EN 1756-1:2001+A1:2008

(Main)Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods

Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods

This European Standard specifies safety requirements for design of tail lifts as defined in 3.1 for mounting on wheeled goods vehicles. It also specifies the verification of such tail lifts and the safety information that shall be provided for their use.

This European Standard deals with the technical requirements to minimize the hazards listed in clause 4 which can arise during the operation of tail lifts when carried out in accordance with the specifications as intended by the manufacturer or his authorized representative.

It applies to tail lifts :

- used for the purpose of loading and/or unloading such vehicles ;

- intended to be fitted, temporarily or permanently, either inside or on the front, side or rear of the wheeled vehicle ;

- driven either by hand or electric powered ;

- equipped with a platform to support loads which comprise goods, an operator, or a combination of the two ;

- with a maximum lifting height not exceeding 3 m above ground, the measurement shall be made when the platform is unloaded ;

- rotary type with a maximum lifting height not exceeding 2 m ;

- used as a link bridge when intended by the manufacturer.

NOTE A tail lift should not be confused with a link bridge attached to a loading dock which is included within the definition of a dock leveller and is outside the scope of this standard.

Loading and/or unloading operations include the use of a tail lift to lift and/or lower loads

This European Standard does not establish the additional requirements for :

- operation in severe conditions (e.g. extreme environmental conditions such as freezer applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields) ;

- operations subject to special rules (e.g. potentially explosive atmospheres) ;

- supply by electrical networks and the electrical circuit ;

- power take off part of the system ;

- cable less remote control and electronic equipment ;

- electromagnetic

Hubladebühnen - Plattformlifte für die Anbringung an Radfahrzeugen - Sicherheitsanforderungen - Teil 1: Hubladebühnen für Güter

Hayons élévateurs - Plates-formes élévatrices à monter sur véhicules roulants - Exigences de sécurité - Partie 1 : Hayons élévateurs pour marchandises

La présente Norme européenne spécifie les exigences de sécurité à respecter pour la conception des hayons élévateurs tels que définis en 3.1 pour le montage sur véhicules roulants de transport de marchandises. Elle spécifie également la vérification de ces hayons élévateurs et les informations de sécurité qui doivent être fournies pour l’utilisation de ces hayons élévateurs.

La présente Norme européenne traite des exigences techniques permettant de réduire au minimum les risques énoncés dans l’article 4 qui peuvent survenir pendant le fonctionnement des hayons élévateurs lorsqu’ils sont utilisés conformément aux spécifications prévues par le fabricant ou son représentant autorisé.

Elle s’applique aux hayons élévateurs :

utilisés pour charger et/ou décharger ces véhicules ;

destinés à être montés de façon temporaire ou permanente, soit à l'intérieur, soit à l'avant, sur le côté ou à l'arrière du véhicule roulant ;

actionnés manuellement ou motorisés ;

équipés d'une plate-forme pour supporter des charges comprenant des marchandises, un opérateur ou une combinaison des deux ;

dont la hauteur de levage maximum ne dépasse pas 3 m au-dessus du sol, la mesure doit être faite lorsque la plate-forme est non chargée ;

de type pivotant, avec une hauteur de levage maximum ne dépassant pas 2 m ;

utilisés comme ponts de liaison, lorsque cela est prévu par le fabricant.

NOTE Il ne convient pas de confondre un hayon élévateur avec un pont de liaison attenant à un quai de chargement qui se trouve inclus dans la définition d’une rampe ajustable et n’entre pas dans le domaine d’application de la présente norme.

Les opérations de chargement et/ou de déchargement comprennent l’utilisation d’un hayon élévateur pour monter et/ou descendre des charges.

