IEC 62047-9:2011

(Main)Semiconductor devices - Micro-electromechanical devices - Part 9: Wafer to wafer bonding strength measurement for MEMS

Semiconductor devices - Micro-electromechanical devices - Part 9: Wafer to wafer bonding strength measurement for MEMS

IEC 62047-9:2011 describes bonding strength measurement method of wafer to wafer bonding, type of bonding process such as silicon to silicon fusion bonding, silicon to glass anodic bonding, etc., and applicable structure size during MEMS processing/assembly. The applicable wafer thickness is in the range of 10 ohmm to several millimeters. The contents of the corrigendum of March 2012 have been included in this copy.

Dispositifs à semiconducteurs - Dispositif microélectromécaniques - Partie 9: Mesure de la résistance de collage de deux plaquettes pour les MEMS

La CEI 62047-9:2011 décrit une méthode de mesure de la résistance de collage de deux plaquettes, le type de processus de liaison, par exemple le collage par fusion de deux plaquettes de silicium, le collage anodique d'une plaquette de silicium et d'une plaquette de verre, etc., et la taille de la structure applicable pendant le traitement ou l'assemblage de systèmes microélectromécaniques (MEMS). L'épaisseur de plaquette applicable est dans la gamme comprise entre 10 ohmm et plusieurs millimètres. Le contenu du corrigendum de mars 2012 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 12-Jul-2011

- Technical Committee

- SC 47F - Micro-electromechanical systems

- Drafting Committee

- WG 1 - TC 47/SC 47F/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 13-Jul-2011

- Completion Date

- 15-Aug-2011

Relations

- Effective Date

- 05-Sep-2023

Overview

The IEC 62047-9:2011 standard provides a comprehensive methodology for measuring wafer-to-wafer bonding strength specifically tailored for Micro-Electromechanical Systems (MEMS). This international standard, published by the International Electrotechnical Commission (IEC), addresses the evaluation of bonding quality in semiconductor devices by defining various test methods applicable to wafer bonding processes such as silicon-to-silicon fusion bonding and silicon-to-glass anodic bonding. It supports measurements for wafers with thicknesses ranging from 10 micrometers to several millimeters, making it highly relevant for MEMS processing and assembly.

Key Topics

Bonding Strength Measurement Techniques

IEC 62047-9:2011 covers multiple practical methods for assessing wafer bonding strength in MEMS devices, including:

- Visual Test: Utilizes color changes and microscopic inspection to verify bonding presence and guide further testing.

- Pull Test: Measures bond strength by applying tensile forces, useful for basic adhesion evaluation.

- Double Cantilever Beam Test Using Blade: Provides insights into fracture mechanics by inserting a blade to create a controlled crack in the bonded interface.

- Electrostatic Test: Applies an electrostatic force to assess bonding integrity, suitable for non-destructive evaluation.

- Blister Test: Examines the bonding quality by pressurizing a cavity to induce delamination, enabling determination of adhesion energies.

- Three-Point Bending Test: Measures the fracture resistance of the bonded interface under bending loads.

- Die Shear Test: Applies shear forces to assess mechanical durability of the bonded layers.

Each method includes standardized equipment, specimen preparation, testing procedures, and result expression to ensure reproducibility and comparability between testing laboratories and manufacturers.

Applicable Bonding Processes and Structures

The standard is applicable to various bonding processes in MEMS fabrication, including:

- Silicon-to-silicon fusion bonding

- Silicon-to-glass anodic bonding

- Other wafer-to-wafer bonding processes commonly used in semiconductor device manufacturing

It supports a wide range of wafer thicknesses (10 µm to several millimeters), making it versatile for various MEMS device architectures.

Normative References

IEC 62047-9 references additional standards such as:

- IEC 60749-19 for die shear strength

- ISO 6892-1 for tensile testing of metallic materials

- ASTM E399 for fracture toughness testing

These references ensure that bonding strength tests are harmonized with broader mechanical and materials testing practices.

Applications

IEC 62047-9:2011 is essential for industries and organizations involved in the development, manufacturing, and quality control of MEMS devices, including:

- MEMS manufacturers aiming to verify and control wafer bonding strength for device reliability.

- Semiconductor device fabricators requiring standardized procedures to evaluate wafer assembly processes.

- Research laboratories and academic institutions working on novel wafer bonding techniques and MEMS device integration.

- Quality assurance teams in MEMS production lines seeking consistent and repeatable measurements of wafer bonding strength.

