EN 1756-1:2001/prA1

(Amendment)Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods

Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods

Predominantly the demand for adding specific protective measures for toe guarding as described in clause B.2.3 of Annex B.

Hubladebühnen - Plattformlifte für die Anbringung an Radfahrzeugen - Sicherheitsanforderungen - Teil 1: Hubladebühnen für Güter

Hayons élévateurs - Plates-formes élévatrices a monter sur véhicules roulants - Prescriptions de sécurité - Partie 1: Hayons élévateurs pour marchandises

Dvižne ploščadi - Dvižne ploščadi, nameščene na cestna vozila - Varnostne zahteve - 1. del: Tovorne dvižne ploščadi

General Information

- Status

- Not Published

- Publication Date

- 26-Jun-2005

- Technical Committee

- CEN/TC 98 - Lifting platforms

- Drafting Committee

- CEN/TC 98/WG 4 - Tail lifts

- Current Stage

- 3098 - Decision to reject - Consensus building

- Start Date

- 20-Feb-2003

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

Overview

EN 1756-1:2001/prA1 (CEN draft amendment) updates the European standard for tail lifts - platform lifts mounted on wheeled vehicles - specifically Part 1: Tail lifts for goods. The amendment focuses predominantly on enhanced protective measures for toe guarding (Annex B, clause B.2.3) and introduces clarifications and additional safety, verification and information requirements across working area design, crushing/shearing protection, platform edges and control arrangements.

Key topics and technical requirements

- Toe guard requirements (Annex B.2.3)

- For vertical movement lifts: a minimum horizontal gap of 75 mm between moving platform parts and vehicle fixed parts, except where adequate toe protection is provided; rear sloping edge of the guard ≤ 30° to vertical (Figure B.3).

- For parallelogram systems: toe guards must be flexible and have a rear sloping edge ≤ 45° to vertical (Figure B.4).

- Interface protection: for every vertical gap up to 35 mm, a minimum horizontal safety distance of 80 mm is required (Figure B.5).

- Assigned operator position (B.2.7)

- Mandatory clear, permanent marking of a safe working area (500 × 500 mm) at least 250 mm from the trapping zone; may include footprints and frame markings (Figure B.11).

- Working area and operator visibility (5.2)

- Means for safe access, positioning, adequate lighting and operator vantage to view load and danger zones.

- Crushing and shearing (5.11)

- Tail lifts must include one or more protective measures selected by the manufacturer; Annex B provides typical examples.

- Edges and bluntness (5.13.2)

- Platform outer edges must avoid sharp angles; radii/bluntness to comply with ISO 12508 to prevent sharp edges.

- Controls and safeguarding (5.17.5)

- Fixed controls for opening/closing require two-hand control; portable controls must require more than one device; specified distances for control placement.

- Other clarifications

- Hydraulic leakage wording, load lifting limits (not exceed 125% of maximum load), verification table updates and installer handbook requirements.

Applications and users

This amendment is relevant to:

- Manufacturers and designers of tail lifts (product design and compliance).

- Installers and maintenance teams (installation handbook and safe installation practices).

- Fleet operators and logistics companies (operational safety, marking of operator positions).

- Safety engineers, conformity assessment bodies and national standards organizations (verification, testing and regulatory compliance with EU directives).

Practical benefits include reduced risk of toe and foot injuries, clearer operator placement, improved guarding solutions for different lift kinematics (vertical vs. parallelogram), and smoother conformity with safety legislation.

Related standards and regulatory context

- ISO 12508:1994 (bluntness of edges) - referenced for platform edge requirements.

- EU Directive 98/37/EC (Essential Requirements) - Annex ZA explains the relationship and presumption of conformity when implemented nationally.

Keywords: tail lifts, platform lifts, safety requirements, toe guard, EN 1756-1, Annex B, CEN, parallelogram lift, two-hand control, ISO 12508.

Frequently Asked Questions

EN 1756-1:2001/prA1 is a draft published by the European Committee for Standardization (CEN). Its full title is "Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements - Part 1: Tail lifts for goods". This standard covers: Predominantly the demand for adding specific protective measures for toe guarding as described in clause B.2.3 of Annex B.

Predominantly the demand for adding specific protective measures for toe guarding as described in clause B.2.3 of Annex B.

