IEC 61020-1:2009

(Main)Electromechanical switches for use in electrical and electronic equipment - Part 1: Generic specification

Electromechanical switches for use in electrical and electronic equipment - Part 1: Generic specification

IEC 61020-1:2009 provides consistency in detail specifications for electromechanical switches by specifying the terminology, symbols, test methods and other necessary information. Switches covered by this specification:

- are devices which open, close, or change the connection of a circuit by the mechanical motion of conducting parts (contacts);

- have a maximum rated voltage of 480 V;

- have a maximum rated current of 63 A.

This second edition constitutes a technical revision and includes the following significant technical changes with respect to the previous edition:

- The requirements of the IEC 60512 series of standards have been integrated.

- Other necessary information concerning switches as specified in IEC 60512 have been implemented.

The following items have been updated with respect to the first edition:

- test methods were reviewed for detailed description;

- the explanation for the test method of the operating force was rewritten in more detail;

- the test voltage for measurement for contact bounce was reviewed;

- the electrical endurance "ON" duration in the duty cycle was harmonized with IEC 61058;

- the requirements for fire hazards have been deleted;

- testing methods of surface mounting switches based on the Japanese industrial standard were added.

Interrupteurs électromécaniques pour équipements électriques et électroniques - Partie 1: Spécification générique

La CEI 61020-1:2009 est destinée à assurer la cohérence des spécifications particulières applicables aux interrupteurs électromécaniques en spécifiant la terminologie, les symboles, les méthodes d'essai et autres informations nécessaires. Les interrupteurs relevant de la présente spécification:

- sont des composants qui ouvrent, ferment ou commutent un circuit par le mouvement mécanique de leurs parties conductrices (contacts);

- ont une tension assignée maximale de 480 V;

- ont un courant assigné maximal de 63 A.

Cette seconde édition constitue une révision technique et elle inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- Les exigences de la série CEI 60512 ont été intégrées.

- En particulier les informations nécessaires par rapport aux connecteurs tels que spécifiés dans la CEI 60512 ont été introduits dans cette norme.

En outre, les points suivants ont été mis à jour par rapport à la première édition:

- des méthodes d'essai pour une description détaillée ont été révisées;

- l'explication pour la méthode d'essai des forces de fonctionnement a été réécrite plus en détails;

- la tension de mesure des rebonds a été révisée;

- la durée de l'endurance électrique "marche" dans le cycle de service a été harmonisée avec la CEI 61058;

- des exigences par rapport aux risques au feu ont été supprimées;

- des méthodes d'essai des connecteurs montés en surface basées sur des normes industrielles japonaises ont été ajoutées.

General Information

- Status

- Published

- Publication Date

- 15-Jul-2009

- Technical Committee

- SC 23J - Switches for appliances

- Drafting Committee

- MT 2 - TC 23/SC 23J/MT 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 16-Jan-2019

- Completion Date

- 30-Dec-2016

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61020-1:2009 is the international standard that defines the generic specifications for electromechanical switches used in electrical and electronic equipment. This standard ensures uniformity and reliability for switches that operate by the mechanical motion of conducting parts (contacts). It applies to switches rated up to 480 volts and 63 amperes, guiding manufacturers and engineers on design, testing, and quality assessment requirements.

This second edition represents a technical revision to align with related standards, such as the IEC 60512 series, and refines test methods, operating force explanations, and endurance criteria. It also introduces testing for surface mounting switches in line with Japanese industrial standards, enhancing relevance for modern electronic components.

Key Topics

- Scope and Object: Establishes terminology, symbols, test procedures, and performance requirements for electromechanical switches used in various electrical and electronic devices.

- Technical Revisions: Incorporates IEC 60512 standards, improves clarity on test methodologies-including mechanical and electrical endurance, contact bounce, and operating forces-and removes fire hazard requirements.

- Test and Measurement Procedures: Detailed testing includes:

- Visual and dimensional examination

- Contact resistance (millivolt level and specified currents)

- Dielectric strength and insulation resistance

- Mechanical strength, shock, vibration, and endurance testing

- Climatic and environmental stress tests such as damp heat and corrosion resistance

- Solderability and heat resistance tests, including for surface mounting switches

- Marking and Units: Defines essential markings, symbols, and measurement units for consistency and clear communication.

