IEC 61482-2:2018

(Main)Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements

Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements

IEC 61482-2:2018 is applicable to protective clothing used in work where there is the risk of exposure to an electric arc hazard. This document specifies requirements and test methods applicable to materials and garments for protective clothing for electrical workers against the thermal hazards of an electric arc. Electric shock hazard is not covered by this document, which is applicable in combination with standards covering such hazards. Other effects than the thermal effects of an electric arc like noise, light emissions, pressure rise, hot oil, electric shock, the consequences of physical and mental shock or toxic influences are not covered by this document. Protection of eyes, face, head, hands and feet against electric arc hazard is not covered by this document. Requirements and tests to cover electric arc hazards to these parts of the body are under development. Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch, is not covered by this document. This second edition cancels and replaces the first edition published in 2009. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: new definition for ELIM, ATPV and EBT as used in accordance with IEC 61482-1-1:–; new requirements for the thermal stability of the intermediate layers; additional material requirement for volume resistance; new test procedure for the thermal resistance of sewing threads and a new symbol for marking.

Key words: Electric Arc, Protective Clothing, Arc Thermal Protection

Travaux sous tension - Vêtements de protection contre les dangers thermiques d'un arc électrique - Partie 2: Exigences

IEC 61482-2:2018est applicable aux vętements de protection utilisés pour réaliser des travaux lorsqu’il y a un risque d’exposition à un danger d’arc électrique. Le présent document spécifie les exigences et les méthodes d’essai applicables aux matériaux et aux articles d’habillement utilisés pour les vętements de protection des travailleurs du domaine électrique contre les dangers thermiques d’un arc électrique. Les dangers de chocs électriques ne sont pas couverts par le présent document, qui est applicable en combinaison avec les normes couvrant ce type de dangers. Le présent document ne couvre que les effets thermiques d’un arc électrique, et ne couvre pas les effets comme le bruit, les émissions lumineuses, l’augmentation de la pression, l’huile chaude, le choc électrique, les conséquences d’un choc physique ou mental ou des effets toxiques lors d’un arc électrique. Le présent document ne couvre pas la protection des yeux, du visage, de la tęte, des mains et des pieds contre le danger d’arc électrique. Les exigences et les essais applicables aux dangers d’arc électrique concernant ces parties du corps sont en cours d’élaboration. Le présent document ne couvre pas les vętements de protection portés pour réaliser des travaux utilisant intentionnellement un arc électrique, par exemple le soudage à l’arc, l'usage d'une torche à plasma. Cette deuxième édition annule et remplace la première édition parue en 2009. La présente édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente: nouvelle définition des valeurs d’ELIM, d’ATPV et d’EBT, telles qu’utilisées conformément à l’IEC 61482-1-1:

- nouvelles exigences relatives à la stabilité thermique des couches intermédiaires;

- exigence supplémentaire du matériau concernant la résistance électrique;

- nouvelle procédure d’essai pour la résistance thermique des fils de couture;

- nouveau symbole de marquage.

Mots-clés: arc électrique, vętements de protection, protection thermique contre l’arc

General Information

- Status

- Published

- Publication Date

- 27-May-2018

- Technical Committee

- TC 78 - Live working

- Drafting Committee

- WG 15 - TC 78/WG 15

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-May-2018

- Completion Date

- 08-Jun-2018

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61482-2:2018 (IEC - Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements) defines requirements and test methods for protective clothing used where there is a risk of exposure to an electric arc. It addresses material and garment performance against the thermal hazards of an electric arc (arc thermal protection), specifying how to demonstrate arc resistance and general textile properties. This part does not cover electric shock protection, eye/face/head/hand/foot protection, or equipment and garments intended for deliberate arc processes (e.g., welding, plasma cutting).

Key Topics and Requirements

- Arc thermal resistance - Verification of arc performance using recognized test methods: arc rating concepts such as ATPV and EBT (per IEC 61482-1-1) and arc protection classes (Class 1 / Class 2 per IEC 61482-1-2).

- Material requirements - General textile properties required for outer, intermediate and innermost layers, including:

- Heat resistance and thermal stability of intermediate layers.

- Volume resistance (electrical resistivity) where specified.

- Limited flame spread characteristics.

- Mechanical properties for woven outer materials and dimensional change after laundering/dry cleaning.

- Component testing - New or revised test procedures, for example thermal resistance of sewing threads, and requirements for threads, accessories and closures.

- Design and workmanship - Garment construction, sizing/ergonomics and ageing considerations to ensure protective function in service.

- Marking and instructions - Mandatory marking (including a new symbol) and user instructions detailing arc performance, care, limitations and conformity information.

- Conformity assessment - Type tests and tests for production-phase conformity to demonstrate ongoing compliance.

Applications and Who Uses This Standard

IEC 61482-2:2018 is used by:

- PPE manufacturers designing arc-rated protective clothing for electrical workers.

- Test laboratories and certification bodies performing arc thermal resistance and textile testing.

- Purchasing and safety managers specifying requirements for clothing in power generation, utilities, industrial maintenance and live-line work.

- Designers and quality engineers responsible for material selection, garment construction and labelling.

Practical applications include specifying and verifying garments for live working tasks where thermal arc risk exists, ensuring proper labelling, maintenance instructions and that garments meet recognized arc thermal protection performance metrics.

Related Standards

- IEC 61482-1-1 (open arc test methods; ATPV/EBT definitions)

- IEC 61482-1-2 (box/directed arc test; arc protection classes)

- IEC 61477 (related live working requirements)

Keywords: Electric Arc, Protective Clothing, Arc Thermal Protection, arc rating, ATPV, EBT, IEC 61482-2:2018.

