IEC 60068-2-82:2019

(Main)Environmental testing - Part 2-82: Tests - Test Xw1: Whisker test methods for components and parts used in electronic assemblies

Environmental testing - Part 2-82: Tests - Test Xw1: Whisker test methods for components and parts used in electronic assemblies

IEC 60068-2-82:2019 specifies tests for the whiskering propensity of surface finishes of electric or electronic components and mechanical parts such as punched/stamped parts (for example, jumpers, electrostatic discharge protection shields, mechanical fixations, press‑fit pins and other mechanical parts used in electronic assemblies) representing the finished stage, with tin or tin-alloy finish. Changes of the physical dimensions of mould compounds, plastics and the like during the required test flow are not considered or assessed. The test methods have been developed by using a knowledge-based approach.

This edition includes the following significant technical changes with respect to the previous edition:

– extension of the scope of the test standard from electronic to electromechanic components and press-fit pins, which are used for assembly and interconnect technology;

– significant reduction of the testing effort by a knowledge-based selection of test conditions i.e. tests not relevant for a given materials system can be omitted (see Annex D);

– harmonization with JESD 201A by omission of severities M, N for temperature cycling tests;

– highly reduced test duration (1 000 h instead of 4 000 h) for damp-heat test by introducing test condition at elevated humidity of 85 % R.H. and a temperature of 85 °C providing increased severity.

Essais d'environnement - Partie 2-82: Essais - Essai Xw1: Méthodes de vérification des trichites pour les composants et les pièces utilisés dans les ensembles électroniques

L'IEC 60068-2-82:2019 spécifie des essais de vérification de la propension au développement des trichites pour les finis de surface des composants électriques ou électroniques et des pièces mécaniques comme les pièces embouties/estampées (par exemple cavaliers, écrans de protection contre les décharges électrostatiques, fixations mécaniques, contacts insérés à force et autres pièces mécaniques utilisées dans les ensembles électroniques) qui représentent la phase de finition, avec un fini en étain ou en alliage d'étain. Les modifications des dimensions physiques des composants moulés, des plastiques et autres pendant le flux d'essai exigé ne sont pas prises en compte ni évaluées. Les méthodes d'essai ont été mises au point en utilisant une approche fondée sur la connaissance.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

– extension du domaine d'application de la norme d'essai des composants électroniques aux composants électromécaniques et aux contacts insérés à force qui sont utilisés pour la technologie d'assemblage et d'interconnexion;

– réduction significative de l'effort d'essai par une sélection de conditions d'essai fondée sur la connaissance, c'est-à-dire que les essais non applicables à un système de matériaux donné peuvent être omis (voir Annexe D);

– harmonisation avec la JESD 201A par omission des sévérités M et N pour les essais de cycle thermique;

– réduction considérable de la durée d'essai (1 000 h au lieu de 4 000 h) pour l'essai de chaleur humide par l'introduction d'une condition d'essai à humidité élevée de 85 % H.R. et d'une température de 85 °C assurant une plus grande sévérité.

General Information

- Status

- Published

- Publication Date

- 13-May-2019

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-May-2019

- Completion Date

- 24-May-2019

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60068-2-82:2019 is an international standard published by the International Electrotechnical Commission (IEC) that specifies environmental testing methods focused on whisker growth in components and parts used in electronic assemblies. Whiskers-tiny, hair-like metallic filaments-can cause short circuits and reliability issues in electronic devices, especially when surface finishes contain tin or tin alloys. The standard provides test procedures to evaluate the whiskering propensity of surface finishes on electric or electronic components including mechanical parts such as jumpers, electrostatic discharge protection shields, press-fit pins, and other stamped or punched parts used in assemblies.

This edition expands the scope to cover electromechanical components and provides updated testing protocols that reduce total test duration and effort by applying a knowledge-based approach to select only relevant tests. Additionally, it harmonizes several test conditions with the related JESD 201A standard and introduces a more severe damp-heat test with shortened duration.

Key Topics

- Whisker Growth Testing: Focuses on methods to induce and measure tin whiskers on surface finishes, including testing under ambient, damp-heat, and temperature cycling conditions.

- Scope Expansion: Extends applicability from purely electronic components to electromechanical components and press-fit pins used in assembly and interconnect technologies.

- Test Methodology: Employs a knowledge-based selection of tests tailored to specific material systems, omitting irrelevant procedures to optimize testing efficiency.

- Test Equipment: Utilizes desiccators, humidity chambers, thermal cycling chambers, and advanced microscopic tools such as scanning electron microscopes and confocal laser microscopes for whisker detection.

