-1.

4.2 Sampling point selection - Representativeness

The sampling point selection should be representative of the waste stream to be examined. In some

waste waters this representativeness may be difficult to obtain because of the spatial and temporal

heterogeneity of the water body. It is necessary to carry out the sampling in the sections where the flow

is well mixed and homogeneous.

The term “representativeness” encompasses two notions depending on the type of environment to be

sampled:

— representativeness in a flow (canal, sewer, manhole, pressurised pipes, etc.);

— representativeness in a storage (tank, lagoons, basins, etc.).

These two notions should be treated in different ways, but the goal remains to obtain a representative

sample of the water body.

Sampling points may be clearly identified (by regulatory text) or not, in which case a preliminary

investigation is recommended. This is generally the case for the selection of sewer sampling locations.

By studying drawings of the sewer system initially, possible locations can be identified. Subsequently, a

site inspection should be conducted to ensure that the locations of the sewers and the path of the waste

stream corresponds to the drawings, and to make sure that the selected location is representative for

the sampling purpose. The tracer studies may be a helpful tool.

Each sampling point should be documented. It is important to gather, for example, the following

information: identification, location of the site, photos, geographical coordinates, site location, type of

flow (open, closed), access conditions and sampling technique.

If necessary, specifically describe and label the sampling site. Select the site so that representative

samples can be obtained and the waste water flow (with the exception of fixed sampling equipment) is

clearly visible from the sampling site.

The following facilities should be available for the for the sampling sites involving a fixed automatic

sampling device:

— access for motor vehicles to the immediate vicinity of the sampling site;

— flat working surfaces at appropriate height above the sampling point for the set-up of sampling

devices;

— adequate lighting and power connection;

— water connection to clean the equipment after sampling;

— adequate safety precautions (e.g. grids, railings, fall arresting devices); and

— flow meters in the case of a flow-dependent sampling.

If the hydraulic conditions do not ensure the representativeness of the sample (absence of flow, reduced

activity, abnormal load rise), this unusual situation should be noted on the sampling report and the

client and the analytical laboratory should be informed.

4.3 Frequency and time of sampling

4.3.1 Number of samples

Analyses should be based on samples taken at regular intervals during a certain period (composite

or spot). The decision on the required number of samples taken during each period should be decided

[1] [2]

based on statistical techniques (see ISO 2602, ISO 3534 (all parts) and ISO 5667-1). But the number

of samples to be taken may often be decided by the regulatory body or pollution control authorities.

4.3.2 Sampling time for effluent stream

The objective of a sampling programme often dictates when and how a sample is collected and is often

determined by legislation or directives. Generally, when sampling sewages and effluents, it is normal to

make allowances for the following sources of variation in quality:

a) diurnal variations (i.e. within-day variability);

b) variations between days of the week;

c) variations between weeks and months;

d) variations between seasons;

e) variations due to storm water episodes; and

f) trends.

If there is little or no diurnal variation, or day-to-day variations, then the particular time of day or day

of the week for sampling is relatively unimportant.

If the identification of the nature and magnitude of peak load are important, sampling should be

restricted to those periods of the day, week or month when peak loads are known to occur.

Relating the times of sampling to the particular process being monitored may be very important when

considering industrial effluent discharges that are either seasonal or operated on a batch basis. In

either case, the discharge will not be continuous, and the sampling programme will need to take this

fact into account.

Sampling for the detection of trends needs careful planning. For example, when detecting trends on a

month-to-month basis, it can be appropriate to always sample on the same day of the week, in order

that any diurnal and daily variations are eliminated from the overall variability of data, thus allowing

trends to be more efficiently detected.

When the number of samples has been decided upon according to 4.3.1, the sampling times should be

determined. The samples should normally be taken at fixed intervals during the whole control period.

The sampling period may be one year, a number of months or weeks, or even shorter periods of time.

4 © ISO 2020 – All rights reserved

If the sampling period covers one year, the days of sampling may be determined using a formula. An

example of this is:

Formula (1) for a number of samples (n), larger than about 25 and from Formula (2) for a number of

samples less than about 25.