La présente Norme européenne n’établit pas d’exigences supplémentaires pour :

Dvižne ploščadi - Dvižne ploščadi, nameščene na cestna vozila - Varnostne zahteve - 1. del: Tovorne dvižne ploščadi

General Information

- Status

- Withdrawn

- Publication Date

- 04-Mar-2008

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 4 - Tail lifts

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Aug-2021

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 22, C 22, C 22, C 22, C 22, C 22, C 22, C 22, C, OJ Date: 28-Jan-2009

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Aug-2018

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 1756-1:2001+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods". This standard covers: This European Standard specifies safety requirements for design of tail lifts as defined in 3.1 for mounting on wheeled goods vehicles. It also specifies the verification of such tail lifts and the safety information that shall be provided for their use. This European Standard deals with the technical requirements to minimize the hazards listed in clause 4 which can arise during the operation of tail lifts when carried out in accordance with the specifications as intended by the manufacturer or his authorized representative. It applies to tail lifts : - used for the purpose of loading and/or unloading such vehicles ; - intended to be fitted, temporarily or permanently, either inside or on the front, side or rear of the wheeled vehicle ; - driven either by hand or electric powered ; - equipped with a platform to support loads which comprise goods, an operator, or a combination of the two ; - with a maximum lifting height not exceeding 3 m above ground, the measurement shall be made when the platform is unloaded ; - rotary type with a maximum lifting height not exceeding 2 m ; - used as a link bridge when intended by the manufacturer. NOTE A tail lift should not be confused with a link bridge attached to a loading dock which is included within the definition of a dock leveller and is outside the scope of this standard. Loading and/or unloading operations include the use of a tail lift to lift and/or lower loads This European Standard does not establish the additional requirements for : - operation in severe conditions (e.g. extreme environmental conditions such as freezer applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields) ; - operations subject to special rules (e.g. potentially explosive atmospheres) ; - supply by electrical networks and the electrical circuit ; - power take off part of the system ; - cable less remote control and electronic equipment ; - electromagnetic

This European Standard specifies safety requirements for design of tail lifts as defined in 3.1 for mounting on wheeled goods vehicles. It also specifies the verification of such tail lifts and the safety information that shall be provided for their use. This European Standard deals with the technical requirements to minimize the hazards listed in clause 4 which can arise during the operation of tail lifts when carried out in accordance with the specifications as intended by the manufacturer or his authorized representative. It applies to tail lifts : - used for the purpose of loading and/or unloading such vehicles ; - intended to be fitted, temporarily or permanently, either inside or on the front, side or rear of the wheeled vehicle ; - driven either by hand or electric powered ; - equipped with a platform to support loads which comprise goods, an operator, or a combination of the two ; - with a maximum lifting height not exceeding 3 m above ground, the measurement shall be made when the platform is unloaded ; - rotary type with a maximum lifting height not exceeding 2 m ; - used as a link bridge when intended by the manufacturer. NOTE A tail lift should not be confused with a link bridge attached to a loading dock which is included within the definition of a dock leveller and is outside the scope of this standard. Loading and/or unloading operations include the use of a tail lift to lift and/or lower loads This European Standard does not establish the additional requirements for : - operation in severe conditions (e.g. extreme environmental conditions such as freezer applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields) ; - operations subject to special rules (e.g. potentially explosive atmospheres) ; - supply by electrical networks and the electrical circuit ; - power take off part of the system ; - cable less remote control and electronic equipment ; - electromagnetic

EN 1756-1:2001+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1756-1:2001+A1:2008 has the following relationships with other standards: It is inter standard links to EN 1756-1:2001/prA1, EN 1756-1:2001, EN 1756-1:2021, EN 61310-1:2008, ISO 12508:1994, EN ISO 12100-2:2003, EN 1005-3:2002+A1:2008, EN ISO 7731:2008, EN 574:1996, EN ISO 12100:2010, EN ISO 14122-2:2016, EN ISO 4413:2010, EN ISO 12100-1:2003, EN ISO 13857:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1756-1:2001+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396, M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1756-1:2001+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goodsDUQRVWQHHayons élévateurs - Plateformes élévatrices à monter sur véhicules roulants - Prescriptions de sécurité - Partie 1: Hayons élévateurs pour marchandisesHubladebühnen - Plattformlifte für die Anbringung and Radfahrzeugen - Sicherheitsanforderungen - Teil 1: Hubladebühnen für GüterTa slovenski standard je istoveten z:EN 1756-1:2001+A1:2008SIST EN 1756-1:2002+A1:2008en,fr53.020.99ICS:SLOVENSKI