- Quality Assessment: Specifies standard procedures for ensuring product reliability and conformity throughout production cycles.

Applications

IEC 61020-1:2009 covers electromechanical switches widely used in sectors requiring reliable and standardized switching devices, including:

- Consumer Electronics: Switches in household appliances, audio-visual equipment, and personal devices.

- Industrial Equipment: Control switches in machinery, automation systems, and industrial electronics.

- Electrical Installations: Circuit breakers, panel-mounted switches, and power distribution components.

- Surface Mount Technology (SMT): Requirements for surface mounting switches support modern circuit board assembly techniques.

- Automotive and Transportation: Reliable switching in vehicle control and electronic modules.

Adherence to IEC 61020-1 ensures that switches meet global safety, performance, and durability benchmarks, facilitating international trade, reducing manufacturing risks, and enhancing product quality.

Related Standards

- IEC 60512 Series: Covers test methods for electromechanical components, integrated into IEC 61020-1 to harmonize testing approaches.

- IEC 61058: Relates to switches for appliances, aligned in electrical endurance test cycles.

- Japanese Industrial Standards (JIS): Adopted for surface mounting switch tests within this edition to address regional manufacturing practices.

- ISO/IEC Directives: Ensures compatibility with general standardization principles and terminologies.

- IEC 61340: For handling electrostatic-sensitive devices, relevant when dealing with sensitive switch components.

Practical Benefits

- Consistency: Uniform test methods and terminology support cohesive product development and cross-border compliance.

- Reliability: Detailed endurance and environmental testing predict real-world performance and extend product lifetime.

- Safety: Although fire hazard requirements were removed, the standard maintains strict electrical and mechanical safety criteria.

- Innovation Support: Inclusion of surface mounting switch tests meets evolving manufacturing technologies.

- Market Access: Compliance with IEC 61020-1 facilitates acceptance in international markets, aligning with regulatory demands.

By following IEC 61020-1:2009, manufacturers can design and produce electromechanical switches that deliver consistent quality, meet modern environmental and mechanical demands, and integrate seamlessly into diverse electrical and electronic systems worldwide.

Frequently Asked Questions

IEC 61020-1:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electromechanical switches for use in electrical and electronic equipment - Part 1: Generic specification". This standard covers: IEC 61020-1:2009 provides consistency in detail specifications for electromechanical switches by specifying the terminology, symbols, test methods and other necessary information. Switches covered by this specification: - are devices which open, close, or change the connection of a circuit by the mechanical motion of conducting parts (contacts); - have a maximum rated voltage of 480 V; - have a maximum rated current of 63 A. This second edition constitutes a technical revision and includes the following significant technical changes with respect to the previous edition: - The requirements of the IEC 60512 series of standards have been integrated. - Other necessary information concerning switches as specified in IEC 60512 have been implemented. The following items have been updated with respect to the first edition: - test methods were reviewed for detailed description; - the explanation for the test method of the operating force was rewritten in more detail; - the test voltage for measurement for contact bounce was reviewed; - the electrical endurance "ON" duration in the duty cycle was harmonized with IEC 61058; - the requirements for fire hazards have been deleted; - testing methods of surface mounting switches based on the Japanese industrial standard were added.

IEC 61020-1:2009 provides consistency in detail specifications for electromechanical switches by specifying the terminology, symbols, test methods and other necessary information. Switches covered by this specification: - are devices which open, close, or change the connection of a circuit by the mechanical motion of conducting parts (contacts); - have a maximum rated voltage of 480 V; - have a maximum rated current of 63 A. This second edition constitutes a technical revision and includes the following significant technical changes with respect to the previous edition: - The requirements of the IEC 60512 series of standards have been integrated. - Other necessary information concerning switches as specified in IEC 60512 have been implemented. The following items have been updated with respect to the first edition: - test methods were reviewed for detailed description; - the explanation for the test method of the operating force was rewritten in more detail; - the test voltage for measurement for contact bounce was reviewed; - the electrical endurance "ON" duration in the duty cycle was harmonized with IEC 61058; - the requirements for fire hazards have been deleted; - testing methods of surface mounting switches based on the Japanese industrial standard were added.

