IEC 61190-1-3:2007

(Main)Attachment materials for electronic assembly - Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications

Attachment materials for electronic assembly - Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications

IEC 61190-1-3:2007 prescribes the requirements and test methods for electronic grade solder alloys, for fluxed and non-fluxed bar, ribbon, powder solders and solder paste, for electronic soldering applications and for "special" electronic grade solders. For the generic specifications of solder alloys and fluxes, see ISO 9453, ISO 9454-1 and ISO 9454-2. This standard is a quality control document and is not intended to relate directly to the material's performance in the manufacturing process. The main changes with regard to the first edition concern a definition of lead-free solder alloy and an amendment to Table B.1 concerning lead-free solder alloys.

Matériaux de fixation pour les assemblages électroniques - Partie 1-3: Exigences relatives aux alliages à braser de catégorie électronique et brasures solides fluxées et non fluxées pour les applications de brasage électronique

La CEI 61190-1-3:2007 prescrit les exigences et méthodes d'essai pour les alliages à braser de catégorie électronique, les brasures en baguette, en ruban et en poudre fluxées et non fluxées, et les pâtes à braser, pour les applications de brasage électronique et pour les brasures de catégorie électronique "spéciales". Pour les spécifications génériques relatives aux alliages et aux flux à braser, voir l'ISO 9453, l'ISO 9454-1 et l'ISO 9454-2. La présente norme est un document de contrôle de la qualité et n'a pas pour objet de s'intéresser directement à la performance du matériau au cours du procédé de fabrication. Les modifications principales par rapport à la première édition concernent une définition de l'alliage à braser sans plomb et un amendement au Tableau B.1 concernant les alliages à braser sans plomb.

General Information

- Status

- Published

- Publication Date

- 25-Apr-2007

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 2 - TC 91/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 13-Dec-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61190-1-3:2007 - Attachment materials for electronic assembly, Part 1‑3 - defines quality and test requirements for electronic grade solder alloys and fluxed and non‑fluxed solid solders used in electronic soldering applications. The standard covers composition and classification of solder alloys, forms (bar, ribbon, powder, solder paste), flux types and proportions, test methods, labelling, inspection and quality assurance. It is a quality control document and is not intended to predict process performance on the production line.

Key topics and requirements

- Scope of materials: Fluxed and non‑fluxed bar, ribbon, powder solders, solder paste and “special” electronic grade solders (e.g., preforms, multi‑alloy powders).

- Alloy classification: Grouping by composition (including cross‑references for tin‑lead, lead‑free and specialty alloys) and solidus/liquidus characteristics (see Annex B).

- Solder forms and flux: Definitions of solder form, flux type, flux percentage and acceptable metal content; tables listing standard powders and flux designations.

- Test methods and inspections: Prescribed test methods and report forms (figures and tables) for materials inspection, qualification and acceptance testing.

- Quality assurance: Requirements for inspection responsibilities, classification of inspections, preparation of test samples, and conformance reporting.

- Delivery and packaging: Preservation, packing, and labelling requirements for product identification and traceability.

- Informative and normative annexes: Annex A (selection guidance) and Annex B (normative lead‑free solder alloy data and cross‑references).

- Notable updates (2007): Inclusion of a definition for lead‑free solder alloy and amendments to Table B.1 regarding lead‑free alloys.

Applications and users

IEC 61190‑1‑3:2007 is aimed at organizations that manufacture, supply or verify solder materials for electronics, including:

- Solder alloy and solder paste manufacturers

- Electronic assembly suppliers and contract manufacturers (PCBA assemblers)

- Incoming materials inspection and quality control laboratories

- Procurement and specification engineers writing material acceptance criteria

- Test labs performing solder alloy qualification and certification

Practical uses include establishing acceptance criteria for incoming solder materials, standardizing test reports, ensuring traceability and supporting supplier audits.

Related standards

- ISO 9453, ISO 9454‑1, ISO 9454‑2 (generic solder alloy and flux specifications)

- IEC 61190‑1‑1 (soldering fluxes) and IEC 61190‑1‑2 (solder pastes)

- IEC 61189‑5 / IEC 61189‑6 (test methods)

- IEC 60194 (terms and definitions), ISO 9001 (quality systems)

Note: IEC 61190‑1‑3 includes patent notices for certain alloy compositions; users should check intellectual‑property status relevant to their region.

IEC 61190-1-3:2007 - Attachment materials for electronic assembly - Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications Released:4/26/2007 Isbn:2831891299

IEC 61190-1-3:2007 - Attachment materials for electronic assembly - Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications Released:4/26/2007 Isbn:2831898382

IEC 61190-1-3:2007+AMD1:2010 CSV - Attachment materials for electronic assembly - Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications Released:11/10/2010 Isbn:9782889121922

Frequently Asked Questions

IEC 61190-1-3:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Attachment materials for electronic assembly - Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic soldering applications". This standard covers: IEC 61190-1-3:2007 prescribes the requirements and test methods for electronic grade solder alloys, for fluxed and non-fluxed bar, ribbon, powder solders and solder paste, for electronic soldering applications and for "special" electronic grade solders. For the generic specifications of solder alloys and fluxes, see ISO 9453, ISO 9454-1 and ISO 9454-2. This standard is a quality control document and is not intended to relate directly to the material's performance in the manufacturing process. The main changes with regard to the first edition concern a definition of lead-free solder alloy and an amendment to Table B.1 concerning lead-free solder alloys.

IEC 61190-1-3:2007 prescribes the requirements and test methods for electronic grade solder alloys, for fluxed and non-fluxed bar, ribbon, powder solders and solder paste, for electronic soldering applications and for "special" electronic grade solders. For the generic specifications of solder alloys and fluxes, see ISO 9453, ISO 9454-1 and ISO 9454-2. This standard is a quality control document and is not intended to relate directly to the material's performance in the manufacturing process. The main changes with regard to the first edition concern a definition of lead-free solder alloy and an amendment to Table B.1 concerning lead-free solder alloys.

IEC 61190-1-3:2007 is classified under the following ICS (International Classification for Standards) categories: 31.190 - Electronic component assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61190-1-3:2007 has the following relationships with other standards: It is inter standard links to IEC 61190-1-3:2007/AMD1:2010, IEC 61190-1-3:2017, IEC 61190-1-3:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61190-1-3:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61190-1-3

Second edition

2007-04

Attachment materials for electronic assembly –

Part 1-3:

Requirements for electronic grade solder alloys

and fluxed and non-fluxed solid solders

for electronic soldering applications

Reference number

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61190-1-3

Second edition

2007-04

Attachment materials for electronic assembly –

Part 1-3:

Requirements for electronic grade solder alloys

and fluxed and non-fluxed solid solders

for electronic soldering applications

PRICE CODE

Commission Electrotechnique Internationale V

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

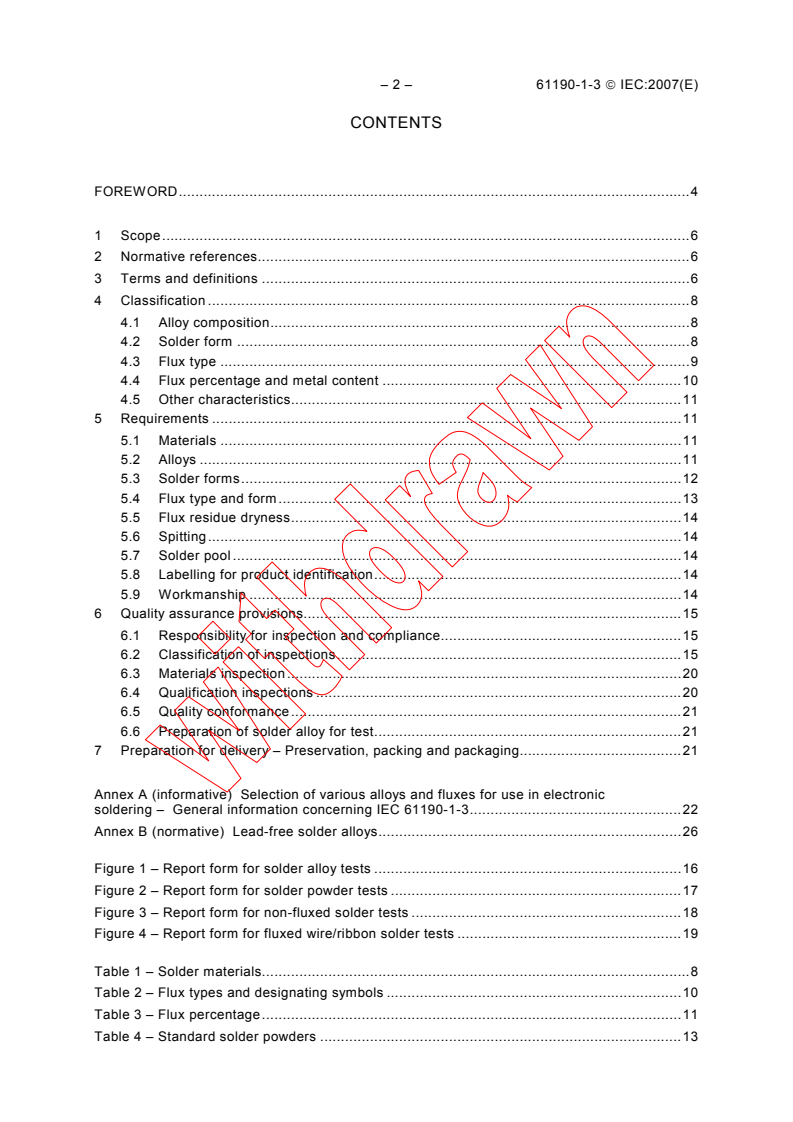

– 2 – 61190-1-3 © IEC:2007(E)

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references.6

3 Terms and definitions .6

4 Classification .8

4.1 Alloy composition.8

4.2 Solder form .8

4.3 Flux type .9

4.4 Flux percentage and metal content .10

4.5 Other characteristics.11

5 Requirements .11

5.1 Materials .11

5.2 Alloys .11

5.3 Solder forms.12

5.4 Flux type and form.13

5.5 Flux residue dryness.14

5.6 Spitting.14

5.7 Solder pool .14

5.8 Labelling for product identification.14

5.9 Workmanship .14

6 Quality assurance provisions.15

6.1 Responsibility for inspection and compliance.15

6.2 Classification of inspections.15

6.3 Materials inspection.20

6.4 Qualification inspections .20

6.5 Quality conformance.21

6.6 Preparation of solder alloy for test.21

7 Preparation for delivery – Preservation, packing and packaging.21

Annex A (informative) Selection of various alloys and fluxes for use in electronic

soldering – General information concerning IEC 61190-1-3.22

Annex B (normative) Lead-free solder alloys.26

Figure 1 – Report form for solder alloy tests .16

Figure 2 – Report form for solder powder tests .17

Figure 3 – Report form for non-fluxed solder tests .18

Figure 4 – Report form for fluxed wire/ribbon solder tests .19

Table 1 – Solder materials.8

Table 2 – Flux types and designating symbols .10

Table 3 – Flux percentage.11

Table 4 – Standard solder powders .13

61190-1-3 © IEC:2007(E) – 3 –

Table 5 – Solder inspections .20

a, b

Table B.1 – Composition, and temperature characteristics of lead-free solder alloys .26

a, b

Table B.2 – Composition and temperature characteristics of common tin-lead alloys .28

Table B.3 – Composition and temperature characteristics for specialty (non-tin/lead)

a,b

alloys .30

Table B.4 – Cross reference from solidus and liquidus temperatures to alloy names by

a

temperature .31

Table B.5 – Cross-reference from ISO 9453 alloy numbers and designations to

IEC 61190-1-3 alloy names .34

– 4 – 61190-1-3 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

ATTACHMENT MATERIALS FOR ELECTRONIC ASSEMBLY –

Part 1-3: Requirements for electronic grade solder alloys and

fluxed and non-fluxed solid solders for electronic soldering applications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

The International Electrotechnical Commission (IEC) draws attention to the fact that it is claimed that compliance

with this document may involve the use of a patent concerning in particular alloy compositions. IEC takes no

position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he/she is willing to negotiate licences under reasonable and

non-discriminatory terms and conditions with applicants throughout the world. In this respect, the statement of the

holder of this patent right is registered with IEC. Information may be obtained from:

For Sn96Ag2,5Bi1Cu,5:

US PAT No. 4879096

Cookson Electronics Assembly Materials

600 Route 440 Jersey City,New Jersey 07304

For Sn96,5Ag3Cu,5, Sn95,8Ag3,5Cu,7 and Sn95,5Ag3,8Cu,7:

US PAT No. 5527628

Iowa State University Research Foundation, Inc.

310 Lab of Mechanics

Ames, Iowa 50011-2131, U.S.A.

61190-1-3 © IEC:2007(E) – 5 –

For Sn88In8Ag3,5Bi,5:

JP PAT No. 3040929

For Sn96,5Ag3Cu,5, Sn95,8Ag3,5Cu,7 and Sn95,5Ag3,8Cu,7:

JP PAT No. 3027441

Matsushita Electric Industrial Co., Ltd.

Matsushita IMP Building 20F 1-3-7, Shiromi, Chouh-ku, Osaka, 540-6319, Japan

For Sn92In4Ag3,5Bi,5

JP PAT No. 2805595

Mitsui Mining & Smelting Co., Ltd.

Gate City Ohsaki-West Tower 19th Fl. 1-11-1 Osaki, Shinagawa-ku, Tokyo, 141-8584, Japan

For Sn96,5Ag3Cu,5, Sn95,8Ag3,5Cu,7, Sn95,5Ag3,8Cu,7 and Sn95,5Ag4,0Cu,5

JP PAT No. 3027441

Senju Metal Industry Co., Ltd.

Senju Hashido-cho 23, Adachi-ku, Tokyo, 120-8555, Japan

NOTE Patent rights vary between country of manufacture, sale, use and final destination; suppliers or users

remain responsible for establishing the exact legal position relevant to their own situation.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights

other than those identified above. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61190-1-3 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This second edition cancels and replaces the first edition, published in 2002, and constitutes a

technical revision. The main changes with regard to the first edition concern a definition of

lead-free solder alloy and an amendment to Table B.1 concerning lead-free solder alloys.

