IEC 60296:2012

(Main)Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear

Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear

IEC 60296:2012 is now available as IEC Standards+ 60296:2012 which contains the International Standard and its Redline version, showing all changes of the technical content compared to the previous edition.

IEC 60296:2012 is applicable to specifications and test methods for unused mineral insulating oils. It applies to oil intended for use in transformers, switchgear and similar electrical equipment in which oil is required for insulation and heat transfer. This edition includes the following significant technical changes with respect to the previous edition:

- specifications for corrosive sulphur compounds that can lead to copper sulphide deposition in transformers (in non-passivated and passivated oils);

- definitions of additives in oil; and

- re-insertion of a missing note on oxidation.

Fluides pour applications électrotechniques - Huiles minérales isolantes neuves pour transformateurs et appareillages de connexion

IEC 60296:2012 est disponible sous forme de IEC Standards+ 60296:2012 qui contient la Norme internationale et sa version Redline, illustrant les modifications du contenu technique depuis l'édition précédente.

IEC 60296:2012 s'applique aux spécifications et méthodes d'essais pour les huiles minérales isolantes neuves. Elle s'applique à l'huile destinée à l'utilisation dans les transformateurs, disjoncteurs et matériels électriques analogues, dans lesquels l'huile est nécessaire comme fluide isolant et caloporteur. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- des spécifications pour les composés soufrés corrosifs qui peuvent entraîner un dépôt de sulfure de cuivre à l'intérieur des transformateurs (dans les huiles non-passivées et passivées);

- les définitions d'additifs dans l'huile; et

- la ré-insertion d'une note manquante concernant l'oxydation.

General Information

- Status

- Published

- Publication Date

- 19-Feb-2012

- Technical Committee

- TC 10 - Fluids for electrotechnical applications

- Drafting Committee

- WG 21 - TC 10/WG 21

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 26-Jun-2020

- Completion Date

- 31-Oct-2018

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

IEC 60296:2012 - Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear - is the 4th edition (redline version) of the International Electrotechnical Commission standard for newly manufactured mineral insulating oils. It defines the scope, classification, delivery and sampling requirements, together with specifications and test methods for oils intended for insulation and heat transfer in transformers, switchgear and similar electrical equipment. The redline edition shows technical changes from the previous edition, notably new provisions for corrosive sulphur, definitions of additives, and a reinstated note on oxidation.

Key Topics

The standard addresses the functional, performance and HSE properties critical to transformer and switchgear oil quality, including:

- Classification and identification of unused mineral insulating oils and additive content (antioxidants, metal passivators, pour-point depressants).

- Properties and test methods such as viscosity, pour point, water content, breakdown voltage, dielectric dissipation factor (DDF), acidity, interfacial tension, density and particle content.

- Sulphur content and corrosive sulphur: requirements and test guidance to reduce risks of copper sulphide deposition in transformers (non-passivated and passivated oils).

- Oxidation stability and related notes on long-term performance.

- Electrostatic charging tendency (ECT), gassing tendency and stray gassing considerations for specific applications.

- Contaminant checks and safety-sensitive parameters: PCBs, polycyclic aromatics (PCAs), 2‑furfural (2‑FAL) and DBDS content are included among monitored items.

- Sampling, delivery and miscibility requirements for procurement and acceptance testing.

Applications

IEC 60296:2012 is used by:

- Transformer and switchgear manufacturers to specify acceptable new insulating oil for assembly and commissioning.

- Electric utilities and asset owners for procurement, acceptance testing and ensuring compatibility with in-service equipment.

- Oil producers and refiners to certify product compliance and label additive content.

- Testing laboratories and inspection bodies to perform standardized tests and report results.

- Engineering consultants and maintenance teams for risk assessment related to corrosive sulphur, oxidation and electrostatic issues.

Practical uses include quality control on delivery, setting contract specifications, selecting oils for cold-start performance (LCSET considerations), and mitigating operational risks such as gassing or copper sulphide deposition.

Related Standards

IEC 60296:2012 complements other IEC publications and industry standards covering in-service oil testing, transformer maintenance and specific test methods. Users should ensure they consult the latest editions and any normative references cited in IEC 60296 when applying the standard.

REDLINE IEC 60296:2012 - Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear Released:2/20/2012 Isbn:9782889129287

IEC 60296:2012 - Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60296:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fluids for electrotechnical applications - Unused mineral insulating oils for transformers and switchgear". This standard covers: IEC 60296:2012 is now available as IEC Standards+ 60296:2012 which contains the International Standard and its Redline version, showing all changes of the technical content compared to the previous edition. IEC 60296:2012 is applicable to specifications and test methods for unused mineral insulating oils. It applies to oil intended for use in transformers, switchgear and similar electrical equipment in which oil is required for insulation and heat transfer. This edition includes the following significant technical changes with respect to the previous edition: - specifications for corrosive sulphur compounds that can lead to copper sulphide deposition in transformers (in non-passivated and passivated oils); - definitions of additives in oil; and - re-insertion of a missing note on oxidation.

IEC 60296:2012 is now available as IEC Standards+ 60296:2012 which contains the International Standard and its Redline version, showing all changes of the technical content compared to the previous edition. IEC 60296:2012 is applicable to specifications and test methods for unused mineral insulating oils. It applies to oil intended for use in transformers, switchgear and similar electrical equipment in which oil is required for insulation and heat transfer. This edition includes the following significant technical changes with respect to the previous edition: - specifications for corrosive sulphur compounds that can lead to copper sulphide deposition in transformers (in non-passivated and passivated oils); - definitions of additives in oil; and - re-insertion of a missing note on oxidation.

