IEC 60068-2-18:2017

(Main)Environmental testing - Part 2-18: Tests - Test R and guidance: Water

Environmental testing - Part 2-18: Tests - Test R and guidance: Water

IEC 60068-2-18:2017 provides methods of test applicable to products which, during transportation, storage or in service, can be subjected to falling water drops, impacting water, immersion or high pressure water impact. The primary purpose of water tests is to verify the ability of enclosures, covers and seals to maintain components and equipment in good working order after and, when necessary, under a standardized drop field or immersion in water.

These tests are not corrosion tests and cannot be considered and used as such.

Established water tests in other standards are not intended to simulate natural rainfall and their quoted intensities are too high to be adopted for that purpose. Therefore, in addition to the high-intensity severities, test R includes an artificial rain test based upon natural conditions but not taking into account high wind speeds generally associated with natural rain.

Guidance is given on the applicability of the tests and the severities to be selected.

This third edition cancels and replaces the second edition published in 2000. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a. addition of the new test method Rb 3.

Essais d'environnement - Partie 2-18: Essais - Essai R et guide: Eau

L’IEC 60068-2-18:2017 spécifie les méthodes d’essai applicables aux produits qui, pendant leur transport, leur stockage, ou alors qu’ils sont en service, peuvent être soumis à des chutes de gouttes d'eau, à des projections d’eau, à une immersion ou à des projections d’eau à haute pression. Le but premier des essais d’eau est de vérifier l’aptitude des enveloppes, des couvercles et des joints d’étanchéité à maintenir les composants et les matériels en bon état de marche après et, si besoin, pendant un arrosage par des gouttes d’eau ou une immersion dans l’eau normalisée.

Ces essais ne sont pas des essais de corrosion et ne peuvent pas être considérés ou utilisés comme tels.

Les essais d’eau déjà établis dans d’autres normes ne sont pas destinés à simuler les chutes de pluie naturelles et leurs intensités correspondantes sont trop élevées pour être utilisées dans ce but. En conséquence, en plus des sévérités de forte intensité, l’essai R comprend un essai de pluie artificielle basé sur des conditions naturelles, mais sans tenir compte des grands vents qui sont généralement associés à la pluie naturelle.

Des préconisations sont données sur l’applicabilité des essais et sur les sévérités à choisir.

Cette troisième édition annule et remplace la deuxième édition parue en 2000. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a. ajout de la nouvelle méthode d'essai Rb 3.

General Information

- Status

- Published

- Publication Date

- 09-Mar-2017

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- MT 18 - TC 104/MT 18

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Mar-2017

- Completion Date

- 17-Mar-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60068-2-18:2017 is an International Electrotechnical Commission (IEC) environmental testing standard that defines Test R - Water and guidance for evaluating equipment exposed to falling drops, impacting water and immersion. The standard specifies laboratory methods to verify that enclosures, covers and seals preserve the functioning of components and equipment during transportation, storage and in-service exposure to water. This third edition (2017) is a technical revision of the 2000 edition and introduces a new method (Rb 3 - fan jet).

Key topics and technical requirements

- Scope and objective: Confirm water ingress protection for enclosures and seals under standardized water exposures; explicitly not a corrosion test.

- Structured test families:

- Ra - Falling drops:

- Ra1: Artificial rain (based on natural conditions but limited wind effects)

- Ra2: Drip box

- Rb - Impacting water:

- Rb1: Oscillating tube and spray nozzle (two variants)

- Rb2: Water jet (hose/nozzle)

- Rb3: Fan jet (new in 2017)

- Rc - Immersion:

- Rc1: Water tank immersion

- Rc2: Pressurized water chamber immersion

- Ra - Falling drops:

- Test sequence elements: preconditioning, initial measurements, controlled exposure (severity selection), recovery, and final measurements - with guidance on what information must be specified for reproducible testing.

- Severities and applicability: Guidance is provided for selecting appropriate severities for product use-cases; many test severities are higher than natural rainfall and are intended to stress enclosures, not to simulate weather exactly.

- Test apparatus and verification: Annexes include recommended apparatus (oscillating tubes, spray/fan nozzles, pressurized chambers), measurement and verification guidance for intensity, drop size, water quality, and impact force.

- Relationship to IP codes: The standard maps test methods to enclosure protection levels and provides equivalence guidance with the IP Code (IEC 60529).

Practical applications - who uses this standard

- Product designers and enclosure manufacturers - to validate sealing designs and select gasket or enclosure classes.

- Test laboratories and QA teams - to perform repeatable water ingress tests for shipping/storage and field-exposure claims.

- Specification writers and procurement - to define contractual test requirements and severities for outdoor or transportable equipment.

- Regulatory and certification bodies - to harmonize test protocols and evidence for water resistance claims.

Related standards

- IEC 60529 (IP Code) - for degrees of protection against ingress of water/solids.

- Other IEC environmental test parts (60068 series) - complementary tests for mechanical, thermal and climatic stresses.

Keywords: IEC 60068-2-18, environmental testing, water tests, artificial rain, drip box, impacting water, immersion, water jet, fan jet, enclosure sealing, ingress protection, IEC 60529.

REDLINE IEC 60068-2-18:2017 - Environmental testing - Part 2-18: Tests - Test R and guidance: Water Released:3/10/2017 Isbn:9782832241066

IEC 60068-2-18:2017 - Environmental testing - Part 2-18: Tests - Test R and guidance: Water

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60068-2-18:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-18: Tests - Test R and guidance: Water". This standard covers: IEC 60068-2-18:2017 provides methods of test applicable to products which, during transportation, storage or in service, can be subjected to falling water drops, impacting water, immersion or high pressure water impact. The primary purpose of water tests is to verify the ability of enclosures, covers and seals to maintain components and equipment in good working order after and, when necessary, under a standardized drop field or immersion in water. These tests are not corrosion tests and cannot be considered and used as such. Established water tests in other standards are not intended to simulate natural rainfall and their quoted intensities are too high to be adopted for that purpose. Therefore, in addition to the high-intensity severities, test R includes an artificial rain test based upon natural conditions but not taking into account high wind speeds generally associated with natural rain. Guidance is given on the applicability of the tests and the severities to be selected. This third edition cancels and replaces the second edition published in 2000. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a. addition of the new test method Rb 3.