IEC 61020-1:2009 is classified under the following ICS (International Classification for Standards) categories: 31.220.20 - Switches. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61020-1:2009 has the following relationships with other standards: It is inter standard links to IEC 61020-1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61020-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61020-1 ®

Edition 2.0 2009-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electromechanical switches for use in electrical and electronic equipment –

Part 1: Generic specification

Interrupteurs électromécaniques pour équipements électriques et

électroniques –

Partie 1: Spécification générique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61020-1 ®

Edition 2.0 2009-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electromechanical switches for use in electrical and electronic equipment –

Part 1: Generic specification

Interrupteurs électromécaniques pour équipements électriques et

électroniques –

Partie 1: Spécification générique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 31.220.20 ISBN 978-2-88910-401-7

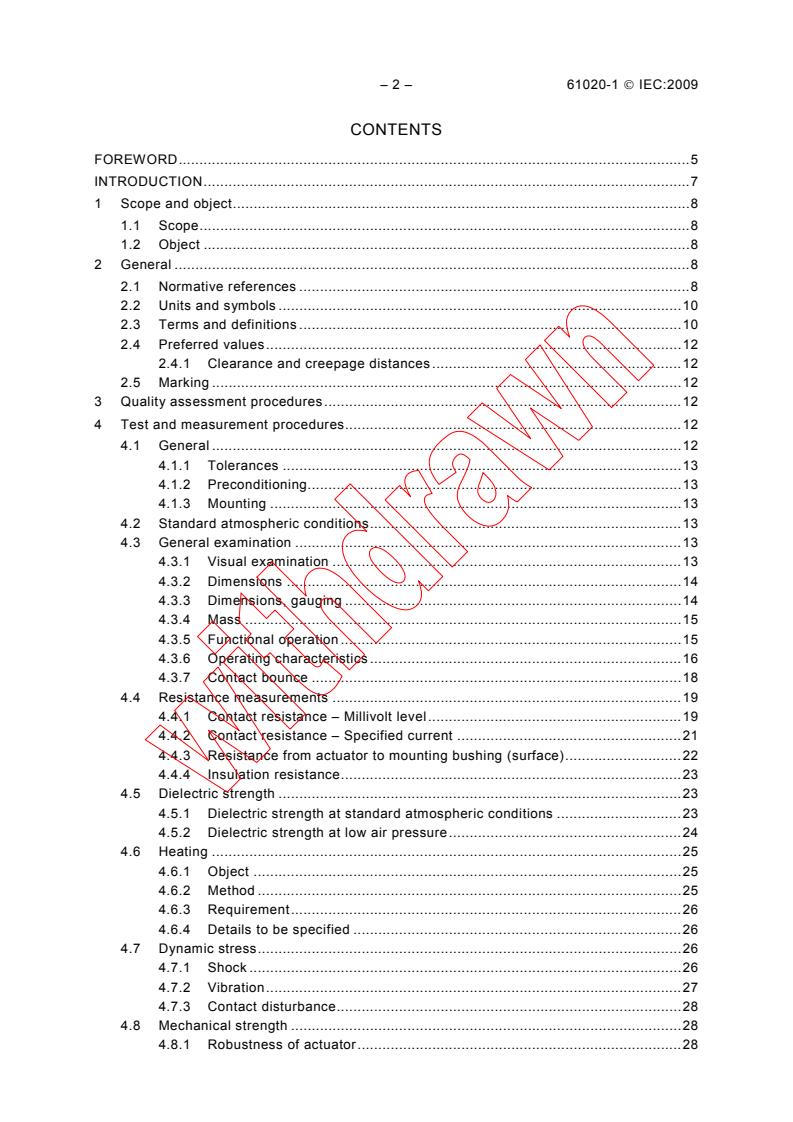

– 2 – 61020-1 © IEC:2009

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope and object.8

1.1 Scope.8

1.2 Object .8

2 General .8

2.1 Normative references .8

2.2 Units and symbols .10

2.3 Terms and definitions .10

2.4 Preferred values.12

2.4.1 Clearance and creepage distances .12

2.5 Marking .12

3 Quality assessment procedures.12

4 Test and measurement procedures.12

4.1 General .12

4.1.1 Tolerances .13

4.1.2 Preconditioning.13

4.1.3 Mounting .13

4.2 Standard atmospheric conditions.13

4.3 General examination .13

4.3.1 Visual examination .13

4.3.2 Dimensions .14

4.3.3 Dimensions, gauging .14

4.3.4 Mass .15

4.3.5 Functional operation .15

4.3.6 Operating characteristics .16

4.3.7 Contact bounce .18

4.4 Resistance measurements .19

4.4.1 Contact resistance – Millivolt level.19

4.4.2 Contact resistance – Specified current .21

4.4.3 Resistance from actuator to mounting bushing (surface).22

4.4.4 Insulation resistance.23

4.5 Dielectric strength .23

4.5.1 Dielectric strength at standard atmospheric conditions .23

4.5.2 Dielectric strength at low air pressure.24

4.6 Heating .25

4.6.1 Object .25

4.6.2 Method .25

4.6.3 Requirement.26

4.6.4 Details to be specified .26

4.7 Dynamic stress.26

4.7.1 Shock .26

4.7.2 Vibration.27

4.7.3 Contact disturbance.28

4.8 Mechanical strength .28

4.8.1 Robustness of actuator.28

61020-1 © IEC:2009 – 3 –

4.8.2 Robustness of mounting bushing .31

4.8.3 Robustness of screw mounting .31

4.8.4 Robustness of terminations .31

4.9 Mechanical endurance.32

4.9.1 Mechanical endurance – Standard atmospheric conditions .32

4.9.2 Mechanical endurance – Category temperature range .33