The text of this standard is based on the following documents:

FDIS Report on voting

91/647/FDIS 91/679/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61190 series, under the general title Attachment materials for

electronic assembly, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – 61190-1-3 © IEC:2007(E)

ATTACHMENT MATERIALS FOR ELECTRONIC ASSEMBLY –

Part 1-3: Requirements for electronic grade solder alloys and

fluxed and non-fluxed solid solders for electronic soldering applications

1 Scope

This part of IEC 61190 prescribes the requirements and test methods for electronic grade

solder alloys, for fluxed and non-fluxed bar, ribbon, powder solders and solder paste, for

electronic soldering applications and for “special” electronic grade solders. For the generic

specifications of solder alloys and fluxes, see ISO 9453, ISO 9454-1 and ISO 9454-2. This

standard is a quality control document and is not intended to relate directly to the material's

performance in the manufacturing process

Special electronic grade solders include all solders which do not fully comply with the

requirements of standard solder alloys and solder materials listed herein. Examples of special

solders include anodes, ingots, preforms, bars with hook and eye ends, multiple-alloy solder

powders, etc.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61190-1-1:2002, Attachment materials for electronic assembly – Part 1-1: Requirements

for soldering fluxes for high-quality interconnects in electronics assembly

IEC 61190-1-2, Attachment materials for electronic assembly – Part 1-2: Requirements for

solder pastes for high-quality interconnections in electronics assembly

IEC 61189-5, Test methods for electrical materials, interconnection structures and assemblies –

Part 5: Test methods for printed board assemblies

IEC 61189-6, Test methods for electrical materials, interconnection structures and assemblies –

Part 6: Test methods for materials used in manufacturing electronic assemblies

ISO 9001, Quality management systems – Requirements

ISO 9453, Soft solder alloys – Chemical compositions and forms

ISO-9454-1:1990, Soft soldering fluxes – Classification and requirements – Part 1: Classifi-

cation, labelling and packing

ISO-9454-2:1998, Soft soldering fluxes – Classification and requirements – Part 2: Perform-

ance requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60194, as well as the

following apply. Terms marked with an asterisk (*) are taken from IEC 60194 and are reprinted

here for convenience.

61190-1-3 © IEC:2007(E) – 7 –

3.1

acceptance tests *

those tests deemed necessary to determine the acceptability of a product and as agreed to by

both purchaser and vendor

3.2

alloy

substance having metallic properties and being composed of two or more chemical elements of

which at least one is an elemental metal

3.3

basis metal *

metal upon which coatings are deposited, also referred to as base metal

3.4

corrosion (chemical/electrolytic) *

attack of chemicals, flux, and flux residues on base metals

3.5

density (phototool) *

mass of a surface per unit volume, usually expressed in grams per cubic centimetre

3.6

dewetting *

condition that results when molten solder coats a surface and then recedes to leave irregularly

shaped mounds of solder that are separated by areas that are covered with a thin film of solder

and with the basis metal not exposed

3.7

eutectic (n.) *

alloy having the composition indicated by the eutectic point on an equilibrium diagram or an

alloy structure of intermixed solid constituents formed by a eutectic reaction

3.8

eutectic (adj.) *

isothermal reversible reaction in which, on cooling, a liquid solution is converted into two or

more intimately mixed solids, with the number of solids formed being the same as the number

of components

3.9

flux *

chemically - and physically-active compound that, when heated, promotes the wetting of a base

metal surface by molten solder by removing minor surface oxidation and other surface films

and by protecting the surfaces from reoxidation during a soldering operation

3.10

flux characterization *

series of tests that determines the basic corrosive and conductive properties of fluxes and flux

residues

3.11

flux residue *

flux-related contaminant that is present on or near the surface of a solder connection

3.12

liquidus

temperature at which a solder alloy changes from a paste form to a liquid form

– 8 – 61190-1-3 © IEC:2007(E)

3.13

nonwetting (solder) *

partial adherence of molten solder to a surface that it has contacted and where basis metal

remains exposed

3.14

lead-free solder

solder alloy the lead content of which h is equal to, or less than 0,10 % by mass

3.15

solder *

metal alloy with a melting temperature that is below 450 °C.

NOTE Metal alloy with a melting temperature less than 450 °C is classified as “soft solder”.

3.16

solderability *

ability of a metal to be wetted by molten solder

3.17

solidus

temperature at which a solder alloy changes from a solid to a paste form

3.18

wetting, solder *

formation of a relatively uniform, smooth, unbroken, and adherent film of solder to a basis

metal.

4 Classification

Soldering materials covered by this standard shall be classified by alloy composition, solder

form, flux type, flux percentage and by other characteristics peculiar to the solder material form.

4.1 Alloy composition

The solder alloys covered by this standard are the alloys listed in Tables B.1, B.2 and B.3 and

include pure tin and pure indium. Each alloy is identified by an alloy name composed of a

series of alphanumeric characters. These characters identify the component elements in the

alloy by chemical symbol and nominal percentage by mass. They terminate with an arbitrarily

assigned alloy variation letter (A, B, C, D). Alloys are also identified by an alloy short name.

This is an alphanumeric designation composed of the chemical symbol for the key element in

the alloy (see Clause A.4), the nominal percentage of that element in the alloy and the

arbitrarily assigned alloy variation letter.

Tables B.1, B.2 and B.3 identify alloy composition, short name and temperature characteristics;

Table B.4 cross-references solidus and liquidus temperatures to alloy names and Table B.5

cross-references ISO alloy numbers and designations from ISO 9453 to alloy names.

4.2 Solder form

Table 1 shows the forms of solder materials covered by this standard listed with their single-

letter designating symbols.

Table 1 – Solder materials

Identifying symbol Solder form

F Flux (only)

61190-1-3 © IEC:2007(E) – 9 –

P Paste (cream)

B Bar

D Powder

R Ribbon

W Wire

S Special

4.3 Flux type

The flux types used in/on solders covered by this standard are listed in Table 2. The

requirements for fluxes are covered by IEC 61190-1-1.

