IEC 62275:2022

(Main)Cable management systems - Cable ties for electrical installations

Cable management systems - Cable ties for electrical installations

IEC 62275:2022 specifies requirements for metallic, non-metallic and composite cable ties and their associated fixing devices as a means used for managing or securing the wiring systems in electrical installations. Cable ties and associated fixing devices can also be suitable for other applications, such as support of wiring systems, and where so used, additional requirements can apply. This fourth edition cancels and replaces the third edition published in 2018. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- scope clarification,

- new definitions,

- deletion of the exception for the stabilization of the moisture content,

- possibility to carry out tensile strength tests with dead weights,

- differentiation of rubber and acrylic adhesive fixings,

- clarification for mechanical testing of integral devices,

- clarifications on Table 6,

- clarifications in 9.1,

- the minimum installation temperature test for cable ties is carried out only when the declared minimum temperature is lower than 0 °C,

- a requirement that metallic cable ties be classified according to 6.2.3,

- definition of colours to be tested for contribution to fire,

- addition of a "some countries" note in Clause 10,

- clarification of the mounting of fixing devices in the resistance to ultraviolet light test,

- clarification on the testing of integral devices in the resistance to ultraviolet light test.

Systèmes de câblage - Colliers pour installations électriques

L'IEC 62275:2022 spécifie les exigences pour les colliers métalliques, non métalliques et composites, ainsi que pour leurs accessoires de fixation associés, comme un moyen utilisé pour l’aménagement et la fixation des systèmes de câblage dans les installations électriques. Les colliers et leurs accessoires de fixation associés peuvent également être utilisés pour d’autres applications, comme le soutien des systèmes de câblage et, dans ce cas, des exigences supplémentaires peuvent s’appliquer. Cette quatrième édition annule et remplace la troisième édition parue en 2018. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

- une clarification du domaine d’application;

- de nouvelles définitions;

- la suppression de l’exception relative au conditionnement pour atteindre la reprise d’humidité;

- la possibilité d’effectuer des essais de tenue à la traction avec des poids morts;

- la différenciation des fixations adhésives en caoutchouc et en acrylique;

- une clarification pour les essais mécaniques des accessoires intégrés;

- des clarifications du Tableau 6;

- des clarifications de 9.1;

- l’essai des colliers à la température minimale d’installation est effectué uniquement lorsque la température minimale déclarée est inférieure à 0 °C;

- une exigence selon laquelle les colliers métalliques sont classés conformément à 6.2.3;

- la définition des couleurs à soumettre à essai en matière de contribution au feu;

- l’ajout d’une note "Dans certains pays" à l’Article 10;

- la clarification du montage des accessoires de fixation dans l’essai de tenue au rayonnement ultraviolet;

- la clarification de l’essai des accessoires intégrés dans l’essai de tenue au rayonnement ultraviolet.

General Information

- Status

- Published

- Publication Date

- 21-Nov-2022

- Technical Committee

- SC 23A - Cable management systems

- Drafting Committee

- MT 17 - TC 23/SC 23A/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Nov-2022

- Completion Date

- 23-Dec-2022

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62275:2022 - "Cable management systems - Cable ties for electrical installations" is the fourth edition of the International Electrotechnical Commission standard that specifies requirements and test methods for metallic, non‑metallic and composite cable ties and their associated fixing devices used to secure and manage wiring in electrical installations. This 2022 revision cancels and replaces the 2018 edition and introduces several technical updates including scope clarifications, new definitions and revised testing options.

Key topics and technical requirements

The standard covers design, classification, marking and a wide range of performance tests. Major technical topics include:

- Materials and construction: classification by material type - metallic, non‑metallic and composite components.

- Loop tensile strength and mechanical strength: defined classifications (Type 1 and Type 2) and detailed tensile testing procedures (including the option to use dead weights).

- Temperature classifications: maximum and minimum operating temperatures, and minimum installation temperature tests (minimum installation temperature test required only if declared minimum < 0 °C).

- Environmental resistance: tests for resistance to ultraviolet (UV) light and corrosion for relevant components; clarifications on mounting and testing of integral devices.

- Contribution to fire: classification for non‑metallic and composite ties (flame‑propagating vs non‑flame‑propagating) and defined colours to be tested for fire contribution.

- Mechanical testing of fixing devices and integral assemblies: impact, vibration, durability and installation tests with clarified procedures.

- Marking and documentation requirements and guidance for compliance checks for products migrating from the 2018 edition.

- Electromagnetic compatibility considerations and specific normative test clauses.

Practical applications and who uses IEC 62275:2022

IEC 62275:2022 is used where consistent performance, safety and conformity of cable ties and fixings are critical:

- Manufacturers - to design, test and certify cable ties and associated fixing devices against international performance requirements.

- Test laboratories - to apply standardized tensile, thermal, UV, corrosion and fire contribution tests.

- Specifiers and procurement teams - to select cable management products that meet required mechanical, thermal and environmental classifications.

- Installers and electrical contractors - to understand suitability for installation and operating temperature limits.

- Certification bodies and regulatory authorities - to assess compliance and harmonize national rules with IEC requirements.

Related standards (guidance)

For complete system compliance, users should consult other IEC publications and national codes dealing with electrical installation safety, materials testing and product certification. Always ensure you reference the latest edition and any national deviations noted in the IEC foreword.

Keywords: IEC 62275:2022, cable ties, cable management systems, electrical installations, loop tensile strength, UV resistance, contribution to fire, fixing devices.

REDLINE IEC 62275:2022 CMV - Cable management systems - Cable ties for electrical installations Released:11/22/2022 Isbn:9782832261279

IEC 62275:2022 - Cable management systems - Cable ties for electrical installations Released:11/22/2022

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62275:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Cable management systems - Cable ties for electrical installations". This standard covers: IEC 62275:2022 specifies requirements for metallic, non-metallic and composite cable ties and their associated fixing devices as a means used for managing or securing the wiring systems in electrical installations. Cable ties and associated fixing devices can also be suitable for other applications, such as support of wiring systems, and where so used, additional requirements can apply. This fourth edition cancels and replaces the third edition published in 2018. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - scope clarification, - new definitions, - deletion of the exception for the stabilization of the moisture content, - possibility to carry out tensile strength tests with dead weights, - differentiation of rubber and acrylic adhesive fixings, - clarification for mechanical testing of integral devices, - clarifications on Table 6, - clarifications in 9.1, - the minimum installation temperature test for cable ties is carried out only when the declared minimum temperature is lower than 0 °C, - a requirement that metallic cable ties be classified according to 6.2.3, - definition of colours to be tested for contribution to fire, - addition of a "some countries" note in Clause 10, - clarification of the mounting of fixing devices in the resistance to ultraviolet light test, - clarification on the testing of integral devices in the resistance to ultraviolet light test.