4.10 Electrical endurance.33

4.10.1 Electrical endurance – Standard atmospheric conditions .33

4.10.2 Electrical endurance – Upper category temperature.35

4.10.3 Electrical endurance – Category temperature range .36

4.10.4 Electrical endurance – Low air pressure .36

4.10.5 Logic loads (TTL) .37

4.10.6 Low level endurance test .38

4.11 Overload .39

4.11.2 Electrical overload .39

4.11.3 Capacitive load switching .40

4.12 Environmental testing.41

4.12.1 Climatic sequence .41

4.12.2 Damp heat, steady state.43

4.12.3 Rapid change of temperature.44

4.12.4 Mould growth (resistance) .44

4.12.5 Corrosion, industrial atmosphere .45

4.12.6 Dust and sand .46

4.12.7 Contact resistance stability.48

4.13 Soldering.49

4.13.1 Solderability, wetting, solder bath method.49

4.13.2 Solderability, wetting, soldering iron method.50

4.13.3 Solderability, de-wetting .51

4.13.4 Resistance to soldering heat, solder bath method.51

4.13.5 Resistance to soldering heat, soldering iron method .52

4.14 Panel seal .53

4.14.1 Drip – Proof .53

4.14.2 Splash – Proof.53

4.14.3 Immersion .53

4.14.4 Submersion .54

4.15 Enclosure seal.55

4.15.1 Watertight immersion.55

4.15.2 Resilient or hermetic seal .55

4.16 Fluid resistance.56

4.16.1 Immersion in cleaning solvents (marking) .56

4.17 Fire hazard.56

4.18 Capacitance .56

4.18.1 Object .56

4.18.2 Method .56

4.18.3 Requirement.57

4.18.4 Details to be specified .57

4.19 Illumination.57

4.19.1 Chromaticity .57

4.19.2 Transmittancy.57

– 4 – 61020-1 © IEC:2009

4.19.3 Temperature of illuminated surface.58

4.20 Soldering for surface mounting switches .58

4.20.1 Solderability, solder bath method (surface mounting switches) .58

4.20.2 Solderability, reflow method (surface mounting switches) .59

4.20.3 Solderability, soldering iron method (surface mounting switches) .60

4.20.4 Resistance to soldering heat , solder bath method (surface mounting

switches) .60

4.20.5 Resistance to soldering heat, reflow method (surface mounting

switches) .61

4.20.6 Resistance to soldering heat, soldering iron method (surface

mounting switches).62

4.21 Mechanical strength (surface mounting switches).62

4.21.1 Substrate bending (surface mounting switches) .62

4.21.2 Pull-off and push-off (surface mounting switches).63

4.21.3 Shear (surface mounting switches) .64

4.21.4 Body strength (surface mounting switches).64

Annex A (informative) Quality assurance procedures .66

Bibliography.67

Figure 1 – Contact bounce test circuit.18

Figure 2 – Typical trace of contact bounce.19

Figure 3 – Application of forces and torques for test 4.81.30

Figure 4 – Submersion seal enclosure .55

Table 1 – Minimum wire length .25

Table 2 – Torque values for mounting screws .31

Table 3 – Methods proposed for corrosion tests.46

Table 4 – Solderability, Bath method: Test severities (duration and temperature) .50