- Preconditioning Procedures: Defines guidelines for mechanical and thermal pre-treatment of samples based on their end-use, such as soldering, welding, or press-fit applications.

- Assessment Criteria: Provides detailed procedures and acceptance criteria for whisker length, density, and statistical evaluation to classify the risk level and reliability.

- Technical Background: Includes annexes explaining whisker growth mechanisms and mitigation strategies to support better design and material selection.

- Report Content: Specifies the required documentation format for test results, including experimental setups, samples, environmental conditions, and classification outcomes.

Applications

IEC 60068-2-82:2019 is essential for quality control, reliability testing, and risk assessment of electronic and electromechanical components, primarily within industries where long-term dependability and safety are critical. Applications include:

- Consumer Electronics: Ensuring the reliability of connectors and PCB components prone to whisker formation.

- Aerospace and Defense: Verifying components that must operate reliably under harsh environmental conditions without failure induced by whiskers.

- Automotive Electronics: Assessing electronic control units and sensors exposed to thermal cycling and humidity.

- Industrial Equipment: Evaluating electromechanical assemblies such as press-fit pins and mechanical fixations that face prolonged operational stresses.

- Medical Devices: Guaranteeing electrical component integrity where even minor failures could compromise safety or performance.

- Manufacturing and Materials Engineering: Guiding the selection of surface finishes and manufacturing processes to mitigate whisker risks effectively.

Related Standards

IEC 60068-2-82 aligns closely with several other standards and technical reports in environmental testing and electronics reliability, including:

- JESD 201A – A U.S. standard that harmonizes test procedures for whisker growth with IEC 60068-2-82.

- IEC 60068 Series – General environmental testing standards covering various types of stress such as temperature, humidity, and mechanical shock.

- IPC-9701 – Test methods for assessing tin whisker growth in electronic products.

- JEDEC JESD22-A121 – Guidelines on tin whisker mitigation and assessment.

- IEC 61340-5-1 – Protection of electronic devices from electrostatic phenomena, complementing whisker-related testing by controlling related failure modes.

By adhering to IEC 60068-2-82:2019, manufacturers and testing laboratories can systematically evaluate whisker risks to improve the reliability and safety of electronic assembly components in diverse operating environments.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-2-82:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-82: Tests - Test Xw1: Whisker test methods for components and parts used in electronic assemblies". This standard covers: IEC 60068-2-82:2019 specifies tests for the whiskering propensity of surface finishes of electric or electronic components and mechanical parts such as punched/stamped parts (for example, jumpers, electrostatic discharge protection shields, mechanical fixations, press‑fit pins and other mechanical parts used in electronic assemblies) representing the finished stage, with tin or tin-alloy finish. Changes of the physical dimensions of mould compounds, plastics and the like during the required test flow are not considered or assessed. The test methods have been developed by using a knowledge-based approach. This edition includes the following significant technical changes with respect to the previous edition: – extension of the scope of the test standard from electronic to electromechanic components and press-fit pins, which are used for assembly and interconnect technology; – significant reduction of the testing effort by a knowledge-based selection of test conditions i.e. tests not relevant for a given materials system can be omitted (see Annex D); – harmonization with JESD 201A by omission of severities M, N for temperature cycling tests; – highly reduced test duration (1 000 h instead of 4 000 h) for damp-heat test by introducing test condition at elevated humidity of 85 % R.H. and a temperature of 85 °C providing increased severity.

IEC 60068-2-82:2019 specifies tests for the whiskering propensity of surface finishes of electric or electronic components and mechanical parts such as punched/stamped parts (for example, jumpers, electrostatic discharge protection shields, mechanical fixations, press‑fit pins and other mechanical parts used in electronic assemblies) representing the finished stage, with tin or tin-alloy finish. Changes of the physical dimensions of mould compounds, plastics and the like during the required test flow are not considered or assessed. The test methods have been developed by using a knowledge-based approach. This edition includes the following significant technical changes with respect to the previous edition: – extension of the scope of the test standard from electronic to electromechanic components and press-fit pins, which are used for assembly and interconnect technology; – significant reduction of the testing effort by a knowledge-based selection of test conditions i.e. tests not relevant for a given materials system can be omitted (see Annex D); – harmonization with JESD 201A by omission of severities M, N for temperature cycling tests; – highly reduced test duration (1 000 h instead of 4 000 h) for damp-heat test by introducing test condition at elevated humidity of 85 % R.H. and a temperature of 85 °C providing increased severity.

