EN 12261:2002

(Main)Gas meters - Turbine gas meters

Gas meters - Turbine gas meters

This Standard specifies the range of application, the requirements and tests for the design, performance and safety of turbine gas meters having in line pipe connections for gas flow measurement. This standard applies to turbine gas meters used to measure the volume of fuel gases of the 1st and 2nd gas families at maximum working pressures up to 25 000 m3/h over a temperature range of at least -5 °C to +35 °C.

Gaszähler - Turbinenradgaszähler

Die vorliegende Norm legt die Messbedingungen fest, Anforderungen und Prüfungen hinsichtlich Konstruktion, Leistung und Sicherheit der axialen und radialen Turbinenradgaszähler mit mechanischen Anzeigegeräten, im Folgenden Zähler genannt, mit in einer Flucht liegenden Rohranschlüssen zur Gasdurchflussmessung.

Die vorliegende Norm gilt für Turbinenradgaszähler, die zur Volumenmessung von Brenngasen der 1. und 2. Gas-familie, deren Zusammensetzung in EN 437 angegeben ist, bei maximalen Betriebsdrücken bis zu 420 bar, Betriebsdurchflüssen bis zu 25 000 m3/h über einem Gastemperaturbereich von mindestens - 10 °C bis + 40 °C benutzt werden.

Soweit in dieser Norm nicht anders angegeben, sind alle dargestellten Drücke als Überdrücke zu verstehen.

Die Abschnitte 1 bis 7 sowie Anhang B gelten nur für Auslegung und Typprüfung mit Ausnahme von 6.2.2.3, 6.2.3.3, 6.6.1.1.2 und 6.6.2.2.2. Anhang C darf als Anleitung während der Durchführung der periodischen Prüfungen verwendet werden. Abschnitt 8 sowie die Anhänge D und E gelten für jeden Zähler vor Versand. Anhang A muss bei beiden, sowohl der Typ- als auch bei der Einzelprüfung, Anwendung finden.

Compteurs de gaz - Compteurs de gaz à turbine

La présente Norme européenne définit les conditions de mesure, les exigences et les essais applicables à la construction, à la performance et à la sécurité des compteurs de gaz à turbine axiale et radiale munis d'indicateurs mécaniques, désignés ci-après sous l'appellation « compteurs », ayant des raccordements sur des canalisations en ligne pour mesure de débit des gaz.

La présente Norme européenne s'applique aux compteurs de gaz à turbine utilisés pour mesurer le volume des gaz combustibles des première et deuxième familles de gaz, dont la composition est spécifiée dans l'EN 437, à des pressions maximales de service allant jusqu'à 420 bar, à des débits réels allant jusqu'à 25 000 m3/h sur une plage de températures du gaz d'au moins 10 °C à + 40 °C.

Sauf indication contraire, toutes les pressions utilisées dans la norme sont relatives.

Les articles 1 à 7 et l'annexe B concernent uniquement la conception et les essais de modèle, à l'exception de 6.2.2.3, 6.2.3.3, 6.6.1.1.2 et 6.6.2.2.2. L'annexe C peut servir de guide pour les essais périodiques lors de l'utilisation. L'article 8 ainsi que les annexes D et E concernent les essais individuels avant livraison. L'annexe A doit être utilisée aussi bien pour les essais de modèle que pour les essais individuels.

Plinomeri - Turbinski plinomeri

General Information

- Status

- Withdrawn

- Publication Date

- 16-Apr-2002

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 237 - Gas meters

- Drafting Committee

- CEN/TC 237/WG 3 - Turbine meters

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Mar-2018

- Completion Date

- 11-Feb-2026

- Directive

- Not Harmonized2004/22/EC - Measuring instrumentsOJ Ref: C 162, C 162, C 162, C 162, C 162, C 162, C 162, C OJ Date: 14-Jul-2007

Relations

- Effective Date

- 04-Apr-2018

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN IEC 60079-11:2024 - Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i" - Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

EN 12261:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas meters - Turbine gas meters". This standard covers: This Standard specifies the range of application, the requirements and tests for the design, performance and safety of turbine gas meters having in line pipe connections for gas flow measurement. This standard applies to turbine gas meters used to measure the volume of fuel gases of the 1st and 2nd gas families at maximum working pressures up to 25 000 m3/h over a temperature range of at least -5 °C to +35 °C.

This Standard specifies the range of application, the requirements and tests for the design, performance and safety of turbine gas meters having in line pipe connections for gas flow measurement. This standard applies to turbine gas meters used to measure the volume of fuel gases of the 1st and 2nd gas families at maximum working pressures up to 25 000 m3/h over a temperature range of at least -5 °C to +35 °C.

