IEC 60747-17:2020

(Main)Semiconductor devices - Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

Semiconductor devices - Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

IEC 60747-17:2020 specifies the terminology, essential ratings, characteristics, safety test and the measuring methods of magnetic coupler and capacitive coupler.

It specifies the principles and requirements of insulation and isolation characteristics for magnetic and capacitive couplers for basic insulation and reinforced insulation.

This first edition cancels and replaces IEC PAS 60747-17:2011. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to IEC PAS 60747-17:2011:

a) introduced lifetime safety factors for improved life time consideration, to comply with widely recognized aging mechanisms of silicone dioxide (TDDB) and thin film polymer isolation layers;

b) significantly improved "end of life testing" paragraph and statistical life time consideration by adding detailed description on process, safety factors, methods of generating data points and respective lifetime interpolations as well as being specific on minimum amount of samples required;

c) introduced concept of certification by similarity, including Annex A, giving guidance on qualification considerations and required certification process;

d) alternative pulse shape allowed for surge pulse testing, to avoid issues due to surge tester availability;

e) various improvements throughout the standard: definitions, for example type of coupler have been improved, introduction of surge impulse VIMP rating, usage of glass transition temperature, pre-conditioning have been redefined for improved usability and better compatibility with today’s design and functionality of couplers, available mold compounds, etc.

The contents of the corrigendum of January 2021 have been included in this copy.

Dispositifs à semiconducteurs - Partie 17 : Coupleur magnétique et capacitif pour l’isolation principale et renforcée

L'IEC 60747-17:2020 spécifie la terminologie, les valeurs assignées essentielles, les caractéristiques, l’essai de sécurité et les méthodes de mesure des coupleurs magnétiques et des coupleurs capacitifs.

Elle spécifie les principes et exigences de l’isolation et les caractéristiques d’isolement des coupleurs magnétiques et capacitifs pour l’isolation principale et l’isolation renforcée.

Cette première édition annule et remplace l’IEC PAS 60747-17:2011. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l’IEC PAS 60747‑17:2011:

a) introduction des facteurs de sécurité de durée de vie pour la prise en considération de la durée de vie améliorée, conformément aux mécanismes de vieillissement du dioxyde de silicium (TDDB) largement reconnus, et couches d’isolement en polymère à couches minces;

b) prise en considération de l’alinéa et de la durée de vie statistique de l’"essai de fin de vie" considérablement améliorée par l’ajout d’une description détaillée du processus, des facteurs de sécurité, des méthodes de génération de points de données et des interpolations de la durée de vie respective, ainsi que par la spécification de la quantité minimale d'échantillons exigés;

c) introduction du concept de certification par similarité, comprenant l’Annexe A, qui donne des recommandations relatives aux considérations de qualification et au processus de certification exigé;

d) forme d'impulsion alternative admise pour l’essai d’impulsion de choc afin d'éviter les problèmes de disponibilité de l’appareil d’essai aux ondes de choc;

e) plusieurs améliorations tout au long de la norme: amélioration des définitions, par exemple des types de coupleurs; introduction de la valeur assignée de l’impulsion de choc VIMP, utilisation d’une température de transition vitreuse, redéfinition du préconditionnement pour une utilisation améliorée et une meilleure compatibilité avec la conception et les fonctionnalités actuelles des coupleurs, les composants moulés disponibles, etc.

Le contenu du corrigendum de janvier 2021 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 20-Sep-2020

- Technical Committee

- SC 47E - Discrete semiconductor devices

- Drafting Committee

- WG 8 - TC 47/SC 47E/WG 8

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Sep-2020

- Completion Date

- 25-Sep-2020

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60747-17:2020 - "Semiconductor devices - Part 17: Magnetic and capacitive coupler for basic and reinforced insulation" - specifies terminology, essential ratings, safety tests and measuring methods for magnetic and capacitive couplers used to provide basic and reinforced insulation. This first edition (2020) replaces IEC PAS 60747-17:2011 and incorporates the January 2021 corrigendum. Revisions include lifetime safety factors, improved end-of-life testing and statistical lifetime methods, certification-by-similarity guidance (Annex A), and expanded surge test options.

Key topics and technical requirements

- Scope and terminology: Definitions for coupler types, insulation classes and datasheet characteristics.

- Insulation and isolation principles: Requirements for achieving protection against electrical shock using basic and reinforced insulation.

- Safety ratings and limits: Essential ratings, safety-limiting values and functional ratings to be declared on datasheets.

- Electrical safety tests: Isolation voltage tests, surge/impulse testing (including 1.2/50 µs surge pulse per IEC 61000‑4‑5 as an allowed equivalent), partial discharge measurements, and maximum surge isolation voltage requirements.

- Measuring methods: Standardized procedures for isolation capacitance (Ciso), isolation resistance (Riso), isolation tests, partial discharge measurement, switching times, and common‑mode transient immunity (CMTI).

- Lifetime and reliability: Introduction of lifetime safety factors to address aging mechanisms such as TDDB (time-dependent dielectric breakdown) in silicon dioxide and degradation of thin-film polymer isolation layers; detailed end-of-life testing and statistical lifetime interpolation methods.

- Qualification and certification: Guidance on certification by similarity (Annex A), pre-conditioning, required sample sizes and certification process.

- Practical test considerations: Use of glass transition temperature, updated pre-conditioning definitions, and alternative surge pulse shapes to improve test accessibility.

Practical applications and who uses this standard

IEC 60747-17 is essential for:

- Semiconductor manufacturers designing magnetic or capacitive isolators and opto‑replacement devices.

- Component qualification and test labs performing isolation, partial discharge and CMTI testing.

- Safety and reliability engineers assessing insulation lifetime, TDDB risks and end‑of‑life behavior.

- Product designers and system integrators in power electronics, industrial automation, medical devices and EV/charger applications that require galvanic isolation for user or system protection.

- Certification bodies reviewing conformity and applying certification-by-similarity principles.

Using IEC 60747-17 helps ensure compliant datasheet declarations, consistent test methods and robust insulation design for semiconductor couplers.