IEC 60296:2012 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 29.040.10 - Insulating oils. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60296:2012 has the following relationships with other standards: It is inter standard links to EN ISO 24022-2:2020, EN ISO 21305-2:2019, EN ISO 20557-2:2018, EN ISO 7792-2:2012, EN ISO 1874-2:2012, EN ISO 20028-2:2017, EN ISO 21306-2:2019, EN ISO 24025-2:2020, EN ISO 20558-2:2019, EN ISO 17855-2:2016, EN ISO 19069-2:2016, EN ISO 21970-2:2018, EN ISO 19064-2:2020, EN ISO 23153-2:2020, EN ISO 19066-2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60296:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60296 ®

Edition 4.0 2012-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

Fluides pour applications électrotechniques – Huiles minérales isolantes neuves

pour transformateurs et appareillages de connexion

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60296 ®

Edition 4.0 2012-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

Fluides pour applications électrotechniques – Huiles minérales isolantes neuves

pour transformateurs et appareillages de connexion

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.040 ISBN 978-2-8891-2928-7

IEC 60296 ®

Edition 4.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

Fluides pour applications électrotechniques – Huiles minérales isolantes neuves

pour transformateurs et appareillages de connexion

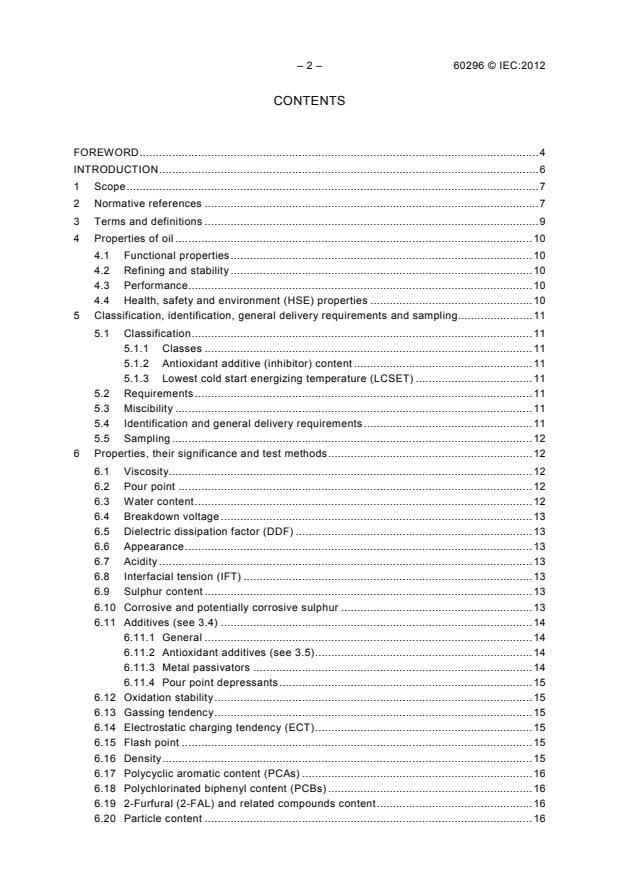

– 2 – 60296 © IEC:2012

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Properties of oil . 10

4.1 Functional properties . 10

4.2 Refining and stability . 10

4.3 Performance . 10

4.4 Health, safety and environment (HSE) properties . 10

5 Classification, identification, general delivery requirements and sampling. 11

5.1 Classification . 11

5.1.1 Classes . 11

5.1.2 Antioxidant additive (inhibitor) content . 11

5.1.3 Lowest cold start energizing temperature (LCSET) . 11

5.2 Requirements . 11

5.3 Miscibility . 11

5.4 Identification and general delivery requirements . 11

5.5 Sampling . 12

6 Properties, their significance and test methods . 12

6.1 Viscosity. 12

6.2 Pour point . 12

6.3 Water content . 12

6.4 Breakdown voltage . 13

6.5 Dielectric dissipation factor (DDF) . 13

6.6 Appearance . 13

6.7 Acidity . 13

6.8 Interfacial tension (IFT) . 13

6.9 Sulphur content . 13

6.10 Corrosive and potentially corrosive sulphur . 13

6.11 Additives (see 3.4) . 14

6.11.1 General . 14

6.11.2 Antioxidant additives (see 3.5) . 14

6.11.3 Metal passivators . 14

6.11.4 Pour point depressants . 15

6.12 Oxidation stability . 15

6.13 Gassing tendency . 15

6.14 Electrostatic charging tendency (ECT) . 15

6.15 Flash point . 15

6.16 Density . 15

6.17 Polycyclic aromatic content (PCAs) . 16

6.18 Polychlorinated biphenyl content (PCBs) . 16

6.19 2-Furfural (2-FAL) and related compounds content . 16

6.20 Particle content . 16

60296 © IEC:2012 – 3 –

6.21 DBDS content . 16

6.22 Stray gassing of oil . 16

7 Specific requirements for special applications . 18

7.1 Higher oxidation stability and low sulphur content . 18

7.2 Electrostatic charging tendency (ECT) . 18

7.3 Gassing tendency . 18

Annex A (informative) Potentially corrosive sulphur . 19

Bibliography . 21

Table 1 – Maximum viscosity and pour point of transformer oil at lowest cold start

energizing temperature (LCSET) . 12

Table 2 – General specifications . 17

– 4 – 60296 © IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FLUIDS FOR ELECTROTECHNICAL APPLICATIONS –

UNUSED MINERAL INSULATING OILS FOR

TRANSFORMERS AND SWITCHGEAR

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60296 has been prepared by IEC technical committee 10: Fluids

for electrotechnical applications.

This fourth edition cancels and replaces the third edition, published in 2003. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– specifications for corrosive sulphur compounds that can lead to copper sulphide

deposition in transformers (in non-passivated and passivated oils);

– definitions of additives in oil; and

– re-insertion of a missing note on oxidation.

60296 © IEC:2012 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

10/878/FDIS 10/885/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60296 © IEC:2012

INTRODUCTION

This International Standard does not purport to address all the safety problems associated

with its use. It is the responsibility of the user of the standard to establish appropriate health

and safety practices and determine the applicability of regulatory limitations prior to use.

The mineral insulating oils which are the subject of this standard should be handled with due

regard to personal hygiene. Direct contact with the eyes may cause irritation. In the case of

eye contact, irrigation with copious quantities of clean running water should be carried out

and medical advice sought. Some of the tests specified in this standard involve the use of

processes that could lead to a hazardous situation. Attention is drawn to the relevant standard

for guidance.

This standard is applicable to mineral insulating oils, chemicals and used sample containers.

The disposal of these items should be carried out according to local regulations with regard to

their impact on the environment. Every precaution should be taken to prevent release of

mineral insulating oil into the environment.

60296 © IEC:2012 – 7 –

FLUIDS FOR ELECTROTECHNICAL APPLICATIONS –

UNUSED MINERAL INSULATING OILS FOR

TRANSFORMERS AND SWITCHGEAR

1 Scope

This International Standard is applicable to specifications and test methods for unused

mineral insulating oils (see Clause 3 for definitions). It applies to oil delivered to the agreed

point and time of delivery, intended for use in transformers, switchgear and similar electrical

equipment in which oil is required for insulation and heat transfer. These oils are obtained by

refining, modifying and/or blending of petroleum products and other hydrocarbons.