Formula (1) indicates the day number during which sampling should take place.

365 365×2 365×3 365×n

A++,,A A+ ,.,A+ (1)

n n n n

where

n is the number of samples;

A 365

is a random number in the interval between − and 0.

n

Formula (2) indicates the week number during which the sampling should take place. The day of each

week should be determined so that samples are taken on every weekday.

52 52×2523× 52×n

B++,,B B+ ,.,B+ (2)

n n n n

where

n is the number of samples;

B 52

is a random number in the interval between − and 0.

n

Similar formulae can be used for other periods, for example, one month, three months, six months, etc.

The period chosen should cover any seasonal variations.

After determining the intervals and the day or week number, it should be ensured that the sampling

does not lead to any risk of systematic error, for example by always taking samples on one day, or by

systematically omitting weekdays.

5 Sampling at specific locations

The concentration profiles of dissolved substances and suspended solids measured in an effluent are

often heterogeneous because they depend on the hydraulic conditions and transport conditions of the

solid phase in the body of water. Observations are:

— A vertical gradient of concentration, due to the flow velocities or the shear stresses near the bottom

are low;

— A very dense layer at the interface between the deposit of the bottom and the water circulating in

the structure;

— An increase of the concentration near the walls;

— An increase of the concentration near the surface of the flow due to the presence of floating matter.

It is therefore necessary to define carefully the positioning of the sample taken within the body of water.

To take a sample theoretically representative of the average concentration of the measured section, it

is advisable to place the sampling point about halfway up the water column and at a sufficient distance

from the walls and deposits to avoid measurement bias.

5.1 Sampling from sewers, channels and manholes

A location should be chosen where the effluent has a high turbulent flow to ensure good mixing. Often

accessibility, lack of site security, or power unavailability may preclude the use of the best sites.

Since effluent channels are generally designed to cope with both effluent and storm-water discharge

conditions and/or for higher flows than those actually occurring, laminar flow may often occur. In the

absence of a location with turbulent flow conditions at permanent sampling location, such conditions

should be induced by restricting the flow, for example with a baffle or weir. The restriction should

be made in such a way that sedimentation upstream of the restriction does not occur (e.g. foresee

enlargement of the downstream effluent channel compared to the upstream channel, to avoid any

pressure increase of the effluent downstream).

The sampling intake point should always be located downstream from the restriction and, as a general

rule, it should be located at least three times the pipe diameter, or width of the channel, downstream of

the restriction. The inlet of the sampling probe should preferably face the direction of flow but may face

downstream if too many blockages result.

The exact location of the sampling point should be evaluated with respect to variations in water

level, types and concentrations of the determinands, etc. The sampling point should be at a minimum

distance from the bottom and walls to avoid sample contamination by deposits or the biofilms that

develop. Generally, a sampling point between one third and one half of the effluent water depth below

the surface of the water may be recommended.

Whenever practicable, permanent sampling locations should be established, care being taken to ensure

reproducible sampling conditions.

Before proceeding with the sampling of industrial discharges and if the information is accessible, the

conditions inside the plant (e.g. processes and production rates) should be noted and recorded along

with any potential hazards.

5.2 Sampling from waste water treatments plants

When choosing sampling locations for waste water treatment plants, it is again important to refer to

the objective of the data collection programme, of which the sampling is a part.

Typical objectives are:

— control of the performance of the entire treatment plant: samples should be collected at the main

inlet and main outlet points;

— control of the operation of individual processing units, or groups of units: samples should be

collected at the inlet and outlet of the units in question.

When sampling at the waste water treatments plants, the importance, the relevance of any bypass

flow should be evaluated, and sampling of such flows may also be needed for the sampling to be

representative for the overall effluent.

When sampling at the inlets of plants, the objective of the sampling programme should be carefully

considered. In some situations, there may be a need to sample raw sewage in the mixture with

recirculated processing liquid (e.g. in the assessment of primary sedimentation tank loadings and

efficiency). In other cases, it may be necessary to exclude the effect of these liquids (e.g. when collecting

data designed to assess domestic/industrial loadings to a plant or to assist in industrial effluent

control).