Buy Documents

IEC 61482-2:2018 RLV - Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements Released:5/28/2018 Isbn:9782832257579

IEC 61482-2:2018 - Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements Released:5/28/2018 Isbn:9782832257173

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61482-2:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements". This standard covers: IEC 61482-2:2018 is applicable to protective clothing used in work where there is the risk of exposure to an electric arc hazard. This document specifies requirements and test methods applicable to materials and garments for protective clothing for electrical workers against the thermal hazards of an electric arc. Electric shock hazard is not covered by this document, which is applicable in combination with standards covering such hazards. Other effects than the thermal effects of an electric arc like noise, light emissions, pressure rise, hot oil, electric shock, the consequences of physical and mental shock or toxic influences are not covered by this document. Protection of eyes, face, head, hands and feet against electric arc hazard is not covered by this document. Requirements and tests to cover electric arc hazards to these parts of the body are under development. Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch, is not covered by this document. This second edition cancels and replaces the first edition published in 2009. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: new definition for ELIM, ATPV and EBT as used in accordance with IEC 61482-1-1:–; new requirements for the thermal stability of the intermediate layers; additional material requirement for volume resistance; new test procedure for the thermal resistance of sewing threads and a new symbol for marking. Key words: Electric Arc, Protective Clothing, Arc Thermal Protection

IEC 61482-2:2018 is applicable to protective clothing used in work where there is the risk of exposure to an electric arc hazard. This document specifies requirements and test methods applicable to materials and garments for protective clothing for electrical workers against the thermal hazards of an electric arc. Electric shock hazard is not covered by this document, which is applicable in combination with standards covering such hazards. Other effects than the thermal effects of an electric arc like noise, light emissions, pressure rise, hot oil, electric shock, the consequences of physical and mental shock or toxic influences are not covered by this document. Protection of eyes, face, head, hands and feet against electric arc hazard is not covered by this document. Requirements and tests to cover electric arc hazards to these parts of the body are under development. Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch, is not covered by this document. This second edition cancels and replaces the first edition published in 2009. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: new definition for ELIM, ATPV and EBT as used in accordance with IEC 61482-1-1:–; new requirements for the thermal stability of the intermediate layers; additional material requirement for volume resistance; new test procedure for the thermal resistance of sewing threads and a new symbol for marking. Key words: Electric Arc, Protective Clothing, Arc Thermal Protection

IEC 61482-2:2018 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.260.99 - Other electrical equipment for working in special conditions. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61482-2:2018 has the following relationships with other standards: It is inter standard links to IEC 61482-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61482-2:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61482-2 ®

Edition 2.0 2018-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Live working – Protective clothing against the thermal hazards of

an electric arc –

Part 2: Requirements

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61482-2 ®

Edition 2.0 2018-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Live working – Protective clothing against the thermal hazards of

an electric arc –

Part 2: Requirements

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 13.220.40; 29.260.99 ISBN 978-2-8322-5757-9

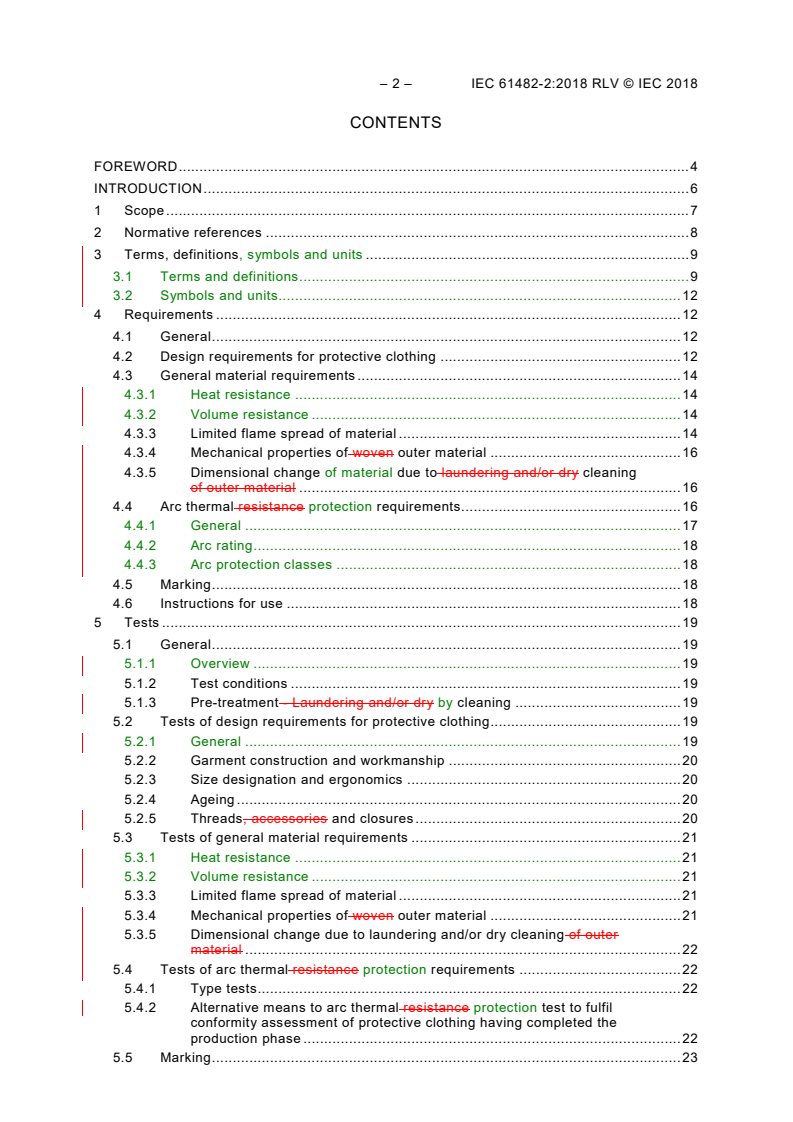

– 2 – IEC 61482-2:2018 RLV © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 8

3 Terms, definitions, symbols and units . 9

3.1 Terms and definitions . 9

3.2 Symbols and units. 12

4 Requirements . 12

4.1 General . 12

4.2 Design requirements for protective clothing . 12

4.3 General material requirements . 14

4.3.1 Heat resistance . 14

4.3.2 Volume resistance . 14

4.3.3 Limited flame spread of material . 14

4.3.4 Mechanical properties of woven outer material . 16

4.3.5 Dimensional change of material due to laundering and/or dry cleaning

of outer material . 16

4.4 Arc thermal resistance protection requirements . 16

4.4.1 General . 17

4.4.2 Arc rating . 18

4.4.3 Arc protection classes . 18

4.5 Marking . 18

4.6 Instructions for use . 18

5 Tests . 19

5.1 General . 19

5.1.1 Overview . 19

5.1.2 Test conditions . 19

5.1.3 Pre-treatment - Laundering and/or dry by cleaning . 19

5.2 Tests of design requirements for protective clothing . 19

5.2.1 General . 19

5.2.2 Garment construction and workmanship . 20

5.2.3 Size designation and ergonomics . 20

5.2.4 Ageing . 20

5.2.5 Threads, accessories and closures . 20

5.3 Tests of general material requirements . 21

5.3.1 Heat resistance . 21

5.3.2 Volume resistance . 21

5.3.3 Limited flame spread of material . 21

5.3.4 Mechanical properties of woven outer material . 21

5.3.5 Dimensional change due to laundering and/or dry cleaning of outer

material . 22

5.4 Tests of arc thermal resistance protection requirements . 22

5.4.1 Type tests . 22

5.4.2 Alternative means to arc thermal resistance protection test to fulfil

conformity assessment of protective clothing having completed the

production phase . 22

5.5 Marking . 23

5.5.1 Visual inspection . 23

5.5.2 Durability of marking . 23

5.6 Instructions for use . 23

6 Conformity assessment of protective clothing having completed the production

phase . 23

7 Modifications . 23

Annex A (normative) Marking and instructions for use . 24

A.1 Marking . 24

A.2 Instructions for use . 25

Annex (informative) Use and maintenance .

