IEC 60068-3-13:2016

(Main)Environmental testing - Part 3-13: Supporting documentation and guidance on Test T - Soldering

Environmental testing - Part 3-13: Supporting documentation and guidance on Test T - Soldering

IEC 60068-3-13:2016 provides background information and guidance for writers and users of specifications for electric and electronic components, containing references to the test standards IEC 60068-2-20, IEC 60068-2-58, IEC 60068-2-69, IEC 60068-2-83, and to IEC 61760-1, which defines requirements to the specification of surface mounting components. This first edition cancels and replaces IEC 60068-2-44:1995 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- information for lead-free solders are added;

- technical update and restructuring.

Essais d'environnement - Partie 3-13: Documentation d'accompagnement et guide sur les essais T - Brasage

L'IEC 60068-3-13:2016 donne des informations de base et des lignes directrices aux rédacteurs et utilisateurs de spécifications relatives aux composants électriques et électroniques, avec des références aux normes d'essai IEC 60068-2-20, IEC 60068-2-58, IEC 60068-2-69 et IEC 60068-2-83, ainsi qu'à l'IEC 61760-1 qui définit les exigences pour la spécification des composants pour montage en surface. L'IEC 60068-3-13 annule et remplace la deuxième édition de l'IEC 60068-2-44. Cette norme constitue une révision technique. Ce document inclut les modifications techniques majeures suivantes par rapport à l'IEC 60068-2-44:

- ajout d'informations sur les brasages sans plomb;

- mise à jour technique et restructuration.

General Information

- Status

- Published

- Publication Date

- 12-May-2016

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 13-May-2016

- Completion Date

- 15-Jun-2016

Relations

- Replaces

IEC 60068-2-44:1995 - Environmental testing - Part 2-44: Tests - Guidance on test T: Soldering - Effective Date

- 05-Sep-2023

Overview

IEC 60068-3-13:2016 is an international standard published by the International Electrotechnical Commission (IEC) that provides in-depth supporting documentation and guidance for Test T – Soldering. This standard serves as a technical revision and updates the previous IEC 60068-2-44:1995 edition with important new information, including considerations for lead-free solders and a comprehensive restructuring of content. It is tailored for writers and users of specifications related to electric and electronic components, ensuring reliable soldering processes and quality assurance in environmental testing.

The standard serves as a companion to the soldering-related test standards IEC 60068-2-20, IEC 60068-2-58, IEC 60068-2-69, IEC 60068-2-83, and references IEC 61760-1, which details surface mounting component specifications. IEC 60068-3-13:2016 is essential for understanding the physics, processes, defects, and evaluation methods associated with solder joints, pivotal for maintaining high-quality electronic assemblies.

Key Topics

Factors Influencing Solder Joint Reliability

Detailed examination of the ability of components to be soldered, including surface wetting physics, solder material properties, and environmental factors that affect solder quality and reliability.Soldering Processes

Overview of general soldering considerations like component design, soldering methods (bath, reflow, iron), material characteristics, and process parameters that influence soldering outcomes.Lead-Free Solder Considerations

Updated guidelines stressing lead-free solder materials, addressing their particular characteristics and implications for environmental compliance and performance.Soldering Defects and Quality Control

Identification of common defects in solder joints, evaluation criteria, visual inspection standards, and quantitative assessment methods to ensure robust solder connections.Moisture Sensitivity and Ageing Effects

Analysis of moisture sensitivity levels in components, storage impacts, oxidation, intermetallic compound formation, and their effects on solderability and joint reliability.Test Methods and Equipment

A detailed survey of soldering test procedures such as wetting balance tests, bath and reflow tests, and soldering iron tests, including execution guidelines and acceptance criteria.

