IEC 61482-1-2:2014

(Main)Live working - Protective clothing against the thermal hazards of an electric arc - Part 1-2: Test methods - Method 2: Determination of arc protection class of material and clothing by using a constrained and directed arc (box test)

Live working - Protective clothing against the thermal hazards of an electric arc - Part 1-2: Test methods - Method 2: Determination of arc protection class of material and clothing by using a constrained and directed arc (box test)

IEC 61482-1-2:2014 specifies procedures to test material and garments intended for use in heat and flame-resistant clothing for workers if there is an electric arc hazard. A directed and constrained electric arc in a test circuit is used to classify material and clothing in two defined arc protection classes. This International Standard is not dedicated toward measuring the arc rating values (ATPV, ELIM, or EBT). Procedures determining these arc rating values are prescribed in IEC 61482-1-1, using an open arc for testing. Other effects than the thermal effects of an electric arc like noise, light emissions, pressure rise, hot oil, electric shock, the consequences of physical and mental shock or toxic influences are not covered by this standard. Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch, is not covered by this standard. This second edition cancels and replaces the first edition, published in 2007. This edition constitutes a technical revision which includes the following significant technical changes with regard to the previous edition:

- new mean values of main control parameters arc energy and incident energy based on an extended statistical database consisting of parameter values measured in four laboratories;

- reduction of validity check ranges of main control parameters;

- determination of the incident energy by averaging the two sensor values of a test (instead of considering each single sensor value);

- determination of the heat curves of transmitted incident energy and an amendment to the heat flux acceptance criterion;

- clarification of the scope;

- and selection of the arc protection classes (test classes) by the amount of the arc energy and incident energy instead of the short-circuit current.

Travaux sous tension - Vêtements de protection contre les dangers thermiques d'un arc électrique - Partie 1-2: Méthodes d'essai - Méthode 2: Détermination de la classe de protection contre l'arc de matériaux et de vêtements au moyen d'un arc dirigé et contraint (enceinte d'essai)

L'IEC 61482-1-2:2014 spécifie des procédures d'essai des matériaux et des articles d'habillement destinés à être utilisés dans les vêtements résistant à la chaleur et à la flamme pour les travailleurs, en cas de danger d'arc (de défaut) électrique. Dans un circuit d'essai, un arc électrique dirigé et contraint permet de classer les matériaux et les vêtements dans deux classes de protection contre les arcs définies. Cette Norme Internationale n'est pas destinée à mesurer les valeurs de performance de l'arc (ATPV, ELIM, ou EBT). Les procédures déterminant les valeurs de performance thermique de l'arc sont présentées dans l'IEC 61482-1-1. Elles utilisent un arc à l'air libre pour les essais. D'autres effets que les effets thermiques d'un arc électrique tel que le bruit, les émissions de lumière, la montée de pression, l'huile chaude, les chocs électriques, les conséquences des chocs physiques et mentaux ou les influences toxiques ne sont pas couvert par cette norme. Les vêtements de protection destinés au travail intentionnel avec un arc électrique, par exemple soudure l'arc, torche au plasma, ne sont pas couvert par cette norme. Cette deuxième édition annule et remplace la première édition parue en 2007. Cette édition constitue une révision technique qui inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- nouvelles valeurs moyennes des paramètres de commande énergie d'arc et énergie incidente selon une base de données statistique étendue des valeurs de paramètre mesurées dans quatre laboratoires;

- réduction des plages de contrôle de validité des principaux paramètres de commande;

- détermination de l'énergie incidente par calcul de la moyenne de deux valeurs de capteur d'un essai (au lieu de considérer chaque valeur unique de capteur);

- détermination des courbes thermiques de l'énergie incidente émise et un amendement au critère d'acceptation de flux thermique;

- clarification du domaine d'application;

- et sélection des classes de protection contre l'arc (classes d'essai) par la quantité d'énergie d'arc et d'énergie incidente à la place du courant de court-circuit.

General Information

- Status

- Published

- Publication Date

- 08-Oct-2014

- Technical Committee

- TC 78 - Live working

- Drafting Committee

- PT 61482-1-2 - TC 78/PT 61482-1-2

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Oct-2014

- Completion Date

- 15-Nov-2014

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61482-1-2:2014 is an international standard published by the International Electrotechnical Commission (IEC) focusing on live working protective clothing designed to protect workers from the thermal hazards of electric arcs. This standard describes test methods, specifically Method 2, which determines the arc protection class of materials and clothing by applying a constrained and directed electric arc-commonly referred to as the box test.

The standard sets procedures for evaluating heat and flame-resistant garments used by workers in environments with potential electric arc hazards, such as electrical maintenance or live-line work. Unlike other standards that measure arc rating values like ATPV or EBT (covered under IEC 61482-1-1), IEC 61482-1-2 provides a reliable classification system using controlled box test conditions.

