IEC 62021-2:2007

(Main)Insulating liquids - Determination of acidity - Part 2: Colourimetric titration

Insulating liquids - Determination of acidity - Part 2: Colourimetric titration

Describes a procedure for determination of the acidity of unused and used electrical mineral insulating oils. The method may be used to indicate relative changes that occur in a mineral insulating oil during use under oxidizing conditions that may or may not be shown by other properties of the resulting mineral oil. The acidity can be used in the quality control of unused mineral oil. As a variety of oxidation products present in used mineral oil contribute to acidity and these products vary widely in their corrosion properties, the test cannot be used to predict corrosiveness of a mineral oil under service conditions.

Liquides isolants - Détermination de l'acidité - Partie 2: Titrage colorimétrique

Décrit une procédure pour la détermination de l'acidité des huiles isolantes minérales électriques neuves et usagées. La méthode peut être utilisée pour indiquer des modifications relatives qui se produisent dans une huile minérale isolante pendant l'utilisation dans des conditions d'oxydation qui peuvent être ou peuvent ne pas être révélées par d'autres propriétés de l'huile minérale résultante. L'acidité peut être utilisée dans le contrôle de la qualité des huiles minérales neuves. Comme divers produits d'oxydation présents dans l'huile minérale usagée contribuent à l'acidité et comme ces produits varient largement du point de vue de leurs propriétés de corrosion, l'essai ne peut pas être utilisé pour prévoir la corrosivité d'une huile minérale dans des conditions de service.

General Information

- Status

- Published

- Publication Date

- 14-May-2007

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- WG 17 - TC 10/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-May-2007

- Completion Date

- 15-Jul-2007

IEC 62021-2:2007 Overview

IEC 62021-2:2007 is an international standard published by the International Electrotechnical Commission (IEC) that specifies a colourimetric titration method for the determination of acidity in electrical mineral insulating oils. This standard covers both unused and used mineral oils commonly employed in electrical equipment such as transformers and capacitors.

The method described provides a way to quantitatively measure the acidity levels through a colour change in the presence of a specific indicator, Alkali Blue 6B, when titrated with an alcoholic potassium hydroxide solution. It is a practical technique widely used for quality control of mineral insulating oils and to monitor their condition during service.

Key Topics Covered

Scope & Purpose

The standard focuses on the acidity measurement to detect changes in mineral insulating oils operating under oxidizing conditions. It highlights that while acidity can indicate oil degradation and quality, it cannot reliably predict corrosiveness due to varying oxidation products.Principle of Method

The acidity is quantified by titrating a sample dissolved in a defined solvent with an alcoholic KOH solution, using a colourimetric indicator for endpoint detection.Reagents and Apparatus

The standard specifies all reagents required, including potassium hydroxide alcoholic solution, 2-propanol solvent, potassium hydrogen phthalate (primary standard), and Alkali Blue 6B as the indicator. Also detailed are the titration vessel, stirrer, and burette requirements to ensure accurate results.Procedure and Sampling

It includes directions for sampling, preparation of reagents, blank and sample titration, and the calculation of acidity results expressed as milligrams of potassium hydroxide per gram of oil.Precision and Reporting

The standard provides guidelines on repeatability and reproducibility of test results and the format for reporting acidity measurements for consistency across laboratories.Safety and Environmental Notes

It underscores the importance of handling mineral oils and chemicals with proper safety practices and the need to dispose of waste responsibly according to national regulations.

Practical Applications

Quality Control of Mineral Insulating Oil

IEC 62021-2 is essential in manufacturing and maintaining high-quality unused mineral oils before deployment in electrical equipment, ensuring their suitability and longevity.Condition Monitoring of Used Oil

By tracking changes in acidity through periodic tests, maintenance teams can assess the degradation state of insulating oils in transformers and other electrical apparatus, aiding preventative maintenance and fault prediction.Research and Development

Laboratories and equipment manufacturers utilize this standard method for comparative studies of oil formulations, additives, and their oxidation behavior under different service conditions.Regulatory Compliance and Standardization

The standard helps unify acidity testing procedures internationally, enabling consistent data interpretation, compliance with environmental and safety laws, and facilitating trade.