Annex B (normative) Type tests . 27

Annex C (normative) Classification of defects . 28

Annex D (informative) Rationale for the classification of defects . 31

Bibliography . 33

Table 1 – Single-layer material . 15

Table 2 – Outer and innermost layer materials . 15

Table 3 – Intermediate layer material not intended for arc thermal protection . 15

Table 4 – Intermediate layer material intended for arc thermal protection . 16

Table B.1 – List of type tests . 27

Table C.1 – Classification of defects and associated requirements and tests . 28

Table D.1 – Justification for the type of defect . 31

– 4 – IEC 61482-2:2018 RLV © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING –

PROTECTIVE CLOTHING AGAINST

THE THERMAL HAZARDS OF AN ELECTRIC ARC –

Part 2: Requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61482-2 has been prepared by IEC technical committee 78: Live

working.

This second edition cancels and replaces the first edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) new definition for ELIM, ATPV and EBT as used in accordance with IEC 61482-1-1:–;

b) new requirements for the thermal stability of the intermediate layers;

c) additional material requirement for volume resistance;

d) new test procedure for the thermal resistance of sewing threads;

e) new symbol for marking.

The text of this standard is based on the following documents:

FDIS Report on voting

78/1205/FDIS 78/1228/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

Terms defined in Clause 3 are given in italic print throughout this standard.

A list of all parts of the IEC 61482 series, published under the general title Live working –

Protective clothing against the thermal hazards of an electric arc, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 61482-2:2018 RLV © IEC 2018

INTRODUCTION

This document has been prepared in accordance with the requirements of IEC 61477.

The products designed and manufactured according to this document contribute to the safety

of the users, provided they are used by skilled persons, in accordance with safe methods of

work and the instructions for use.

The product covered by this document may have an impact on the environment during some

or all stages of its life cycle. These impacts can range from slight to significant, be of short-

term or long-term duration, and occur at the global, regional or local level.

This document does not include requirements and test provisions for the manufacturers of the

product, or recommendations to the users of the product for environmental improvement.

However, all parties intervening in its design, manufacture, packaging, distribution, use,

maintenance, repair, reuse, recovery and disposal are invited to take account of

environmental considerations.

LIVE WORKING –

PROTECTIVE CLOTHING AGAINST

THE THERMAL HAZARDS OF AN ELECTRIC ARC –

Part 2: Requirements

1 Scope

This part of IEC 61482 is applicable to protective clothing used in work where there is the risk

of exposure to an electric arc hazard.

This document specifies requirements and test methods applicable to materials and garments

for protective clothing for electrical workers against the thermal hazards of an electric arc

based on.

– relevant general properties of the textiles, tested with selected textile test methods, and

– arc thermal resistance properties, such as

• the arc rating of materials (ATPV or E ), when tested with an open electric arc

BT50

under defined laboratory conditions according to IEC 61482-1-1, or

• the arc protection class of materials and garments (Class 1 or Class 2), when tested

with a directed and constrained electric arc under defined laboratory conditions

according to IEC 61482-1-2.

Requirements of this standard do not address electric shock hazards. The present standard is

applicable in combination with standards covering such hazards.

NOTE 1 If conductive fibres are used in the construction of the garments the risk for electric shock hazard should

be considered.

This standard does not contain requirements for the protection of head, hands and feet.

NOTE 2 Requirements and tests to cover these hazards are under development.

Requirements of this standard do not cover the electric arc hazards of electric shock, noise,

UV emissions, pressure shrapnel, hot oil, the consequences of physical and mental shock and

the toxic influences.

NOTE 3 The standard is applicable in combination with standards covering such hazards.

Electric shock hazard is not covered by this document, which is applicable in combination with

standards covering such hazards.

Other effects than the thermal effects of an electric arc like noise, light emissions, pressure

rise, hot oil, electric shock, the consequences of physical and mental shock or toxic

influences are not covered by this document.

Protection of eyes, face, head, hands and feet against electric arc hazard is not covered by

this document.

NOTE Requirements and tests to cover electric arc hazards to these parts of the body are under development.

Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch,

is not covered by this document.

– 8 – IEC 61482-2:2018 RLV © IEC 2018

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60417, Graphical symbols for use on equipment (available at: http://www.graphical-

symbols.info/equipment)

IEC 61318:2007, Live working – Conformity assessment applicable to tools, devices and

equipment

IEC 61340-2-3:2016, Electrostatics – Part 2-3: Methods of test for determining the resistance

and resistivity of solid materials used to avoid electrostatic charge accumulation

IEC 61477, Live working – Minimum requirements for the utilization of tools, devices and

equipment

, Live working – Protective clothing against the thermal hazards of an

IEC 61482-1-1:–

electric arc – Part 1-1: Test methods – Method 1: Determination of the arc rating (ELIM, ATPV

and/or E EBT) of flame resistant materials for clothing materials and of protective clothing

BT50

using an open arc

IEC 61482-1-2:2007, Live working – Protective clothing against the thermal hazards of an

electric arc – Part 1-2: Test methods – Method 2: Determination of arc protection class of

material and clothing by using a constrained and directed arc (box test)

ISO 3175-2, Textiles – Professional care, drycleaning and wetcleaning of fabrics and

garments – Part 2: Procedure for testing performance when cleaning and finishing using

tetrachloroethene

ISO 3146, Plastics – Determination of melting behaviour (melting temperature or melting

range) of semi-crystalline polymers by capillary tube and polarizing-microscope methods

ISO 3758, Textiles – Care labelling code using symbols

ISO 5077, Textiles – Determination of dimensional change in washing and drying

ISO 6330, Textiles – Domestic washing and drying procedures for textile testing

ISO 13688:1998 2013, Protective clothing – General requirements

ISO 13934-1, Textiles – Tensile properties of fabrics – Part 1: Determination of maximum

force and elongation at maximum force using the strip method

ISO 13937-2, Textiles – Tear properties of fabrics – Part 2: Determination of tear force of

trouser-shaped test specimens (Single tear method)

ISO 13938-1, Textiles – Bursting properties of fabrics – Part 1: Hydraulic method for

determination of bursting strength and bursting distension

___________

Under preparation. Stage at time of publication: IEC CDV 61482-1-1:2017.

