EN 12621:2006+A1:2010

(Main)Machinery for the supply and circulation of coating materials under pressure - Safety requirements

Machinery for the supply and circulation of coating materials under pressure - Safety requirements

This European Standard applies to the design and construction of machinery for the supply and circulation of coating and/or auxiliary materials under pressure in the following called "machine" (see 3.1).

The coating material is supplied by air pressure or airless.

NOTE Machines covered by this European Standard may be linked with e.g. colour mixing machinery, atomising and spraying equipment, spray booths and stands and/or automated coating machinery.

The pressure related parts of the machines covered are classified as no higher than category I under article 9 of the Pressure Equipment Directive 97/23/EC.

This European Standard deals with the significant hazards, hazardous situations and events relevant to the machinery for the supply and circulation of coating and/or auxiliary materials under pressure, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4).

Machinery for the supply and circulation of coating and/or auxiliary materials under pressure consists of the following equipment:

- pump units;

- pressure vessels;

- non-pressurised containers;

- interconnecting pipes and hoses

- flanges, nozzles, couplings, supports, lifting equipment etc.;

- agitators;

- filters;

- pulsation damping devices;

- all safety devices (e.g. level monitoring equipment);

- equipment for heating and/or cooling of the coating materials.

The machine may be fixed or mobile.

1.2 This European Standard excludes:

- pressure related hazards of equipment classified as higher than category 1 under article 9 of the Pressure Equipment Directive 97/23/EC;

- atomising and spraying equipment as dealt with in EN 1953:1998 and the supply hoses for this equipment;

- atomising and spraying equipment as dealt with in EN 50144-2-7:2001, EN 50260-2-7:2002 and the supply hoses for this equipment.

This European Standard does not apply to:

- machinery for processing of foodstuffs and pharmaceuticals;

Förder- und Umlaufanlagen für Beschichtungsstoffe unter Druck - Sicherheitsanforderungen

Diese Europäische Norm gilt für Gestaltung und Konstruktion von Förder- und Umlaufanlagen für

Beschichtungs- und/oder Hilfsstoffe unter Druck — im Folgenden als „Anlage“ bezeichnet (siehe 3.1).

Die Beschichtungsstoffe können unter Druck oder drucklos zugeführt werden.

ANMERKUNG Anlagen nach diesem Dokument können z. B. mit Farbmischgeräten, Spritz- und Sprüheinrichtungen,

Spritzkabinen und -ständen und/oder stationären Ausrüstungen zum Beschichten verbunden sein.

Die durch diese Norm abgedeckten druckbetriebenen Teile der Anlagen dürfen die in der Druckgeräte-

Richtlinie 97/23/EG, Artikel 9 festgelegte Kategorie I nicht übersteigen.

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und

Gefährdungsereignisse, die auf Förder- und Umlaufanlagen für Beschichtungs- und/oder Hilfsstoffe unter

Druck zutreffen, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des

Herstellers verwendet werden (siehe Abschnitt 4).

Förder- und Umlaufanlagen für Beschichtungs- und/oder Hilfsstoffe unter Druck enthalten z. B. folgende

Komponenten:

⎯ Pumpeinheiten;

⎯ Druckbehälter;

⎯ drucklose Behälter;

⎯ Verbindungsrohre und -schläuche;

⎯ Flansche, Düsen, Kupplungen, Halterungen, Hebezeuge usw.;

⎯ Rührwerke;

⎯ Filter;

⎯ Pulsation dämpfende Einrichtungen;

⎯ alle Sicherheits-, Mess- und Regeleinrichtungen (z. B. Überwachungseinrichtung für den Füllstand);

⎯ Einrichtungen zum Erwärmen und/oder Kühlen der Beschichtungsstoffe.

Die Anlage kann ortsfest oder ortsbeweglich sein.

1.2 Dieses Dokument gilt nicht für:

⎯ druckbetriebene Teile der Anlage, die die in Artikel 9 der Druckgeräte-Richtlinie 97/23/EG festgelegte

Kategorie I übersteigen;

⎯ durch EN 1953:1998 abgedeckte Spritz- und Sprüheinrichtungen und die Versorgungsschläuche für

diese Einrichtungen;

⎯ durch EN 50144-2-7:2000 und EN 50260-2-7:2002 abgedeckte Spritz- und Sprüheinrichtungen und die

Versorgungsschläuche für diese Einrichtungen.