STANDARDSIST EN 1756-1:2002+A1:200801-maj-2008

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1756-1:2001+A1

March 2008 ICS 53.020.99 Supersedes EN 1756-1:2001 English Version

Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods

Hayons élévateurs - Plateformes élévatrices à monter sur véhicules roulants - Prescriptions de sécurité - Partie 1: Hayons élévateurs pour marchandises

Hubladebühnen - Plattformlifte für die Anbringung and Radfahrzeugen - Sicherheitsanforderungen - Teil 1: Hubladebühnen für Güter This European Standard was approved by CEN on 30 September 2001 and includes Amendment 1 approved by CEN on 5 January 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1756-1:2001+A1:2008: E

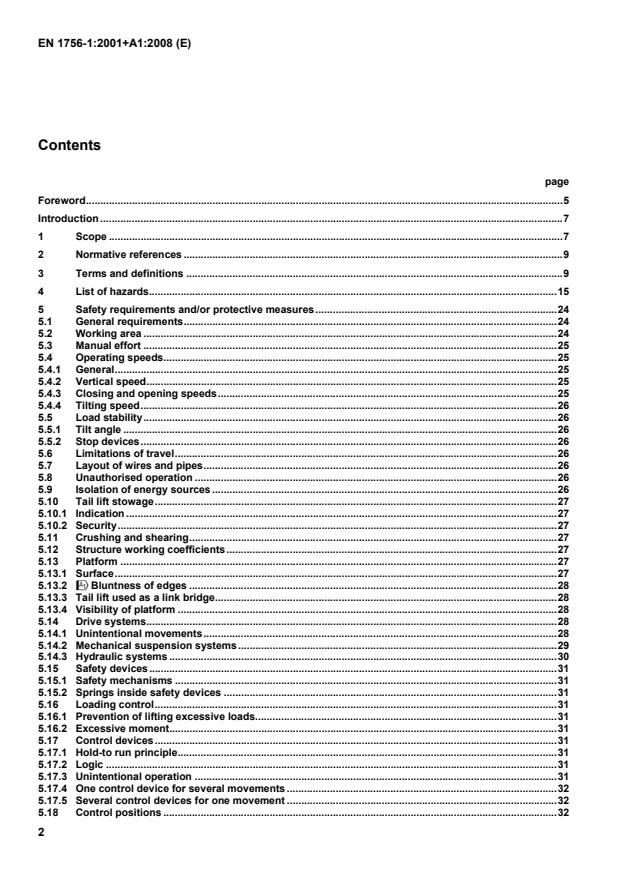

Tail lift mechanisms and types.41 A.1 Mechanisms.41 A.1.1 Parallelogram.41 A.1.2 Column.42 A.1.3 Telescopic.43 A.2 Types.43 A.2.1 Conventional : (full and part width).43 A.2.2 Folding platform.44 A.2.3 Retractable.45 A.2.4 Rotary.46 A.2.5 Door mounted.47 A.2.6 Inset.48 A.2.7 Internally mounted.48 Annex B (normative)

Crushing and shearing.49 B.1 General.49 B.2 Platform lifting and lowering.49 B.2.1 Two-hand control.49 B.2.2 Two-foot control.50 B.2.3 Toe guard.50 B.2.4 Hinged foot protector.53 B.2.5 Safety cut-out.54 B.2.6 Automatic toe protector.55 B.3 Platforms capable of lifting above vehicle floor level.57 B.4 Platform closure.57 B.4.1 Two-hand control.57 B.4.2 Safety cut-out.57 Annex C (informative)