IEC 62275:2022 specifies requirements for metallic, non-metallic and composite cable ties and their associated fixing devices as a means used for managing or securing the wiring systems in electrical installations. Cable ties and associated fixing devices can also be suitable for other applications, such as support of wiring systems, and where so used, additional requirements can apply. This fourth edition cancels and replaces the third edition published in 2018. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - scope clarification, - new definitions, - deletion of the exception for the stabilization of the moisture content, - possibility to carry out tensile strength tests with dead weights, - differentiation of rubber and acrylic adhesive fixings, - clarification for mechanical testing of integral devices, - clarifications on Table 6, - clarifications in 9.1, - the minimum installation temperature test for cable ties is carried out only when the declared minimum temperature is lower than 0 °C, - a requirement that metallic cable ties be classified according to 6.2.3, - definition of colours to be tested for contribution to fire, - addition of a "some countries" note in Clause 10, - clarification of the mounting of fixing devices in the resistance to ultraviolet light test, - clarification on the testing of integral devices in the resistance to ultraviolet light test.

IEC 62275:2022 is classified under the following ICS (International Classification for Standards) categories: 29.120.10 - Conduits for electrical purposes; 29.120.99 - Other electrical accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62275:2022 has the following relationships with other standards: It is inter standard links to IEC 62275:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62275:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62275 ®

Edition 4.0 2022-11

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Cable management systems – Cable ties for electrical installations

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a

Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62275 ®

Edition 4.0 2022-11

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Cable management systems – Cable ties for electrical installations

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.10; 29.120.99 ISBN 978-2-8322-6127-9

