IEC 60601-1-9:2007

(Main)Medical electrical equipment - Part 1-9: General requirements for basic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design

Medical electrical equipment - Part 1-9: General requirements for basic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design

IEC 60601-1-9:2007 The objective of this collateral standard is to improve the environmental impact for the entire range of medical electrical equipment, taking into account all stages of the product life cycle:

- product specification;

- design;

- manufacturing;

- sales, logistics, installation;

- use;

- end of life management. This means protecting the environment and human health from hazardous substances, conserving raw materials and energy, minimizing the generation of waste, as well as minimizing the adverse environmental impacts associated with waste. The criteria needed to reach this goal must be integrated into all stages of the medical electrical equipment life cycle from the specification stage to end of life management. The environmental impacts of me equipment through all life-cycle stages are determined from the medical electrical equipment's environmental aspects defined during the identification of need, product planning, and design stages. Consideration of environmental aspects as early as possible in these stages can produce numerous benefits that might include lower costs, stimulation of innovation and creativity, and increased knowledge about the product. It can also provide new business opportunities, and improved product quality as well as reduction of adverse environmental impacts. The assessment of the environmental aspects and impacts of medical electrical equipment is a developing science and it is anticipated that this collateral standard will require periodic updating as the science develops. The requirements given in this collateral standard do not replace national or international laws and regulations. Environmental protection is one element of the overall risk management process as required by the general standard. The acceptability of medical electrical equipment's environmental impacts are balanced against other factors, such as the product's intended function, performance, safety, cost, marketability, quality, legal and regulatory requirements. This balance can differ depending on the intended function of the medical electrical equipment. For example, a solution appropriate for life-saving or life-supporting medical electrical equipment might not be appropriate for a device intended to correct a minor ailment. A manufacturer of medical electrical equipment might have to justify, as a result of risk management, that a medical benefit outweighs the associated adverse environmental impacts.

Appareils électromédicaux - Partie 1-9: Exigences générales pour la sécurité de base et les performances essentielles - Norme collatérale: Exigences pour une conception éco-responsable

La CEI 60601-1-9:2007 L'objectif de la présente norme collatérale est d'améliorer l'impact environnemental pour toute la gamme d'appareils électromédicaux en tenant compte de toutes les étapes du cycle de vie du produit:

- spécification du produit;

- conception;

- fabrication;

- ventes, logistique, installation;

- utilisation;

- gestion de la fin de vie. Cela signifie protéger l'environnement et la santé des personnes contre les substances dangereuses, économiser les matières premières et l'énergie, minimiser la production de déchets, ainsi que minimiser les impacts environnementaux négatifs associés aux déchets. Les critères nécessaires pour atteindre ce but doivent être intégrés dans toutes les étapes du cycle de vie des appareils électromédicaux, dès l'étape de spécifications jusqu'à la gestion de fin de vie. Les impacts environnementaux des appareils électromédicaux à travers toutes les étapes du cycle de vie sont déterminés à partir des aspects environnementaux des appareils électromédicaux définis pendant les étapes d'identification des besoins, de planification et de conception du produit. La prise en compte des aspects environnementaux le plus tôt possible pendant ces étapes peut apporter de nombreux bénéfices qui pourraient inclure des coûts réduits, une stimulation de l'innovation et de la créativité et une meilleure connaissance du produit. Elle peut aussi apporter des nouvelles opportunités d'affaires, une meilleure qualité du produit ainsi qu'une réduction des impacts environnementaux négatifs. L'analyse des aspects et impacts environnementaux des appareils électromédicaux est une science en cours de développement et il est prévu que cette norme collatérale exige une mise à jour périodique au fur et à mesure que la science se développe. Les exigences données dans la présente norme collatérale ne remplacent pas les lois et réglementations nationales ou internationales. La protection environnementale est un des éléments du processus de gestion des risques global tel que demandé par la norme générale. L'acceptabilité des impacts environnementaux des appareils électromédicaux est prise en compte par rapport à d'autres facteurs, tels que la fonction prévue du produit, sa performance, sa sécurité, son prix, sa facilité de mise sur le marché, sa qualité, les exigences légales et réglementaires. L'équilibre peut être différent et dépend de la fonction prévue de l'appareil électromédical. Par exemple, une solution appropriée pour les appareils électromédicaux de sauvetage ou de maintien de la vie peut ne pas être appropriée pour un dispositif destiné à corriger une maladie mineure. Un fabricant d'appareils électromédicaux pourrait être amené à justifier, comme résultat de la gestion des risques, qu'un bénéfice médical à un poids plus important que les impacts environnementaux négatifs associés.

General Information

- Status

- Published

- Publication Date

- 09-Jul-2007

- Technical Committee

- SC 62A - Common aspects of medical equipment, software, and systems

- Drafting Committee

- WG 20 - TC 62/SC 62A/WG 20

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Jul-2007

- Completion Date

- 15-Sep-2007

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60601-1-9:2007 is an international collateral standard developed by the International Electrotechnical Commission (IEC) that defines the general requirements for environmentally conscious design of medical electrical equipment. This standard complements the general safety and essential performance requirements outlined in IEC 60601-1, focusing specifically on reducing the environmental impact throughout the entire product life cycle.

The standard aims to promote sustainable practices by integrating environmental considerations into every stage of medical electrical equipment development, from initial specification and design to manufacturing, use, and end-of-life management. It balances environmental protection with safety, performance, and regulatory compliance to help manufacturers achieve both medical and ecological objectives.

Key Topics

Environmental Impact Reduction

Emphasizes minimizing negative effects on the environment and human health caused by hazardous substances, resource consumption, energy use, and waste generation related to medical electrical equipment.Life Cycle Approach

Covers all stages of the product life cycle:- Product specification

- Design and development

- Manufacturing processes

- Sales, logistics, and installation

- Operational use

- End-of-life disposal and recycling

Identification of Environmental Aspects

Requires manufacturers to identify and assess environmental aspects early during product planning and design to reduce adverse impacts proactively.Risk Management Integration

Incorporates environmental protection as part of the overall risk management process, allowing trade-offs between environmental impacts and product performance, safety, cost, and legal requirements.Continuous Improvement and Updating

Recognizes that the assessment of environmental aspects is evolving, with the standard subject to periodic revision based on advances in environmental science and technology.Compliance and Justification

While not replacing legal obligations, the standard encourages manufacturers to justify design decisions where environmental impacts may be balanced against medical benefits, especially for critical life-saving devices.

Applications

IEC 60601-1-9 is essential for manufacturers, designers, regulatory bodies, and healthcare providers involved with medical electrical equipment, ensuring products:

- Are developed with environmental sustainability in mind, reducing waste and hazardous material use.