Key Topics

Test Principle

Uses a constrained and directed electric arc within a test circuit to evaluate the thermal protection offered by materials and garments. Tests are performed on samples placed within a test box equipped with sensors to measure incident arc energy and heat transfer.Arc Protection Classes

Materials and clothing are classified into two arc protection classes (Class 1 and Class 2), based on the amount of arc energy and incident energy absorbed in the test.Test Apparatus

Includes a test box, electrodes, sensors, electric supply, and precise data acquisition systems. The standard details the construction and calibration of testing apparatus to ensure reproducibility and accuracy.Test Procedures

Specifies preparation, conditioning, mounting of specimens, and calibration steps before testing. It also defines acceptance criteria for test results based on sensor readings and visual inspection of specimens after exposure.Limitations

The standard focuses solely on thermal hazards from electric arcs and does not cover other arc effects such as noise, light emissions, pressure shocks, or toxic influences. It is not intended for arc welding or plasma torch applications.Technical Updates

The 2014 edition made significant revisions, including updated mean values for arc energy parameters from extensive inter-lab data, refined validity check ranges, and improved calculation of incident energy by averaging sensor outputs.

Applications

IEC 61482-1-2:2014 is essential for manufacturers, safety engineers, and testing laboratories involved in the design, selection, certification, and quality assurance of protective clothing for electrical workers exposed to arc flash hazards. Its practical uses include:

- Evaluating protective fabrics and assembled garments to verify compliance with arc protection class requirements.

- Supporting workplace safety programs where workers face electric arc risks by ensuring appropriate garment performance.

- Guiding product development for heat- and flame-resistant clothing designed to withstand constrained electric arcs.

- Compliance with occupational health and safety regulations that specify the use of certified protective clothing during live electrical work.

- Assessing new materials and clothing designs under controlled, reproducible test conditions, facilitating innovation in arc-resistant textiles.

Related Standards

For comprehensive safety management around electric arcs, IEC 61482-1-2:2014 should be used alongside other international standards:

- IEC 61482-1-1 – Test methods using open air arc to determine arc thermal performance values (ATPV, ELIM, EBT).

- IEC 60903 – Live working-Insulating gloves for electrical purposes.

- IEC 61482-2 – Design requirements for protective clothing against electric arc hazards.

- ISO 13688 – Protective clothing-General requirements for ergonomics, sizing, and labeling.

- NFPA 70E – Standard for Electrical Safety in the Workplace (provides U.S. guidance on arc flash protective apparel).

Employing IEC 61482-1-2:2014 alongside these complementary standards helps organizations ensure worker safety from electric arc hazards by covering material testing, garment design, electrical personal protective equipment, and workplace practices.

IEC 61482-1-2:2014 remains a cornerstone document for the testing and classification of arc-resistant protective clothing, enabling improved safety for electrical workers exposed to high-risk thermal scenarios. Its detailed methodology and rigorous test procedures help stakeholders achieve reliable and standardized arc hazard protection globally.

Buy Documents

IEC 61482-1-2:2014 - Live working - Protective clothing against the thermal hazards of an electric arc - Part 1-2: Test methods - Method 2: Determination of arc protection class of material and clothing by using a constrained and directed arc (box test)

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61482-1-2:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Live working - Protective clothing against the thermal hazards of an electric arc - Part 1-2: Test methods - Method 2: Determination of arc protection class of material and clothing by using a constrained and directed arc (box test)". This standard covers: IEC 61482-1-2:2014 specifies procedures to test material and garments intended for use in heat and flame-resistant clothing for workers if there is an electric arc hazard. A directed and constrained electric arc in a test circuit is used to classify material and clothing in two defined arc protection classes. This International Standard is not dedicated toward measuring the arc rating values (ATPV, ELIM, or EBT). Procedures determining these arc rating values are prescribed in IEC 61482-1-1, using an open arc for testing. Other effects than the thermal effects of an electric arc like noise, light emissions, pressure rise, hot oil, electric shock, the consequences of physical and mental shock or toxic influences are not covered by this standard. Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch, is not covered by this standard. This second edition cancels and replaces the first edition, published in 2007. This edition constitutes a technical revision which includes the following significant technical changes with regard to the previous edition: - new mean values of main control parameters arc energy and incident energy based on an extended statistical database consisting of parameter values measured in four laboratories; - reduction of validity check ranges of main control parameters; - determination of the incident energy by averaging the two sensor values of a test (instead of considering each single sensor value); - determination of the heat curves of transmitted incident energy and an amendment to the heat flux acceptance criterion; - clarification of the scope; - and selection of the arc protection classes (test classes) by the amount of the arc energy and incident energy instead of the short-circuit current.