– 2 – IEC 62275:2022 CMV © IEC 2022

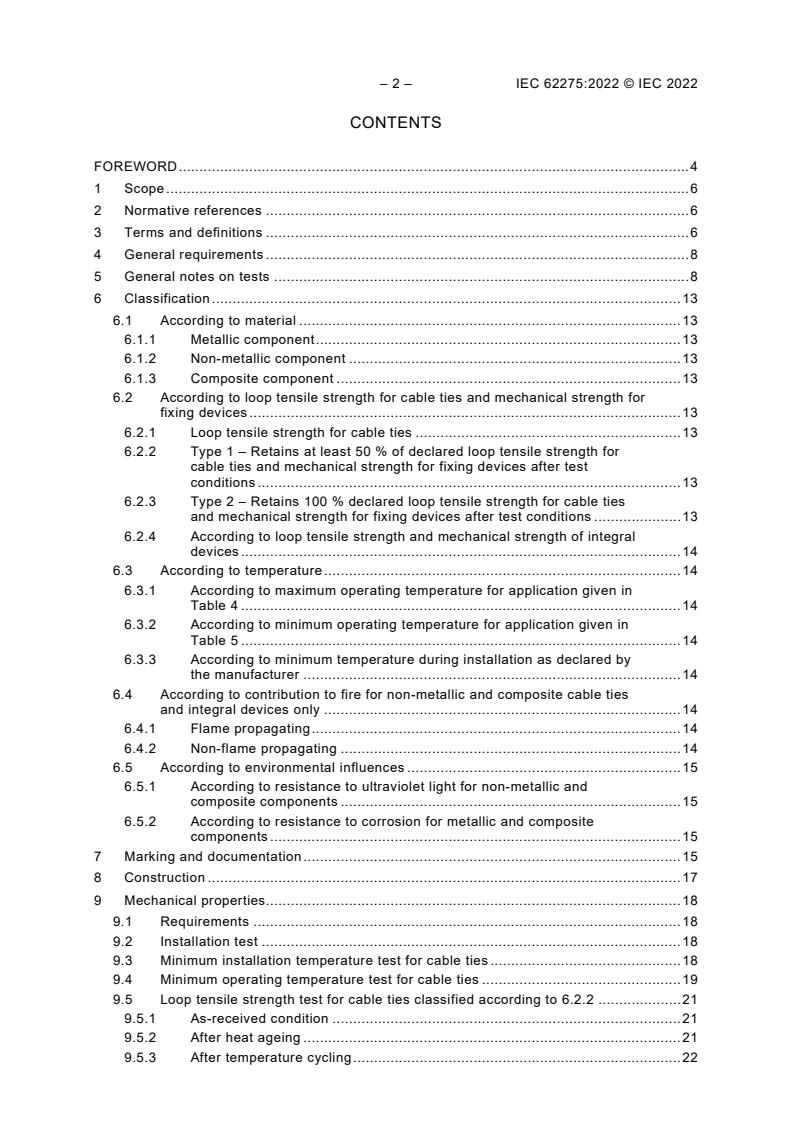

CONTENTS

FOREWORD .4

1 Scope .7

2 Normative references .7

3 Terms and definitions .7

4 General requirements .9

5 General notes on tests .9

6 Classification . 14

6.1 According to material . 14

6.1.1 Metallic component . 14

6.1.2 Non-metallic component . 14

6.1.3 Composite component . 14

6.2 According to loop tensile strength for cable ties and mechanical strength for

fixing devices . 14

6.2.1 Loop tensile strength for cable ties . 14

6.2.2 Type 1 – Retains at least 50 % of declared loop tensile strength for cable

ties and mechanical strength for fixing devices after test conditions . 14

6.2.3 Type 2 – Retains 100 % declared loop tensile strength for cable ties and

mechanical strength for fixing devices after test conditions . 14

6.2.4 According to loop tensile strength and mechanical strength of integral

assemblies devices . 15

6.3 According to temperature . 15

6.3.1 According to maximum operating temperature for application given in

Table 4 . 15

6.3.2 According to minimum operating temperature for application given in

Table 5 . 15

6.3.3 According to minimum temperature during installation as declared by

the manufacturer . 15

6.4 According to contribution to fire for non-metallic and composite cable ties and

integral assemblies devices only . 15

6.4.1 Flame propagating . 15

6.4.2 Non-flame propagating . 15

6.5 According to environmental influences . 16

6.5.1 According to resistance to ultraviolet light for non-metallic and

composite components . 16

6.5.2 According to resistance to corrosion for metallic and composite

components. 16

7 Marking and documentation . 16

8 Construction . 18

9 Mechanical properties . 19

9.1 Requirements . 19

9.2 Installation test . 19

9.3 Minimum installation temperature test for cable ties . 19

9.4 Minimum operating temperature test for cable ties . 20

9.5 Loop tensile strength test for cable ties classified according to 6.2.2 . 22

9.5.1 As-received condition . 22

9.5.2 After heat ageing . 22

9.5.3 After temperature cycling . 23

9.6 Loop tensile strength test for cable ties classified according to 6.2.3 . 23

9.6.1 As-received condition . 23

9.6.2 After heat ageing . 24

9.6.3 After temperature cycling . 24

9.6.4 After vibration test for metallic cable ties . 24

9.7 Mechanical strength test for fixing devices and integral assemblies devices . 26

9.7.1 As-received condition . 26

9.7.2 After heat ageing . 32

9.7.3 After temperature cycling . 33

10 Contribution to fire . 34

11 Environmental influences . 36

11.1 Resistance to ultraviolet light . 36

11.2 Resistance to corrosion . 39

12 Electromagnetic compatibility . 39

Annex A (normative) Compliance checks to be carried out for cable ties and fixing

devices currently complying with IEC 62275:20132018 (Edition 3) in order to comply

with IEC 62275:2022 (Edition 4) (i.e., this document) . 40

Bibliography . 42

List of comments . 43

Figure 1 – Reference thickness for cable ties . 10

Figure 2 – Typical arrangements for cable tie orientation on split mandrel

for tensile test . 13

Figure 3 – Test piston for durability test for marking . 17

Figure 4 – Test apparatus for cable tie impact test . 22

Figure 5 – Typical arrangement for the vibration test . 26

Figure 6 – Typical arrangement of test assembly for fixing devices and for integral

fixing devices . 32

Figure 7 – Arrangement for the needle flame test . 36

Figure 8 – Recommended sample repositioning for ultraviolet light and water exposure . 38

Table 1 – Stabilization time for samples . 10

Table 2 – Test mandrel diameter . 11

Table 3 – Loop tensile strength . 14

Table 4 – Maximum operating temperature for application . 15

Table 5 – Minimum operating temperature for application . 15

Table 6 – Literature information . 18

Table 7 – Energy values of hammer . 22

Table A.1 – Required compliance checks . 40

– 4 – IEC 62275:2022 CMV © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CABLE MANAGEMENT SYSTEMS –

CABLE TIES FOR ELECTRICAL INSTALLATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This commented version (CMV) of the official standard IEC 62275:2022 edition 4.0 allows

the user to identify the changes made to the previous IEC 62275:2018 edition 3.0.

Furthermore, comments from IEC SC 23A experts are provided to explain the reasons of

the most relevant changes, or to clarify any part of the content.

A vertical bar appears in the margin wherever a change has been made. Additions are in

green text, deletions are in strikethrough red text. Experts' comments are identified by a

blue-background number. Mouse over a number to display a pop-up note with the

comment.

This publication contains the CMV and the official standard. The full list of comments is

available at the end of the CMV.

IEC 62275 has been prepared by subcommittee 23A: Cable management systems, of IEC

technical committee 23: Electrical accessories. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2018. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) scope clarification,

b) new definitions,

c) deletion of the exception for the stabilization of the moisture content,

d) possibility to carry out tensile strength tests with dead weights,

e) differentiation of rubber and acrylic adhesive fixings,

f) clarification for mechanical testing of integral devices,

g) clarifications on Table 6,

h) clarifications in 9.1,

i) the minimum installation temperature test for cable ties is carried out only when the declared

minimum temperature is lower than 0 °C,

j) a requirement that metallic cable ties be classified according to 6.2.3,

k) definition of colours to be tested for contribution to fire,

l) addition of a "some countries" note in Clause 10,

m) clarification of the mounting of fixing devices in the resistance to ultraviolet light test,

n) clarification on the testing of integral devices in the resistance to ultraviolet light test.

The text of this International Standard is based on the following documents:

Draft Report on voting

23A/1025/FDIS 23A/1029/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The following differing practices of a less permanent nature exist in the countries indicated

below.

– 6.2.2: Additional type classifications are applicable when pre-qualified moulding materials

are used (Canada, USA).

– 6.2.3: Additional type classifications are applicable when pre-qualified moulding materials

are used (Canada, USA).

– 7.3: Some marking information is required to be placed on the packaging (Canada, Russia,

USA).

In this document, the following print types are used:

– Requirements proper: in roman type.

– 6 – IEC 62275:2022 CMV © IEC 2022

– Test specifications: in italic type.

– Notes: in smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

CABLE MANAGEMENT SYSTEMS –

CABLE TIES FOR ELECTRICAL INSTALLATIONS

1 Scope

This document specifies requirements for metallic, non-metallic and composite cable ties and

their associated fixing devices as a means used for managing or securing the management and

support of 1 wiring systems in electrical installations. Cable ties and associated fixing devices

can also be suitable for other applications, such as support of wiring systems, and where so

used, additional requirements can apply.

This document does not contain requirements that evaluate any electrical insulation properties

of the cable tie or mechanical protection of the cables provided by the cable tie. This document

contains requirements for the mechanical interface of an adhesive fixing device to a solid

surface. It does not consider the mechanical behaviour of the solid surface in itself.

This document does not consider the mechanical interface, for example the mounting screw, of

a fixing device other than adhesive to a solid surface.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60216-4-1:2006, Electrical insulating materials – Thermal endurance properties – Part 4‑1:

Ageing ovens – Single-chamber ovens

IEC 60695-11-5:2016, Fire hazard testing – Part 11-5: Test flames – Needle-flame test method

– Apparatus, confirmatory test arrangement and guidance

ISO 4892-2:2013, Plastics – Methods of exposure to laboratory light sources – Part 2:

Xenon-arc lamps

ISO 4892-2:2013/AMD1:2021

ISO 9227:2017, Corrosion tests in artificial atmospheres – Salt spray tests

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC 62275:2022 CMV © IEC 2022

3.1

cable tie

band or length of material, employing a locking device, used for bundling or tying groups of

cables together, securing and/or supporting the cables

Note 1 to entry: Type 1 and Type 2 cable ties are classified in 6.2.2 and 6.2.3.