Related standards

- IEC 60747 series (semiconductor devices)

- IEC 61000-4-5 (surge testing referenced for 1.2/50 µs pulse)

IEC 60747-17:2020 - Semiconductor devices - Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

IEC 60747-17:2020 - Semiconductor devices - Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

Frequently Asked Questions

IEC 60747-17:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Part 17: Magnetic and capacitive coupler for basic and reinforced insulation". This standard covers: IEC 60747-17:2020 specifies the terminology, essential ratings, characteristics, safety test and the measuring methods of magnetic coupler and capacitive coupler. It specifies the principles and requirements of insulation and isolation characteristics for magnetic and capacitive couplers for basic insulation and reinforced insulation. This first edition cancels and replaces IEC PAS 60747-17:2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to IEC PAS 60747-17:2011: a) introduced lifetime safety factors for improved life time consideration, to comply with widely recognized aging mechanisms of silicone dioxide (TDDB) and thin film polymer isolation layers; b) significantly improved "end of life testing" paragraph and statistical life time consideration by adding detailed description on process, safety factors, methods of generating data points and respective lifetime interpolations as well as being specific on minimum amount of samples required; c) introduced concept of certification by similarity, including Annex A, giving guidance on qualification considerations and required certification process; d) alternative pulse shape allowed for surge pulse testing, to avoid issues due to surge tester availability; e) various improvements throughout the standard: definitions, for example type of coupler have been improved, introduction of surge impulse VIMP rating, usage of glass transition temperature, pre-conditioning have been redefined for improved usability and better compatibility with today’s design and functionality of couplers, available mold compounds, etc. The contents of the corrigendum of January 2021 have been included in this copy.

IEC 60747-17:2020 specifies the terminology, essential ratings, characteristics, safety test and the measuring methods of magnetic coupler and capacitive coupler. It specifies the principles and requirements of insulation and isolation characteristics for magnetic and capacitive couplers for basic insulation and reinforced insulation. This first edition cancels and replaces IEC PAS 60747-17:2011. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to IEC PAS 60747-17:2011: a) introduced lifetime safety factors for improved life time consideration, to comply with widely recognized aging mechanisms of silicone dioxide (TDDB) and thin film polymer isolation layers; b) significantly improved "end of life testing" paragraph and statistical life time consideration by adding detailed description on process, safety factors, methods of generating data points and respective lifetime interpolations as well as being specific on minimum amount of samples required; c) introduced concept of certification by similarity, including Annex A, giving guidance on qualification considerations and required certification process; d) alternative pulse shape allowed for surge pulse testing, to avoid issues due to surge tester availability; e) various improvements throughout the standard: definitions, for example type of coupler have been improved, introduction of surge impulse VIMP rating, usage of glass transition temperature, pre-conditioning have been redefined for improved usability and better compatibility with today’s design and functionality of couplers, available mold compounds, etc. The contents of the corrigendum of January 2021 have been included in this copy.

IEC 60747-17:2020 is classified under the following ICS (International Classification for Standards) categories: 01 - GENERALITIES. TERMINOLOGY. STANDARDIZATION. DOCUMENTATION; 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60747-17:2020 has the following relationships with other standards: It is inter standard links to IEC PAS 60747-17:2011, IEC 60747-17:2020/COR1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60747-17:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60747-17 ®

Edition 1.0 2020-09

INTERNATIONAL

STANDARD

Semiconductor devices –

Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60747-17 ®

Edition 1.0 2020-09

INTERNATIONAL

STANDARD

Semiconductor devices –

Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.080.99 ISBN 978-2-8322-8801-6

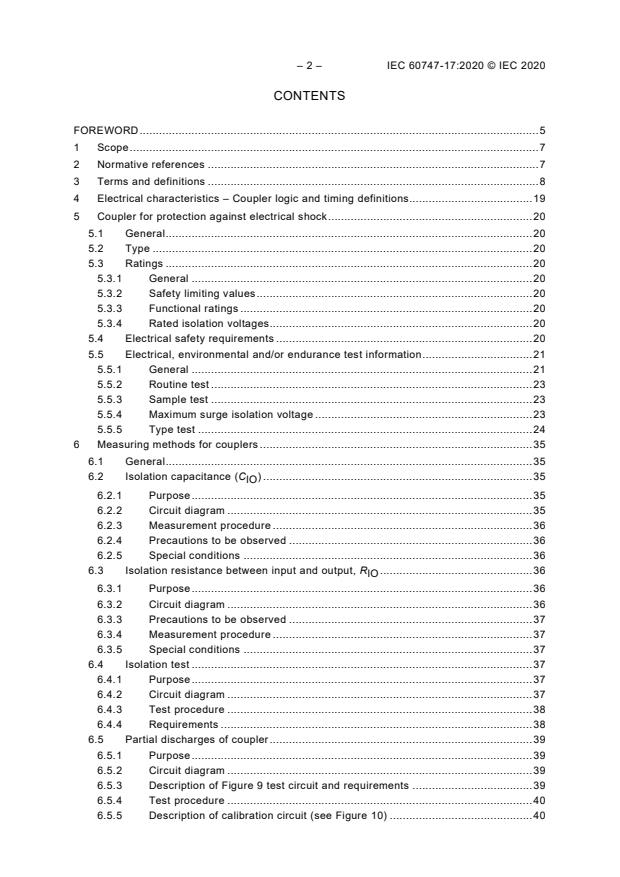

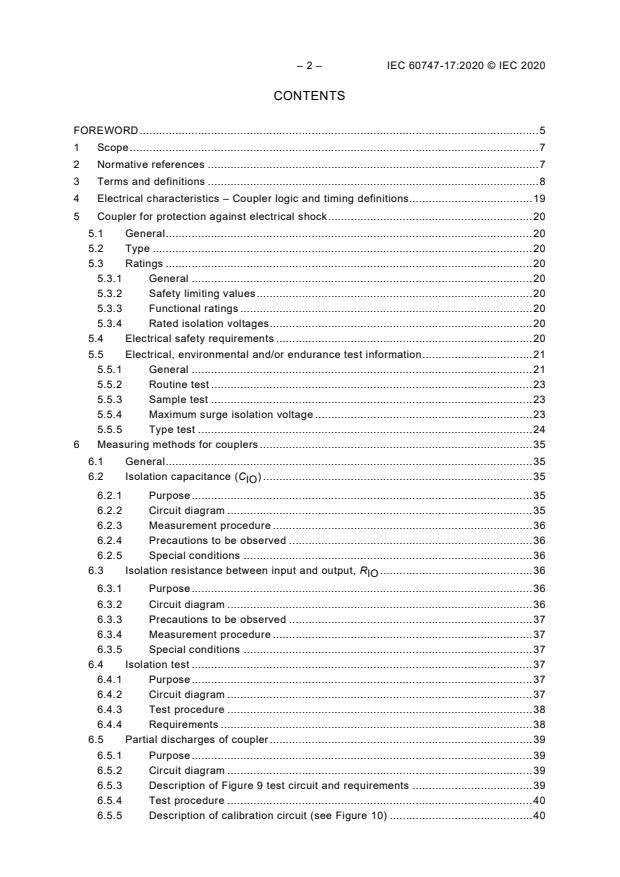

– 2 – IEC 60747-17:2020 © IEC 2020

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Electrical characteristics – Coupler logic and timing definitions . 19