EN 1756-1:2001/prA1 is classified under the following ICS (International Classification for Standards) categories: 53.020.99 - Other lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1756-1:2001/prA1 has the following relationships with other standards: It is inter standard links to EN 1756-1:2001+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1756-1:2001/prA1 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396, M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1756-1:2001/prA1 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI SIST EN 1756-

1:2002/oprA1:2006

PREDSTANDARD

januar 2006

Dvižne ploščadi – Dvižne ploščadi, nameščene na cestna vozila – Varnostne

zahteve – 1. del: Tovorne dvižne ploščadi

(istoveten EN 1756-1:2001/prA1:2005)

Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety requirements -

Part 1: Tail lifts for goods

ICS 53.020.99 Referenčna številka

SIST EN 1756-1:2002/oprA1:2006(en)

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

DRAFT

EN 1756-1:2001

NORME EUROPÉENNE

EUROPÄISCHE NORM

prA1

November 2005

ICS

English Version

Tail lifts - Platform lifts for mounting on wheeled vehicles - Safety

requirements - Part 1: Tail lifts for goods

Hayons élévateurs - Plates-formes élévatrices à monter sur Hubladebühnen - Plattformlifte für die Anbringung an

véhicules roulants - Prescriptions de sécurité - Partie 1: Radfahrzeugen - Sicherheitsanforderungen - Teil 1:

Hayons élévateurs pour marchandises Hubladebühnen für Güter

This draft amendment is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 98.

This draft amendment A1, if approved, will modify the European Standard EN 1756-1:2001. If this draft becomes an amendment, CEN

members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for inclusion of this amendment

into the relevant national standard without any alteration.

This draft amendment was established by CEN in three official versions (English, French, German). A version in any other language made

by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same status

as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1756-1:2001/prA1:2005:2005: E

worldwide for CEN national Members.

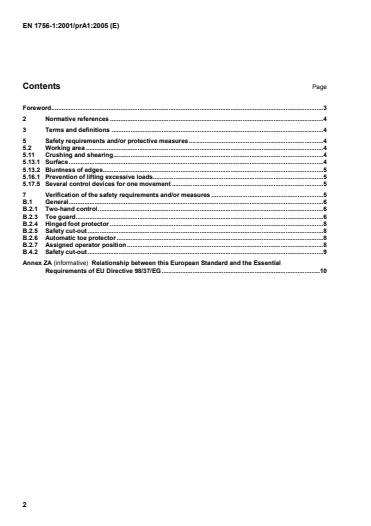

Contents Page

Foreword.3

2 Normative references.4

3 Terms and definitions .4

5 Safety requirements and/or protective measures.4

5.2 Working area.4

5.11 Crushing and shearing.4

5.13.1 Surface.4

5.13.2 Bluntness of edges.5

5.16.1 Prevention of lifting excessive loads.5

5.17.5 Several control devices for one movement .5

7 Verification of the safety requirements and/or measures .5

B.1 General.6

B.2.1 Two-hand control.6

B.2.3 Toe guard.6

B.2.4 Hinged foot protector .8

B.2.5 Safety cut-out.8

B.2.6 Automatic toe protector .8

B.2.7 Assigned operator position.8

B.4.2 Safety cut-out.9

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 98/37/EG.10

Foreword

This document (EN 1756-1:2001/prA1:2005) has been prepared by Technical Committee CEN/TC 98 “Lifting

platforms”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

2 Normative references

The following new normative reference is added:

"ISO 12508:1994, Earth-moving machinery — Operator station and maintenance areas — Bluntness of

edges"

3 Terms and definitions

3.21

control device

In the example ".or a combination of these" is deleted.

any device used to operate the tail lift

EXAMPLE button, switch, joystick, pedal, lever.

5 Safety requirements and/or protective measures

5.2 Working area

As a first paragraph before the present text the following text is added:

"Tail lift working areas and operators locations shall be provided with means to allow safe access, position

and work. Where necessary, these shall include the provision of suitable work lighting to the loading area. The

operator's positions shall allow an adequate view of the working area, the load and any danger zones."

5.11 Crushing and shearing

The present text is replaced by:

"Tail lifts shall be equipped with one or more protective measures to avoid the operator being exposed to

crushing and shearing. The selection of the type of protective measure is made by the manufacturer,

depending on actual type and design of the tail lift.

Safety measures shall be adopted to ensure that any other persons standi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...