Applications

IEC 60068-3-13:2016 is highly relevant for:

Electronics Manufacturers and Assembly Lines

Who require comprehensive testing guidelines to assure consistent, reliable solder joints across various component types and assembly methods.Quality Assurance and Compliance Teams

Needing structured methods and acceptance criteria to audit soldering processes, manage defect prevention, and comply with international environmental and safety regulations-especially regarding lead-free solder use.Component Designers and Specifiers

Developing solderability specifications that align with industry best practices and environmental testing standards to enhance product reliability.Research and Development in Electronics Manufacturing

Facilitating innovation in soldering techniques and materials through a deep understanding of wettability, solder joint physics, and effects of ageing and moisture.

Related Standards

IEC 60068-3-13:2016 complements and references several standards to provide a comprehensive framework for environmental testing related to soldering:

- IEC 60068-2-20 - Test T: Solderability tests for electronic components with leads.

- IEC 60068-2-58 - Test U: Solderability of surface mounting devices.

- IEC 60068-2-69 - Test V: Resistance of soldered joints to mechanical loading.

- IEC 60068-2-83 - Test W: Additional solderability and wetting balance assessments.

- IEC 61760-1 - Surface mounting components specifications and requirements.

These interconnected standards create a robust ecosystem for environmental and mechanical testing focused on solder joint integrity and component mounting reliability.

Keywords: IEC 60068-3-13, soldering test guidance, environmental testing, electric components, electronic components, solder joint reliability, lead-free solder, solderability, soldering defects, wetting balance test, moisture sensitivity, surface mounting devices, IEC standards, electronic assembly testing.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-3-13:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 3-13: Supporting documentation and guidance on Test T - Soldering". This standard covers: IEC 60068-3-13:2016 provides background information and guidance for writers and users of specifications for electric and electronic components, containing references to the test standards IEC 60068-2-20, IEC 60068-2-58, IEC 60068-2-69, IEC 60068-2-83, and to IEC 61760-1, which defines requirements to the specification of surface mounting components. This first edition cancels and replaces IEC 60068-2-44:1995 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - information for lead-free solders are added; - technical update and restructuring.

IEC 60068-3-13:2016 provides background information and guidance for writers and users of specifications for electric and electronic components, containing references to the test standards IEC 60068-2-20, IEC 60068-2-58, IEC 60068-2-69, IEC 60068-2-83, and to IEC 61760-1, which defines requirements to the specification of surface mounting components. This first edition cancels and replaces IEC 60068-2-44:1995 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - information for lead-free solders are added; - technical update and restructuring.

IEC 60068-3-13:2016 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-3-13:2016 has the following relationships with other standards: It is inter standard links to IEC 60068-2-44:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-3-13:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-3-13 ®

Edition 1.0 2016-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 3-13: Supporting documentation and guidance on Test T – Soldering

Essais d'environnement –

Partie 3-13: Documentation d'accompagnement et guide sur les essais T –

Brasage

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60068-3-13 ®

Edition 1.0 2016-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 3-13: Supporting documentation and guidance on Test T – Soldering