Representative sampling is often facilitated by using locations downstream of a measuring flume or

weir (see also 5.1).

When sampling effluents from processes employing more than one individual treatment unit (e.g.

several sedimentation tanks), care should be exercised in ensuring that the sample is representative of

6 © ISO 2020 – All rights reserved

the overall effluent stream rather than any one specific treatment unit (unless that unit forms the basis

of a specific study).

Frequent reviews of a plant's sampling locations need to be made to ensure that any relevant changes

in the operation of unit processes are considered when sampling. For example, the percolating filter

operation may be changed from a "single-pass" operation to a "recirculation" or "alternating-double

filtration" operation. Treatment plant operation may involve changes in the manner in which feed

or return liquors are introduced to the plant (e.g. return of sewage from storm tanks, changes in the

position at which processing liquors are returned to the treatment plant).

Whenever sampling waste waters, great care should be exercised to overcome or minimize the

substantial heterogeneity caused by suspended solids that are often present. Similarly, thermal

stratification of separate industrial effluent streams may be found when sampling effluents or

discharges from industrial processes, and measures have to be taken to promote the mixing of such

streams before sampling.

5.3 Sampling from industrial sites

Sampling liquid effluents involves sampling a certain representative amount before and/or after they

are transferred to discharge channels or collectors.

The sampling method depends on the type of discharge or transfer taking place. The following should

therefore be distinguished:

— planned discharges, which require a preceding inspection before the discharge takes place. These

may be, for example, discharges from facilities’ liquid effluent tanks prior to their transfer to general

collectors or buffer pools before being discharged into the environment (refer to 7.4);

— permanent discharges, which concern effluents that are continuously discharged. They are

monitored based on sequential or continuous sampling of the discharged effluent. These may be, for

example, discharges from an effluent collector at the outlet of a nuclear site or a rainwater collector,

prior to discharge into the environment.

As such, the kind of sampling and the creation of representative samples shall be adapted to suit the

type of discharge and its potential heterogeneity (e.g. the presence of suspended matter or any density

or thermal stratification).

For this, and to guarantee the representative nature, the samples shall be produced:

— ensuring sampling only takes place after obtaining suitable effluent homogeneity;

— ensuring there is no change to the nature of the effluent or cross-contamination; and

— taking account of the volumes of the tanks, the flow rates and the flow conditions in the lines, to

enable quantification of the discharges from the facility in question (see Annex A, Figure A.1 for an

example of tank sampling).

Sampling may be performed based on several configurations, depending on the facilities:

— in a tank prior to its discharge (see Annex A, Figures A.1 and A.3);

— in a continuous or discontinuous flow in a line or a discharge channel (see Annex A, Figure A.1).

5.4 Sampling from cooling systems

The selection of sampling points in industrial cooling processes using water as a coolant depends on the

cooling water system to be tested.

In continuous-flow cooling systems, fresh water (ground water, bank filtrate, surface water) or saline

water are used in one or repeated flow. The sampling points are located both in front and behind the

aggregates, which shall be cooled.

During cooling via primary and/or secondary circuit, two cooling circuits are coupled to one another,

wherein a closed secondary circuit is re-cooled with a primary circuit. The primary circuit can

consist of a continuous cooling system, an open or closed recooling plant or a refrigerating plant (e.g.

brine cooling). The sampling site should be on the return side and on a well through-flow site of the

circulatory system.

In many cases, the cooling water is precooled in an open system by evaporation cooling, whereby water

losses due to evaporation, spraying and desludging (desalination) will be replaced by fresh water. In the

closed recooling process, the cooling water flows through pipes, which are cooled from outside by air or

water. The methods of open and closed recooling can be combined. The sampling site is located on the

return side of the circulatory system.

Representative sampling locations throughout the system shall be defined for periodic microbiological/

hygiene checks. Microbiological sampling guidance is given in ISO 19458. The sample is preferably

taken from the circulating water between the running pump at the spraying/trickling stage. A sampling

facility (sampling tap allowing disinfection, preferably by flaming, and draining) is to be provided at

this location. Allow the water to drain for at least 30 s before sampling. Sampling shall be performed in

such a manner that results are not distorted by biocide dosage. The sampling location shall be upstream

of the point of biocide dosage.