ISO 13938-2, Textiles – Bursting properties of fabrics – Part 2: Pneumatic method for

determination of bursting strength and bursting distension

ISO 14116:2007, Protective clothing – Protection against heat and flame – Limited flame

spread materials, material assemblies and clothing

ISO 15025:2000, Protective clothing – Protection against heat and flame – Method of test for

limited flame spread

ISO 17493:2016, Clothing and equipment for protection against heat – Test method for

convective heat resistance using a hot air circulating oven

ISO 30023, Textiles – Qualification symbols for labelling workwear to be industrially laundered

3 Terms, definitions, symbols and units

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61318 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

arc protection class

APC

category of arc thermal protection of a material and/or product tested in

accordance with the box test (APC 1 or APC 2)

Note 1 to entry: The arc protection class is characterized by the test energy level of arc exposure (arc energy and

incident energy).

Note 2 to entry: Tested material and/or products show arc thermal protection at minimum up to the class energy

level but, in general, the actual exposure energy limit up to which the material and/or product provide protection is

higher.

3.1.2

arc rating

numerical value attributed to a product, that describes its protective

performance when exposed to an electric arc

Note 1 to entry: The arc rating can be the arc thermal performance value (ATPV), the breakopen threshold energy

(EBT) or the incident energy limit (ELIM).

2 2

Note 2 to entry: The arc rating is expressed in kJ/m (cal/cm ).

3.1.3

arc thermal protection

degree of thermal protection offered against electric arc under specific

arc testing conditions indicated by either arc rating or arc protection class

Note 1 to entry: For materials, the arc thermal performance protection is obtained from the measurement of the

transmitted energy and by evaluation of other thermal parameters (burning time, hole formation, melting).

Note 2 to entry: For garments, the arc thermal performance protection is obtained by evaluation of thermal

parameters (burning time, hole formation, melting) of the material(s) from which the garment is made and of the

functioning of fasteners the closures and accessories.

– 10 – IEC 61482-2:2018 RLV © IEC 2018

[Definition 3.5 of IEC 61482-1-2:2007]

3.1.4

arc thermal performance value

ATPV

in arc testing, the incident energy on a material or a multilayer system of materials that results

in a 50 % probability that sufficient heat transfer through the tested specimen is predicted to

cause the onset of a second degree skin burn injury based on the Stoll curve, without

breakopen

2 2 2 )

NOTE ATPV is expressed in kJ/m or kW·s/m (cal/cm ).

[Definition 3.1.4 of IEC 61482-1-1]

numerical value of incident energy attributed to a product that describes

its thermal properties of attenuating (reducing) a heat flux generated by an electric arc

Note 1 to entry: The ATPV of a material or material assembly is calculated using logistic regression analysis

applied to the data points obtained from testing a set of test specimens. It is the value of incident energy at which

the heat transfer through the test specimens is enough to reach the Stoll criteria with 50 % probability.

Note 2 to entry: The ATPV attributed to a garment or garment assembly is either equal to or lower than the ATPV

of the material or material assembly of which it is made, depending on whether the tested specimen(s) fulfil also

additional visual design and performance assessment criteria.

3.1.5

breakopen threshold energy

E EBT

BT50

incident energy on a fabric or material that results in a 50 % probability that sufficient heat

transfer through the tested specimen is predicted to cause the tested specimen to break open

2 2 2 )

NOTE The breakopen threshold energy is expressed in kJ/m or kW·s/m (cal/cm ).

[Definition 3.1.8 of IEC 61482-1-1, modified]

numerical value of incident energy attributed to a product that describes

its breakopen properties when exposed to heat flux generated by an electric arc

Note 1 to entry: The EBT of a material or material assembly is calculated using logistic regression analysis

applied to the data points obtained from testing a set of test specimens. It is the value of incident energy at which

breakopen occurs with 50 % probability.

Note 2 to entry: The EBT attributed to a garment or garment assembly is either equal to or lower than the EBT of

the material or material assembly of which it is made, depending on whether the tested specimen(s) fulfil also

additional visual design and performance assessment criteria.

3.4

clothing

assembly of garments worn by workers

3.1.6

electric arc

self-maintained gas conduction for which most of the charge carriers are electrons supplied

by primary-electron emission

Note 1 to entry: During live working, the electric arc is generated by gas ionization arising from an unintentional

electrical conducting connection or breakdown between live parts or a live part and the earth path of an electrical

installation or an electrical device. During testing, the electric arc is initiated by the blowing of a fuse wire.

___________

2) 2 2 2 2

Correlation 1 cal/cm = 41,868 kJ/m ; 1 kJ/m = 0,023885 cal/cm .

3) 2 2 2 2

Correlation 1 cal/cm = 41,868 kJ/m ; 1 kJ/m = 0,023885 cal/cm .

[SOURCE: IEC 60050-121:1998, 121-13-12, modified – Note 1 to entry has been added to

refer specifically to live working and arc testing.]

3.1.7

electric arc hazard

potential harm from an energy release from an electric arc usually caused by a short circuit or

equipment failure in electrotechnical work

Note 1 to entry: An electric arc hazard exists when live electrical conductors or parts are exposed and when they

are inside an item of equipment, even when guarded or enclosed, if a worker is interacting with the equipment in a

way which could cause an electric arc. Under normal operating conditions, enclosed energized equipment that has

been properly designed, installed and maintained is not likely to pose an electric arc hazard.

Note 2 to entry: Documents such as NFPA 70E, IEEE 1584, ISSA Guide, and DGUV-I 203-77 help to assess

hazards from the practical perspective.

Note 3 to entry: The hazards may include thermal effects, noise, pressure wave effects, ejected parts effects,

molten metal, optical and other effects. Different PPE (personal protective equipment) may be required to protect

from different effects. It is important that the risk assessment consider all the potential effects.