Oils with and without additives are both within the scope of this standard.

This standard is applicable only to unused mineral insulating oils.

Recycled oils are beyond the scope of this standard.

NOTE Definitions and specifications for recycled oils will be covered by IEC 62701 .

This standard does not apply to mineral insulating oils used as impregnants in cables or

capacitors.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60076-2, Power transformers – Part 2: Temperature rise for liquid-immersed transformers

IEC 60156, Insulating liquids – Determination of the breakdown voltage at power frequency –

Test method

IEC 60247, Insulating liquids – Measurement of relative permittivity, dielectric dissipation

factor (tan δ) and d.c. resistivity

IEC 60422, Mineral insulating oils in electrical equipment – Supervision and maintenance

guidance

IEC 60475, Method of sampling liquid dielectrics

IEC 60628:1985, Gassing of insulating liquids under electrical stress and ionization

IEC 60666, Detection and determination of specified additives in mineral insulating oils

IEC 60814, Insulating liquids – Oil-impregnated paper and pressboard – Determination of

water by automatic coulometric Karl Fischer titration

—————————

In preparation.

– 8 – 60296 © IEC:2012

IEC 60970, Insulating liquids – Methods for counting and sizing particles

IEC 61125:1992, Unused hydrocarbon-based insulating liquids – Test methods for evaluating

the oxidation stability

Amendment 1 (2004)

IEC 61198, Mineral insulating oils – Methods for the determination of 2-furfural and related

compounds

IEC 61619, Insulating liquids – Contamination by polychlorinated biphenyls (PCBs) – Method

of determination by capillary column gas chromatography

IEC 61620, Insulating liquids – Determination of the dielectric dissipation factor by

measurement of the conductance and capacitance – Test method

IEC 61868, Mineral insulating oils – Determination of kinematic viscosity at very low

temperatures

IEC 62021-1, Insulating liquids – Determination of acidity – Part 1: Automatic potentiometric

titration

IEC 62021-2, Insulating liquids – Determination of acidity – Part 2: Colourimetric titration

IEC 62535:2008, Insulating liquids – Test method for detection of potentially corrosive sulphur

in used and unused insulating oils

ISO 2719, Determination of flash point – Pensky-Martens closed cup method

ISO 3016, Petroleum products – Determination of pour point

ISO 3104, Petroleum products – Transparent and opaque liquids – Determination of kinematic

viscosity and calculation of dynamic viscosity

ISO 3675, Crude petroleum and liquid petroleum products – Laboratory determination of

density – Hydrometer method

ISO 12185, Crude petroleum and petroleum products – Determination of density – Oscillating

U-tube method

ISO 14596, Petroleum products – Determination of sulfur content – Wavelength-dispersive X-

ray fluorescence spectrometry

ASTM D971, Standard Test Method for Interfacial Tension of Oil Against Water by the Ring

Method

ASTM D7150, Standard Test Method for the Determination of Gassing Characteristics of

Insulating Liquids Under Thermal Stress at Low temperature

DIN 51353, Testing of insulating oils; detection of corrosive sulfur; Silver strip test

EN 14210, Surface active agents – Determination of interfacial tension of solutions of surface

active agents by the stirrup or ring method

IP 346, Determination of polycyclic aromatics in lubricant base oils and asphaltene free

petroleum fractions – Dimethylsulfoxide refractive method

60296 © IEC:2012 – 9 –

IP 373, Determination of the sulphur content of light and middle distillates – Oxidative

microcoulometry

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

transformer oil

mineral insulating oil for transformers and similar electrical equipment

3.2

low temperature switchgear oil

mineral insulating oil for oil-filled switchgear for outdoor application in very cold climatic

conditions

3.3

mineral insulating oil

insulating oil obtained by refining, modifying and/or blending of petroleum products and other

hydrocarbons

Note 1 to entry This does not include insulating liquids such as esters, synthetic aromatics or silicone fluids.

3.4

additive

chemical substance that is added to mineral insulating oil in order to improve certain

characteristics

Note 1 to entry Examples include antioxidants, metal passivators, metal deactivators, electrostatic charging

tendency depressants, gas absorbers, pour point depressants, anti-foam agents and refining process improvers.

3.5

antioxidant additive

additive incorporated in mineral insulating oil that improves oxidation stability

Note 1 to entry A large number of additives which improve oxidation stability, including inhibitors, peroxide

decomposers, metal passivators and metal deactivators, are available and may be used in oils if declared (see

6.11.1 and 6.11.2).

3.5.1

inhibitor

antioxidant additives of the phenolic-or amine- type, such as DBPC and DBP described in

IEC 60666

Note 1 to entry DBPC = 2,6-di-tert-butyl-para-cresol; DBP = 2,6-di-tert-butyl-phenol.

3.5.2

other antioxidant additive

antioxidant additive of the sulphur- or phosphorous- type

3.5.3

passivator

metal passivator additive used primarily as electrostatic charging depressant, but which may

also improve oxidation stability

Note 1 to entry Metal passivators are sometimes described as metal deactivators or corrosion inhibitors.

3.6

uninhibited oil

mineral insulating oil containing no inhibitor

– 10 – 60296 © IEC:2012

Note 1 to entry No inhibitor means that the total inhibitor content is below the detection limit of 0,01 % indicated

in IEC 60666.

3.7

trace inhibited oil

mineral insulating oil containing less than 0,08 % of total inhibitor content as measured by

IEC 60666

3.8

inhibited oil

mineral insulating oil containing a minimum of 0,08 % and a maximum of 0,40 % of total

inhibitor content as measured by IEC 60666

3.9

unused mineral insulating oil

mineral insulating oil not recycled as delivered by the supplier

Note 1 to entry Such an oil has not been used in, nor been in contact with electrical equipment or other equipment

not required for manufacture, storage or transport. The manufacturer and supplier of unused oil will have taken all

reasonable precautions to ensure that there is no contamination with polychlorinated biphenyls or terphenyls (PCB,

PCT), used, reclaimed or dechlorinated oil or other contaminants.

Note 2 to entry The definition of recycled oils will be given in IEC 62701 (in preparation).