IEC 61482-1-2:2014 specifies procedures to test material and garments intended for use in heat and flame-resistant clothing for workers if there is an electric arc hazard. A directed and constrained electric arc in a test circuit is used to classify material and clothing in two defined arc protection classes. This International Standard is not dedicated toward measuring the arc rating values (ATPV, ELIM, or EBT). Procedures determining these arc rating values are prescribed in IEC 61482-1-1, using an open arc for testing. Other effects than the thermal effects of an electric arc like noise, light emissions, pressure rise, hot oil, electric shock, the consequences of physical and mental shock or toxic influences are not covered by this standard. Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch, is not covered by this standard. This second edition cancels and replaces the first edition, published in 2007. This edition constitutes a technical revision which includes the following significant technical changes with regard to the previous edition: - new mean values of main control parameters arc energy and incident energy based on an extended statistical database consisting of parameter values measured in four laboratories; - reduction of validity check ranges of main control parameters; - determination of the incident energy by averaging the two sensor values of a test (instead of considering each single sensor value); - determination of the heat curves of transmitted incident energy and an amendment to the heat flux acceptance criterion; - clarification of the scope; - and selection of the arc protection classes (test classes) by the amount of the arc energy and incident energy instead of the short-circuit current.

IEC 61482-1-2:2014 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.260.99 - Other electrical equipment for working in special conditions. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61482-1-2:2014 has the following relationships with other standards: It is inter standard links to IEC 61482-1-2:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61482-1-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61482-1-2 ®

Edition 2.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Protective clothing against the thermal hazards of an electric

arc –

Part 1-2: Test methods – Method 2: Determination of arc protection class of

material and clothing by using a constrained and directed arc (box test)

Travaux sous tension – Vêtements de protection contre les dangers thermiques

d'un arc électrique –

Partie 1-2: Méthodes d’essai – Méthode 2: Détermination de la classe de

protection contre l’arc de matériaux et de vêtements au moyen d’un arc dirigé

et contraint (enceinte d'essai)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61482-1-2 ®

Edition 2.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Protective clothing against the thermal hazards of an electric

arc –

Part 1-2: Test methods – Method 2: Determination of arc protection class of

material and clothing by using a constrained and directed arc (box test)

Travaux sous tension – Vêtements de protection contre les dangers thermiques

d'un arc électrique –

Partie 1-2: Méthodes d’essai – Méthode 2: Détermination de la classe de

protection contre l’arc de matériaux et de vêtements au moyen d’un arc dirigé

et contraint (enceinte d'essai)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX U