61020-1 © IEC:2009 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROMECHANICAL SWITCHES

FOR USE IN ELECTRICAL AND ELECTRONIC EQUIPMENT –

Part 1: Generic specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61020-1 has been prepared by subcommittee 23J: Switches for

appliances, of IEC technical committee 23: Electrical accessories.

This second edition cancels and replaces the first edition published in 1991. This second

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition.

a) The requirements of the IEC 60512 series of standards have been integrated in this

second edition of IEC 61020-1. In particular the test methods, terminology, symbols and

other necessary information concerning switches as specified in IEC 60512 have been

implemented in this standard.

b) Additionally, the following items have been updated with respect to the first edition:

– test methods were reviewed for detailed description;

– 6 – 61020-1 © IEC:2009

– the explanation for the test method of the operating force was rewritten in more detail;

– the test voltage for measurement for contact bounce was reviewed;

– the electrical endurance “ON” duration in the duty cycle was harmonized with

IEC 61058;

– the requirements for fire hazards have been deleted;

– testing methods of surface mounting switches based on the Japanese industrial

standard were added.

The text of this standard is based on the following documents:

FDIS Report on voting

23J/325/FDIS 23J/328/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61020-1 © IEC:2009 – 7 –

INTRODUCTION

This generic specification covers the general requirements and test methods for

electromechanical switches with optional quality assurance procedures. It provides the

general requirements and test methods for use in any detail specifications for pushbutton

switches, rotary switches, sensitive switches, toggle switches, and other electromechanical

switches. It also provides guidelines for appropriate quality assurance procedures in Annex A

(informative).

Where it is intended that an electromechanical switch comply with requirements related to

safety, the specific safety requirements are specified in IEC 61058-1.

– 8 – 61020-1 © IEC:2009

ELECTROMECHANICAL SWITCHES

FOR USE IN ELECTRICAL AND ELECTRONIC EQUIPMENT –

Part 1: Generic specification

1 Scope and object

1.1 Scope

This generic specification relates to electromechanical switches intended for use in electrical

and electronic appliances. Switches covered by this specification:

a) are devices which open, close, or change the connection of a circuit by the mechanical

motion of conducting parts (contacts);

b) have a maximum rated voltage of 480 V;

c) have a maximum rated current of 63 A.

This generic specification does not include keyboards and keypads which are intended for use

in information-handling systems. Electromechanical key switches may be included under the

scope of this generic specification.

Switch families shall be described in any detail specifications that will reference this generic

specification.

1.2 Object

The object of this generic specification is to provide consistency in detail specifications for

electromechanical switches by specifying the terminology, symbols, test methods and other

necessary information.

2 General

2.1 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60027 (all parts), Letter symbols to be used in electrical technology

IEC 60050-581:2008, International Electrotechnical Vocabulary – Part 581: Electromechanical

components for electronic equipment

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

Amendment 1 (1992)

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-1:2007, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2:2007, Environmental testing – Part 2-2: Tests – Test B: Dry heat

61020-1 © IEC:2009 – 9 –

IEC 60068-2-10:2005, Environmental testing – Part 2-10: Tests – Test J and guidance: Mould

growth

IEC 60068-2-13:1983, Environmental testing – Part 2-13: Tests – Test M: Low air pressure

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-17:1994, Environmental testing – Part 2-17: Tests – Test Q: Sealing

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-21:2006, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-30:2005, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12+12-hour cycle)

IEC 60068-2-42:2003, Environmental testing – Part 2-42: Tests – Test Kc: Sulphur dioxide

test for contacts and connections

IEC 60068-2-43:2003, Environmental testing – Part 2-43: Tests – Test Kd: Hydrogen sulphide

test for contacts and connections

IEC 60068-2-45:1980, Environmental testing – Part 2-45: Tests – Test XA and guidance:

Immersion in cleaning solvents

Amendment 1 (1993)

IEC 60068-2-49:1983, Environmental testing – Part 2-49: Tests – Guidance to Test Kc:

Sulphur dioxide test for contacts and connections

IEC 60068-2-58:1999, Environmental testing Part 2-58: Tests – Tests Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-61:1991, Environmental testing – Part 2-61: Test methods – Test Z/ABDM:

Climatic sequence

IEC 60068-2-68:1994, Environmental testing – Part 2-68: Tests – Test L: Dust and sand

IEC 60068-2-78:2001, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat,

steady state

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

Amendment 1 (2001)

IEC 60617, Graphical symbols for diagrams

IEC 61058-1:2000, Switches for appliances – Part 1: General requirements

Amendment 1 (2001)

Amendment 2 (2007)

ISO 1000:1992, SI units and recommendation for the use of their multiples and of certain

other units

– 10 – 61020-1 © IEC:2009

2.2 Units and symbols

Units, graphic symbols, and letter symbols shall be, whenever possible, in accordance with

ISO 1000, IEC 60027 and IEC 60617.

Graphic symbols and letter symbols peculiar to a particular switch subfamily shall be defined

in the applicable detail specification. Graphic symbols and letter symbols peculiar to a group

of structurally similar switches shall be defined in the detail specification. When additional

units or symbols are required, they shall be derived in accordance with the principles of the

documents listed above whenever possible.

2.3 Terms and definitions

For the purposes of this document the terminology of IEC 60050-581 as well as the following

terms and definitions apply.

Terminology peculiar to a particular switch subfamily shall be defined in the applicable detail

specification. Terminology peculiar to a group of structurally similar switches shall be defined

in the detail specification.

The following terminology is common to all electromechanical switches. Where the definition

is compatible with an established IEC 60050 definition, the IEV number for the related

definition is given in brackets.

2.3.1

category temperature range

range of ambient temperature for which the switch has been designed to operate continuously

2.3.2

clearance

shortest distance in air between two conductive parts

2.3.3

contact bounce

intermittent and random opening of closed contacts and closing of open contacts which may

occur after contact transfer and which is caused by the switch mechanism

2.3.4

contact bounce time

time period measured from the moment of first closure of two mating contacts or first opening

of two closed contacts to the moment when all contact bounce ceases

2.3.5

contact disturbance

intermittent and random closing of open contacts and/or opening of closed contacts caused by

external influences such as shock and vibration

2.3.6

contact separation (gap)

distance between mating contacts when the contacts are open

2.3.7

contact set

group of contacts which all function in relation to the same pole of a switch

2.3.8

creepage distance

shortest distance along the surface of the insulation material between two conductive parts

61020-1 © IEC:2009 – 11 –

[IEV 151-15-50 modified]

2.3.9

double break switch

switch that opens a conductor at two points in series with each other

2.3.10

double throw

term applied to a contact arrangement to denote that each contact form included is a make-

break

2.3.11

duty cycle

ratio of conducting (ON) time to the total time for one cycle; for example, 30 % ON

2.3.12

electromechanical switch

switch which opens, closes, or changes the connection of an electrical circuit by the

mechanical motion of conducting parts (contacts)

2.3.13

lower category temperature

minimum ambient temperature for which a switch has been designed to operate continuously

2.3.14

pole of a switch

the part of the switch associated exclusively with one, electrically separated, conducting path

of the switch

NOTE 1 Those parts that provide a means for mounting and operating all poles together are excluded from the

definition of a pole.

NOTE 2 A switch is called "single-pole" if it has only one pole. If it has more than one pole, it may be called

"multi-pole" (two-pole, three-pole, etc.) provided that the poles are coupled in such a manner as to operate

together.