– 10 – 61190-1-3 © IEC:2007(E)

Table 2 – Flux types and designating symbols

Flux materials Flux activity levels IEC flux ISO flux

a c d

of composition designator designator

b

wt. % halide

Rosin Low (<0,01) L0 ROL0 1.1.1

(RO) Low (<0,15) L1 ROL1 1.1.2.W, 1.1.2.X

Moderate (<0,01) M0 ROM0 1.1.3.W

Moderate (0,15–2,0) M1 ROM1 1.1.2.Y, 1.1.2.Z

High (<0,01) H0 ROH0 1.1.3.X

High (>2,0) H1 ROH1 1.1.2.Z

Resin Low (<0,01) L0 REL0 1.2.1

(RE) Low (<0,15) L1 REL1 1.2.2.W, 1.2.2.X

Moderate (<0,01) M0 REM0 1.2.3.W

Moderate (0, 15 – 2,0) M1 REM1 1.2.2.Y, 1.2.2.Z

High (<0,01) H0 REH0 1.2.3.X

High (>2,0) H1 REH1 1.2.2.Z

Organic Low (<0,01) L0 ORL0 2.1., 2.2.3.E

(OR) Low (<0, 15) L1 ORL1 -

Moderate (<0,01) M0 ORM0 -

Moderate (0, 15 – 2,0) M1 ORM1 2.1.2, 2.2.2

High (<0,01) H0 ORH0 2.2.3.0

High (>2,0) H1 ORH1 2.2.2

Inorganic Low (<0,01) L0 INL0 Not applicable

(IN) Low (<0, 15) L1 INL1 (inorganic ISO flux is

different)

Moderate (<0,01) M0 INM0

Moderate (0, 15 – 2,0) M1 INM1

High (<0,01) H0 INH0

High (>2,0) H1 INH1

a

Fluxes are available in S (solid), P (paste/cream) or L (liquid) forms.

b

See 7.1 and 7.2 of IEC 61190-1-1 for comparisons of RO, RE, OR and IN composition classes and L, M and H

activity levels with the traditional classes such as R, RMA, RA, water soluble and low solids ”no-clean.''.

c

The 0 and 1 indicate absence and presence of halides, respectively. See 4.2.3 of IEC 61190-1-1 for an

explanation of L, M and H nomenclature.

d

ISO designations are similar to IEC designators with minor differences in characteristics

4.4 Flux percentage and metal content

The nominal percentage of flux, by mass, in solid-form solder products is identified as the flux

percentage. The flux percentage in/on solid solders is identified by a single alphanumeric

character in accordance with Table 3. “Metal content” refers to the percentage of metal in

solder paste (see IEC 61190-1-2).

61190-1-3 © IEC:2007(E) – 11 –

Table 3 – Flux percentage

Design Nominal Allowable Design Nominal Allowable Design Allowable

Nominal

symbol range symbol range symbol range

% % % % % %

0 None 5 2,5 2,2 – 2,8 A 5,0 4,7 – 5,3

1 0,5 0,2 – 0,8 6 3,0 2,7 – 3,3 B 5,5 5,2 – 5,8

2 1,0 0,7 – 1,3 7 3,5 3,2 – 3,8 C 6,0 5,7 – 6,3

3 1,5 1,2 – 1,8 8 4,0 3,7 – 4,3 D 6,5 6,2 – 6,8

4 2,0 1,7 – 2,3 9 4,5 4,2 – 4,8

4.5 Other characteristics

Standard bar solders are further classified by unit mass. Wire solders are further classified by

wire size (outside diameter) and unit mass. Ribbon solders are further classified by thickness,

width and unit mass. Powder solders are further classified by powder particle size distribution

and unit mass.

5 Requirements

5.1 Materials

Materials shall be used which permit the solder product to conform to the specified

requirements. The use of recovered or recycled materials is encouraged. Recovered or

recycled materials shall conform to or exceed comparable standards for virgin raw materials.

5.2 Alloys

The solder alloy shall be as specified (see Annex B). For the purposes of this standard,

electronic grade solder alloys are all those listed in Tables B.1, B.2 and B.3, including pure tin

(Sn99) and pure indium (In99). The elements listed in Tables B.1, B.2 and B.3 for an alloy are

considered to be the component elements of that alloy. Only the component elements of an

alloy are desirable and all other elements are impurities for that alloy. To the maximum extent

feasible and unless otherwise specified, solder alloy metal, including solder powder, shall be a

homogenous mixture of the component elements of the alloy, such that each particle of the

metal is the same alloy. Unless otherwise specified, the percentage by mass of impurity

elements in alloys which are identified with an “A”, “B”, or “C” suffix shall not exceed the

following values and the values listed in 5.2.1, 5.2.2, and 5.2.3 respectively, and the

percentage by mass of impurity elements in alloys which are identified with a “D” suffix shall

conform to the requirements in 5.2.4.

Ag: 0,05 Au: 0,05 Cu: 0,05 Ni: 0,01 Sn: 0,25

Al: 0,001 Bi: 0,10 Fe: 0,02 Pb: 0,10 Zn: 0,001

As: 0,03 Cd: 0,002 In: 0,10

The percentage of each element in an alloy shall be determined by any standard analytical

procedure. Wet chemistry shall be used as the referee procedure.

5.2.1 Variation A alloys

In alloys which are identified with an “A” suffix, the percentage by mass of antimony (Sb) as an

impurity element shall not exceed 0,50.

– 12 – 61190-1-3 © IEC:2007(E)

5.2.2 Variation B alloys

In alloys which are identified with a “B” suffix, the percentage by mass of antimony as an

impurity element shall not exceed 0,20.

5.2.3 Variation C alloys

In alloys which are identified with a “C” suffix, the percentage by mass of antimony as an

impurity element shall not exceed 0,05.

5.2.4 Variation D alloys

Alloys identified with a “D” suffix are ultra-pure alloys that are intended for use in barrier-free

die attachment applications. In alloys identified with a “D” suffix, the combined total percentage

by mass of all impurity elements shall not exceed 0,05 and the combined total percentage by

mass of each of the following sets of impurity elements shall not exceed 0,000 5:

Set 1: Be, Hg, Mg, and Zn. Set 2: As, Bi, P, and Sb.

5.3 Solder forms

This standard covers solders in the form of bars, wires, ribbons, and powders, and special

solders. Normally bar solders and solder powder are not fluxed, and wire, ribbon, and special

solders may be non-fluxed, flux-cored, flux-coated, or both flux-cored and flux-coated. Users

should determine from prospective sources the standard solder form characteristics that are

available and should specify standard characteristics to the maximum extent feasible.

5.3.1 Bar solder

The nominal cross-section area, the nominal length, and the nominal mass shall be as

specified (see Clause A.2 c)). Unless otherwise specified (see Clause A.2 d)), the actual cross-

section area shall not vary from the nominal value by more than 50 %, the actual length shall

not vary from the nominal value by more than 20 %, and the actual mass shall not vary from

the nominal value by more than 10 %. Bars with special end configurations, such as hooks or

eyes, are classified as special solders.

5.3.2 Wire solder

The wire size, flux type, and flux percentage shall be as specified (see Clause A.2 e)). Unless

otherwise specified (see Clause A.2f)), wire solders shall have a circular cross-section, the

wire size shall indicate the nominal outside diameter of the wire and the actual outside

diameter shall not vary from the nominal diameter by more than ±5 % or ±0,05 mm, whichever

is greater.

5.3.3 Ribbon solder

The ribbon thickness and width, flux type, and flux percentage shall be as specified (see

Clause A.2 g)). Unless otherwise specified (see Clause A.2 h)), ribbon solders shall have a

rectangular cross-section, and the actual thickness and width shall not vary from their nominal

values by more than ±5 % or ±0,05 mm, whichever is greater.

5.3.4 Solder powder

The powder size and shape shall be as specified (see Clauses A.2 i)) and A.2 j)). The

characteristics of six standard solder powders, sizes 1 through 6, are listed in Table 4. When

shape is not specified, solder powder shall be spherical. Solder powder shall be smooth and

bright and free of adhering small particles and oxides to the maximum extent possible.