ICS 13.220.40, 29.260, 29.260.99 ISBN 978-2-8322-1881-5

– 2 – IEC 61482-1-2:2014 © IEC 2014

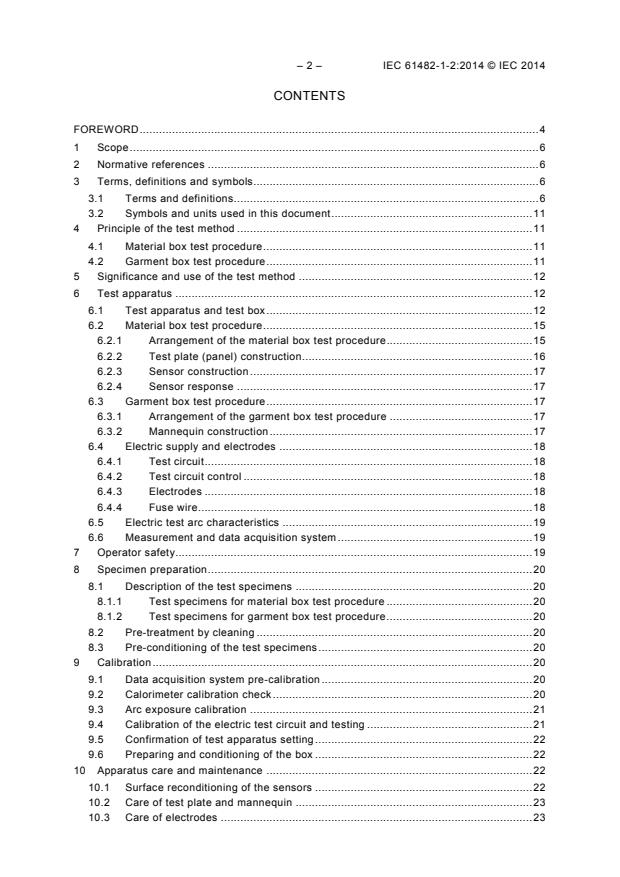

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols. 6

3.1 Terms and definitions . 6

3.2 Symbols and units used in this document . 11

4 Principle of the test method . 11

4.1 Material box test procedure . 11

4.2 Garment box test procedure . 11

5 Significance and use of the test method . 12

6 Test apparatus . 12

6.1 Test apparatus and test box . 12

6.2 Material box test procedure . 15

6.2.1 Arrangement of the material box test procedure . 15

6.2.2 Test plate (panel) construction . 16

6.2.3 Sensor construction . 17

6.2.4 Sensor response . 17

6.3 Garment box test procedure . 17

6.3.1 Arrangement of the garment box test procedure . 17

6.3.2 Mannequin construction . 17

6.4 Electric supply and electrodes . 18

6.4.1 Test circuit . 18

6.4.2 Test circuit control . 18

6.4.3 Electrodes . 18

6.4.4 Fuse wire . 18

6.5 Electric test arc characteristics . 19

6.6 Measurement and data acquisition system . 19

7 Operator safety . 19

8 Specimen preparation . 20

8.1 Description of the test specimens . 20

8.1.1 Test specimens for material box test procedure . 20

8.1.2 Test specimens for garment box test procedure . 20

8.2 Pre-treatment by cleaning . 20

8.3 Pre-conditioning of the test specimens . 20

9 Calibration . 20

9.1 Data acquisition system pre-calibration . 20

9.2 Calorimeter calibration check . 20

9.3 Arc exposure calibration . 21

9.4 Calibration of the electric test circuit and testing . 21

9.5 Confirmation of test apparatus setting . 22

9.6 Preparing and conditioning of the box . 22

10 Apparatus care and maintenance . 22

10.1 Surface reconditioning of the sensors . 22

10.2 Care of test plate and mannequin . 23

10.3 Care of electrodes . 23

11 Test procedures . 23

11.1 Test parameters . 23

11.2 Number of tests . 23

11.3 Test conditions and initial temperature . 24

11.4 Specimen mounting . 24

11.4.1 Material box test procedure . 24

11.4.2 Garment box test procedure . 24

11.5 Specimen description . 24

12 Interpretation of results . 25

12.1 Heat transfer . 25

12.1.1 Determining time zero . 25

12.1.2 Plotting sensor response . 25

12.1.3 Incident energy E . 25

i

12.1.4 Sensor response versus Stoll curve . 25

12.2 Visual inspection . 25

12.3 Test result. 26

12.3.1 Acceptance criteria of material box test procedure . 26

12.3.2 Acceptance criteria of garment box test procedure . 26

13 Test report . 27

Annex A (informative) Precision of the test method . 28

Bibliography . 29

Figure 1 – Test box . 14

Figure 2 – Test set-up . 15

Figure 3 – Test plate with sensors (calorimeters in mounting boards) . 16

Table 1 – Test validity check range of direct exposure incident energy (permissible

direct exposure incident energy range) . 21

Table 2 – Test validity check range of arc energy (permissible arc energy range) . 22

Table 3 – Test parameters for Classes 1 and 2 . 23

Table 4 – Acceptance criteria for tests on materials . 26

Table 5 – Acceptance criteria for tests on garments . 26

Table A.1 – Repeatability and reproducibility values of test procedure . 28

– 4 – IEC 61482-1-2:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING – PROTECTIVE CLOTHING AGAINST

THE THERMAL HAZARDS OF AN ELECTRIC ARC –

Part 1-2: Test methods –

Method 2: Determination of arc protection class of material

and clothing by using a constrained and directed arc (box test)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61482-1-2 has been prepared by IEC technical committee 78: Live

working.

This second edition cancels and replaces the first edition, published in 2007. This edition

constitutes a technical revision.

It includes the following significant technical changes with regard to the previous edition:

• new mean values of main control parameters arc energy and incident energy based on an

extended statistical database consisting of parameter values measured in four

laboratories;

• reduction of validity check ranges of main control parameters;

• determination of the incident energy by averaging the two sensor values of a test (instead

of considering each single sensor value);

• determination of the heat curves of transmitted incident energy and an amendment to the

heat flux acceptance criterion;

• information on precision (repeatability and reproducibility) of the test method;

• clarification of the scope;

• selection of the arc protection classes (test classes) by the amount of the arc energy and

incident energy instead of the short-circuit current;

• permitting electrode design without bores;

• recommendations of the heat resistance materials to be used for the box and for the test

plate;

• clarification of the conditions for cleaning and replacing the box;

• requirement for including in the test report the differences ∆E of the transmitted energy

i

values to the Stoll limit value at t and the information if the heat curves of transmitted

max

incident energy exceed the Stoll curve during the exposure time;

• preconditioning of the samples according to manufacturer’s instruction.