Note 2 to entry: In some countries, such as Canada and the United States, additional Type classifications are

applicable when prequalified moulding materials are used. See UL 62275/CSA C22.2 No. 62275.

3.2

fixing device

component (such as a block or bracket) specifically designed to secure the cable tie to a

mounting surface

3.3

metallic component

component that consists of metal only

Note 1 to entry: A metallic cable tie having a thin non-metallic or organic coating, where the coating does not

contribute to the determination of the loop tensile strength, is considered a metallic component.

Note 2 to entry: In case of doubt, "as-received condition" tests with and without coating can be carried out.

3.4

non-metallic component

component that consists of non-metallic material only

3.5

composite component

component comprising both metallic and non-metallic materials where both metallic and non-

metallic materials contribute to the determination of the loop tensile strength

3.6

environmental influence

effect of environmental hazards such as corrosive substances or solar radiation, etc.

3.7

loop tensile strength

reference mechanical characteristic of a cable tie with its locking mechanism engaged

3.8

locking device

feature of a cable tie for fixing it in a closed position

3.9

low hygroscopic polymer

polymer having the characteristic of not enabling attraction or holding water greater than 1,0 %

by weight of the material from the surrounding environment at 23 °C and 50 % relative humidity

Note 1 to entry: Examples of low hygroscopic polymers include polypropylene, acetal, ethylene tetrafluoroethylene,

ethylene chlorotrifluoroethylene, nylon 12, polyetheretherketone.

3.10

equilibrium moisture content

state at which a polymer neither absorbs nor releases moisture when exposed to a surrounding

environment of 23 °C and 50 % relative humidity

3.11

integral assembly device 2

single component, as produced, incorporating a cable tie and a fixing device that are not

separable

3.12

adhesive fixing device

fixing device provided with an adhesive tape specifically designed to secure the cable tie to a

mounting surface

3.13

type test 3

conformity test made on one or more items representative of the production

[SOURCE: IEC 60050-151:2001, 151-16-16]

3.14

bundle 4

collection of wires or cables gathered or tied together

4 General requirements

A cable tie and a fixing device shall withstand the stresses likely to occur during recommended

installation practice and perform under the conditions of classifications in Clause 6 as declared

by the manufacturer.

Compliance is checked by carrying out all the appropriate specified tests.

NOTE Annex A details the compliance checks to be carried out for cable ties and fixing devices currently complying

with IEC 62275:20132018 in order to comply with IEC 62275:2022, Edition 4 (i.e., this document).

5 General notes on tests

5.1 Tests according to this document are type tests. Unless otherwise specified, tests are

carried out with the cable ties and their associated fixing devices, where available, installed as

in normal use according to the manufacturer's instructions.

Unless otherwise specified, requirements and tests for fixing devices also apply to adhesive

fixing devices.

NOTE For guidance in determining product types and sample sets, a family of cable ties or fixing devices having

material, construction characteristics, and classifications according to Clause 6, in common, are considered of the

same product type. Examples for consideration are identical generic material description, material colours, or variable

lengths of a cable tie of otherwise similar construction. The sample sets selected for testing from each product type

is representative of the extremes of the range (example: shortest and longest), and the minimum performance level

obtained for either extreme is determined considered to be representative of the entire range. Consideration is given

to minor construction variations that can be determined by inspection to have no effect on performance, when

determining product types.

5.2 Unless otherwise specified, tests on non-metallic and composite components shall

commence when the samples have been removed from their packaging and then stabilized at

a temperature of (23 ± 5) °C and at a relative humidity of (50 ± 5) %, for a period as indicated

in Table 1.

NOTE This stabilization intends to achieve equilibrium moisture content for all samples before and after further

conditioning and testing.

– 10 – IEC 62275:2022 CMV © IEC 2022

Table 1 – Stabilization time for samples

Reference thickness (RT) of device Stabilization time

mm days

RT ≤ 1,2 7 ± 1

1,2 < RT ≤ 1,4 21

−7

1,4 < RT 35

−7

All thicknesses of materials known to 2 ± 1/3

have for low hygroscopic characteristics

polymers

The reference thickness of a cable tie is measured at the midpoint of the strap. The reference

thickness of a fixing device shall be the smallest cross-section in the area that interfaces with

the cable tie or as declared by the manufacturer. See Figure 1.

When the equilibrium moisture content for a material at (23 ± 5) °C and (50 ± 5) % relative

humidity is determined through a method agreed to by the manufacturer and the testing

laboratory, the stabilization time in Table 1 may be reduced when all of the following conditions

are met:

a) the product's moisture content in the as-received condition and after each appropriate

conditioning is measured using a calibrated moisture analyzer device;

b) the samples are subjected to exposure to a constant temperature not exceeding 50 °C and

a relative humidity not exceeding 80 %; and

c) the product's equilibrium moisture content at (23 ± 5) °C and (50 ± 5) % relative humidity is

verified using a calibrated moisture analyzer device. This verification process is repeated

until equilibrium is determined. 5

Key

A reference thickness of cable tie

Figure 1 – Reference thickness for cable ties

5.3 Unless otherwise specified, the tests shall be carried out at an ambient temperature of

(23 ± 5) °C and with a relative humidity of between 40 % and 60 %.

5.4 Unless otherwise specified, three new samples are submitted to the tests and the

requirements are satisfied if all the tests are met. If only one of the samples does not satisfy a

test owing to an assembly or manufacturing fault, that test and any preceding one which may

have influenced the results of the test shall be repeated. The tests that follow shall be carried

out in the required sequence on another full set of samples, all of which shall comply with the

requirements.

NOTE The applicant, when submitting the first set of samples, can also submit an additional set of samples which

may can be necessary if one sample fails. The test station will then without further request test the additional set of

samples and will reject only if a further failure occurs. If the additional set of samples is not submitted at the same

time, a failure of one sample will entail a rejection.

5.5 When toxic or hazardous processes are used, due regard shall be taken of the safety of

persons within the test area.