IEC 60068-2-18:2017 provides methods of test applicable to products which, during transportation, storage or in service, can be subjected to falling water drops, impacting water, immersion or high pressure water impact. The primary purpose of water tests is to verify the ability of enclosures, covers and seals to maintain components and equipment in good working order after and, when necessary, under a standardized drop field or immersion in water. These tests are not corrosion tests and cannot be considered and used as such. Established water tests in other standards are not intended to simulate natural rainfall and their quoted intensities are too high to be adopted for that purpose. Therefore, in addition to the high-intensity severities, test R includes an artificial rain test based upon natural conditions but not taking into account high wind speeds generally associated with natural rain. Guidance is given on the applicability of the tests and the severities to be selected. This third edition cancels and replaces the second edition published in 2000. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a. addition of the new test method Rb 3.

IEC 60068-2-18:2017 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing; 29.060.10 - Wires. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-18:2017 has the following relationships with other standards: It is inter standard links to IEC 60068-2-18:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-2-18:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-18 ®

Edition 3.0 2017-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Environmental testing –

Part 2-18: Tests – Test R and guidance: Water

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60068-2-18 ®

Edition 3.0 2017-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Environmental testing –

Part 2-18: Tests – Test R and guidance: Water

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.040 ISBN 978-2-8322-4106-6

– 2 – IEC 60068-2-18:2017 RLV © IEC 2017

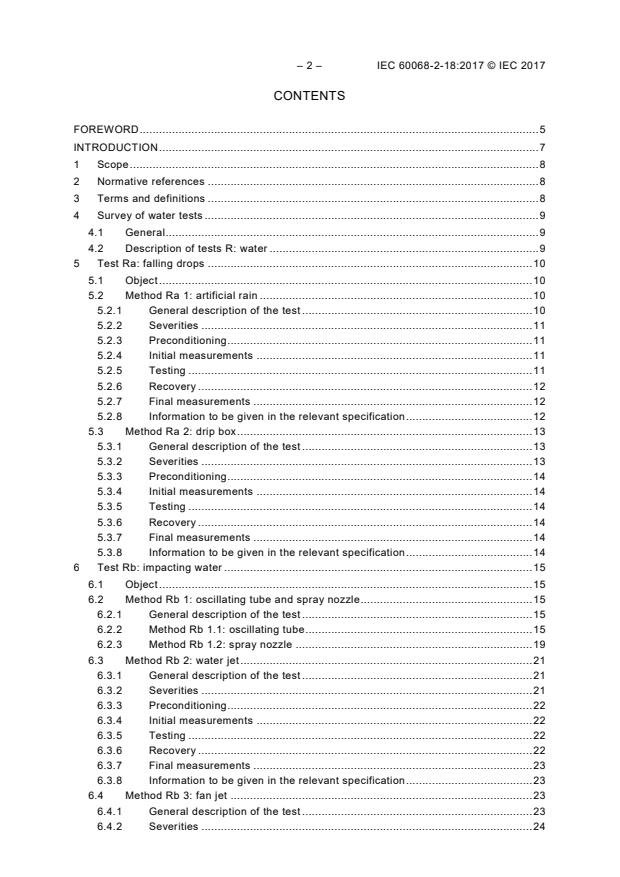

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope and object . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Survey of water tests . 9