Testing bonded wafers using IEC 62047-9 methods helps ensure product performance, durability, and minimizes failures related to weak interfacial adhesion in MEMS packaging and assembly.

Related Standards

Professionals utilizing IEC 62047-9 should also consider the following related standards for comprehensive MEMS and semiconductor device testing:

- IEC 60749-19: Mechanical and climatic test methods for semiconductor devices, specifically die shear strength.

- ISO 6892-1: Metallic materials tensile testing, important for mechanical property evaluation of substrates and bonding layers.

- ASTM E399: Standard test method for fracture toughness, valuable for understanding crack propagation through bonded interfaces.

Integration of IEC 62047-9 with these standards supports robust quality control systems and helps comply with international testing and certification requirements in MEMS manufacturing.

Keywords: IEC 62047-9, wafer to wafer bonding, MEMS bonding strength, silicon fusion bonding, anodic bonding, bonding strength measurement, micro-electromechanical devices, MEMS testing standards, semiconductor wafer bonding, die shear test, pull test, blister test, three-point bend test.

Frequently Asked Questions

IEC 62047-9:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Micro-electromechanical devices - Part 9: Wafer to wafer bonding strength measurement for MEMS". This standard covers: IEC 62047-9:2011 describes bonding strength measurement method of wafer to wafer bonding, type of bonding process such as silicon to silicon fusion bonding, silicon to glass anodic bonding, etc., and applicable structure size during MEMS processing/assembly. The applicable wafer thickness is in the range of 10 ohmm to several millimeters. The contents of the corrigendum of March 2012 have been included in this copy.

IEC 62047-9:2011 describes bonding strength measurement method of wafer to wafer bonding, type of bonding process such as silicon to silicon fusion bonding, silicon to glass anodic bonding, etc., and applicable structure size during MEMS processing/assembly. The applicable wafer thickness is in the range of 10 ohmm to several millimeters. The contents of the corrigendum of March 2012 have been included in this copy.

IEC 62047-9:2011 is classified under the following ICS (International Classification for Standards) categories: 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62047-9:2011 has the following relationships with other standards: It is inter standard links to IEC 62047-9:2011/COR1:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62047-9:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62047-9 ®

Edition 1.0 2011-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Micro-electromechanical devices –

Part 9: Wafer to wafer bonding strength measurement for MEMS

Dispositifs à semiconducteurs – Dispositif microélectromécaniques –

Partie 9: Mesure de la résistance de collage de deux plaquettes pour les MEMS

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62047-9 ®

Edition 1.0 2011-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Semiconductor devices – Micro-electromechanical devices –

Part 9: Wafer to wafer bonding strength measurement for MEMS

Dispositifs à semiconducteurs – Dispositif microélectromécaniques –

Partie 9: Mesure de la résistance de collage de deux plaquettes pour les MEMS

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 31.080.99 ISBN 978-2-88912-585-2