Note 3 to entry A blend of unused and recycled oil in any proportion is regarded as being recycled.

4 Properties of oil

NOTE Oil characteristics are listed in Tables 1 and 2 and in Clause 6.

4.1 Functional properties

Properties of oil that have an impact on its function as an insulating and cooling liquid.

NOTE Functional properties include viscosity, density, pour point, water content, breakdown voltage and dielectric

dissipation factor.

4.2 Refining and stability

Properties of oil that are influenced by quality and type of refining and additives.

NOTE These can include appearance, interfacial tension, sulphur content, acidity, corrosive sulphur, 2-furfural

and related compounds content and stray gassing.

4.3 Performance

Properties that are related to the long-term behaviour of oil in service and/or its reaction to

high electric stress and temperature.

NOTE Examples include oxidation stability, gassing tendency and electrostatic charging tendency (ECT).

4.4 Health, safety and environment (HSE) properties

Oil properties related to safe handling and environment protection.

NOTE Examples can include flash point, density, PCA (polycyclic aromatics) and PCB/PCT (polychlorinated

biphenyls/ terphenyls).

60296 © IEC:2012 – 11 –

5 Classification, identification, general delivery requirements and sampling

5.1 Classification

5.1.1 Classes

For the purposes of this standard, mineral insulating oils are classified into two classes:

– transformer oils;

– low temperature switchgear oils.

5.1.2 Antioxidant additive (inhibitor) content

Transformer oils are classified into three groups, according to their content of antioxidant

additive:

– uninhibited transformer oils: marked with U;

– trace inhibited transformer oils: marked with T;

– inhibited transformer oils: marked with I.

5.1.3 Lowest cold start energizing temperature (LCSET)

After the inhibitor marking, the LCSET shall be indicated.

Standard LCSET in this standard is –30 °C; optionally, other LCSET can be selected

according to Table 1.

5.2 Requirements

General requirements of this standard are given in Table 2.

Specific requirements are defined under Clause 7.

5.3 Miscibility

Unused mineral insulating oils of the same class (5.1.1), the same group (5.1.2), same

LCSET (5.1.3) and containing the same types of additives are considered to be miscible and

compatible with each other (see IEC 60422).

5.4 Identification and general delivery requirements

Identification and general delivery requirements are as follows:

a) Oil is normally delivered in bulk, rail tank cars, tank containers or packed in drums or IBC

(intermediate bulk containers). These shall be clean and suitable for this purpose to avoid

any contamination.

b) Oil drums and sample containers shall carry at least the following markings:

– supplier's designation;

– classification (see 5.1);

– oil quantity.

c) As agreed between the supplier and purchaser each oil delivery may be accompanied by a

document specifying the supplier’s designation, oil classification and compliance

certificate.

NOTE This standard may be traceable to a specific batch of oil processed.

– 12 – 60296 © IEC:2012

d) The supplier shall declare the generic type of all additives, and their concentrations in the

cases of inhibitors and passivators.

5.5 Sampling

Sampling shall be carried out in accordance with the procedure described in IEC 60475.

6 Properties, their significance and test methods

6.1 Viscosity

Viscosity influences heat transfer and therefore the temperature rise of the equipment.

The lower the viscosity, the easier the oil circulates leading to improved heat transfer. At low

temperatures, the resulting higher viscosity of oil is a critical factor for the cold start of

transformers with poor or no circulation of oil and therefore possible overheating at the hot

spots, and negatively influences the speed of moving parts such as in power circuit breakers,

switchgear, on-load tap changer mechanisms, pumps and regulators. The viscosity at the

lowest cold start energizing temperature (LCSET) shall not exceed 1 800 mm /s (respectively

/s at –40 °C, see Table 1). This lowest cold start energizing temperature (LCSET)

2 500 mm

for transformer oils is defined in this standard as being –30 °C (this is 5 K lower than

indicated in IEC 60076-2). Other LCSET (see Table 1) can be agreed between supplier and

purchaser.

Low temperature switchgear oil should have a lower viscosity at LCSET: max. 400 mm /s.

Standard LCSET of low temperature switchgear oil is defined at –40 °C but other LCSET may

be agreed between supplier and purchaser.

Table 1 – Maximum viscosity and pour point of transformer oil

at lowest cold start energizing temperature (LCSET)

LCSET Maximum viscosity Maximum pour point

°C mm /s °C

0 1 800 –10

–20 1 800 –30

–30 1 800 –40

–40 2 500 –50

Viscosity shall be measured according to ISO 3104, and viscosity at very low temperatures

according to IEC 61868.

6.2 Pour point

The pour point of mineral insulating oil is the lowest temperature at which the oil will just flow.

It is recommended that the pour point should be at least 10 K below the lowest cold start

energizing temperature (LCSET). If a pour point depressant additive is used, this shall be

declared by the supplier to the user. Pour point shall be measured in accordance with

ISO 3016.

6.3 Water content

A low water content of mineral insulating oil is necessary to achieve adequate breakdown

voltage and low dissipation losses. To avoid separation of free water, unused insulating oil

should have limited water content. Before filling the electrical equipment, the oil should be

treated to meet the requirements of IEC 60422. Water content shall be measured in

accordance with IEC 60814.

60296 © IEC:2012 – 13 –

6.4 Breakdown voltage

The breakdown voltage of transformer oil indicates its ability to resist electrical stress in

electrical equipment. Breakdown voltage shall be measured in accordance with IEC 60156.

The supplier shall demonstrate that after treatment to reduce particles, water and dissolved

air by a vacuum procedure (see note), the oil shall have a high dielectric strength (breakdown

voltage >70 kV).

NOTE This treatment referred to consists of filtration of the oil at 60 °C by vacuum (pressure below 2,5 kPa)

through a sintered glass filter (with a maximum pore size of 2,5 µm).

6.5 Dielectric dissipation factor (DDF)

DDF is a measure for dielectric losses within the oil. DDF values above requirements of

Table 2 can indicate contamination of the oil by polar contaminants or poor refining quality.

DDF shall be measured in accordance with IEC 60247 or IEC 61620 at 90 °C. In case of

dispute, IEC 60247 at 90 °C should be used.

NOTE By agreement between parties, DDF can be measured at temperatures other than 90 °C. In such cases the

temperature of measurement can be stated in the report.