2.3.15

operating cycle

succession of operations from one position to another and back to the first position through all

other positions, if any

[IEV 441-16-02]

2.3.16

opposite polarity

two parts of a switch such that when connected together may result in operation of the line

fuses to the power supply

2.3.17

single throw

term applied to a contact arrangement to denote that each contact form included is a single

contact pair

2.3.18

snap-action

type of switching action in which the speed of the moving contact is relatively independent of

the speed of the actuating mechanism

– 12 – 61020-1 © IEC:2009

2.3.19

surface mounting switch

small-sized switch which is suitable for surface mounting on the printed wiring board,

consisting of terminals and framing parts

2.3.20

upper category temperature

maximum ambient temperature for which a switch has been designed to operate continuously

2.4 Preferred values

The detail specification may prescribe any preferred values for rated and limiting values,

characteristics, tolerances, requirements and dimensions applicable to the whole subfamily.

2.4.1 Clearance and creepage distances

The detail specification shall specify either the minimum clearance and creepage distances or

the minimum dielectric test voltage under specified air pressure for functional insulation. For

basic, supplementary or reinforced insulation the minimum clearance and creepage distances

shall be specified in accordance with Clause 20 of IEC 61058-1.

2.5 Marking

Where space permits after national or contractual marking requirements (for example, safety

requirements) have been satisfied, each switch shall be marked with the following information:

a) manufacturer's name or trademark;

b) identification number;

c) terminal identification when specified by the detail specification;

d) date code: the date code shall be in accordance with IEC 60062.

Other markings may be applied to the switches provided they do not obscure or confuse the

required markings. When conditions do not permit full marking on the switch, the markings

shall be applied in the order of preference shown above. Any required marking that cannot be

applied to the switch, shall be marked on the smallest packing unit of the switch.

3 Quality assessment procedures

NOTE See Annex A (informative) for guidelines on quality assurance procedures.

4 Test and measurement procedures

4.1 General

Any detail specification shall contain tables showing the tests to be conducted, the

measurements to be made before and after each test or group of tests, and the sequence in

which they shall be carried out. The measuring conditions shall be the same for initial and

final measurements. When tests are performed in a sequence, the final measurements of one

test may be taken as the initial measurements for the succeeding test.

If national specifications within any quality assessment system include test methods other

than those specified in the above documents, the test methods shall be fully described.

Not all the test methods prescribed herein are applicable to all types of switches. The detail

specification shall prescribe the test methods which are applicable for that type of switch.

61020-1 © IEC:2009 – 13 –

When necessary, additional test methods and/or details of the test methods shall be

prescribed by the detail specification.

4.1.1 Tolerances

Unless otherwise specified, the actual value of the parameters, for example test voltage, test

current, test force or test torque shall be within 5 % of the specified values of the switch.

4.1.2 Preconditioning

Unless specified by the test method, the switches shall not be subjected to any special

preparations, such as cleaning, prior to or during the tests.

4.1.3 Mounting

When mounting is prescribed by the test method, the switch shall be rigidly mounted by its

normal mounting means and connected as specified in the detail specification. The method of

mounting and the materials used for mounting shall not adversely affect the electrical or

mechanical performance of the switch.

4.2 Standard atmospheric conditions

The standard atmospheric conditions shall be in accordance with Clause 5 of IEC 60068-1.

4.3 General examination

4.3.1 Visual examination

4.3.1.1 Method

The visual examination shall be carried out by one of the following methods:

a) with the naked eye (normal strength of vision, normal colour perception, at the most

favourable viewing distance and with suitable illumination);

b) with magnifiers, if specified.

For the purpose of this standard, special methods, for example using polarized light (for

observing internal tensions in materials) or other indicators (for observing internal material

cracks or pores), are not permitted unless explicitly required by the detail specification.

4.3.1.2 Features

The following features shall be examined without magnification:

a) markings according to 2.5;

b) general appearance;

c) workmanship.

4.3.1.3 Requirement

The markings shall be correct and legible. The switch shall be manufactured in a careful and

workmanlike manner.

4.3.1.4 Details to be specified

When this test is required by the detail specification, the following details shall be specified:

a) details to be examined;

b) features to be checked;

– 14 – 61020-1 © IEC:2009

c) acceptability;

d) power of magnifier, if specified;

e) any deviation from the standard test method.

4.3.2 Dimensions

4.3.2.1 Method

The examination of dimensions shall be carried out with appropriate measuring equipment, for

example:

a) with a vernier gauge, a micrometer and a dial gauge;

b) with a measuring projector with a suitable linear magnification;

c) with a measuring microscope.