– 2 – 62047-9 IEC:2011

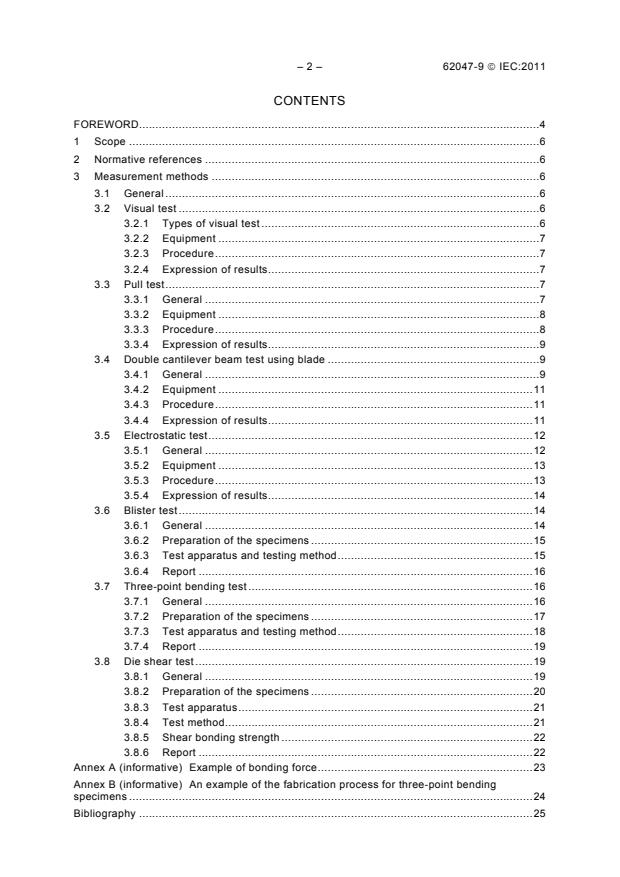

CONTENTS

FOREWORD. 4

1 Scope . 6

2 Normative references . 6

3 Measurement methods . 6

3.1 General . 6

3.2 Visual test . 6

3.2.1 Types of visual test . 6

3.2.2 Equipment . 7

3.2.3 Procedure . 7

3.2.4 Expression of results . 7

3.3 Pull test . 7

3.3.1 General . 7

3.3.2 Equipment . 8

3.3.3 Procedure . 8

3.3.4 Expression of results . 9

3.4 Double cantilever beam test using blade . 9

3.4.1 General . 9

3.4.2 Equipment . 11

3.4.3 Procedure . 11

3.4.4 Expression of results . 11

3.5 Electrostatic test . 12

3.5.1 General . 12

3.5.2 Equipment . 13

3.5.3 Procedure . 13

3.5.4 Expression of results . 14

3.6 Blister test . 14

3.6.1 General . 14

3.6.2 Preparation of the specimens . 15

3.6.3 Test apparatus and testing method . 15

3.6.4 Report . 16

3.7 Three-point bending test . 16

3.7.1 General . 16

3.7.2 Preparation of the specimens . 17

3.7.3 Test apparatus and testing method . 18

3.7.4 Report . 19

3.8 Die shear test . 19

3.8.1 General . 19

3.8.2 Preparation of the specimens . 20

3.8.3 Test apparatus . 21

3.8.4 Test method . 21

3.8.5 Shear bonding strength . 22

3.8.6 Report . 22

Annex A (informative) Example of bonding force . 23

Annex B (informative) An example of the fabrication process for three-point bending

specimens . 24

Bibliography . 25

62047-9 IEC:2011 – 3 –

Figure 1 – Bonding strength measurement – pull test . 8

Figure 2 – Bonding strength measurement – double cantilever beam (DCB) test

specimen using blade . 10

Figure 3 – Bonding strength measurement – electrostatic test . 13

Figure 4 – A specimen for blister test . 15

Figure 5 – Three-point bending specimen and loading method . 17

Figure 6 – Specimen geometry of three-point bending specimen . 18

Figure 7 – Die shear testing set-up . 19

Figure 8 – Size requirement of control tool and specimen . 20

Figure 9 – Example of bonded region in test piece . 20

Figure 10 – Setting of contact tool . 22

Figure A.1 – An example of bonding force or load measurement with time at constant

rate of upper fixture moving . 23

Figure B.1 – An example of specimen preparation for three-point bending test . 24

Table 1 – Example of visual test . 7

Table 2 − Example of pull test . 9

Table 3 – Example of Double Cantilever Beam test using blade . 12

Table 4 – Example of electrostatic test . 14

– 4 – 62047-9 IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SEMICONDUCTOR DEVICES –

MICRO-ELECTROMECHANICAL DEVICES –

Part 9: Wafer to wafer bonding strength measurement for MEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62047-9 has been prepared by subcommittee 47F: Micro-

electromechanical systems, of IEC technical committee 47: Semiconductor devices:

The text of this standard is based on the following documents:

FDIS Report on voting

47F/82/FDIS 47F/92/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62047-9 IEC:2011 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of March August 2012 have been included in this copy.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62047-9 IEC:2011

SEMICONDUCTOR DEVICES –

MICRO-ELECTROMECHANICAL DEVICES –

Part 9: Wafer to wafer bonding strength measurement for MEMS

1 Scope

This standard describes bonding strength measurement method of wafer to wafer bonding,

type of bonding process such as silicon to silicon fusion bonding, silicon to glass anodic

bonding, etc., and applicable structure size during MEMS processing/assembly. The

applicable wafer thickness is in the range of 10 µm to several millimeters.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60749-19, Semiconductor devices – Mechanical and climatic test methods – Part 19: Die

shear strength

ISO 6892-1: 2009, Metallic materials – Tensile testing – Part1: Method of test at room

temperature

ASTM E399-06e2: 2008, Standard Test Method for Linear-Elastic Plane-Strain Fracture

Toughness K Ic of Metallic Materials

3 Measurement methods

3.1 General

There are different ways to measure bonding strength such as visual test, pull test, double

cantilever beam test using blade, electrostatic test, blister test, three-point bend test, and die

shear test.