The text of this standard is based on the following documents:

FDIS Report on voting

78/1053/FDIS 78/1089/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this standard terms defined in Clause 3 appear in italics.

A list of all parts in the IEC 61482 series, published under the general title Live working –

Protective clothing against the thermal hazards of an electric arc, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61482-1-2:2014 © IEC 2014

LIVE WORKING – PROTECTIVE CLOTHING AGAINST

THE THERMAL HAZARDS OF AN ELECTRIC ARC –

Part 1-2: Test methods –

Method 2: Determination of arc protection class of material

and clothing by using a constrained and directed arc (box test)

1 Scope

This part of IEC 61482 specifies procedures to test material and garments intended for use in

heat and flame-resistant clothing for workers if there is an electric arc hazard. A directed and

constrained electric arc in a test circuit is used to classify material and clothing in two defined

arc protection classes.

This International Standard is not dedicated toward measuring the arc rating values (ATPV ,

2 3

or EBT ). Procedures determining these arc rating values are prescribed in

ELIM

IEC 61482-1-1, using an open arc for testing.

Other effects than the thermal effects of an electric arc like noise, light emissions, pressure

rise, hot oil, electric shock, the consequences of physical and mental shock or toxic

influences are not covered by this standard.

Protective clothing for work intentionally using an electric arc, e.g. arc welding, plasma torch,

is not covered by this standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

ISO 9151:1995, Protective clothing against heat and flame – Determination of heat

transmission on exposure to flame

3 Terms, definitions and symbols

For the purposes of this document, the following terms, definitions and symbols apply.

3.1 Terms and definitions

3.1.1

arc current

I

arc

current actually flowing in the electric test circuit during arc duration (through the arc)

___________

ATPV = arc thermal performance value.

ELIM= incident energy limit

EBT= breakopen energy threshold

Note 1 to entry: Arc current is expressed in kA rms.

Note 2 to entry: The arc current flowing during arc duration fluctuates due to the non-linear arc impedance

stochastically varying with time.

3.1.2

arc duration

time duration of the arc

Note 1 to entry: Arc duration is expressed in ms.

3.1.3

arc energy

W

arc

electrical energy supplied to the arc and converted in the arc

Note 1 to entry: Arc energy is the sum of the instantaneous arc voltage values multiplied by the instantaneous arc

current values multiplied by the incremental time values during the arc duration.

Note 2 to entry: Arc energy is expressed in kJ or kW·s.

3.1.4

arc gap

distance between the arc electrodes

Note 1 to entry: Arc gap is expressed in mm.

3.1.5

arc protection class

category of arc thermal protection of material and protective clothing tested in the box test

(class 1 or class 2)

Note 1 to entry: The arc protection class is characterized by the test energy level of arc exposure (arc energy and

incident energy).

Note 2 to entry: Tested material and protective clothing show arc thermal protection at minimum up to the class

energy level. In general the actual exposure energy limit up to which the material and protective clothing provide

protection is higher.

3.1.6

arc thermal protection

degree of thermal protection offered against electric arc under specific arc testing conditions

Note 1 to entry: For materials, the arc thermal performance is obtained from the measurement of the transmitted

energy and by evaluation of other thermal parameters (burning time, hole formation, melting).

Note 2 to entry: For garments, the arc thermal performance is obtained by evaluation of thermal parameters

(burning time, hole formation, melting) and of the functioning of fasteners and accessories.

3.1.7

arc voltage

voltage across the arc

Note 1 to entry: Arc voltage is expressed in V.

3.1.8

burning time

after flame time

time for which a flaming of the test specimen is visible after the end of the electric arc

duration

Note 1 to entry: Burning time is expressed in s.

– 8 – IEC 61482-1-2:2014 © IEC 2014

3.1.9

calorimeter

assembly of a copper disc with attached thermocouple used for measuring the heat flux and

incident energy

3.1.10

charring

formation of carbonaceous residue as the result of pyrolysis or incomplete combustion

3.1.11

clothing

assembly of garments worn by workers

3.1.12

delta peak temperature

∆T

p

difference between the maximum temperature and the initial temperature of the sensor during

the test exposure time

Note 1 to entry: Delta peak temperature is expressed in °C.

Note 2 to entry: The symbol ∆T is used without index when testing with material; an additional index “0” is used

p

when testing without material for calibration (∆T ).

p0

3.1.13

direct exposure incident energy

E

i0

heat energy or incident energy emitted by the electric arc and received at a calorimeter

directly exposed to the arc without material influence

Note 1 to entry: Direct exposure incident energy is used for calibration.

2 2 2 4

Note 2 to entry: Direct exposure incident energy is expressed in kJ/m or kW·s/m (cal/cm ) .