5 Coupler for protection against electrical shock . 20

5.1 General . 20

5.2 Type . 20

5.3 Ratings . 20

5.3.1 General . 20

5.3.2 Safety limiting values . 20

5.3.3 Functional ratings . 20

5.3.4 Rated isolation voltages. 20

5.4 Electrical safety requirements . 20

5.5 Electrical, environmental and/or endurance test information . 21

5.5.1 General . 21

5.5.2 Routine test . 23

5.5.3 Sample test . 23

5.5.4 Maximum surge isolation voltage . 23

5.5.5 Type test . 24

6 Measuring methods for couplers . 35

6.1 General . 35

6.2 Isolation capacitance (C ) . 35

lO

6.2.1 Purpose . 35

6.2.2 Circuit diagram . 35

6.2.3 Measurement procedure . 36

6.2.4 Precautions to be observed . 36

6.2.5 Special conditions . 36

6.3 Isolation resistance between input and output, R . 36

lO

6.3.1 Purpose . 36

6.3.2 Circuit diagram . 36

6.3.3 Precautions to be observed . 37

6.3.4 Measurement procedure . 37

6.3.5 Special conditions . 37

6.4 Isolation test . 37

6.4.1 Purpose . 37

6.4.2 Circuit diagram . 37

6.4.3 Test procedure . 38

6.4.4 Requirements . 38

6.5 Partial discharges of coupler . 39

6.5.1 Purpose . 39

6.5.2 Circuit diagram . 39

6.5.3 Description of Figure 9 test circuit and requirements . 39

6.5.4 Test procedure . 40

6.5.5 Description of calibration circuit (see Figure 10) . 40

6.5.6 Test methods . 41

6.5.7 Specified conditions . 41

6.5.8 Test voltage conditions . 42

6.6 Switching times of couplers . 42

6.6.1 Purpose . 42

6.6.2 Circuit diagram . 42

6.6.3 Measurement procedure . 43

6.6.4 Specified conditions . 44

6.7 Measuring methods of common-mode transient immunity (CMTI) for

magnetic and capacitive couplers . 44

6.7.1 Purpose . 44

6.7.2 Circuit diagram . 44

6.7.3 Precautions to be observed . 45

6.7.4 Static CMTI measuring procedure . 46

6.7.5 Specified conditions . 47

6.7.6 Dynamic CMTI measuring procedure . 47

Annex A (informative) Qualification guidance . 48

Bibliography . 51

Figure 1 – Time intervals for methods a and b of the test voltage . 15

Figure 2 –1,2/50 µs surge pulse according 61000-4-5:2014 allowed as equivalent

impulse for isolation testing . 24

Figure 3 – Determination of time to failure (referring to method in 5.5.5.8) . 31

Figure 4 – Determination of working voltage (referring to method in 5.5.5.8 for

exponential model) . 32

Figure 5 – Determination of working voltage (referring to method in 5.5.5.8 for non-

linear model) . 33

Figure 6 – Isolation capacitance measurement circuit . 36

Figure 7 – Isolation resistance measurement circuit . 37

Figure 8 – Isolation voltage measurement circuit . 38

Figure 9 – Partial discharge test circuit . 39

Figure 10 – Connections for the calibration of the complete test arrangement . 40

Figure 11 – Switching time test circuit . 43

Figure 12 – Transition time waveform measurement . 43

Figure 13 – Propagation delay time waveform measurement . 44

Figure 14 – Static versus dynamic data source signal VI . 45

Figure 15 – Common-mode transient immunity (CMTI) test setup for both static and

dynamic testing . 45

Figure 16 – Static common-mode transient immunity (CMTI) and V and low to high

CM

data transition waveform . 47

Figure A.1 – Lifetime verification . 49

Table 1 – Overview on characteristics and symbols . 19

Table 2 – Datasheet characteristics . 21

Table 3 – Tests and test sequence for coupler providing basic insulation and reinforced

insulation for protection against electrical shock . 22

Table 4 – Test conditions . 23

– 4 – IEC 60747-17:2020 © IEC 2020

Table 5 – Safety factor F. 41

Table 6 – Specified conditions for method a and method b. 42

Table A.1 – Front end process changes within component . 49

Table A.2 – Front End Process Changes within SiO/SiN/imide-passivation . 50

Table A.3 – Layout changes . 50

Table A.4 – Backend changes . 50

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

Part 17: Magnetic and capacitive coupler

for basic and reinforced insulation

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60747-17 has been prepared by subcommittee SC 47E: Discrete

semiconductor devices, of IEC technical committee TC 47: Semiconductor devices.

This first edition cancels and replaces IEC PAS 60747-17:2011. This edition constitutes a

technical revision.

This edition includes the following significant technical changes with respect to

IEC PAS 60747-17:2011:

a) introduced lifetime safety factors for improved life time consideration, to comply with

widely recognized aging mechanisms of silicone dioxide (TDDB) and thin film polymer

isolation layers;

b) significantly improved "end of life testing" paragraph and statistical life time consideration

by adding detailed description on process, safety factors, methods of generating data

points and respective lifetime interpolations as well as being specific on minimum amount

of samples required;

– 6 – IEC 60747-17:2020 © IEC 2020

c) introduced concept of certification by similarity, including Annex A, giving guidance on

qualification considerations and required certification process;

d) alternative pulse shape allowed for surge pulse testing, to avoid issues due to surge tester

availability;

e) various improvements throughout the standard: definitions, for example type of coupler

have been improved, introduction of surge impulse V rating, usage of glass transition

IMP

temperature, pre-conditioning have been redefined for improved usability and better

compatibility with today’s design and functionality of couplers, available mold compounds,

etc.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47E/711/FDIS 47E/715/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60747 series, published under the general title Semiconductor

devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

SEMICONDUCTOR DEVICES –

Part 17: Magnetic and capacitive coupler

for basic and reinforced insulation

1 Scope

This part of IEC 60747 specifies the terminology, essential ratings, characteristics, safety test

and the measuring methods of magnetic coupler and capacitive coupler.

It specifies the principles and requirements of insulation and isolation characteristics for

magnetic and capacitive couplers for basic insulation and reinforced insulation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-1:2007, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2:2007, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-30:2005, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-58:2015, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-67:1995, Environmental testing – Part 2: Tests – Test Cy: Damp heat, steady

state, accelerated test primarily intended for components

IEC 60112:2003, Method for the determination of the proof and the comparative tracking

indices of solid insulating materials

IEC 60216-1:2013, Electrical insulating materials – Thermal endurance properties – Part 1:

Ageing procedures and evaluation of test results

IEC 60216-2:2005, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of

test criteria

IEC 60664-1:2007, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

– 8 – IEC 60747-17:2020 © IEC 2020

IEC 60672-2:1999, Ceramic and glass insulating materials – Part 2: Methods of test

IEC 60695-11-5:2016, Fire hazard testing – Part 11-5: Test flames – Needle-flame test

method – Apparatus, confirmatory test arrangement and guidance

IEC 62539:2007, Guide for the statistical analysis of electrical insulation breakdown data

3 Terms and definitions

3.1

details of outline and encapsulation

information related method of encapsulation and terminal connections within the coupler's

isolation system

3.1.1

outline drawing

drawing or sketch restricted to line to describe the shape of objects or circuitry

3.1.2

method of encapsulation

encapsulating materials used forming part of the isolation system

3.1.3

terminal identification

terminal identification and indication of any connection between a terminal and the case

3.2

type of coupler

internal construction and insulation method of coupler to achieve basic or reinforced

insulation

3.2.1

SiO isolator

isolator with an internal insulation construction utilizing silicon dioxide based material

3.2.2

thin film polymer isolator

isolator with an internal insulation construction, utilising a thin film polymer insulation

3.3

isolation

ability to reject electrical and magnetic interference or noise

3.4

insulation

part of an electromechanical product which galvanically separates the conducting parts at

different electrical potentials

3.4.1

reinforced insulation

insulation of hazardous-live-parts which provides a degree of protection against electric shock

equivalent to double insulation

Note 1 to entry: Reinforced insulation may comprise several layers which cannot be tested singly as basic

insulation or supplementary insulation.

[SOURCE: IEC 60664-1:2007, 3.17.5]

3.4.2

basic insulation

insulation providing a basic safeguard against electric shock

3.5

isolation side

all terminals of side 1 which are isolated from all terminals of side 2 by an isolation barrier,

forming a two-terminal device

3.6

isolation capacitance

C

IO

total capacitance between the terminals on side 1 of the isolation barrier connected together

and the terminals on side 2 of the isolation barrier connected together forming a two-terminal

device

Note 1 to entry: See IEC 60747-5-5:2007, 4.3.

3.7

isolation resistance

R

IO

resistance between the terminals on side 1 of the isolation barrier connected together and all

the terminals on side 2 of the isolation barrier connected together forming a two-terminal

device

3.8

isolation resistance at safety limiting temperature

R

IO_S

resistance at safety limiting temperature T between the terminals on side 1 of the isolation

S

barrier connected together and all the terminals on side 2 of the isolation barrier connected

together forming a two-terminal device which should be larger or equal to 1E9 Ω

3.9

isolation voltage

voltage between any specified terminals connected together on side 1 of the isolation barrier

and any terminals connected together on side 2 of the isolation barrier

3.10

logic state match

condition in which an output logic state matches the associated input logic state

3.11

logic state transition match

condition in which an output logic state change follows the associated input logic state change

3.12

common mode transient immunity

CMTI

maximum tolerable rate-of-rise (or fall) of a common-mode voltage

Note 1 to entry: The common mode transient immunity is given in volts per second. CMTl should include the

amplitude of the common-mode voltage that can be tolerated.

3.12.1

common mode transient immunity at logic high output

|CM |

H

common mode transient immunity of the coupler with logic at high output

– 10 – IEC 60747-17:2020 © IEC 2020

3.12.2

common mode transient immunity at logic low output

|CM |

L

common mode transient immunity of the coupler with logic at low output

3.12.3

common mode transient immunity at logic dynamic output

|CM |

D

maximum slew rate of a common-mode voltage (V ) at which the coupler transmits the data

CM

without missing the transition or creating unexpected transitions for all combinations of slew

rate polarity and data edges

Note 1 to entry: The data transition shall occur in the specified time frame, and invalid data in terms of delay

times, transitions or number of transitions, or magnitude (not meeting minimum logic V or maximum logic low

OH

V specifications) will be construed as a failure.

OL

3.12.4

CMTI performance

dV /dt

CM

maximum slew rate of a common mode voltage at which the output of the coupler remains at

the specific logic level and at the specified timing

3.12.5

common mode voltage

V

CM

common mode voltage at which the slew rate is measured

3.13

propagation delay

t t

pLH , pHL

time required for a change in the input state of a digital coupler to propagate to the

corresponding output

Note 1 to entry: The propagation delay from LOW to HIGH is expressed by t .

pLH

Note 2 to entry: The propagation delay from HIGH to LOW is expressed by t .

pHL

3.14

pulse width distortion

|t – t |

pLH pHL

PWD

unintentional and generally undesired change in the form of a signal causing the signal input

pulse width to differ from signal output pulse width

3.15

supply voltage

V

DD

supply voltages supplied on input and output side of coupler

Note 1 to entry: The supply voltage is also commonly expressed by V

CC.

3.16

integrated circuit

IC

microcircuit in which all or some of the circuit elements are inseparably associated and

electrically interconnected so that it is considered to be indivisible for the purpose of

construction and commerce on side 1 and side 2

[SOURCE: IEC 60050-521:2002, 521-10-03, modified – The words "on side 1 and side 2"

have been added.]

3.17

input and output terminal

I/O

side 1 and side 2 terminals of an integrated circuit providing signal conditioning to the internal

coupling element

3.18

ground potential

GND

reference potential for any side of a coupler

3.19

input voltage

V

I

input voltage, either V , V or analog level

IL IH

3.20

output voltage

V

O

output voltage, either V , V or analog level

OL OH

3.21

maximum ambient operating temperature

T

op max

maximum ambient operating temperature allowed during operation of coupler

3.22

reference-point temperature

T

REF

temperature defined by the manufacturer to refer to a defined point such as junction

temperature, case temperature, etc.

3.23

characteristic lifetime

t63

refers to characteristic lifetime (t63 %) when applying Weibull distribution to determine the

mean lifetime

Note 1 to entry: In general, lifetime reliability is defined as the mean lifetime (t50 %) at which cumulative failure

rate reaches 50 %. When Weibull distribution is used, a characteristic lifetime (t63 %) is considered for the mean

lifetime. This is referred to as t63 in the statistical lifetime consideration.

3.24

general safety ratings of couplers for basic and reinforced insulation

thermal and mechanical operating conditions that exceed the specified ratings (limiting

values) for normal operation, and to which the specified safety requirements refer

Note 1 to entry: The couplers may become permanently inoperative when safety ratings are applied.

3.25

electrical safety ratings of couplers for basic and reinforced insulation

electrical requirements that have to be met and maintained after the couplers have been

subjected to specified safety ratings, to ensure protection against electrical shock

Note 1 to entry: The couplers may become permanently inoperative when safety ratings are applied.

– 12 – IEC 60747-17:2020 © IEC 2020

[SOURCE: IEC 60747-5-5:2007, 5.2, modified – In the term, the word "requirements" has

been replaced with "ratings", and "isolation" with insulation. In the definition, the word

"photocoupler" has been replaced by "couplers".]

3.25.1

partial discharge

PD

localized electrical discharge which occurs in the insulation between all terminals of the side 1

and all terminals of side 2 of the coupler

3.25.2

apparent charge

q

pd

electrical discharge caused by a partial discharge in the coupler

3.25.3

threshold apparent charge

q

pd(TH)

specified value of apparent charge that is as small as technically feasible, which determines

the partial-discharge extinction voltage.

Note 1 to entry: A threshold apparent charge of 5 pC was found to be a practicable criterion for couplers.

Otherwise, it should be defined on each individual device design. Smaller threshold values are desirable but not

required if accurate measurement in a production environment is not practical. This threshold shall not be

exceeded at any time.

Note 2 to entry: In actual testing, this criterion applies to the apparent charge pulse with the maximum value.

Note 3 to entry: The term "specified discharge magnitude" (see 6.1.3.5.4.1 of IEC 60664-1:2007) is synonymous

with "threshold apparent charge".

3.26

test voltage

V

pd(t)

voltage applied during the test period of the partial discharge test between all terminals of

side 1 (connected together) and all terminals of side 2 (connected together) to the coupler

under test

3.26.1

initial test voltage for partial discharge

V

pd(ini)

test voltage applied during the initial test time t

ini

3.26.2

initial test voltage for partial discharge, method a

V

pd(ini),a

value of the voltage applied at the beginning of the measurement, for a specified time t ,

ini

which is intended to simulate the occurrence of a transient overvoltage

Note 1 to entry: Refer to Figure 1, method a.

3.26.3

initial test voltage for partial discharge, method b

V

pd(ini),b

isolation test voltage applied between all terminals of side 1 (connected together) and all

terminals of side 2 (connected together) at routine test (method b) which is equal or higher to

the manufacturer's maximum transient voltage rating

3.27

multiplying factor

F

multiplying factor applied for method a and method b

Note 1 to entry: See Table 5 for more information.

3.28

apparent charge measuring voltage

V

pd(m)

test voltage at which apparent charge is measured

Note 1 to entry: Specified values of this voltage may be expressed as multiple of the specified value of the rated

repetitive peak isolation voltage: V = F × V . Refer to 3.27.

pd(m) IORM

Note 2 to entry: This is a test voltage where the apparent charge shall be equal or less than the specified value.

3.29

partial-discharge inception voltage

V

pd(I)

lowest peak value of an AC test voltage at which the apparent charge is greater than the

specified threshold apparent charge, if the test voltage is increased from a lower value where

no partial discharge occurs

3.30

partial-discharge extinction voltage

V

pd(e)

lowest peak value of an AC test voltage at which the apparent charge is smaller than the

specified threshold apparent charge, if the test voltage is reduced from a higher value where

such discharge occurs

Note 1 to entry: The equivalent RMS value of an AC test voltage may also be used.

3.31

reference voltage for lifetime determination

V

REF

maximum predicated voltage which is determined by the end of life (EOL) test according

5.5.5.8

3.32

lifetime safety factor

lifetime safety factor applied to V to reflect safety consideration on coupler lifetime

REF

3.33

time intervals

duration and sequence of test voltages for partial discharge measurements as shown in

Figure 1

– 14 – IEC 60747-17:2020 © IEC 2020

Time intervals for method a

Time intervals for method b1

Time intervals for method b2

Key

t initial time method a only

ini

t isolation test time method b

ini,b

t (partial-discharge) stress time

st

t (partial-discharge) stress time

st2

t isolation test stress time (method b only)

st1

t (partial-discharge) measuring time

m

t , t , t , t settling times

1 2 3 4

Figure 1 – Time intervals for methods a and b of the test voltage

3.34

lifetime

minimum required time in years to failure based on an insulation grade correlated failure rate

3.35

SiO time dependent dielectric breakdown

SiO TDDB

aging effect observed in isolators using internal constructions utilizing SiO based materials

3.36

thin film polymer space charge degradation

aging effect observed in isolators using internal insulation constructions utilizing thin film

polymer dielectric materials

Note 1 to entry: This constitutes test requirements to establish the maximum safe operating voltage at which

space charge aging does not impact the safety related values V and V .

IORM IOTM

3.37

failure rate over lifetime

FROL

maximum allowed failure rate due to isolation break down using lifetime prediction

3.38

statistical model

mathematical model that embodies a set of statistical assumptions concerning the generation

of sample data

– 16 – IEC 60747-17:2020 © IEC 2020

Note 1 to entry: The type of curve fit shall be based on the material type as defined in 3.2.1 and 3.2.2.

Note 2 to entry: In cases where the insulation material type is not compatible or defined with models in 3.38.1 and

3.38.2, such isolators may only be used in case the specific distinctiveness of such insulation material has been

considered and properly addressed by the regulatory experts and has been added as into the standard.

3.38.1

exponential model

modelling method used for material types defined in 3.2.1 (SiO isolators):

kV

L= ce

where

L is the time-to-failure at test voltage V;

V is the test voltage;

c and k are the coefficients

Note 1 to entry: For the usage of k × V dependency, an adequate data set with sufficient measurement points

shall be provided which clearly proves the k × V dependency according to IEC 62539:2007.

3.38.2

non linear model

modelling method used for material types defined in 3.2.2 (thin film polymer isolators):

−n

kV

= L ce

where

L is the time-to-failure at test voltage V;

V is the test voltage;

c, n and k are the coefficients

-n

Note 1 to entry: For the usage of k × V dependency, an adequate data set with sufficient measurement points

-n

shall be provided which clearly proves the k × V dependency according to IEC 62539:2007.

3.38.3

rated isolation voltages

3.38.3.1

DC isolation voltage

V

IO

value of the constant isolation voltage

3.38.3.2

maximum rated isolation working voltage

V

IOWM

RMS value of isolation voltage V assigned by the manufacturer of the couplers,

IORM

characterizing the specified (long term) withstand capability of its isolation

3.38.3.3

maximum rated repetitive peak isolation voltage

V

IORM

repetitive peak isolation voltage assigned by the manufacturer of the couplers, characterizing

the specified withstand capability of its isolation against repetitive peak voltages

Note 1 to entry: This peak isolation voltage includes all repetitive transient voltages, but excludes all non-

repetitive transient voltages.

Note 2 to entry: A repetitive transient voltage is usually a function of the circuit. A non-repetitive transient voltage

is usually due to an external cause and it is assumed that its effect has completely disappeared before the next

non-repetitive voltage transient arrives.

Note 3 to entry: Since the degradation of the galvanic isolation depends normally on the peak voltage, V is

IORM

the repetitive peak value of the absolute envelope voltage over time.

Note 4 to entry: See IEC 60747-5-5:2007, 5.3, from which the description has been modified to define V as

IORM

repetitive peak or equivalent DC value and state it includes all repetitive transient voltages.

3.38.3.4

maximum rated transient isolation voltage

V

IOTM

peak isolation voltage which includes all non-repetitive transient voltages and applies to the

package clearance as well as internal insulation

Note 1 to entry: See IEC 60664-1:2007.

Note 2 to entry: See IEC 60747-5-5:2007, 5.3, from which the description has been modified to emphasize that

V includes all non-repetitive transient voltages and applies to package clearance as well as internal insulation.

IOTM

3.38.3.5

withstanding isolation voltage

V

ISO

maximum isolation withstanding AC RMS voltage for one minute

3.38.3.6

surge isolation voltage

V

IOSM

highest instantaneous value of an isolation voltage pulse with short time duration and of

specified wave form (1,2/50 µs) applied across the internal insulation of the device

Note 1 to entry: Testing of required V levels as specified in 5.5.4 may be conducted for example in oil to

IOSM

exclude arcing across the surface or in air.

Note 2 to entry: See IEC 60747-5-5:2007, 5.3, from which description has been modified to provide additional

information on duration and wave form.

3.38.3.7

impulse voltage

V

IMP

highest peak value of impulse voltage without flashover and solid insulation breakdown

Note 1 to entry: Wave form and polarity are described in 6.1.2.2.1 of IEC 60664-1:2007.

3.39

absolute maximum ratings

qualifications such as time, frequency, pulse duration, humidity

Note 1 to entry: Exceeding the maximum ratings can lead to damage of the isolation barrier.

3.39.1

minimum and maximum storage temperatures

T

stg

temperatures in non-operation condition

3.39.2

minimum and maximum ambient temperatures

T

amb

temperatures of the air surrounding a component

– 18 – IEC 60747-17:2020 © IEC 2020

3.39.3

maximum soldering temperature

T

sld

maximum soldering time and minimum distance to case which should be specified

3.39.4

maximum continuous input power

P

SI

maximum continuous input power at ambient or a reference point temperature of 25 °C and

derating curve or derating factor

3.39.5

maximum output power dissipation

P

SO

maximum output power dissipation of the output stage at ambient or a reference point

temperature of 25 °C and a derating curve or derating factor

3.39.6

maximum total power dissipation of the package

P

tot

maximum total power dissipation at ambient or reference-point temperature of 25 °C and

derating curve or derating factor

3.39.7

maximum power transmission

P

TR

power transferred across isolation barrier during operation

3.40

F

LT

working voltage safety factor at applicable lifetime of coupler

3.41

maximum ambient safety temperature

T

S

highest ambient temperature permitted in the event of a fault

3.42

maximum output current

I

SO

current used for power dissipation considerations to determine safety limitation

4 Electrical characteristics – Coupler logic and timing definitions

Clause 4 relates to definitions and logic related coupler operation (see Table 1).

Table 1 – Overview on characteristics and symbols

Conditions at

T or T = 25 °C

No. Characteristics Symbols Requirements

amb case

unless otherwise stated

Input logic level voltage high

V

4.1.1 min.

a IH

(logic high input voltage)

Input logic level voltage low

V

4.1.2 max.

a IL

(logic low input voltage)

Output logic level voltage high

V

4.1.3 min.

a OH

(logic high output voltage)

Defined load

Output logic level voltage

V

4.1.4 max.

a OL

(logic low output voltage)

Propagation delay input to output

t

4.1.5 at change low to high output max.

pLH

voltage

Load conditions defined 10 %

to 90 % or 50 % to 50 %

Propagation delay input to output

t

4.1.6 at change high to low output max.

pHL

voltage

|t – t |

4.1.7 Pulse width distortion As defined in 3.14 max.

pLH pHL

t

4.1.8 Output rise time 10 % to 90 %, load defined max.

r

t

4.1.9 Output fall time 90 % to 10 %, load defined max.

f

4.1.10 Working frequency f max.

Isolation resistance between input

V specified R

4.1.11 typ

IO IO

and output

Isolation capacitance between

C

4.1.12 As tested in 6.2 typ

IO

input and output

I

f = 0 Hz min. max.

CC1

4.1.13 Side 1 supply current

f = f I

min. max.

max CC1

I

min. max.

f = 0 Hz

CC2

4.1.14 Side 2 supply current

f = f , defined load I

min. max.

max CC2

Common mode transient immunity

|CM |

min.

b H

at logic high output

V defined in datasheet at

Common mode transient immunity

O

|CM |

4.1.15 min.

b L

at logic low output

common mode conditions

Common mode transient immunity

|CM |

min.

b D

at logic dynamic output

maximum total power dissipation

P

4.1.16 Max.

tot

of the package

a

3 V and/or 5 V TTL compatible logic.

b

Preferably consistent with datasheet specifications: minimum V and maximum V .

OH OL

– 20 – IEC 60747-17:2020 © IEC 2020

5 Coupler for protection against electrical shock

5.1 General

All requirements contained in Clause 5 are valid for couplers with a solid insulation in one

package, whatever the configuration of the input and/or the output is (e.g. IC input, output,

etc.).

5.2 Ty

...

IEC 60747-17 ®

Edition 1.0 2020-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices –

Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

Dispositifs à semiconducteurs –

Partie 17: Coupleur magnétique et capacitif pour l’isolation principale et

renforcée

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60747-17 ®

Edition 1.0 2020-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices –

Part 17: Magnetic and capacitive coupler for basic and reinforced insulation

Dispositifs à semiconducteurs –

Partie 17: Coupleur magnétique et capacitif pour l’isolation principale et

renforcée

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.080.99 ISBN 978-2-8322-8924-2

– 2 – IEC 60747-17:2020 © IEC 2020

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Electrical characteristics – Coupler logic and timing definitions . 19

5 Coupler for protection against electrical shock . 20

5.1 General . 20

5.2 Type . 20

5.3 Ratings . 20

5.3.1 General . 20

5.3.2 Safety limiting values . 20

5.3.3 Functional ratings . 20

5.3.4 Rated isolation voltages. 20

5.4 Electrical safety requirements . 20

5.5 Electrical, environmental and/or endurance test information . 21

5.5.1 General . 21

5.5.2 Routine test . 23

5.5.3 Sample test . 23

5.5.4 Maximum surge isolation voltage . 23

5.5.5 Type test . 24

6 Measuring methods for couplers . 35

6.1 General . 35

6.2 Isolation capacitance (C ) . 35

lO

6.2.1 Purpose . 35

6.2.2 Circuit diagram . 35

6.2.3 Measurement procedure . 36

6.2.4 Precautions to be observed . 36

6.2.5 Special conditions . 36

6.3 Isolation resistance between input and output, R . 36

lO

6.3.1 Purpose . 36

6.3.2 Circuit diagram . 36

6.3.3 Precautions to be observed . 37

6.3.4 Measurement procedure . 37

6.3.5 Special conditions . 37

6.4 Isolation test . 37

6.4.1 Purpose . 37

6.4.2 Circuit diagram . 37

6.4.3 Test procedure . 38

6.4.4 Requirements . 38

6.5 Partial discharges of coupler . 39

6.5.1 Purpose . 39

6.5.2 Circuit diagram . 39

6.5.3 Description of Figure 9 test circuit and requirements . 39

6.5.4 Test procedure . 40

6.5.5 Description of calibration circuit (see Figure 10) . 40

6.5.6 Test methods . 41

6.5.7 Specified conditions . 41

6.5.8 Test voltage conditions . 42

6.6 Switching times of couplers . 42

6.6.1 Purpose . 42

6.6.2 Circuit diagram . 42

6.6.3 Measurement procedure . 43

6.6.4 Specified conditions . 44

6.7 Measuring methods of common-mode transient immunity (CMTI) for

magnetic and capacitive couplers . 44

6.7.1 Purpose . 44

6.7.2 Circuit diagram . 44

6.7.3 Precautions to be observed . 45

6.7.4 Static CMTI measuring procedure . 46

6.7.5 Specified conditions . 47

6.7.6 Dynamic CMTI measuring procedure . 47

Annex A (informative) Qualification guidance . 48

Bibliography . 51

Figure 1 – Time intervals for methods a and b of the test voltage . 15

Figure 2 –1,2/50 µs surge pulse according 61000-4-5:2014 allowed as equivalent

impulse for isolation testing . 24

Figure 3 – Determination of time to failure (referring to method in 5.5.5.8) . 31

Figure 4 – Determination of working voltage (referring to method in 5.5.5.8 for

exponential model) . 32

Figure 5 – Determination of working voltage (referring to method in 5.5.5.8 for non-

linear model) . 33

Figure 6 – Isolation capacitance measurement circuit . 36

Figure 7 – Isolation resistance measurement circuit . 37

Figure 8 – Isolation voltage measurement circuit . 38

Figure 9 – Partial discharge test circuit . 39

Figure 10 – Connections for the calibration of the complete test arrangement . 40

Figure 11 – Switching time test circuit . 43

Figure 12 – Transition time waveform measurement . 43

Figure 13 – Propagation delay time waveform measurement . 44

Figure 14 – Static versus dynamic data source signal VI . 45

Figure 15 – Common-mode transient immunity (CMTI) test setup for both static and

dynamic testing . 45

Figure 16 – Static common-mode transient immunity (CMTI) and V and low to high

CM

data transition waveform . 47

Figure A.1 – Lifetime verification . 49

Table 1 – Overview on characteristics and symbols . 19

Table 2 – Datasheet characteristics . 21

Table 3 – Tests and test sequence for coupler providing basic insulation and reinforced

insulation for protection against electrical shock . 22

Table 4 – Test conditions . 23

– 4 – IEC 60747-17:2020 © IEC 2020

Table 5 – Safety factor F. 41

Table 6 – Specified conditions for method a and method b. 42

Table A.1 – Front end process changes within component . 49

Table A.2 – Front End Process Changes within SiO/SiN/imide-passivation . 50

Table A.3 – Layout changes . 50

Table A.4 – Backend changes . 50

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

Part 17: Magnetic and capacitive coupler

for basic and reinforced insulation

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60747-17 has been prepared by subcommittee SC 47E: Discrete

semiconductor devices, of IEC technical committee TC 47: Semiconductor devices.

This first edition cancels and replaces IEC PAS 60747-17:2011. This edition constitutes a

technical revision.

This edition includes the following significant technical changes with respect to

IEC PAS 60747-17:2011:

a) introduced lifetime safety factors for improved life time consideration, to comply with

widely recognized aging mechanisms of silicone dioxide (TDDB) and thin film polymer

isolation layers;

b) significantly improved "end of life testing" paragraph and statistical life time consideration

by adding detailed description on process, safety factors, methods of generating data

points and respective lifetime interpolations as well as being specific on minimum amount

of samples required;

– 6 – IEC 60747-17:2020 © IEC 2020

c) introduced concept of certification by similarity, including Annex A, giving guidance on

qualification considerations and required certification process;

d) alternative pulse shape allowed for surge pulse testing, to avoid issues due to surge tester

availability;

e) various improvements throughout the standard: definitions, for example type of coupler

have been improved, introduction of surge impulse V rating, usage of glass transition

IMP

temperature, pre-conditioning have been redefined for improved usability and better

compatibility with today’s design and functionality of couplers, available mold compounds,

etc.

The text of this International Standard is based on the following documents:

FDIS Report on voting

47E/711/FDIS 47E/715/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60747 series, published under the general title Semiconductor

devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

SEMICONDUCTOR DEVICES –

Part 17: Magnetic and capacitive coupler

for basic and reinforced insulation

1 Scope

This part of IEC 60747 specifies the terminology, essential ratings, characteristics, safety test

and the measuring methods of magnetic coupler and capacitive coupler.

It specifies the principles and requirements of insulation and isolation characteristics for

magnetic and capacitive couplers for basic insulation and reinforced insulation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-1:2007, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2:2007, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-30:2005, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-58:2015, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-67:1995, Environmental testing – Part 2: Tests – Test Cy: Damp heat, steady

state, accelerated test primarily intended for components

IEC 60112:2003, Method for the determination of the proof and the comparative tracking

indices of solid insulating materials

IEC 60216-1:2013, Electrical insulating materials – Thermal endurance properties – Part 1:

Ageing procedures and evaluation of test results

IEC 60216-2:2005, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of

test criteria

IEC 60664-1:2007, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

– 8 – IEC 60747-17:2020 © IEC 2020

IEC 60672-2:1999, Ceramic and glass insulating materials – Part 2: Methods of test

IEC 60695-11-5:2016, Fire hazard testing – Part 11-5: Test flames – Needle-flame test

method – Apparatus, confirmatory test arrangement and guidance

IEC 62539:2007, Guide for the statistical analysis of electrical insulation breakdown data

3 Terms and definitions

3.1

details of outline and encapsulation

information related method of encapsulation and terminal connections within the coupler's

isolation system

3.1.1

outline drawing

drawing or sketch restricted to line to describe the shape of objects or circuitry

3.1.2

method of encapsulation

encapsulating materials used forming part of the isolation system

3.1.3

terminal identification

terminal identification and indication of any connection between a terminal and the case

3.2

type of coupler

internal construction and insulation method of coupler to achieve basic or reinforced

insulation

3.2.1

SiO isolator

isolator with an internal insulation construction utilizing silicon dioxide based material

3.2.2

thin film polymer isolator

isolator with an internal insulation construction, utilising a thin film polymer insulation

3.3

isolation

ability to reject electrical and magnetic interference or noise

3.4

insulation

part of an electromechanical product which galvanically separates the conducting parts at

different electrical potentials

3.4.1

reinforced insulation

insulation of hazardous-live-parts which provides a degree of protection against electric shock

equivalent to double insulation

Note 1 to entry: Reinforced insulation may comprise several layers which cannot be tested singly as basic

insulation or supplementary insulation.

[SOURCE: IEC 60664-1:2007, 3.17.5]

3.4.2

basic insulation

insulation providing a basic safeguard against electric shock

3.5

isolation side

all terminals of side 1 which are isolated from all terminals of side 2 by an isolation barrier,

forming a two-terminal device

3.6

isolation capacitance

C

IO

total capacitance between the terminals on side 1 of the isolation barrier connected together

and the terminals on side 2 of the isolation barrier connected together forming a two-terminal

device

Note 1 to entry: See IEC 60747-5-5:2007, 4.3.

3.7

isolation resistance

R

IO

resistance between the terminals on side 1 of the isolation barrier connected together and all

the terminals on side 2 of the isolation barrier connected together forming a two-terminal

device

3.8

isolation resistance at safety limiting temperature

R

IO_S

resistance at safety limiting temperature T between the terminals on side 1 of the isolation

S

barrier connected together and all the terminals on side 2 of the isolation barrier connected

together forming a two-terminal device which should be larger or equal to 1E9 Ω

3.9

isolation voltage

voltage between any specified terminals connected together on side 1 of the isolation barrier

and any terminals connected together on side 2 of the isolation barrier

3.10

logic state match

condition in which an output logic state matches the associated input logic state

3.11

logic state transition match

condition in which an output logic state change follows the associated input logic state change

3.12

common mode transient immunity

CMTI

maximum tolerable rate-of-rise (or fall) of a common-mode voltage

Note 1 to entry: The common mode transient immunity is given in volts per second. CMTl should include the

amplitude of the common-mode voltage that can be tolerated.

3.12.1

common mode transient immunity at logic high output

|CM |

H

common mode transient immunity of the coupler with logic at high output

– 10 – IEC 60747-17:2020 © IEC 2020

3.12.2

common mode transient immunity at logic low output

|CM |

L

common mode transient immunity of the coupler with logic at low output

3.12.3

common mode transient immunity at logic dynamic output

|CM |

D

maximum slew rate of a common-mode voltage (V ) at which the coupler transmits the data

CM

without missing the transition or creating unexpected transitions for all combinations of slew

rate polarity and data edges

Note 1 to entry: The data transition shall occur in the specified time frame, and invalid data in terms of delay

times, transitions or number of transitions, or magnitude (not meeting minimum logic V or maximum logic low

OH

V specifications) will be construed as a failure.

OL

3.12.4

CMTI performance

dV /dt

CM

maximum slew rate of a common mode voltage at which the output of the coupler remains at

the specific logic level and at the specified timing

3.12.5

common mode voltage

V

CM

common mode voltage at which the slew rate is measured

3.13

propagation delay

t t

pLH , pHL

time required for a change in the input state of a digital coupler to propagate to the

corresponding output

Note 1 to entry: The propagation delay from LOW to HIGH is expressed by t .

pLH

Note 2 to entry: The propagation delay from HIGH to LOW is expressed by t .

pHL

3.14

pulse width distortion

|t – t |

pLH pHL

PWD

unintentional and generally undesired change in the form of a signal causing the signal input

pulse width to differ from signal output pulse width

3.15

supply voltage

V

DD

supply voltages supplied on input and output side of coupler

Note 1 to entry: The supply voltage is also commonly expressed by V .

CC

3.16

integrated circuit

IC

microcircuit in which all or some of the circuit elements are inseparably associated and

electrically interconnected so that it is considered to be indivisible for the purpose of

construction and commerce on side 1 and side 2

[SOURCE: IEC 60050-521:2002, 521-10-03, modified – The words "on side 1 and side 2"

have been added.]

3.17

input and output terminal

I/O

side 1 and side 2 terminals of an integrated circuit providing signal conditioning to the internal

coupling element

3.18

ground potential

GND

reference potential for any side of a coupler

3.19

input voltage

V

I

input voltage, either V , V or analog level

IL IH

3.20

output voltage

V

O

output voltage, either V , V or analog level

OL OH

3.21

maximum ambient operating temperature

T

op max

maximum ambient operating temperature allowed during operation of coupler

3.22

reference-point temperature

T

REF

temperature defined by the manufacturer to refer to a defined point such as junction

temperature, case temperature, etc.

3.23

characteristic lifetime

t63

refers to characteristic lifetime (t63 %) when applying Weibull distribution to determine the

mean lifetime

Note 1 to entry: In general, lifetime reliability is defined as the mean lifetime (t50 %) at which cumulative failure