The following details shall apply.

a) The specified outline dimensions, detailed dimensions, clearances and creepage

distances shall be measured.

b) The accuracy and resolution of the measuring equipment (micrometers, callipers, visual

comparators, etc.) shall be commensurate with the dimensions being measured.

4.3.2.2 Requirement

The dimensions shall be within the limits specified by the detail specification.

4.3.2.3 Details to be specified

When this test is required by the detail specification, the following details shall be specified:

a) features to be checked;

b) gauging details, if applicable;

c) type and power of measuring equipment;

d) acceptability;

e) any deviation from the standard test method.

4.3.3 Dimensions, gauging

4.3.3.1 Method

The dimensions prescribed by the detail specifications as being suitable for gauging shall be

checked using the gauges or gauge dimensions specified by the detail specification.

4.3.3.2 Requirement

The switch shall comply with the prescribed gauging.

4.3.3.3 Details to be specified

When this test is required by the detail specification, the following details shall be specified:

a) features to be checked;

b) gauging details, if applicable;

c) type and power of measuring equipment;

d) acceptability;

e) any deviation from the standard test method.

61020-1 © IEC:2009 – 15 –

4.3.4 Mass

4.3.4.1 Method

The checking of mass should be carried out with appropriate measuring equipment, for

example, with a balance.

The following details shall apply.

a) The accuracy and resolution of the measuring equipment shall be commensurate with the

mass being measured.

b) The measurement shall include all removable parts (mounting hardware, etc.) prescribed

by the detail specification.

4.3.4.2 Requirement

The mass shall be within the limits specified by the detail specification.

4.3.4.3 Details to be specified

When this test is required by the detail specification, the following details shall be specified:

a) features to be checked;

b) gauging details, if applicable;

c) type and power of measuring equipment;

d) acceptability;

e) any deviation from the standard test method.

4.3.5 Functional operation

4.3.5.1 Object

The objective of the examination is the assessment of the proper functioning of all switching

operations.

4.3.5.2 Method

For coded switches, each switching circuit shall be connected to a monitoring circuit which

has a maximum current of 150 mA, and provides an indication of current flow. With the

exception of coded switches, the test facility may use the contact resistance test to check the

switching circuit.

The correct functioning of all mechanical detents, latching, locking, interlocking, and self-

return mechanisms shall be checked.

The correct functioning of all electrical non-switching operations, such as lamp circuits or

solenoids, shall be checked at their rated voltage and/or rated current.

4.3.5.3 Requirement

The functional operation of the switch, including the sequence of contact operations, shall

comply with the requirements specified by the detail specification.

– 16 – 61020-1 © IEC:2009

4.3.6 Operating characteristics

4.3.6.1 Operating force

4.3.6.1.1 Object

The objective of this test is to measure the force to move the actuating part of a switch from

any one position to the next.

4.3.6.1.2 Preparation of specimens

The specimens shall be prepared as specified by the detail specification.

The specimens shall be rigidly mounted on a metal plate using the fixing devices specified in

the detail specification. The metal plate shall be strong enough to withstand the forces

applied. The length and width of the metal plate shall be such that the contour of the

specimen is exceeded.

4.3.6.1.3 Method of measurement

The force shall be applied to the actuating part in the direction and at the point specified in

the detail specification. Unless otherwise specified, the force shall be applied until the

actuating part has travelled from a first stable equilibrium position to its next stable

equilibrium position or a stop, and the switch has operated electrically or the specified contact

resistance is achieved.” The maximum force necessary to move the actuating part to the next

stable position or stop shall be measured and recorded. In the case of a switch in which the

actuator does not take up a second stable equilibrium position (momentary position), the force

required to move the actuator to the operating position shall be measured and recorded.

If appropriate, the measurements of operating force shall be carried out in both directions. In

each direction, the number of measurements shall be as specified in the detail specification.

The method for measuring other mechanical operating characteristics shall be specified by

the detail specification. The method for measuring other operating characteristics such as

temperature, air pressure, etc. shall be specified by the detail specification.

4.3.6.1.4 Requirement

All measured values shall be within the limits specified in the detai

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...