NOTE Solder powders made with high-lead alloys are not “bright” by nature, but they should not appear unusually

dark. Solder powders which contain more than one solder alloy (multiple-alloy powders) are classified as special

solders.

61190-1-3 © IEC:2007(E) – 13 –

Table 4 – Standard solder powders

Powder Percentages of powder by mass

size

None larger Less than 1 % At least 80 % At least 90 % Less than 10 %

symbol

than larger than between between smaller than

μm μm μm μm μm

1 160 150 150 – 75 20

2 80 75 75 – 45 20

3 50 45 45 – 25 20

4 40 38 38 – 20 20

5 28 25 25 – 15 15

6 18 15 15 – 5 5

5.3.4.1 Powder size

Maximum particle size shall be determined in accordance with IEC 61189-6, Test method 6X04.

Powder particle size distribution shall be determined in accordance with IEC 61189-6, Test

methods 6X01, 6X02 or 6X03.

5.3.4.2 Powder shape

Solder powder shape shall be determined by visual observation using a binocular microscope

with sufficient magnification, by the light beam scatter method, or by a suitable microscopic

imaging analysis method. Solder powders visually determined to have at least 90 % of the

particles with a length to width ratio of 1:2 or less shall be classified as spherical powders.

Solder powders having a light beam scatter deviation result or an image analysis result that is

equivalent to the above visual results shall be classified as spherical powders. All other

powders shall be classified as non-spherical.

5.3.5 Special solder

All pertinent characteristics and tolerances for special form solders shall be specified (see

Clause A.2 k)). Special solders include all solders which do not fully conform to another solder

classification identified herein or in IEC 61190-1-2. Special solders include, but are not

necessarily limited to, anodes, bars with hook or eye ends, chips, ingots, multiple-alloy

powders, pellets, preforms, rings, sleeves, etc.

5.4 Flux type and form

The flux type and form shall be as specified (see Clause A.2 l)). Fluxes used in the

manufacture of solder products shall conform to the requirements of IEC 61190-1-1. Fluxes

shall have been fully tested and characterized in accordance with IEC 61190-1-1, and shall

have not been altered since being tested except for the addition of inert plasticizers.

5.4.1 Flux percentage

The percentage by mass of flux in/on solders shall be as specified (see Clause A.2 m)). For

fluxed solders other than solder paste, the flux percentage is identified in accordance with

Table 3. The flux percentage of flux-coated and/or flux-cored solder shall be determined in

accordance with IEC 61189-6, Test method 6C09.

5.4.2 Solder cores

Unless otherwise specified (see Clause A.2 n)), the core(s) of flux-cored solders may be of any

construction, provided it is (they are) continuous, uniform in cross-section, and symmetrically

disposed in the solder. When appropriate, the core(s) in the solder should be sealed at both

ends by a suitable means to prevent flux from leaking out.

– 14 – 61190-1-3 © IEC:2007(E)

5.4.3 Solder coatings

Unless otherwise specified (see Clause A.2 o)), the coatings on flux-coated solders shall be

dry and tack-free such that individual pieces do not stick together when the temperature and

humidity are maintained at, or below, 25 °C and 60 % RH.

5.5 Flux residue dryness

When specified (see Clause A.2 p)), the dryness characteristics of the reflowed residue of

fluxed solders shall be determined in accordance with IEC 61189-5, Test method 5X12. When

a fluxed solder is tested in accordance with Test method 5X12, the flux residue of “no-clean”

solders and, when specified, other flux type solders, shall be free of tackiness (‘not tacky’).

5.6 Spitting

When specified (see Clause A.2q)), the spitting characteristics of flux-cored wire and ribbon

solders shall be determined in accordance with IEC 61189-5, Test method 5X13.

5.7 Solder pool

When specified (see Clause A.2 r)), the solder pool characteristics of fluxed solder shall be

determined in accordance with IEC 61189-5, Test method 5X14. When fluxed solder is tested

in accordance with test method 5X14, the flux shall promote the spreading of molten solder

over the coupon to form integrally thereon a coat of solder which shall feather out to a thin

edge. There shall be no evidence of dewetting or nonwetting. Neither shall there be any

evidence of spattering, as indicated by the presence of flux and/or flux residue particles outside

the main pool of residue. Irregularly shaped solder pools do not necessarily indicate dewetting

or nonwetting.

5.8 Labelling for product identification

Unless otherwise specified (see Clause A.2 s)), solder bars shall be marked with the alloy

name or alloy short name and the manufacturer's name or commonly accepted symbol. Unless

otherwise specified, spools, packages, and containers of wire, ribbon, and powder solders, and

written documentation accompanying bar and special solders shall be marked with the

following information.

a) the manufacturer's name and address;

b) the number and revision designation of this standard;

c) the solder product description, and the manufacturer's designation of the solder product;

d) the net mass of the solder (and nominal unit mass of bar solder);

e) the batch number(s);

f) the date(s) of manufacture;

g) expected useful life of solder product, if applicable;

h) all applicable health and safety markings including lead free marking or lead containing

marking;

i) any other information which may be pertinent to the particular solder form;

j) any other markings or labelling specified in the contract or purchase order.

5.9 Workmanship

Solder products shall be made uniform in quality and free from defects which limit service life

or affect the serviceability or appearance.

61190-1-3 © IEC:2007(E) – 15 –

6 Quality assurance provisions

6.1 Responsibility for inspection and compliance

The user shall specify the qualification and quality conformance inspections (see Clause A.2 t)).

The solder product manufacturer is responsible for the performance of qualification and quality

conformance inspections. The manufacturer may use his own or any other facility for the

performance of these inspections, unless the facility is disapproved by the user.

It is the responsibility of the manufacturer to ascertain that all solder products or supplies

delivered to the user, or submitted for user acceptance, conform to the requirements of the

contract or purchase order and Clause 5 above. The absence of any inspection requirements

shall not relieve the vendor of this responsibility.

Materials covered by this specification shall meet all the requirements of Clause 5. The

inspection(s) excluding the performance inspections defined in this specification shall become

a part of the contractor's overall inspection system or quality programme. The vendor has

responsibility for ensuring that all products or supplies submitted to the user for acceptance

comply with all requirements of the purchase order contract.

6.1.1 Quality assurance programme

When required by the user, a quality assurance programme for material furnished under this

specification shall be established and maintained in accordance with ISO 9001, or as otherwise

agreed on between user and manufacturer, and shall be monitored by the qualifying activity.

6.1.2 Test equipment and inspection facilities

Test/measuring equipment and inspection facilities of sufficient accuracy, quality and quantity

to permit performance of the required inspection(s) shall be established and maintained or

designated by the supplier. Establishment and maintenance of a calibration system to control

the accuracy of the measuring and test equipment shall be in accordance with the general

requirements of IEC 61189-5 and IEC 61189-6, as appropriate.

6.1.3 Inspection conditions

Unless otherwise specified, all inspections shall be performed in accordance with the test

conditions specified in Clause 5.