IEC 60068-2-82:2019 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-82:2019 has the following relationships with other standards: It is inter standard links to IEC 60068-2-82:2007, IEC 60068-2-82:2007/COR1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-2-82:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-82 ®

Edition 2.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Environmental testing –

Part 2-82: Tests – Test Xw1: Whisker test methods for components and parts

used in electronic assemblies

Essais d'environnement –

Partie 2-82: Essais – Essai Xw1: Méthodes de vérification des trichites

pour les composants et les pièces utilisés dans les ensembles électroniques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60068-2-82 ®

Edition 2.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Environmental testing –

Part 2-82: Tests – Test Xw : Whisker test methods for components and parts

used in electronic assemblies

Essais d'environnement –

Partie 2-82: Essais – Essai Xw : Méthodes de vérification des trichites

pour les composants et les pièces utilisés dans les ensembles électroniques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.040 ISBN 978-2-8322-6863-6

– 2 – IEC 60068-2-82:2019 © IEC 2019

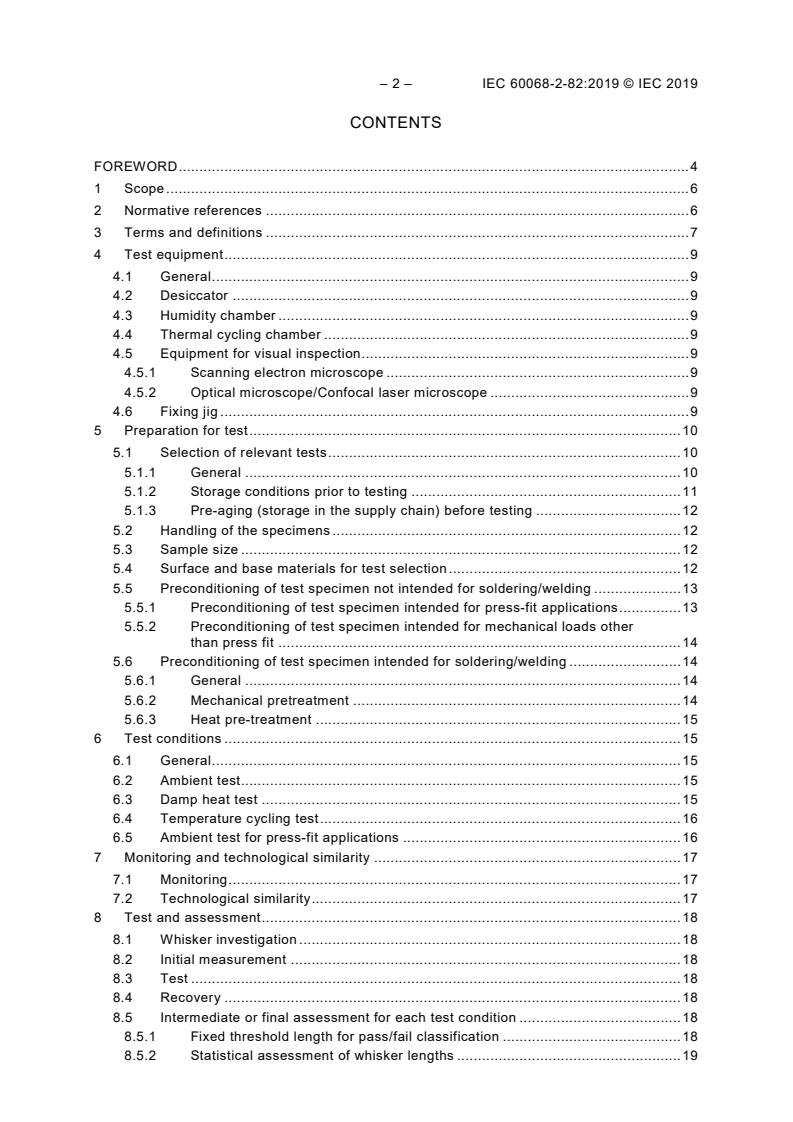

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Test equipment . 9

4.1 General . 9

4.2 Desiccator . 9

4.3 Humidity chamber . 9

4.4 Thermal cycling chamber . 9

4.5 Equipment for visual inspection . 9

4.5.1 Scanning electron microscope . 9

4.5.2 Optical microscope/Confocal laser microscope . 9

4.6 Fixing jig . 9

5 Preparation for test . 10

5.1 Selection of relevant tests . 10

5.1.1 General . 10

5.1.2 Storage conditions prior to testing . 11

5.1.3 Pre-aging (storage in the supply chain) before testing . 12

5.2 Handling of the specimens . 12

5.3 Sample size . 12

5.4 Surface and base materials for test selection . 12

5.5 Preconditioning of test specimen not intended for soldering/welding . 13

5.5.1 Preconditioning of test specimen intended for press-fit applications . 13

5.5.2 Preconditioning of test specimen intended for mechanical loads other

than press fit . 14

5.6 Preconditioning of test specimen intended for soldering/welding . 14

5.6.1 General . 14

5.6.2 Mechanical pretreatment . 14

5.6.3 Heat pre-treatment . 15

6 Test conditions . 15

6.1 General . 15

6.2 Ambient test . 15

6.3 Damp heat test . 15

6.4 Temperature cycling test . 16

6.5 Ambient test for press-fit applications . 16

7 Monitoring and technological similarity . 17

7.1 Monitoring . 17

7.2 Technological similarity . 17

8 Test and assessment . 18

8.1 Whisker investigation . 18

8.2 Initial measurement . 18

8.3 Test . 18

8.4 Recovery . 18

8.5 Intermediate or final assessment for each test condition . 18

8.5.1 Fixed threshold length for pass/fail classification . 18

8.5.2 Statistical assessment of whisker lengths . 19

9 Technology or manufacturing process changes . 19

10 Content of final report . 20

Annex A (normative) Measurement of whisker length . 22

Annex B (informative) Examples of whiskers . 23

Annex C (informative) Guidance on acceptance criteria . 25