- Deliver medical benefits while minimizing ecological footprints throughout usage and disposal.

- Comply with international standards that facilitate global market acceptance and support corporate environmental responsibility goals.

- Enable innovative design approaches that can reduce energy consumption and resource depletion.

- Support improved product quality and cost-effectiveness by integrating environmental criteria from the early stages of development.

Related Standards

IEC 60601-1: Medical Electrical Equipment – Part 1: General Requirements for Basic Safety and Essential Performance

Provides the foundational safety and performance requirements with which IEC 60601-1-9 is used in conjunction.ISO 14000 Series (Environmental Management)

Guides environmental management systems and practices that align with lifecycle considerations suggested in IEC 60601-1-9.RoHS Directive (Restriction of Hazardous Substances)

National and regional regulations complementing this standard by restricting the use of specific hazardous materials in electrical and electronic equipment.WEEE Directive (Waste Electrical and Electronic Equipment)

Governs the end-of-life management and recycling of medical electrical devices consistent with the lifecycle approach promoted by IEC 60601-1-9.

By adhering to IEC 60601-1-9:2007, stakeholders can foster environmentally conscious design practices that improve sustainability, safety, and regulatory compliance in medical electrical equipment, ultimately contributing to better healthcare outcomes with reduced environmental impact.

IEC 60601-1-9:2007 - Medical electrical equipment - Part 1-9: General requirements for basic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design

IEC 60601-1-9:2007+AMD1:2013 CSV - Medical electrical equipment - Part 1-9: General requirements forbasic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design Released:6/18/2013 Isbn:9782832208762

IEC 60601-1-9:2007+AMD1:2013+AMD2:2020 CSV - Medical electrical equipment - Part 1-9: General requirements for basic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design Released:7/22/2020

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC 60601-1-9:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Medical electrical equipment - Part 1-9: General requirements for basic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design". This standard covers: IEC 60601-1-9:2007 The objective of this collateral standard is to improve the environmental impact for the entire range of medical electrical equipment, taking into account all stages of the product life cycle: - product specification; - design; - manufacturing; - sales, logistics, installation; - use; - end of life management. This means protecting the environment and human health from hazardous substances, conserving raw materials and energy, minimizing the generation of waste, as well as minimizing the adverse environmental impacts associated with waste. The criteria needed to reach this goal must be integrated into all stages of the medical electrical equipment life cycle from the specification stage to end of life management. The environmental impacts of me equipment through all life-cycle stages are determined from the medical electrical equipment's environmental aspects defined during the identification of need, product planning, and design stages. Consideration of environmental aspects as early as possible in these stages can produce numerous benefits that might include lower costs, stimulation of innovation and creativity, and increased knowledge about the product. It can also provide new business opportunities, and improved product quality as well as reduction of adverse environmental impacts. The assessment of the environmental aspects and impacts of medical electrical equipment is a developing science and it is anticipated that this collateral standard will require periodic updating as the science develops. The requirements given in this collateral standard do not replace national or international laws and regulations. Environmental protection is one element of the overall risk management process as required by the general standard. The acceptability of medical electrical equipment's environmental impacts are balanced against other factors, such as the product's intended function, performance, safety, cost, marketability, quality, legal and regulatory requirements. This balance can differ depending on the intended function of the medical electrical equipment. For example, a solution appropriate for life-saving or life-supporting medical electrical equipment might not be appropriate for a device intended to correct a minor ailment. A manufacturer of medical electrical equipment might have to justify, as a result of risk management, that a medical benefit outweighs the associated adverse environmental impacts.

IEC 60601-1-9:2007 The objective of this collateral standard is to improve the environmental impact for the entire range of medical electrical equipment, taking into account all stages of the product life cycle: - product specification; - design; - manufacturing; - sales, logistics, installation; - use; - end of life management. This means protecting the environment and human health from hazardous substances, conserving raw materials and energy, minimizing the generation of waste, as well as minimizing the adverse environmental impacts associated with waste. The criteria needed to reach this goal must be integrated into all stages of the medical electrical equipment life cycle from the specification stage to end of life management. The environmental impacts of me equipment through all life-cycle stages are determined from the medical electrical equipment's environmental aspects defined during the identification of need, product planning, and design stages. Consideration of environmental aspects as early as possible in these stages can produce numerous benefits that might include lower costs, stimulation of innovation and creativity, and increased knowledge about the product. It can also provide new business opportunities, and improved product quality as well as reduction of adverse environmental impacts. The assessment of the environmental aspects and impacts of medical electrical equipment is a developing science and it is anticipated that this collateral standard will require periodic updating as the science develops. The requirements given in this collateral standard do not replace national or international laws and regulations. Environmental protection is one element of the overall risk management process as required by the general standard. The acceptability of medical electrical equipment's environmental impacts are balanced against other factors, such as the product's intended function, performance, safety, cost, marketability, quality, legal and regulatory requirements. This balance can differ depending on the intended function of the medical electrical equipment. For example, a solution appropriate for life-saving or life-supporting medical electrical equipment might not be appropriate for a device intended to correct a minor ailment. A manufacturer of medical electrical equipment might have to justify, as a result of risk management, that a medical benefit outweighs the associated adverse environmental impacts.

IEC 60601-1-9:2007 is classified under the following ICS (International Classification for Standards) categories: 11.040.01 - Medical equipment in general; 13.020.01 - Environment and environmental protection in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60601-1-9:2007 has the following relationships with other standards: It is inter standard links to IEC 60601-1-9:2007/AMD1:2013, IEC 60601-1-9:2007/AMD2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60601-1-9:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

CEI

60601-1-9

NORME

First edition

INTERNATIONALE

Première édition

2007-07

Medical electrical equipment –

Part 1-9:

General requirements for basic

safety and essential performance –

Collateral Standard: Requirements for

environmentally conscious design

Appareils électromédicaux –

Partie 1-9:

Exigences générales pour la sécurité

de base et les performances essentielles –

Norme collatérale: Exigences pour une

conception éco-responsable

Reference number

Numéro de référence

IEC/CEI 60601-1-9:2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de

référence, texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou

remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

CEI

60601-1-9

NORME

First edition

INTERNATIONALE

Première édition

2007-07

Medical electrical equipment –

Part 1-9:

General requirements for basic

safety and essential performance –

Collateral Standard: Requirements for

environmentally conscious design

Appareils électromédicaux –

Partie 1-9:

Exigences générales pour la sécurité

de base et les performances essentielles –

Norme collatérale: Exigences pour une

conception éco-responsable

PRICE CODE

U

CODE PRIX

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

Pour prix, voir catalogue en vigueur

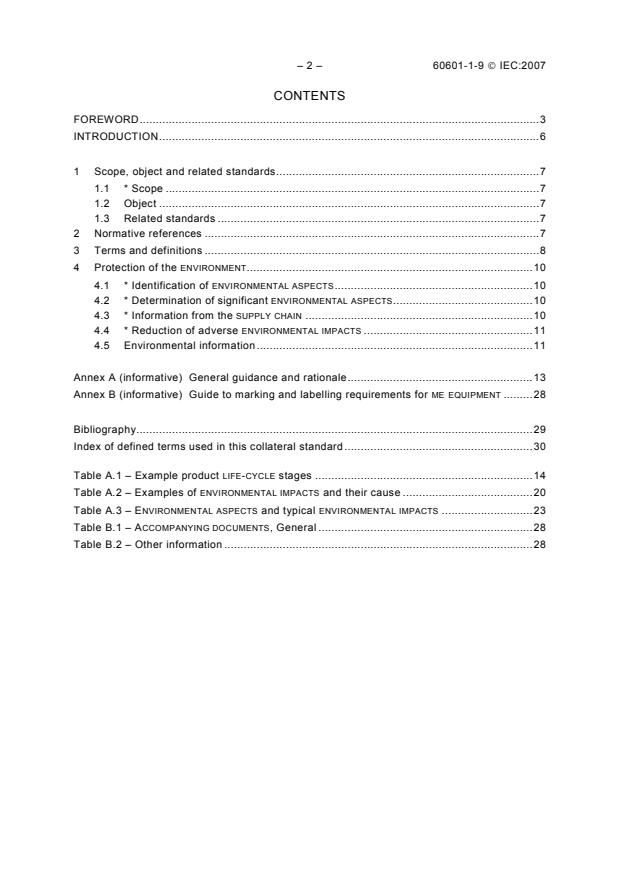

– 2 – 60601-1-9 © IEC:2007

CONTENTS

FOREWORD.3

INTRODUCTION.6

1 Scope, object and related standards.7

1.1 * Scope .7

1.2 Object .7

1.3 Related standards .7

2 Normative references .7

3 Terms and definitions .8

4 Protection of the ENVIRONMENT.10

4.1 * Identification of ENVIRONMENTAL ASPECTS.10

4.2 * Determination of significant ENVIRONMENTAL ASPECTS.10

4.3 * Information from the SUPPLY CHAIN .10

4.4 * Reduction of adverse ENVIRONMENTAL IMPACTS .11

4.5 Environmental information.11

Annex A (informative) General guidance and rationale.13

Annex B (informative) Guide to marking and labelling requirements for ME EQUIPMENT .28

Bibliography.29

Index of defined terms used in this collateral standard.30

Table A.1 – Example product LIFE-CYCLE stages .14

Table A.2 – Examples of ENVIRONMENTAL IMPACTS and their cause .20

Table A.3 – ENVIRONMENTAL ASPECTS and typical ENVIRONMENTAL IMPACTS .23

Table B.1 – ACCOMPANYING DOCUMENTS, General .28

Table B.2 – Other information .28

60601-1-9 © IEC:2007 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEDICAL ELECTRICAL EQUIPMENT –

Part 1-9: General requirements for basic safety

and essential performance –

Collateral Standard:

Requirements for environmentally conscious design

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International standard IEC 60601-1-9 has been prepared by IEC subcommittee 62A: Common

aspects of electrical equipment used in medical practice, of IEC technical committee 62:

Electrical equipment in medical practice.

This first edition constitutes a collateral standard to IEC 60601-1: Medical electrical

equipment – Part 1: General requirements for safety and essential performance hereafter

referred to as the general standard.

– 4 – 60601-1-9 © IEC:2007

The text of this standard is based on the following documents:

FDIS Report on voting

62A/571/FDIS 62A/575/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

In the 60601 series of publications, collateral standards specify general requirements for

safety applicable to:

– a subgroup of MEDICAL ELECTRICAL EQUIPMENT (e.g. radiological equipment); or

– a specific characteristic of all MEDICAL ELECTRICAL EQUIPMENT, not fully addressed in the

general standard (e.g. alarm systems).

In this collateral standard, the following print types are used:

– Requirements and definitions: roman type.

– Test specifications: italic type.

– Informative material appearing outside of tables, such as notes, examples and references: in smaller type.

Normative text of tables is also in a smaller type.

– TERMS DEFINED IN CLAUSE 3 OF THE GENERAL STANDARD, IN THIS COLLATERAL STANDARD OR AS

NOTED: SMALL CAPITALS.

In referring to the structure of this standard, the term

– “clause” means one of the four numbered divisions within the table of contents, inclusive

of all subdivisions (e.g. Clause 4 includes subclauses 4.1, 4.2, etc.);

– “subclause” means a numbered subdivision of a clause (e.g. 4.1, 4.5 and 4.5.1 are all

subclauses of Clause 4).

References to clauses within this standard are preceded by the term “Clause” followed by the

clause number. References to subclauses within this standard are by number only.

In this standard, the conjunctive “or” is used as an “inclusive or” so a statement is true if any

combination of the conditions is true.

The verbal forms used in this standard conform to usage described in Annex H of the ISO/IEC

Directives, Part 2. For the purposes of this standard, the auxiliary verb:

– “shall” means that compliance with a requirement or a test is mandatory for compliance

with this standard;

– “should” means that compliance with a requirement or a test is recommended but is not

mandatory for compliance with this standard;

– “may” is used to describe a permissible way to achieve compliance with a requirement or

test.

Clauses, subclauses and definitions for which a rationale is provided in informative Annex A

are marked with an asterisk (*).

A list of all parts of the IEC 60601 series, published under the general title Medical electrical

equipment, can be found on the IEC website.

60601-1-9 © IEC:2007 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 60601-1-9 © IEC:2007

INTRODUCTION

The objective of this collateral standard is to improve the ENVIRONMENTAL IMPACT for the entire

range of MEDICAL ELECTRICAL EQUIPMENT, taking into account all stages of the product LIFE

CYCLE:

– product specification;

– design;

– manufacturing;

– sales, logistics, installation;

– use;

– END OF LIFE management.

This means protecting the ENVIRONMENT and human health from HAZARDOUS SUBSTANCES,

conserving raw materials and energy, minimizing the generation of WASTE, as well as

minimizing the adverse ENVIRONMENTAL IMPACTS associated with WASTE. The criteria needed to

reach this goal must be integrated into all stages of the MEDICAL ELECTRICAL EQUIPMENT LIFE

CYCLE from the specification stage to END OF LIFE management.