5.6 Unless otherwise specified, the cross-head speed of a tensile machine used during the

tests shall be (25 ± 2,5) mm/min. Dead weights can be used for conducting loop tensile strength

tests for cable ties and integral devices classified according to 6.2.3, provided that no sudden

application of force occurs. 6

5.7 Where required for heat ageing, a full draft circulating-air oven as specified in

IEC 60216-4-1:2006 shall be used. A portion of the air shall be allowed to re-circulate and a

substantial amount of air shall be admitted continuously to maintain the normal air content

surrounding the samples. The oven shall be adjusted to achieve more than five complete

fresh-air changes per hour.

5.8 An integral assembly device shall be tested as a complete sample. The integral assembly

device shall be subjected to the conditionings for the cable tie prior to conducting the

mechanical strength test for the fixing device in accordance with 9.7.

A fixing device, the performance of which is dependent on the mounting hole size, the thickness

of the material sheet to which it is to be mounted, or the mounting orientation declared by the

manufacturer in accordance with Table 7 Table 6, shall comply with all applicable tests when

the device is assembled to the minimum and maximum thickness of each mounting surface, in

the largest hole size, and in each intended mounting orientation declared by the manufacturer.

When it can be determined that a particular mounting orientation represents the most onerous

condition, the results of the tests in that orientation may represent all mounting orientations.

An adhesive fixing device, the performance of which is dependent on the mounting surface or

the mounting orientation, shall comply with all applicable tests when the device is assembled

on the surfaces for which it is intended, and in each intended mounting orientation declared by

the manufacturer. When it can be determined that a particular mounting orientation represents

the most onerous condition, the results of the tests in that orientation may represent all

mounting orientations.

5.9 Unless otherwise specified, when conducting the tests on cable ties in Clause 9, the

samples shall be installed according to the manufacturer's instructions on a steel or aluminium

mandrel which has a diameter A according to Table 2.

If the minimum declared diameter of the cable tie is greater than the diameter of the test mandrel

specified in Table 2, then a test mandrel that has the minimum diameter as declared by the

manufacturer shall be used.

The width B of the mandrel shall be at least 5 mm greater than the maximum width of the cable

tie as shown in Figure 2.

– 12 – IEC 62275:2022 CMV © IEC 2022

Table 2 – Test mandrel diameter

Maximum declared diameter Test mandrel diameter (A)

mm mm

≤ 20 9,5 ± 1

> 20 and ≤ 38 20 ± 2

> 38 38 ± 2

For the loop tensile strength tests, the mandrel shall be split in two equal parts and the cable

ties positioned as shown in Figure 2a).

A metallic cable tie having a parallel entry strap shall be mounted to the mandrel as shown in

Figure 2 a). Non-metallic or composite cable ties having a parallel entry strap shall be mounted

to the mandrel as shown in Figure 2 b). 7

The excess end (tail) of the cable tie is permitted to be cut off after assembly, except in the

tests where marking is required for the purpose of measurement (see 9.6).

The use of separate steel or aluminium conditioning mandrels is permitted. The conditioning

mandrels need not be split but shall have a diameter approximately equivalent to the

appropriate test mandrel to allow transfer of the sample to the test mandrel. Conditioned

samples shall be carefully transferred to the appropriate test mandrel for carrying out the loop

tensile test. Where it has been determined that the transfer of the samples from the conditioning

mandrel to a test mandrel has influenced the test results, an additional sample set shall be

conditioned and tested.

For integral devices, when it is determined impractical to condition the samples mounted to a

rigid support, samples shall be conditioned separately. When conditioning separately, they shall

be installed on a solid mandrel of similar size to the test fixture and the entire sample set may

be installed on the same mandrel. After conditioning, each sample shall be mounted to the rigid

support test fixture prior to the appropriate tensile pull. Where it has been determined that the

transfer of the samples from the conditioning mandrel to a test mandrel has influenced the test

results, an additional sample set shall be conditioned and tested. 8

Key

1 locking device (head)

2 split line

3 mandrel

4 cable tie

A diameter of test mandrel

B width of test mandrel

Mandrels shall be made of steel or aluminium and shall be smooth and free of burrs.

Care should be taken that the separation of the two halves of the mandrel remains parallel to the split line.

Figure 2 a) – Typical arrangement for a right-angle non-metallic and composite cable tie

and a parallel entry metallic cable tie orientation on split mandrel for tensile test – Right angle entry strap

– 14 – IEC 62275:2022 CMV © IEC 2022

Key

1 locking device (head)

2 split line

3 mandrel

4 cable tie

A diameter of test mandrel

B width of test mandrel

Mandrels shall be made of steel or aluminium and shall be smooth and free of burrs.

Care should be taken that the separation of the two halves of the mandrel remains parallel to the split line.

Figure 2 b) – Typical arrangement for non-metallic and composite cable

tie orientation on split mandrel for tensile test – Parallel entry strap

Figure 2 – Typical arrangements for cable tie orientation

on split mandrel for tensile test

5.10 Tests for rubber adhesive fixing devices and integral devices on stainless steel or

aluminium bare panel cover installation on any bare metal surface and on the following painted

metal surfaces:

– any bare metal surface,

– enamel painted metal surface,

– epoxy painted metal surface,

– polyester painted metal surface.

The installation on other surfaces requires testing on these materials and other painted surfaces

shall be tested.

5.11 Tests for acrylic adhesive fixing devices and integral devices on stainless steel or

aluminium bare panel cover the installation on any bare metal surface. The installation on other

surfaces shall be tested. 9

5.12 Any other generic type of adhesive used on a fixing device or an integral device shall be

tested on each surface.

5.13 Unless specified otherwise by the manufacturer, the samples are to be held to the panel

+1

for a period of 5 s with a force of (50 ± 5) N prior to the start of the prescribed pre-conditioning

period or other exposures. Before applying any force, the time preconditioning period

recommended by the manufacturer shall be respected.

NOTE In Canada and the United States, an adhesive previously evaluated to the appropriate requirements for

polymeric adhesive systems according to UL 746C or CAN/CSA-C22.2 No. 0.17 only requires the evaluation

according to 9.7 on one substrate.

6 Classification

6.1 According to material

6.1.1 Metallic component

6.1.2 Non-metallic component

6.1.3 Composite component

6.2 According to loop tensile strength for cable ties and mechanical strength for

fixing devices

6.2.1 Loop tensile strength for cable ties

As given in Table 3.