3.1.14

dripping

material response evidenced by flowing of the fibre polymer

3.1.15

electric arc

self-maintained gas conduction for which most of the charge carriers are electrons supplied

by primary-electron emission

Note 1 to entry: During live working, the electric arc is generated by gas ionisation arising from an unintentional

electrical conducting connection or breakdown between live parts or a live part and the earth path of an electrical

installation or an electrical device. During testing, the electric arc is initiated by the blowing of a fuse wire.

[SOURCE: IEC 60050-121:1998, 121-13-12, modified – the Note 1 to entry has been added to

refer specifically to live working and arc testing.]

3.1.16

embrittlement

formation of a brittle residue as the result of pyrolysis or incomplete combustion

3.1.17

exposure time

total test time interval of observation and measurement

___________

4 2 2 2 2

Correlation: 1 cal/cm = 41,868 kJ/m ; 1 kJ/m = 0,023 885 cal/cm .

Note 1 to entry: Exposure time is expressed in s.

3.1.18

garment

single item of clothing which may consist of single or multiple layers

3.1.19

heat flux

thermal intensity of an electric arc indicated by the amount of energy transmitted per unit area

and time

Note 1 to entry: Heat flux is expressed in kW/m .

3.1.20

hole formation

existence of openings in the test specimen material with minimum 5 mm in any direction

3.1.21

ignition

initiation of flaming and combustion

3.1.22

incident energy

E

i

heat energy (total heat) received at a unit surface area as a result of an electric arc

Note 1 to entry: Incident energy is measured as a proportional peak temperature rise ∆T of a calorimeter sensor.

p

2 2 2

Note 2 to entry: Incident energy is expressed in kJ/m or kW·s/m (cal/cm ).

3.1.23

material

fabric or other substances of which the garment is made

Note 1 to entry: The material may consist of single or multiple layers.

3.1.24

material response

reaction of the material to an electric arc characterized by burning time (after flame), ignition,

hole formation, melting, dripping, charring, embrittlement, shrinkage and transmitted energy

3.1.25

melting

material response evidenced by softening and deformation

Note 1 to entry: Materials which melt are normally polymer(s).

3.1.26

prospective short-circuit current

predicted current flowing when the arc electrodes are connected by a conductor of negligible

impedance (short-circuit of supply)

Note 1 to entry: Prospective short-circuit current is expressed in kA rms.

Note 2 to entry: There is in general a difference between the actual arc current I and the test current I as

arc class

defined. The actual arc current flowing during the arc duration is smaller and fluctuates due to the non-linear arc

impedance stochastically varying with time. Reproducible test conditions may only be defined by means of the

prospective short-circuit current to be expected in case of impedance-less connected arc electrodes. This

prospective short-circuit current is, by the way, also a parameter which describes the practically interesting points

in the electrical systems or installations where arc exposure has to be considered.

– 10 – IEC 61482-1-2:2014 © IEC 2014

3.1.27

protective clothing

clothing which covers or replaces personal clothing, and which is designed to provide

protection against one or more hazards

[SOURCE: ISO 13688:2013, 3.5, modified – the definition has been modified to clarify it by

removing the unclear term “protector”]

3.1.28

sensor

assembly with a calorimeter and a non-conductive heat-resistant material in which the

calorimeter is mounted

3.1.29

shrinkage

material response evidenced by the reduction in specimen size

3.1.30

Stoll curve

an empirical predicted second-degree skin burn injury model defining a relationship between

the amount of thermal energy transferred to human tissue and the time of exposure

3.1.31

test current

I

class

prospective short-circuit current of the electric test circuit (predicted current)

Note 1 to entry: Test current is expressed in kA rms (symmetrical a.c. component).

3.1.32

test voltage

no-load a.c. voltage of the test circuit source at 50 Hz or 60 Hz

Note 1 to entry: Test voltage is expressed in V rms.

3.1.33

time to delta peak temperature

t

max

time from beginning of the initiation of the arc to the time the delta peak temperature is

reached

Note 1 to entry: Time to delta peak temperature is expressed in s.

3.1.34

transmitted energy

E

it

incident energy received at a calorimeter when testing material or clothing

Note 1 to entry: Transmitted energy is the fraction of the emitted incident energy which is transmitted through the

specimen.

2 2 2

Note 2 to entry: Transmitted energy is expressed in kJ/m or kW·s/m (cal/cm ).

3.1.35

X/R ratio

ratio of system inductive reactance to resistance

Note 1 to entry: The X/R ratio is proportional to the L/R ratio of time constant, and is, therefore, indicative of the

rate of decay of any d.c. offset. A large X/R ratio corresponds to a large time constant and a slow rate of decay.

