EN 10216-2:2013+A1:2019

(Main + Amendment)Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

This European Standard specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel.

This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary modification should be agreed at the time of enquiry and order.

NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESR) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

Nahtlose Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 2: Rohre aus unlegierten und legierten Stählen mit festgelegten Eigenschaften bei erhöhten Temperaturen

Diese Europäische Norm enthält die technischen Lieferbedingungen für nahtlose Rohre mit kreisförmigem Querschnitt aus unlegiertem und legiertem Stahl mit festgelegten Eigenschaften bei erhöhten Temperaturen und legt dafür zwei Prüfkategorien fest.

Dieser Teil der EN 10216 kann auch für Rohre mit nichtkreisförmigem Querschnitt angewendet werden; notwendige Anpassungen sollten bei der Anfrage und Bestellung vereinbart werden.

ANMERKUNG Nach Veröffentlichung dieser Norm im EU Amtsblatt (OJEU) unter der Richtlinie 2014/68/EU ! ist die Annahme ihrer Konformität mit den grundlegenden Anforderungen (ESR) der Richtlinie 2014/68/EU " auf die technischen Daten von Werkstoffen in dieser Europäischen Norm beschränkt, und es darf nicht angenommen werden, dass damit die Eignung des Werkstoffs für ein bestimmtes Ausrüstungsteil festgestellt ist. Folglich müssen die in dieser Werkstoffnorm angegebenen technischen Parameter im Hinblick auf die konstruktiven Anforderungen dieses bestimmten Ausrüstungsteils ermittelt werden, um damit zu verifizieren, dass den ESR der Druckgeräterichtlinie entsprochen wird. Dies muss durch den Ausleger oder den Hersteller der Druckgeräte geschehen, der auch den nachfolgenden Herstellungsprozess berücksichtigen muss, der die Eigenschaften des Grundmaterials verändern kann.

Tubes sans soudure en acier pour service sous pression - Conditions techniques de livraison - Partie 2: Tubes en acier non allié et allié avec caractéristiques spécifiées à température élevée

Cette Norme Européenne spécifie les conditions techniques de livraison, selon deux catégories d’essai, pour les

tubes sans soudure à section circulaire en acier non allié et allié, avec caractéristiques spécifiées à température

élevée.

La présente partie de l’EN 10216 peut aussi s’appliquer pour des tubes de section non circulaire ; les modifications

nécessaires doivent faire l’objet d’un accord lors de l’appel d’offres et de la commande.

NOTE Dès lors que la présente Norme européenne est publiée dans le Journal Officiel de l’Union européenne (JOUE) en

lien avec la Directive 97/23/CE, la présomption de conformité avec les exigences essentielles de sécurité de la Directive

97/23/CE se limite aux données techniques des matériaux spécifiées dans la présente Norme européenne et ne suppose pas

l’adéquation des matériaux avec un appareil en particulier. Par conséquent, il doit être procédé à l’évaluation des données

techniques spécifiées dans la présente norme de matériaux par rapport aux exigences concernant la conception de cet

équipement spécifique, afin de vérifier que les exigences essentielles de sécurité de la Directive 97/23/CE soient satisfaites.

Nevarjene jeklene cevi za tlačne posode - Tehnični dobavni pogoji - 2. del: Nelegirane in legirane jeklene cevi s specificiranimi lastnostmi za delo pri povišanih temperaturah

Ta evropski standard določa tehnične dobavne pogoje v dveh preskusnih kategorijah za nevarjene cevi s krožnim prerezom iz nelegiranega in legiranega jekla ter specificiranimi lastnostmi za delo pri povišanih temperaturah. Ta del standarda EN 10216 se lahko uporablja tudi za cevi z nekrožnim prerezom, pri čemer naj bi se o potrebni spremembi dogovorili ob oddaji povpraševanja in naročila.

OPOMBA: Ko bo ta standard objavljen v Uradnem listu Evropske unije (OJEU) v okviru Direktive 97/23/ES, bodo zagotovila o skladnosti z osnovnimi varnostnimi zahtevami (ESR) Direktive 97/23/ES omejena na tehnične podatke o materialih, navedene v tem evropskem standardu, standard pa ne bo zagotavljal ustreznosti materiala za določen element opreme. Zato bo treba oceniti tehnične podatke, podane v tem standardu za materiale, glede na zahteve o zasnovi določenega elementa opreme, da se zagotovi, da so upoštevane osnovne varnostne zahteve Direktive o tlačni opremi. Oceno opravi projektant ali proizvajalec tlačne opreme ob upoštevanju nadaljnjih proizvodnih postopkov, ki lahko vplivajo na lastnosti osnovnih materialov.

General Information

- Status

- Withdrawn

- Publication Date

- 17-Dec-2019

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 110/WG 1 - Tubes for pressure purposes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Nov-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 04-Sep-2019

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 10216-2:2013+A1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties". This standard covers: This European Standard specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel. This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary modification should be agreed at the time of enquiry and order. NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESR) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

This European Standard specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel. This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary modification should be agreed at the time of enquiry and order. NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESR) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

EN 10216-2:2013+A1:2019 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10216-2:2013+A1:2019 has the following relationships with other standards: It is inter standard links to EN 10216-2:2013/FprA1, EN 10216-2:2024, ISO 11484:2009, EN ISO 6892-2:2011, EN ISO 10893-3:2011, EN 10020:2000, EN ISO 10893-10:2011, EN ISO 8495:2013, EN 10168:2004, EN 10021:2006, EN ISO 8493:2004, EN 10204:2004, EN ISO 6892-1:2009, EN ISO 10893-1:2011, EN ISO 8496:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10216-2:2013+A1:2019 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10216-2:2013+A1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2020