Related IEC and ISO Standards

IEC 62021-1: Potentiometric titration method for acidity determination in insulating liquids, providing an alternative analytical approach using potentiometric endpoint detection.

IEC 60296: Specifications for unused mineral insulating oils, originally including the colourimetric titration method before its removal, now referenced for oil quality requirements.

IEC 60475: Method of sampling liquid dielectrics relevant to obtaining representative insulating oil samples for various analyses.

IEC 60567: Guidelines for sampling gases and oil for dissolved gas analysis, complementing oil quality assessment.

ISO 6619: Potentiometric titration method for petroleum products neutralization number, related for standardization in acid number measurements.

ISO 5725: Standards on accuracy (trueness and precision) of measurement methods and results, informing the precision requirements of this standard.

Keywords: IEC 62021-2, insulating liquids, acidity determination, colourimetric titration, electrical mineral insulating oils, potassium hydroxide titration, oil quality control, insulating oil acidity, mineral oil testing, Alkali Blue 6B indicator, electrical equipment maintenance, electrical oil analysis standards.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62021-2:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Insulating liquids - Determination of acidity - Part 2: Colourimetric titration". This standard covers: Describes a procedure for determination of the acidity of unused and used electrical mineral insulating oils. The method may be used to indicate relative changes that occur in a mineral insulating oil during use under oxidizing conditions that may or may not be shown by other properties of the resulting mineral oil. The acidity can be used in the quality control of unused mineral oil. As a variety of oxidation products present in used mineral oil contribute to acidity and these products vary widely in their corrosion properties, the test cannot be used to predict corrosiveness of a mineral oil under service conditions.

Describes a procedure for determination of the acidity of unused and used electrical mineral insulating oils. The method may be used to indicate relative changes that occur in a mineral insulating oil during use under oxidizing conditions that may or may not be shown by other properties of the resulting mineral oil. The acidity can be used in the quality control of unused mineral oil. As a variety of oxidation products present in used mineral oil contribute to acidity and these products vary widely in their corrosion properties, the test cannot be used to predict corrosiveness of a mineral oil under service conditions.

IEC 62021-2:2007 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 29.040.10 - Insulating oils. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62021-2:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

CEI

62021-2

NORME

First edition

INTERNATIONALE

Première édition

2007-05

Insulating liquids –

Determination of acidity

Part 2:

Colourimetric titration

Liquides isolants –

Détermination de l’acidité

Partie 2:

Titrage colorimétrique

Reference number

Numéro de référence

IEC/CEI 62021-2:2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de

référence, texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou

remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

CEI

62021-2

NORME

First edition

INTERNATIONALE

Première édition

2007-05

Insulating liquids –

Determination of acidity

Part 2:

Colourimetric titration

Liquides isolants –

Détermination de l’acidité

Partie 2:

Titrage colorimétrique

PRICE CODE

P

CODE PRIX

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

Pour prix, voir catalogue en vigueur

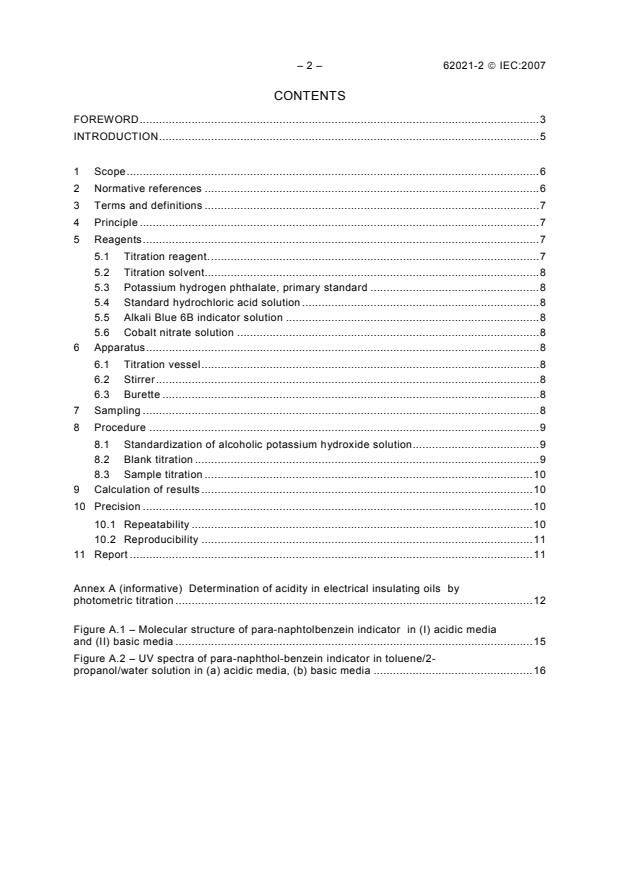

– 2 – 62021-2 © IEC:2007

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

4 Principle .7

5 Reagents.7

5.1 Titration reagent.7

5.2 Titration solvent.8

5.3 Potassium hydrogen phthalate, primary standard .8

5.4 Standard hydrochloric acid solution .8

5.5 Alkali Blue 6B indicator solution .8

5.6 Cobalt nitrate solution .8

6 Apparatus.8

6.1 Titration vessel.8

6.2 Stirrer.8

6.3 Burette .8

7 Sampling .8

8 Procedure .9

8.1 Standardization of alcoholic potassium hydroxide solution.9

8.2 Blank titration .9

8.3 Sample titration .10

9 Calculation of results .10

10 Precision .10

10.1 Repeatability .10

10.2 Reproducibility .11

11 Report .11

Annex A (informative) Determination of acidity in electrical insulating oils by

photometric titration .12

Figure A.1 – Molecular structure of para-naphtolbenzein indicator in (I) acidic media

and (II) basic media .15

Figure A.2 – UV spectra of para-naphthol-benzein indicator in toluene/2-

propanol/water solution in (a) acidic media, (b) basic media .16

62021-2 © IEC:2007 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

INSULATING LIQUIDS –

DETERMINATION OF ACIDITY –

Part 2: Colourimetric titration

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62021-2 has been prepared by IEC technical committee 10: Fluids

for electrotechnical applications.

The text of this standard is based on the following documents:

FDIS Report on voting

10/692/FDIS 10/696/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 62021-2 © IEC:2007

A list of all parts of IEC 62021 series, under the general title Insulating liquids – Determination

of acidity can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

62021-2 © IEC:2007 – 5 –

INTRODUCTION

The standardized method given in IEC 62021-1 is a method for measurement of acidity in

used and unused mineral oil and is a potentiometric titration requiring special instrumentation

for measurement of acidity. Historically, acidity of insulating oil was measured by

colourimetric titration as described in IEC 60296, 1982 edition. With the revision of IEC 60296,

the colourimetric titration was deleted as that method used high volumes of sample and

solvent, generating undesirable volumes of waste.

However, there is still a market requirement for having colourimetric titration as many labs

use this method.

Health and safety

This International Standard does not purport to address all the safety problems associated

with its use. It is the responsibility of the user of the Standard to establish appropriate health

and safety practices and determine the applicability of regulatory limitations prior to use.

The mineral oils which are the subject of this standard should be handled with due regard to

personal hygiene. Direct contact with eyes may cause slight irritation. In the case of eye

contact, irrigation with copious quantities of clean running water should be carried out and

medical advice sought.

Some of the tests specified in this standard involve the use of processes that could lead to a

hazardous situation. Attention is drawn to the relevant standard for guidance.

This standard involves mineral oils, chemicals and used sample containers. The disposal of

these items should be carried out in accordance with current national legislation with regard

to the impact on the environment. Every precaution should be taken to prevent the release

into the environment of mineral oil.

– 6 – 62021-2 © IEC:2007

INSULATING LIQUIDS –

DETERMINATION OF ACIDITY –

Part 2: Colourimetric titration

1 Scope

This part of IEC 62021 describes a procedure for determination of the acidity of unused and

used electrical mineral insulating oils.

NOTE 1 In unused and used mineral insulating oils, the constituents that may be considered to have acidic

characteristics include organic acids, phenolic compounds, some oxidation products, resins, organometallic salts

and additives.

The method may be used to indicate relative changes that occur in a mineral insulating oil

during use under oxidizing conditions that may or may not be shown by other properties of the

resulting mineral oil.

The acidity can be used in the quality control of unused mineral oil.

As a variety of oxidation products present in used mineral oil contribute to acidity and these

products vary widely in their corrosion properties, the test cannot be used to predict

corrosiveness of a mineral oil under service conditions.

NOTE 2 The acidity results obtained by this test method may or may not be numerically the same as those

obtained by potentiometric methods, but they are generally of the same magnitude. The potentiometric method

uses an endpoint at pH 11,3 to ensure titration of all species, whereas the colourimetric methods uses an indicator

changing colour at approximately pH 9,5. This may lead to slightly higher results for oils with acidities above

0,3 mg KOH/g oil when using the potentiometric method.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60475: Method of sampling liquid dielectrics

IEC 60567: Oil-filled electrical equipment – Sampling of gases and of oil for analysis of free

and dissolved gases – Guidance

ISO 5725: Accuracy (trueness and precision) of measurement methods and results

ISO 6619: Petroleum products and lubricants – Neutralization number – Potentiometric

titration method

62021-2 © IEC:2007 – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

acidity

quantity of base, expressed in milligrams of potassium hydroxide per gram of sample,

required to titrate colourimetrically a test portion in a specified solvent to the neutralization

point of Alkali Blue 6B

3.2

unused oil

mineral insulating oil that has not been used in, or been in contact with electrical equipment

4 Principle

The test portion is dissolved in a specified solvent and titrated colourimetrically with alcoholic

potassium hydroxide to a specified colour using Alkali Blue 6B indicator.

5 Reagents

Only reagents of recognized analytical grade and de-ionized water or water of equivalent

purity shall be used.

5.1 Titration reagent

Standard alcoholic solution 0,05 mol/l potassium hydroxide.

Add 3,0 g of potassium hydroxide to 1 000 ml ± 10 ml of 2-propanol. Boil gently for 10 min to

effect solution. Cool and stopper the flask.

Allow the solution to stand in the dark for 2 days and then filter the supernatant liquid through

a 5 μm membrane filter. Store in a suitable amber glass bottle.

The concentration of this solution is approximately 0,05 mol/l and shall be standardized as

described in 8.1. For periodic tests on equipment in service, faster titration may be achieved

by the use of 0,1 mol/l potassium hydroxide by agreement between the laboratory and the

equipment owner, although this may result in poorer precision and detection limit.

Commercial alcoholic potassium hydroxide solution may be used, if necessary diluting to

0,05 mol/l with 2-propanol. This shall be standardized as described in 8.1.

Store and use in such a manner that the solution is protected from atmospheric carbon

dioxide and in such a way that it does not come into contact with cork, rubber or saponifiable

stopcock grease. The solution may be protected by inert gas or by means of a guard tube

containing soda-lime absorbent.

– 8 – 62021-2 © IEC:2007

5.2 Titration solvent

2-propanol (isopropanol; IPA), pure.

5.3 Potassium hydrogen phthalate, primary standard

This should be dried before use for 2 h at 105 °C.

5.4 Standard hydrochloric acid solution

A 0,1 mol/l solution of hydrochloric acid in de-ionized water, prepared as in ISO 6619, may be

used. Other acids may be used, provided they are certified against a primary standard.

5.5 Alkali blue 6B indicator solution

Dissolve 2 g ± 0.1 g of alkali blue 6B in 100 ml of 2-propanol or azeotropic ethanol containing

1 ml of the hydrochloric acid solution. After 24 h, carry out a titration to check whether the

indicator has been sufficiently sensitized. The indicator is satisfactory if the colour changes

distinctly from blue to red comparable to that of a 10 % solution of cobalt nitrate. If

sensitization is insufficient, repeat the addition of the hydrochloric acid solution and check

again after 24 h. Continue until sensitization is satisfactory. Filter and store in a brown bottle

in the dark.

Commercial alkali blue 6B solution may be used as an alternative if the concentration is within

the range 0,05 % to 5 %. If the concentration is not 2 %, the amount added to the solvent in

8.2 and 8.3 should be adjusted to maintain the same ultimate concentration.

5.6 Cobalt nitrate solution

Co(NO ) .6H O solution, 10 % in water.

3 2 2

6 Apparatus

6.1 Titration vessel

This should be as small as possible, sufficient to contain the solvent, sample and stirrer and

be inert to the reagents. Glass conical vessels are preferred.

6.2 Stirrer

Stirring may be manual by swirling the solution on the titration vessel, or mechanically using a

variable speed stirrer fitted with a propeller, paddle or magnetic bar of chemically inert

surface material.

6.3 Burette

A burette or syringe capable of adding aliquots of 0,001 ml shall be used.

7 Sampling

Samples shall be taken following the procedure given in IEC 60475 and/or IEC 60567.

Ensure that the test portion is representative by thoroughly mixing, as any sediment present

may be acidic or have adsorbed acidic material from the liquid phase.

62021-2 © IEC:2007 – 9 –

8 Procedure

Rinse and fill the burette with 0,05 mol/l alcoholic potassium hydroxide solution (5.1).

Standardize the alcoholic potassium hydroxide solution at least every two weeks against

potassium hydrogen phthalate (5.3) or certified standard 0,1 mol/l acid.

Carry out a blank titration on the solvent (5.2) each day and after changing to a fresh batch of

solvent.

8.1 Standardization of alcoholic potassium hydroxide solution

Standardize the alcoholic potassium hydroxide solution, using a suitable indicator, against

0,1 g to 0,16 g of potassium hydrogen phthalate, weighed to an accuracy of 0,000 2 g and

dissolved in approximately 100 ml of carbon dioxide free water.

Alternatively the standardization can be performed by potentiometric titration.

Calculate the molarity M to the nearest 0,000 5 using Equation (1):

1 000 × m × p

Molarity = (1)

204,23 ×V

where

m is the mass of potassium hydrogen phthalate, in grams;

p is the percent purity of the potassium hydrogen phthalate;

V is the volume of potassium hydroxide solution, in millilitres.

Alternatively, certified standard 0,1 mol/l acid may be used to standardize the alcoholic

potassium hydroxide solution.

Calculate the molarity M to the nearest 0,000 5 using Equation (2):

V × M

1 A

Molarity = (2)

V

where

V is the volume of 0,1 mol/l standard acid used to titrate the solution, in millilitres;

M is the molarity of the standard hydrochloric acid;

A

V is the volume of potassium hydroxide solution, in millilitres.

8.2 Blank titration

Perform a blank titration at a temperature not above 25 °C on 10 ml ± 0,1 ml aliquots of the

solvent containing 0,5 % of alkali blue 6B indicator solution (5.5) using the standardized

alcoholic potassium hydroxide solution. The endpoint shall be as soon as a colour change

from blue to a red colour comparable to that of the cobalt nitrate solution (5.6) is obtained and

persists for at least 15 s.

Carry out triplicate titrations and calculate the mean result, in millilitres to the nearest

0,001 ml, as the blank value V .

– 10 – 62021-2 © IEC:2007

Protect the solvent from atmospheric carbon dioxide and use within 8 h.

8.3 Sample titration

Weigh 5 g of sample to the nearest 0,01 g into the titration vessel. Add 10 ml ± 0,1 ml of the

solvent solution containing 0,5 % of alkali blue 6B indicator solution (5.5). Swirl to dissolve

the oil and immediately titrate at a temperature not above 25 °C with the standardized

potassium hydroxide solution. A typical end point is as described in 8.2. However, since the

colour change may vary for different oils, pre-titration may be necessary to establish this. In

such cases, the endpoint shall be reached as soon as a stable colour change, which persists

for at least 15 s, is obtained.

NOTE Before titrating, the colour may vary from blue to green and at the endpoint from red to light orange to dark

yellow-brown, depending on the original colour of the oil.

Carry out determinations for each oil sample and note the result, in millilitres, to the nearest

0,001 ml, as the titration value V .

9 Calculation of results

Calculate, for each determination, the acidity to the nearest 0,005, expressed as mg KOH/g of

oil, using Equation (3):

()V −V × M × 56,1

1 0

Acidity = (3)

m

where

V is the volume of alcoholic KOH solution used to titrate the test sample, in millilitres;

V is the mean volume of alcoholic KOH solution used for the blank titration, in millilitres;

M is the molarity of alcoholic KOH solution;

m is the mass of the test portion used, in grams.

10 Precision

The repeatability and reproducibility limits were established in accordance with ISO 5725.

10.1 Repeatability

The difference between successive test results obtained by the same operator with the same

apparatus under constant operating conditions on identical test material would, in the long run,

in the normal and correct operation of the test method, exceed the values shown below only in

one case in 20:

− unused oils –15 %;

− used oils –10 %.

NOTE The repeatability values for unused oils only apply where the result is significantly above the quantification

limit, which has been established as 0,01 mg KOH/g oil.

62021-2 © IEC:2007 – 11 –

10.2 Reproducibility

The difference between two single and independent results obtained by different operators

working in different laboratories on identical test material would, in the long run, in the normal

and correct operation of the test method, exceed the values shown below only in one case

in 20:

− unused oils – 35 %;

− used oils – 20 %.

NOTE The reproducibility values for unused oils only apply where the result is significantly above the

quantification limit, which has been established as 0,01 mg KOH/g oil.

11 Report

The test report shall contain at least the following information.

– The type and identification of the product tested.

– A reference to this International Standard.

– The result of the test (see Clause 9) expressed to the nearest 0,01 mg KOH/g of oil.

– Any deviation, by agreement or otherwise, from the procedure specified.

– The date of the test.

– 12 – 62021-2 © IEC:2007

Annex A

(informative)

Determination of acidity in electrical insulating oils

by photometric titration

A.1 Principle

A sample of new or used oil is dissolved in a mixture of toluene and 2-propanol containing a

small amount of water. The solution is titrated at ambient temperature with alcoholic

potassium hydroxide. The neutralization of acid components in oil is detected by the colour

change of the added para-naphtolbenzein indicator, using a photometric sensor at 660 nm.

A.2 Reagents and solvents

– Para-naphtolbenzein indicator (1 % in alcoholic solution)

– Potassium hydroxide solution in 2-propanol (1 mol/l)

– Potassium hydrogen phthalate

– 2-Propanol, anhydrous, HPLC grade

– Toluene, HPLC grade

– Demineralized water, conductivity < 0,1 μS/cm

– Methanol, HPLC grade

– CO absorbing agent, 8-20 mesh

– Water absorbing agent, 10-20 mesh

NOTE It is recommended to filter all solvents, solutions and oil samples prior to use.

A.2.1 Preparation of titration solutions and solvents

A.2.1.1 Potassium hydroxide alcoholic solution (0,05 mol/l)

Introduce 50 ml of the potassium hydroxide solution in 2-propanol (1 mol/l) into a volumetric

vessel of 1 l. Make up to 1,0 l with 2-propanol.

A.2.1.2 Potassium hydrogen phthalate solution (0,05 mol/l)

Crush 10 g of potassium hydrogen phthalate in a mortar and dry at 120 °C for 1 h, then cool in

a desiccator containing a water-absorbing agent. Weigh about 5 g of dried potassium

hydrogen phthalate precisely in a scoop and introduce it in a volumetric vessel of 500 ml.

Wash the scoop several times with small amounts of water into the volumetric vessel. Make

up to 500,0 ml with demineralised water.

Calculate the molarity to the nearest 0,000 5 using following Equation (A.1):

m

Molarity (M KPH) = (A.1)

204,23 × 0,5

where m is the mass of potassium hydrogen phthalate, in gram.

62021-2 © IEC:2007 – 13 –

A.2.1.3 Titration solvent

The composition of the titration solvent in % volume/volume is: 50 % toluene, 49,5 %

2-propanol, 0,5 % demineralized water. 500 μl of para-naphtolbenzein indicator solution is

added per 100 ml of titration solvent.

A.3 Apparatus

A.3.1 Volumetric titrator

The apparatus shall be equipped with an automatic burette of 5 ml capacity with a dispensing

accuracy of ±0,01ml. A guard tube containing the water and carbon dioxide absorbing agents

is necessary for the reservoir for the alcoholic potassium hydroxide solution.

A.3.2 Titration vessel

The titration vessel shall have a 100 ml capacity and be inert to the reagents.

NOTE The vessel volume should be such that the photometer probe is covered by liquid during the titration.

A.3.3 Titration stand

A suitable stand shall be provided to support the titration vessel, stirrer, automatic burette and

photometric sensor.

A.3.4 Stirrer

The stirrer shall be mechanical or electrical, having variable speed.

A.3.5 Recorder/printer

A device shall be required to record/print out the data coming from the titrator and

photometric sensor.

NOTE 1 Installing the titration apparatus in a fume hood will eliminate solvent vapours from the laboratory

environment.

NOTE 2 An automatic sampler may be used to increase the productivity of analyses.

A.3.6 Photometric sensor

A suitable sensor is equipped with a glass-fibre light guide probe measuring the transmission

of light in the visible region, equipped with a filter allowing measurements to be made in a

bandwidth of less than 10 nm at any visible wavelength.

The molecular structures of para-naphtolbenzein indicator in acidic and basic media are

indicated in Figure A.1. The UV transmission rate is maximum at 660 nm in acidic media,

giving the solution an orange colour (Figure A.2). It is minimum at 660 nm in basic media,

changing the solution to green colour. The wavelength of the photometric sensor therefore is

set at 660 nm.

NOTE Phenolphthalein indicator may also be used at 550 nm.

A.4 Procedure

A.4.1 Preparation and maintenance of the titration system

It is necessary to clean the titration vessel, stirrer and photometric sensor with methanol and

to air-dry them before each use.

– 14 – 62021-2 © IEC:2007

NOTE If the photometer and its controller cannot be set to achieve the manufacturer’s recommended parameters,

this may be an indication that the photometer is dirty and should be cleaned more thoroughly.

A.4.2 Determination of acidity of the titration solvent

Install the photometric sensor on the titration stand and connect it to the titrator. Flush the

automatic burette 3 times into a beaker using the KOH solution. The tubes carrying the KOH

solution should not contain bubbles after these operations. Fix a cleaned titration vessel to

the titration stand.

Introduce 50 ml ± 0,1 ml of titration solvent into the titration vessel. Start the stirrer. Place the

tip of the automatic burette in the centre of the solution, at about 2,5 cm from the stirrer. The

optical path of the photometric sensor should be void of any bubbles. If there are bubbles,

adjust stirring speed to eliminate them. Set the voltage on the photometric sensor at 1 000 mV.

Start titrating with the potassium hydroxide alcoholic solution (0,05 mol/l) and the automatic

burette. The printer will print the titration curve (in mV vs. ml), the first derivative of the

titration curve (in mV/ml vs. ml) and the volume of KOH solution used (in ml). Note volume of

KOH used for neutralization of titration solvent as V .

NOTE The above procedure should be carried out daily.

A.4.3 Determination of molarity of the potassium hydroxide alcoholic solution

(0,05 mol/l)

Proceed as follows:

a) fix a cleaned titration vessel to the titration stand;

b) introduce 1 ml ± 0,01 of potassium hydrogen phthalate water solution (0,05 mol/l) into the

titration vessel. Add 50 ml of titration solvent;

c) titrate as in A.4.2.

Calculate the molarity of the KOH solution to the nearest 0,000 5 using the following Equation

(A:2):

1× M

KHP

Molarity = (A.2)

V

where

M is molarity of potassium hydrogen phthalate;

KHP

V is volume of potassium hydroxide solution, in millilitres.

Calculate the final value of molarity as the average of 3 determinations.

NOTE Procedure A.4.3 need only be carried out each month. The potassium hydroxide alcoholic solution has

been found quite stable with time when suitably stored; see 5.1.

A.4.4 Titration of soluble acidity in the oil sample

Proceed as follows:

a) fix a cleaned titration vessel to the titration stand;

b) for new oils or only slightly used oils, introduce 20 g ± 0,01 g of oil in the titration vessel.

For highly used oils, introduce 5 g ± 0,01 g of oil;

c) add 50 ml ± 0,1 ml of titration solvent and titrate as in A.4.2.