Table 3 – Loop tensile strength

Loop tensile strength

N

50 530

80 800

130 890

180 1 150

220 1 300

360 2 200

Other values may be declared at the manufacturer's discretion.

NOTE Loop tensile strength does not provide an indication of long-term static load-bearing capabilities.

6.2.2 Type 1 – Retains at least 50 % of declared loop tensile strength for cable ties

and mechanical strength for fixing devices after test conditions

NOTE In some countries, such as Canada and the United States, additional type classifications are applicable when

pre-qualified moulding materials are used. See UL 62275/CSA C22.2 No.62275.

6.2.3 Type 2 – Retains 100 % declared loop tensile strength for cable ties and

mechanical strength for fixing devices after test conditions

Metallic cable ties and fixing devices shall be classified according to 6.2.3. 10

NOTE In some countries, such as Canada and the United States, additional type classifications are applicable when

pre-qualified moulding materials are used. See UL 62275/CSA C22.2 No.62275.

– 16 – IEC 62275:2022 CMV © IEC 2022

6.2.4 According to loop tensile strength and mechanical strength of integral

assemblies devices

An integral assembly device shall have a single type classification, according to 6.2.2 or 6.2.3.

6.3 According to temperature

6.3.1 According to maximum operating temperature for application given in Table 4

Table 4 – Maximum operating temperature for application

Temperature

°C

Additional ratings above 150 °C may be declared in 10 °C increments.

6.3.2 According to minimum operating temperature for application given in Table 5

Table 5 – Minimum operating temperature for application

Temperature

°C

−5

−15

−25

−40

−60

6.3.3 According to minimum temperature during installation as declared by the

manufacturer

6.4 According to contribution to fire for non-metallic and composite cable ties and

integral assemblies devices only

6.4.1 Flame propagating

NOTE Owing to the small mass of material, cable ties classified as flame propagating are considered to present

only a minor potential contribution in the case of fire.

6.4.2 Non-flame propagating

Metallic cable ties and metallic integral assemblies devices without a non-metallic coating are

considered non-flame propagating.

6.5 According to environmental influences

6.5.1 According to resistance to ultraviolet light for non-metallic and composite

components

6.5.1.1 Not declared

6.5.1.2 Resistant to ultraviolet light

6.5.2 According to resistance to corrosion for metallic and composite components

6.5.2.1 Not declared

6.5.2.2 Resistant to corrosion

7 Marking and documentation

7.1 Each cable tie and fixing device shall be marked with:

– the manufacturer's or responsible vendor's name or trademark, and

– an identifying symbol as defined by the manufacturer.

Compliance is checked by inspection.

Where it is not possible to mark a cable tie or fixing device with the identifying symbol (for

example, due to the small size of the cable tie or fixing device), then this symbol may be marked

on the packaging.

NOTE 1 The identifying symbol can be a reference number, letter, etc.

NOTE 2 Marking can be applied, for example, by moulding, pressing, engraving, printing, adhesive labels, etc.

7.2 Marking on cable ties, fixing devices and integral assemblies devices shall be legible,

durable and indelible.

Laser marking directly on the product and marking made by moulding, pressing or engraving

are not subjected to the test set out in the paragraphs below.

Compliance is checked by inspection, using normal or corrected vision, without additional

magnification.

The test is made by rubbing the marking for 15 s with a piece of cotton cloth soaked with water

and again for 15 s with a piece of cotton cloth soaked with n-hexane 95 % (Chemical Abstracts

Service Registry Number, CAS RN, 110-54-3).

NOTE n-hexane 95 % is available from a variety of chemical suppliers as a high-pressure liquid chromatography

(HPLC) solvent.

When using the liquid specified for the test, precautions as stated in the relative material safety

datasheet provided by the chemical supplier shall be taken to safeguard the laboratory

technicians.

After the test with water, the marking surface to be tested shall be dried.

Rubbing shall commence immediately after soaking the piece of cotton, applying a compression

force of (5 ± 1) N at a rate of about one cycle per second (a cycle comprising a forward and

backward movement along the length of the marking). For markings longer than 20 mm, rubbing

can be limited to a part of the marking, over a path of at least 20 mm length.

– 18 – IEC 62275:2022 CMV © IEC 2022

The compression force is applied by means of a test piston which is wrapped with cotton

comprising cotton wool covered by a piece of cotton medical gauze. The test piston is shown

in Figure 3.

The test piston shall have the dimensions shown in Figure 3 and shall be made of an elastic

material that is inert against the test liquids and has a Shore-A hardness of 47 ± 5 (for example

synthetic rubber). When it is not possible to carry out the test on the specimens owing to the

shape/size of the product, a suitable piece having the same characteristics as the product can

be submitted to the test.

Dimensions

mm

A B C

20 20 2

Figure 3 – Test piston for durability test for marking

7.3 The manufacturer or responsible vendor shall provide in their literature the information

according to Table 6.

Table 6 – Literature information

Information Cable ties Fixing devices Integral

assemblies

devices

Classification according to material according to 6.1 X X X

a

Loop tensile strength according to 6.2.1 X

X

a

The manufacturer's declared mechanical strength X

X

Type designation according to 6.2.2 or 6.2.3 X X X

Maximum operating temperature for application X X X

according to 6.3.1

Minimum operating temperature for application for X X X

non-metallic and composite according to 6.3.2

Minimum temperature during installation for non- X X

metallic and composite according to 6.3.3

Contribution to fire for non-metallic and composite X X

according to 6.4

Resistance to ultraviolet light for non-metallic and X X X

composite according to 6.5.1

Resistance to corrosion for metallic and composite X X X

according to 6.5.2

The maximum and minimum bundle diameter in mm X X

The recommended

...