3.2 Visual test

3.2.1 Types of visual test

From colour change of silicon substrate and surface of glass, this method tells you only a

general information like whether the material is bonded or not. The visual test shall be

performed to confirm whether substantial other bonding tests are required, and/or to identify

the area that the bonding tests shall be conducted.

Optical microscope shall be used to evaluate the bonding interface of glass to silicon and

glass to glass.

An infrared (IR) camera shall be used to observe voids existing in the bonding interface of

silicon to silicon

NOTE Visual test is a simple qualitative test method.

62047-9 IEC:2011 – 7 –

3.2.2 Equipment

One or a few equipments of optical microscope, scanning acoustic microscope, scanning

electron microscope (SEM), transmission electron microscope (TEM), and IR or optical

camera can be used.

3.2.3 Procedure

Steps to measure voids areas are as follows:

a) To observe voids, use the IR or optical microscope.

b) To take images of voids, use the IR or optical camera, or scanning acoustic microscope.

c) Measure voids areas using the observed images.

3.2.4 Expression of results

Check and simply indicate using the mark “V” the observation result based on Note 1 in

Table 1 for each case.

Table 1 – Example of visual test

good fair poor

Visual test

NOTE 1 good – complete bonded area fraction larger than 95 %, fair – complete bonded area fraction larger than

75 %, poor – complete bonded area fraction less than 75 %.

3.3 Pull test

3.3.1 General

As shown in Figure 1 this method is used to measure wafer bonding strength using general

tensile test method. After preparing for bonded wafer using various methods, a bonded wafer

is divided to square shaped specimens by dicing process. After dicing, dimensions of areas

(A) are measured. Top-side and back-side of a specimen of wafer bonded are glued to top

stud connected with load cell and bottom stud, respectively, using selective adhesive. And

then it is pulled upward until fracturing. In case that the wafer-to-wafer bonding to be tested is

very strong, fracture often occurs from the adhesive. In the case, pull test is not applicable.

Therefore, pull test is applicable only the case that bonding is not very strong and fracture

occurred at the bonding interface. During pulling process, applied force or fracture force (F )

c

is measured with time as shown in Annex A. Therefore, bonding strength could be calculated

by Equation (1).

F

c

σ = (1)

c

A

where

σ is bonding strength when debonding or fracture occurs;

c

F is applied force (fracture force) when the debonding or fracture occurs;

c

A is the area of the test sample.

– 8 – 62047-9 IEC:2011

Load cell

F

Upper stud

Adhesive

Specimen under test

Bottom stud

Base plate

IEC 1657/11

Key

Components Connections and supplies

specimen under

test: a dice of bonded wafer load cell: variable source of force

adhesive: to glue with upper stud and bottom stud F force: supplying for a testing specimen

upper stud: to connect with a load cell

bottom stud: to connect with a base plate

base plate: fixture to keep a rigid state

Figure 1 – Bonding strength measurement – pull test

3.3.2 Equipment

General tensile tester with force meter or load cell should be used as shown in ISO 6892.

3.3.3 Procedure

Steps to observe fractured specimens are as follows:

a) After bonding processes, for example, silicon to silicon bonding, silicon to glass bonding,

bonded wafers are cut into square shape with dimension, for example, 5 mm by 5 mm to

10 mm by 10 mm using dicing process. Maximum load to specimens is limited by the

capacity of load cell. So, maximum specimen size is also limited by the capacity of load

cell. And the accuracy of load cell shall be equal to or less than 1 % of full scale and 1 %

of reading.

b) Specimens attached to upper and lower studs using adhesive. Adhesives should be well

selected through consideration of specifications of them to endure until fracturing. And

adhesive should not be applied at sides of bonded wafers.

c) Lower stud is fixed to the bottom of apparatus and upper stud is connected to load cell or

force meter to measure stress at fracture of specimens at room temperature. Stress vs.

time curve shows maximum stress at fracture. Loading rate is in the range of 0,5 mm/min

62047-9 IEC:2011 – 9 –

to 1,5 mm/min. From fracture load data, we can calculate maximum strength. An example

of load vs. time curve is shown in Annex B.

d) After fracturing, observe fractured specimens by optical microscope or SEM.

e) At least 10 specimens shall be tested for reliable data.

3.3.4 Expression of results

Check and write the force measured value in Table 2.

Table 2 – Example of pull test

Reference standard

Type of material (fabrication method)

Bonding method

Shape and size of specimen

Type of adhesive (or glue)

Number of specimen

Loading speed

Measured fracture force (F )

c

Bonded area of the test specimen (A)

Bonding strength (σ )

c

3.4 Double cantilever beam test using blade

3.4.1 General

The wedge-opening test is also called the double cantilever beam test (DCB) as shown in

Figure 2. This testing method is suitable for bonded wafers using silicon to silicon fusion

bonding and anodic bonding. In case that examined wafer-to-wafer bonding is too strong, one

of the bonded wafers often breaks during this test procedure. In such a case, this method

cannot be used as a quantitative test but as a qualitative test.

– 10 – 62047-9 IEC:2011

IR

camera

a

Wafer 1

h

Specimen

Wedge

d

under test

Wafer 2 h

IR

source

IEC 1658/11

Key

Components or observation tool Dimensions of components

specimen under test: a piece of wafer bonded with different h : thickness of wafer 1

kinds of wafer 1 and wafer 2.

wafer 1: bonded with wafer 2 h : thickness of wafer 2

wafer 2: bonded with wafer 1 a: cracking length of split state layer

between bonded wafer 1 and wafer 2

wedge: part of a blade to drive a cracking layer in d: thickness of wedge part of the blade

the specimen

IR source: infrared beam source

IR camera: to measure cracked state length of the

specimen

Figure 2 – Bonding strength measurement –

double cantilever beam (DCB) test specimen using blade

The crack length is resulted from energy balance between strain energy of freely loaded

cantilevers and bonding energy at the bonding interface. Therefore, in this method, bonding

strength is evaluated not by fracture stress but by critical strain energy release rate. Critical

train energy release rate is calculated as follows

3 3

3 E E h h d

1 2 1 2

G = (2)

c

3 3 4

(E h + E h ) a

1 1 2 2

where

G is critical strain energy release rate (interfacial fracture toughness),

c

E and E are elastic coefficient of wafer 1 and 2;

1 2

h and h are thickness of wafer;

1 2

d is thickness of blade;

a is crack length.

62047-9 IEC:2011 – 11 –

In case of E =E and h = h , Equation (2) becomes

1 2 1 2

3 2

3 Eh d

G = (3)

c

16 a

In case of h <

1 2

3 2

3 E h d

1 1

G =

(4)

c

a

3.4.2 Equipment

Blade to test and sample fixture to fix should be used [1] .

Recommended blade thicknesses are in the range of 30 μm to 200 μm.

3.4.3 Procedure

a) After bonding processes, for example, silicon to silicon bonding, silicon to glass bonding,

the bonded wafer pair is cut into strips with the edges of wafers on at least one of their

ends. Width of strip specimens should be smaller than the width of the blade.

b) Set the stripe specimen to the sample fixture.

c) Insert a blade from one end of the stripe specimen using a gap resulted from rounded

wafer edges. Drive a crack along interface.

d) Measure the crack length using an optical or IR camera, or a scanning acoustic

microscope.

e) Calculate the interfacial fracture toughness using Equation (2)

f) At least 10 specimens should be tested for reliable data.

3.4.4 Expression of results

Write the measured values in Table 3. Then calculate G according to Equation (2), (3) or (4)

c

and write the value in Table 3.

___________

Numbers in square brackets refer to the Bibliography.

– 12 – 62047-9 IEC:2011

Table 3 – Example of Double Cantilever Beam test using blade

Shape of bonded specimen

Fixing method of specimen

Inserting speed of blade (optional)

Number of specimens

Crack length (a)

Thickness of blade (d)

Material of wafer 1

Material of wafer 2

Thickness of wafer 1 (h )

Thickness of wafer 2 (h )

Elastic coefficient of wafer 1 (E )

Elastic coefficient of wafer 2 (E )

Critical strain energy release late (G )

c

3.5 Electrostatic test

3.5.1 General

As shown in Figure 3, between Si wafer with patterned SiO films and glass wafer, anodic

bonding is done. Ranges of wafer thicknesses are normally 50 µm to 1 mm. By the

measurement of unbonded lengths depended on bonding strengths around patterned SiO

films on Si wafer, we can compare bonding strengths of anodic bonded wafers. So, this

method is convenient to utilize and allows you to compare qualitative bonding strength. The

measurement condition was at room temperature. Wafer level sizes in the range of 1 ” to 8 ”

2 2

or chip level sizes in the range of 1 cm to 4 cm are suitable for this experimental. Even

though this method could be used for bonded wafer using other bonding methods, in order to

avoid the difficulty to observe the unbonded length after bonding, it is better to use for only

anodic bonded wafer between Si and glass wafers.

62047-9 IEC:2011 – 13 –

SiO

t

g

Glass

Specimen

t

s

under test

Si

a

IEC 1659/11

Key

Configurations or specimen Dimensions of specimen under test

specimen under test: bonded piece between Si wafer with t : thickness of glass

g

patterned SiO films and glass wafer

SiO : patterned film state layer bonded with a t : thickness of silicon

2 s

kind of glass layer and a silicon layer

Si: silicon base layer to be observed unbonded length at a a: unbonded length

cross sectional view

glass: layer bonded with Si and SiO by anodic

bonding processes

Figure 3 – Bonding strength measurement –

electrostatic test

3.5.2 Equipment

Anodic bonder shall be used. General anodic bonder consists of vacuum chamber, holders for

holding top wafer and bottom wafer before bonding process, load cell to push top wafer

toward bottom wafer for initial bonding, electrical system to supply negative field to positive

+

ion contained wafer, for example, Na contained glass, and heater to maintain constant

temperature during process.

3.5.3 Procedure

Steps to measure the length of the unbonded area are as follows:

a) In order to make specimens, the anodic bonding between Si wafer with patterned SiO

films and glass wafer is performed. SiO thickness is more than 1 µm [2]. Anodic bonding

is a simple process to join together a silicon wafer and a alkali ion containing glass

substrate. The bonding is performed at a temperature between 200 °C and 500 °C in

vacuum, air or in an inert gas environment. The application of 500 V to 1500 V across the

two substrates, with the glass held at negative potential, causes mobile positive ions

+

(mostly Na ) in the glass to migrate away from the silicon glass interface toward the

cathode, leaving behind fixed negative charges in the glass. The bonding is complete

when the ion current vanishes, indicating that all mobile ions have reached the cathode.

The electrostatic attraction between the fixed negative charge in the glass and positive

mirror charge induced in the silicon holds the two substrates together and facilitates the

chemical bonding of glass to silicon [3]. Make the sample as shown in Figure 3 using

anodic bonding process.

b) Measure the length of the unbonded area using optical microscope or SEM (scanning

electron microscope) for cross-section observation.

c) At least ten specimens shall be tested for reliable data.

– 14 – 62047-9 IEC:2011

3.5.4 Expression of results

Write the measured values in Table 4. This method is not exact quantitative method, but

qualitative method. It is better that only this method could be used for quick and simple

comparison method.

Table 4 – Example of electrostatic test

Bonding temperature

Applied voltage

Applied time of voltage

Heating and cooling speed

Thickness of SiO

SiO pattern (dotted or linear)

Shape of bonded specimen

Testing temperature and humidity

Glass Material

Elastic coefficient of Glass (E )

g

Thickness of glass (t )

g

Thickness of silicon (t )

s

Unbonded length (a)

3.6 Blister test

3.6.1 General

Blister test is suitable for evaluation of strong bond which is difficult to be evaluated by tensile

test and double cantilever beam test. Tensile test has a problem of debonding from adhesive

glue. Double cantilever beam test has a problem of breaking one of the bonded wafers before

crack driving through the bonding interface. Blister test can minimize these problems. This

testing method can be applied to any type of wafer bonding, provided that specimens can be

prepared.

In this test, a bonded specimen with a hole, a channel and a thin cavity as shown in Figure 4

is used. Hydrostatic pressure line is connected to the specimen by mechanical clamping using

a flange and a back side plate with O-rings. Through the hole and channel, hydrostatic

pressure is applied to two inner surface of the cavity until debonding takes place.

62047-9 IEC:2011 – 15 –

2a

w w

3 2

w

w

h

t

t

p

IEC 1660/11

Key

1 a part of flange

2 a front side plate

3 O-rings

4 specimen

5 a back side plate

Figure 4 – A specimen for blister test

3.6.2 Preparation of the specimens

The hole, channel, and cavity structure should be made on one of the bonded wafers before

bonding using a micro-fabrication method such as photolithography and etching, which do not

introduce micro cracks. The shape of the cavity should be circle or square. Then the wafer is

bonded to another wafer. After bonding, the bonded wafer pair is diced into the shape shown

in Figure 4. Recommended dimensions of the specimen are as follows:

– a > 5t , 5t

1 2

– w , w > 2a

1 2

– w > 4a

– w < a/5

– h < t /20, t /20

1 2

3.6.3 Test apparatus and testing method

3.6.3.1 Number of specimens

At least ten specimens shall be measured.

3.6.3.2 Fixing of specimens

Hydrostatic pressure line is connected to the specimen by mechanical clamping using a

flange and a back side plate with O-rings.

– 16 – 62047-9 IEC:2011

3.6.3.3 Applying hydrostatic pressure and bonding strength measurement

Hydrostatic pressure is applied to the cavity using gas pressure. Pressure increasing rate

should be controlled by gas flow controller. The gas pressure should be gradually increased

so that quasi-static conditions are satisfied. The pressure should be monitored by pressure

gauge until the debonding. Debonding can be detected by specimen fracture, sudden

decrease of gas pressure. Optical observation by visible light for transparent materials or by

IR light for silicon is also effective to detect the initiation of debonding.

3.6.3.4 Environmental control

The temperature and humidity shall be kept at constant levels in the test environment during

the test.

3.6.4 Report

The test report shall include details on all of the following points, at minimum:

a) reference to this standard;

b) the bonded materials;

c) the method and conditions of bonding;

d) the shape of the specimen;

e) the pressure at the debonding.

3.7 Three-point bending test

3.7.1 General

As shown in Figure 5, this testing method is a measurement method for evaluating the bond

strength of bonding wafers by three-point bending. A specimen cut from the bonded wafer, in

which an unbonded region is introduced into the interface, is subjected to a three point

bending test to fracture the bonded interface. The bending fracture stress is then calculated

with Equation (5).

62047-9 IEC:2011 – 17 –

F

Supplying tool

Glass Si

Specimen under test

w

Thickness B

thickness B

a

Supporsupporting tting ooltoo l

Ssupporupportitng tingool too l

s s

IEC 1661/11

Key

Configurations or specimen Supply and dimensions of specimen under

test

specimen under test: region bonded piece between Si wafer w: width of the specimen

and glass layer with unbonded

Si bonded with a kind of glass layer B: thickness of the specimen

glass: a kind of layer bonded with Si layer a: length of the unbonded region

supporting tools : a kind of tools to receive loading force s: length of the span between tops of

through testing specimen supporting tools

F:

supplying tool a kind of tool to apply loading force loading force supplied by a kind of load cell

supplied from a load cell

Figure 5 – Three-point bending specimen and loading method

6F S

c

σ = (5)

c

B(W− a)

where

σ is fracture stress;

c

F is fracture force of the specimen;

c

S is span;

W is width of the specimen;

B is thickness of the specimen;

a is length of the unbonded region.

This testing method can be applied to any type of bonding wafers, provided that specimens

can be prepared. It has been developed for use with specimens of about 1 mm in thickness, in

order to minimize the size effect.

3.7.2 Preparation of the specimens

A process as similar as possible to that applied to the device should be used to fabricate the

test piece, including the bonding interface. The dimensions of specimens shown in Figure 6

are recommended as standard sizes. An unbonded region shall be introduced into the

specimen in the manner shown in the figure. The recommended combination of the length (S),

the width (W), and the length of the unbonded region (a) can be found by referring to Annex

A3 of ASTM E399-06e2:2008. The width of the unbonded regions should be 0,01 mm. An

example of the process to prepare the specimens is shown in Annex B. As the size may differ

from specimen to specimen, all of the dimensions shall be measured before testing. These

measurements shall have an accuracy of ± 1 %.

– 18 – 62047-9 IEC:2011

Glass

Si

a B = 0,5

0,01

s = 1,0 s = 1,0

IEC 1662/11

Figure 6 – Specimen geometry of three-point bending specimen

3.7.3 Test apparatus and testing method

3.7.3.1 Number of specimens

At least ten specimens shall be measured.

3.7.3.2 Fixing of specimens

The specimen shall be fixed to apply a three-point bending load, as shown in Figure 5. The

following conditions shall be ensured during this step:

a) the bonding boundary of the specimen and the loading axis of the test equipment are

aligned;

b) the specimen is set in a position where force can be applied parallel to the bonding

boundary.

A good way to achieve this condition is to magnify the specimen fixture and loading part with

an optical microscope. The rollers used to apply the load should be made from a material that

will not significantly deform under the force applied during the testing. The recommended

roller radius is 0,3 mm.

3.7.3.3 Applying force

The force should be applied with a mechanical testing machine capable of applying

compressive loads on micro materials. Instrumented indentation equipment can be also used.