4.1 General . 9

4.2 Description of tests R: water . 9

5 Test Ra: falling drops . 10

5.1 Object . 10

5.2 Method Ra 1: artificial rain . 10

5.2.1 General description of the test . 10

5.2.2 Severities . 11

5.2.3 Preconditioning . 11

5.2.4 Initial measurements . 11

5.2.5 Testing . 11

5.2.6 Recovery . 12

5.2.7 Final measurements . 12

5.2.8 Information to be given in the relevant specification . 12

5.3 Method Ra 2: drip box . 13

5.3.1 General description of the test . 13

5.3.2 Severities . 13

5.3.3 Preconditioning . 14

5.3.4 Initial measurements . 14

5.3.5 Testing . 14

5.3.6 Recovery . 14

5.3.7 Final measurements . 14

5.3.8 Information to be given in the relevant specification . 14

6 Test Rb: impacting water . 15

6.1 Object . 15

6.2 Method Rb 1: oscillating tube and spray nozzle . 15

6.2.1 General description of the test . 15

6.2.2 Method Rb 1.1: oscillating tube . 15

6.2.3 Method Rb 1.2: spray nozzle . 19

6.3 Method Rb 2: water jet . 21

6.3.1 General description of the test . 21

6.3.2 Severities . 21

6.3.3 Preconditioning . 22

6.3.4 Initial measurements . 22

6.3.5 Testing . 22

6.3.6 Recovery . 22

6.3.7 Final measurements . 23

6.3.8 Information to be given in the relevant specification . 23

6.4 Method Rb 3: fan jet . 23

6.4.1 General description of the test . 23

6.4.2 Severities . 24

6.4.3 Preconditioning . 24

6.4.4 Initial measurements . 24

6.4.5 Testing . 24

6.4.6 Recovery . 24

6.4.7 Final measurements . 24

6.4.8 Information to be given in the relevant specification . 25

7 Test Rc: immersion . 25

7.1 Object . 25

7.2 Method Rc 1: water tank . 25

7.2.1 General description . 25

7.2.2 Severities . 25

7.2.3 Preconditioning . 26

7.2.4 Initial measurements . 26

7.2.5 Testing . 26

7.2.6 Recovery . 26

7.2.7 Final measurements . 26

7.2.8 Information to be given in the relevant specification . 26

7.3 Method Rc 2: pressurized water chamber . 27

7.3.1 General description of the test . 27

7.3.2 Severities . 27

7.3.3 Preconditioning . 27

7.3.4 Initial measurements . 27

7.3.5 Testing . 27

7.3.6 Recovery . 28

7.3.7 Final measurements . 28

7.3.8 Information to be given in the relevant specification . 28

Annex A (informative) Water characteristics to be considered when writing the

relevant specification . 29

A.1 General . 29

A.2 Purity . 29

A.2.1 General . 29

A.2.2 Effect on test specimen . 29

A.2.3 Effect on test apparatus . 29

A.2.4 Ingress of water into the specimen . 30

A.3 Water quality for tests R . 30

A.3.1 Test Ra: falling drops. 30

A.3.2 Test Rb: impacting water . 30

A.3.3 Test Rc: immersion . 30

Annex B (informative) General guidance . 31

B.1 General . 31

B.2 Factors affecting the test severity . 31

Annex C (informative) Guidance for test Ra . 32

C.1 General . 32

C.2 Example of test apparatus . 32

C.2.1 Method Ra 1: artificial rain . 32

C.2.2 Method Ra 2: drip box . 33

C.3 Verification of test apparatus . 34

C.3.1 Intensity . 34

C.3.2 Drop size . 34

– 4 – IEC 60068-2-18:2017 RLV © IEC 2017

C.3.3 Resistivity and pH value . 34

Annex D (informative) Guidance for test Rb . 36

D.1 General . 36

D.2 Example of test apparatus . 36

D.2.1 Method Rb 1: oscillating tube and spray nozzle . 36

D.2.2 Method Rb 2: water jet . 37

D.2.3 Method Rb 3: fan jet nozzle . 38

Annex E (informative) Guidance for test Rc. 45

E.1 General . 45

E.2 Example of test apparatus . 45

E.2.1 Method Rc 1: water tank . 45

E.2.2 Method Rc 2: pressurized water chamber . 45

E.3 Verification of test apparatus . 45

Bibliography . 46

Figure 1 – Structuring of test methods and equivalence with the IP Code of IEC 60529 . 10

Figure 2 – Test Ra, definitions of angles and axes . 12

Figure C.1 – Test Ra 1, test apparatus and measurement setup for drop sizes and

intensity for artificial rain method . 33

Figure C.2 – Test Ra 2, recommended test apparatus for the drip box method . 35

Figure D.1 – Test Rb 1.1, recommended test apparatus for the oscillating tube method . 37

Figure D.2 – Distribution of mean value of precipitation intensity in the oscillating tube

area for the above-specified measurement conditions . 39

Figure D.3 – Test Rb 1.2, recommended test apparatus for the spray nozzle method . 40

Figure D.4 – Standard test nozzle for the water jet method (hose nozzle) . 40

Figure D.5 – Standard test nozzle for the fan jet method . 41

Figure D.6 – Fan jet nozzle resulting dimensions of spraying hole for checking purpose . 41

Figure D.7 – Example of different quality achievements of the surface finish of the fan

jet nozzle . 42

Figure D.8 – Set-up for measuring the impact force of the water jet for determining the

protection against high-pressure and high-temperature water jets . 43

Figure D.9 – Impact force distribution . 43

Figure D.10 – Test setup for determining the protection against high-pressure and

high-temperature water jet for small enclosures . 44

Table 1 – Oscillating tube – Relationship of number of nozzles and total water flow to

tube radius . 17

Table A.1 – Typical characteristics of water with approximate values . 30

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-18: Tests – Test R and guidance: Water

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 60068-2-18:2017 RLV © IEC 2017

International Standard IEC 60068-2-18 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This third edition cancels and replaces the second edition published in 2000. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) addition of the new test method Rb 3.

The text of this standard is based on the following documents:

FDIS Report on voting

104/719/FDIS 104/722/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

1)

It is the intention of this part of IEC 60068 to fulfil the function of a basic publication by

making water tests available to product committees.

A number of water tests are described in other IEC publications. Some of them are well

established, for example, the test for classification of the second characteristic numeral of the

IP Code, of IEC 60529.

This document incorporates the majority of the most widely used tests, as well as making

available further methods and increasing the number of severities.

________

1)

IEC Guide 108:1994, The relationship between technical committees with horizontal functions and product

committees and the use of basic publications

– 8 – IEC 60068-2-18:2017 RLV © IEC 2017

ENVIRONMENTAL TESTING –

Part 2-18: Tests – Test R and guidance: Water

1 Scope and object

This part of IEC 60068 provides methods of test applicable to products which, during

transportation, storage or in service, may can be subjected to falling water drops, impacting

water, immersion or high pressure water impact. The primary purpose of water tests is to

verify the ability of enclosures, covers and seals to maintain components and equipment in

good working order after and, when necessary, under a standardized drop field or immersion

in water.

These tests are not corrosion tests and should not cannot be considered and used as such.

The effects of a large temperature difference between the water and the specimen, such as

increased water ingress resulting from pressure changes, as well as thermal shock, are not

simulated.

Established water tests in other standards are not intended to simulate natural rainfall and

their quoted intensities are too high to be adopted for that purpose. Therefore, in addition to

the high-intensity severities, test R includes an artificial rain test based upon natural

conditions but not taking into account high wind speeds generally associated with natural rain.

Guidance is given on the applicability of the tests and the severities to be selected.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60068. For dated references, subsequent

amendments to, or revisions of, these publications do not apply. However, parties to

agreements based on this part of IEC 60068 are encouraged to investigate the possibility of

applying the most recent edition of the normative documents indicated below. For undated

references, the latest edition of the normative documents referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardisation at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

rain

precipitation in the form of water drops

Note 1 to entry: Both the amount that falls and the actual falling action of the water drops are often called rainfall.

3.2

drizzle

precipitation in the form of very small, numerous and uniformly dispersed water drops that

may appear to float while following air currents

3.3

raindrop

drop of water having a diameter greater than 0,5 mm falling through the atmosphere

3.4

drizzledrop

drop of water having a diameter of 0,2 mm to 0,5 mm falling through the atmosphere

3.5

R

rainfall or drizzle intensity

amount that falls per unit of time

Note 1 to entry: Rainfall intensity (R) is given in millimetres per hour (mm/h) where 1 l/(m · h) equals 1 mm/h.

3.6

D

median volume diameter

diameter of a drop whose size is such that 50 % of the volume of water reaching the ground is

comprised of smaller (or larger) drops

Note 1 to entry: Median volume diameter can be calculated using the formula:

0,19

D = 1,21 R (mm)

where R is the rainfall intensity (see 3.5).

4 Survey of water tests

4.1 General

This survey indicates the general structure of the various tests included in this document.

The structuring of the different tests is given in Figure 1.

4.2 Description of tests R: water

The water tests are structured into three groups.

• Ra: "falling drops" which, in principle, is a test with artificial rain and a test simulating

falling drops from condensation or leakage.