Essais d'environnement –

Partie 3-13: Documentation d'accompagnement et guide sur les essais T –

Brasage

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.040 ISBN 978-2-8322-3359-7

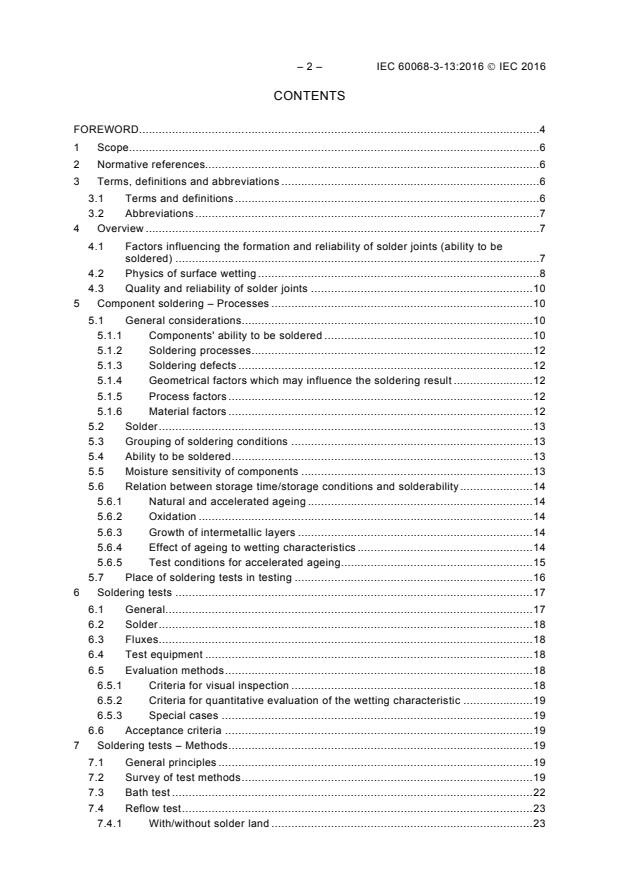

– 2 – IEC 60068-3-13:2016 IEC 2016

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references. 6

3 Terms, definitions and abbreviations . 6

3.1 Terms and definitions . 6

3.2 Abbreviations . 7

4 Overview . 7

4.1 Factors influencing the formation and reliability of solder joints (ability to be

soldered) . 7

4.2 Physics of surface wetting . 8

4.3 Quality and reliability of solder joints . 10

5 Component soldering – Processes . 10

5.1 General considerations . 10

5.1.1 Components' ability to be soldered . 10

5.1.2 Soldering processes . 12

5.1.3 Soldering defects . 12

5.1.4 Geometrical factors which may influence the soldering result . 12

5.1.5 Process factors . 12

5.1.6 Material factors . 12

5.2 Solder . 13

5.3 Grouping of soldering conditions . 13

5.4 Ability to be soldered . 13

5.5 Moisture sensitivity of components . 13

5.6 Relation between storage time/storage conditions and solderability . 14

5.6.1 Natural and accelerated ageing . 14

5.6.2 Oxidation . 14

5.6.3 Growth of intermetallic layers . 14

5.6.4 Effect of ageing to wetting characteristics . 14

5.6.5 Test conditions for accelerated ageing . 15

5.7 Place of soldering tests in testing . 16

6 Soldering tests . 17

6.1 General . 17

6.2 Solder . 18

6.3 Fluxes . 18

6.4 Test equipment . 18

6.5 Evaluation methods . 18

6.5.1 Criteria for visual inspection . 18

6.5.2 Criteria for quantitative evaluation of the wetting characteristic . 19

6.5.3 Special cases . 19

6.6 Acceptance criteria . 19

7 Soldering tests – Methods . 19

7.1 General principles . 19

7.2 Survey of test methods . 19

7.3 Bath test . 22

7.4 Reflow test . 23

7.4.1 With/without solder land . 23

7.4.2 Selection of solder paste (flux system and activity grade) . 23

7.5 Soldering iron test . 23

7.6 Resistance to dissolution of metallization and soldering heat . 23

7.6.1 General . 23

7.6.2 Limitations . 23

7.6.3 Choice of severity . 24

7.7 Wetting balance test . 24

7.7.1 General . 24

7.7.2 Test methods available . 25

7.7.3 Limitations . 25

8 Requirements and statistical character of results . 25

Bibliography . 27

Figure 1 – Sessile drop of solder on oxidised copper . 8

Figure 2 – Sessile drop of solder plus flux on clean copper . 9

Figure 3 – Sessile drop equilibrium forces . 9

Figure 4 – Typical soldering processes . 12

Figure 5 – Soldering tests for devices with leads . 21

Figure 6 – Soldering tests for SMDs . 22

Table 1 – Solder process groups . 13

– 4 – IEC 60068-3-13:2016 IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 3-13: Supporting documentation and guidance on Test T – Soldering

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-3-13 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This first edition cancels and replaces IEC 60068-2-44:1995 and constitutes a technical

revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– information for lead-free solders are added;

– technical update and restructuring.