The ENVIRONMENTAL IMPACTS of ME EQUIPMENT through all LIFE-CYCLE stages are determined

from the MEDICAL ELECTRICAL EQUIPMENT’S ENVIRONMENTAL ASPECTS defined during the

identification of need, product planning, and design stages (see Table A.1). Consideration of

ENVIRONMENTAL ASPECTS as early as possible in these stages can produce numerous benefits

that might include lower costs, stimulation of innovation and creativity, and increased

knowledge about the product. It can also provide new business opportunities, and improved

product quality as well as reduction of adverse ENVIRONMENTAL IMPACTS. The assessment of

the ENVIRONMENTAL ASPECTS and IMPACTS of MEDICAL ELECTRICAL EQUIPMENT is a developing

science and it is anticipated that this collateral standard will require periodic updating as the

science develops.

The requirements given in this collateral standard do not replace national or international laws

and regulations.

Environmental protection is one element of the overall RISK MANAGEMENT PROCESS as required

by the general standard.

The acceptability of MEDICAL ELECTRICAL EQUIPMENT'S ENVIRONMENTAL IMPACTS are balanced

against other factors, such as the product’s intended function, performance, safety, cost,

marketability, quality, legal and regulatory requirements. This balance can differ depending on

the intended function of the MEDICAL ELECTRICAL EQUIPMENT. For example, a solution

appropriate for life-saving or life-supporting MEDICAL ELECTRICAL EQUIPMENT might not be

appropriate for a device intended to correct a minor ailment. A MANUFACTURER of MEDICAL

ELECTRICAL EQUIPMENT might have to justify, as a result of RISK MANAGEMENT, that a medical

benefit outweighs the associated adverse ENVIRONMENTAL IMPACTS.

60601-1-9 © IEC:2007 – 7 –

MEDICAL ELECTRICAL EQUIPMENT –

Part 1-9: General requirements for basic safety

and essential performance –

Collateral Standard:

Requirements for environmentally conscious design

1 Scope, object and related standards

1.1 * Scope

This International Standard applies to the reduction of adverse ENVIRONMENTAL IMPACTS of

MEDICAL ELECTRICAL EQUIPMENT, hereafter referred to as ME EQUIPMENT.

MEDICAL ELECTRICAL SYSTEMS are excluded from the scope of this collateral standard.

1.2 Object

The object of this collateral standard is to specify general requirements, in addition to those of

the general standard, for the reduction of the adverse ENVIRONMENTAL IMPACT of

ME EQUIPMENT, and to serve as the basis for particular standards.

1.3 Related standards

1.3.1 IEC 60601-1

For ME EQUIPMENT, this collateral standard complements IEC 60601-1.

When referring to IEC 60601-1 or to this collateral standard, either individually or in

combination, the following conventions are used:

– "the general standard" designates IEC 60601-1 alone;

– "this collateral standard" designates IEC 60601-1-9 alone;

– "this standard" designates the combination of the general standard and this collateral

standard.

1.3.2 Particular standards

A requirement in a particular standard takes priority over the corresponding requirement in

this collateral standard.

1.3.3 Environmental standards

This standard takes into account the ISO 14000 series of environmental standards with

1)

particular emphasis on ISO 14062 [8] .

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

—————————

1)

Figures in square brackets refer to the Bibliography.

– 8 – 60601-1-9 © IEC:2007

IEC 60601-1:2005, Medical electrical equipment – Part 1: General requirements for basic

safety and essential performance

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60601-1:2005 and

the following definitions apply.

NOTE An index of defined terms is found beginning on page 30.

3.1

DESIGN AND DEVELOPMENT

set of PROCESSES that transforms requirements into specified characteristics or into the

specification of a product, PROCESS or system

NOTE 1 The terms “design” and “development” are sometimes used synonymously and sometimes used to define

different stages of the overall PROCESS of turning an idea into a product.

NOTE 2 Product development is the PROCESS of taking a product idea from planning to market launch and post-

market review of the product, in which business strategies, marketing considerations, research methods and design

aspects are used to take a product to a point of practical use. It includes improvements or modifications to existing

products or PROCESSES

NOTE 3 The integration of ENVIRONMENTAL ASPECTS into product DESIGN AND DEVELOPMENT can also be termed

design for the ENVIRONMENT (DFE), eco-design, the environmental part of product stewardship, etc.

[ISO/TR 14062:2002, definition 3.3]

3.2

END OF LIFE

EOL

state of a ME EQUIPMENT when it is finally removed from its INTENDED USE

NOTE Adapted from IEC Guide 109:2003, Definition 3.1.

3.3

ENVIRONMENT

surroundings in which an ORGANIZATION operates, including air, water, land, natural resources,

flora, fauna, humans and their interrelation

NOTE Surroundings in this context extend from within an ORGANIZATION to the global system.

[ISO 14001:2004, definition 3.5]

3.4

* ENVIRONMENTAL ASPECT

element of an ORGANIZATION’S activities, products or services that can interact with the

ENVIRONMENT

NOTE A significant ENVIRONMENTAL ASPECT has or can have a significant ENVIRONMENTAL IMPACT.

[ISO 14001:2004, definition 3.6]

3.5

* ENVIRONMENTAL IMPACT

any change to the ENVIRONMENT, whether adverse or beneficial, wholly or partially resulting

from an ORGANIZATION'S ENVIRONMENTAL ASPECTS

[ISO 14001:2004, definition 3.7]

60601-1-9 © IEC:2007 – 9 –

3.6

HAZARDOUS SUBSTANCE

substance which can affect human health or the ENVIRONMENT with an immediate or retarded

effect

[IEC Guide 109: 2003, definition 3.6, modified]

3.7

LIFE CYCLE

consecutive and interlinked stages of a product system, from raw material acquisition or

generation from natural resources to final disposal

[ISO 14040:2006, definition 3.1]

3.8

LIFE-CYCLE ASSESSMENT

LCA

compilation and evaluation of the inputs, outputs and the potential ENVIRONMENTAL IMPACTS of

a product system throughout its LIFE CYCLE

[ISO 14040:2006, definition 3.2]

3.9

ORGANIZATION

company, corporation, firm, enterprise, authority or institution, or part or combination thereof,

whether incorporated or not, public or private, that has its own functions and administration

NOTE For ORGANIZATIONS with more than one operating unit, a single operating unit may be defined as an

ORGANIZATION.