C.1 Risks attributed to whiskers . 25

C.2 Acceptance criteria for whisker length . 25

C.3 Acceptance criteria for whisker density . 26

C.4 Statistical evaluation of number and length of whiskers. 26

C.5 Example of statistic evaluation . 26

Annex D (informative) Technical background of whisker growth . 29

Annex E (normative) Transition scenarios for the changeover of the damp-heat test

conditions . 30

Bibliography . 32

Figure 1 – Cross-sectional views of component termination surface finishes . 8

Figure 2 – Selection of test methods . 11

Figure 3 – . 14

Flow for treatment and/or bending and heat treatment

Figure A.1 – Estimation of whisker length . 22

Figure A.2 – Example for whisker length measurement . 22

Figure B.1 – Nodule . 23

Figure B.2 – Column whisker . 23

Figure B.3 – Filament whisker . 24

Figure B.4 – Kinked whisker . 24

Figure B.5 – Spiral whisker . 24

Figure C.1 – Smallest distance of components and circuit boards . 25

Figure C.2 – Histogram of whisker lengths and fitted log-normal distribution . 27

Figure C.3 – Histogram of whisker lengths and fitted log-normal distribution . 28

Figure C.4 – Histogram of whisker lengths and fitted log-normal distribution . 28

Figure E.1 –Transition paths for damp-heat testing of components . 30

Table 1 – Material systems recognized for effective whisker mitigation . 13

Table 2 –

Preconditioning conditions and test legs for components for different

............................................................................................................. 15

assembly processes

Table 3 – Conditions for the ambient test . 15

Table 4 – Conditions for the damp heat test . 16

Table 5 – Conditions for the ambient test . 16

Table 6 – Conditions for the ambient test applicable to press-fit terminations . 17

Table 7 – Classification for measured whisker length . 19

Table 8 – Surface finish technology and manufacturing process change acceptance

parameters . 19

Table 9 – Final report . 21

Table C.1 – Classification for measured whisker length . 27

Table E.1 – Conclusion matrix for parallel damp heat testing . 31

– 4 – IEC 60068-2-82:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-82: Tests – Test Xw1: Whisker test methods for components

and parts used in electronic assemblies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-82 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This second edition cancels and replaces the first edition published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– extension of the scope of the test standard from electronic to electromechanic components

and press-fit pins, which are used for assembly and interconnect technology;

– significant reduction of the testing effort by a knowledge-based selection of test conditions

i.e. tests not relevant for a given materials system can be omitted (see Annex D);

– harmonization with JESD 201A by omission of severities M, N for temperature cycling

tests;

– highly reduced test duration (1 000 h instead of 4 000 h) for damp-heat test by introducing

test condition at elevated humidity of 85 % R.H. and a temperature of 85 °C providing

increased severity.