3.2 Symbols and units used in this document

2 2 2

E incident energy kJ/m or kW·s/m (cal/cm )

i

2 2

1 cal/cm = 41,868 kJ/m ;

2 2

1 kJ/m = 0,023885 cal/cm

2 2 2

E direct exposure incident energy kJ/m or kW·s/m (cal/cm )

i0

2 2 2

E transmitted energy kJ/m or kW·s/m (cal/cm )

it

I arc current kA

arc

I test current (prospective short-circuit current) kA

class

t time to delta peak temperature s

max

T ambient temperature °C

a

T initial sensor temperature °C

W arc energy kJ, kW·s

arc

∆T delta peak temperature °C

p

delta peak temperature by calibration °C

∆T

p0

4 Principle of the test method

4.1 Material box test procedure

The box test method comprises two procedures: the material box test procedure and the

garment box test procedure.

The material box test procedure covered by this standard determines the behaviour of

materials when exposed to heat energy from electric arcs with specific characteristics.

With the material box test procedure the amount of heat energy transferred by the flat

material(s) is measured during and after exposure to a specified electric arc.

Material performance for this procedure is determined from the amount of heat transmitted

through the specimen(s) and other thermal parameters.

The heat flux of the exposure during the calibration shot and the heat flux transferred by the

test specimen(s) during a test shot are measured with copper calorimeters. The degree to

which the temperature of the calorimeters increases is a direct measure of the heat energy

received.

Heat transfer data is used to assess the occurrence of a second-degree burn using the Stoll

curve.

Material response shall be further described by recording the observed effects of the electric

arc exposure on the specimens.

4.2 Garment box test procedure

The garment box test procedure covered by this standard determines the behaviour of

garments when exposed to heat energy from electric arcs with specific characteristics.

Garment performance for this procedure is determined by evaluating the function of the

protective clothing after exposure to a specified electric arc, including all the garment

findings, sewing thread, fastenings and other accessories.

With the garment box test procedure, no heat flux will be measured.

– 12 – IEC 61482-1-2:2014 © IEC 2014

5 Significance and use of the test method

This test method is for testing material and garments of protective clothing used for

electrotechnical work if there is an electrical arc risk.

The test method permits to assess the arc thermal performance of materials (material box test

procedure) and garments (garment box test procedure) in terms of the energy level of the

selected protection class. The protection class energy level is represented by the level of the

arc energy and the corresponding level of the direct exposure incident energy according to

the test conditions.

NOTE 1 There are two protection classes: Class 1 represents a basic protection level, class 2 an increased

protection.

NOTE 2 In practice there can be situations with higher arc energy levels. Performing an electrical arc risk

assessment, the potential arc energy of an arc flash is determined for the specific equipment and network

conditions.

NOTE 3 This standard is for testing purposes. Guidance for the selection of the right protective clothing can be

found in IEC 61482-2 and in an ISSA Guideline [1] . Furthermore, there is a preliminary work of TC78 on a

technical report for correlating the results of arc test methods to electrotechnical applications in order to select the

proper electric arc protective equipment.

NOTE 4 Work continues to evaluate higher energy exposures.

With the box test set-up it is possible to evaluate materials and garments based on the use of

a directed and constrained electric arc under defined laboratory conditions. A practical

scenario concerning test set-up and test conditions, electrical and constructional parameters

is selected.

The heat energy transfer and impact of the test arc are due to radiation, convection by the hot

plasma and gas cloud, direct contact with the plasma cloud or parts of it, and hot molten

metal particles and splash.

The test box set-up is introduced to meet typical arc fault conditions and particularly to cover

actual arc exposure conditions in electrical equipment and switchgear, mainly in opened

compact equipment, e.g. service entrance boxes, cable distribution cabinets, distribution

substations or comparable installations where the electric arc is directed to the front of a

worker at the height of his breastbone.

NOTE 5 The test set-up configuration of this standard leads to high heat transmission. Other exposure conditions

such as vertical electrodes open-arc conditions are also covered by the test set-up.

The test set-ups maintain the specimen in a static vertical position and do not involve

movement except that resulting from the exposure.

The test method specifies a standard set of exposure conditions. Different exposure

conditions may produce more or less severe results. In addition to the standard set of

exposure conditions, other conditions representative of the expected hazard may be used.

6 Test apparatus

6.1 Test apparatus and test box

The test apparatus shall consist of the following elements:

– test box for both procedures;

___________

Numbers in square brackets refer to the Bibliography.

– two-sensor test plate for material box test procedure;

– mannequin for garment box test procedure;

– electric supply and electrode configuration;

– recorder;

– data acquisition system.

The test box arrangement (identical for both procedures) is shown in Figure 1.