The text of this standard is based on the following documents:

FDIS Report on voting

91/1345/FDIS 91/1356/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60068-3-13:2016 IEC 2016

ENVIRONMENTAL TESTING –

Part 3-13: Supporting documentation and guidance on Test T – Soldering

1 Scope

This part of IEC 60068 provides background information and guidance for writers and users of

specifications for electric and electronic components, containing references to the test

standards IEC 60068-2-20, IEC 60068-2-58, IEC 60068-2-69, IEC 60068-2-83, and to

IEC 61760-1, which defines requirements to the specification of surface mounting

components.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-20:2008, Environmental testing – Part 2: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-58, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-69, Environmental testing – Part 2-69: Tests – Test Te: Solderability testing of

electronic components for surface mounting devices (SMD) by the wetting balance method

IEC 60068-2-83, Environmental testing – Part 2-83: Tests – Test Tf: Solderability testing of

electronic components for surface mounting devices (SMD) by the wetting balance method

using solder paste

IEC 61760-1, Surface mounting technology – Part 1: Standard method for the specification of

surface mounting components (SMDs)

IEC 62137-3, Electronics assembly technology – Part 3: Selection guidance of environmental

and endurance test methods for solder joints

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document the following terms and definitions apply.

3.1.1

solderability

ability of the lead, termination or electrode of a component to be wetted by solder at the

temperature of the termination or electrode, which is assumed to be the lowest temperature in

the soldering process within the applicable temperature range of the solder alloy

________________

A new edition (third edition) is currently under consideration.

Note 1 to entry: The term “solderability” is often used in combination with the term “test”, indicating a specific

method to evaluate the wettability or ability to be soldered of a surface under worst case conditions (soldering

temperature and contact time with solder). It is not to be confused with the concepts “ability to be soldered” (see

4.1, 5.1.1) or “soldering ability” (see 3.1.4).

3.1.2

resistance to soldering heat

ability of the component to withstand the highest temperature stress in terms of temperature

gradient, peak temperature and duration of the soldering process, where the temperature of

the component body is within the applicable temperature range of solder alloy

3.1.3

wettability

intrinsic property of the termination material to form an alloy with the solder

Note 1 to entry: Wettability depends on the base metal used to produce the termination or, in the case of a plated

termination, the condition and material used to plate the base metal.

3.1.4

soldering ability

ability of a specific combination of components to facilitate the formation of a proper solder

joint

Note 1 to entry: See 3.1.3, wettability.

3.2 Abbreviations

SMD Surface mounted device

SMT Surface mounting technology

THD Through-hole mounting device

THT Through-hole mounting technology

THR Through-hole reflow soldering

4 Overview

4.1 Factors influencing the formation and reliability of solder joints (ability to be

soldered)

The conditions of ease of production and the reliability of a soldered joint can be classified in

three groups, as follows.

a) The joint design, determined by the choice of the two metallic elements to be joined (their

shape, size, composition, etc.) and of the assembly method (relative position, initial

fastening, etc.).

b) The wettability of the surfaces to be joined.

c) The conditions adopted for the soldering operation (temperature, time, flux, solder alloy,

equipment, etc.).

The choice of conditions of groups a) and c) concerns the manufacturer of equipment or

subassemblies, who shall know the importance of each of the conditions and the limits of their

variation. Condition b) depends to a large extent on the component manufacturer, except in

cases of unusual handling or storage conditions by the equipment manufacturer. The

wettability of surfaces needs to be defined with whatever degree of precision is necessary to

allow the equipment manufacturer to choose conditions of classes a) and c) appropriate to

that wettability. On the other hand, components of satisfactory surface quality will not

necessarily prevent rejectable joints arising from faults in joint design or joining conditions.

– 8 – IEC 60068-3-13:2016 IEC 2016

This often complex overlapping of responsibilities between component manufacturers and

equipment manufacturers creates a need to be able to define with considerable precision the

wettability of component terminations or, more generally, the solderability of components.