6.6 Appearance

A visual inspection of insulating oil (oil sample in transmitted light under a thickness of

approximately 10 cm and at ambient temperature) will indicate the presence of visible

contaminants, free water or suspended matter.

6.7 Acidity

Unused mineral insulating oil should be free from any acidic compound. Acidity shall be

measured according to IEC 62021-1 or IEC 62021-2.

6.8 Interfacial tension (IFT)

Low IFT sometimes indicates the presence of polar compounds. IFT shall be measured in

accordance with EN 14210 or ASTM D971.

6.9 Sulphur content

Different organo-sulphur compounds are present in mineral oils, dependent on the crude oil

origin and the degree and type of refining. Refining reduces the content of sulphur and

aromatic hydrocarbons. As some naturally present sulphur compounds have an affinity to

metals, they may act as natural oxidation inhibitors or they may promote corrosion.

Sulphur content is a specific requirement of 7.1.

Sulphur content should be measured following IP 373 or ISO 14596.

6.10 Corrosive and potentially corrosive sulphur

Some sulphur compounds, e.g. mercaptans, are very corrosive to metal surfaces, i.e. steel,

copper and silver (switchgear contacts) and shall not be present in new oil. This type of

corrosive sulphur should be detected following DIN 51353.

Some other sulphur compounds, e.g. dibenzyldisulphide (DBDS), may result in the deposition

S) in paper insulation, reducing its electrical insulation properties (see

of copper sulphide (Cu

Annex A). This has resulted in several equipment failures in service.

– 14 – 60296 © IEC:2012

IEC 62535, based on work performed by CIGRE WG A2.32, provides the best currently

available method to detect potentially corrosive sulphur compounds in oil. It applies only to

oils that do not contain a metal passivator additive (declared or undeclared).

For passivator-containing oils, see Clause A.3.

6.11 Additives (see 3.4)

6.11.1 General

The generic type of all additives shall be declared in product data sheets and certificates of

compliance. For antioxidant additives and passivators, their concentrations shall also be

stated.

6.11.2 Antioxidant additives (see 3.5)

Antioxidants slow down the oxidation of oil and therefore the formation of degradation

products such as oil sludge and acidity. It is useful to know whether and in what proportion

antioxidant additives have been added in order to monitor additive depletion during service.

Additives that slow down the oxidation of mineral insulating oils include:

– inhibitors such as phenols and amines (see 3.5.1). The most widely used inhibitors are

DBPC and DBP (see 3.5.1). Detection and measurement of DBPC and DBP shall be

carried out in accordance with IEC 60666. IEC test methods are not available for other

types of inhibitors.

– other antioxidant additives such as sulphur- and phosphor- containing compounds, e.g.

organic polysulfides and dithiophosphates (see 3.5.2). An antioxidant additive of this type

is DBDS (see 6.10), but it is not accepted as it is known to be corrosive to copper and will

likely result in the oil failing the potentially corrosive sulphur test of IEC 62535. IEC test

methods are in preparation only for DBDS (see 6.21) and not for the other antioxidant

additives of this type.

– metal passivators (see 6.11.3).

6.11.3 Metal passivators

Some of these additives form thin films on copper, preventing the catalytic effect of copper in

oil and the formation of harmful copper sulphide deposits in paper by reaction with corrosive

sulphur compounds contained in the oil. Some of them protect the oil from the catalytic action

of metals and slow down the rate of oxidation of oil. Passivators therefore slow down the

oxidation process in IEC 61125 as they passivate the surface of the catalysing copper-wire,

thus leading to an optimistic result of the oxidation stability test. Some of them are also used

to reduce the electrostatic charging tendency of oils (see 6.14).

Three main types of benzotriazole derivatives are typically used as metal passivator additives:

N-bis(2-Ethylhexyl)-aminomethyl-tolutriazole (TTAA), benzotriazole (BTA) and

5-methyl-1H-benzotriazole (TTA). Detection and measurement of these additives shall be

according to IEC 60666.

Several other compounds can be used as metal passivator additives, such as

N,N-bis(2-ethylhexyl)-1H-1,2,4-triazole-1 methanamine (TAA), diamino-diphenyldisulphide,

nicotinic acid, hydroquinoline and other sulphur-based compounds, for which no IEC test

methods are available .

—————————

Examples of commercially available TTAA and TAA are Irgamet 39 © and Irgamet 30 ©, respectively. This

information is given for the convenience of users of this standard and does not constitute an endorsement by

the IEC of these products.

60296 © IEC:2012 – 15 –

6.11.4 Pour point depressants

These additives are used to improve the viscosity and pour point of oils at very low

temperatures. Detection and measurement of the two main types of pour point depressant

additives used (polynaphthalenes and polymethacrylates) shall be according to IEC 60666.

6.12 Oxidation stability

Oxidation of oil gives rise to acidity and sludge formation. This can be reduced by using oils

with a high oxidation stability leading to longer service life time by minimizing sludge

deposition and maximizing insulation life. Oxidation stability is measured in accordance with

Method C of IEC 61125:1992. There is an option for stricter limits for special applications. In

some countries more stringent limits and/or additional requirements and tests may be

requested.

Test durations for oils containing inhibitors shall be as indicated in Table 2. Test duration for

oils containing other antioxidant additives and metal passivators shall be 500 h.

Passivator-containing oils shall be tested for oxidation stability before the passivator additive

has been added to the oil (when possible), using the test durations of Table 2 .

6.13 Gassing tendency

Gassing tendency of mineral insulating oil, i.e. the gas absorbing property of oil when

subjected to corona partial discharges, is only necessary and important for special equipment

like HV (high voltage) instrument transformers and bushings. It is a measure of the rate of

absorption or evolution of gas into oil under prescribed laboratory conditions. Gas absorption

properties could be related to oil aromatic content. Gassing tendency is measured using

Method A of IEC 60628:1985.

Gassing tendency testing is a specific requirement of 7.3.

NOTE Additives such as 1,2,3,4- tetrahydronaphtalene (tetralin), mono or dibenzyltoluene and others have been

proposed to reduce the gassing tendency of some oils, but are not described in IEC 60666. Mono and

dibenzyltoluene are described in IEC 60867.

6.14 Electrostatic charging tendency (ECT)

ECT of oil is an important property for certain designs of HV and EHV transformers which

have oil pumping rates that can give rise to the build-up of electrostatic charge. This charge

can result in energy discharge causing transformer failure.

ECT testing is a specific requirement of 7.2.