3.1.8

garment

single item of clothing which may can consist of single or multiple layers of material

3.1.9

garment system

garment assembly for which a specific arc rating or arc protection class is attributed after

having performed an arc test

3.1.10

hardware

non-fabric items forming part of or optional extras in a garment

3.1.11

incident energy limit

ELIM

numerical value of incident energy attributed to a product, below which

there is no data point with the amount of heat transmitted through the product reaching the

Stoll criteria or with the product exhibiting breakopen

Note 1 to entry: The ELIM of a material or material assembly is calculated from data points obtained from testing

a set of test specimens, which are also used for the determination of the ATPV and/or EBT.

Note 2 to entry: The ELIM attributed to a garment or garment assembly is either equal to or lower than the ELIM

of the material or material assembly of which it is made, depending on whether the tested specimen(s) fulfil also

additional visual design and performance assessment criteria.

3.1.12

material

fabric or other substances of which the garment is made, this may consist of single or multiple

layers

substances, excluding hardware, of which an item of clothing is made

[SOURCE ISO 11612:2015, 3.13]

3.1.13

open arc

electric arc between two vertically opposing electrodes intended to

provide an equal distribution of emitted energy around the centre line formed by the

electrodes and where the emitted energy is not directed by means of any physical constraints

(e.g. enclosure, wall)

– 12 – IEC 61482-2:2018 RLV © IEC 2018

3.1.14

protective clothing

clothing which covers or replaces personal clothing, and which is designed to provide clothing

which covers or replaces personal clothing and which is designed to provide protection

against one or more hazards

[Definition 3.4 of ISO 13688:1998 SOURCE: ISO/TR 11610:2004, 3.178]

3.9

Stoll curve

curve of thermal energy and time produced from data on human tissue tolerance to heat and

used to predict the onset of second-degree burn injury

[Definition 3.29 of IEC 61482-1-2:2007]

3.10

test current

I ,

arc class

prospective short-circuit current of the electric test circuit (predicted current), characterising a

test class, r.m.s. value (symmetrical AC component)

NOTE Test current is expressed in A.

[Definition 3.30 of IEC 61482-1-2:2007]

3.2 Symbols and units

APC arc protection class 1 or 2

2 2

ATPV arc thermal performance value kJ/m or cal/cm

2 2

EBT breakopen threshold energy kJ/m or cal/cm

2 2

ELIM incident energy limit kJ/m or cal/cm

2 2 2 2

NOTE 1 kJ/m = 1 kW·s/m = 0,1 J/cm = 0,023 885 cal/cm

2 2 2

1 cal/cm = 41,840 kJ/m = 41,840 kW·s/m

4 Requirements

4.1 General

General requirements for protective clothing against the thermal hazard of an electric arc

which are not specifically covered in this document shall be in accordance with ISO 13688.

4.2 Design requirements for protective clothing

The garment shall be designed in a way, that they do not influence or hinder the wearer

performing work.

Garments protecting the upper part of the body shall have long sleeves.

Fasteners of the garment shall be designed in a way that the opening function is still present

after being exposed to an accidental arc.

Thread, accessories and closures used in garment construction shall not contribute to the

severity of the injuries to the wearer in the event of a momentary electric arc and related

thermal exposure.

No exposed external metal shall be permitted in the clothing. If internal metal and/or melting

parts (e.g. fasteners, buttons, and accessories) are used they shall be covered to the inside

to avoid skin contact.

All parts of a garment shall be made of arc thermal resistant materials. In case different

materials are used e.g. for the front and back the exact information shall be given where the

weaker area is located (e.g. by means of a drawing of the garment including dimensions and

warning indication).

The front side of the garment and the complete sleeves (all around the arms and over the

complete length of the arms) of the garment (e.g. jackets) shall fulfil the same arc thermal

resistance requirements. If due to comfort requirements the garment is not produced of the

same materials in all areas then this shall be clearly stated in the instructions for use.

NOTE 1 These requirements are also valid for garments protecting the lower part of the body (e.g. trousers,

chaps, leggings).

Sewing thread utilized in the construction of garments shall be made of an inherently flame-

resistant fibre and shall not melt when tested at a temperature of 260 °C in accordance with

ISO 17493. There are many seams in a garment that have no influence on protection, e.g.

hems, pocket seams, etc. The sewing thread there need not be flame resistant.

During its service life, protective clothing shall keep its arc thermal properties when cleaned

according to the instructions for use.

If a single manufacturer makes claims for a garment system as arc thermal protective

clothing, then this garment system shall be tested and shall fulfil the requirements of this

standard.

NOTE 2 If the user is wearing a garment system (e.g. jacket + shirt) from different manufacturers as arc thermal

protective clothing, then this garment system should be tested to determine how the system fulfils the requirements

of this standard.

Garments protecting the upper part of the body shall have sleeves which extend to provide full

coverage to the wrists and shall provide coverage up to the neck. Garments protecting the

lower part of the body shall provide full coverage from the waist to the ankles.

Closures of the garment shall be designed in a way that the opening function is still present

after being exposed to an arc when tested according to 5.2.5.

Accessories (e.g. labels, badges, retro-reflective material) and closures used in garment

construction shall not contribute to the severity of the injuries to the wearer in the event of an

electric arc and related thermal exposure when the clothing is tested according to the garment

test in 5.4. Separation of the closure shall not occur.

Sewing thread utilized in the construction of garments shall be made of an inherently flame-

resistant fibre and shall not melt when tested according to 5.2.5. Threads in seams that have

no influence on protection, e.g. hems, pocket seams, need not be flame resistant.

No uncovered outside metal parts shall be permitted in the clothing. Hardware penetrating the

outer material of the garment shall not be exposed to the innermost surface of the garment.

All exposed parts of a garment shall be made of arc thermal protection materials. In case

different materials are used for the front and back of the garment, the exact information shall

be given in the instructions for use where the weakest area is located (e.g. by means of a

drawing of the garment including dimensions and warning indication).

– 14 – IEC 61482-2:2018 RLV © IEC 2018

NOTE 1 The user can carry out a hazard risk assessment to determine the level of protection needed. Documents

such as NFPA 70E, IEEE 1584, ISSA Guide, and DGUV-I 203-77 help to assess hazards from the practical

perspective.

For garments covering torso and arms, the front side and the sleeves all around the arms and

over their complete length shall fulfil the same arc thermal protection.

For garments covering legs, the front over the complete length shall fulfil the same arc

thermal protection.

For coveralls, both requirements for garments covering torso and arms and garments covering

legs shall be fulfilled.