6.2 Classification of inspections

The inspections specified in this standard are classified as follows:

a) materials inspection (6.3);

b) qualification inspection (6.4);

c) quality conformance (6.5).

Figures 1 through 4 are suitable for, and recommended for, recording the results of alloy and of

solid form solder inspections. Where applicable, definitive results should be entered on the

report forms. Where definitive results are not required or appropriate, successful completion of

inspections should be indicated by check marks on the report forms.

– 16 – 61190-1-3 © IEC:2007(E)

Test report on solder alloy (for suffix A, B, and C alloys)

Enter appropriate information in top portion and requirements columns of report and complete

report by entering the test results or checkmarks in the appropriate spaces.

Alloy designation: _______________________________________________________________

Manufacturer's identification: ______________________________________________________

Manufacturer's batch number: _____________________________________________________

Date of manufacture: ____________________________________________________________

Date inspection completed: __________________ Overall results : ___Pass ___Fail

Testing methods used: ___________________________________________________________

_____________________________________________________________

Inspection performed by: __________________ Witnessed by __________________________

Elements Required percentages

Percentage in Tested by

Pass/Fail

As an alloy As an impurity

sample and date

element element

Ag 0,05 Max

Al 0,001 Max

As 0,03 Max

Au 0,05 Max

Bi 0,10 Max

Cd 0,002 Max

Cu 0,05 Max

Fe 0,02 Max

In 0,10 Max

Ni 0,01 Max

Pb 0,10 Max

Sb ___ 0,50 Max

___ 0,20 Max

___ 0,05 Max

Sn 0,25 Max

Zn 0,001 Max

1. Overall results: Check "Pass" if the test results for all elements conform to the requirements, otherwise check

"Fail."

2. Pass/Fail: Enter "P" for an element if test results conform to the actual requirement, otherwise, enter "F."

3. When antimony (Sb) is an impurity in the alloy being tested, check the appropriate Sb percentage requirement in

column 3.

Comments: ____________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Figure 1 – Report form for solder alloy tests

61190-1-3 © IEC:2007(E) – 17 –

Test report on solder powder

Enter appropriate information in top portion and requirements columns of report and complete

report by entering the test results or checkmarks in the appropriate spaces.

Alloy designation: _________________________ Powder size number ____________________

Manufacturer's identification: ______________________________________________________

Manufacturer's batch number: _____________________________________________________

Date of manufacture: ____________________________________________________________

Date inspection completed: __________________ Overall results : ___Pass ___Fail

Testing methods used: ___________________________________________________________

_____________________________________________________________

Inspection performed by: __________________ Witnessed by __________________________

Inspections Requirements Test results Pass/fail Tested by

obtained and date

Material

Visual

Alloy

Max. powder size:

0 % larger than _____ μm

Powder size:

< 1 % larger than _____ μm

≥ 80 % between ___ − ___ μm

≥ 90 % between ___ − ___ μm

< 10 % smaller than _____ μm

Powder shape

1. Overall results: Check "Pass" if the test results for all elements conform to the requirements, otherwise check

"Fail."

2. Pass/Fail: Enter "P" for an element if test results conform to the actual requirement, otherwise, enter "F."

Comments: ___________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

Figure 2 – Report form for solder powder tests

– 18 – 61190-1-3 © IEC:2007(E)

Test report on non-fluxed solder

Enter appropriate information in top portion and requirements columns of report and complete

report by entering the test results or checkmarks in the appropriate spaces.

Solder designation: ______________________________________________________________

Inspection purpose: QPL I.D. Number: ______________________________________

____ Qualification Manufacturer's identification:______________________________

____ Quality conformance A Manufacturer's batch number: _____________________________

____ Quality conformance B Date of manufacture: ____________________________________

____ Shelf-life extension Original USE-BY date: ___________________________________

____ Performance Revised USE-BY dat

...

IEC 61190-1-3

Edition 2.0 2007-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Attachment materials for electronic assembly –

Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-

fluxed solid solders for electronic soldering applications

Matériaux de fixation pour les assemblages électroniques –

Partie 1-3: Exigences relatives aux alliages à braser de catégorie électronique et

brasures solides fluxées et non fluxées pour les applications de brasage

électronique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61190-1-3

Edition 2.0 2007-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Attachment materials for electronic assembly –

Part 1-3: Requirements for electronic grade solder alloys and fluxed and non-

fluxed solid solders for electronic soldering applications

Matériaux de fixation pour les assemblages électroniques –

Partie 1-3: Exigences relatives aux alliages à braser de catégorie électronique et

brasures solides fluxées et non fluxées pour les applications de brasage

électronique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

W

CODE PRIX

ICS 31.190 ISBN 2-8318-9838-2

– 2 – 61190-1-3 © IEC:2007

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references.6

3 Terms and definitions .7

4 Classification .8

4.1 Alloy composition.8

4.2 Solder form .9

4.3 Flux type .9

4.4 Flux percentage and metal content .10

4.5 Other characteristics.11

5 Requirements .11

5.1 Materials .11

5.2 Alloys .11

5.3 Solder forms.12

5.4 Flux type and form.13

5.5 Flux residue dryness.14

5.6 Spitting.14

5.7 Solder pool .14

5.8 Labelling for product identification.14

5.9 Workmanship .14

6 Quality assurance provisions.15

6.1 Responsibility for inspection and compliance.15

6.2 Classification of inspections.15

6.3 Materials inspection.20

6.4 Qualification inspections .20

6.5 Quality conformance.20

6.6 Preparation of solder alloy for test.21

7 Preparation for delivery – Preservation, packing and packaging.21

Annex A (informative) Selection of various alloys and fluxes for use in electronic

soldering – General information concerning IEC 61190-1-3.22

Annex B (normative) Lead-free solder alloys.26

Figure 1 – Report form for solder alloy tests .16

Figure 2 – Report form for solder powder tests .17

Figure 3 – Report form for non-fluxed solder tests .18

Figure 4 – Report form for fluxed wire/ribbon solder tests .19

Table 1 – Solder materials.9

Table 2 – Flux types and designating symbols .10

Table 3 – Flux percentage.11

Table 4 – Standard solder powders .13

Table 5 – Solder inspections .20

a,b

Table B.1 – Composition and temperature characteristics of lead-free solder alloys .26

a,b

Table B.2 – Composition and temperature characteristics of common tin-lead alloys .28

61190-1-3 © IEC:2007 – 3 –

Table B.3 – Composition and temperature characteristics for specialty (non-tin/lead)

a,b

alloys .30

Table B.4 – Cross reference from solidus and liquidus temperatures to alloy names by

a

temperature .31

Table B.5 – Cross-reference from ISO 9453 alloy numbers and designations to

IEC 61190-1-3 alloy names .34

– 4 – 61190-1-3 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

ATTACHMENT MATERIALS FOR ELECTRONIC ASSEMBLY –

Part 1-3: Requirements for electronic grade solder alloys and

fluxed and non-fluxed solid solders for electronic soldering applications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

The International Electrotechnical Commission (IEC) draws attention to the fact that it is claimed that compliance

with this document may involve the use of a patent concerning in particular alloy compositions. IEC takes no

position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he/she is willing to negotiate licences under reasonable and

non-discriminatory terms and conditions with applicants throughout the world. In this respect, the statement of the

holder of this patent right is registered with IEC. Information may be obtained from:

For Sn96Ag2,5Bi1Cu,5:

US PAT No. 4879096

Cookson Electronics Assembly Materials

600 Route 440 Jersey City,New Jersey 07304

For Sn96,5Ag3Cu,5, Sn95,8Ag3,5Cu,7 and Sn95,5Ag3,8Cu,7:

US PAT No. 5527628

Iowa State University Research Foundation, Inc.