Structure and drive system.58 Annex D (normative)

Drive systems - Steel wire ropes and chains.60 D.1 Recommended specifications of steel wire ropes.60 D.2 Dimensions of pulley grooves.60 D.3 Flare angle.60 D.4 Fleet angles.61 D.5 Pitch circle.62 Annex E (normative)

Examples of controls logic.63 Annex F (informative)

Marking.65 Annex G (informative)

Unintentional operation.66 Annex H (normative)

Verification by the installer.67 H.1 Compatibility between the lift and the vehicle.67 H.2 Static test.67 H.2.1 Deformation.67 H.2.2 Drift.67 H.3 Dynamic test.67 H.4 Test of operation and safety function.67 H.5 Test to verify that the tail lift cannot lift excessive load.68

Overloads onto a platform at vehicle floor level.69 Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.70 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC.71 Bibliography.72

NOTE A tail lift should not be confused with a link bridge attached to a loading dock which is included within the definition of a dock leveller and is outside the scope of this standard. Loading and/or unloading operations include the use of a tail lift to lift and/or lower loads This European Standard does not establish the additional requirements for : operation in severe conditions (e.g. extreme environmental conditions such as freezer applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields) ; operations subject to special rules (e.g. potentially explosive atmospheres) ; supply by electrical networks and the electrical circuit ; power take off part of the system ; cable less remote control and electronic equipment ; electromagnetic compatibility (emission-immunity) ; static electricity problems ; handling of loads the nature of which could lead to dangerous situations (e.g. molten metal, acids/bases, radiating materials, specially brittle loads) ; hazards occurring during installation, transportation, decommissioning ; hazards occurring when handling suspended loads which may swing freely ; requirement related to the use on public roads ; wind pressure in and out of use ; direct contact with foodstuffs ; earthquake ; lightning.

NOTE This is a restricted version of the definition given in !EN ISO 12100-1:2003". 3.8 manufacturer one which makes the tail lift 3.9 travelling position any configuration which the tail lift is intended to have while the vehicle is in motion 3.10 working position any configuration of the tail lift in which the platform is intended to handle a load in an operating position 3.11 operating position any configuration of the tail lift other than its travelling position 3.11.1 opening any movement of the platform between a travelling position and a working position 3.11.2 closing any movement of the platform from a working position to a travelling position 3.11.3 tilting any angular movement to adjust vertically the platform when it is in a working position 3.12 working area area on and around the platform and the controls 3.13 danger zone any zone on, under or in the path of the platform as well as around any part of the mechanism in which a person is exposed to risk of injury or damage to health

NOTE This definition shall not preclude the platform being a working area 3.14 platform width dimension of the platform measured parallel to the edge adjacent to the vehicle in the position of Figure 1

Key

1 Platform depth 2 Platform width Figure 1 — Platform width and depth 3.16 platform vertical travel distance distance between the lowest and the highest positions respectively the platform can assume when its surface is horizontal (see Figure 2)

NOTE The travel distance is a different concept from the height.

Key 1 Vertical travel distance Figure 2 — Platform vertical travel distance 3.17 vertical speed platform vertical travel distance divided by the time taken by the platform to move through this distance 3.18 load any mass applied to the platform surface. It includes payload plus any load handling equipment and the mass of the operator if he is standing on the platform 3.19 maximum load greatest permitted load as a function of the position of its centre of gravity on the platform as specified by the manufacturer (see Figure 3) 3.20 nominal load maximum load having its centre of gravity on the centre line of the platform and placed at a distance from the edge adjacent to the vehicle in elevated working position of either half the platform depth or 600 mm, whichever is the lesser distance (see Figures 3 and 4)