Installations d'alimentation et de circulation de produits de revêtement sous pression - Prescriptions de sécurité

1.1 La présente Norme européenne s'applique à la conception et à la fabrication de systèmes pour l'alimentation et la circulation de produits de revêtement et/ou auxiliaires sous pression, désignés ci-après par le terme «machine» (voir 3.1).

Le produit de revêtement est alimenté soit par air comprimé, soit par pulvérisation sans air.

NOTE Les machines concernées par la présente Norme européenne peuvent être associés par exemple à des machines de mélange de teintes, des équipements d'atomisation et de pulvérisation, des cabines et postes d’application de peinture et/ou des machines de revêtement automatiques.

Les composants soumis à la pression des machines concernées ne peuvent pas être classés au-delà de la catégorie I conformément à l’article 9 de la Directive 97/23/CE «Équipements sous pression».

La présente Norme européenne traite de tous les phénomènes dangereux, situations dangereuses et événements dangereux liés aux installations d'alimentation et de circulation de produits de revêtement et/ou auxiliaires sous pression, utilisés selon et dans les conditions prévues par le fabricant (voir Article 4).

Les installations pour l'alimentation et la circulation de produits de revêtement et/ou auxiliaires sous pression comprennent les équipements suivants :

- unités de pompe ;

- récipients sous pression ;

- containers non pressurisés;

- tuyaux et flexibles d’interconnexion ;

- brides, buses, raccords, supports, équipement de levage, etc. ;

- agitateurs ;

- filtres ;

- dispositifs de réduction des à-coups ;

- tout dispositif de sécurité (par exemple, équipement de contrôle de niveau) ;

- équipement pour réchauffer ou refroidir les produits de revêtement.

Le système peut être fixe ou mobile.

1.2 Sont exclus de la présente Norme européenne :

- les phénomènes dangereux liés à la pression d’équipements classés dans une catégorie supérieure à la catégorie 1 conformément à l’article 9 de la Directive 97/23/CE «Équipements sous pression» ;

Naprave za dovod in obtok premaznih materialov s pomočjo tlaka - Varnostne zahteve (vključno z dopolnilom A1)

1.1 Ta evropski standard velja za načrtovanje in izdelavo naprav za dovod in obtok premaznih in/ali pomožnih materialov s pomočjo tlaka – v nadaljevanju se imenujejo »naprave« (glej 3.1). Premazni material se dovaja pod zračnim tlakom ali brezzračno. OPOMBA: Naprave, ki jih zajema ta evropski standard, so lahko povezane z npr. napravami za mešanje barv, opremo za razprševanje in brizganje, kabinami in stojali za brizganje in/ali napravami za avtomatsko premazovanje. Deli zajetih naprav, povezani s tlakom, niso razvrščeni višje kot v kategorijo I po členu 9 Direktive 97/23/ES o tlačni opremi. Ta evropski standard obravnava vse bistvene nevarnosti, nevarna stanja in dogodke v zvezi z napravami za dovod in obtok premaznih in/ali pomožnih materialov, kadar se uporabljajo v skladu z namembnostjo in pod pogoji, kot jih je predvidel proizvajalec (glej Klavzulo 4). Naprave za dovod in obtok premaznih in/ali pomožnih materialov s pomočjo tlaka so sestavljene iz naslednje opreme:

- črpalnih enot;

- tlačnih posod;

- vsebnikov, ki niso pod tlakom;

- povezovalnih cevi in cevk;

- prirobnic, razpršilnih šob, spojk, podpor, opreme za dviganje, itd.;

- stresalnikov;

- filtrov;

- pripomočkov za dušenje pulziranja;

- vseh varnostnih pripomočkov (npr. opreme za spremljanje ravni);

- opreme za gretje in/ali hlajenje premaznih materialov.

Naprava je lahko stacionarna ali premična.

1.2 Ta evropski standard izključuje:

- s tlakom povezane nevarnosti opreme, ki so razvrščene višje kot v kategorijo I po členu 9 Direktive 97/23/ES o tlačni opremi;

- opremo za razprševanje in brizganje, kot jo obravnava EN 1953:1998, in dovodne cevke za to opremo;

- opremo za razprševanje in brizganje, kot jo obravnavata EN 50144-2-7:2001 in EN 50260-2-7:2002, in dovodne cevke za to opremo.

1.3 Ta evropski standard ne velja za:

- naprave za obdelavo živil in zdravil;

- načrtovanje in izdelavo cevi in cevk;

- načrtovanje in izdelavo stiskalnic za premazovanje (glej točko 3.23);

- naprav za dovod premaznega materiala v prahu.

1.4. Ta evropski standard ne velja za naprave za dovod in obtok premaznih materialov s pomočjo tlaka, ki so bile izdelane pred datumom, ko je CEN objavil ta dokument.

General Information

- Status

- Withdrawn

- Publication Date

- 01-Jun-2010

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 271 - Surface treatment equipment - Safety

- Drafting Committee

- CEN/TC 271/WG 2 - Machines for coating and color mixing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Feb-2025

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 284, C 284, C 284, C 284, C 284, C 284, C 284, C OJ Date: 20-Oct-2010

Harmonized Standard2014/34/EU - Directive 2014/34/EU Of The European Parliament And Of The Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres (recast)OJ Ref: HARMONIZIRAN, C 293/52, C 293/52, C 126, C 126, C, OJ Date: 08-Apr-2016

Not Harmonized94/9/EC - Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX)OJ Ref: C 251, C 251, C 251, C 251, C 251, C 251, C 251, C OJ Date: 17-Sep-2010

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 03-Apr-2010

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Frequently Asked Questions

EN 12621:2006+A1:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Machinery for the supply and circulation of coating materials under pressure - Safety requirements". This standard covers: This European Standard applies to the design and construction of machinery for the supply and circulation of coating and/or auxiliary materials under pressure in the following called "machine" (see 3.1). The coating material is supplied by air pressure or airless. NOTE Machines covered by this European Standard may be linked with e.g. colour mixing machinery, atomising and spraying equipment, spray booths and stands and/or automated coating machinery. The pressure related parts of the machines covered are classified as no higher than category I under article 9 of the Pressure Equipment Directive 97/23/EC. This European Standard deals with the significant hazards, hazardous situations and events relevant to the machinery for the supply and circulation of coating and/or auxiliary materials under pressure, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Machinery for the supply and circulation of coating and/or auxiliary materials under pressure consists of the following equipment: - pump units; - pressure vessels; - non-pressurised containers; - interconnecting pipes and hoses - flanges, nozzles, couplings, supports, lifting equipment etc.; - agitators; - filters; - pulsation damping devices; - all safety devices (e.g. level monitoring equipment); - equipment for heating and/or cooling of the coating materials. The machine may be fixed or mobile. 1.2 This European Standard excludes: - pressure related hazards of equipment classified as higher than category 1 under article 9 of the Pressure Equipment Directive 97/23/EC; - atomising and spraying equipment as dealt with in EN 1953:1998 and the supply hoses for this equipment; - atomising and spraying equipment as dealt with in EN 50144-2-7:2001, EN 50260-2-7:2002 and the supply hoses for this equipment. This European Standard does not apply to: - machinery for processing of foodstuffs and pharmaceuticals;

This European Standard applies to the design and construction of machinery for the supply and circulation of coating and/or auxiliary materials under pressure in the following called "machine" (see 3.1). The coating material is supplied by air pressure or airless. NOTE Machines covered by this European Standard may be linked with e.g. colour mixing machinery, atomising and spraying equipment, spray booths and stands and/or automated coating machinery. The pressure related parts of the machines covered are classified as no higher than category I under article 9 of the Pressure Equipment Directive 97/23/EC. This European Standard deals with the significant hazards, hazardous situations and events relevant to the machinery for the supply and circulation of coating and/or auxiliary materials under pressure, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Machinery for the supply and circulation of coating and/or auxiliary materials under pressure consists of the following equipment: - pump units; - pressure vessels; - non-pressurised containers; - interconnecting pipes and hoses - flanges, nozzles, couplings, supports, lifting equipment etc.; - agitators; - filters; - pulsation damping devices; - all safety devices (e.g. level monitoring equipment); - equipment for heating and/or cooling of the coating materials. The machine may be fixed or mobile. 1.2 This European Standard excludes: - pressure related hazards of equipment classified as higher than category 1 under article 9 of the Pressure Equipment Directive 97/23/EC; - atomising and spraying equipment as dealt with in EN 1953:1998 and the supply hoses for this equipment; - atomising and spraying equipment as dealt with in EN 50144-2-7:2001, EN 50260-2-7:2002 and the supply hoses for this equipment. This European Standard does not apply to: - machinery for processing of foodstuffs and pharmaceuticals;

EN 12621:2006+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 87.100 - Paint coating equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12621:2006+A1:2010 has the following relationships with other standards: It is inter standard links to EN 12621:2006, EN 12621:2025, EN 61000-6-4:2001, EN 61010-1:2001, EN 50176:1996, EN 61310-1:1995, EN 50050:2006, EN 61000-6-1:2001, EN 61000-6-2:2001, EN 61000-6-3:2001, EN 50059:1990, EN 60079-0:2009, EN 60079-15:2005, EN 60204-1:1997, ISO 3864-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12621:2006+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC, 98/37/EC; Standardization Mandates: M/396, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12621:2006+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.9DUQRVWQHFörder- und Umlaufanlagen für Beschichtungsstoffe unter Druck - SicherheitsanforderungenInstallations d'alimentation et de circulation de produits de revêtement sous pression - Prescriptions de sécuritéMachinery for the supply and circulation of coating materials under pressure - Safety requirements87.100Oprema za nanašanje premazovPaint coating equipmentICS:Ta slovenski standard je istoveten z:EN 12621:2006+A1:2010SIST EN 12621:2006+A1:2010en,fr,de01-oktober-2010SIST EN 12621:2006+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12621:2006+A1

June 2010 ICS 87.100 Supersedes EN 12621:2006English Version

Machinery for the supply and circulation of coating materials under pressure - Safety requirements

Installations d'alimentation et de circulation de produits de revêtement sous pression - Prescriptions de sécurité

Förder- und Umlaufanlagen für Beschichtungsstoffe unter Druck - Sicherheitsanforderungen This European Standard was approved by CEN on 9 December 2005 and includes Amendment 1 approved by CEN on 30 April 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12621:2006+A1:2010: ESIST EN 12621:2006+A1:2010

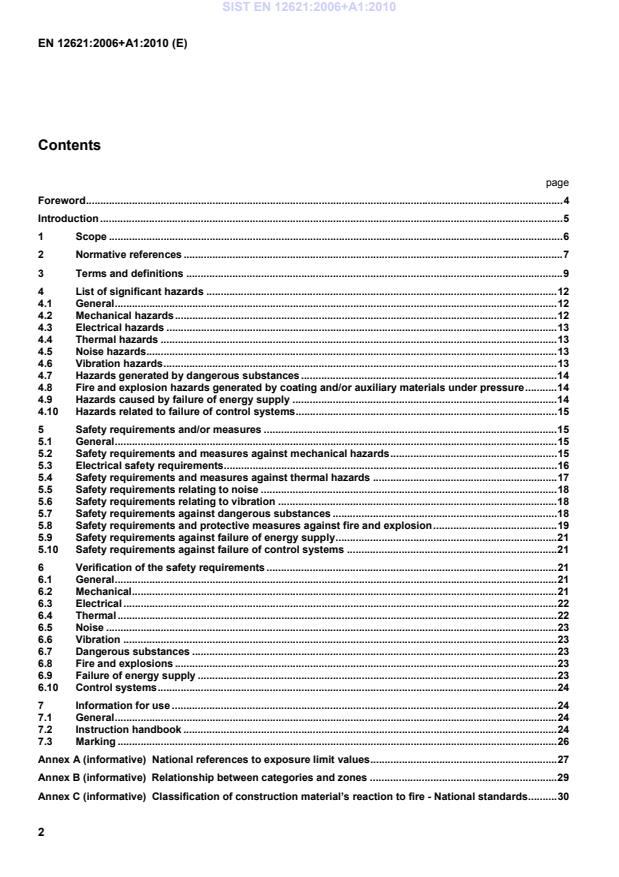

National references to exposure limit values . 27Annex B (informative)

Relationship between categories and zones . 29Annex C (informative)

Classification of construction material’s reaction to fire - National standards . 30SIST EN 12621:2006+A1:2010

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 31Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC . 32Bibliography . 33

1 Scope 1.1 This European Standard applies to the design and construction of machinery for the supply and circulation of coating and/or auxiliary materials under pressure – in the following called "machine" (see 3.1). The coating material is supplied by air pressure or airless. NOTE Machines covered by this European Standard may be linked with e.g. colour mixing machinery, atomising and spraying equipment, spray booths and stands and/or automated coating machinery.

The pressure related parts of the machines covered are classified as no higher than category I under article 9 of the Pressure Equipment Directive 97/23/EC. This European Standard deals with the significant hazards, hazardous situations and events relevant to the machinery for the supply and circulation of coating and/or auxiliary materials under pressure, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). Machinery for the supply and circulation of coating and/or auxiliary materials under pressure consists of the following equipment: pump units; pressure vessels; non-pressurised containers; interconnecting pipes and hoses flanges, nozzles, couplings, supports, lifting equipment etc.; agitators; filters; pulsation damping devices; all safety devices (e.g. level monitoring equipment); equipment for heating and/or cooling of the coating materials. The machine may be fixed or mobile. 1.2 This European Standard excludes: pressure related hazards of equipment classified as higher than category 1 under article 9 of the Pressure Equipment Directive 97/23/EC; atomising and spraying equipment as dealt with in EN 1953:1998 and the supply hoses for this equipment; atomising and spraying equipment as dealt with in EN 50144-2-7:2001, EN 50260-2-7:2002 and the supply hoses for this equipment. 1.3 This European Standard does not apply to: !machinery for" processing of foodstuffs and pharmaceuticals; SIST EN 12621:2006+A1:2010

painting and finishing EN 50176:1996, Automatic electrostatic spraying installations for flammable liquid spraying material !EN 60079-0:2009, Explosive atmospheres — Part 0: Equipment — General requirements

(IEC 60079-0:2007)" !EN 60079-15:2005, Electrical apparatus for explosive gas atmospheres — Part 15: Construction, test and marking of type of

protection "n" electrical apparatus (IEC 60079-15:2005)" EN 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:1997) EN 61000-6-1:2001, Electromagnetic compatibility (EMC) — Part 6-1: Generic standards — Immunity for residential, commercial and light-industrial environments (IEC 61000-6-1:1997, modified) EN 61000-6-2:2001, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for industrial environments (IEC 61000-6-2:1999, modified) EN 61000-6-3:2001, Electromagnetic compatibility (EMC) — Part 6-3: Generic standards — Emission standard for residential, commercial and light-industrial environments (IEC 61000-6-3:1996, modified) EN 61000-6-4:2001, Electromagnetic compatibility (EMC) — Part 6-4: Generic standards — Emission standard for industrial environments (IEC 61000-6-4:1997, modified) SIST EN 12621:2006+A1:2010

sealers and adhesives. 3.11 auxiliary material material used for functions e.g.: solvents, compressed air (for cleaning), water, compressed air (for maintenance) 3.12 flammable substance substance in form of gas, vapour, liquid, solid, or mixtures of these, able to undergo an exothermic reaction with air when ignited !(see 3.48 of EN 13237:2003)" NOTE “Flammable substances” and “combustible material” are equivalently used terms in this European Standard. 3.13 explosion range range of concentration of a flammable substance with air, within which an explosion can occur !(see 3.33 of

EN 13237:2003)" 3.14 hazardous areas areas where hazards due to explosive atmosphere may exist. The probability of occurrence of explosive atmospheres is classified in zones NOTE Limits of hazardous zones are given in Annex B 3.14.1 zone 0 place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently !(see 3.119-1 of EN 13237:2003)" SIST EN 12621:2006+A1:2010

EN 61000-6-1:2001 or EN 61000-6-2:1994. NOTE It is recommended that manufacturers use only components that have been identified as conforming for immunity and emission to harmonised EMC standards and apply them in accordance with the supplier’s recommendations. 5.4 Safety requirements and measures against thermal hazards Machines with equipment for heating and/or cooling of coating material shall be designed and constructed to minimise any risk of injury caused by contact, radiation or convection from hot or very cold surfaces of the machine and its parts or coating material. Limits of temperatures of touchable surfaces given in EN 563 shall be observed. The hazard of touching hot surfaces shall preferably be reduced by: limitation of coating material temperature; insulation; guarding to keep distance (screen, barrier, according to EN 953). and where necessary: marking and warning signals according to EN 894-1, EN 894-2, EN 894-3, EN 61310-1 and EN 981; instructions of use of personal protective equipment (see 7.2). Protection against burns by hot surfaces shall be secured by means of appropriate insulation or protection against contact of all elements within arm's reach and within the working area. According to EN 563 at an ambient temperature of 20 °C the surface temperature shall be less than 60 °C. Exceptions are permissible in small localised areas of the surface (for example flanges of burners, bolts). Any parts of the machine not normally in contact with the human body which may exceed these temperatures will require special warnings in the instruction handbook including recommended contact time limits as shown in EN 563. Such surfaces shall also be fitted with warning labels indicating the risks and stating the maximum temperature that these surfaces may reach. For pipelines, 1 label/3m is required. For non-metallic components such as hoses and seals, the manufacturer's recommendations shall be observed. Machines with equipment for heating and/or cooling of coating material shall be safeguarded to prevent the coating material exceeding the maximum allowable temperature for the intended use. When temperature limiting controls are used, over-temperature shall be at least be avoided by end of scale of the temperature setting device or protection of the maximum set point by key lock or code system. SIST EN 12621:2006+A1:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...