• Rb: "impacting water" where water jets impinge upon the test specimen with a certain

force and may assume any angle towards the test specimen.

• Rc: "immersion" where the test specimen is immersed in water to specified depths or

equivalent pressures.

– 10 – IEC 60068-2-18:2017 RLV © IEC 2017

Water tests

R

Falling drops Impacting water Immersion

Ra Rb Rc

Method Rc 1

Method Ra 1 Method Rb 1

Water tank

Artificial rain

– Method Rb 1.1

IPX7

Oscillating tube

IPX3 and IPX4

or

– Method Rb 1.2

Spray nozzle

(Hand-held shower)

IPX3 and IPX4

Method Ra 2

Method Rb 2

Method Rc 2

Drip box Water jet

Pressurized water

IPX1 and IPX2 IPX5 and IPX6

chamber

Method Rb 3

Fan jet

IPX9

IEC

Figure 1 – Structuring of test methods and equivalence with the IP Code of IEC 60529

5 Test Ra: falling drops

5.1 Object

This test is applicable to products which, during transportation, storage or in service may be

exposed to vertical falling drops, the origin of these being, for example, natural rain, seepage

or condensation. It shall be clearly stated in the relevant specification whether a product

hereinafter referred to as a specimen has to function during testing or merely to survive

conditions of falling drops. In either case, the relevant specification shall always prescribe

specify the acceptable tolerances in performance.

5.2 Method Ra 1: artificial rain

5.2.1 General description of the test

The test specimen is mounted on an appropriate fixture or base support. It is then subjected

to falling waterdrops, which simulate natural rain.

The basic requirements for the test apparatus are as follows.

• Drop-generating nozzle or nozzles (see C.2.1 and Figure C.1).

• Fixture for the specimen

The fixture shall simulate as far as possible the mounting of the specimen when in service;

for example, for wall-mounted equipment the fixture shall simulate a wall.

• Support of the test specimen

The support shall have a base area which is smaller than the base area of the specimen.

The support shall be either a turntable which has a rotation speed of 1 r/min and the

eccentricity (distance between turntable axis and specimen axis) is approximately

100 mm, or a table which does not turn. The support shall be able to hold the specimen in

any test position and, if necessary, be tilted to a maximum of 90° from the vertical plane.

• Water supply with controls

The water used for the test shall be fresh tap water of good quality. In order to avoid

clogging of the nozzles, the water shall be filtered and may be demineralized. Details of

the characteristics of the water are given in Annex A. During the test, the water

temperature shall not differ by more than 5 K from the temperature of the specimen under

test. If the water temperature is more than 5 K below the temperature of the specimen, a

pressure balance shall be provided for the specimen.

5.2.2 Severities

The severities, as indicated by intensity (and associated drop-size distribution), duration and

tilt angle of specimen shall be prescribed specified in the relevant specification. The values

shall be selected from those given below, a longer duration may be specified in the relevant

specification. Wind-driven rain is not simulated by this test as the wind velocity is not a

parameter of test.

• Intensity, mm/h and (associated drop-size distribution, mm):

10 ± 5 (D = 1,9 ± 0,2); 100 ± 20 (D = 2,9 ± 0,3); 400 ± 50 (D = 3,8 ± 0,4).

50 50 50

• Duration, min:

10, 30, 60, 120.

• Tilt angle α, degrees:

0, 15, 30, 60, 90.

NOTE The relevant specification may prescribe a longer duration.

5.2.3 Preconditioning

Preconditioning of the specimen and seals shall be carried out if prescribed specified in the

relevant specification.

5.2.4 Initial measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribed

by specified in the relevant specification. All features of the specimen likely to affect the test

result, for example surface treatment, enclosures, covers or seals, shall be inspected to

ensure that the instructions of the relevant specification have been followed.

5.2.5 Testing

The specimen shall be mounted on the support either

• in its normal operating position, as prescribed specified in the relevant specification; or

• tilted from the normal operating position and provision made for rotating the specimen in a

plane perpendicular to the tilted axis. The rotation may be achieved by a rotating support

table or by repositioning the specimen at regular intervals during the test. Alternatively,

the specimen can be oscillated through an arc of 270° to avoid the need for slip-ring

contacts.

– 12 – IEC 60068-2-18:2017 RLV © IEC 2017

The relevant specification shall specify the tilt angle or angles, the face or faces to be

exposed to the drop field and the duration of exposure for each side, or whether the specimen

shall be continuously rotated or oscillated through 270°. See also Figure 2.

The specimen shall be subjected to artificial rain with severities selected from 5.2.2 and

prescribed by specified in the relevant specification.

The relevant specification shall state whether the specimen shall be operated during testing

and if intermediate measurements shall be made.

Appropriate safety precautions shall be taken when testing the specimen in the energized

condition.

5.2.6 Recovery

Unless otherwise required in the relevant specification, the specimen shall be thoroughly

dried externally by wiping or by applying low-velocity forced air at room temperature.

Z

Z

α

Tilt angle

X

Y

Gimballed and rotatable table

IEC

Figure 2 – Test Ra, definitions of angles and axes

5.2.7 Final measurements

The specimen shall be examined for ingress of water and submitted to visual, dimensional

and functional checks prescribed by specified in the relevant specification.

Any ingress of water should be quantified if possible and reported.

5.2.8 Information to be given in the relevant specification

Where this test is included in the relevant specification, the following details shall be given in

so far as they are applicable. The relevant specification shall supply information as required in

the subclauses listed below, paying particular attention to the items marked with an asterisk

(*) as this information is always required.

Subclause

a) Severities* 5.2.2

b) Preconditioning 5.2.3

c) Initial measurements* 5.2.4

d) Mounting of specimen* 5.2.5

e) Specimen position or positions during testing* 5.2.5

f) State of the specimen during testing* 5.2.5

g) Intermediate measurements 5.2.5

h) Recovery 5.2.6

i) Final measurements* 5.2.7

5.3 Method Ra 2: drip box

5.3.1 General description of the test

The test specimen is mounted on an appropriate fixture placed under the drip box. The test

specimen is subjected to water drops, which simulate water falling as a result of condensation

or leakage.

The basic requirements for the test apparatus are as follows.