Where protection is provided by an outer two-piece suit, it shall be determined that, when

correctly sized for the wearer, an overlap between the jacket and trousers remains when one

standing wearer firstly fully extends both arms above the head and then bends over until the

fingertips touch the ground when tested according to 5.2.1.

If a manufacturer makes claims for a garment system as arc thermal protective clothing, then

this garment system shall be tested and shall fulfil the requirements of this document.

NOTE 2 If the user is wearing garments from different manufacturers as arc thermal protective clothing, he is

responsible for assessing how the assembly fulfils the requirements of this document.

4.3 General material requirements

4.3.1 Heat resistance

Materials shall not ignite, melt or shrink by more than 5 % when tested according to 5.3.1.

4.3.2 Volume resistance

Materials of the garment using electrically conductive fibres, except for garments meeting

IEC 60895, when tested according to 5.3.2, shall have a volume resistance of at least 10 Ω.

4.3.3 Limited flame spread of material

4.3.3.1 Classification of limited flame spread index

All materials claiming compliance with this standard shall achieve a specified limited flame

spread index when tested in accordance with ISO 15025 Procedure A (see 5.3.1) and

classified according to ISO 14116.

All materials shall achieve a specified limited flame spread index when tested according to

5.3.3 and shall be classified according to Tables 1 to 4.

4.3.3.2 Single-layer material

If a single-layer material is used in the garment, this material shall fulfil the limited flame

spread index 3 requirements given in Table 1.

Table 1 – Single-layer material

Property Requirement

Flame spread No specimen shall permit any part of the lowest boundary of any flame to reach the upper or

either vertical edge.

Flaming debris No specimen shall give flaming or molten debris.

Hole formation No specimen shall give hole formation of 5 mm or greater in any direction.

Afterglow Afterglow time shall be ≤ 2 s.

A glowing inside the charred area is defined in ISO 15025 as afterglow without combustion and,

for the purpose of 4.3.3.2, shall not be regarded as afterglow.

Afterflame Afterflame time shall be ≤ 2 s.

4.3.3.3 Multi-layer material

If a multi-layer material is used in the garment, the following requirements shall be fulfilled:

– all outer layer and innermost layer materials shall fulfil the limited flame spread index 3,

– all middle layers shall fulfil in minimum the flame spread index 1.

If the garment consists of multiple layers, all outer-layer and innermost-layer materials shall

fulfil the requirements given in Table 2.

Table 2 – Outer and innermost layer materials

Property Requirement

Flame spread No specimen shall permit any part of the lowest boundary of any flame to reach the upper or

either vertical edge.

Flaming debris No specimen shall give flaming or molten debris.

Hole formation No specimen shall give hole formation of 5 mm or greater in any direction.

Afterglow Afterglow time shall be ≤ 2 s.

A glowing inside the charred area is defined in ISO 15025 as afterglow without combustion and,

for the purpose of 4.3.3.3, shall not be regarded as afterglow.

Afterflame Afterflame time shall be ≤ 2 s.

In addition, if the garment consists of more than two layers, each intermediate layer,

depending on the intention declared by the manufacturer to contribute either to the arc

thermal protection or not, shall fulfil Table 4 or Table 3, respectively.

Table 3 – Intermediate layer material not intended for arc thermal protection

Property Requirement

Flame spread No specimen shall permit any part of the lowest boundary of any flame or hole to reach the

upper or either vertical edge.

Flaming debris No specimen shall give flaming or molten debris.

Afterglow Afterglow time shall be ≤ 2 s.

A glowing inside the charred area is defined in ISO 15025 as afterglow without combustion and,

for the purpose of 4.3.3.3, shall not be regarded as afterglow.

NOTE Such intermediate layers are only used for specific protection other than arc thermal protection, for

example protection against liquid penetration and/or wind.

– 16 – IEC 61482-2:2018 RLV © IEC 2018

Table 4 – Intermediate layer material intended for arc thermal protection

Property Requirement

Flame spread No specimen shall permit any part of the lowest boundary of any flame to reach the upper or

either vertical edge.

Flaming debris No specimen shall give flaming or molten debris.

Hole formation No specimen shall give hole formation of 5 mm or greater in any direction.

Afterglow Afterglow time shall be ≤ 2 s.

A glowing inside the charred area is defined in ISO 15025 as afterglow without combustion and,

for the purpose of 4.3.3.3, shall not be regarded as afterglow.

Afterflame Afterflame time shall be ≤ 2 s.

NOTE Such intermediate layers are designated to increase the arc thermal protection.

4.3.4 Mechanical properties of woven outer material

4.3.4.1 Tear resistance

Woven and laminated outer material shall have a tear resistance of at least 15 N for weight

2 2 2

higher than 220 g/m or at least 10 N for weight within 150 g/m and of 220 g/m or below in

the machine and the cross directions when tested according to ISO 13937-2 5.3.4.1.

4.3.4.2 Tensile strength

Woven and laminated outer material shall have a tensile strength of at least 400 N for weight

2 2 2

higher than 220 g/m or at least 250 N for weight within 150 g/m and of 220 g/m or below in

the machine and the cr

...

IEC 61482-2 ®

Edition 2.0 2018-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Protective clothing against the thermal hazards of an electric

arc –

Part 2: Requirements

Travaux sous tension – Vêtements de protection contre les dangers thermiques

d'un arc électrique –

Partie 2: Exigences

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 61482-2 ®

Edition 2.0 2018-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Protective clothing against the thermal hazards of an electric

arc –

Part 2: Requirements

Travaux sous tension – Vêtements de protection contre les dangers thermiques

d'un arc électrique –

Partie 2: Exigences

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.220.40; 29.260.99 ISBN 978-2-8322-5717-3