The text of this International Standard is based on the following documents:

FDIS Report on voting

91/1562/FDIS 91/1573/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60068-2-82:2019 © IEC 2019

ENVIRONMENTAL TESTING –

Part 2-82: Tests – Test Xw1: Whisker test methods for components

and parts used in electronic assemblies

1 Scope

This part of IEC 60068 specifies tests for the whiskering propensity of surface finishes of

electric or electronic components and mechanical parts such as punched/stamped parts (for

example, jumpers, electrostatic discharge protection shields, mechanical fixations, press-fit

pins and other mechanical parts used in electronic assemblies) representing the finished

stage, with tin or tin-alloy finish. Changes of the physical dimensions of mould compounds,

plastics and the like during the required test flow are not considered or assessed. The test

methods have been developed by using a knowledge-based approach.

This document can also be used at sub-suppliers, like plating shops, stamping shops or other

service providers to ensure a consistent surface quality within the supply chain.

These test methods are employed with defined acceptance criteria by a relevant component

or application specification.

The tests described in this document are applicable for initial qualification, for periodic

monitoring in accordance with Clause 7, and for changes of technology or manufacturing

processes of existing surfaces in accordance with Clause 9.

The mating area of connectors is not covered by this test method. IEC 60512-16-21 applies

for the mating areas of connectors.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1:2013, Environmental testing – Part 1: General and guidance

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-20, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-58, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-67, Environmental testing – Part 2-67: Tests – Test Cy: Damp heat, steady state,

accelerated test primarily intended for components

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 61192-3:2002, Workmanship requirements for soldered electronic assemblies – Part 3:

Through-hole mount assemblies

IEC 60512-16-21:2012, Connectors for electronic equipment – Tests and measurements –

Part 16-21: Mechanical tests on contacts and terminations – Test 16u: Whisker test via the

application of external mechanical stresses

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

whisker

metallic protrusion that grows spontaneously during storage or use

Note 1 to entry: Whiskers typically do not require any electrical field for their growth and are not to be confused

with products of electrochemical migration. Signs of whiskers include:

– striations in growth direction;

– typically no branching;

– typically constant diameters.

Exceptions are known, but are rare and can require detailed investigation.

For the purposes of this document, whiskers are considered if:

– they have an aspect ratio (length/width) greater than 2;

– they have a length of 10 µm or more.

Note 2 to entry: For the purposes of this document, whiskers have the following characteristics

(see also Annex B):

– they can be kinked, bent, or twisted; they usually have a uniform cross-sectional shape;

– they may have rings around the circumference of the column.

Note 3 to entry: Whiskers are not to be confused with dendrites, which are fern-like growths on the surface of a

material, which can be formed as a result of electro(chemical)-migration of an ionic species or produced during

solidification.

Note 4 to entry: Whiskers are not to be confused with slivers as generated by mechanical metal processing.

Whiskers are not to be confused with tubular SnO structures, which may develop under damp-heat test conditions.

These structures are hollow and are typically lacking striations occurring on Sn whiskers.

3.2

termination

solderable element of a component consisting of the following elements

– base material;

– underlayer (or underlayer system, if more than one underlayer is present), if any, located

under the final plating;

– final tin or tin alloy finish

___________

Withdrawn publication.

– 8 – IEC 60068-2-82:2019 © IEC 2019

SEE: Figure 1

a) Gull wing termination b) Chip termination

Key

a base material

b underlayer (or underlayer system, if more than one underlayer is present), if any, located under the final plating

c final tin or tin alloy finish

Figure 1 – Cross-sectional views of component termination surface finishes

3.3

ΔCTE

CTE mismatch

coefficient of thermal expansion mismatch

coefficient calculated by taking the absolute after subtracting the CTE of the base material

from the CTE of the surface finish layer:

∆CTE = | CTE − CTE |

finish base material

Note 1 to entry: No underlayer system (e.g. Ni, Cu) has any influence on the CTE mismatch.

3.4

mechanical load

load related to the intended mounting/assembly condition of a particular specimen (e.g. press-

fit application: stress exerted by the plated through-hole on the press-fit pin), or as a

transitional load related to a mechanical process in a trim and form operation to adapt the

shape of the specimen to the intended use condition (e.g. bending of a connector pin)

Note 1 to entry: Mechanical load in the context of these test methods is not related to external factors, e.g.

thermo-mechanical loads arising from the mismatch of the coefficients of thermal expansion of the various

constituents of a particular test specimen upon temperature change.

3.5

classification

3.5.1

level A

consumer products, some computer and computer peripherals,

and hardware suitable for applications where the major requirement is function of the

completed assembly

3.5.2

level B

communications equipment, sophisticated business

machines, and instruments where high performance and extended life is required, and for

which uninterrupted service is desired but not mandatory

Note 1 to entry: Typically, the end-use environment would not cause failures.