• Drip box

The drip box shall normally have a base area larger than the projected area of the

specimen. If the base of the drip box is smaller than that of the specimen under test, the

latter may be divided into several sections, the area of each section being large enough to

be covered by the dripping water. The test is continued until the whole area of the

specimen has been sprinkled for the specified time. The drip box shall be capable of

providing a uniform drop field with a precipitation of the specified intensity.

The grid pattern of the nozzles shall be 20 mm (for IP Code tests) or 25 mm. The distance

from the bottom of the drip box to the highest point of the specimen shall be adjustable to

either 0,2 m or 2 m. A suitable drip-box layout is described in C.2.2 and in Figure C.2.

• Fixture for the specimen

The fixture shall simulate as far as possible the mounting of the specimen when in service;

for example, for wall-mounted equipment the fixture shall simulate a wall.

• Support of the test specimen

The support shall have a base area which is smaller than the base area of the specimen.

The support shall either be a turntable which has a rotation speed of 1 r/min and an

eccentricity (distance between turntable axis and specimen axis) of approximately

100 mm, or a table which does not turn. The support shall be able to hold the specimen in

any test position and, if necessary, be tilted to a maximum of 45° from the vertical plane.

• Water supply with controls

The water used for the test shall be fresh tap water of good quality. In order to avoid

clogging of the nozzles, the water shall be filtered and may be demineralized. Details of

the characteristics of the water are given in annex A. During the test, the water

temperature shall not differ by more than 5 K from the temperature of the specimen under

test. If the water temperature is more than 5 K below the temperature of the specimen, a

pressure balance shall be provided for the specimen.

5.3.2 Severities

The severities, as indicated by drop falling height, tilt angle of specimen, duration and water

intensity, shall be prescribed specified in the relevant specification. The values shall be

selected from the following:

– 14 – IEC 60068-2-18:2017 RLV © IEC 2017

• Drop falling height, (h), m: 0,2; 2

• Tilt angle α, degrees: 0; 15; 30; 45

• Duration, min: 3; 10; 30; 60

NOTE The 3 min duration applies only when a tilt angle of 0° is specified.

+30 +30

• Water intensity, mm/h: 60 ; 180

0 0

5.3.3 Preconditioning

Preconditioning of the specimen and seals shall be carried out if prescribed specified in the

relevant specification.

5.3.4 Initial measurements

The specimen shall be submitted to the visual, dimensional and functional checks prescribed

by specified in the relevant specification. All the features of the specimen likely to affect the

test result, for example, surface treatment, covers or seals, shall be inspected to ensure that

the instructions of the relevant specification have been followed.

5.3.5 Testing

The specimen shall be mounted on the support in its normal operating position under the drip

box. The support shall then either be rotated or tilted to the specified angle in each of the four

positions of tilt. These positions are on either side of the vertical in two mutually perpendicular

planes. If a special mounting condition is required (for example, wall or ceiling), it shall be

prescribed by specified in the relevant specification.

In both cases, the test shall be carried out in the conditions specified in 5.3.1 and the severity

selected from 5.3.2.

In the case of tilted support, the duration shall be divided equally between the four positions.

The relevant specification shall state whether the specimen shall be operated during testing

and if intermediate measurements shall be made. Appropriate safety precautions shall be

taken when testing the specimen in the energized condition.

5.3.6 Recovery

Unless otherwise required in the relevant specification, the specimen shall be thoroughly

dried externally by wiping or by applying low-velocity forced air at room temperature.

5.3.7 Final measurements

The specimen shall be examined for ingress of water and submitted to visual, dimensional

and functional checks prescribed by specified in the relevant specification.

Any ingress of water should be quantified if possible and reported.

5.3.8 Information to be given in the relevant specification

Where this test is included in the relevant specification, the following details shall be given in

so far as they are applicable. The relevant specification shall supply information as required

in the subclauses listed below, paying particular attention to the items marked with an asterisk

(*) as this information is always required.

Subclause

a) Severities* 5.3.2

b) Preconditioning 5.3.3

c) Initial measurements* 5.3.4

d) Mounting of specimen* 5.3.5

e) Specimen position or positions during testing* 5.3.5

f) State of the specimen during testing* 5.3.5

g) Intermediate measurements 5.3.5

h) Recovery 5.3.6

i) Final measurements* 5.3.7

6 Test Rb: impacting water

6.1 Object

This test is applicable to products which, during transportation, storage or in service may be

subjected to impacting water. The origin for this can be water from cloudbursts, heavy driving

rain, sprinkler systems, pressure cleaning, spray from wheels, sluicing or breaking seas. The

relevant specification should clearly prescribe specify whether a product tested separately,

hereinafter referred to as a specimen, has to function during testing or merely survive

conditions of impacting water. In either case, the relevant specification shall always prescribe

specify the acceptable tolerances in performance.

6.2 Method Rb 1: oscillating tube and spray nozzle

6.2.1 General description of the test

The tests are intended to simulate spraying or splashing water, for example, the results of

water action of sprinkler systems. Guidance for this test is given in Annex D. The test is made

using either the test device described in Figure D.1 or the test device described in Figure D.3

in accordance with the relevant specification. The test specimen is mounted on an appropriate

fixture and is subjected to impacting water generated from either a semicircular tube or a

spray nozzle.

6.2.2 Method Rb 1.1: oscillating tube

6.2.2.1 Test apparatus

The basic requirements for the test apparatus are as follows.

• Oscillating tubes

Three types of tube may be used. The tube shall be provided with nozzles of either

0,4 mm diameter for type 1 and type 2 or 0,8 mm diameter for type 3, at a 50 mm

centre-to-centre distance over an arc of 60° on either side of the vertical for type 1 or 90°

on either side of the vertical for type 2 and type 3. The tube shall be able to oscillate

through an angle of 60° on either side of the vertical for type 1 or 180° on either side of

the vertical for type 2 and type 3.

The maximum acceptable radius of the oscillating tubes, type 1 and type 2 is 1 600 mm.

For oscillating tube type 3, the radius shall not exceed 800 mm. The radius shall be

selected in such a way that the clearance between the specimen and the inside of the tube

does not exceed 200 mm.

The relationship between the number of nozzles, each having a mean flow rate of

0,07 l/min or 0,6 l/min and the total flow rate is given in Table 2.

A suitable apparatus is shown in Figure D.1.