NOTE A method to measure ECT is proposed by CIGRE Technical Brochure 170. ECT can be reduced by using

metal passivator additives such as BTA and TTA.

6.15 Flash point

The safe operation of electrical equipment requires an adequately high flash point that is

measured in accordance with ISO 2719 (Pensky-Martens closed cup procedure).

6.16 Density

In cold climates, density of oil shall be low enough to avoid the ice that results from the

freezing of free water to float to the oil surface and possibly lead to fault conditions

—————————

Alternatively, passivator-containing oils may be tested for oxidation stability AFTER the passivator additive

has been removed by absorption from the oil, using for example Procedure 1 of Clause A.3.

– 16 – 60296 © IEC:2012

developing such as flashover of conductors. Density shall be measured in accordance with

ISO 3675 (reference method) but ISO 12185 as well is accepted.

6.17 Polycyclic aromatic content (PCAs)

Some PCAs are classified to be carcinogens and therefore need to be controlled to an

acceptable level in mineral insulating oil. The total amount of PCAs can be measured by

extraction with DMSO (dimethylsulfoxide) under the conditions of IP 346.

NOTE Acceptable limits of total or individual PCAs are specified in national and local regulations.

6.18 Polychlorinated biphenyl content (PCBs)

Unused mineral insulating oil shall be free from PCBs. The reference test method is

IEC 61619.

NOTE Acceptable limits of total or individual PCBs are specified in national and local regulations. Further

European specifications are described in Directive 96/59/EC.

6.19 2-Furfural (2-FAL) and related compounds content

2-FAL and related compounds in unused mineral insulating oils can result either from

improper re-distillation after solvent extraction during refining or from contamination with used

oil.

Unused mineral insulating oils should have a low level of 2-FAL and related compounds;

measurement should be carried out according to IEC 61198.

NOTE “Related compounds” are: 5-hydroxymethyl-2-furfural (5HMF), 2-furfurylalcohol (2FOL), 2-acetylfuran

(2ACF) and 5-methyl-2-furfural (5MEF).

6.20 Particle content

Particles in unused mineral insulating oil may result from manufacturing, storage or handling

of the oil, and may affect its breakdown voltage (see 6.4). Measurement should be carried out

according to IEC 60970.

6.21 DBDS content

This compound is corrosive at normal transformer operating temperatures and can produce

copper sulphide. It therefore shall not be present in unused oil (see 6.10). For the test method

for measuring DBDS, see IEC 62697-1 (in preparation).

6.22 Stray gassing of oil

Some oils can produce gases such as hydrogen, hydrocarbons and carbon oxides at low

temperatures (< 120 °C) without thermal or electrical faults in a transformer, sometimes even

without operational stress. This phenomenon could result in a high production of gases and a

misinterpretation of DGA results.

NOTE Methods to measure stray gassing are described in C

...

IEC 60296 ®

Edition 4.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

Fluides pour applications électrotechniques – Huiles minérales isolantes neuves

pour transformateurs et appareillages de connexion

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60296 ®

Edition 4.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

Fluides pour applications électrotechniques – Huiles minérales isolantes neuves

pour transformateurs et appareillages de connexion

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 29.040 ISBN 978-2-88912-928-7

– 2 – 60296 © IEC:2012

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Properties of oil . 10

4.1 Functional properties . 10

4.2 Refining and stability . 10

4.3 Performance . 10

4.4 Health, safety and environment (HSE) properties . 10

5 Classification, identification, general delivery requirements and sampling. 11

5.1 Classification . 11

5.1.1 Classes . 11

5.1.2 Antioxidant additive (inhibitor) content . 11

5.1.3 Lowest cold start energizing temperature (LCSET) . 11

5.2 Requirements . 11

5.3 Miscibility . 11

5.4 Identification and general delivery requirements . 11

5.5 Sampling . 12

6 Properties, their significance and test methods . 12

6.1 Viscosity. 12

6.2 Pour point . 12

6.3 Water content . 12

6.4 Breakdown voltage . 13

6.5 Dielectric dissipation factor (DDF) . 13

6.6 Appearance . 13

6.7 Acidity . 13

6.8 Interfacial tension (IFT) . 13

6.9 Sulphur content . 13

6.10 Corrosive and potentially corrosive sulphur . 13

6.11 Additives (see 3.4) . 14

6.11.1 General . 14

6.11.2 Antioxidant additives (see 3.5) . 14

6.11.3 Metal passivators . 14

6.11.4 Pour point depressants . 15

6.12 Oxidation stability . 15

6.13 Gassing tendency . 15

6.14 Electrostatic charging tendency (ECT) . 15

6.15 Flash point . 15

6.16 Density . 15

6.17 Polycyclic aromatic content (PCAs) . 16

6.18 Polychlorinated biphenyl content (PCBs) . 16

6.19 2-Furfural (2-FAL) and related compounds content . 16

6.20 Particle content . 16

60296 © IEC:2012 – 3 –

6.21 DBDS content . 16

6.22 Stray gassing of oil . 16

7 Specific requirements for special applications . 18

7.1 Higher oxidation stability and low sulphur content . 18

7.2 Electrostatic charging tendency (ECT) . 18

7.3 Gassing tendency . 18

Annex A (informative) Potentially corrosive sulphur . 19

Bibliography . 21

Table 1 – Maximum viscosity and pour point of transformer oil at lowest cold start

energizing temperature (LCSET) . 12

Table 2 – General specifications . 17

– 4 – 60296 © IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FLUIDS FOR ELECTROTECHNICAL APPLICATIONS –

UNUSED MINERAL INSULATING OILS FOR

TRANSFORMERS AND SWITCHGEAR

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60296 has been prepared by IEC technical committee 10: Fluids

for electrotechnical applications.

This fourth edition cancels and replaces the third edition, published in 2003. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– specifications for corrosive sulphur compounds that can lead to copper sulphide

deposition in transformers (in non-passivated and passivated oils);

– definitions of additives in oil; and

– re-insertion of a missing note on oxidation.

60296 © IEC:2012 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

10/878/FDIS 10/885/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60296 © IEC:2012

INTRODUCTION

This International Standard does not purport to address all the safety problems associated

with its use. It is the responsibility of the user of the standard to establish appropriate health

and safety practices and determine the applicability of regulatory limitations prior to use.