IEC 62275 ®

Edition 4.0 2022-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Cable management systems – Cable ties for electrical installations

Systèmes de câblage – Colliers pour installations électriques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 300 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

19 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62275 ®

Edition 4.0 2022-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Cable management systems – Cable ties for electrical installations

Systèmes de câblage – Colliers pour installations électriques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.120.10; 29.120.99 ISBN 978-2-8322-6060-9

– 2 – IEC 62275:2022 © IEC 2022

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 8

5 General notes on tests . 8

6 Classification . 13

6.1 According to material . 13

6.1.1 Metallic component . 13

6.1.2 Non-metallic component . 13

6.1.3 Composite component . 13

6.2 According to loop tensile strength for cable ties and mechanical strength for

fixing devices . 13

6.2.1 Loop tensile strength for cable ties . 13

6.2.2 Type 1 – Retains at least 50 % of declared loop tensile strength for

cable ties and mechanical strength for fixing devices after test

conditions . 13

6.2.3 Type 2 – Retains 100 % declared loop tensile strength for cable ties

and mechanical strength for fixing devices after test conditions . 13

6.2.4 According to loop tensile strength and mechanical strength of integral

devices . 14

6.3 According to temperature . 14

6.3.1 According to maximum operating temperature for application given in

Table 4 . 14

6.3.2 According to minimum operating temperature for application given in

Table 5 . 14

6.3.3 According to minimum temperature during installation as declared by

the manufacturer . 14

6.4 According to contribution to fire for non-metallic and composite cable ties

and integral devices only . 14

6.4.1 Flame propagating . 14

6.4.2 Non-flame propagating . 14

6.5 According to environmental influences . 15

6.5.1 According to resistance to ultraviolet light for non-metallic and

composite components . 15

6.5.2 According to resistance to corrosion for metallic and composite

components . 15

7 Marking and documentation . 15

8 Construction . 17

9 Mechanical properties. 18

9.1 Requirements . 18

9.2 Installation test . 18

9.3 Minimum installation temperature test for cable ties . 18

9.4 Minimum operating temperature test for cable ties . 19

9.5 Loop tensile strength test for cable ties classified according to 6.2.2 . 21

9.5.1 As-received condition . 21

9.5.2 After heat ageing . 21

9.5.3 After temperature cycling . 22

9.6 Loop tensile strength test for cable ties classified according to 6.2.3 . 22

9.6.1 As-received condition . 22

9.6.2 After heat ageing . 23

9.6.3 After temperature cycling . 23

9.6.4 After vibration test for metallic cable ties . 24

9.7 Mechanical strength test for fixing devices and integral devices . 25

9.7.1 As-received condition . 25

9.7.2 After heat ageing . 31

9.7.3 After temperature cycling . 32

10 Contribution to fire . 33

11 Environmental influences . 35

11.1 Resistance to ultraviolet light . 35

11.2 Resistance to corrosion . 38

12 Electromagnetic compatibility . 38

Annex A (normative) Compliance checks to be carried out for cable ties and fixing

devices currently complying with IEC 62275:2018 (Edition 3) in order to comply with

Bibliography . 40

Figure 1 – Reference thickness for cable ties . 9

Figure 2 – Typical arrangements for cable tie orientation on split mandrel

for tensile test . 12

Figure 3 – Test piston for durability test for marking . 16

Figure 4 – Test apparatus for cable tie impact test . 21

Figure 5 – Typical arrangement for the vibration test . 25

Figure 6 – Typical arrangement of test assembly for fixing devices and for integral

devices . 31

Figure 7 – Arrangement for the needle flame test . 35

Figure 8 – Recommended sample repositioning for ultraviolet light and water exposure . 37

Table 1 – Stabilization time for samples . 9

Table 2 – Test mandrel diameter . 10

Table 3 – Loop tensile strength . 13

Table 4 – Maximum operating temperature for application . 14

Table 5 – Minimum operating temperature for application . 14

Table 6 – Literature information . 17

Table 7 – Energy values of hammer . 21

Table A.1 – Required compliance checks . 39

– 4 – IEC 62275:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CABLE MANAGEMENT SYSTEMS –

CABLE TIES FOR ELECTRICAL INSTALLATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62275 has been prepared by subcommittee 23A: Cable management systems, of IEC

technical committee 23: Electrical accessories. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2018. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) scope clarification,

b) new definitions,

c) deletion of the exception for the stabilization of the moisture content,

d) possibility to carry out tensile strength tests with dead weights,

e) differentiation of rubber and acrylic adhesive fixings,

f) clarification for mechanical testing of integral devices,

g) clarifications on Table 6,

h) clarifications in 9.1,

i) the minimum installation temperature test for cable ties is carried out only when the declared

minimum temperature is lower than 0 °C,

j) a requirement that metallic cable ties be classified according to 6.2.3,

k) definition of colours to be tested for contribution to fire,

l) addition of a "some countries" note in Clause 10,

m) clarification of the mounting of fixing devices in the resistance to ultraviolet light test,

n) clarification on the testing of integral devices in the resistance to ultraviolet light test.

The text of this International Standard is based on the following documents:

Draft Report on voting

23A/1025/FDIS 23A/1029/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The following differing practices of a less permanent nature exist in the countries indicated

below.

– 6.2.2: Additional type classifications are applicable when pre-qualified moulding materials

are used (Canada, USA).

– 6.2.3: Additional type classifications are applicable when pre-qualified moulding materials

are used (Canada, USA).

– 7.3: Some marking information is required to be placed on the packaging (Canada, Russia,

USA).

In this document, the following print types are used:

– Requirements proper: in roman type.

– Test specifications: in italic type.

– Notes: in smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 62275:2022 © IEC 2022

CABLE MANAGEMENT SYSTEMS –

CABLE TIES FOR ELECTRICAL INSTALLATIONS

1 Scope

This document specifies requirements for metallic, non-metallic and composite cable ties and

their associated fixing devices as a means used for managing or securing the wiring systems

in electrical installations. Cable ties and associated fixing devices can also be suitable for other

applications, such as support of wiring systems, and where so used, additional requirements

can apply.

This document does not contain requirements that evaluate any electrical insulation properties

of the cable tie or mechanical protection of the cables provided by the cable tie. This document

contains requirements for the mechanical interface of an adhesive fixing device to a solid

surface. It does not consider the mechanical behaviour of the solid surface in itself.

This document does not consider the mechanical interface, for example the mounting screw, of

a fixing device other than adhesive to a solid surface.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60216-4-1:2006, Electrical insulating materials – Thermal endurance properties – Part 4‑1:

Ageing ovens – Single-chamber ovens

IEC 60695-11-5:2016, Fire hazard testing – Part 11-5: Test flames – Needle-flame test method

– Apparatus, confirmatory test arrangement and guidance

ISO 4892-2:2013, Plastics – Methods of exposure to laboratory light sources – Part 2:

Xenon-arc lamps

ISO 4892-2:2013/AMD1:2021

ISO 9227:2017, Corrosion tests in artificial atmospheres – Salt spray tests

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

cable tie

band or length of material, employing a locking device, used for bundling or tying groups of

cables together, securing and/or supporting the cables

Note 1 to entry: Type 1 and Type 2 cable ties are classified in 6.2.2 and 6.2.3.

Note 2 to entry: In some countries, such as Canada and the United States, additional Type classifications are

applicable when prequalified moulding materials are used. See UL 62275/CSA C22.2 No. 62275.

3.2

fixing device

component (such as a block or bracket) specifically designed to secure the cable tie to a

mounting surface

3.3

metallic component

component that consists of metal only

Note 1 to entry: A metallic cable tie having a thin non-metallic or organic coating, where the coating does not

contribute to the determination of the loop tensile strength, is considered a metallic component. In case of doubt,

"as-received condition" tests with and without coating can be carried out.

3.4

non-metallic component

component that consists of non-metallic material only

3.5

composite component

component comprising both metallic and non-metallic materials where both metallic and non-

metallic materials contribute to the determination of the loop tensile strength

3.6

environmental influence

effect of environmental hazards such as corrosive substances or solar radiation, etc.

3.7

loop tensile strength

reference mechanical characteristic of a cable tie with its locking mechanism engaged

3.8

locking device

feature of a cable tie for fixing it in a closed position

3.9

low hygroscopic polymer

polymer having the characteristic of not enabling attraction or holding water greater than 1,0 %

by weight of the material from the surrounding environment at 23 °C and 50 % relative humidity

Note 1 to entry: Examples of low hygroscopic polymers include polypropylene, acetal, ethylene tetrafluoroethylene,

ethylene chlorotrifluoroethylene, nylon 12, polyetheretherketone.

3.10

equilibrium moisture content

state at which a polymer neither absorbs nor releases moisture when exposed to a surrounding

environment of 23 °C and 50 % relative humidity

3.11

integral device

single component, as produced, incorporating a cable tie and a fixing device that are not

separable

– 8 – IEC 62275:2022 © IEC 2022

3.12

adhesive fixing device

fixing device provided with an adhesive tape specifically designed to secure the cable tie to a

mounting surface

3.13

type test

conformity test made on one or more items representative of the production

[SOURCE: IEC 60050-151:2001, 151-16-16]

3.14

bundle

collection of wires or cables gathered or tied together

4 General requirements

A cable tie and a fixing device shall withstand the stresses likely to occur during recommended

installation practice and perform under the conditions of classifications in Clause 6 as declared

by the manufacturer.

Compliance is checked by carrying out all the appropriate specified tests.

NOTE Annex A details the compliance checks to be carried out for cable ties and fixing devices currently complying

with IEC 62275:2018 in order to comply with IEC 62275:2022, Edition 4 (i.e., this document).

5 General notes on tests

5.1 Tests according to this document are type tests. Unless otherwise specified, tests are

carried out with the cable ties and their associated fixing devices, where available, installed as

in normal use according to the manufacturer's instructions.

Unless otherwise specified, requirements and tests for fixing devices also apply to adhesive

fixing devices.

NOTE For guidance in determining product types and sample sets, a family of cable ties or fixing devices having

material, construction characteristics, and classifications according to Clause 6, in common, are considered of the

same product type. Examples for consideration are identical generic material description, material colours, or variable

lengths of a cable tie of otherwise similar construction. The sample sets selected for testing from each product type

is representative of the extremes of the range (example: shortest and longest), and the minimum performance level

obtained for either extreme is considered to be representative of the entire range. Consideration is given to minor

construction variations that can be determined by inspection to have no effect on performance, when determining

product types.

5.2 Unless otherwise specified, tests on non-metallic and composite components shall

commence when the samples have been removed from their packaging and then stabilized at

a temperature of (23 ± 5) °C and at a relative humidity of (50 ± 5) %, for a period as indicated

in Table 1.

NOTE This stabilization intends to achieve equilibrium moisture content for all samples before and after further

conditioning and testing.

Table 1 – Stabilization time for samples

Reference thickness (RT) of device Stabilization time

mm days

RT ≤ 1,2 7 ± 1

1,2 < RT ≤ 1,4 21

−7

1,4 < RT 35

−7

All thicknesses for low hygroscopic 2 ± 1/3

polymers

The reference thickness of a cable tie is measured at the midpoint of the strap. The reference

thickness of a fixing device shall be the smallest cross-section in the area that interfaces with

the cable tie or as declared by the manufacturer. See Figure 1.

Key

A reference thickness of cable tie

Figure 1 – Reference thickness for cable ties

5.3 Unless otherwise specified, the tests shall be carried out at an ambient temperature of

(23 ± 5) °C and with a relative humidity of between 40 % and 60 %.

5.4 Unless otherwise specified, three new samples are submitted to the tests and the

requirements are satisfied if all the tests are met. If only one of the samples does not satisfy a

test owing to an assembly or manufacturing fault, that test and any preceding one which may

have influenced the results of the test shall be repeated. The tests that follow shall be carried

out in the required sequence on another full set of samples, all of which shall comply with the

requirements.

NOTE The applicant, when submitting the first set of samples, can also submit an additional set of samples which

can be necessary if one sample fails. The test station will then without further request test the additional set of

samples and will reject only if a further failure occurs. If the additional set of samples is not submitted at the same

time, a failure of one sample will entail a rejection.

5.5 When toxic or hazardous processes are used, due regard shall be taken of the safety of

persons within the test area.

– 10 – IEC 62275:2022 © IEC 2022

5.6 Unless otherwise specified, the cross-head speed of a tensile machine used during the

tests shall be (25 ± 2,5) mm/min. Dead weights can be used for conducting loop tensile strength

tests for cable ties and integral devices classified according to 6.2.3, provided that no sudden

application of force occurs.

5.7 Where required for heat ageing, a full draft circulating-air oven as specified in

IEC 60216-4-1:2006 shall be used. A portion of the air shall be allowed to re-circulate and a

substantial amount of air shall be admitted continuously to maintain the normal air content

surrounding the samples. The oven shall be adjusted to achieve more than five complete

fresh-air changes per hour.

5.8 An integral device shall be tested as a complete sample. The integral device shall be