– 16 – IEC 60068-2-18:2017 RLV © IEC 2017

• Fixture for the specimen

The fixture shall simulate as far as possible the mounting structure to be used in the real

use of products; for example, for wall-mounted equipment, the fixture shall simulate a wall.

• Support for the specimen

The support for the specimen shall not be perforated for type 1 and shall

...

IEC 60068-2-18 ®

Edition 3.0 2017-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Environmental testing –

Part 2-18: Tests – Test R and guidance: Water

Essais d’environnement –

Partie 2-18: Essais – Essai R et guide: Eau

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60068-2-18 ®

Edition 3.0 2017-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Environmental testing –

Part 2-18: Tests – Test R and guidance: Water

Essais d’environnement –

Partie 2-18: Essais – Essai R et guide: Eau

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.040 ISBN 978-2-8322-4019-9

– 2 – IEC 60068-2-18:2017 © IEC 2017

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Survey of water tests . 9

4.1 General . 9

4.2 Description of tests R: water . 9

5 Test Ra: falling drops . 10

5.1 Object . 10

5.2 Method Ra 1: artificial rain . 10

5.2.1 General description of the test . 10

5.2.2 Severities . 11

5.2.3 Preconditioning . 11

5.2.4 Initial measurements . 11

5.2.5 Testing . 11

5.2.6 Recovery . 12

5.2.7 Final measurements . 12

5.2.8 Information to be given in the relevant specification . 12

5.3 Method Ra 2: drip box . 13

5.3.1 General description of the test . 13

5.3.2 Severities . 13

5.3.3 Preconditioning . 14

5.3.4 Initial measurements . 14

5.3.5 Testing . 14

5.3.6 Recovery . 14

5.3.7 Final measurements . 14

5.3.8 Information to be given in the relevant specification . 14

6 Test Rb: impacting water . 15

6.1 Object . 15

6.2 Method Rb 1: oscillating tube and spray nozzle . 15

6.2.1 General description of the test . 15

6.2.2 Method Rb 1.1: oscillating tube . 15

6.2.3 Method Rb 1.2: spray nozzle . 19

6.3 Method Rb 2: water jet . 21

6.3.1 General description of the test . 21

6.3.2 Severities . 21

6.3.3 Preconditioning . 22

6.3.4 Initial measurements . 22

6.3.5 Testing . 22

6.3.6 Recovery . 22

6.3.7 Final measurements . 23

6.3.8 Information to be given in the relevant specification . 23

6.4 Method Rb 3: fan jet . 23

6.4.1 General description of the test . 23

6.4.2 Severities . 24

6.4.3 Preconditioning . 24

6.4.4 Initial measurements . 24

6.4.5 Testing . 24

6.4.6 Recovery . 24

6.4.7 Final measurements . 24

6.4.8 Information to be given in the relevant specification . 25

7 Test Rc: immersion . 25

7.1 Object . 25

7.2 Method Rc 1: water tank . 25

7.2.1 General description . 25

7.2.2 Severities . 25

7.2.3 Preconditioning . 26

7.2.4 Initial measurements . 26

7.2.5 Testing . 26

7.2.6 Recovery . 26

7.2.7 Final measurements . 26

7.2.8 Information to be given in the relevant specification . 26

7.3 Method Rc 2: pressurized water chamber . 27

7.3.1 General description of the test . 27

7.3.2 Severities . 27

7.3.3 Preconditioning . 27

7.3.4 Initial measurements . 27

7.3.5 Testing . 27

7.3.6 Recovery . 28

7.3.7 Final measurements . 28

7.3.8 Information to be given in the relevant specification . 28

Annex A (informative) Water characteristics to be considered when writing the

relevant specification . 29

A.1 General . 29

A.2 Purity . 29

A.2.1 General . 29

A.2.2 Effect on test specimen . 29

A.2.3 Effect on test apparatus . 29

A.2.4 Ingress of water into the specimen . 30

A.3 Water quality for tests R . 30

A.3.1 Test Ra: falling drops. 30

A.3.2 Test Rb: impacting water . 30

A.3.3 Test Rc: immersion . 30

Annex B (informative) General guidance . 31

B.1 General . 31

B.2 Factors affecting the test severity . 31

Annex C (informative) Guidance for test Ra . 32

C.1 General . 32

C.2 Example of test apparatus . 32

C.2.1 Method Ra 1: artificial rain . 32

C.2.2 Method Ra 2: drip box . 33

C.3 Verification of test apparatus . 34

C.3.1 Intensity . 34

C.3.2 Drop size . 34

– 4 – IEC 60068-2-18:2017 © IEC 2017

C.3.3 Resistivity and pH value . 34

Annex D (informative) Guidance for test Rb . 36

D.1 General . 36

D.2 Example of test apparatus . 36

D.2.1 Method Rb 1: oscillating tube and spray nozzle . 36

D.2.2 Method Rb 2: water jet . 37

D.2.3 Method Rb 3: fan jet nozzle . 38

Annex E (informative) Guidance for test Rc. 45

E.1 General . 45

E.2 Example of test apparatus . 45

E.2.1 Method Rc 1: water tank . 45

E.2.2 Method Rc 2: pressurized water chamber . 45

E.3 Verification of test apparatus . 45

Bibliography . 46

Figure 1 – Structuring of test methods and equivalence with the IP Code of IEC 60529 . 10

Figure 2 – Test Ra, definitions of angles and axes . 12

Figure C.1 – Test Ra 1, test apparatus and measurement setup for drop sizes and

intensity for artificial rain method . 33

Figure C.2 – Test Ra 2, recommended test apparatus for the drip box method . 35

Figure D.1 – Test Rb 1.1, recommended test apparatus for the oscillating tube method . 37

Figure D.2 – Distribution of mean value of precipitation intensity in the oscillating tube

area . 39

Figure D.3 – Test Rb 1.2, recommended test apparatus for the spray nozzle method . 40

Figure D.4 – Standard test nozzle for the water jet method (hose nozzle) . 40

Figure D.5 – Standard test nozzle for the fan jet method . 41

Figure D.6 – Fan jet nozzle resulting dimensions of spraying hole for checking purpose . 41

Figure D.7 – Example of different quality achievements of the surface finish of the fan

jet nozzle . 42

Figure D.8 – Set-up for measuring the impact force of the water jet for determining the

protection against high-pressure and high-temperature water jets . 43

Figure D.9 – Impact force distribution . 43

Figure D.10 – Test setup for determining the protection against high-pressure and

high-temperature water jet for small enclosures . 44

Table 1 – Oscillating tube – Relationship of number of nozzles and total water flow to

tube radius . 17

Table A.1 – Typical characteristics of water with approximate values . 30

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-18: Tests – Test R and guidance: Water

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-18 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This third edition cancels and replaces the second edition published in 2000. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) addition of the new test method Rb 3.