3.5.3

level C

equipment where continued performance or

performance-on-demand is mandatory; equipment downtime cannot be tolerated, end-use

environment may be uncommonly harsh, and the equipment shall function when required,

such as life support systems and other critical systems

Note 1 to entry: The classification of levels A, B and C is based on IEC 61191-1.

4 Test equipment

4.1 General

The test equipment shall comprise the following elements.

4.2 Desiccator

The desiccator shall be capable of providing the conditions of temperature and humidity

specified in 6.2 and 6.5.

4.3 Humidity chamber

The humidity chamber shall meet all the requirements of IEC 60068-2-78 and be capable of

providing the conditions specified in 6.3.

4.4 Thermal cycling chamber

The thermal cycling chamber shall meet all the requirements of IEC 60068-2-14, test Na and

be capable of providing the conditions specified in 6.4.

4.5 Equipment for visual inspection

4.5.1 Scanning electron microscope

A scanning electron microscope (SEM) capable of investigating the surface of the specimen,

preferably equipped with a handling system capable of tilting and rotating the specimen, is the

preferred method of investigation owing to its high depth of focus.

4.5.2 Optical microscope/Confocal laser microscope

If not otherwise specified by the relevant specification, an optical microscope shall meet the

following requirements:

– A stereo light microscope capable of using a magnification of at least 50 × (but variable

magnification can be required for investigating different features) should be used for

surveying the specimens.

– An optical microscope allowing at least magnifications of 200 × should be used for

measuring whisker lengths. Illumination and/or specimen stage should be capable of

illuminating whiskers from different directions (e.g. use of ring lights, flexible light-guides

or rotatable fixing jigs).

– Availability of a wide range of working distances to achieve multiple focal planes.

– A suitable confocal laser microscope may also be employed.

4.6 Fixing jig

The jigs used for inspecting specimens in the optical microscope and the SEM shall meet the

following requirements:

– the jig shall be capable of tilting in every direction, up to a tilt angle of 45°;

– 10 – IEC 60068-2-82:2019 © IEC 2019

– parts shall be firmly attached on the fixture when the jig is tilted.

Care shall be taken to avoid whiskers breaking off while attaching the specimen to, and

handling the specimen with, the fixture jig.

5 Preparation for test

5.1 Selection of relevant tests

5.1.1 General

The samples shall represent finished (final) products as supplied to the customer (including

sub-process steps like trim and form, brushing, post-plating). The appropriate test methods

shall be selected according to the decision tree given in Figure 2.

Figure 2 – Selection of test methods

5.1.2 Storage conditions prior to testing

The specimen shall be kept for at least 2 h in the standard atmospheric conditions defined by

IEC 60068-1:2013, 4.3 prior to any preconditioning or test.

– 12 – IEC 60068-2-82:2019 © IEC 2019

5.1.3 Pre-aging (storage in the supply chain) before testing

Different manufacturing processes and different manufacturing routes require adapted pre-

aging times. The storage time prior to submitting specimens to preconditioning and testing

shall be at least 30 days, but not longer than 120 days after tin (alloy) plating.

5.2 Handling of the specimens

It is recommended that specimens be handled with a fixing jig as specified in 4.6 to prevent

contamination. Wherever possible, the fixing jig should not make contact with the metallic

surfaces of the specimens. However, contamination inherent to the production process and

the pre-conditioning shall not be removed (e.g. residues from plating or soldering, such as

flux residues).

The specimens shall be handled carefully to prevent whiskers from breaking off unexpectedly.

For required intermediate results reporting, already identified and broken whiskers (e.g. by

handling) shall be recorded in the final report (see Clause 10).

5.3 Sample size

The following minimum sample size shall be adopted for each test condition and for each kind

of preconditioning, unless other sample sizes are prescribed by the relevant specification.

Sample sizes for tests:

• All pins from 40 components with pin count per component < 4 pins.

• All pins from 20 components with pin count per component ≥ 4 pins and < 20 pins.

• All pins from 10 components with pin count per component ≥ 20 pins and < 40 pins.

• All pins from 5 components with pin count per component ≥ 40 pins, but not more than 400

pins.

• For mechanical parts like ESD protection shields, mechanical fixtures: ≥ 10 parts, up to an

area of 25 cm .

• For press-fit applications: ≥ 200 single pins.

