EN 13445-1:2002

(Main)Unfired pressure vessels - Part 1: General

Unfired pressure vessels - Part 1: General

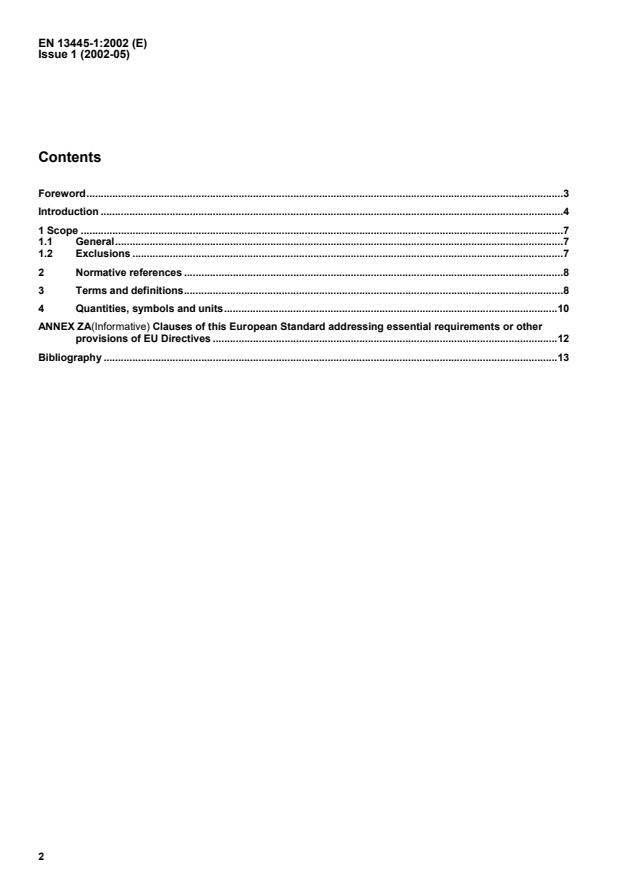

This Part of this European Standard defines the terms, definitions, symbols and units that are used throughout the EN 13445.

This Part of EN 13445 also gives guidelines on the principles on which each part of the standard has been based. This information is aimed to aid the user of the EN 13445. This European Standard applies to unfired pressure vessels subject to a maximum allowable pressure greater than 0,5 bar gauge but may be used for vessels operating at lower pressures, including vacuum.

This European Standard applies to maximum allowable temperatures for which creep effects need not be considered, i.e. for maximum allowable temperatures for which the corresponding maximum calculation temperature renders a relevant proof strength smaller than the 100 000 h creep rupture strength. For ferritic steels the temperature limit corresponds to calculation temperatures below approximately 380 °C

In EN13445-3:2002 two methods of Design by Analysis (DBA) are given in Annex B and Annex C respectively. Both of these are normative. However Parts 2, 4 and 5 of this edition of the standard do not include provision within their respective areas of responsibility for vessels designed using Design by Analysis - Direct Route (DBA) of Annex B of EN13445-3

NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during operation are covered in prEN 764-7.

Unbefeuerte Druckbehälter - Teil 1: Allgemeines

Der vorliegende Tel dieser Europäischen Norm legt die für die gesamte EN 13445 geltenden Begriffe, Symbole und Einheiten fest.

Dieser Teil der EN 13445 enthält außerdem einen Leitfaden zu den Grundsätzen, auf denen jeder einzelne Teil der Norm basiert. Diese Information soll den Anwendern der EN 13445 als Hilfestellung dienen. Die vorliegende

Europäische Norm gilt für unbefeuerte Druckbehälter für einen maximalen zulässigen Druck über 0,5 bar, sie kann jedoch auch für Behälter angewendet werden, die bei niedrigeren Drücken, einschließlich Vakuum, betrieben

werden.

Diese Europäische Norm gilt für maximale zulässige Temperaturen, bei denen das Zeitstandverhalten nicht

berücksichtigt werden muss, d. h. für maximale zulässige Temperaturen, bei denen die entsprechende maximale Berechnungstemperatur eine jeweilige Druckfestigkeit ergibt, die unter der 100 000 h-Zeitstandfestigkeit liegt. Bei ferritischen Stählen entspricht die Temperaturgrenze Berechnungstemperaturen unter ca. 380 °C.

ANMERKUNG Die Auswahl, Anwendung und der Einbau von Ausrüstungsteilen mit Sicherheitsfunktion zum Schutz der Druckbehälter während des Betriebes sind in prEN 764-7 behandelt.

Récipients sous pression non soumis à la flamme - Partie 1: Généralités

Cette Partie de la présente Norme européenne définit les termes, définitions, symboles et unités qui sont utilisés tout au long de l'EN 13445.

Cette Partie de l'EN 13445 donne également des lignes directrices sur les principes sous-tendant chacune des Parties de la norme. Cette information est destinée à aider l'utilisateur de la norme. Cette Norme européenne s'applique aux récipients sous pression non soumis à la flamme et soumis à une pression maximale admissible supérieure à 0,5 bar, mais peut être utilisée pour des récipients soumis à des pressions inférieures, y compris des pressions négatives.

Cette Norme européenne s'applique à des températures maximales admissibles pour lesquelles les effets du fluage n'ont pas besoin d'être pris en compte, c'est-à-dire à des températures maximales admissibles pour lesquelles la température de calcul maximale correspondante aboutit à une résistance d'épreuve inférieure à la résistance pour la rupture au fluage en 100 000 h. Pour les aciers ferritiques, la limite de température correspond à des températures de calcul approximativement inférieures à 380 °C.

Dans l'EN 13445-3:2002 deux méthodes de conception par analyse (DBA) sont données en Annexe B et en Annexe C respectivement. Ces deux méthodes sont normatives. Cependant, les Parties 2, 4 et 5 de la présente version de la norme n'incluent pas, dans leur champ de compétence respectif, de dispositions pour des récipients conçus en utilisant la Conception par analyse - Voie directe (DBA) de l'annexe B de l'EN 13445-3.

NOTE Le choix, la mise en ¿uvre et l'installation des accessoires de sécurité destinés à protéger les récipients à pression en service font l'objet du prEN 764-7.

Neogrevane tlačne posode - 1. del: Splošno

General Information

- Status

- Withdrawn

- Publication Date

- 28-May-2002

- Withdrawal Date

- 21-Jul-2009

- Technical Committee

- CEN/TC 54 - Unfired pressure vessels

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Jul-2009

- Completion Date

- 22-Jul-2009

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Referred By

EN 13831:2007 - Closed expansion vessels with built in diaphragm for installation in water - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13445-1:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Unfired pressure vessels - Part 1: General". This standard covers: This Part of this European Standard defines the terms, definitions, symbols and units that are used throughout the EN 13445. This Part of EN 13445 also gives guidelines on the principles on which each part of the standard has been based. This information is aimed to aid the user of the EN 13445. This European Standard applies to unfired pressure vessels subject to a maximum allowable pressure greater than 0,5 bar gauge but may be used for vessels operating at lower pressures, including vacuum. This European Standard applies to maximum allowable temperatures for which creep effects need not be considered, i.e. for maximum allowable temperatures for which the corresponding maximum calculation temperature renders a relevant proof strength smaller than the 100 000 h creep rupture strength. For ferritic steels the temperature limit corresponds to calculation temperatures below approximately 380 °C In EN13445-3:2002 two methods of Design by Analysis (DBA) are given in Annex B and Annex C respectively. Both of these are normative. However Parts 2, 4 and 5 of this edition of the standard do not include provision within their respective areas of responsibility for vessels designed using Design by Analysis - Direct Route (DBA) of Annex B of EN13445-3 NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during operation are covered in prEN 764-7.

This Part of this European Standard defines the terms, definitions, symbols and units that are used throughout the EN 13445. This Part of EN 13445 also gives guidelines on the principles on which each part of the standard has been based. This information is aimed to aid the user of the EN 13445. This European Standard applies to unfired pressure vessels subject to a maximum allowable pressure greater than 0,5 bar gauge but may be used for vessels operating at lower pressures, including vacuum. This European Standard applies to maximum allowable temperatures for which creep effects need not be considered, i.e. for maximum allowable temperatures for which the corresponding maximum calculation temperature renders a relevant proof strength smaller than the 100 000 h creep rupture strength. For ferritic steels the temperature limit corresponds to calculation temperatures below approximately 380 °C In EN13445-3:2002 two methods of Design by Analysis (DBA) are given in Annex B and Annex C respectively. Both of these are normative. However Parts 2, 4 and 5 of this edition of the standard do not include provision within their respective areas of responsibility for vessels designed using Design by Analysis - Direct Route (DBA) of Annex B of EN13445-3 NOTE The selection, application and installation of safety related accessories intended to protect pressure vessels during operation are covered in prEN 764-7.

EN 13445-1:2002 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13445-1:2002 has the following relationships with other standards: It is inter standard links to EN 13445-1:2009, EN 12952-14:2004, EN 13831:2007, EN 12621:2006+A1:2010, EN 378-2:2008+A2:2012, EN 13445-1:2002/A3:2007, EN 13445-1:2002/A2:2006, EN 13445-1:2002/A1:2007; is excused to EN 764-7:2002, EN 13445-2:2002, EN 13445-4:2002, EN 13445-3:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13445-1:2002 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13445-1:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Unfired pressure vessels - Part 1: GeneralRécipients sous pression non soumis a la flamme - Partie 1: GénéralitésUnbefeuerte Druckbehälter - Teil 1: AllgemeinesTa slovenski standard je istoveten z:EN 13445-1:2002SIST EN 13445-1:2002en23.020.30ICS:SLOVENSKI

STANDARDSIST EN 13445-1:200201-november-2002

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13445-1May 2002ICS 23.020.30English versionUnfired pressure vessels - Part 1: GeneralRécipients sous pression non soumis à la flamme - Partie1: GénéralitésUnbefeuerte Druckbehälter - Teil 1: AllgemeinesThis European Standard was approved by CEN on 23 May 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13445-1:2002 E

to direct generated heat or flame impingement from a firedprocess. This does not exclude vessels subject to electrical heating or heated process streams.In Parts 1 to 5 only pressure vessels manufactured from steels and steel castings as detailed in Part 2 of thisstandard are covered. Part 6 specifically deals with spheroidal graphite cast iron and special considerations apply.Part 1This Part outlines the basic principles underpinning the standard.

The manufacturer is required to declare that thetechnical design specification and the supporting documentation are in compliance with the requirements of thisstandard.Unforeseen factors may arise that require design modifications and/or manufacturing concessions. These need tobe handled with the same rigour as the original design.Part 2This Part deals with the general philosophy on materials, material grouping and low temperature behaviour inrelation to Room Temperature performance. It is limited to steel with sufficient ductility and excludes at presentmaterials operating in the creep range. Part 2 provides the general requirements for establishing technical deliveryconditions.Furthermore Part 2 includes the requirements for marking. Four annexes give further details. The normativeAnnex A includes the material grouping system, which is in accordance with CR ISO 15608:2000. This system isused throughout the whole standard. Furthermore Annex A adds a list of all those material grades based uponEuropean base material standards which are accepted to be used for unfired pressure vessels made to thisstandard The normative Annex B gives the necessary information on the requirements for the prevention of brittlefracture in the base material and the welds. Two methods based upon a code of practice developed from fracturemechanics are covered. The informative Annex C gives information on technical delivery conditions for cladproducts. Annex D gives an informative survey on European base material and component standards and theirsystematic nomenclature.Part 3This Part of this standard gives the rules to be used for design and calculation under internal and/or externalpressure (as applicable) of pressure bearing components of Pressure Vessels, such as shells of various shapes,flat walls, flanges, heat exchanger tubesheets, including the calculation of reinforcement of openings. Rules arealso given for components subject to local loads and to actions other than pressure.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...