[ISO 14001:2004, definition 3.16]

3.10

PACKAGING

material that is used to protect or contain a product during transportation, storage and

marketing

NOTE 1 For the purposes of this standard, the term PACKAGING also includes any item that is physically attached

to, or included with, a product or its container for the purpose of marketing the product.

NOTE 2 Adapted from ISO 14021:1999, definition 3.1.10.

3.11

RECYCLING

reprocessing in a production PROCESS of the WASTE materials for the original purpose or for

other purposes but excluding energy recovery

[IEC Guide 109:2003, definition 3.16]

3.12

REUSE

utilization of ME EQUIPMENT or a part of ME EQUIPMENT, after it has been disposed of by the

RESPONSIBLE ORGANIZATION as WASTE, for a similar purpose to that for which it was originally

intended by the MANUFACTURER

3.13

SUPPLY CHAIN

those involved, through upstream and downstream linkages, in PROCESSES and activities

delivering value in the form of products to the MANUFACTURER

NOTE 1 In practice, the expression “interlinked chain” applies from suppliers to those involved in END OF LIFE

processing.

NOTE 2 In practice, the expressions “product chain”, “value chain” are often used.

NOTE 3 Adapted from ISO/TR 14062:2002, definition 3.9.

– 10 – 60601-1-9 © IEC:2007

3.14

WASTE

substance or object which the holder disposes of, or is required to dispose of, pursuant to the

provisions of national law in force

[IEC Guide 109:2003, definition 3.18]

4 Protection of the ENVIRONMENT

4.1 * Identification of ENVIRONMENTAL ASPECTS

HE MANUFACTURER shall establish, implement and maintain a PROCESS to identify and

T

document the relevant ENVIRONMENTAL ASPECTS of ME EQUIPMENT across all LIFE-CYCLE stages.

Examples of ENVIRONMENTAL ASPECTS are:

– use of HAZARDOUS SUBSTANCES;

– emissions to air;

– releases to surface water and ground water;

– WASTE, especially HAZARDOUS SUBSTANCES;

– use of natural resources, energy and raw materials;

– noise, vibration, odour, dust, electromagnetic fields etc.;

– transport (both for goods and services and employees);

– RISKS from environmental accidents and ENVIRONMENTAL IMPACTS arising, or likely to arise,

as consequences of incidents, accidents and potential emergency situations; and

– use and contamination of the biosphere.

Compliance is checked by inspection of the relevant design documents and PROCESS

description.

4.2 * Determination of significant ENVIRONMENTAL ASPECTS

MANUFACTURER shall establish, implement and maintain a PROCESS to qualitatively or

The

quantitatively determine and document the ENVIRONMENTAL ASPECTS that can have significant

ENVIRONMENTAL IMPACTS (i.e. significant ENVIRONMENTAL ASPECTS) during all LIFE-CYCLE stages

of the ME EQUIPMENT.

Compliance is checked by inspection of the relevant design documents and PROCESS

description.

4.3 * Information from the SUPPLY CHAIN

The MANUFACTURER shall establish, implement and maintain PROCESSES to:

– identify those suppliers (including services) that are likely to contribute significant

ENVIRONMENTAL ASPECTS to the ME EQUIPMENT; and

– obtain from those SUPPLIERS the information necessary to assist the MANUFACTURER in

identifying and assessing the ENVIRONMENTAL ASPECTS of the ME EQUIPMENT as required in

4.1 and 4.2.

If, despite the MANUFACTURER’S efforts, ORGANIZATIONS within the SUPPLY CHAIN fail to provide

the information requested by the MANUFACTURER, the MANUFACTURER shall provide an

estimation of the missing information and document the rationale.

NOTE To fully assess the ENVIRONMENTAL ASPECTS across the entire life of the ME EQUIPMENT it is necessary for

the MANUFACTURER to gather information and involve the environmentally significant SUPPLIERS during the concept

and design stage.

60601-1-9 © IEC:2007 – 11 –

Compliance is checked by inspection of the relevant design documents and PROCESS

description.

4.4 * Reduction of adverse ENVIRONMENTAL IMPACTS

The MANUFACTURER shall establish and document targets for the significant ENVIRONMENTAL

ASPECTS of the ME EQUIPMENT to minimize as far as reasonable the adverse ENVIRONMENTAL

IMPACTS across all LIFE-CYCLE stages. The documented targets shall be based on functional as

well as environmental requirements, and, when available, previous product designs.

During the ME EQUIPMENT concept and specification setting stage, the MANUFACTURER shall

consider, as far as reasonable, novel emerging or alternative technologies and/or solutions for

the ME EQUIPMENT that reduce significant adverse ENVIRONMENTAL IMPACTS.

The MANUFACTURER shall assess and document the actual significant ENVIRONMENTAL ASPECTS

across all LIFE-CYCLE stages of a representative prototype of the final design of the ME

EQUIPMENT. Any deviations from the targets shall be assessed and documented for

consideration in future designs.

Compliance is checked by inspection of the relevant design documents.

4.5 Environmental information

4.5.1 * PACKAGING of ME EQUIPMENT

The MANUFACTURER shall make available information on the type and mass of PACKAGING

material(s).

NOTE ‘Type’ of PACKAGING refers, as a minimum, to the generic description (e.g. cardboard, plastic, wood, glass

etc).

Compliance is checked by verifying the availability of the information.

4.5.2 * Instructions for minimizing ENVIRONMENTAL IMPACT during NORMAL USE

The MANUFACTURER shall provide instructions for minimizing the ENVIRONMENTAL IMPACT of the

ME EQUIPMENT during NORMAL USE in the ACCOMPANYING DOCUMENTS.

The instructions shall cover the following items where applicable:

– instructions on how to install the ME EQUIPMENT in order to minimize the ENVIRONMENTAL

IMPACT during its EXPECTED SERVICE LIFE;

– instructions on how to use and maintain the ME EQUIPMENT in order to minimize the

ENVIRONMENTAL IMPACT during its EXPECTED SERVICE LIFE;

– consumption during NORMAL USE (e.g. energy, consumable materials/parts, disposables,

water, gasses, chemicals/reagents etc.);

– emissions during NORMAL USE (e.g. WASTE water, WASTE consumable materials, acoustic

energy, heat, gasses, vapours, particulates, HAZARDOUS SUBSTANCES and other WASTE);

and

– information on the location within the ME EQUIPMENT of HAZARDOUS SUBSTANCES,

radioactive sources and induced radioactive materials.

Compliance is checked by inspection of the ACCOMPANYING DOCUMENTS.

– 12 – 60601-1-9 © IEC:2007

4.5.3 * Information for END OF LIFE management

The MANUFACTURER shall provide the RESPONSIBLE ORGANIZATION with information for the

proper disposal of the ME EQUIPMENT at END OF LIFE.