The mineral insulating oils which are the subject of this standard should be handled with due

regard to personal hygiene. Direct contact with the eyes may cause irritation. In the case of

eye contact, irrigation with copious quantities of clean running water should be carried out

and medical advice sought. Some of the tests specified in this standard involve the use of

processes that could lead to a hazardous situation. Attention is drawn to the relevant standard

for guidance.

This standard is applicable to mineral insulating oils, chemicals and used sample containers.

The disposal of these items should be carried out according to local regulations with regard to

their impact on the environment. Every precaution should be taken to prevent release of

mineral insulating oil into the environment.

60296 © IEC:2012 – 7 –

FLUIDS FOR ELECTROTECHNICAL APPLICATIONS –

UNUSED MINERAL INSULATING OILS FOR

TRANSFORMERS AND SWITCHGEAR

1 Scope

This International Standard is applicable to specifications and test methods for unused

mineral insulating oils (see Clause 3 for definitions). It applies to oil delivered to the agreed

point and time of delivery, intended for use in transformers, switchgear and similar electrical

equipment in which oil is required for insulation and heat transfer. These oils are obtained by

refining, modifying and/or blending of petroleum products and other hydrocarbons.

Oils with and without additives are both within the scope of this standard.

This standard is applicable only to unused mineral insulating oils.

Recycled oils are beyond the scope of this standard.

NOTE Definitions and specifications for recycled oils will be covered by IEC 62701 .

This standard does not apply to mineral insulating oils used as impregnants in cables or

capacitors.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60076-2, Power transformers – Part 2: Temperature rise for liquid-immersed transformers

IEC 60156, Insulating liquids – Determination of the breakdown voltage at power frequency –

Test method

IEC 60247, Insulating liquids – Measurement of relative permittivity, dielectric dissipation

factor (tan δ) and d.c. resistivity

IEC 60422, Mineral insulating oils in electrical equipment – Supervision and maintenance

guidance

IEC 60475, Method of sampling liquid dielectrics

IEC 60628:1985, Gassing of insulating liquids under electrical stress and ionization

IEC 60666, Detection and determination of specified additives in mineral insulating oils

IEC 60814, Insulating liquids – Oil-impregnated paper and pressboard – Determination of

water by automatic coulometric Karl Fischer titration

—————————

In preparation.

– 8 – 60296 © IEC:2012

IEC 60970, Insulating liquids – Methods for counting and sizing particles

IEC 61125:1992, Unused hydrocarbon-based insulating liquids – Test methods for evaluating

the oxidation stability

Amendment 1 (2004)

IEC 61198, Mineral insulating oils – Methods for the determination of 2-furfural and related

compounds

IEC 61619, Insulating liquids – Contamination by polychlorinated biphenyls (PCBs) – Method

of determination by capillary column gas chromatography

IEC 61620, Insulating liquids – Determination of the dielectric dissipation factor by

measurement of the conductance and capacitance – Test method

IEC 61868, Mineral insulating oils – Determination of kinematic viscosity at very low

temperatures

IEC 62021-1, Insulating liquids – Determination of acidity – Part 1: Automatic potentiometric

titration

IEC 62021-2, Insulating liquids – Determination of acidity – Part 2: Colourimetric titration

IEC 62535:2008, Insulating liquids – Test method for detection of potentially corrosive sulphur

in used and unused insulating oils

ISO 2719, Determination of flash point – Pensky-Martens closed cup method

ISO 3016, Petroleum products – Determination of pour point

ISO 3104, Petroleum products – Transparent and opaque liquids – Determination of kinematic

viscosity and calculation of dynamic viscosity

ISO 3675, Crude petroleum and liquid petroleum products – Laboratory determination of

density – Hydrometer method

ISO 12185, Crude petroleum and petroleum products – Determination of density – Oscillating

U-tube method

ISO 14596, Petroleum products – Determination of sulfur content – Wavelength-dispersive X-

ray fluorescence spectrometry

ASTM D971, Standard Test Method for Interfacial Tension of Oil Against Water by the Ring

Method

ASTM D7150, Standard Test Method for the Determination of Gassing Characteristics of

Insulating Liquids Under Thermal Stress at Low temperature

DIN 51353, Testing of insulating oils; detection of corrosive sulfur; Silver strip test

EN 14210, Surface active agents – Determination of interfacial tension of solutions of surface

active agents by the stirrup or ring method

IP 346, Determination of polycyclic aromatics in lubricant base oils and asphaltene free

petroleum fractions – Dimethylsulfoxide refractive method

60296 © IEC:2012 – 9 –

IP 373, Determination of the sulphur content of light and middle distillates – Oxidative

microcoulometry

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

transformer oil

mineral insulating oil for transformers and similar electrical equipment

3.2

low temperature switchgear oil

mineral insulating oil for oil-filled switchgear for outdoor application in very cold climatic

conditions

3.3

mineral insulating oil

insulating oil obtained by refining, modifying and/or blending of petroleum products and other

hydrocarbons

Note 1 to entry This does not include insulating liquids such as esters, synthetic aromatics or silicone fluids.

3.4

additive

chemical substance that is added to mineral insulating oil in order to improve certain

characteristics

Note 1 to entry Examples include antioxidants, metal passivators, metal deactivators, electrostatic charging

tendency depressants, gas absorbers, pour point depressants, anti-foam agents and refining process improvers.

3.5

antioxidant additive

additive incorporated in mineral insulating oil that improves oxidation stability

Note 1 to entry A large number of additives which improve oxidation stability, including inhibitors, peroxide

decomposers, metal passivators and metal deactivators, are available and may be used in oils if declared (see

6.11.1 and 6.11.2).

3.5.1

inhibitor

antioxidant additives of the phenolic-or amine- type, such as DBPC and DBP described in

IEC 60666

Note 1 to entry DBPC = 2,6-di-tert-butyl-para-cresol; DBP = 2,6-di-tert-butyl-phenol.

3.5.2

other antioxidant additive

antioxidant additive of the sulphur- or phosphorous- type

3.5.3

passivator

metal passivator additive used primarily as electrostatic charging depressant, but which may

also improve oxidation stability

Note 1 to entry Metal passivators are sometimes described as metal deactivators or corrosion inhibitors.

3.6

uninhibited oil

mineral insulating oil containing no inhibitor

– 10 – 60296 © IEC:2012

Note 1 to entry No inhibitor means that the total inhibitor content is below the detection limit of 0,01 % indicated

in IEC 60666.