• For all other parts like jumpers, wires, parts for electrical connections, male multipoint

connectors: ≥ 80 parts.

• For strip/belt galvanic: 25 cm or minimum 30 cm taken from the start and the end of the

coil.

The sample size applies to specimens with or without heat treatment in accordance with 5.5

and 5.6 and to each test condition selected from 5.1.

Similarity rules as given in 7.2 may be employed for the selection of samples.

5.4 Surface and base materials for test selection

Table 1 summarizes material systems recognized for their effective whisker mitigation, for

which certain test conditions may be omitted (see Figure 2 and Annex D). The technical

background for the omission of certain test conditions is briefly discussed in Annex D.

Table 1 applies to:

– copper-based base materials;

– ceramic-based materials;

– Fe and FeNi alloy base materials;

– other base materials which are covered with by a continuous Cu underlayer (those shall

be treated as 'Cu alloy' in Table 1), with the exception of CuZn alloys. If a CuZn alloy is

used, an Ni underlayer (0,5 µm to 4 µm) not exhibiting voids or cracks is required.

Table 1 – Material systems recognized for effective whisker mitigation

Part Sn finish layer Top Base Post-treatment

d

underlayer material

c

Galvanic Ni

Cu alloy

0,5 µm to

4 µm

Minimum No post-

3 µm Sn treatment

c

Ceramic, Fe

Galvanic Ni

2 µm to and FeNi

15 µm alloy

Galvanic matt

Reflow process

Cu alloy

a

Minimum

(Carbon content in the

Ceramic, Fe

3 µm Sn

No post-

Electronic

finish < 150 parts per

and FeNi

treatment

components

million in weight. Target

alloy

value, measured minimum

Solder area of

2 µm below the surface).

b

Cu alloy

electro- Annealing

mechanic

components Ceramic, Fe

No post-

Minimum

such as and FeNi

treatment

7 µm Sn

connectors, alloy

shieldings, etc.

c

No post-

Galvanic Ni

Cu alloy

treatment

1 µm to 3 µm

Cu alloy

Ceramic, Fe

Hot dip plating of Minimum No post-

and FeNi

Sn/SnAg/SnAgCu/SnCu0,7 3 µm Sn treatment

alloy

c

Galvanic Ni

Cu alloy

1 µm to 3 µm

Other Sn alloys not covered by Table 1 may be used, but for these alloys, the ambient test cannot be omitted.

Concerning the effectiveness of whisker mitigation, the use of galvanic matt Sn alloy finishes is currently under

discussion. In particular, the following alloying elements are considered: Ag, Bi, Cu and Pb.

a

The Sn finish shall melt during the reflow process (e.g. > 10 s at 235 °C), without exhibiting discoloration or

de-wetting.

b

Annealing shall take place within 24 h after plating for at least one hour at a temperature of 150 °C or

comparable conditions (e.g. 10 min at a temperature of 180 °C).

c

Ni-layer shall not exhibit voids or cracks (ductile Ni).

d

The post-treatment shall establish a homogeneous layer of Cu Sn and/or Cu Sn with a thickness of at least

6 5 3

0,5 µm.

The temperature-cycling test of 6.4 may be omitted if the CTE mismatch (∆CTE) (see 3.3) is

−6

less than 8 × 10 /K. The test conditions and the selection of test methods do not depend on

the presence of any underlayer system (e.g. Ni, Cu).

5.5 Preconditioning of test specimen not intended for soldering/welding

5.5.1 Preconditioning of test specimen intended for press-fit applications

Unless otherwise specified by the relevant specification, press-fit pins shall be inserted into a

plated through-hole of a laminated circuit board consisting of copper-clad epoxy woven

E-glass (for example, in accordance with IEC 61249-2-7, IEC 61249-2-35 or IEC 61249-2-22)

with the appropriate thickness and nominal finished hole diameter.

– 14 – IEC 60068-2-82:2019 © IEC 2019

The circuit board shall be pre-conditioned by subjecting it to two reflow temperature cycles in

accordance with IEC 60068-2-58 before insertion of the pins. After pin insertion, the sample

shall be stored under ambient conditions. No further thermal treatment at elevated

temperatures shall be performed.

5.5.2 Preconditioning of test specimen intended for mechanical loads other than

press fit

This preconditioning shall be applied to components like electromagnetic compatibility

protection shields, punched/stamped parts, mechanical fixations, insulation displacement

connectors and further mechanical applications.