The MANUFACTURER shall make available information to WASTE treatment facilities necessary

for the environmentally responsible management of END OF LIFE ME EQUIPMENT. The

information shall contain:

– the location of components and parts within the ME EQUIPMENT that contain stored energy

or pose other HAZARDS that can result in an unacceptable RISK to disassemblers or others

and methods for controlling such RISKS;

– the identity and location of HAZARDOUS SUBSTANCES requiring special handling and

treatment; and

– disassembly instructions sufficient for the safe removal of these HAZARDOUS SUBSTANCES

including radioactive sources and induced radioactive materials within the ME EQUIPMENT.

Compliance is checked by verifying the availability of the information.

60601-1-9 © IEC:2007 – 13 –

Annex A

(informative)

General guidance and rationale

A.1 General guidance

In the future, MANUFACTURERS and RESPONSIBLE ORGANIZATIONS will be required to holistically

meet enhanced environmental criteria and to further improve product quality and safety.

ME EQUIPMENT is intended to have beneficial effects on humans. However if the damage to the

ENVIRONMENT caused by the ME EQUIPMENT outweighs the medical benefits, this is counter-

productive to the intended function of the ME EQUIPMENT. ME EQUIPMENT should be designed,

manufactured, used and discarded in a manner that is environmentally responsible.

The objective of this collateral standard is to reduce the ENVIRONMENTAL IMPACTS of the

ME EQUIPMENT taking into account all the ME EQUIPMENT LIFE-CYCLE stages. Benefits of

implementing this collateral standard include, for example, the reduction of potential sources

of HARM, HAZARDOUS SUBSTANCES and WASTE, and savings of natural resources, raw materials

and energy. Benefits can be grouped into transportation reduction, cost reduction and a

positive public perception of the MANUFACTURER as a good corporate citizen.

LIFE-CYCLE ASSESSMENT is a tool that can be used to reduce the ENVIRONMENTAL IMPACT of ME

EQUIPMENT. The principle and framework for LIFE-CYCLE ASSESSMENT is described in

ISO 14040 [7]. MANUFACTURERS undertaking LIFE-CYCLE ASSESSMENT will have to select or

develop their own PROCESSES and assessment tools to achieve product-related environmental

improvements.

The ENVIRONMENTAL IMPACTS of ME EQUIPMENT are largely determined during the DESIGN AND

DEVELOPMENT stage. Therefore, in order to reduce the adverse ENVIRONMENTAL IMPACTS of the

new ME EQUIPMENT:

– adverse ENVIRONMENTAL IMPACT reduction should be seen as starting at the identification of

need and flowing throughout DESIGN AND DEVELOPMENT;

– it is highly desirable to start the ENVIRONMENTAL ASPECT/IMPACT assessment as early as

possible in product planning.

Typically the ME EQUIPMENT LIFE CYCLE includes the stages in Table A.1. Table A.1 contains

both environmental considerations and, where applicable, examples of ENVIRONMENTAL

ASPECTS for each LIFE-CYCLE stage.

Environmental protection is not a subject that is covered in all engineering training.

Consequently this rationale is more detailed than normal for a standard of this type.

The following is one of many examples of the LIFE-CYCLE stages of ME EQUIPMENT.

– 14 – 60601-1-9 © IEC:2007

Table A.1 – Example product LIFE-CYCLE stages

Stage Activity Characteristics Environmental considerations

Identification of a market need (including It might be possible to meet the identified need

environmental expectations). For example, by solutions not requiring the production of a

Exploration,

market needs can be defined from direct new product. The ENVIRONMENTAL ASPECTS of

identification of

customer demand or market feedback. adapting existing products or non-physical

opportunities and

product solutions (e.g. a time counter can be

management

replaced by a software module or hardware

decision

can be replaced by a service solution) should

be explored.

A solution requiring a product has been Define and assess ENVIRONMENT-related

identified. Comparison of the expected targets. Identify requirements that result from

ENVIRONMENTAL IMPACTS of the proposed these targets. Establish these requirements in

product against previous or competitive the requirement specification (e.g. reduce

products is appropriate. Legal and other energy consumption over the product LIFE

normative information needs to be CYCLE by 20%).

considered.

Requirement

specification

The Requirement specification is created.

The requirement specification should detail

required performance and not propose

specific solutions, so as to allow innovative

and novel approaches.

The project is formalized.

The point at which preliminary solutions to The optimal stage at which to consider creative

the need are explored. Ideas will be solutions to reduce adverse ENVIRONMENTAL

documented informally; the design will be IMPACTS. e.g. consideration can be given to:

very fluid. Up to this point, there has been

– modifying, upgrading, refurbishing

little commitment of time or materials.

existing products

Communications with suppliers are informal

– novel technologies

and exploratory.

– creative design solutions

– alternative material choice (Including

reduction/removal of HAZARDOUS

SUBSTANCES)

– use of recycled materials

– use of recovered components/assemblies

– new production PROCESSES

– alternative energy sources

– PACKAGING

– Reduction/elimination of consumables

Product concept

– Service and maintenance

– Extended durability

– Marketing and promotional materials

– END OF LIFE REUSE/RECYCLING and

material recovery

There might be experimentation with different

configurations so that the design solution with

the optimum balance between product benefit,

performance and ENVIRONMENTAL IMPACT can

be easily and cost-effectively established.

Most appropriate point at which the

assessment of product ENVIRONMENTAL

ASPECTS and ENVIRONMENTAL IMPACTS can be

determined. Strategic suppliers become

involved in the design solutions and start to

become important to the environmental profile

of the ME EQUIPMENT.

Identification of

Planning

need

60601-1-9 © IEC:2007 – 15 –

Table A.1 – Example product LIFE-CYCLE stages (continued)

Stage Activity Characteristics Environmental considerations

Design solution now becoming Establish environmental targets and

established. Information necessary requirements for the design, considering all

to turn the concept into a formal LIFE-CYCLE stages, in the design specification.

product is gathered. Components

The design is refined and incremental

and assemblies are developed or

environmentally beneficial changes can

sourced. Although changes to the

usually be made, especially in the areas of

specification can be made, this now

material reduction and component selection.

starts to incur costs.

Appropriate production PROCESSES should be

considered as these can be a significant

source of adverse ENVIRONMENTAL IMPACTS. All

suppliers start to become integrated into the

development PROCESS and their environmental

performance will have effects on the overall

DESIGN AND

ENVIRONMENTAL IMPACT of the ME EQUIPMENT.