Key

1 Load 2 Distance 3 Maximum load 4 Nominal load 5 Distance as defined by the manufacturer Figure 3 — Maximum and nominal load on the platform

Key

1 Centre of gravity of the load 2 Half platform depth or 600 mm Figure 4 — Nominal load 3.21 control device any device used to operate the tail lift EXAMPLE button, switch, joystick, pedal, lever !deleted text". 3.22 control position any location equipped with the necessary control devices to allow the tail lift to be operated. In the case of portable controls, the control position is any location in which the operator may stand when using the portable control 3.23 drive system any devices used to generate the movements of the tail lift (see for examples annex C) 3.24 working pressure pressure at which each components is designed to operate in steady-state lifting and/or tilting conditions 3.25 maximum working pressure pressure resulting from transient conditions or from the application of permitted load to the platform for example during link bridge operations or when the vehicle is standing on a gradient 3.26 installer any person or organization fitting the tail lift onto the vehicle and commissioning it

- machine parts or workpieces, e.g. :

a) shape ; X

5.13.3

b) relative location

X

c) mass and stability (potential energy of elements which may move under the effect of gravity) X

5.5.2 ; 5.13 ; annex I

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion) ; X

5.4.2 ; 5.4.3 ; 5.4.4

e) inadequacy of mechanical strength X

5.12 ; 5.14.2.1 ; 5.14.2.2 ; 5.14.3.2 ; 5.14.3.3

- accumulation of energy inside the machinery, e.g. :

f) elastic elements (springs) X

8.4.2.4

g) liquids and gases under pressure ; X

5.14.3.2 ; 5.14.3.3 4.1.1 Crushing hazard X

5.11 ; annex B

4.1.2 Shearing hazard X

5.11 ; annex B 4.1.3 Cutting or severing hazard X

NOT DEALT WITH 4.1.4 Entanglement hazard X

5.14.2.1 4.1.5 Drawing-in or trapping hazard X

8.4.1 ; annex B 4.1.6 Impact hazard X

5.2 ; 5.4 ; 5.10.2 ; 5.13.3 ; 5.18.2 4.1.7 Stabbing or puncture hazard

X

(continued)

X

4.1.9 High pressure fluid injection or ejection hazard X

5.14.3.2 ; 5.14.3.3 4.2 Electrical hazards, due to :

4.2.1 Contact of persons with live parts (direct contact) X

NOT DEALT WITH 4.2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) X

NOT DEALT WITH 4.2.3 Approach to live parts under high voltage X

NOT DEALT WITH 4.2.4 Electrostatics phenomena

X

4.2.5 Thermal radiation or other phenomena such as the projection of molten particles and chemical effects from short circuits, overloads, etc.

X

4.3 Thermal hazards, resulting in :

4.3.1 Burns, scalds and other injuries by a possible contact of persons with object or materials with an extreme high or low temperature, by flames or explosions and also by the radiation of heat sources

X

4.3.2 Damage to health by hot or cold working environment

X

4.4 Hazards generated by noise, resulting in

4.4.1 Hearing loss (deafness), other physiological disorders (e.g. loss of balance, loss of awareness

X

4.4.2 Interference with speech communication, acoustic signals, etc.

X

4.5 Hazards generated by vibration

4.5.1 Use of hand-held machines resulting in a variety of neurological and vascular disorders

X

(continued)

!Table 1" — List of significant hazards (continued) Clause Hazards Ap-plica-ble Not Ap-plica-ble Clause of prEN 1756-1 4.5.2 Whole body vibration, particularly when combined with poor postures