Nevarjene jeklene cevi za tlačne posode - Tehnični dobavni pogoji - 2. del:

Nelegirane in legirane jeklene cevi s specificiranimi lastnostmi za delo pri

povišanih temperaturah

Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non-

alloy and alloy steel tubes with specified elevated temperature properties

Nahtlose Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 2:

Rohre aus unlegierten und legierten Stählen mit festgelegten Eigenschaften bei erhöhten

Temperaturen

Tubes sans soudure en acier pour service sous pression - Conditions techniques de

livraison - Partie 2: Tubes en acier non allié et allié avec caractéristiques spécifiées à

température élevée

Ta slovenski standard je istoveten z: EN 10216-2:2013+A1:2019

ICS:

23.020.32 Tlačne posode Pressure vessels

77.140.75 Jeklene cevi in cevni profili Steel pipes and tubes for

za posebne namene specific use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 10216-2:2013+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2019

EUROPÄISCHE NORM

ICS 23.040.10; 77.140.75 Supersedes EN 10216-2:2013

English Version

Seamless steel tubes for pressure purposes - Technical

delivery conditions - Part 2: Non-alloy and alloy steel tubes

with specified elevated temperature properties

Tubes sans soudure en acier pour service sous Nahtlose Stahlrohre für Druckbeanspruchungen -

pression - Conditions techniques de livraison - Partie 2: Technische Lieferbedingungen - Teil 2: Rohre aus

Tubes en acier non allié et allié avec caractéristiques unlegierten und legierten Stählen mit festgelegten

spécifiées à température élevée Eigenschaften bei erhöhten Temperaturen

This European Standard was approved by CEN on 17 August 2013 and includes Amendment 1 approved by CEN on 23

September 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 10216-2:2013+A1:2019 E

worldwide for CEN national Members.

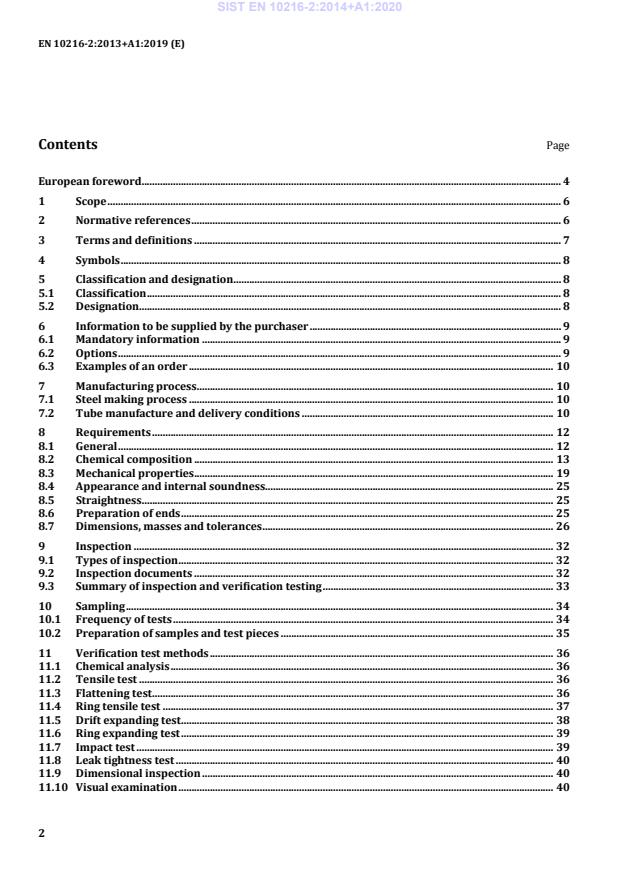

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols . 8

5 Classification and designation . 8

5.1 Classification . 8

5.2 Designation. 8

6 Information to be supplied by the purchaser . 9

6.1 Mandatory information . 9

6.2 Options . 9

6.3 Examples of an order . 10

7 Manufacturing process . 10

7.1 Steel making process . 10

7.2 Tube manufacture and delivery conditions . 10

8 Requirements . 12

8.1 General . 12

8.2 Chemical composition . 13

8.3 Mechanical properties . 19

8.4 Appearance and internal soundness. 25

8.5 Straightness . 25

8.6 Preparation of ends . 25

8.7 Dimensions, masses and tolerances . 26

9 Inspection . 32

9.1 Types of inspection . 32

9.2 Inspection documents . 32

9.3 Summary of inspection and verification testing . 33

10 Sampling . 34

10.1 Frequency of tests . 34

10.2 Preparation of samples and test pieces . 35

11 Verification test methods . 36

11.1 Chemical analysis . 36

11.2 Tensile test . 36

11.3 Flattening test . 36

11.4 Ring tensile test . 37

11.5 Drift expanding test . 38

11.6 Ring expanding test . 39

11.7 Impact test . 39

11.8 Leak tightness test . 40

11.9 Dimensional inspection . 40

11.10 Visual examination . 40

11.11 Non-destructive testing . 40

11.12 Material identification . 41

11.13 Retests, sorting and reprocessing . 41

12 Marking . 41

12.1 Marking to be applied . 41

12.2 Additional marking . 42

13 Protection . 42

Annex A (informative) Creep rupture strength values . 43

Annex B (informative) Technical changes from the previous edition . 49

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of Directive 2014/68/EU aimed to be covered. 50

Bibliography . 51

European foreword

This document (EN 10216-2:2013+A1:2019) has been prepared by Technical Committee CEN/TC 459

SC/10 “Steel tubes, and iron and steel fittings”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2020, and conflicting national standards shall be

withdrawn at the latest by June 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 23 September 2019.