DEVELOPMENT

Consideration must be given to limiting the

amount and number of materials used in the

ME EQUIPMENT. (As a general rule the smaller

and lighter the better, as this has a

subsequent benefit on PACKAGING,

transportation and END OF LIFE as well.)

Efforts should be made to eliminate

HAZARDOUS SUBSTANCES both in the product

and during the production PROCESS.

Where the use of HAZARDOUS SUBSTANCES is

unavoidable ME EQUIPMENT construction and

operation should consider RISKS.

Design now established and major The ENVIRONMENTAL IMPACT of the ME

changes now only possible at great EQUIPMENT design should be confirmed against

Prototype expense. A physical model exists. the assessment documented at the product

testing Testing against the specification will concept stage.

including TYPE have commenced and design will be

Significant deviations from expected results

TESTING validated against original need.

should be investigated.

Representative sample(s) can be

submitted for TYPE TESTING.

Manufactured ME EQUIPMENT Consideration should be given to

subjected to final testing to ensure ENVIRONMENTAL ASPECTS resulting from

Product testing

quality and confirm conformance extreme operating conditions (e.g. as a result

with standards. of safety factor / margin).

The design of the ME EQUIPMENT is Production PROCESS ENVIRONMENTAL ASPECTS

now fixed and is being manufactured (e.g. production WASTE, water usage, energy

to revision controlled drawings and consumption, component logistics, HAZARDOUS

Product

assembly method sheets. SUBSTANCES) should be considered.

manufacturing

SUPPLY CHAIN PROCESSES and work sub-

contracted out should also be considered.

Production Testing Design

– 16 – 60601-1-9 © IEC:2007

Table A.1 – Example product LIFE-CYCLE stages (continued)

Stage Activity Characteristics Environmental considerations

ME EQUIPMENT can be in final Consideration needs to be given to adverse

PACKAGING and is stored pending ENVIRONMENTAL IMPACTS caused by failure of

Storage shipment to RESPONSIBLE the ME EQUIPMENT when stored outside the

ORGANIZATIONS. specified storage conditions, e.g. by bursting a

container that leaks corrosive materials.

ME EQUIPMENT being shipped to Consideration needs to be given to type and

designated sites. reusability of PACKAGING, transportation

method, weight of ME EQUIPMENT and whether

the ME EQUIPMENT can be assembled on site or

shipped assembled. Logistical efficiency can

be enhanced by:

– contracting suppliers / subcontractors to

Product

deliver directly to the RESPONSIBLE

transport

ORGANIZATION / distributor if possible

– by ensuring that packaged ME EQUIPMENT

can stack efficiently in standard generic

transportation containers.

– collecting old products for REUSE,

recovery or RECYCLING.

New ME EQUIPMENT is installed at Although installation is not normally

site prior to being used. environmentally significant, should the product

require substantial quantities of HAZARDOUS

SUBSTANCES (e.g. transformer oil)

consideration has to be given to ease of

transportation and handling of these

Installation

substances, as well as the disposal of any

excess at the end of the installation PROCESS.

The use of specialized mechanical handling or

assembly tools should be avoided where

possible.

Distribution

60601-1-9 © IEC:2007 – 17 –

Table A.1 – Example product LIFE-CYCLE stages (continued)

Stage Activity Characteristics Environmental considerations

NORMAL USE INTENDED USE of ME EQUIPMENT Examples of ENVIRONMENTAL ASPECTS during

NORMAL USE include:

− energy

− consumables (including batteries)

− chemicals (especially HAZARDOUS

SUBSTANCES)

− natural resources, e.g. water

− smoke or gasses

− WASTE (including contaminated material)

− heat (e.g. ME EQUIPMENT could make

substantial demands on air-conditioning)

The consumption of energy during NORMAL USE

can be a major ENVIRONMENTAL ASPECT of ME

EQUIPMENT and should not be overlooked.

Repair and ME EQUIPMENT is maintained or Examples of ENVIRONMENTAL ASPECTS to be

maintenance repaired to ensure continued considered are:

operation to specification.

– WASTE (service materials, spare parts)

– transportation (technical staff / spare

parts)

– HAZARDOUS SUBSTANCES (used in technical

maintenance)

– PACKAGING WASTE (spare parts)

– energy use (testing and calibration)

– emissions to:

– air

– soil

– ground water/rivers

– sewer

– water usage:

– ground (water extraction)

– purchased / purified

Service and maintenance can be very

important in ensuring that ME EQUIPMENT works

at peak efficiency.

Removal from RESPONSIBLE ORGANIZATION has no RESPONSIBLE ORGANIZATION decides whether

service further use for the ME EQUIPMENT. to:

a

– sell second hand

– transfer to the MANUFACTURER or other

b

authorized ORGANIZATION

– The ME EQUIPMENT is refurbished

and resold

– The ME EQUIPMENT is disassembled

and parts / components are

incorporated into new products or

used as spare parts

– The ME EQUIPMENT is disassembled

and parts/components recycled

(EOL)

– The ME EQUIPMENT is put to landfill /

incineration (EOL)

– disposed of as WASTE. (EOL)

– send to treatment centre for

RECYCLING

– THE ME EQUIPMENT is landfilled

c

/incinerated

END OF LIFE (EOL) Use

– 18 – 60601-1-9 © IEC:2007

Table A.1 – Example product LIFE-CYCLE stages (continued)

Stage Activity Characteristics Environmental considerations

Consideration must be given to the following.

The ME EQUIPMENT is disassembled

and parts / components reused or – MANUFACTURERS can gain new product

recycled. development information from the

examination of EOL components.

– It should generally be easy and safe for

people to remove HAZARDOUS SUBSTANCES

(e.g., consumable parts such as batteries

and oil) from the EOL ME EQUIPMENT. Full

instructions must be available to enable

RESPONSIBLE ORGANIZATIONS or others to

undertake these tasks.

The MANUFACTURER should provide

guidance if trained personnel are required

to remove the HAZARDOUS SUBSTANCES

(e.g. radioactive material)

– HAZARDS that can result in an

unacceptable RISK to disassemblers or

others (e.g. retained energy sources)

should be detailed. This is particularly

important if there is a possibility of those

working on the ME EQUIPMENT being

END OF LIFE

exposed to a biohazard.

(EOL)

management

– All HAZARDOUS SUBSTANCES with the

potential for leaching or which could

continue to present long-term RISK to

health or the ENVIRONMENT should be

removed from ME EQUIPMENT prior to

landfill. All local laws and regulations

controlling landfill disposal and

incineration should be complied with.