X

4.6 Hazards generated by radiation

4.6.1 Low frequency, radio frequency radiation, micro waves

X

4.6.2 Infrared, visible and ultraviolet light

X

4.6.3 X and gamma rays

X

4.6.4 Alpha, bet rays, electron or ion beams, neutrons

X

4.6.5 Lasers

X

4.7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery

4.7.1 Hazards from contact with or inhalation of harmful fluids, gases, mists, fumes and dusts

X

4.7.2 Fire or explosion hazard X

5.9 4.7.3 Biological or microbiological (viral or bacterial) hazards

X

4.8 Hazards generated by neglecting ergonomic principles in machinery design as, e.g. hazards from :

4.8.1 Unhealthy postures or excessive effort X

5.2 ; 5.3 ; 5.18.2 ; annex B

4.8.2 Inadequate consideration of hand-arm or foot-leg anatomy X

5.2 ; 5.18.2 , annex B ; annex E

4.8.3 Neglected use of personal protection equipment X

8.4.2.3 4.8.4 Inadequate local lighting X

5.2 ; 8.4.2 4.8.5 Mental overload and underload, stress

X

(continued)

5.17 ; 5.10 ; 8.4.1 ; annex B ; annex E

4.8.7 Inadequate design, location or identification of manual controls X

5.17 ; 5.18 , annex B ; annex F 4.8.8 Inadequate design or location of visual display units

X

4.9 Combination of hazards

4.10 Unexpected start-up, unexpected over-run/over-speed (or any similar malfunction) from :

4.10.1 Failure/disorder of the control system X

5.8 ; 5.9 ; 5.15.1 ; 5.17 ; 5.18.1 ; 5.14 ; annex D 4.10.2 Restoration of energy supply after an interruption X

5.9 ; 5.17.1 4.10.3 External influences on electrical equipmentX

NOT DEALT WITH (E.M.C.) 4.10.4 Other external influences (gravity, wind, etc.) X

NOT DEALT WITH 4.10.5 Errors in the software X

NOT DEALT WITH 4.10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities) X

5.17.1 ; 5.17.2 ; 5.17.3 ; 5.17.4 ; clause 8 ; annex E ; annex F 4.11 Impossibility of stopping the machine in the best possible conditions X

NOT DEALT WITH 4.12 Variations in the rotational speed of tools

X

4.13 Failure of the power supply X

5.9 4.14 Failure of the control circuit X

5.8 ; 5.9 ; 5.17 ; 5.18.1 ; 5.14 4.15 Errors of fitting X

8.4.2 ; annex H ;

4.16 Break-up during operation X

5.12 ; 5.13 ; 5.14 ; annex C ; annex D 4.17 Falling or ejected objects or fluids X

5.5 ; 5.4 ; 5.6 ; 5.13 ; 5.7 ; 5.14.1 4.18 Loss of stability / overturning of machinery X

5.16; clause 6; annex I

(continued)

5.2 ; 5.13 Additional hazards, hazardous situations and hazardous events due to mobility 4.20 Relating to the travelling function

4.20.1 Movement when starting the engine

X

4.20.2 Movement without a driver at the driving position

X

4.20.3 Movement without all parts in a safe position X

8.4.2.3 ; 5.10.1 4.20.4 Excessive speed of pedestrian controlled machinery

X

4.20.5 Excessive oscillations when moving

X

4.20.6 Insufficient ability of machinery to be slowed down, stopped and immobilised

X

4.21 Linked to the work position (including driving station) on the machine

4.21.1 Fall of persons during access to (or at/from) the work position

X

4.21.2 Exhaust gases/lack of oxygen at the work position

X

4.21.3 Fire (flammability of the cab, lack of extinguishing means)

X

4.21.4 Mechanical hazards at the work position

a) contact with the wheels

X

b) rollover

X

c) fall of objects, penetration by objects X

5.4 ; 5.5 ; 5.6 ; 5.13.1

d) break-up of parts rotating at high speed

X

e) contact of persons with machine parts or tools (pedestrian controlled machines)

X

(continued)

!Table 1" — List of significant hazards (continued) Clause Significant hazards Ap-plica-ble Not Ap-plica-ble Clause of this standard 4.21.5 Insufficient visibility from the work positionsX