3.7

trace inhibited oil

mineral insulating oil containing less than 0,08 % of total inhibitor content as measured by

IEC 60666

3.8

inhibited oil

mineral insulating oil containing a minimum of 0,08 % and a maximum of 0,40 % of total

inhibitor content as measured by IEC 60666

3.9

unused mineral insulating oil

mineral insulating oil not recycled as delivered by the supplier

Note 1 to entry Such an oil has not been used in, nor been in contact with electrical equipment or other equipment

not required for manufacture, storage or transport. The manufacturer and supplier of unused oil will have taken all

reasonable precautions to ensure that there is no contamination with polychlorinated biphenyls or terphenyls (PCB,

PCT), used, reclaimed or dechlorinated oil or other contaminants.

Note 2 to entry The definition of recycled oils will be given in IEC 62701 (in preparation).

Note 3 to entry A blend of unused and recycled oil in any proportion is regarded as being recycled.

4 Properties of oil

NOTE Oil characteristics are listed in Tables 1 and 2 and in Clause 6.

4.1 Functional properties

Properties of oil that have an impact on its function as an insulating and cooling liquid.

NOTE Functional properties include viscosity, density, pour point, water content, breakdown voltage and dielectric

dissipation factor.

4.2 Refining and stability

Properties of oil that are influenced by quality and type of refining and additives.

NOTE These can include appearance, interfacial tension, sulphur content, acidity, corrosive sulphur, 2-furfural

and related compounds content and stray gassing.

4.3 Performance

Properties that are related to the long-term behaviour of oil in service and/or its reaction to

high electric stress and temperature.

NOTE Examples include oxidation stability, gassing tendency and electrostatic charging tendency (ECT).

4.4 Health, safety and environment (HSE) properties

Oil properties related to safe handling and environment protection.

NOTE Examples can include flash point, density, PCA (polycyclic aromatics) and PCB/PCT (polychlorinated

biphenyls/ terphenyls).

60296 © IEC:2012 – 11 –

5 Classification, identification, general delivery requirements and sampling

5.1 Classification

5.1.1 Classes

For the purposes of this standard, mineral insulating oils are classified into two classes:

– transformer oils;

– low temperature switchgear oils.

5.1.2 Antioxidant additive (inhibitor) content

Transformer oils are classified into three groups, according to their content of antioxidant

additive:

– uninhibited transformer oils: marked with U;

– trace inhibited transformer oils: marked with T;

– inhibited transformer oils: marked with I.

5.1.3 Lowest cold start energizing temperature (LCSET)

After the inhibitor marking, the LCSET shall be indicated.

Standard LCSET in this standard is –30 °C; optionally, other LCSET can be selected

according to Table 1.

5.2 Requirements

General requirements of this standard are given in Table 2.

Specific requirements are defined under Clause 7.

5.3 Miscibility

Unused mineral insulating oils of the same class (5.1.1), the same group (5.1.2), same

LCSET (5.1.3) and containing the same types of additives are considered to be miscible and

compatible with each other (see IEC 60422).

5.4 Identification and general delivery requirements

Identification and general delivery requirements are as follows:

a) Oil is normally delivered in bulk, rail tank cars, tank containers or packed in drums or IBC

(intermediate bulk containers). These shall be clean and suitable for this purpose to avoid

any contamination.

b) Oil drums and sample containers shall carry at least the following markings:

– supplier's designation;

– classification (see 5.1);

– oil quantity.

c) As agreed between the supplier and purchaser each oil delivery may be accompanied by a

document specifying the supplier’s designation, oil classification and compliance

certificate.

NOTE This standard may be traceable to a specific batch of oil processed.

– 12 – 60296 © IEC:2012

d) The supplier shall declare the generic type of all additives, and their concentrations in the

cases of inhibitors and passivators.

5.5 Sampling

Sampling shall be carried out in accordance with the procedure described in IEC 60475.

6 Properties, their significance and test methods

6.1 Viscosity

Viscosity influences heat transfer and therefore the temperature rise of the equipment.

The lower the viscosity, the easier the oil circulates leading to improved heat transfer. At low

temperatures, the resulting higher viscosity of oil is a critical factor for the cold start of

transformers with poor or no circulation of oil and therefore possible overheating at the hot

spots, and negatively influences the speed of moving parts such as in power circuit breakers,

switchgear, on-load tap changer mechanisms, pumps and regulators. The viscosity at the

lowest cold start energizing temperature (LCSET) shall not exceed 1 800 mm /s (respectively

/s at –40 °C, see Table 1). This lowest cold start energizing temperature (LCSET)

2 500 mm

for transformer oils is defined in this standard as being –30 °C (this is 5 K lower than

indicated in IEC 60076-2). Other LCSET (see Table 1) can be agreed between supplier and

purchaser.

Low temperature switchgear oil should have a lower viscosity at LCSET: max. 400 mm /s.

Standard LCSET of low temperature switchgear oil is defined at –40 °C but other LCSET may

be agreed between supplier and purchaser.

Table 1 – Maximum viscosity and pour point of transformer oil

at lowest cold start energizing temperature (LCSET)

LCSET Maximum viscosity Maximum pour point

°C mm /s °C

0 1 800 –10

–20 1 800 –30

–30 1 800 –40

–40 2 500 –50

Viscosity shall be measured according to ISO 3104, and viscosity at very low temperatures

according to IEC 61868.

6.2 Pour point

The pour point of mineral insulating oil is the lowest temperature at which the oil will just flow.

It is recommended that the pour point should be at least 10 K below the lowest cold start

energizing temperature (LCSET). If a pour point depressant additive is used, this shall be

declared by the supplier to the user. Pour point shall be measured in accordance with

ISO 3016.

6.3 Water content

A low water content of mineral insulating oil is necessary to achieve adequate breakdown

voltage and low dissipation losses. To avoid separation of free water, unused insulating oil

should have limited water content. Before filling the electrical equipment, the oil should be

treated to meet the requirements of IEC 60422. Water content shall be measured in

accordance with IEC 60814.

60296 © IEC:2012 – 13 –

6.4 Breakdown voltage

The breakdown voltage of transformer oil indicates its ability to resist electrical stress in

electrical equipment. Breakdown voltage shall be measured in accordance with IEC 60156.

The supplier shall demonstrate that after treatment to reduce particles, water and dissolved