– In the case of the REUSE of components of

ME EQUIPMENT, consideration needs to be

made of the ENVIRONMENTAL ASPECTS

associated with the REUSE, in comparison

to the ENVIRONMENTAL ASPECTS of

producing a new (and possibly more

efficient) component with lower

ENVIRONMENTAL IMPACTS.

– Recovered materials must be channelled

into the appropriate recovery stream

– Transportation can have a significant

effect on the viability of any recovery

operation.

The ME EQUIPMENT (or Landfilling or incinerating WASTE

parts / components) are ME EQUIPMENT / components / parts is the least

landfilled/incinerated. environmentally desirable route of disposal.

Landfill or incineration should only be

considered when all other options have been

explored, and found to be unfeasible. Many

countries have very strict laws on what may or

may not be landfilled.

a

Continued use of equipment can have significant environmental advantages, however the continued use of

ME EQUIPMENT in a clinical application can carry higher PATIENT RISK.

b

"Authorized ORGANIZATION" is an ORGANIZATION authorised by the MANUFACTURER and/or national authorities, t

...

IEC 60601-1-9 ®

Edition 1.1 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Medical electrical equipment –

Part 1-9: General requirements for basic safety and essential performance –

Collateral Standard: Requirements for environmentally conscious design

Appareils électromédicaux –

Partie 1-9: Exigences générales pour la sécurité de base et les performances

essentielles – Norme collatérale: Exigences pour une conception éco-

responsable

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60601-1-9 ®

Edition 1.1 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Medical electrical equipment –

Part 1-9: General requirements for basic safety and essential performance –

Collateral Standard: Requirements for environmentally conscious design

Appareils électromédicaux –

Partie 1-9: Exigences générales pour la sécurité de base et les performances

essentielles – Norme collatérale: Exigences pour une conception éco-

responsable

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 11.040; 13.020 ISBN 978-2-8322-0876-2

– 2 – 60601-1-9 IEC:2007+A1:2013

CONTENTS

FOREWORD . 3

INTRODUCTION . 6

INTRODUCTION TO THE AMENDMENT . 7

1 Scope, object and related standards . 8

1.1 * Scope . 8

1.2 Object . 8

1.3 Related standards . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Protection of the ENVIRONMENT . 11

4.1 * Identification of ENVIRONMENTAL ASPECTS . 11

4.2 * Determination of significant ENVIRONMENTAL ASPECTS . 11

4.3 * Information from the SUPPLY CHAIN . 11

4.4 * Reduction of adverse ENVIRONMENTAL IMPACTS . 12

4.5 Environmental information . 12

Annex A (informative) General guidance and rationale . 14

Annex B (informative) Guide to marking and labelling requirements for ME EQUIPMENT . 29

Bibliography . 30

Index of defined terms used in this collateral standard . 31

Table A.1 – Example product LIFE-CYCLE stages . 15

Table A.2 – Examples of ENVIRONMENTAL IMPACTS and their cause . 21

Table A.3 – ENVIRONMENTAL ASPECTS and typical ENVIRONMENTAL IMPACTS . 24

Table B.1 – ACCOMPANYING DOCUMENTS, General . 29

Table B.2 – Other information . 29

60601-1-9 IEC:2007+A1:2013 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEDICAL ELECTRICAL EQUIPMENT –

Part 1-9: General requirements for basic safety

and essential performance –

Collateral Standard:

Requirements for environmentally conscious design

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 60601-1-9 consists of the first edition (2007)

[documents 62A/571/FDIS and 62A/575/RVD] and its amendment 1 (2013) [documents

62A/874/FDIS and 62A/881/RVD]. It bears the edition number 1.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

– 4 – 60601-1-9 IEC:2007+A1:2013

International standard IEC 60601-1-9 has been prepared by IEC subcommittee 62A: Common

aspects of electrical equipment used in medical practice, of IEC technical committee 62:

Electrical equipment in medical practice.

The first edition of this publication constitutes a collateral standard to IEC 60601-1: Medical

electrical equipment – Part 1: General requirements for safety and essential performance

hereafter referred to as the general standard.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

In the 60601 series of publications, collateral standards specify general requirements for

safety applicable to:

– a subgroup of MEDICAL ELECTRICAL EQUIPMENT (e.g. radiological equipment); or

– a specific characteristic of all MEDICAL ELECTRICAL EQUIPMENT, not fully addressed in the

general standard (e.g. alarm systems).

In this collateral standard, the following print types are used:

– Requirements and definitions: roman type.

– Test specifications: italic type.

– Informative material appearing outside of tables, such as notes, examples and references: in smaller type.

Normative text of tables is also in a smaller type.

– TERMS DEFINED IN CLAUSE 3 OF THE GENERAL STANDARD, IN THIS COLLATERAL STANDARD OR AS

NOTED: SMALL CAPITALS.

In referring to the structure of this standard, the term

– “clause” means one of the four numbered divisions within the table of contents, inclusive

of all subdivisions (e.g. Clause 4 includes subclauses 4.1, 4.2, etc.);

– “subclause” means a numbered subdivision of a clause (e.g. 4.1, 4.5 and 4.5.1 are all

subclauses of Clause 4).

References to clauses within this standard are preceded by the term “Clause” followed by the

clause number. References to subclauses within this standard are by number only.

In this standard, the conjunctive “or” is used as an “inclusive or” so a statement is true if any

combination of the conditions is true.

The verbal forms used in this standard conform to usage described in Annex H of the ISO/IEC

Directives, Part 2. For the purposes of this standard, the auxiliary verb:

– “shall” means that compliance with a requirement or a test is mandatory for compliance

with this standard;

– “should” means that compliance with a requirement or a test is recommended but is not

mandatory for compliance with this standard;

– “may” is used to describe a permissible way to achieve compliance with a requirement or

test.

Clauses, subclauses and definitions for which a rationale is provided in informative Annex A

are marked with an asterisk (*).

A list of all parts of the IEC 60601 series, published under the general title Medical electrical

equipment, can be found on the IEC website.

60601-1-9 IEC:2007+A1:2013 – 5 –

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

NOTE The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC or

ISO publication in which to make products in accordance with the new requirements and to equip themselves for

conducting new or revised tests. It is the recommendation of the committee that the content of this publication be

adopted for mandatory implementation nationally not earlier than 3 years from the date of publication.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – 60601-1-9 IEC:2007+A1:2013

INTRODUCTION

The objective of this collateral standard is to improve the ENVIRONMENTAL IMPACT for the entire

range of MEDICAL ELECTRICAL EQUIPMENT, taking into account all stages of the product LIFE

CYCLE:

– product specification;

– design;

– manufacturing;

– sales, logistics, installation;

– use;

– END OF LIFE management.