4.2 Physics of surface wetting

In order to obtain wetting between a substrate and molten solder, the tin in the solder shall

react with the substrate to form an alloy. In order to form an alloy the tin and the substrate

has to come into molecular contact. In order to do this the surface of both the molten solder

and the substrate shall be free from contamination.

In order to better understand how molten solder spreads over a substrate, and what

determines solderability, the surface tension property of the solder needs to be examined.

A free droplet of molten solder held in free space will form into a globule shape, just as a free

drop of water will form into a spherical shape. The droplet is held in this shape by the surface

tension force of the molten solder. Inside the droplet the atoms are uniformly surrounded by

other atoms, and the net force on them is zero, ignoring thermal motion. At the surface there

is an imbalance in the inter-atomic attraction forces, as the surface atoms experience a net

force into the body of the droplet.

The complete system tries to adopt a shape that has the minimum free energy, which means

the minimum surface-to-volume ratio. This situation is achieved when the molten solder forms

into a sphere. The strength of the surface tension force is determined by the bond energies

between the atoms within the molten solder.

If the molten sphere of solder is placed onto a heated, oxidised copper plate, the shape of the

sphere is depressed by gravity, to form a sessile drop, as shown in Figure 1 below.

Solder

Oxide layer

IEC

Figure 1 – Sessile drop of solder on oxidised copper

If a suitable flux is added to the sessile drop on the oxidised copper, the oxide layer will be

removed from the copper and the solder, and the tin in the solder will react with the copper to

form an intermetallic layer, allowing the solder to spread, as shown in Figure 2 below.

Solder

Diffusion layer

IEC

Figure 2 – Sessile drop of solder plus flux on clean copper

The final shape of the spreading solder will depend on the surface tension forces acting at the

interfaces. Solid and solid-liquid interfaces also exert a surface tension force, and all try to

reduce their surface areas to a minimum to attain a minimum free energy. As a result

equilibrium is reached whereby the net force at the advancing solder front is zero.

Figure 3 below shows the forces acting at the advancing solder front. The surface tension of

the solid copper in air is balanced by the surface tension between the liquid solder and the air,

and the liquid solder and the solid copper.

γ

LA

θ

γ

γ LS

SA

IEC

Figure 3 – Sessile drop equilibrium forces

The resulting forces at the advancing solder front can be written as follows:

γ = γ + γ cos θ

SA LS LA

where

γ is surface tension between solid copper and air;

SA

γ is surface tension between liquid solder and solid copper;

LS

γ is surface tension between liquid solder and air.

LA

This equation is known as Young’s equation. The contact angle θ can be used as a measure

of the degree of spreading obtained. The smaller the contact angle, the greater the spreading,

and the better the wetting obtained.

If the cohesive forces within the solder are greater than the adhesive forces between the

solder and the copper, then the solder will remain as a non-spreading sessile drop, and the

contact angle will be greater than 90°. If the adhesive forces exceed the cohesive forces, then

it is energetically favourable for the solder to react with the copper and spread outward,

reducing the contact angle below 90°.

– 10 – IEC 60068-3-13:2016 IEC 2016

The surface tension between solid and air, γ , will be high when the solid is free from oxides,

SA

sulphides, chlorides, hydrocarbons and other surface contaminants, which will all reduce the

surface tension.

For the surface tension between liquid and solid, γ , to be low, a metallurgical bond has to

LS

be formed between the tin and the substrate.

The surface tension between liquid solder and air, or flux film, will depend on the solder alloy,

the soldering temperature and the flux used to solder the parts. The surface tension of the

alloy can be markedly affected by the impurities in the solder. Very small levels of impurity

can have a large effect on the surface tension. This is because the surface tension of a liquid

is determined by the surface composition of the solder and not the composition of the bulk of

the solder. Impurities with low surface energies will rapidly segregate to the surface of the

liquid, reducing the surface tension, γ .

LA

Impurities in the solder alloy, and changes to the alloy composition may also affect the

surface tension between the liquid and the solid, altering the intermetallic formation, and can

also affect the surface tension between the solid and the air, affecting the diffusion process

across the solid, ahead of the liquid front.