The bonding boundary of the specimen and the loading axis of the testing equipment shall be

aligned to ensure that the force is applied uniformly at the bonding interface.

3.7.3.4 Speed of testing

The load should be applied to the specimen at a loading speed of 0,1 mm/min using a fine

drive mechanism that allows displacement control.

3.7.3.5 Force measurement

The force measurement shall be performed with a load cell (force sensor) with a guaranteed

resolution accuracy of 5 % of the measured fracture force.

3.7.3.6 Environmental control

The temperature and humidity shall be kept at constant levels in the test environment during

the test.

w = 0,5

62047-9 IEC:2011 – 19 –

3.7.3.7 Calculation of bending fracture stress

The bending fracture stress shall be calculated by Equation (5).

3.7.4 Report

The test report shall include details on all of the following points, at minimum:

a) reference to this standard;

b) the bonded materials;

c) the method and conditions of bonding;

d) the shape of the specimen;

e) the bending fracture stress.

3.8 Die shear test

3.8.1 General

The Die Shear Test is a method for measuring the shear bonding strength, as shown in

Figure 7. One side of the bonding wafer is fixed, and shear force is applied to the other side

of the wafer with a contact tool. The shear bonding force at the point of debonding is

calculated by Equation (6).

Contact tool

Direction of force

Test piece

Bonding part

IEC 1663/11

Key

Configurations or specimen Supplies

test piece: bonded piece of Si wafer with a bonded region direction of force: loading force supplied a kind

of load cell

bonding part: bonded layer within the bonded piece contact tool: to supply loading force to a

side surface of the bonded

piece

Figure 7 – Die shear testing set-up

Q

c

(6)

τ =

c

A

b

where

τ is shear bonding strength;

c

Q is shear force at the point of debonding;

c

A is bonded area.

b

IEC 60749-19 has already been established for die shear testing to assess the strength of

solder joints. The same standard can be applied for the measurement of wafer bonding

strength for MEMS devices by reducing the dimensions of the specimens down to several

millimeters and accounting for the method of specimen fabrication.

– 20 – 62047-9 IEC:2011

3.8.2 Preparation of the specimens

3.8.2.1 Shape and dimensions

The plane shape of the specimen should be several millimeters square. The length of one

side of the specimen shall be smaller than that of the contact tool (see Figure 8). The

thickness of each specimen should be determined based on the thicknesses of the wafers.

b

b < a

b

a

Test piece

Direction of force

Contact tool

IEC 1664/11

Key

Specimen and contact tool to supply loading force Supply and dimensions of specimen under test

test piece: bonded piece of a kind of diced wafer with direction of loading force supplied a kind of load

a bonded region force: cell

contact tool: supply loading force to a side surface of a: length of a side of the contact tool to

the bonded piece receive loading force by a load cell

b: length of sides of the bonded piece

Figure 8 – Size requirement of control tool and specimen

3.8.2.2 Bonded region

To avoid damaging the bonded region during dicing, the bonded region shall be formed in the

middle of the specimen. An unbonded region, meanwhile, should be prepared around the

edge of the specimen (See Figure 9). If the bond is not to be patterned, however, the bonded

region can be extended to the edges. The area and shape of the bonded region should have

the same dimensions in all specimens.

Unbonded region

A A’

Cross section of A-A’

Test piece

Bonded region

IEC 1665/11

Figure 9 – Example of bonded region in test piece

3.8.2.3 Method for fabricating the specimen

The wafers shall be bonded after the bonded region is patterned, then diced after the bonding

process is completed. The size of the planar shape and thickness of the specimens shall be

measured after the patterning, bonding, and dicing.

62047-9 IEC:2011 – 21 –

3.8.3 Test apparatus

The apparatus for this testing shall be equipped with a force-applying instrument with an

accuracy of 5 % of the full scale or 500 mN, whichever corresponds to greater tolerance. For

testing, the apparatus should consist of a lever or linear motion force-applying instrument

capable of applying the required stress. The test equipment shall also have the following

features and capabilities:

a) a contact tool capable of applying uniform force to the edge of the specimen;

b) the contact tool shall be vertical to the edge of the specimen;

c) a fixture with rotational capability relative to the specimen and the contact tool, to ensure

line contact with the edge of the specimen. This tool shall come into contact with the

whole edge of the specimen;

d) a facility fitted with a suitable light source to allow visual observation (e.g., at 10 x

magnification) of the specimen and contact tool during testing.

3.8.4 Test method

3.8.4.1 Number of specimens

At least ten specimens shall be m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...