310 Lab of Mechanics

Ames, Iowa 50011-2131, U.S.A.

61190-1-3 © IEC:2007 – 5 –

For Sn88In8Ag3,5Bi,5:

JP PAT No. 3040929

For Sn96,5Ag3Cu,5, Sn95,8Ag3,5Cu,7 and Sn95,5Ag3,8Cu,7:

JP PAT No. 3027441

Matsushita Electric Industrial Co., Ltd.

Matsushita IMP Building 20F 1-3-7, Shiromi, Chouh-ku, Osaka, 540-6319, Japan

For Sn92In4Ag3,5Bi,5

JP PAT No. 2805595

Mitsui Mining & Smelting Co., Ltd.

Gate City Ohsaki-West Tower 19th Fl. 1-11-1 Osaki, Shinagawa-ku, Tokyo, 141-8584, Japan

For Sn96,5Ag3Cu,5, Sn95,8Ag3,5Cu,7, Sn95,5Ag3,8Cu,7 and Sn95,5Ag4,0Cu,5

JP PAT No. 3027441

Senju Metal Industry Co., Ltd.

Senju Hashido-cho 23, Adachi-ku, Tokyo, 120-8555, Japan

NOTE Patent rights vary between country of manufacture, sale, use and final destination; suppliers or users

remain responsible for establishing the exact legal position relevant to their own situation.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights

other than those identified above. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61190-1-3 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This second edition cancels and replaces the first edition, published in 2002, and constitutes a

technical revision. The main changes with regard to the first edition concern a definition of

lead-free solder alloy and an amendment to Table B.1 concerning lead-free solder alloys.

This bilingual version, published in 2008-05, corresponds to the English version.

The text of this standard is based on the following documents:

FDIS Report on voting

91/647/FDIS 91/679/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61190 series, under the general title Attachment materials for

electronic assembly, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 61190-1-3 © IEC:2007

ATTACHMENT MATERIALS FOR ELECTRONIC ASSEMBLY –

Part 1-3: Requirements for electronic grade solder alloys and

fluxed and non-fluxed solid solders for electronic soldering applications

1 Scope

This part of IEC 61190 prescribes the requirements and test methods for electronic grade

solder alloys, for fluxed and non-fluxed bar, ribbon, powder solders and solder paste, for

electronic soldering applications and for “special” electronic grade solders. For the generic

specifications of solder alloys and fluxes, see ISO 9453, ISO 9454-1 and ISO 9454-2. This

standard is a quality control document and is not intended to relate directly to the material's

performance in the manufacturing process

Special electronic grade solders include all solders which do not fully comply with the

requirements of standard solder alloys and solder materials listed herein. Examples of special

solders include anodes, ingots, preforms, bars with hook and eye ends, multiple-alloy solder

powders, etc.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 61190-1-1:2002, Attachment materials for electronic assembly – Part 1-1: Requirements

for soldering fluxes for high-quality interconnects in electronics assembly

IEC 61190-1-2, Attachment materials for electronic assembly – Part 1-2: Requirements for

solder pastes for high-quality interconnections in electronics assembly

IEC 61189-5, Test methods for electrical materials, interconnection structures and assemblies

– Part 5: Test methods for printed board assemblies

IEC 61189-6, Test methods for electrical materials, interconnection structures and assemblies

– Part 6: Test methods for materials used in manufacturing electronic assemblies

ISO 9001, Quality management systems – Requirements

ISO 9453, Soft solder alloys – Chemical compositions and forms

ISO-9454-1:1990, Soft soldering fluxes – Classification and requirements – Part 1: Classifi-

cation, labelling and packing

ISO-9454-2:1998, Soft soldering fluxes – Classification and requirements – Part 2: Perform-

ance requirements

61190-1-3 © IEC:2007 – 7 –

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60194, as well as the

following apply. Terms marked with an asterisk (*) are taken from IEC 60194 and are reprinted

here for convenience.

3.1

acceptance tests *

those tests deemed necessary to determine the acceptability of a product and as agreed to by

both purchaser and vendor

3.2

alloy

substance having metallic properties and being composed of two or more chemical elements of

which at least one is an elemental metal

3.3

basis metal *

metal upon which coatings are deposited, also referred to as base metal

3.4

corrosion (chemical/electrolytic) *

attack of chemicals, flux, and flux residues on base metals

3.5

density (phototool) *

mass of a surface per unit volume, usually expressed in grams per cubic centimetre

3.6

dewetting *

condition that results when molten solder coats a surface and then recedes to leave irregularly

shaped mounds of solder that are separated by areas that are covered with a thin film of solder

and with the basis metal not exposed

3.7

eutectic (n.) *

alloy having the composition indicated by the eutectic point on an equilibrium diagram or an

alloy structure of intermixed solid constituents formed by a eutectic reaction

3.8

eutectic (adj.) *

isothermal reversible reaction in which, on cooling, a liquid solution is converted into two or

more intimately mixed solids, with the number of solids formed being the same as the number

of components

3.9

flux *

chemically - and physically-active compound that, when heated, promotes the wetting of a base

metal surface by molten solder by removing minor surface oxidation and other surface films

and by protecting the surfaces from reoxidation during a soldering operation

3.10

flux characterization *

series of tests that determines the basic corrosive and conductive properties of fluxes and flux

residues

– 8 – 61190-1-3 © IEC:2007

3.11

flux residue *

flux-related contaminant that is present on or near the surface of a solder connection

3.12

liquidus

temperature at which a solder alloy changes from a paste form to a liquid form

3.13

nonwetting (solder) *

partial adherence of molten solder to a surface that it has contacted and where basis metal

remains exposed

3.14

lead-free solder

solder alloy the lead content of which is equal to, or less than 0,10 % by mass

3.15

solder *

metal alloy with a melting temperature that is below 450 °C.

NOTE Metal alloy with a melting temperature less than 450 °C is classified as “soft solder”.

3.16

solderability *

ability of a metal to be wetted by molten solder

3.17

solidus

temperature at which a solder alloy changes from a solid to a paste form

3.18

wetting, solder *

formation of a relatively uniform, smooth, unbroken, and adherent film of solder to a basis

metal.

4 Classification

Soldering materials covered by this standard shall be classified by alloy composition, solder

form, flux type, flux percentage and by other characteristics peculiar to the solder material form.

4.1 Alloy composition

The solder alloys covered by this standard are the alloys listed in Tables B.1, B.2 and B.3 and

include pure tin and pure indium. Each alloy is identified by an alloy name composed of a

series of alphanumeric characters. These characters identify the component elements in the

alloy by chemical symbol and nominal percentage by mass. They terminate with an arbitrarily

assigned alloy variation letter (A, B, C, D). Alloys are also identified by an alloy short name.