62021-2 © IEC:2007 – 15 –

Calculate the acidity of the oil sample KOH to the nearest 0,000 5, using the following

Equation (A.3):

()V −V × M × 56,1

1 0

Acidity = (A.3)

m

where

V is the volume of alcoholic KOH solution used to titrate the test sample, in millilitres;

V is the mean volume of alcoholic KOH solution used for the blank titration (titration

solvent), in millilitres;

M is the molarity of alcoholic KOH solution;

m is the mass of the test portion used, in grams.

NOTE On modern equipment, data measured in A.4.2, A.4.3 and A.4.4 may be stored in the memory of the

equipment to automate calculations.

–+

OH O K

KHO

C HO C

H O

–+

O O K

IEC 681/07

Figure A.1 – Molecular structure of para-naphtolbenzein indicator

in (I) acidic media and (II) basic media

– 16 – 62021-2 © IEC:2007

b

a

350 450 550 650

Wavelength nm

IEC 682/07

Figure A.2 – UV spectra of para-naphthol-benzein indicator in toluene/2-propanol/water

solution in (a) acidic media, (b) basic media

____________

Transmission %

– 18 – 62021-2 © CEI:2007

SOMMAIRE

AVANT-PROPOS.19

INTRODUCTION.21

1 Domaine d’application .22

2 Références normatives.22

3 Termes et définitions .23

4 Principe.23

5 Réactifs.23

5.1 Réactif titrant.23

5.2 Solvant titrant.24

5.3 Hydrogénophthalate de potassium, étalon primaire .24

5.4 Solution d’acide chlorhydrique normalisée.24

5.5 Solution indicatrice de Bleu Alcalin 6B.24

5.6 Solution de nitrate de cobalt.24

6 Appareillage .24

6.1 Récipient de titrage .24

6.2 Agitateur .24

6.3 Burette .24

7 Échantillonnage.24

8 Mode opératoire .25

8.1 Détermination du titre de la solution alcoolique d’hydroxyde de potassium .25

8.2 Titrage à blanc .25

8.3 Titrage d’échantillons .26

9 Calcul des résultats .26

10 Précision .26

10.1 Répétabilité.26

10.2 Reproductibilité .27

11 Rapport .27

Annexe A (informative) Détermination de l’acidité dans les huiles isolantes électriques

par titrage photométrique.28

Figure A.1 – Structure moléculaire d'indicateur de para-naphtol-benzene dans les

supports acides (I) et de base (II) .31

Figure A.2 – Spectres UV de l’indicateur de para-naphtol-benzène dans la solution

aqueuse toluène/2-propanol dans les supports acides (a) et de base (b) . .32

62021-2 © CEI:2007 – 19 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

___________

LIQUIDES ISOLANTS –

DÉTERMINATION DE L’ACIDITÉ –

Partie 2: Titrage colorimétrique

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités techniques – tous les comités nationaux de la CEI qui sont intéressés par le sujet traité peuvent

participer à ces travaux d’élaboration. Des organisations internationales, gouvernementales et non

gouvernementales peuvent également participer à ces travaux en liaison avec la CEI. La CEI collabore

étroitement avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord

entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre toute Publication de la CEI et toute publication nationale ou

régionale correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 62021-2 a été établie par le comité d’études 10 de la CEI:

Fluides pour applications électrotechniques.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

10/692/FDIS 10/696/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

– 20 – 62021-2 © CEI:2007

Une liste de toutes les parties de la série CEI 62021, présentées sous le titre général

Liquides isolants – Détermination de l’acidité peut être consultée sur le site web de la CEI.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous «http://webstore.iec.ch» dans les

données relatives à la publication recherchée. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

62021-2 © CEI:2007 – 21 –

INTRODUCTION

La méthode normalisée existante dans la CEI 62021-1 est la méthode de mesure de l’acidité

dans les huiles minérales neuves et usagées et il s'agit d'un titrage potentiométrique

nécessitant des appareils de mesure spéciaux en vue de la mesure de l’acidité.

Historiquement, l’acidité des huiles isolantes a été mesurée par titrage colorimétrique comme

décrit dans la CEI 60296, édition 1982. Avec la révision de la CEI 60296, le titrage

colorimétrique a été supprimé parce quecette méthode utilisait de grands volumes

d’échant

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...