Alloy additions or impurities may also affect the spreading and wetting properties of an alloy,

by altering the viscosity of the liquid solder.

4.3 Quality and reliability of solder joints

The quality of solder joints is characterised by wetted area, wetting angle, microstructure and

specific visual criteria.

One factor affecting the reliability of electronic assemblies is solder joint microstructure, which

in turn depends on the thermal conditions under which the solder joint solidifies. Both the bulk

microstructure of the solder and the intermetallic layer structure at the interfaces between

solder and component termination should be taken into consideration.

IEC 62137-3 gives guidance to test methods for the evaluation of solder joint reliability under

consideration of the above described four elements.

5 Component soldering – Processes

5.1 General considerations

5.1.1 Components' ability to be soldered

Because of the large variety of processing conditions a component can no longer simply be

classified as suitable e.g. for “flow soldering” or “reflow soldering”, or “lead-free soldering”.

Specific attention should be given to the fact, that the suitability of a component for “lead-free

soldering” cannot be stated because of the variety of lead-free solder alloys and processing

conditions. Typical soldering processes and related process conditions are described in

IEC 61760-1.

To be suitable for a certain soldering process a component shall fulfil the following

requirements:

a) material and surface of the component termination shall be suitable to be soldered with

the solder alloy and soldering method;

b) it shall possess thermal characteristics (thermal demand) small enough for a temperature

sufficiently higher than the liquidus of the solder alloy used, to be reached and maintained

for the length of time for wetting to occur;

c) it shall withstand without short-term or long-term change the thermal stresses associated

with the soldering cycle (including rework and possible repair by soldering iron);

d) it shall withstand without short-term or long-term damage the mechanical and chemical

stresses accompanying cleaning operations for the removal of flux residues. Cleaning

considerations are not emphasized in this Guide.

Thus, certain components containing lubricated mechanical parts (e.g. switches), or being

unsealed are sensitive to contamination (e.g. relays, potentiometers), or containing plastic

material with poor heat resistance (e.g. certain capacitors with thermoplastic dielectric), shall

be carefully selected for mass-soldering operations because of their inability to withstand one

or more of the stresses associated with the process.

For these reasons careful distinction shall be made between the processability (ability to be

soldered) of the component, which refers to the total suitability for industrial soldering, and

the wettability of the termination, which refers only to the ease of coating the termination with

solder. Unfortunately, these concepts are often confused in ordinary language, and such

confusion can prevent smooth running of production.

Furthermore, unsuitability of a component for soldering under the general conditions specified

(see below) does not mean that its terminations cannot be soldered to a printed circuit board

or other support. It entails only that it is necessary to take special precautions depending on

the condition it does not satisfy, such as having thermally sensitive insulation, or

incompatibility with some or all solvents. Only defective wettability of the terminations

prevents the use of soldering for mounting the component. This quality is of prime importance,

but does not exclude consideration of the others.

The standardised tests referred to here are all directed to simulating some part of the effects

of this set of conditions.

The appropriate choice of a group of these tests, in conjunction with electrical and mechanical

measurements, allows to answer the question: "ls this component solderable by the methods

normally used in electronics?" This is one of the questions which the equipment manufacturer

shall consider before putting a component on a soldering line.

The principle of each standardised test and the degree of information it supplies are defined

in Clause 7.

In this way the component specifier can, in full knowledge of the reasons, select the number

and type of tests needed to establish the behaviour of the component during soldering, as

well as the requirements that shall be determined in every case to reflect the general

requirements of the method of manufacture.

Similarly, the person conducting the tests will appreciate the degree of information given.

– 12 – IEC 60068-3-13:2016 IEC 2016

5.1.2 Soldering processes

Figure 4 shows typical soldering processes grouped into types.