– 6 – IEC 60068-2-18:2017 © IEC 2017

The text of this standard is based on the following documents:

FDIS Report on voting

104/719/FDIS 104/722/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

A number of water tests are described in other IEC publications. Some of them are well

established, for example, the test for classification of the second characteristic numeral of the

IP Code, of IEC 60529.

This document incorporates the majority of the most widely used tests, as well as making

available further methods and increasing the number of severities.

– 8 – IEC 60068-2-18:2017 © IEC 2017

ENVIRONMENTAL TESTING –

Part 2-18: Tests – Test R and guidance: Water

1 Scope

This part of IEC 60068 provides methods of test applicable to products which, during

transportation, storage or in service, can be subjected to falling water drops, impacting water,

immersion or high pressure water impact. The primary purpose of water tests is to verify the

ability of enclosures, covers and seals to maintain components and equipment in good

working order after and, when necessary, under a standardized drop field or immersion in

water.

These tests are not corrosion tests and cannot be considered and used as such.

Established water tests in other standards are not intended to simulate natural rainfall and

their quoted intensities are too high to be adopted for that purpose. Therefore, in addition to

the high-intensity severities, test R includes an artificial rain test based upon natural

conditions but not taking into account high wind speeds generally associated with natural rain.

Guidance is given on the applicability of the tests and the severities to be selected.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardisation at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

rain

precipitation in the form of water drops

Note 1 to entry: Both the amount that falls and the actual falling action of the water drops are often called rainfall.

3.2

drizzle

precipitation in the form of very small, numerous and uniformly dispersed water drops that

may appear to float while following air currents

3.3

raindrop

drop of water having a diameter greater than 0,5 mm falling through the atmosphere

3.4

drizzledrop

drop of water having a diameter of 0,2 mm to 0,5 mm falling through the atmosphere

3.5

R

rainfall or drizzle intensity

amount that falls per unit of time

Note 1 to entry: Rainfall intensity (R) is given in millimetres per hour (mm/h) where 1 l/(m · h) equals 1 mm/h.

3.6

D

median volume diameter

diameter of a drop whose size is such that 50 % of the volume of water reaching the ground is

comprised of smaller (or larger) drops

Note 1 to entry: Median volume diameter can be calculated using the formula:

0,19

D = 1,21 R (mm)

where R is the rainfall intensity (see 3.5).

4 Survey of water tests

4.1 General

This survey indicates the general structure of the various tests included in this document.

The structuring of the different tests is given in Figure 1.

4.2 Description of tests R: water

The water tests are structured into three groups.

• Ra: "falling drops" which, in principle, is a test with artificial rain and a test simulating

falling drops from condensation or leakage.

• Rb: "impacting water" where water jets impinge upon the test specimen with a certain

force and may assume any angle towards the test specimen.

• Rc: "immersion" where the test specimen is immersed in water to specified depths or

equivalent pressures.

– 10 – IEC 60068-2-18:2017 © IEC 2017

Water tests

R

Falling drops Impacting water Immersion

Ra Rb Rc

Method Rc 1

Method Ra 1 Method Rb 1

Water tank

Artificial rain

– Method Rb 1.1

IPX7

Oscillating tube

IPX3 and IPX4

or

– Method Rb 1.2

Spray nozzle

(Hand-held shower)

IPX3 and IPX4

Method Ra 2

Method Rb 2

Method Rc 2

Drip box Water jet

Pressurized water

IPX1 and IPX2

IPX5 and IPX6

chamber

Method Rb 3

Fan jet

IPX9

IEC

Figure 1 – Structuring of test methods and equivalence with the IP Code of IEC 60529

5 Test Ra: falling drops

5.1 Object

This test is applicable to products which, during transportation, storage or in service may be

exposed to vertical falling drops, the origin of these being, for example, natural rain, seepage

or condensation. It shall be clearly stated in the relevant specification whether a product

hereinafter referred to as a specimen has to function during testing or merely to survive

conditions of falling drops. In either case, the relevant specification shall always specify the

acceptable tolerances in performance.

5.2 Method Ra 1: artificial rain

5.2.1 General description of the test

The test specimen is mounted on an appropriate fixture or base support. It is then subjected

to falling waterdrops, which simulate natural rain.

The basic requirements for the test apparatus are as follows.

• Drop-generating nozzle or nozzles (see C.2.1 and Figure C.1).

• Fixture for the specimen

The fixture shall simulate as far as possible the mounting of the specimen when in service;

for example, for wall-mounted equipment the fixture shall simulate a wall.

• Support of the test specimen

The support shall have a base area which is smaller than the base area of the specimen.

The support shall be either a turntable which has a rotation speed of 1 r/min and the

eccentricity (distance between turntable axis and specimen axis) is approximately

100 mm, or a table which does not turn. The support shall be able to hold the specimen in

any test position and, if necessary, be tilted to a maximum of 90° from the vertical plane.

• Water supply with controls

The water used for the test shall be fresh tap water of good quality. In order to avoid

clogging of the nozzles, the water shall be filtered and may be demineralized. Details of

the characteristics of the water are given in Annex A. During the test, the water

temperature shall not differ by more than 5 K from the temperature of the specimen under

test. If the water temperature is more than 5 K below the temperature of the specimen, a

pressure balance shall be provided for the specimen.

5.2.2 Severities

The severities, as indicated by intensity (and associated drop-size distribution), duration and

tilt angle of specimen shall be specified in the relevant specification. The values shall be

selected from those given below, a longer duration may be specified in the relevant

specification. Wind-driven rain is not simulated by this test as the wind velocity is not a

parameter of test.

• Intensity, mm/h and (associated drop-size distribution, mm):

10 ± 5 (D = 1,9 ± 0,2); 100 ± 20 (D = 2,9 ± 0,3); 400 ± 50 (D = 3,8 ± 0,4).