If sampling is not possible at this location, the sample can be taken from the sprayed water or by bail

[3]

sampling from the circulating-water basin .

Special cooling processes are usually used when the medium to be cooled is very hot (e.g. waste heaters,

heat pumps) or when very low flow temperatures are required (e.g. brine cooling). For special cooling

processes in the high temperature range (temperature > 100 °C), ISO 5667-7 shall apply.

6 Main types of waste water sampling

6.1 Spot sampling

In the case of spot sampling (refer Annex B), it is possible to implement:

a) direct sampling in the waste water body:

1) directly by using laboratory bottles;

2) using a ballasted sample collector equipped with laboratory bottles;

3) using an automatic sampler.

b) indirect sampling in the waste water body:

1) using a sampling rod equipped with a collection container;

2) using a bucket or other equipment.

NOTE Spot samples are usually taken manually, but may be taken by automatic sampling equipment or by

event-triggered automatic samplers.

6.2 Composite sampling

Composite sampling consists of several discrete samples. It can be done automatically or manually

(refer Annex B).

For automatic composite sampling, there are several types of composite sample (see ISO 5667-1). It is

possible to implement:

— constant volume variable time sampling (C.V.V.T)

— constant time variable volume sampling (C.T.V.V)

8 © ISO 2020 – All rights reserved

— constant time constant volume sampling (C.T.C.V)

For manual composite sampling, this approach is equivalent to sampling with fixed time, fixed flow and

fixed volume.

7 Waste water sampling

7.1 General aspects

The client should clearly define the purpose of the sampling so that the sampling operative implements

the appropriate sampling strategies.

7.1.1 Preparation of the sampling campaign

Controlled sampling is conditioned by good preparation of the sampling campaign and knowledge of

the activity of the establishment, type and mode of operation.

Sampling operative should take all necessary steps to ensure that the coordinates and the feasibility

of the operations requested are established beforehand. The use of a GPS and the exploitation of the

photos and/or plans made available or the observations collected during the preliminary investigation

make it possible to avoid any localization errors.

The sampling operative shall have at their disposal in their vehicles the procedures relating to sampling

operations and measurements, as well as the notices specific to in-situ measurement apparatus (pH

meter, conductivity, etc.).

All equipment (in-situ measurement apparatus, sampling equipment, refrigerated device) should have

been checked. Use dedicated equipment for waste water sampling.

Laboratory bottles should be selected and prepared according to the type of analysis requested and

respecting the packaging and preservation conditions prescribed by the laboratory.

Recordings of sampling operations (field form, label, other) should be prepared and possibly pre-filled.

Ensure the safety conditions (see Clause 12) before any intervention.

7.1.2 Arrival on site

It is important to confirm on site, the location of the points where the sampling operation will be carried

out. In case of pollution identification, consider the extent of pollution.

If possible, the sample should be taken out below the surface of the water in order not to collect floating

materials or fluids which cannot be representatively sampled. Avoid manipulations (such as transfer,

shaking) of the samples to a minimum, as this may cause changes. The sample volume depends on

the study programme and extent of analysis and can vary within wide limits from a few millilitres to

many litres.

As a rule, floating substances and sedimented substances cannot be taken representatively out of

flowing water. For identification, expediently they are taken in a separate sample; a poor quantification

is often not useful.

When sampling out of sewers using ladles, care should be taken that the scoop is moved in the direction

of flow under the surface of the water at a rate adapted to the flow. The opening of the scoop is in the

flow direction.

To avoid contamination of the sample, make sure that the scoop does not touch the wall of the sampling

manhole or the bottom of the sewer.

In many cases, pipes specially designed for sampling with a small nominal width, which either have a

continuous flow of waste water or cooling water (by-pass line) or with a shut-off device (sampling device)

are used. It is best to take the samples from vertical pipes in turbulent flow. When laying the sampling

lines, longer horizontal pipe sections should be avoided. The length of the sampling lines should be at

least five times the pipe diameter from th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...