Reflow Special soldering

Flow

soldering processes

soldering

Wave

Soldering iron

Convection

(double, single)

(with or without IR support)

Hot air

Selective

Hot plate

(mini-wave, solder pot,

Vapour phase

dip soldering)

Induction / microwave

soldering

Laser

Hot bar

IEC

Figure 4 – Typical soldering processes

5.1.3 Soldering defects

The series IEC 61191 and IEC 61192 provide information about requirements for soldered

electrical and electronic assemblies and related workmanship standards.

• Non wetting, dewetting

• Tombstoning

• Shifting

• Wicking

• Bridging

5.1.4 Geometrical factors which may influence the soldering result

• Land pattern design

• Component geometry

• Component terminal geometry

• Insertion hole diameter

• Annular ring

5.1.5 Process factors

• Time – Temperature profile

• Temperature spread (different temperatures at solder joints)

• Atmosphere (air, nitrogen)

5.1.6 Material factors

• Solder paste, solder alloy

• Flux activity

5.2 Solder

The composition of the solder alloy affects the surface tension of the liquid solder. Relatively

small concentrations of impurities in the solder can have a marked effect on the wetting

properties of the solder. Thus, the solder alloy used for soldering and for tests shall be

described in the relevant specification.

5.3 Grouping of soldering conditions

The melting temperatures of lead free solder alloys selected for industrial processes are

significantly different from those of tin lead solder alloy. Moreover, the melting temperatures

of present solder alloys are different from each other but can be clustered in groups. The

ability of the SMD to withstand the typical temperature and dwell time conditions shall match

the exposure to the process temperature groups using the selected alloys.

The following groups of soldering processes in Table 1 are given as a guideline for selecting

the severities for the wetting and resistance to soldering heat tests against the specified

soldering heat profile.

Table 1 – Solder process groups

Process temperature 1 2 3 4

group Low Medium Medium-high High

Typical solder alloy

Sn-Bi Sn-Pb Sn-Ag-Cu Sn-Cu

family

Flow – (235 to 250)°C (250 to 260)°C (250 to 260)°C

Reflow (170 to 210)°C (210 to 240)°C (235 to 250)°C –

5.4 Ability to be soldered

The ability to be soldered is determined mainly by the following three properties of a

component.

• Solderability of components

The determination of solderability can be made at the time of manufacture, at receipt of the

components by the user, or just before assembly and soldering.

• Thermal demand

It is necessary to bring the joint area to the soldering temperature. It is possible that the

component design will allow the heat being applied to the joint area to be drained away into

the component body, causing the temperature at the joint site to fall too low to produce an

adequate solder joint. Preheat may be used to overcome thermal demand issues.

• Resistance to soldering heat

The component shall be able to withstand the thermal stress of the soldering process without

any loss of functionality. This is particularly important with current assembly methods where

components may experience rapidly changing thermal gradients.

The result of this definition is that a matrix of soldering tests standards have evolved, which

measure some or all of these three properties individually or in some cases a combination of

the first two properties (see 7.2).

5.5 Moisture sensitivity of components

The relevant specification may prescribe a moisture soak procedure to determine the

sensitivity of a component against the influence of humidity during storage to the component

body.

– 14 – IEC 60068-3-13:2016 IEC 2016

NOTE 1 As distinguished from moisture soak the sensitivity of the component terminal surface against humidity is

described by accelerated ageing (see 5.6.4).

Typical soak conditions are: 85 °C/85 % r.h., 85 °C/60 % r.h., 60 °C/60 % r.h., 30 °C/60 % r.h.

Duration of moisture soak (168 h to 696 h) depends on the diffusion speed of water and the

absorption characteristics of the material. Thus, it needs specific investigation.

NOTE 2 Examples for suitable soak procedures for semiconductor components may be found in IEC 60749-20 or

J-STD-020. Applicable pre-drying and soak conditions for other types of components are under consideration. See

also IEC 61760-4.

5.6 Relation between storage time/storage conditions and solderability

5.6.1 Natural and accelerated ageing

Ageing is the natural process by which the solderability of a component decreases with time.

The correlation between natural ageing and accelerated conditions (“accelerated ageing”) is

difficult to be determined and cannot be generalized.