50 50 50

• Duration, min:

10, 30, 60, 120.

• Tilt angle α, degrees:

0, 15, 30, 60, 90.

5.2.3 Preconditioning

Preconditioning of the specimen and seals shall be carried out if specified in the relevant

specification.

5.2.4 Initial measurements

The specimen shall be submitted to the visual, dimensional and functional checks specified in

the relevant specification. All features of the specimen likely to affect the test result, for

example surface treatment, enclosures, covers or seals, shall be inspected to ensure that the

instructions of the relevant specification have been followed.

5.2.5 Testing

The specimen shall be mounted on the support either

• in its normal operating position, as specified in the relevant specification; or

• tilted from the normal operating position and provision made for rotating the specimen in a

plane perpendicular to the tilted axis. The rotation may be achieved by a rotating support

table or by repositioning the specimen at regular intervals during the test. Alternatively,

the specimen can be oscillated through an arc of 270° to avoid the need for slip-ring

contacts.

The relevant specification shall specify the tilt angle or angles, the face or faces to be

exposed to the drop field and the duration of exposure for each side, or whether the specimen

shall be continuously rotated or oscillated through 270°. See also Figure 2.

– 12 – IEC 60068-2-18:2017 © IEC 2017

The specimen shall be subjected to artificial rain with severities selected from 5.2.2 and

specified in the relevant specification.

The relevant specification shall state whether the specimen shall be operated during testing

and if intermediate measurements shall be made.

Appropriate safety precautions shall be taken when testing the specimen in the energized

condition.

5.2.6 Recovery

Unless otherwise required in the relevant specification, the specimen shall be thoroughly

dried externally by wiping or by applying low-velocity forced air at room temperature.

Z

Z

α

Tilt angle

X

Y

Gimballed and rotatable table

IEC

Figure 2 – Test Ra, definitions of angles and axes

5.2.7 Final measurements

The specimen shall be examined for ingress of water and submitted to visual, dimensional

and functional checks specified in the relevant specification.

Any ingress of water should be quantified if possible and reported.

5.2.8 Information to be given in the relevant specification

Where this test is included in the relevant specification, the following details shall be given in

so far as they are applicable. The relevant specification shall supply information as required in

the subclauses listed below, paying particular attention to the items marked with an asterisk

(*) as this information is always required.

Subclause

a) Severities* 5.2.2

b) Preconditioning 5.2.3

c) Initial measurements* 5.2.4

d) Mounting of specimen* 5.2.5

e) Specimen position or positions during testing* 5.2.5

f) State of the specimen during testing* 5.2.5

g) Intermediate measurements 5.2.5

h) Recovery 5.2.6

i) Final measurements* 5.2.7

5.3 Method Ra 2: drip box

5.3.1 General description of the test

The test specimen is mounted on an appropriate fixture placed under the drip box. The test

specimen is subjected to water drops, which simulate water falling as a result of condensation

or leakage.

The basic requirements for the test apparatus are as follows.

• Drip box

The drip box shall normally have a base area larger than the projected area of the

specimen. If the base of the drip box is smaller than that of the specimen under test, the

latter may be divided into several sections, the area of each section being large enough to

be covered by the dripping water. The test is continued until the whole area of the

specimen has been sprinkled for the specified time. The drip box shall be capable of

providing a uniform drop field with a precipitation of the specified intensity.

The grid pattern of the nozzles shall be 20 mm (for IP Code tests) or 25 mm. The distance

from the bottom of the drip box to the highest point of the specimen shall be adjustable to

either 0,2 m or 2 m. A suitable drip-box layout is described in C.2.2 and in Figure C.2.

• Fixture for the specimen

The fixture shall simulate as far as possible the mounting of the specimen when in service;

for example, for wall-mounted equipment the fixture shall simulate a wall.

• Support of the test specimen

The support shall have a base area which is smaller than the base area of the specimen.

The support shall either be a turntable which has a rotation speed of 1 r/min and an

eccentricity (distance between turntable axis and specimen axis) of approximately

100 mm, or a table which does not turn. The support shall be able to hold the specimen in

any test position and, if necessary, be tilted to a maximum of 45° from the vertical plane.

• Water supply with controls

The water used for the test shall be fresh tap water of good quality. In order to avoid

clogging of the nozzles, the water shall be filtered and may be demineralized. Details of

the characteristics of the water are given in annex A. During the test, the water

temperature shall not differ by more than 5 K from the temperature of the specimen under

test. If the water temperature is more than 5 K below the temperature of the specimen, a

pressure balance shall be provided for the specimen.

5.3.2 Severities

The severities, as indicated by drop falling height, tilt angle of specimen, duration and water

intensity, shall be specified in the relevant specification. The values shall be selected from the

following:

– 14 – IEC 60068-2-18:2017 © IEC 2017

• Drop falling height, (h), m: 0,2; 2

• Tilt angle α, degrees: 0; 15; 30; 45

• Duration, min: 3; 10; 30; 60

NOTE The 3 min duration applies only when a tilt angle of 0° is specified.

+30 +30

• Water intensity, mm/h: 60 ; 180

0 0

5.3.3 Preconditioning

Preconditioning of the specimen and seals shall be carried out if specified in the relevant

specification.

5.3.4 Initial measurements

The specimen shall be submitted to the visual, dimensional and functional checks specified in

the relevant specification. All the features of the specimen likely to affect the test result, for

example, surface treatment, covers or seals, shall be inspected to ensure that the instructions

of the relevant specification have been followed.

5.3.5 Testing

The specimen shall be mounted on the support in its normal operating position under the drip

box. The support shall then either be rotated or tilted to the specified angle in each of the four

positions of tilt. These positions are on either side of the vertical in two mutually perpendicular

planes. If a special mounting condition is required (for example, wall or ceiling), it shall be

specified in the relevant specification.

In both cases, the test shall be carried out in the conditions specified in 5.3.1 and the severity

selected from 5.3.2.

In the case of tilted support, the duration shall be divided equally between the four positions.

The relevant specification shall state whether the specimen shall be operated during testing

and if intermediate measurements shall be made. Appropriate safety precautions shall be

taken when testing the specimen in the energized condition.

5.3.6 Recovery