Unless otherwise specified by the relevant specification, specimens intended for mechanical

load shall be subjected to a form operation, under nominal geometrical requirements of the

intended use case. The sample size according to 5.3 shall be selected for each test condition

selected in 5.1.

Further tests, if required, shall be described in the relevant detail specification.

5.6 Preconditioning of test specimen intended for soldering/welding

5.6.1 General

All parts intended for soldering/welding shall be subjected to a heat pre-treatment according

to Figure 3. The sample size in accordance with 5.3 shall be selected for each test leg of

Figure 3.

Figure 3 – Flow for treatment and/or bending and heat treatment

5.6.2 Mechanical pretreatment

For parts intended for soldering and additional mechanical load during production

(e.g. stitching, bending, trim and form), a characteristic preconditioning is required.

Such parts shall be subjected to a mechanical load corresponding to the intended use case,

under nominal geometrical requirements pertaining to the intended use case. In cases where

components are intended to be subjected to mechanical stress after delivery to a customer

(e.g. the forming of leads), a representative preconditioning is also required.

Unless otherwise specified by the relevant specification, the terminations of each specimen

with leads shall be bent 90° to a constant inner bending radius specified as the minimum

radius in Figure 1 of IEC 61192-3:2002.

5.6.3 Heat pre-treatment

Table 2 summarizes the required preconditioning and test legs (see Figure 3) for specimens

intended for surface-mount technology (SMT), through-hole technology (THT) and welding.

Table 2 – Preconditioning conditions and test legs for components

for different assembly processes

Test leg Component designed for assembly process

Surface-mount Through-hole Welding

technology technology

With heat treatment Mounted on PCB or non- Temperature and flux in As prescribed by the

(see Figure 3) wettable surface, in accordance with relevant specification.

accordance with IEC 60068-2-20, Test Ta,

IEC 60068-2-58, Test Method 1.

Td , Method 2.

Dipping depth: minimum

4 mm, but maximum 50 %

Alternative test: about

of termination.

50 % of the surface area

of the components'

termination shall be

wetted with flux according

to Test Td , Method 1.

Without heat treatment Product as delivered Product as delivered Product as delivered

This preconditioning shall also apply to the soldering area of connectors. A whisker test of the

connecting area shall be performed in accordance with IEC 60512-16-21.

6 Test conditions

6.1 General

The selection of the required test conditions shall be done in accordance with 5.1 and with

Figure 1.

6.2 Ambient test

The conditions given in Table 3 shall be applied for the ambient test.

Table 3 – Conditions for the ambient test

Temperature (25 ± 10) °C

Relative humidity (50 ± 25) %

Duration 4 000 h

NOTE A test chamber running at (30 ± 2) °C and (60 ± 3) % relative humidity

meets these conditions and thus can be used for this test.

6.3 Damp heat test

The procedure of IEC 60068-2-67 shall be employed for the damp heat test with one of the

test conditions given in Table 4.

– 16 – IEC 60068-2-82:2019 © IEC 2019

Table 4 – Conditions for the damp heat test

Test condition 1 Test condition 2

Temperature (85 ± 3) °C (55 ± 3) °C

Relative humidity (85 ± 5) % (85 ± 5) %

Duration 1 000 h 2 000 h or 4 000 h

NOTE 1 Test condition 1 has been introduced to offer a higher severity for the

damp heat test. This permits the achievement of an improved discrimination of the

specimens' susceptibility to whisker growth within a reasonably limited time span.

NOTE 2 Test condition 2 with a duration of 2 000 h succeeds the damp heat test

conditions prescribed in the prior edition of this document. The alternative duration

of 4 000 h has been added to achieve an improved discrimination of the specimens'

susceptibility to whisker growth.

Test condition 1 in Table 4 is the more severe test condition for the damp heat test and shall

be employed for every new qualification of the whiskering propensity of termination finishes of

components, unless components are intended exclusively for use in level A or B applications

(cf. 3.5). In particular, test condition 1 shall be adopted for all new qualifications of

components intended for use in level C high-performance/harsh environment electronic

products, for example, components undergoing qualification testing according to AEC-Q

qualification routines.

In the context of monitoring, a transition to test condition 1 is not required: for monitoring of

existing qualifications based on test condition 2, test condition 2 can be used continuously.

See Annex E for the transition from prior damp heat test conditions to test condition 1.

Condensation shall not be allowed to form on the specimen at any time during the test. The

chamber shall be such that no condensed water from the walls and roof of the test chamber

can be transferred to the test specimens.

If contamination with condensate (by condensation or water-droplet exposure) occurs, the

affected s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...