The majority of component terminations are formed from a base material over which a

solderable coating is applied to retain the solderability of the termination. It is common

practice to plate a barrier layer over the base metal, before applying the solder coating,

particularly if the base metal has a high solubility in solder.

5.6.2 Oxidation

Tin forms an oxide SnO with the atmosphere, which forms a protective layer on the substrate.

The rate of oxidation is accelerated by temperature and moisture in the atmosphere.

Lead also forms an oxide PbO with the atmosphere, but generally SnO is formed

preferentially as the tin has a greater affinity for oxygen.

Sulphur levels in the atmosphere are generally low and tin and lead have very little reaction

with sulphur at low concentration levels. Silver, however, reacts with sulphur at very low

levels to form a black sulphide layer, which reduces the solderability of the substrate.

Nitrous oxide (NO ) and chlorine both react with tin and lead to form lead nitrate (PbNO ) and

2 3

tin and lead chlorides (SnCl ) (PbCl ). Lead nitrate forms a non-protective coating, which is

2 2

difficult to solder. Both the chlorides are also non-protective and again reduce solderability

(although the lead chloride is usually reduced to lead nitrate which cannot be soldered with

normal electronic grade fluxes).

5.6.3 Growth of intermetallic layers

The vast majority of electronic component terminations are coated with tin or tin-lead, and so

most of the intermetallic layers contain tin. We have just seen that while the solder is molten

the intermetallic layer is continually forming and being dissolved. In the solid state migration

of the tin in the solder towards the intermetallic layer still continues, combined with diffusion

of the substrate through the intermetallic, resulting in an increase in the thickness of the

intermetallic layer into the solder coating.

This process is proportional to the square root of the temperature and is significant even at

room temperature.

5.6.4 Effect of ageing to wetting characteristics

Typical ageing effects are:

• degradation of metallic layers (oxidation);

• degradation of organic constituents of galvanic platings;

• growth of intermetallic phases through solderable surface;

• cracking of the solderable surface.

Degradation of wetting normally occurs in three distinct phases.

a) Firstly the wetting time starts to increase as the solderability is reduced by the formation

of oxides or corrosion products on the solder surface.

b) Then there is a phase where no further deterioration occurs as the solder oxide layer

protects the solder from further oxidation, by reducing the diffusion through the oxide layer

and a chemical passivation of the surface.

c) In the third phase the intermetallic layer has grown through to the surface of the solder

coating, and the wetting time again begins to increase.

Intermetallic growth is a major factor in the deterioration of the solderability of a solderable

substrate, but the initial degradation is due to the reaction of the solderable coating with the

atmosphere.

5.6.5 Test conditions for accelerated ageing

The natural ageing process of a component is a very complicated process that would be

impossible to accurately reproduce for each component, as we would need to be able to

predict the storage environment and temperature over a long period. We therefore need to

compress the ageing process into a much shorter time so that we can predict how

components will age as they enter the factory.

Clearly, it is impossible to produce an ageing method that will provide the same ageing

mechanism as natural ageing. The international solderability specifications include a number

of methods to accelerate the ageing process and provide data parallel to natural ageing,

although the exact mechanism could never be the same.

Typical ageing conditions are (see IEC 60068-2-20):

• dry heat: at 155 °C for 2 h, 4 h, 16 h;

• damp heat: at 40 °C, 93 % r.h. for 4 days, 10 days;

• steam: in steam for 1 h, 4 h;

• unsaturated pressurized vapour: at 125 °C, 85 % r.h. for 4 h.

These methods either affect the surface of the solder by use of moisture or a corrosive

atmosphere, or accelerate the rate of intermetallic growth by the use of high temperatures.

Care has to be taken when using these methods as we have already seen that different

pollutants in the atmosphere will produce different modifications to the solder surface.

The aim of accelerated ageing methods is to compress one or two years of natural ageing into

a few hours. We have seen that this is not possible as the mechanism of the ageing process

changes as we increase the temperat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...