This document supersedes !EN 10216-2:2013".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

For the list of the most significant technical changes that !were made in EN 10216-2:2013", see

Annex B.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

This European Standard consists of the following parts, under the general title "Seamless steel tubes for

pressure purposes – Technical delivery conditions":

— Part 1: Non-alloy steel tubes with specified room temperature properties

— Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties (the present

document)

— Part 3: Alloy fine grain steel tubes

— Part 4: Non-alloy and alloy steel tubes with specified low temperature properties

— Part 5: Stainless steel tubes

Another European Standard series covering tubes for pressure purposes is:

EN 10217, Welded steel tubes for pressure purposes – Technical delivery conditions

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

!deleted text"

1 Scope

This European Standard specifies the technical delivery conditions in two test categories for seamless

tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and

alloy steel.

This Part of EN 10216 may also be applied for tubes of non-circular cross section; necessary

modification should be agreed at the time of enquiry and order.

NOTE Once this standard is published in the Official Journal of the European Union (OJEU) under Directive

2014/68/EU, presumption of conformity to the Essential Safety Requirements (ESR) of Directive 2014/68/EU is

limited to technical data of materials in this standard and does not presume adequacy of the material to a specific

item of equipment. Consequently, the assessment of the technical data stated in this material standard against the

design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive

are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into

account the subsequent manufacturing processes which may affect properties of the base materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

!EN 10020:2000", Definitions and classification of grades of steel

!EN 10021:2006", General technical delivery requirements for steel products

EN 10027-1, Designation systems for steels - Part 1: Steel names

EN 10027-2, Designation systems for steels - Part 2: Numerical system

EN 10168:2004, Steel products - Inspection documents - List of information and description

EN 10204:2004, Metallic products - Types of inspection documents

EN 10220, Seamless and welded steel tubes - Dimensions and masses per unit length

!EN 10266:2003", Steel tubes, fittings and structural hollow sections - Symbols and definitions of

terms for use in product standards

CEN/TR 10261, Iron and steel - Review of available methods of chemical analysis

EN ISO 148-1:2010, Metallic materials - Charpy pendulum impact test - Part 1: Test method (ISO 148-

1:2009)

EN ISO 377:2013, Steel and steel products - Location and preparation of samples and test pieces for

mechanical testing (ISO 377:2013)

EN ISO 2566-1, Steel - Conversion of elongation values - Part 1: Carbon and low-alloy steels (ISO 2566-1)

!EN ISO 4885:2018, Ferrous materials –Heat treatments – Vocabulary (ISO 4885:2018)"

EN ISO 6892-1:2009, Metallic materials - Tensile testing - Part 1: Method of test at room temperature

(ISO 6892-1:2009)

EN ISO 6892-2:2011, Metallic materials - Tensile testing - Part 1: Method of test at elevated temperature

(ISO 6892-2:2011)

!EN ISO 8492:2013", Metallic materials - Tube - Flattening test (ISO 8492)

!EN ISO 8493:2004", Metallic materials - Tube - Drift expanding test (ISO 8493)

!EN ISO 8495:2013", Metallic materials - Tube - Ring expanding test (ISO 8495)

!EN ISO 8496:2013", Metallic materials - Tube - Ring tensile test (ISO 8496)

EN ISO 10893-1, Non-destructive testing of steel tubes - Part 1: Automated electromagnetic testing of

seamless and welded (except submerged arc-welded) steel tubes for the verification of hydraulic leak-

tightness (ISO 10893-1)

EN ISO 10893-3, Non-destructive testing of steel tubes - Part 3: Automated full peripheral flux leakage

testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for the detection

of longitudinal and/or transverse imperfections (ISO 10893-3)

EN ISO 10893-8, Non-destructive testing of steel tubes - Part 8: Automated ultrasonic testing of seamless

and welded steel tubes for the detection of laminar imperfections (ISO 10893-8)

EN ISO 10893-10, Non-destructive testing of steel tubes - Part 10: Automated full peripheral ultrasonic

testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of longitudinal

and/or transverse imperfections (ISO 10893-10)

EN ISO 14284:2002, Steel and iron - Sampling and preparation of samples for the determination of

chemical composition (ISO 14284:1996)

ISO 11484:2009, Steel products - Employer's qualification system for non-destructive testing (NDT)

personnel

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 10020, EN 10021,

!EN ISO 4885" and EN 10266 and the following apply.

3.1

test category

classification that indicates the extent and level of inspection and testing

3.2

employer

organization for which a person works on a regular basis

Note 1 to entry: The employer may be either the tube manufacturer or supplier or a third party organization

providing Non-Destructive Testing (NDT) services.

4 Symbols

For the purposes of this document, the symbols given in EN 10266 and the following apply:

— d specified inside diameter

— d specified minimum inside diameter

min

— T specified minimum wall thickness

min

— D calculated outside diameter

c

— d calculated inside diameter

c

— T calculated wall thickness

c

— TC test category

5 Classification and designation

5.1 Classification

In accordance with the classification system in EN 10020, the steel grades P195GH, P235GH and

P265GH are classified as non-alloy quality steels and the other steel grades are classified as alloy special

steels.

5.2 Designation

5.2.1 For the tubes covered by this Part of EN 10216, the steel designation consists of:

— the number of this Part of EN 10216;

plus either:

— the steel name in accordance with EN 10027-1;

or:

— the steel number allocated in accordance with EN 10027-2.

5.2.2 The steel name of non-alloy steel grades is designated by:

— the capital letter P for pressure purposes;

— the indication of the specified minimum yield strength at room temperature for wall thickness less

than or equal to 16 mm, expressed in MPa (see Table 4);

— the symbols GH for elevated temperature.

5.2.3 The steel name of alloy steel grades is designated by the chemical composition (see Table 2) and

the symbols for the heat treatment, where specified in column 3 and footnote c of Table 1.

6 Information to be supplied by the purchaser

6.1 Mandatory information

The following information shall be supplied by the purchaser at the time of enquiry and order:

a) the quantity (mass or total length or number);

b) the term "tube";

c) the dimensions (outside diameter D and wall thickness T or a set of dimensions covered by Option

11) (see Table 6);

d) the designation of the steel grade in accordance with this Part of EN 10216 (see 5.2);

e) the test category (TC) for non-alloy steel (see 9.3).

6.2 Options

A number of options are specified in this Part of EN 10216 and these are listed below. In the event that

the purchaser does not indicate a wish to implement any of these options at the time of enquiry and

order, the tubes shall be supplied in accordance with the basic specification (see 6.1).

1) Cold finishing (see 7.2.2);

2) restriction on copper and tin content (see Table 2);

3) product analysis (see 8.2.2);

4) verification of impact energy (see Table 4);

5) verification of longitudinal impact energy at -10° C for non-alloy steel grades (see Table 4);

6) verification of elevated temperature properties (see 8.3.2);

7) selection test method for verification of leak-tightness (see 8.4.2.1);

8) Non-Destructive Testing for test category 2 tubes for detection of transverse imperfections (see

8.4.2.2);

9) Non-Destructive Testing for test category 2 tubes for detection of laminar imperfections (see

8.4.2.2);

10) special ends preparation (see 8.6);

11) set of dimensions other than D and T (see 8.7.1);

12) exact lengths (see 8.7.3);

13) the type of inspection certificate 3.2 other than the standard document (see 9.2.1);

14) test pressure for hydrostatic leak-tightness test (see 11.8.1);

15) wall thickness measurement away from the ends (see 11.9);

16) Non-Destructive Testing method (see 11.11.1);

17) additional marking (see 12.2);

18) protection (see Clause 13).

6.3 Examples of an order

6.3.1 Example 1

100 t of seamless tube with an outside diameter of 168,3 mm, a wall thickness of 4,5 mm, in accordance

with EN 10216-2, made of steel grade P265GH, to test category 1 with a 3.2 inspection certificate in

accordance with EN 10204:

EXAMPLE 100 t - Tube - 168,3 x 4,5 - EN 10216-2 - P265GH - TC1 - Option 13: 3.2

6.3.2 Example 2

100 m of seamless tube with a minimum inside diameter of 240 mm, a minimum wall thickness of 40

mm in accordance with !EN 10216-2", made of steel grade 10CrMo9-10, with a 3.2 inspection

certificate in accordance with EN 10204:

EXAMPLE 100 m - Tube - d 240 x T 40 - EN 10216-2 - 10CrMo9-10 - Option 13: 3.2

min min

7 Manufacturing process

7.1 Steel making process

The steelmaking process is at the discretion of the manufacturer with the exception that the open

hearth (Siemens-Martin) process shall not be employed unless in combination with a secondary

steelmaking or ladle refining process.

Steels shall be fully killed.

NOTE This excludes the use of rimming, balanced or semi-killed steel.

7.2 Tube manufacture and delivery conditions

7.2.1 All NDT activities shall be carried out by qualified and competent level 1,2 and/or 3 personnel

authorized to operate by the employer.

The qualification shall be in accordance with ISO 11484 or, at least, an equivalent to it.

It is recommended that the level 3 personnel be certified in accordance with EN ISO 9712 or, at least, an

equivalent to it.

The operating authorization issued by the employer shall be in accordance with a written procedure.

NDT operations shall be authorized by level 3 NDT individual approved by the employer.

NOTE The definition of level 1, 2 and 3 can be found in appropriate standards, e.g. EN ISO 9712 and ISO

11484.

7.2.2 The tubes shall be manufactured by a seamless process.

Unless option 1 is specified, the tubes may be either hot or cold finished at the discretion of the

manufacturer. The terms “ hot finished “ and “ cold finished “ apply to the condition of the tube before it

is heat treated in accordance with !7.2.3".

Option 1: The tubes shall be cold finished before heat treatment.

7.2.3 The tubes shall be supplied in the relevant heat treatment conditions as specified in Table 1.

Table 1 — Heat treatment conditions

Steel grade Austenitizing Tempering

Heat

Temperature Temperature

a

Steel Cooling Cooling

treatment

Steel name

number Medium medium

°C °C

b

P195GH 1.0348 880 to 940 air - -

+N

b

P235GH 1.0345 880 to 940 air - -

+N

b

P265GH 1.0425 +N 880 to 940 air - -

b

20MnNb6 1.0471 900 to 960 air - -

+N

b

16Mo3 1.5415 890 to 950 air - -

+N

b

8MoB5-4 1.5450 920 to 960 air - -

+N

b c

14MoV6-3 1.7715 930 to 990 air 680 to730 air

+NT

b c

10CrMo5-5 1.7338 900 to 960 air 650 to 750 air

+NT

b c

13CrMo4-5 1.7335 900 to 960 air 660 to 730 air

+NT

b c

10CrMo9-10 1.7380 900 to 960 air 680 to 750 air

+NT

11CrMo9-10 1.7383 +QT 900 to 960 air or liquid 680 to 750 air

25CrMo4 1.7218 +QT 860 to 900 air or liquid 620 to 680 air

20CrMoV13-5-5 1.7779 +QT 980 to 1030 air or liquid 680 to 730 air

c

15NiCuMoNb5-6-4 1.6368 880 to 980 air 580 to 680 air

+NT

d

7CrWVMoNb9-6 1.8201 1 040 to 1 080 air 730 to 780 air

+NT

d

7CrMoVTiB10-10 1.7378 980 to 1 020 air 730 to 770 air

+NT

Furnace

X11CrMo5+I 1.7362+I +I 890 to 950 - -

atmosphere

1.7362+NT

X11CrMo5+NT1 +NT1 930 to 980 Air 730 to 770 air

1.7362+NT

c

X11CrMo5+NT2 930 to 980 air 710 to 750 air

+NT2

Furnace

X11CrMo9-1+I 1.7386+I +I 950 to 980 - -

atmosphere

c

X11CrMo9-1+NT 1.7386+NT 890 to 950 air 720 to 800 air

+NT

Steel grade Austenitizing Tempering

Heat

Temperature Temperature

a

Steel Cooling Cooling

treatment

Steel name

number Medium medium

°C °C

c

X10CrMoVNb9-1 1.4903 1 040 to 1 090 air 730 to 780 air

+NT

c

X10CrWMoVNb9-2 1.4901 +NT 1 040 to 1 090 Air 730 to 780 air

X11CrMoWVNb9-

c

1.4905 1 040 to 1 080 Air 740 to 780 air

+NT

1-1

c

X20CrMoV11-1 1.4922 1 020 to 1 080 air 730 to 780 air

+NT

a

+N = Normalizing, +NT = Normalizing + Tempering, +QT = Quenching + Tempering (air or liquid), +I = Isothermal Annealing.

b

Normalizing includes Normalizing Forming. Normalized Forming shall be carried out in a temperature range from 880 °C to 1 000 °C.

c

For these steel grades it may be necessary in the case of wall thickness T above 10 mm or T/D > 0,15 to apply quenching and

tempering in order to achieve the intended structure and material properties. The decision shall be left to the discretion of the

manufacturer but shall be stated to the customer at the time of enquiry and order. Steel tubes treated in such a way shall be

designated by the steel name supplemented by the symbol “+QT “.

d

For these steel grades it may be necessary in case of wall thickness T above 16 mm or T/D > 0,15 to apply quenching and

tempering in order to achieve the intended structure and material properties. The decision shall be left to the discretion of the

manufacturer but shall be stated to the customer at the time of enquiry and order. Steel tubes treated in such a way shall be

designated by the steel name supplemented by the symbol “+QT”.

8 Requirements

8.1 General

When supplied in a delivery condition indicated in 7.2 and inspected in accordance with Clauses 9, 10

and 11, the tubes shall conform to the requirements of this Part of EN 10216.

In addition, the general technical delivery requirements specified in EN 10021 shall apply.

Tubes shall be suitable for hot and cold bending provided the bending is carried out in an appropriate

manner.

When tubes are specified in the order by d, d or T the following formulae, with all terms in mm,

min min

shall apply for the calculation of outside diameter D , inside diameter d and wall thickness T , instead of

c c c

D, d and T for the relevant requirements in 8.4.1.4, 10.2.2.2, 11.3, 11.8.1, 11.9, 11.11.4, 12.1 and Table 1,

footnote c, Tables 4, 5, 8, 10, 13 and 14:

D = d+ 2T (1)

c

tolerance⋅of⋅d

min

D = (2)

c d + + 2T

min

tolerance⋅of⋅d

min

d = (3)

c d +

min

tolerance⋅of⋅T

min

T = (4)

c T +

min

For tolerances, see Tables 8, 9 and 10.

8.2 Chemical composition

8.2.1 Cast analysis

The cast analysis reported by the steel producer shall apply and conform to the requirements of Table

2.

When welding tubes produced in accordance with this Part of this EN 10216, account should be taken of

the fact that the behaviour of the steel during and after welding is dependent not only on the steel, but

also on the applied heat treatment and the conditions of preparing for and carrying out the welding.

8.2.2 Product analysis

Option 3: Product analysis for the tubes shall be supplied.

Table 3 specifies the permissible deviations of the product analysis from the specified limits on cast

analysis given in Table 2.

a

Table 2 — Chemical composition (cast analysis) , in % by mass

Steel grade

Ti Cr+Cu

P S

C Si Mn Cr Mo Ni Al Cu Nb V Others

tot

Steel

max max

Steel name max +Mo+Ni

number

b c d d d

≤ 0,13 ≤ 0,70

P195GH 1.0348 ≤ 0,35 0,025 0,010 ≤ 0,30 ≤ 0,08 ≤ 0,30 ≤ 0,70 -

≥ 0,020 ≤ 0,30 ≤ 0,010 0,040 ≤ 0,02

b c d d d

≤ 0,16 ≤ 1,20

P235GH 1.0345 ≤ 0,35 0,025 0,010 ≤ 0,30 ≤ 0,08 ≤ 0,30 ≤ 0,70 -

≥ 0,020 ≤ 0,30 ≤ 0,020 0,040 ≤ 0,02

b c d d d

≤ 0,20 ≤ 1,40

P265GH 1.0425 ≤ 0,40 0,025 0,010 ≤ 0,30 ≤ 0,08 ≤ 0,30 ≤ 0,70 -

≥ 0,020 ≤ 0,30 ≤ 0,020 0,040 ≤ 0,02

≤ 0,22 0,15 1,00 0,015

c

20MnNb6 1.0471 to to 0,025 0,010 - - - ≤ 0,060 to - - - -

≤ 0,30

0,35 1,50 0,10

0,12 0,40

0,25

c

to to

16Mo3 1.5415 ≤ 0,35 0,025 0,010 ≤ 0,30 to ≤ 0,30 ≤ 0,040 - - - - -

≤ 0,30

e 0,90

0,35

0,20

0,06 0,10 0,60 0,40 0,002

c

8MoB5-4 1.5450 to to to 0,025 0,010 ≤ 0,20 to - ≤ 0,060 - 0,060 - - B = to

≤ 0,30

0,10 0,35 0,80 0,50 0,006

0,10 0,15 0,40 0,30 0,50 0,22

c

14MoV6-3 1.7715 to to to 0,025 0,010 to to ≤ 0,30 ≤ 0,040 - - to - -

≤ 0,30

0,15 0,35 0,70 0,60 0,70 0,28

≤ 0,15 0,50 0,30 1,00 0,45

c

10CrMo5-5 1.7338 to to 0,025 0,010 to to ≤ 0,30 ≤ 0,040 - - - - -

≤ 0,30

1,00 0,60 1,50 0,65

0,10 0,40

0,70 0,40

c

to to

13CrMo4-5 1.7335 ≤ 0,35 0,025 0,010 to to ≤ 0,30 ≤ 0,040 - - - - -

≤ 0,30

e 0,70

1,15 0,60

0,17

0,08 0,30 2,00 0,90

10CrMo9-

c

1.7380 to ≤ 0,50 to 0,020 0,010 to to ≤ 0,30 ≤ 0,040 - - . - -

≤ 0,30

0,14 0,70 2,50 1,10

0,08 0,40 2,00 0,90

11CrMo9-

c

1.7383 to ≤ 0,50 to 0,025 0,010 to to ≤ 0,30 ≤ 0,040 - - . - -

≤ 0,30

0,15 0,80 2,50 1,10

Table 2 (continued)

Steel grade

Cr+Cu

P S

C Si Mn Cr Mo Ni Al Cu Nb Ti V Others

tot

Steel

max max

+Mo+Ni

Steel Grade

Number

0,22 0,60 0,90 0,15

c

25CrMo4 1.7218 to ≤ 0,40 to 0,025 0,010 to to ≤ 0,3 ≤ 0,040 - - - - -

≤ 0,30

0,29 0,90 1,20 0,30

0,17 0,15 0,30 3,00 0,50 0,45

c

20CrMoV13-5-5 1.7779 to to to 0,025 0,010 to to ≤ 0,3 ≤ 0,040 - - to - -

≤ 0,30

0,23 0,35 0,50 3,30 0,60 0,55

0,25 0,80 0,25 1,00 0,50 0,015

15NiCuMoNb5-

1.6368 ≤ 0,17 to to 0,025 0,010 ≤ 0,30 to to ≤ 0,050 to to - - - -

6-4

0,50 1,20 0,50 1,30 0,80 0,045

N ≤ 0,015

B = 0,0010

0,005

0,05 0,02

to 0,006

0,04 to 0,10 to 1,90 to 0,20 to

to

7CrWVMoNb9-6 1.8201 ≤ 0,50 0,030 0,010 to - ≤ 0,030 - to -

0,10 0,60 2,60 0,30

W = 1,45 to

0,30 0,08

0,060

1,75

g

Ti/N ≥3,5

N ≤ 0,010

0,90 0,05

7CrMoVTiB10- 0,05 to 0,15 to 0,30 to 2,20 to 0,20 to

1.7378 0,020 0,010 to - ≤ 0,020 - - to -

B = 0,0015

10 0,10 0,45 0,70 2,60 0,30

1,10 0,10

to 0,0070

X11CrMo5+I 1.7362+I 0,08 0,15 0,30 4,0 0,45

c

X11CrMo5+NT1 1.7362+NT1 to to to 0,025 0,010 to to - ≤ 0,040 - - - - -

≤ 0,30

X11CrMo5+NT2 1.7362+NT2 0,15 0,50 0,60 6,0 0,65

X11CrMo9-1+I 1.7386+I 0,08 0,25 0,30 8,0 0,90

c

0,025 0,010 - ≤ 0,040 - - - - -

X11CrMo9-1+NT 1.7386+NT to to to to to

≤ 0,30

0,15 1,00 0,60 10,0 1.10

0,030

N = to

0,08 0,20 0,30 8,0 0,85 0,06 0,18

0,01

c

0,070

X10CrMoVNb9-1 1.4903 0,020 0,005 ≤ 0,40 ≤ 0,02 -

to to to to to to to

≤ 0,30

max

0,12 0,50 0,60 9,5 1,05 0,10 0,25

Zr = 0,01

max

Table 2 (concluded)

Steel grade

Cr+Cu

P S

C Si Mn Cr Mo Ni Al tot Cu Nb Ti V Others

Steel name Steel

max max

+Mo+Ni

number

- N = 0,030 to

0,070

B = 0,001 to

0,04 to

0,07 8,5 0,30 0,15

0,006

0,30 to 0,01

0,09

X10CrWMoVNb9-2 1.4901 to ≤ 0,50 0,020 0,010 to to ≤ 0,40 ≤ 0,02 - to

0,60 max

W = 1,50 to

0,13 9,5 0,60 0,25

2,00

Zr = 0,01

max

- N = 0,050 to

0,090

B = 0,0005

0,09 8,5 0,90 0,10 0,06 0,18

to 0,005

0,10 to 0,30 to 0,01

X11CrMoWVNb9-1-1 1.4905 to 0,020 0,010 to to to ≤ 0,02 - to to

0,50 0,60 max

W = 0,90 to

0,13 9,5 1,10 0,40 0,10 0,25

1,10

Zr = 0,01

max

0,17 - -

0,15 10,0 0,80 0,30 0,25

≤ 0,30

to

X20CrMoV11-1 1.4922 to ≤ 1,00 0,025 0,010 to to to ≤ 0,040 - - to

c

f

0,50 12,5 1,20 0,80 0.35

0,23

a

Elements not included in this table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing

the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steel making process.

b

This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements which shall be reported. When using titanium, the

producer shall verify that (Al+Ti/2) ≥ 0,020 %.

c

Option 2: In order to facilitate subsequent forming operations, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.

d

The content of these elements need not to be reported unless intentionally added to the cast.

e

For wall thickness T ≥ 30 mm the carbon content may be increased by 0,02 % for cast and product analysis.

f

The upper carbon value of 0,23 % shall not be exceeded for product analysis.

g

Alternatively, in lieu of the minimum ratio the material shall a have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to

room temperature, but before tempering. Hardness testing shall be performed at mid thickness of the product. The !testing" frequency shall be two samples of product per

heat treatment lot and the hardness testing results shall be reported.

Table 3 — Permissible deviations of the product analysis from specified limits on cast analysis

given in Table 2

Limiting value for the cast

Permissible deviation of the

analysis in accordance with

product analysis

Element

Table 2

% by mass

% by mass

C ≤ 0,29 ± 0,02

≤ 0,40 ± 0,05

Si

> 0,40 to ≤ 1,00 ± 0,06

≤ 1,00 ± 0,05

Mn

> 1,00 to ≤ 1,50 ± 0,10

P ≤ 0,030 + 0,005

≤ 0,010 + 0,003

S

> 0,010 to ≤ 0,020 + 0,005

Al ≤ 0,060 ± 0,005

B ≤ 0,007 + 0,000 5

≤ 1,00 ± 0,05

Cr > 1,00 to ≤ 10,0 ± 0,10

> 10,0 to ≤ 12,5 ± 0,15

Cu ≤ 0,80 ± 0,05

≤ 0,35 ± 0,03

Mo

> 0,35 to ≤ 1,20 ± 0,04

N ≤ 0,070 ± 0,01

Nb ≤ 0,10 ± 0,005

≤ 0,35 ± 0,05

Ni

> 0,35 to ≤ 1,30 ± 0,07

Ti ≤ 0,060 + 0,010

≤ 0,10 + 0,01

V

> 0,10 to ≤ 0,55 ± 0,03

W ≤ 2,00 ± 0,10

EN 10216-2:2013 (E)

8.3 Mechanical properties

8.3.1 Mechanical properties at and below room temperature

The mechanical properties at and below room temperature of the tubes shall conform to the

requirements in Table 4 and in 11.3, 11.4, 11.5 and 11.6 irrespective of whether they are verified or

not (see Table 13).

8.3.2 Proof strength at elevated temperature

The minimum proof strength R values at elevated temperature are given in Table 5.

p0,2

Option 6: Proof strength R shall be verified. The test temperature shall be specified at the time of

p0,2

enquiry and order.

8.3.3 Creep rupture strength

The creep rupture strength values are given in Annex A for information.

Table 4 — Mechanical properties

a b

Steel grade Tensile properties at room temperature

Impact properties

Upper yield strength or proof strength Tensile Elongation Minimum average absorbed energy

h

strength

KV

R or R for wall thickness T A min. 2

eH p0,2

Rm

a h

J

min.

%

at a temperature of

Steel

Steel name

number

°C

T ≤ 16 16 < T ≤ 40 40 < T ≤ 60 60 < T ≤ l t

l t

g g g g g

20 0 -10 20 0

MPa MPa MPa MPa MPa

c d c

P195GH 1.0348 195 - - - 320 to 440 27 25 - -

40 28 27

c d c

P235GH 1.0345 235 225 215 - 360 to 500 25 23 - -

40 28 27

c d c

P265GH 1.0425 265 255 245 - 410 to 570 23 21 - -

40 28 27

c c

20MnNb6 1.0471 355 345 335 - 500 to 650 22 20 . - -

40 27

c c

16Mo3 1.5415 280 270 260 - 450 to 600 22 20 - - -

40 27

c c

8MoB5-4 1.5450 400 - - - 540 to 690 19 17 - - -

40 27

c f c f

14MoV6-3 1.7715 320 320 310 - 460 to 610 20 18 - - -

40 27

c c

10CrMo5-5 1.7338 275 275 265 - 410 to 560 22 20 - - -

40 27

c c

13CrMo4-5 1.7335 290 290 280 - 440 to 590 22 20 - - -

40 27

c c

10CrMo9-10 1.7380 280 280 270 - 480 to 630 22 20 - - -

40 27

c c

11CrMo9-10 1.7383 355 355 355 - 540 to 680 20 18 - - -

40 27

c f c f

25CrMo4 1.7218 345 345 345 - 540 to 690 18 15 - - -

40 27

c f c f

20CrMoV13-5-5 1.7779 590 590 590 - 740 to 880 16 14 - - -

40 27

e c f c f

15NiCuMoNb5-6-4 1.6368 440 440 440 610 to 780 19 17 - - -

440 40 27

c f c f

7CrWVMoNb9-6 1.8201 400 400 400 - 510 to 740 20 18 - - -

40 27

EN 10216-2:2013 (E)

Table 4 — (concluded)

a b

Tensile properties at room temperature

Steel grade

Impact properties

Upper yield strength or proof strength Tensile Elongation Minimum average absorbed energy

h

strength

KV

R or R for wall thickness T A min.

eH p0,2

Rm

J

a h

min.

%

at a temperature of

Steel

Steel name

number

°C

T ≤ 16 16 < T ≤ 40 40 < T ≤ 60 60 < T ≤ l t l t

g g g g g

20 0 -10 20 0

MPa MPa MPa MPa MPa

c f c f

7CrMoVTiB10-10 1.7378 450 430 430 - 565 to 840 17 15 - - -

40 27

c c

X11CrMo5+I 1.7362+I 175 175 175 175 430 to 580 22 20 - - -

40 27

c c

X11CrMo5+NT1 1.7362+NT 280 280 280 280 480 to 640 20 18 - - -

40 27

c c

X11CrMo5+NT2 1.7362+NT 390 390 390 390 570 to 740 18 16 - - -

40 27

c c

X11CrMo9-1+I 1.7386+I 210 210 210 - 460 to 640 20 18 - - -

40 27

c c

X11CrMo9-1+NT 1.7386+NT 390 390 390 - 590 to 740 18 16 - - -

40 27

c f c f

X10CrMoVNb9-1 1.4903 450 450 450 450 630 to 830 19 17 - - -

40 27

c f c f

X10CrWMoVNb9-2 1.4901 440 440 440 440 620 to 850 19 17 - - -

40 27

c f c f

X11CrMoWVNb9-1-1 1.4905 450 450 450 450 620 to 850 19 17 - - -

40 27

c f c f

X20CrMoV11-1 1.4922 490 490 490 490 690 to 840 17 14 - - -

40 27

a

l = longitudinal; t = transverse.

b

f

!To be verified when Option 4 or Option 5 or both is/are specified, unless footnote applies."

c

!Option 4: Impact energy shall be verified for Group B (see Table 13; for specimen direction see 10.2.2.4)."

d

Option 5: Longitudinal impact energy shall be verified !at −10 °C.".

e

For wall thickness 60 mm < T ≤ 80 mm.

f

Impact test verification (longitudinal or transversal) is mandatory for wall thickness T ≥ 16 mm.

g

1 MPa = 1 N/mm .

h

.

Observe that the A value 14 % and the minimum average KV value 27 J is exactly on the design requirements levels according to!European Legislation for Pressure Equipment"

min

EN 10216-2:2013 (E)

Table 5 — Minimum proof strength R at elevated temperature

p0,2

a

Steel grade Wall

Minimum proof strength R MPa

p0,2

thickness

at a temperature of °C

mm

Steel name Steel 100 150 200 250 300 350 400 450 500 550 600

number

P195GH 1.0348 ≤16 175 165 150 130 113 102 94 - - - -

P235GH 1.0345 ≤ 60 198 187 170 150 132 120 112 108 - - -

P265GH 1.0425 ≤ 60 226 213 192 171 154 141 134 128 - - -

20MnNb6 1.0471 ≤ 60 312 292 264 241 219 200 186 174 - - -

16Mo3 1.5415 ≤ 60 243 237 224 205 173 159 156 150 146 - -

8MoB5-4 1.5450 ≤ 16 368 368 368 368 368 368 368 - - - -

14MoV6-3 1.7715 ≤ 60 282 276 267 241 225 216 209 203 200 197 -

10CrMo5-5 1.7338 ≤ 60 240 228 219 208 165 156 148 144 143 - -

13CrMo4-5 1.7335 ≤ 60 264 253 245 236 192 182 174 168 166 - -

10CrMo9-10 1.7380 ≤ 60 249 241 234 224 219 212 207 193 180 - -

11CrMo9-10 1.7383 ≤ 60 323 312 304 296 289 280 275 257 239 - -

25CrMo4 1.7218 ≤ 60 - 315 305 295 285 265 225 185 - - -

20CrMoV13-5-5 1.7779 ≤ 60 - 575 570 560 550 510 470 420 370 - -

15NiCuMoNb5-6-4 1.6368 ≤ 80 422 412 402 392 382 373 343 304 - - -

7CrWVMoNb9-6 1.8201 ≤ 60 379 370 363 361 359 351 345 338 330 299 266

7CrMoVTiB10-10 1.7378 !≤ 60" 397 383 373 366 359 352 345 336 324 301 248

X11CrMo5+I 1.7362+I ≤ 100 156 150 148 147 145 142 137 129 116 - -

X11CrMo5+NT1 1.7362+NT1 ≤ 100 245 237 230 223 216 206 196 181 167 - -

X11CrMo5+NT2 1.7362+NT2 ≤ 100 366 350 334 332 309 299 289 280 265 - -

Table 5 — (concluded)

a

Steel grade Wall

Minimum proof strength R MPa

p0,2

thickness

at temperature of °C

mm

Steel name Steel 100 150 200 250 300 350 400 450 500 550 600

number

X11CrMo9-1+I 1.7386+I ≤ 60 187 186 178 177 175 171 164 153 142 120 -

X11CrMo9-1+NT 1.7386+NT ≤ 60 363 348 334 330 326 322 316 311 290 235 -

X10CrMoVNb9-1 1.4903 ≤ 100 410 395 380 370 360 350 340 320 300 270 215

X10CrWMoVNb9-2 1.4901 ≤ 100 420 412 405 400 392 382 372 360 340 300 248

X11CrMoWVNb9-1-1 1.4905 ≤ 100 412 401 390 383 376 367 356 342 319 287 231

X20CrMo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...