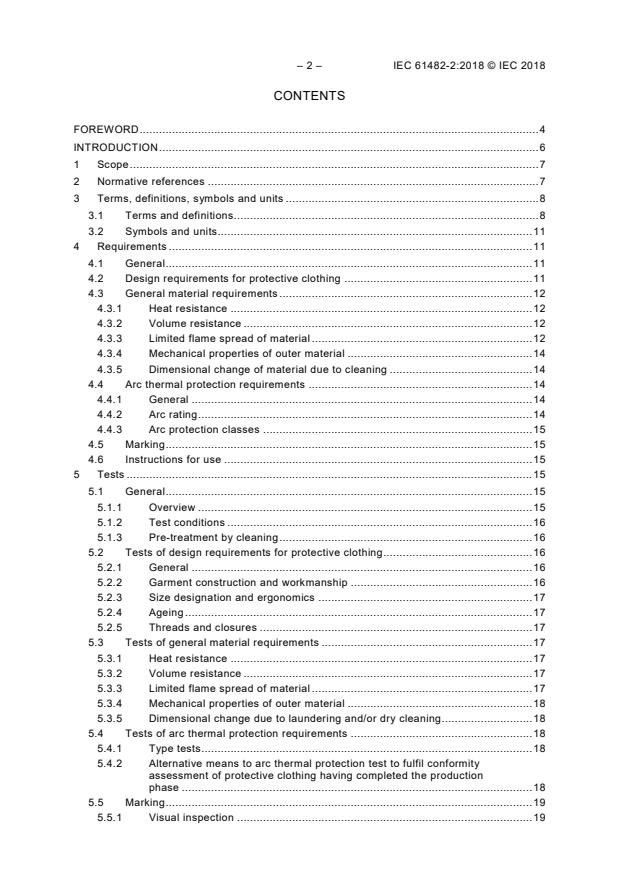

– 2 – IEC 61482-2:2018 © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and units . 8

3.1 Terms and definitions . 8

3.2 Symbols and units. 11

4 Requirements . 11

4.1 General . 11

4.2 Design requirements for protective clothing . 11

4.3 General material requirements . 12

4.3.1 Heat resistance . 12

4.3.2 Volume resistance . 12

4.3.3 Limited flame spread of material . 12

4.3.4 Mechanical properties of outer material . 14

4.3.5 Dimensional change of material due to cleaning . 14

4.4 Arc thermal protection requirements . 14

4.4.1 General . 14

4.4.2 Arc rating . 14

4.4.3 Arc protection classes . 15

4.5 Marking . 15

4.6 Instructions for use . 15

5 Tests . 15

5.1 General . 15

5.1.1 Overview . 15

5.1.2 Test conditions . 16

5.1.3 Pre-treatment by cleaning . 16

5.2 Tests of design requirements for protective clothing . 16

5.2.1 General . 16

5.2.2 Garment construction and workmanship . 16

5.2.3 Size designation and ergonomics . 17

5.2.4 Ageing . 17

5.2.5 Threads and closures . 17

5.3 Tests of general material requirements . 17

5.3.1 Heat resistance . 17

5.3.2 Volume resistance . 17

5.3.3 Limited flame spread of material . 17

5.3.4 Mechanical properties of outer material . 18

5.3.5 Dimensional change due to laundering and/or dry cleaning . 18

5.4 Tests of arc thermal protection requirements . 18

5.4.1 Type tests . 18

5.4.2 Alternative means to arc thermal protection test to fulfil conformity

assessment of protective clothing having completed the production

phase . 18

5.5 Marking . 19

5.5.1 Visual inspection . 19

5.5.2 Durability of marking . 19

5.6 Instructions for use . 19

6 Conformity assessment of protective clothing having completed the production

phase . 19

7 Modifications . 19

Annex A (normative) Marking and instructions for use . 20

A.1 Marking . 20

A.2 Instructions for use . 21

Annex B (normative) Type tests . 22

Annex C (normative) Classification of defects . 23

Annex D (informative) Rationale for the classification of defects . 24

Bibliography . 26

Table 1 – Single-layer material . 12

Table 2 – Outer and innermost layer materials . 13

Table 3 – Intermediate layer material not intended for arc thermal protection . 13

Table 4 – Intermediate layer material intended for arc thermal protection . 13

Table B.1 – List of type tests . 22

Table C.1 – Classification of defects and associated requirements and tests . 23

Table D.1 – Justification for the type of defect . 24

– 4 – IEC 61482-2:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING –

PROTECTIVE CLOTHING AGAINST

THE THERMAL HAZARDS OF AN ELECTRIC ARC –

Part 2: Requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61482-2 has been prepared by IEC technical committee 78: Live

working.

This second edition cancels and replaces the first edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) new definition for ELIM, ATPV and EBT as used in accordance with IEC 61482-1-1:–;

b) new requirements for the thermal stability of the intermediate layers;

c) additional material requirement for volume resistance;

d) new test procedure for the thermal resistance of sewing threads;

e) new symbol for marking.

The text of this standard is based on the following documents:

FDIS Report on voting

78/1205/FDIS 78/1228/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

Terms defined in Clause 3 are given in italic print throughout this standard.

A list of all parts of the IEC 61482 series, published under the general title Live working –

Protective clothing against the thermal hazards of an electric arc, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61482-2:2018 © IEC 2018

INTRODUCTION

This document has been prepared in accordance with the requirements of IEC 61477.

The products designed and manufactured according to this document contribute to the safety

of the users, provided they are used by skilled persons, in accordance with safe methods of

work and the instructions for use.

The product covered by this document may have an impact on the environment during some

or all stages of its life cycle. These impacts can range from slight to significant, be of short-

term or long-term duration, and occur at the global, regional or local level.

This document does not include requirements and test provisions for the manufacturers of the

product, or recommendations to the users of the product for environmental improvement.

However, all parties intervening in its design, manufacture, packaging, distribution, use,

maintenance, repair, reuse, recovery and disposal are invited to take account of

environmental considerations.

LIVE WORKING –

PROTECTIVE CLOTHING AGAINST

THE THERMAL HAZARDS OF AN ELECTRIC ARC –

Part 2: Requirements

1 Scope

This part of IEC 61482 is applicable to protective clothing used in work where there is the risk

of exposure to an electric arc hazard.

This document specifies requirements and test methods applicable to materials and garments

for protective clothing for electrical workers against the thermal hazards of an electric arc.

Electric shock hazard is not covered by this document, which is applicable in combination with

standards covering such hazards.

Other effects than the thermal effects of an electric arc like noise, light emissions, pressure

rise, hot oil, electric shock, the consequences of physical and mental shock or toxic

influences are not covered by this document.

Protection of eyes, face, head, hands and feet against electric arc hazard is not covered by

this document.

NOTE Requirements and tests to cover electric arc hazards to these parts of the body are under development.

Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch,

is not covered by this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60417, Graphical symbols for use on equipment (available at: http://www.graphical-

symbols.info/equipment)

IEC 61318, Live working – Conformity assessment applicable to tools, devices and equipment

IEC 61340-2-3:2016, Electrostatics – Part 2-3: Methods of test for determining the resistance

and resistivity of solid materials used to avoid electrostatic charge accumulation

IEC 61477, Live working – Minimum requirements for the utilization of tools, devices and

equipment

– 8 – IEC 61482-2:2018 © IEC 2018

IEC 61482-1-1:– , Live working – Protective clothing against the thermal hazards of an

electric arc – Part 1-1: Test methods – Method 1: Determination of the arc rating (ELIM, ATPV

and/or EBT) of clothing materials and of protective clothing using an open arc

IEC 61482-1-2, Live working –Protective clothing against the thermal hazards of an electric

arc – Part 1-2: Test methods – Method 2: Determination of arc protection class of material

and clothing by using a constrained and directed arc (box test)

ISO 3146, Plastics – Determination of melting behaviour (melting temperature or melting

range) of semi-crystalline polymers by capillary tube and polarizing-microscope methods

ISO 3758, Textiles – Care labelling code using symbols

ISO 5077, Textiles – Determination of dimensional change in washing and drying

ISO 13688:2013, Protective clothing – General requirements

ISO 13934-1, Textiles – Tensile properties of fabrics – Part 1: Determination of maximum

force and elongation at maximum force using the strip method

ISO 13937-2, Textiles – Tear properties of fabrics – Part 2: Determination of tear force of

trouser-shaped test specimens (Single tear method)

ISO 13938-1, Textiles – Bursting properties of fabrics – Part 1: Hydraulic method for

determination of bursting strength and bursting distension

ISO 13938-2, Textiles – Bursting properties of fabrics – Part 2: Pneumatic method for

determination of bursting strength and bursting distension

ISO 15025, Protective clothing – Protection against flame – Method of test for limited flame

spread

ISO 17493:2016, Clothing and equipment for protection against heat – Test method for

convective heat resistance using a hot air circulating oven

ISO 30023, Textiles – Qualification symbols for labelling workwear to be industrially laundered

3 Terms, definitions, symbols and units

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61318 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

___________

Under preparation. Stage at time of publication: IEC CDV 61482-1-1:2017.

3.1.1

arc protection class

APC

category of arc thermal protection of a material and/or product tested in

accordance with the box test (APC 1 or APC 2)

Note 1 to entry: The arc protection class is characterized by the test energy level of arc exposure (arc energy and

incident energy).

Note 2 to entry: Tested material and/or products show arc thermal protection at minimum up to the class energy

level but, in general, the actual exposure energy limit up to which the material and/or product provide protection is

higher.

3.1.2

arc rating

numerical value attributed to a product, that describes its protective

performance when exposed to an electric arc

Note 1 to entry: The arc rating can be the arc thermal performance value (ATPV), the breakopen threshold energy

(EBT) or the incident energy limit (ELIM).

2 2

Note 2 to entry: The arc rating is expressed in kJ/m (cal/cm ).

3.1.3

arc thermal protection

degree of thermal protection offered against electric arc under specific

arc testing conditions indicated by either arc rating or arc protection class

Note 1 to entry: For materials, the arc thermal protection is obtained from the measurement of the transmitted

energy and by evaluation of other thermal parameters (burning time, hole formation, melting).

Note 2 to entry: For garments, the arc thermal protection is obtained by evaluation of thermal parameters (burning

time, hole formation, melting) of the material(s) from which the garment is made and of the functioning of the

closures and accessories.

3.1.4

arc thermal performance value

ATPV

numerical value of incident energy attributed to a product that describes

its thermal properties of attenuating (reducing) a heat flux generated by an electric arc

Note 1 to entry: The ATPV of a material or material assembly is calculated using logistic regression analysis

applied to the data points obtained from testing a set of test specimens. It is the value of incident energy at which

the heat transfer through the test specimens is enough to reach the Stoll criteria with 50 % probability.

Note 2 to entry: The ATPV attributed to a garment or garment assembly is either equal to or lower than the ATPV

of the material or material assembly of which it is made, depending on whether the tested specimen(s) fulfil also

additional visual design and performance assessment criteria.

3.1.5

breakopen threshold energy

EBT

numerical value of incident energy attributed to a product that describes

its breakopen properties when exposed to heat flux generated by an electric arc

Note 1 to entry: The EBT of a material or material assembly is calculated using logistic regression analysis

applied to the data points obtained from testing a set of test specimens. It is the value of incident energy at which

breakopen occurs with 50 % probability.

Note 2 to entry: The EBT attributed to a garment or garment assembly is either equal to or lower than the EBT of

the material or material assembly of which it is made, depending on whether the tested specimen(s) fulfil also

additional visual design and performance assessment criteria.

– 10 – IEC 61482-2:2018 © IEC 2018

3.1.6

electric arc

self-maintained gas conduction for which most of the charge carriers are electrons supplied

by primary-electron emission

Note 1 to entry: During live working, the electric arc is generated by gas ionization arising from an unintentional

electrical conducting connection or breakdown between live parts or a live part and the earth path of an electrical

installation or an electrical device. During testing, the electric arc is initiated by the blowing of a fuse wire.

[SOURCE: IEC 60050-121:1998, 121-13-12, modified – Note 1 to entry has been added to

refer specifically to live working and arc testing.]

3.1.7

electric arc hazard

potential harm from an energy release from an electric arc usually caused by a short circuit or

equipment failure in electrotechnical work

Note 1 to entry: An electric arc hazard exists when live electrical conductors or parts are exposed and when they

are inside an item of equipment, even when guarded or enclosed, if a worker is interacting with the equipment in a

way which could cause an electric arc. Under normal operating conditions, enclosed energized equipment that has

been properly designed, installed and maintained is not likely to pose an electric arc hazard.

Note 2 to entry: Documents such as NFPA 70E, IEEE 1584, ISSA Guide, and DGUV-I 203-77 help to assess

hazards from the practical perspective.

Note 3 to entry: The hazards may include thermal effects, noise, pressure wave effects, ejected parts effects,

molten metal, optical and other effects. Different PPE (personal protective equipment) may be required to protect

from different effects. It is important that the risk assessment consider all the potential effects.

3.1.8

garment

single item of clothing which can consist of single or multiple layers of material

3.1.9

garment system

garment assembly for which a specific arc rating or arc protection class is attributed after

having performed an arc test

3.1.10

hardware

non-fabric items forming part of or optional extras in a garment

3.1.11

incident energy limit

ELIM

numerical value of incident energy attributed to a product, below which

there is no data point with the amount of heat transmitted through the product reaching the

Stoll criteria or with the product exhibiting breakopen