The test box shall be of electrically and thermally non-conductive, heat resistant material.

If plaster is used, then plaster material which gives a smooth and solid surface shall be used.

TM

NOTE Besides others, the use of Keraquick moulding compound, a ceramic powder for relief casting, has

shown suitable results.

___________

TM

Keraquick is the trade name of a product supplied by KnorrPrandell GmbH, 96215 Lichtenfels, Germany. This

information is given for the convenience of users of this standard and does not constitute an endorsement by

IEC of the product named. Equivalent products may be used if they can be shown to lead to the same results.

– 14 – IEC 61482-1-2:2014 © IEC 2014

Dimensions in millimetres

Front view

IEC

Cut A profile

Key

1 box, non-conductive heat resistant material (e.g. plaster)

insulating plate, thickness > 15

electrode ∅ 25 ± 0,1 (aluminum)

4 electrode ∅ 25 ± 0,1 (copper)

Figure 1 – Test box

6.2 Material box test procedure

6.2.1 Arrangement of the material box test procedure

The material box test procedure is used to measure and find material response to an arc

exposure when tested in a flat configuration. A quantitative measurement of the arc thermal

performance by means of the heat flux or energy transmitted through the material is made.

The arrangement is shown in Figure 2.

The distance from electrode (centre line) to test plate (surface) shall be 300 mm ± 5 mm.

The gap between electrodes shall be 30 mm ± 1 mm (arc gap).

Dimensions in millimetres

R

IEC

Key

test plate with specimen (400 × 400, thickness >10 ) or test mannequin (torso)

2 cable connector

3 test box

connecting cable (R > 1 000)

5 horizontal centre line

Figure 2 – Test set-up

– 16 – IEC 61482-1-2:2014 © IEC 2014

6.2.2 Test plate (panel) construction

The test plate construction is shown in Figure 3.

The test plate shall be of non-conductive heat resistant material (e.g. Marinite A, Monolux

TM

500, asbestosfree transite board, oven insulation, phenolic resin PF CP 201 ).

Size: (400 ± 10) mm × (400 ± 10) mm

Thickness: minimum 10 mm

Sensors: sensor with calorimeters according to 5.2 of ISO 9151:1995 with

thermocouples type T

number: 2

configuration: in the test plate, see Figure 3.

Dimensions in millimetres

IEC

Key

1 test plate (see also Figure 2)

2 horizontal centre line

3 centre line parallel to the arc axis

4 sensor (calorimeter in mounting board)

Figure 3 – Test plate with sensors

(calorimeters in mounting boards)

___________

TM

7 Marinite A, Monolux 500 and phenolic resin PF CP 201 are examples of suitable products available

commercially. This information is given for the convenience of users of this standard and does not constitute an

endorsement by IEC of the product named. Equivalent products may be used if they can be shown to lead to

the same results.

6.2.3 Sensor construction

The sensor consists of a calorimeter embedded in an insulating board. The sensor diameter is

90 mm ± 5 mm (see Figure 3). The calorimeter consists of a 18 g ± 1 g copper disc of

40 mm ± 0,1 mm in diameter, thickness of 1,6 mm ± 0,1 mm, a purity of at least 99 % and of a

copper-constantan thermocouple T type. The disc shall be accurately weighted before

assembly. The calorimeter shall be constructed from grade copper.

The copper-constantan wire thermocouple (type T) shall be mounted with the constantan wire

in the copper disc centre and the copper wire at any distance outside the disc centre. The

disc of the calorimeter shall be embedded in an insulating board. It shall be mounted flush

with the surface of this mounting board. The surface area of the copper disc intended for heat

receiving shall be covered by a thin layer of optical-black high temperature paint with an

emissivity > 0,9.

6.2.4 Sensor response

The conversion of the sensor response in the form of the temperature rise in °C to heat

energy (incident energy) in units of kJ/m is to be done by multiplying the delta temperature

values by the constant factor 5,52 kJ/m °C.

NOTE 1 The constant factor (sensor constant) is based on an average value for the copper thermal capacity C

p

equal to 0,385 J/g°C (80°C) in the tested temperature range, multiplied by the calorimeter copper plate mass of

18 g (resulting from a diameter of 40 mm and a thickness of 1,6 mm) and divided by the plate cross sectional area

of 12,56 cm .

NOTE 2 Another way to consider the temperature dependency of copper thermal capacity C is to use the

p

correction described in IEC 61482-1-1.

6.3 Garment box test procedure

6.3.1 Arrangement of the garment box test procedure

Instead of flat panels, a mannequin shall be employed for the garment box test procedure.

The procedure is used to test the function of the protective clothing after an arc exposure

including all the garment finding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...