This is an alphanumeric designation composed of the chemical symbol for the key element in

the alloy (see Clause A.4), the nominal percentage of that element in the alloy and the

arbitrarily assigned alloy variation letter.

Tables B.1, B.2 and B.3 identify alloy composition, short name and temperature characteristics;

Table B.4 cross-references solidus and liquidus temperatures to alloy names and Table B.5

cross-references ISO alloy numbers and designations from ISO 9453 to alloy names.

61190-1-3 © IEC:2007 – 9 –

4.2 Solder form

Table 1 shows the forms of solder materials covered by this standard listed with their single-

letter designating symbols.

Table 1 – Solder materials

Identifying symbol Solder form

F Flux (only)

P Paste (cream)

B Bar

D Powder

R Ribbon

W Wire

S Special

4.3 Flux type

The flux types used in/on solders covered by this standard are listed in Table 2. The

requirements for fluxes are covered by IEC 61190-1-1.

– 10 – 61190-1-3 © IEC:2007

Table 2 – Flux types and designating symbols

Flux materials Flux activity levels IEC flux ISO flux

a c d

of composition designator designator

b

wt. % halide

Rosin Low (<0,01) L0 ROL0 1.1.1

(RO) Low (<0,15) L1 ROL1 1.1.2.W, 1.1.2.X

Moderate (<0,01) M0 ROM0 1.1.3.W

Moderate (0,15–2,0) M1 ROM1 1.1.2.Y, 1.1.2.Z

High (<0,01) H0 ROH0 1.1.3.X

High (>2,0) H1 ROH1 1.1.2.Z

Resin Low (<0,01) L0 REL0 1.2.1

(RE) Low (<0,15) L1 REL1 1.2.2.W, 1.2.2.X

Moderate (<0,01) M0 REM0 1.2.3.W

Moderate (0,15 – 2,0) M1 REM1 1.2.2.Y, 1.2.2.Z

High (<0,01) H0 REH0 1.2.3.X

High (>2,0) H1 REH1 1.2.2.Z

Organic Low (<0,01) L0 ORL0 2.1., 2.2.3.E

(OR) Low (<0,15) L1 ORL1 -

Moderate (<0,01) M0 ORM0 -

Moderate (0,15 – 2,0) M1 ORM1 2.1.2, 2.2.2

High (<0,01) H0 ORH0 2.2.3.0

High (>2,0) H1 ORH1 2.2.2

Inorganic Low (<0,01) L0 INL0 Not applicable

(IN) Low (<0,15) L1 INL1 (inorganic ISO flux is

different)

Moderate (<0,01) M0 INM0

Moderate (0,15 – 2,0) M1 INM1

High (<0,01) H0 INH0

High (>2,0) H1 INH1

a

Fluxes are available in S (solid), P (paste/cream) or L (liquid) forms.

b

See 7.1 and 7.2 of IEC 61190-1-1 for comparisons of RO, RE, OR and IN composition classes and L, M and H

activity levels with the traditional classes such as R, RMA, RA, water soluble and low solids ”no-clean.''.

c

The 0 and 1 indicate absence and presence of halides, respectively. See 4.2.3 of IEC 61190-1-1 for an

explanation of L, M and H nomenclature.

d

ISO designations are similar to IEC designators with minor differences in characteristics

4.4 Flux percentage and metal content

The nominal percentage of flux, by mass, in solid-form solder products is identified as the flux

percentage. The flux percentage in/on solid solders is identified by a single alphanumeric

character in accordance with Table 3. “Metal content” refers to the percentage of metal in

solder paste (see IEC 61190-1-2).

61190-1-3 © IEC:2007 – 11 –

Table 3 – Flux percentage

Design Nominal Allowable Design Nominal Allowable Design Allowable

Nominal

symbol range symbol range symbol range

% % % % % %

0 None 5 2,5 2,2 – 2,8 A 5,0 4,7 – 5,3

1 0,5 0,2 – 0,8 6 3,0 2,7 – 3,3 B 5,5 5,2 – 5,8

2 1,0 0,7 – 1,3 7 3,5 3,2 – 3,8 C 6,0 5,7 – 6,3

3 1,5 1,2 – 1,8 8 4,0 3,7 – 4,3 D 6,5 6,2 – 6,8

4 2,0 1,7 – 2,3 9 4,5 4,2 – 4,8

4.5 Other characteristics

Standard bar solders are further classified by unit mass. Wire solders are further classified by

wire size (outside diameter) and unit mass. Ribbon solders are further classified by thickness,

width and unit mass. Powder solders are further classified by powder particle size distribution

and unit mass.

5 Requirements

5.1 Materials

Materials shall be used which permit the solder product to conform to the specified

requirements. The use of recovered or recycled materials is encouraged. Recovered or

recycled materials shall conform to or exceed comparable standards for virgin raw materials.

5.2 Alloys

The solder alloy shall be as specified (see Annex B). For the purposes of this standard,

electronic grade solder alloys are all those listed in Tables B.1, B.2 and B.3, including pure tin

(Sn99) and pure indium (In99). The elements listed in Tables B.1, B.2 and B.3 for an alloy are

considered to be the component elements of that alloy. Only the component elements of an

alloy are desirable and all other elements are impurities for that alloy. To the maximum extent

feasible and unless otherwise specified, solder alloy metal, including solder powder, shall be a

homogenous mixture of the component elements of the alloy, such that each particle of the

metal is the same alloy. Unless otherwise specified, the percentage by mass of impurity

elements in alloys which are identified with an “A”, “B”, or “C” suffix shall not exceed the

following values and the values listed in 5.2.1, 5.2.2, and 5.2.3 respectively, and the

percentage by mass of impurity elements in alloys which are identified with a “D” suffix shall

conform to the requirements in 5.2.4.

Ag: 0,05 Au: 0,05 Cu: 0,05 Ni: 0,01 Sn: 0,25

Al: 0,001 Bi: 0,10 Fe: 0,02 Pb: 0,10 Zn: 0,001

As: 0,03 Cd: 0,002 In: 0,10

The percentage of each element in an alloy shall be determined by any standard analytical

procedure. Wet chemistry shall be used as the referee procedure.

5.2.1 Variation A alloys

In alloys which are identified with an “A” suffix, the percentage by mass of antimony (Sb) as an

impurity element shall not exceed 0,50.

– 12 – 61190-1-3 © IEC:2007

5.2.2 Variation B alloys

In alloys which are identified with a “B” suffix, the percentage by mass of antimony as an

impurity element shall not exceed 0,20.

5.2.3 Variation C alloys

In alloys which are identified with a “C” suffix, the percentage by mass of antimony as an

impurity element shall not exceed 0,05.

5.2.4 Variation D alloys

Alloys identified with a “D” suffix are ultra-pure alloys that are intended for use in barrier-free

die attachment applications. In alloys identified with a “D” suffix, the combined total percentage

by mass of all impurity elements shall not exceed 0,05 and the combined total percentage by

mass of each of the following sets of impurity elements shall not exceed 0,000 5: