EN 16517:2021

(Main)Agricultural and forestry machinery - Mobile yarders for timber logging - Safety

Agricultural and forestry machinery - Mobile yarders for timber logging - Safety

This document gives safety requirements, and the means of verification, for the design and construction of mobile yarders for logging of forest products and their mounting. It counts for all logging operations with cable yarders both in sloped and flat terrain. In addition, it specifies the type of information on safe working practices (including residual risks) meant to be provided by the manufacturer.

It deals with the significant hazards (as listed in Table 1), hazardous situations and events relevant to mobile yarders used as intended and under the conditions of misuse foreseeable by the manufacturer (see Clauses 4 and 5).

Emission of noise (with regard to airborne noise) is not covered by this document.

It is not applicable to:

- rope splicing;

- ancillary loaders or cable cranes;

- cableways for material transport (other than wood); and

- skidder winches (skidding).

The specifications of cabin in this context are only relevant for the yarder or a yarder-loader combination. The cabin and the chassis of the vehicle (prime mover), to which the yarder is mounted are not part of this document.

This document is not applicable to mobile yarders manufactured before the date of its publication.

Land- und Forstmaschinen - Mobile Seilgeräte für den Holztransport - Sicherheit

Dieses Dokument liefert Sicherheitsanforderungen sowie die Mittel zur Verifizierung der Auslegung und Konstruktion von mobilen Seilgeräten für den Transport von Holzprodukten sowie deren Befestigung. Es gilt für alle Vorgänge der Holztransport mit mobilen Seilgeräten, sowohl in steilem als auch in flachem Gelände. Zusätzlich legt es die Informationen zu sicheren Arbeitspraktiken (einschließlich der Restrisiken) fest, die vom Hersteller bereitzustellen sind.

Es behandelt die signifikanten Gefährdungen (wie in Tabelle 1 angeführt), Gefährdungssituationen und Gefährdungsereignisse, die für mobile Seilgeräte relevant sind, die bestimmungsgemäß und unter den vom Hersteller vorhersehbaren Bedingungen der Fehlanwendung verwendet werden (siehe Abschnitt 4 und Abschnitt 5).

Die Geräuschemission (in Bezug auf den Luftschall) wird in diesem Dokument nicht behandelt.

Dieses Dokument ist nicht anzuwenden für:

— das Spleißen von Seilen;

— Seilkräne oder Kabelkräne;

— Seilbahnen für den Materialtransport (außer Rohholz); und

— Seilwinden von Seilschleppern (Skidder).

Die Festlegungen für eine Schutzkabine sind in diesem Zusammenhang nur für die Seilgeräte oder eine Kombination aus mobilem Seilgerät und Ladekran relevant. Die Fahrzeugkabine und das Fahrgestell des Fahrzeugs (der Antriebsmaschine), auf dem das Seilgerät aufgebaut ist, ist nicht Gegenstand dieses Dokuments.

Dieses Dokument ist nicht anzuwenden für mobile Seilgeräte, die vor dem Datum der Veröffentlichung dieses Dokuments hergestellt wurden.

Matériel agricole et forestier - Téléphériques forestiers mobiles pour l'exploitation du bois - Sécurité

Le présent document spécifie les prescriptions de sécurité et les moyens de vérification pour la conception et la construction de téléphériques forestiers mobiles pour l'exploitation de produits forestiers et leur montage. Il tient compte de toutes les opérations d'exploitation forestière réalisées au moyen de téléphériques forestiers, sur terrain en pente et sur terrain plat. En outre, il spécifie le type d'informations que le fabricant doit donner sur les pratiques d'utilisation sûre (y compris les risques résiduels).

Il traite tous les phénomènes dangereux (tels qu'énumérés au Tableau 1), situations et événements dangereux significatifs engendrés par les téléphériques forestiers mobiles lorsqu’ils sont utilisés normalement et dans les conditions de mauvais usage prévues par le fabricant (voir Articles 4 et 5).

L’émission de bruit (en ce qui concerne l’émission de bruit aérien) n’est pas traitée par le présent document.

Il ne s’applique pas aux :

- épissure de cordes ;

- chargeurs auxiliaires ou aux blondins ;

- câbles aériens pour le transport de matériaux (autres que le bois) ; et

- aux treuils de débardeuses (débardage).

Dans ce contexte, les spécifications de la cabine s'appliquent uniquement au téléphérique forestier ou à la combinaison téléphérique-chargeur. La cabine et le châssis du véhicule (moteur), sur lequel est monté le téléphérique forestier, ne relève pas du domaine d'application du présent document.

Le présent document ne s’applique pas aux téléphériques forestiers mobiles fabriqués avant sa date de publication.

Kmetijski in gozdarski stroji - Mobilni žični žerjavi za spravilo lesa - Varnost

Ta evropski standard določa varnostne zahteve in načine preverjanja zahtev za načrtovanje ter gradnjo mobilnih žičnih žerjavov za spravilo lesa in njegovo nakladanje. Uporablja se za vsakovrstno sečnjo s pomočjo žičnih žerjavov tako na nagnjenem kot ravnem terenu. Določa tudi vrsto informacij o varnih delovnih praksah (vključno z ostalimi tveganji), ki jih mora zagotoviti proizvajalec.

Opisuje večje nevarnosti (navedene v preglednici 1), nevarne situacije in dogodke v zvezi z mobilnimi žičnimi žerjavi, kadar se ti uporabljajo v skladu s svojim namenom in pod pogoji, ki jih je predvidel proizvajalec (glej točki 4 in 5).

Standard se ne uporablja za:

– splete vrvi,

– pomožne nakladalnike ali kabelske žerjave,

– žičnice za prevoz materiala (razen lesa) in

– drsne vitle (drsenje).

Specifikacije kabine v tem kontekstu so pomembne samo za žerjav ali kombinacijo žerjava in nakladalnika. Kabina in podvozje vozila (primarni pogon), na katerega je pritrjen žerjav, nista obravnavana v tem dokumentu.

Dokument obravnava vse večje nevarnosti (navedene v preglednici 1), nevarne situacije in dogodke v zvezi z mobilnimi žerjavi, kadar se ti uporabljajo v skladu s svojim namenom in pod pogoji nepravilne uporabe, ki jih je razumno predvidel proizvajalec (glej točki 4 in 5). Ta dokument se ne uporablja za mobilne žerjave, izdelane pred datumom objave tega dokumenta.

General Information

- Status

- Published

- Publication Date

- 21-Dec-2021

- Withdrawal Date

- 29-Jun-2022

- Technical Committee

- CEN/TC 144 - Tractors and machinery for agriculture and forestry

- Drafting Committee

- CEN/TC 144/WG 8 - Forestry machinery

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 22-Dec-2021

- Due Date

- 23-Feb-2019

- Completion Date

- 22-Dec-2021

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

EN 16517:2021 - Overview

EN 16517:2021 (CEN) specifies safety requirements and means of verification for the design, construction and mounting of mobile yarders for timber logging. The standard covers cable yarder operations in both sloped and flat terrain and defines the information manufacturers must provide about safe working practices and residual risks. It is a Type‑C standard (per EN ISO 12100) intended to be used alongside general machinery safety standards. Emissions of airborne noise are excluded. The standard does not apply to rope splicing, ancillary loaders/cable cranes, non‑wood material cableways, skidder winches, or yarders manufactured before publication.

Key topics and technical requirements

EN 16517 details the significant hazards, hazardous situations and verification methods relevant to mobile yarders. Major technical topics include:

- Structural calculations and stress analysis - required load cases, load combinations and documentation for structural safety.

- Mechanical arrangements - tower design, guying, stabilizers and transport securing.

- Rope drive and winches - requirements for ropes, drums, traction sheaves, blocks and braking systems.

- Carriage systems - derailing protection, stopping devices, clamps, pulleys and load balance.

- Hydraulic and electrical systems - safety principles for power systems and control integrity.

- Limiting and indicating devices - load limiters, motion/speed limiters, general safe stop (GSS), and acoustic/visual warnings.

- Controls and control stations - design for operator cabins and ground controls, emergency devices, symbols and ergonomics.

- Access and maintenance - platforms, ladders, strength/rigidity requirements and assembly/mounting instructions.

- Information and markings - manufacturer/operator manuals, mounting instructions, nameplates, load/warning signs and documented residual risks.

- Verification and testing - procedures to demonstrate conformity with requirements (see Clause 6).

The standard also includes Annex A (risk zone) and Annex ZA linking EN 16517 to the essential requirements of EU Directive 2006/42/EC.

Applications and who uses it

EN 16517 is intended for:

- Manufacturers and designers of mobile yarders for safe product development and CE conformity.

- Health & safety authorities, market surveillance and regulators evaluating compliance with machinery directives.

- Forest operators, contractors and employers using cable yarding systems to set procurement and operational safety standards.

- Maintenance and service providers assembling, mounting or inspecting yarders.

- Technical authors and trainers preparing operator manuals, mounting instructions and safety training.

Practical uses include risk assessment, equipment specification, design verification, conformity assessment, and compiling operator/mounting documentation.

Related standards

- EN ISO 12100 (general principles for risk assessment and risk reduction)

- Annex ZA of EN 16517 (relationship to EU Machinery Directive 2006/42/EC)

Keywords: EN 16517:2021, mobile yarders, timber logging safety, cable yarders, forestry equipment, CEN standard, machinery safety.

Frequently Asked Questions

EN 16517:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Agricultural and forestry machinery - Mobile yarders for timber logging - Safety". This standard covers: This document gives safety requirements, and the means of verification, for the design and construction of mobile yarders for logging of forest products and their mounting. It counts for all logging operations with cable yarders both in sloped and flat terrain. In addition, it specifies the type of information on safe working practices (including residual risks) meant to be provided by the manufacturer. It deals with the significant hazards (as listed in Table 1), hazardous situations and events relevant to mobile yarders used as intended and under the conditions of misuse foreseeable by the manufacturer (see Clauses 4 and 5). Emission of noise (with regard to airborne noise) is not covered by this document. It is not applicable to: - rope splicing; - ancillary loaders or cable cranes; - cableways for material transport (other than wood); and - skidder winches (skidding). The specifications of cabin in this context are only relevant for the yarder or a yarder-loader combination. The cabin and the chassis of the vehicle (prime mover), to which the yarder is mounted are not part of this document. This document is not applicable to mobile yarders manufactured before the date of its publication.

This document gives safety requirements, and the means of verification, for the design and construction of mobile yarders for logging of forest products and their mounting. It counts for all logging operations with cable yarders both in sloped and flat terrain. In addition, it specifies the type of information on safe working practices (including residual risks) meant to be provided by the manufacturer. It deals with the significant hazards (as listed in Table 1), hazardous situations and events relevant to mobile yarders used as intended and under the conditions of misuse foreseeable by the manufacturer (see Clauses 4 and 5). Emission of noise (with regard to airborne noise) is not covered by this document. It is not applicable to: - rope splicing; - ancillary loaders or cable cranes; - cableways for material transport (other than wood); and - skidder winches (skidding). The specifications of cabin in this context are only relevant for the yarder or a yarder-loader combination. The cabin and the chassis of the vehicle (prime mover), to which the yarder is mounted are not part of this document. This document is not applicable to mobile yarders manufactured before the date of its publication.

EN 16517:2021 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16517:2021 has the following relationships with other standards: It is inter standard links to EN 60947-5-5:1997/A2:2017, EN 60204-1:2018, ISO 16625:2013, EN 60947-5-5:1997, ISO 6750-1:2019, EN 60947-5-5:1997/A1:2005, EN 61000-6-4:2007/A1:2011, ISO 730:2009/Amd 1:2014, EN 61000-6-4:2007, EN 60204-32:2008, EN 61000-6-2:2005, EN 60947-5-5:1997/A11:2013, EN ISO 16739:2016, EN 13557:2003+A2:2008, EN 17067:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16517:2021 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/393, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16517:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2022

Kmetijski in gozdarski stroji - Mobilni žični žerjavi za spravilo lesa - Varnost

Agricultural and forestry machinery - Mobile yarders for timber logging - Safety

Land- und Forstmaschinen - Mobile Seilkrananlagen für den Holztransport - Sicherheit

Matériel agricole et forestier - Téléphériques forestiers mobiles pour l'exploitation du bois

- Sécurité

Ta slovenski standard je istoveten z: EN 16517:2021

ICS:

53.020.99 Druga dvigalna oprema Other lifting equipment

65.060.80 Gozdarska oprema Forestry equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16517

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 53.020.20; C

English Version

Agricultural and forestry machinery - Mobile yarders for

timber logging - Safety

Matériel agricole et forestier - Téléphériques forestiers Land- und Forstmaschinen - Mobile Seilkrananlagen

mobiles pour l'exploitation du bois - Sécurité für den Holztransport - Sicherheit

This European Standard was approved by CEN on 24 October 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16517:2021 E

worldwide for CEN national Members.

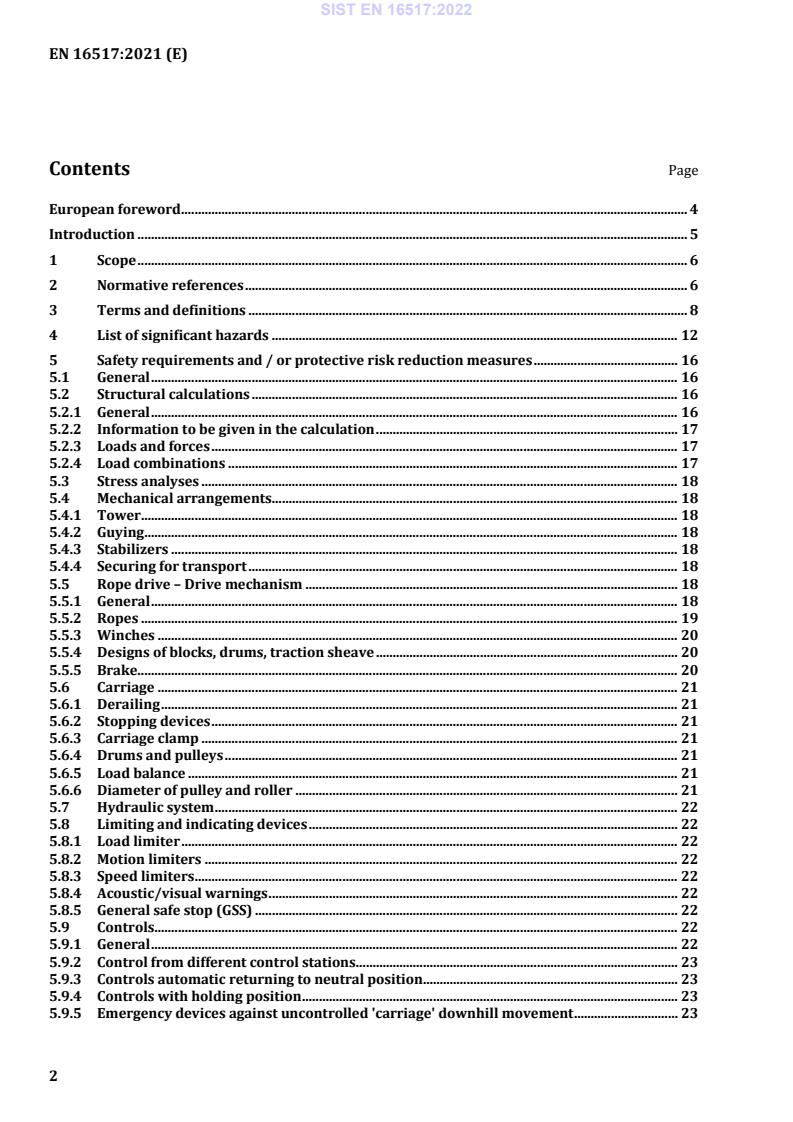

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 List of significant hazards . 12

5 Safety requirements and / or protective risk reduction measures . 16

5.1 General . 16

5.2 Structural calculations . 16

5.2.1 General . 16

5.2.2 Information to be given in the calculation . 17

5.2.3 Loads and forces . 17

5.2.4 Load combinations . 17

5.3 Stress analyses . 18

5.4 Mechanical arrangements. 18

5.4.1 Tower. 18

5.4.2 Guying . 18

5.4.3 Stabilizers . 18

5.4.4 Securing for transport . 18

5.5 Rope drive – Drive mechanism . 18

5.5.1 General . 18

5.5.2 Ropes . 19

5.5.3 Winches . 20

5.5.4 Designs of blocks, drums, traction sheave . 20

5.5.5 Brake. 20

5.6 Carriage . 21

5.6.1 Derailing . 21

5.6.2 Stopping devices . 21

5.6.3 Carriage clamp . 21

5.6.4 Drums and pulleys . 21

5.6.5 Load balance . 21

5.6.6 Diameter of pulley and roller . 21

5.7 Hydraulic system . 22

5.8 Limiting and indicating devices . 22

5.8.1 Load limiter . 22

5.8.2 Motion limiters . 22

5.8.3 Speed limiters . 22

5.8.4 Acoustic/visual warnings . 22

5.8.5 General safe stop (GSS) . 22

5.9 Controls . 22

5.9.1 General . 22

5.9.2 Control from different control stations . 23

5.9.3 Controls automatic returning to neutral position . 23

5.9.4 Controls with holding position . 23

5.9.5 Emergency devices against uncontrolled 'carriage' downhill movement . 23

5.9.6 Symbols . 23

5.10 Control stations . 23

5.10.1 General . 23

5.10.2 Operator cabin . 24

5.10.3 Safety . 24

5.10.4 Ground control . 24

5.10.5 Control station for setting up . 24

5.11 Platform and ladder . 24

5.11.1 Platform . 24

5.11.2 Ladder . 24

5.11.3 Strength and rigidity of components . 25

5.12 Electrical systems . 25

5.13 Assembly of machine components . 25

5.13.1 Attachment to three-point hitch system . 25

5.13.2 Combination of components of different manufacturers . 25

6 Verification of safety requirements and measures . 25

7 Information for use . 26

7.1 Mounting instructions. 26

7.1.1 General . 26

7.1.2 Instructions for assembly . 26

7.2 Markings . 27

7.2.1 General . 27

7.2.2 Manufacturer's plate . 27

7.2.3 Installer's plate . 28

7.2.4 Load signs . 28

7.2.5 Warnings . 28

7.3 Operator's manual. 28

Annex A (informative) Risk zone . 30

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC aimed to be covered. 32

Bibliography . 35

European foreword

This document (EN 16517:2021) has been prepared by Technical Committee CEN/TC 144 “Tractors

and machinery for agriculture and forestry”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

Cable yarders in the context of this document are machines consisting of a yarder (including all

components), ropes (cables, lines) and a transporter system (carriage, rider block or butt rigg) where

the trees/logs/wooden biomass is hooked on to the transporter. The yarder is mounted on a chassis

(wheeled, tracked or sledge frame) and is designed for a quick change of location. In most cases, the

logging operations change position on a 1-3 day frequency.

Typical operation for cable yarders is the close collaboration of mechanized components with workers,

often in rough terrain. Cable yarding includes a lot of manual work in very difficult terrain where the

weight of the tools and ropes has a direct impact on the operators' ergonomic workload. Ergonomics

play therefore an important role in choosing adequate working coefficients for all elements. A review of

the relevant literature; historical experience and operation of cable yarders have indicated a wide range

of working coefficients (safety factor) with a focus on 2, 5 to 3 for the skyline and mainline.

This document is a type-C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the

market players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events

are covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those, which are stated in type-A or type-

B standards, the requirements of this type-C standard take precedence over the requirements of the

other standards for machines that have been designed and built according to the requirements of this

type-C standard.

1 Scope

This document gives safety requirements, and the means of verification, for the design and construction

of mobile yarders for logging of forest products and their mounting. It counts for all logging operations

with cable yarders both in sloped and flat terrain. In addition, it specifies the type of information on safe

working practices (including residual risks) meant to be provided by the manufacturer.

It deals with the significant hazards (as listed in Table 1), hazardous situations and events relevant to

mobile yarders used as intended and under the conditions of misuse foreseeable by the manufacturer

(see Clauses 4 and 5).

Emission of noise (with regard to airborne noise) is not covered by this document.

It is not applicable to:

— rope splicing;

— ancillary loaders or cable cranes;

— cableways for material transport (other than wood); and

— skidder winches (skidding).

The specifications of cabin in this context are only relevant for the yarder or a yarder-loader

combination. The cabin and the chassis of the vehicle (prime mover), to which the yarder is mounted

are not part of this document.

This document is not applicable to mobile yarders manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 353-1:2014+A1:2017, Personal fall protection equipment - Guided type fall arresters including an

anchor line - Part 1: Guided type fall arresters including a rigid anchor line

EN 353-2:2002, Personal protective equipment against falls from a height - Part 2: Guided type fall

arresters including a flexible anchor line

EN 12077-2:1998+A1:2008, Cranes safety - Requirements for health and safety - Part 2: Limiting and

indicating devices

EN 12385-1:2002+A1:2008, Steel wire ropes - Safety - Part 1: General requirements

EN 12385-2:2002+A1:2008, Steel wire ropes - Safety - Part 2: Definitions, designation and classification

EN 12385-3:2020, Steel wire ropes - Safety - Part 3: Information for use and maintenance

EN 12385-4:2002+A1:2008, Steel wire ropes - Safety - Part 4: Stranded ropes for general lifting

applications

EN 12965:2019, Tractors and machinery for agriculture and forestry - Power take-off (PTO) drive shafts

and their guards - Safety

EN 12999:2020, Cranes - Loader cranes

EN 13001-3-1:2012+A2:2018, Cranes - General Design - Part 3-1: Limit States and proof competence of

steel structure

EN 13001-3-2:2014, Cranes - General design - Part 3-2: Limit states and proof of competence of wire ropes

in reeving systems

EN 13557:2003+A2:2008, Cranes - Controls and control stations

EN 13586:2020, Cranes - Access

EN 17067:2018, Forestry machinery - Safety requirements on radio remote controls

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016)

EN 60204-32:2008, Safety of machinery - Electrical equipment of machines - Part 32: Requirements for

hoisting machines (IEC 60204-32:2008)

EN 60947-5-5:1997, Low-voltage switchgear and controlgear - Part 5-5: Control circuit devices and

switching elements - Electrical emergency stop device with mechanical latching function

(IEC 60947-5-5:1997)

EN 61000-6-2:2005, Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments (IEC 61000-6-2:2005)

EN 61000-6-4:2007, Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments (IEC 61000-6-4:2006)

EN ISO 3411:2007, Earth-moving machinery - Physical dimensions of operators and minimum operator

space envelope (ISO 3411:2007)

EN ISO 3449:2008, Earth-moving machinery - Falling-object protective structures - Laboratory tests and

performance requirements (ISO 3449:2005)

EN ISO 4413:2010, Hydraulic fluid power - General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2015)

As impacted by EN 60947-5-5:1997/A1:2005, EN 60947-5-5:1997/A2:2017 and EN 60947-5-5:1997/A11:2013.

As impacted by EN 61000-6-2:2005/AC:2005.

As impacted by EN 61000-6-4:2007/A1:2011.

EN ISO 13850:2015, Safety of machinery - Emergency stop function - Principles for design (ISO

13850:2015)

EN ISO 13854:2019, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

(ISO 13854:2017)

EN ISO 13857:2019, Safety of machinery - Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

ISO 730:2009, Agricultural wheeled tractors — Rear-mounted three-point linkage — Categories 1N, 1,

2N, 2, 3N, 3, 4N and 4

ISO 3600:2015, Tractors, machinery for agriculture and forestry, powered lawn and garden equipment —

Operator's manuals — Content and format

ISO 4309:2017, Cranes — Wire ropes — Care and maintenance, inspection and discard

ISO 6750-1:2019, Earth-moving machinery — Operator's manual — Part 1: Contents and format

ISO 7000:2019, Graphical symbols for use on equipment — Registered symbols

ISO 8083:2006, Machinery for forestry — Falling-object protective structures (FOPS) — Laboratory tests

and performance requirements

ISO 8084:2003, Machinery for forestry — Operator protective structures — Laboratory tests and

performance requirements

ISO 16625:2013, Cranes and hoists — Selection of wire ropes, drums and sheaves

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

cableway

suspended cable used as an elevated rope along which a carriage can be pulled or moved

As impacted by ISO 730:2009/AMD 1:2014.

3.2

yarder

mobile or semi mobile unit that consists of a set of winch drums/pulley’s to operate lines for a

temporary cableway

Note 1 to entry: An ancillary carriage is pulled or moved by a cable (main line and/or haul back line) on the

suspended cable way which is used to bring the trees/logs/wooden biomass to the unloading zone. It can be

mounted on a sledge, behind or on a tractor, skidder or a truck.

3.3

tower yarder

yarder mounted to a vehicle or a trailer (prime mover) with integrated tower that can be tilted and/or

telescoped to horizontal position or retracted for transport reasons

3.4

butt rig

system of swivels, chain-like links, shackles, and bull hooks connected between the mainline and the

haul back line

Note 1 to entry: Chokers are attached to the butt rig with choker hooks (see 3.22).

3.5

rider block

block running (riding) on the haul backline to lift the butt rig which is connected to the rider block with

a short strap or chain

3.6

carriage

wheeled equipment that moves along the skyline with components to transport and lift loads

(trees/logs/wooden biomass)

Note 1 to entry: Movement can be provided by the mainline, haul-backline or separate integral engine.

3.7

skyline

cable on which the carriage rides

Note 1 to entry: It is the top line in the system.

3.8

main line

haul-in line

cable to pull the carriage directly to the yarder that can also be used for lifting, lowering and lateral

hauling of the load (log)

3.9

haul-back line

cable to pull the carriage away from the yarder that can also be used for lifting, lowering and lateral

hauling of the load (log)

Note 1 to entry: In high lead systems, it takes over the carrying function.

3.10

auxiliary line

cable for additional functions without carrying or retaining function

3.11

slack-pulling line

cable activating clamps or switching operations at the carriage without carrying or retaining function

3.12

setup-line

cable to supply the setup; without carrying or retaining function

3.13

lift line

cable exclusively to lower, lift and lateral haul the load (trees/logs/wooden biomass)

3.14

guy line

fixed ropes to rig the yarder, the intermediate supports or spar trees under the applied loads

3.15

tensioning line

cable as component of a tensioning tool

3.16

skidding line dutchman

cable (separate drive) to pull away the loads from the landing zone that can be used for lateral

positioning of the other lines on the area of operations

3.17

mounting (straw) line

light weight cable (separate drive) exclusively for installation and dismantling purposes

3.18

transverse line

cross line

cable or chain to carry the block or support saddle

3.19

fixing line

cable, belt, strap or chain to attach components to stumps, trees, plate and pin, earth anchors or rock

bolts

3.20

intermediate support line

line to keep intermediate supports in position

3.21

auxillary equipment

accessories which are subordinated

EXAMPLE Choker.

3.22

choker

equipment to bundle/concentrate the load constructed from either polypropylene rope, steel rope or

chain links

Note 1 to entry: Chokers are lifting accessories for fixing the load to lift line.

3.23

anchoring line

system of cables, chains, belts and similar parts to setup, fix towers and supports in a stable position

3.24

fail-safe brake

automatically applied brake

brake that applies when the control device is not actively held in the open position

3.25

control station

operator work station

position where the control units of the yarder/cable-winch and/or carriage are placed

3.26

stabilizer

mechanical parts to guarantee (sometimes in combination with guylines) to keep the tower yarder in

balance

3.27

load limiter

element to avoid overstepping of the maximum allowable force in ropes

3.28

motion limiter

element to limit uncontrolled moves of the carriage or the load

Note 1 to entry: That is important for automatic controlled moves in order to avoid driving into areas where

other activities need the attention of operators and hinder them from taking over the control of the movements.

3.29

speed limiter

element to limit the speed of the carriage

3.30

uphill yarding

yarding system where the logs are pulled uphill

Note 1 to entry: If the inclination of the cableway is steep enough, gravity is used to bring the carriage down to

the loading spots

3.31

downhill yarding

yarding system where the logs are moved downhill

Note 1 to entry: The traditional system had a sled winch at the uphill position and used gravity to move the

carriage with the load downhill. Modern tower yarders are positioned on the bottom, of the skyline. A haul back

line or self-propelled carriage is used to bring the carriage upward to the loading spot.

3.32

all-terrain yarding

yarding system for flat areas where the carriage has to be actively moved in both directions (in and out)

3.33

standing skyline

system where the skyline is fixed on both ends, with the forces resulting of the pretension, the payload

and the position of the carriage (maximum in mid of the longest span)

3.34

living skyline

system where the skyline can be hauled in or out during operation, used to lead the logs hooked to the

carriage close to the terrain

Note 1 to entry: Part of the load is on the ground and therefore the payload is reduced.

3.35

running skyline

system where the skyline is installed as a loop with a winch on both ends, the rider block, carriage or a

simple butt rig being fixed between the skyline (mainline) and the haul back line

Note 1 to entry: The most common running skyline system is high lead yarding.

4 List of significant hazards

Table 1 gives the significant hazard(s), the significant hazardous situation(s) and hazardous event(s)

covered by this document that have been identified by risk assessment as being significant for this type

of machine, and which require specific action by the designer or manufacturer to eliminate or reduce

the risk.

Attention is drawn to the necessity to verify that the safety requirements specified in this document

apply to each significant hazard presented by a given machine and to validate that the risk assessment.

Table 1 — List of significant hazards associated with mobile yarders

Clause/ subclause of

No. Hazard, hazardous situation or hazardous event

this document

1 Mechanical hazards

1.1 By machine parts and components: e.g. 7.2.5, 7.3

1.1 a Form 7.2.5, 7.3

1.1 b Spatial assembly 7.2.5, 7.3

1.1 c Mass and stability (potential energy of parts, moving by gravity) 5.2, 5.3

1.1 d Mass and Speed (kinetic energy of parts in case of controlled or 5.2, 5.3, 5.4, 5.5, 5.6

uncontrolled inadequate mechanical strength)

1.1 e Inadequate mechanical strength. 5.2, 5.3, 5.4, 5.5.2.1,

5.6

1.1 f Energy accumulation inside the machine 5.5, 5.7, 5.12

1.1 g Caused by elastic elements (spring) 5.5, 5.7

1.1 h Caused by liquids and gases under pressure; 5.7

Clause/ subclause of

No. Hazard, hazardous situation or hazardous event

this document

1.1 i By vacuums –

1.2 Basic mechanical hazards

1.2 a Crushing 5.2, 5.5, 5.6, 5.10.2

1.2 b Shearing 5.2, 5.5, 5.6, 5.10.2

1.2 c Cutting 5.2, 5.5, 5.6, 5.10.2

1.2 d Entanglement 5.2, 5.5, 5.6, 5.10.2

1.2 e Drawing-in or trapping 5.2, 5.5, 5.6, 5.10.2

1.2 f Impact 5.2, 5.5, 5.6, 5.10.2

1.2 g Stabbing or puncture 5.2, 5.5, 5.6, 5.10.2

1.2 h Friction and abrasion 5.2, 5.5, 5.6, 5.10.2

1.2 i High pressure fluid injection or ejection 5.7

2 Electrical Hazards

2.1 Contact of persons with live parts (direct contact) 7.3

2.2 Contact of persons with parts which have become live under faulty 7.3

conditions (indirect contact)

2.3 Approach to live parts under high voltage 7.3

2.4 Electrostatic phenomena 7.3

2.5 Thermal radiation or other phenomena such as the projection of molten 7.3

particles and chemical effects from short circuits, overloads, etc.

3 Thermal Hazards resulting in

3.1 Burns, scalds and other injuries by a possible contact of persons with 5.10.2

objects or materials with an extreme high or low temperature, by flames

or explosions and also by the radiation of heat sources

3.2

Damage to health by hot or cold working environment 5.10.2

5 Hazards generated by vibration

5.1 Usage of hand-held machinery generating angiopathy or neural –

disturbances Hand-arm vibration syndrome (HAVs)

5.2

Whole body vibrations (WBV) 5.10.2

6 Hazard generated by radiation

6.1 Low frequencies, radio frequency and micro waves –

7 Hazards generated by materials and substances (and their

constituent elements) processed or used by the machinery

7.1 Hazard by contact or inhale of hazardous liquids, gases, mist, steam, or 5.10.3

dust

7.2 Hazard by fire or explosion –

Clause/ subclause of

No. Hazard, hazardous situation or hazardous event

this document

7.3 Biologic and micro biologic hazards (viruses and bacteria) –

8 Hazards generated by neglecting ergonomic principles in

machinery design, as e.g. hazards from:

8.1 Unhealthy postures or excessive effort 5.10.2

8.2 Inadequate consideration of hand-arm or foot-leg anatomy 5.10.2

8.3 Neglected use of personal protection equipment 7.2.5, 7.3

8.4 Inadequate local lighting 7.2.5, 7.3

8.5 Mental under load or overload, stress 7.2.5, 7.3

8.6 Human error, human behaviour 7.2.5, 7.3

8.7 Inadequate design, location or identification of manual controls 5.8

8.8 Inadequate design or location of visual display units 5.8

9 Combination of hazards 7.3

10 Unexpected start-up, unexpected overrun/over speed (or any 7.3

similar malfunction) from

10.1 Failure/disorder of the control system 5.9.1, 5.8.5, 5.12

10.2 Return of energy after breaks 5.7,

10.3 External influences on electrical resources (tools and materials) 5.12,

10.4 Other external influences (gravity, wind, atmosphere, etc.) 5.10,

10.5 Software bugs - bugs in control logic 5.12

10.6 Handling error (see also 8.6) 5.9.3

11 Hazard caused by missing option to shut down the machine under 7.3

optimal conditions

12 Change of rotation frequency of tools –

13 Energy blackout 5.5.3, 5.5.5

14 Loss of control system 5.5.5.6

15 Assembly errors 7.3 u)

16 Structural defect during operation 7.3

17 Hazard caused by falling down / spraying of parts or liquids 5.7

18 Loss of stability/ overturning of machine 5.4.2

19 Slipping, stumbling and falling of persons 5.11, 7.2.5, 7.3

20 Hazards due to the mobility of machinery 7.2.5, 7.3

20.1 Unintended/ unexpected movements of the vehicle during the start of 7.2.5, 7.3

the vehicle engine

20.2 Unintended/ unexpected movements without driver 7.2.5, 7.3

20.3 Transfer without all parts secured 7.2.5, 7.3

Clause/ subclause of

No. Hazard, hazardous situation or hazardous event

this document

20.4 Too high speed of trailers –

20.5 Too high vibrations during transfer –

20.6 Inadequate equipment to slow down and stop the machinery 5.5.5

21 Hazards caused by the position of the control station (including 5.10

operators cab)

21.1 Slump and fall of persons during access of control stations (see also 19) 5.11

21.2 Health risk by exhaust gases or lack of oxygen at the workplace 5.10, 7.3

21.3 Fire risk at the control stations 5.10, 7.3

21.4 Mechanical risk at the control stations: (see also 1.1) 5.10, 7.3

21.4.a Contact with wheels 7.3

21.4.b Risk of overturning –

21.4.c Hazard caused by falling down / puncture of parts 5.10.3

21.4.d Breakage of rotating parts (on high speed) 7.2.5, 7.3

21.4.e Contact of persons with parts and tools of machinery 7.2.5, 7.3

21.5 Inadequate visibility field from control stations 5.9.2

21.6 Inadequate lightening of work space 7.3

21.7 Inadequate seat 5.10.2

21.9 Vibration at the workplace 7.3

21.10 Insufficient possibility to leave the control station in case of need. 7.3

22 Hazards caused by the control unit.

22.1 Inadequate location of control levers 5.9.1

22.2 Inadequate design of control levers and mode of operation 5.9.1

23 Hazard caused by usage / setup of the machine (missing structural 7.3 u)

stability)

24 Hazards caused by operating power and power transmission 5.5.1

24.1 By engine and batteries 5.5.1

24.2 By power transmission between machines 5.7

24.3 By clutch and wire rope 5.5, 5.5.3.1

25 By / for other persons 7.3

25.1 Unauthorized start-up / use 5.9

25.2 Movement of parts beyond the limiting position 5.8.2

25.3 Missing or insufficient optic and acoustic warning signals 5.6, 7.3

26 Hazards due to insufficient instructions for operator/driver 7.1, 7.3

Clause/ subclause of

No. Hazard, hazardous situation or hazardous event

this document

27 Mechanical Hazards and hazardous events due to lifting (chapter 4

of the directive)

27.1 From load falls, collision, machine tipping caused by: 5.5

27.1.1 Lack of stability 7.1,7.3

27.1.2 Uncontrolled loading – overloading – overturning moments exceeded 7.2.4, 7.3

27.1.3 Uncontrolled amplitude of movements 7.3

27.1.4 Unexpected / unintended movement of loads 7.3

27.1.5 Inadequate holding devices / accessories 7.3

27.1.6 Collision of machines 7.1,7.3

27.2 Access of persons to the risk area of load 7.3

27.3 Derailing 5.6.1

27.4 Insufficient mechanical strength of parts 5.2

27.5 Insufficient design of load pick up, hook, drums. 5.5

27.6 Inadequate choice / assembly of chains, wire rope, attachment devices 5.5.2

27.7 Lowering the load by friction brake 5.5

27.8 From abnormal conditions for assembly / testing/ use/ maintenance Clause 6, 7.2

27.9 Crash of persons into load / counterweight 7.1, 7.3

28 Electrical hazards 7.3

28.1 Lightning 7.3

29 Hazards generated by neglecting ergonomic principles 5.9

29.1 Insufficient visibility from the operator position / 5.10, 5.5.3.1

5 Safety requirements and / or protective risk reduction measures

5.1 General

Machinery shall comply with the safety requirements and/or protective/risk reduction measures of this

Clause.

In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

relevant but not significant hazards which are not dealt with by this document.

5.2 Structural calculations

5.2.1 General

For load-bearing parts, all relevant forces, their possible direction of application and possible load

combinations that result from the setup configurations shall be taken into account.

The minimum safety factor of lifting accessories is 2,0. For ropes, the minimum safety factors are given

in 5.5.2.

The calculation of the forces in ropes shall take into account the maximum pulling forces of winches and

forces arising from the application of brakes.

Dynamic coefficients are not necessary, it can be demonstrated that appropriate elements provide

sufficient prevention of significant dynamic effects (e.g. increased loading avoided by elasticity of

cables, multiple spans with slipping over cable supports).

Calculation procedures necessary for the user for the correct setup and use of the equipment shall be

given in the operator’s manual.

5.2.2 Information to be given in the calculation

The following information shall be given in the calculation:

a) type of yarder and mode of operation;

b) the assumed loading conditions for all relevant set-up situations;

c) details of the load carrying system reflecting actual service conditions including outline drawings

and principal dimensions;

d) the material for the individual components and joints;

e) the shapes, dimensions and static cross-section values of all load-carrying members;

f) the minimum working coefficient of ropes (e.g. skyline, mainline, haul-back line, guy lines).

5.2.3 Loads and forces

The following loads and forces shall be taken into account:

a) Regular loads:

1) dead loads;

2) cable forces;

3) dynamic forces, e.g.: abrupt braking, catching of load and trapped load.

b) Occasional loads:

1) loads on stairways, platforms and hand rails. See 5.11.

c) Exceptional loads:

1) test loads;

2) emergency stop, hydraulic hose failure and subsequent application of hose rupture valve;

3) sudden release of the load, e.g. rope failure, sling failure.

NOTE See 7.3 a) 2) for wind forces.

5.2.4 Load combinations

Loads shall be combined in the most unfavourable way to determine the maximum stresses the yarder

will experience during normal operation.

5.3 Stress analyses

The strength of the steel structure may be assessed in connection with EN 13001-3-1:2012+A2:2018.

The limit states as given in EN 13001-3-1:2012+A2:2018 shall be used in conjunction with a static

analysis made for all foreseen cable setups.

5.4 Mechanical arrangements

5.4.1 Tower

5.4.1.1 In working position, the tower shall be mechanically secured (e.g. bolt with locking nut or

pin). For hydraulically operated tower extensions unintended movements (e.g. by failure or leakage of

the hydraulic system) shall be prevented in each working position (e.g. by mechanical elements). The

secure position of automatic locking systems shall be visible from outside.

Manual tower extensions shall have pull out stops which are, for example, spring loaded to provide

automatic positive (form defined) and mechanical locking when engaged.

5.4.1.2 The stability of the yarder shall be guaranteed by the use of guy-lines or stabilizers. This

shall limit the movement of the tower and avoid tower collapse in case of cable failure. These limiters

shall not disturb regular operations. The use of multiple guy lines could fulfil this requirement.

5.4.2 Guying

The stability of yarders during operation shall be ensured by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...