5.2 ; 5.18 ; annex B ; annex E 4.21.6 Inadequate lighting X

5.2 ; 8.4.2.3 4.21.7 Inadequate seating

X

4.21.8 Noise at the work position

X

4.21.9 Vibration at the work position

X

4.21.10 Insufficient means for evacuation / emergency exit

X

4.22 Due to the control system

4.22.1 Inadequate location of manual controls X

5.18 ; annex B 4.22.2 Inadequate design of manual controls and their mode operation X

5.17.2 ; 5.17.3 ; annex E ; annex F 4.23 From handling the machine (lack of stability)

X

4.24 Due to the power source and to the transmission of power

4.24.1 Hazards from the engine and the batteries X

NOT DEALT WITH 4.24.2 Hazards from transmission of power between machines X

NOT DEALT WITH 4.24.3 Hazards from coupling and towing

X

4.25 From/to third persons

4.25.1 Unauthorised start-up/use X

5.8 4.25.2 Drift of

part away from its stopping position X

H.2.2 4.25.3 Lack or inadequacy of visual or acoustic warning means X

8.4.1 ; 5.13.3 ; 5.17.3 ; 5.2 4.26 Insufficient instructions for the driver/operator X

8.4.2.3 Additional hazards, hazardous situations and hazardous events due to lifting (continued)

!Table 1" — List of significant hazards (continued) Clause Significant hazards Ap-plica-ble Not Ap-plica-ble Clause of this standard 4.27 Mechanical hazards and hazardous events

4.27.1 From load falls, collisions, machine tipping caused by :

4.27.1.1 Lack of stability X

5.5 ; 5.6 ; annex I ; 5.2 ; 5.13 4.27.1.2 Uncontrolled loading – overloading – overturning moments exceeded X

5.16 ; annex I 4.27.1.3 Uncontrolled amplitude of movements X

5.4 4.27.1.4 Unexpected/unintended movement of loads X

5.5.2 ; 5.13 ; 6 4.27.1.5 Inadequate holding devices/accessories X

5.5.2 4.27.1.6 Collision of more than one machine

X

4.27.2 From access of persons to load support

X

4.27.3 From derailment

X

4.27.4 From insufficient mechanical strength of parts X

5.12 ; 5.13 ; 5.14 ; annex D 4.27.5 From inadequate design of pulleys, drums X

5.12 ; 5.14 ; annex D 4.27.6 From inadequate selection of chains, ropes, lifting and accessories and their inadequate integration into the machine X

5.12 ; 5.14 ; annex D 4.27.7 From lowering of the load under the control of friction brake

X

4.27.8 From abnormal conditions of assembly/testing/use/maintenance X

5.19 ; 8.3.1 ; 8.4.2 ; annex E ; annex F ; annex G ; annex H ; annex I 4.27.9 From the effect of load on persons (impact by load or counterweight)

X

4.28 Electrical hazards

4.28.1 From lightning

X

4.29 Hazards generated by neglecting ergonomic principles

(continued)

!Table 1" — List of significant hazards (concluded) Clause Significant hazards Ap-plica-ble Not Ap-plica-ble Clause of this standard 4.29.1 Insufficient visibility from the driving position X

5.18 ; annex B Additional hazards, hazardous situations and hazardous events due to underground work 4.30 Mechanical hazards and hazardous

events due to :

4.30.1 Lack of stability of powered roof supports

X

4.30.2 Failing accelerator or brake control of machinery running on rails

X

4.30.3 Failing or lack of deadman's control of machinery running on rails

X

4.31 Restricted movement of persons

X

4.32 Fire and explosion

X

4.33 Emissions of dust, gases etc.

X

Additional hazards, hazardous situations and hazardous events due to the lifting or moving of persons 4.34 Mechanical hazards and hazardous events due to :

4.34.1 Inadequate mechanical strength – Inadequate working coefficients X

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...