EN 12261:2002 is classified under the following ICS (International Classification for Standards) categories: 17.120.10 - Flow in closed conduits. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12261:2002 has the following relationships with other standards: It is inter standard links to EN 12261:2018, EN 62246-1:2015, EN IEC 60079-0:2018, EN 60947-5-6:2000, EN 60529:1991, EN IEC 60079-11:2024, EN 437:2021, EN ISO 9001:2015, EN 12631:1999, EN 10204:2004, EN ISO 5167-1:1995, EN ISO 11064-3:1999, EN 12261:2002/A1:2006, EN 12261:2002/AC:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12261:2002 is associated with the following European legislation: EU Directives/Regulations: 2004/22/EC; Standardization Mandates: M/374. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12261:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Plinomeri - Turbinski plinomeriGaszähler - TurbinenradgaszählerCompteurs de gaz - Compteurs de gaz a turbineGas meters - Turbine gas meters91.140.40Sistemi za oskrbo s plinomGas supply systemsICS:Ta slovenski standard je istoveten z:EN 12261:2002SIST EN 12261:2004en01-februar-2004SIST EN 12261:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12261April 2002ICS 17.120.10English versionGas meters - Turbine gas metersCompteurs de gaz - Compteurs de gaz à turbineGaszähler - TurbinenradgaszählerThis European Standard was approved by CEN on 2 September 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12261:2002 ESIST EN 12261:2004

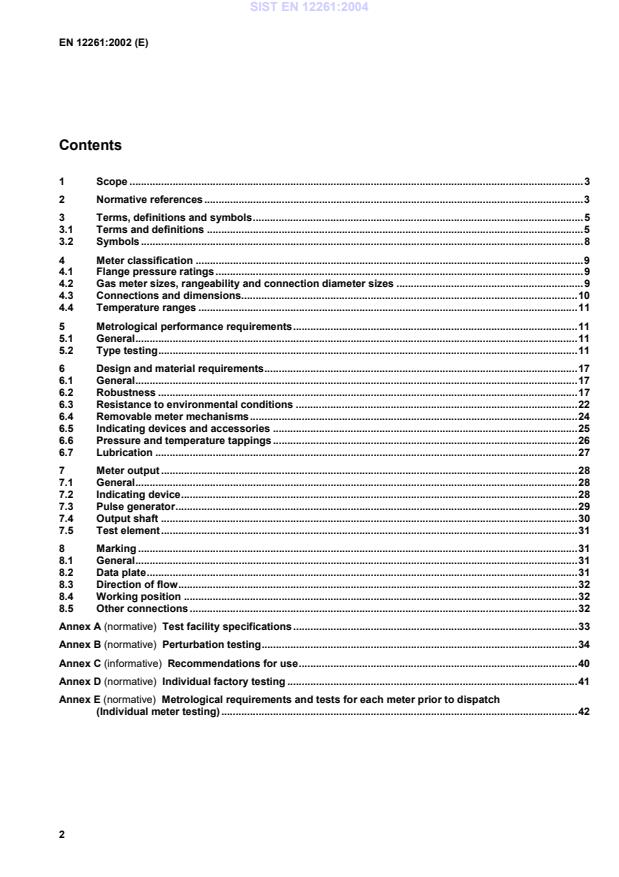

Test facility specifications.33Annex B (normative)

Perturbation testing.34Annex C (informative)

Recommendations for use.40Annex D (normative)

Individual factory testing.41Annex E (normative)

Metrological requirements and tests for each meter prior to dispatch(Individual meter testing).42SIST EN 12261:2004

(pm)absolute gas pressure to which the indicated volume of gas is related3.1.7.2operating pressuregas pressure within the piping containing the meter3.1.7.3working pressure rangeallowable pressure range over which the meter is calibrated and performs within the metrologicalrequirements3.1.7.4working temperature rangerange of metering temperatures over which the meter operates within the metrological requirements3.1.7.5maximum design pressure (pmax)pressure on which design calculations are basedSIST EN 12261:2004

DQ

= R´´35370,ewhere the value of D is given by the internal pipe diameter. The parameters (variables) in the aboveequation and their units are defined in Table 13.1.11error of

indicationindication of a turbine meter minus the reference value of the measurandErrors (E) are expressed as relative values (as a percentage) by the ratio of the difference between theindicated volume (Vi) and a reference volume (Vc) of the gas which has passed through the gas meter tothis latter value: 100

VV

V = Ecci´-3.1.12pressure lossnon-recoverable pressure drop caused by the presence of the turbine meter in the conduit3.1.13pulse valuenumber of pulses per cubic metre indicated3.1.14gas families3.1.14.11st familya gas having a Wobbe index between:23,8 MJ × m-3 and 31,4 MJ × m-3according to EN 437 related on gross calorific valueSIST EN 12261:2004

s -1Density of the gaskg

m –3Subscripts:iSummation indexmMetering conditions of the gasmaxMaximum valueminMinimum valuesSpecified conditionstTransitionalSIST EN 12261:2004

less

than the maximum permissibleerrors specified in Table 4, taking account of Table 5.Table 4 — Maximum permissible errorsFlow rate QMaximum permissible errorsQmin £ Q < Qt± 2 %Qt £ Q £ Qmax± 1 %Table 5 — Transitional flow rate QtRangeabilityQt1 : 100,20 × Qmax1 : 200,20 × Qmax1 : 300,15 × Qmax³1 : 500,10 × QmaxSIST EN 12261:2004

times. The testshall be carried out with a gas at atmospheric conditions (± 100 mbar) or at the lowest pressuredesignated on the meter.The nine resulting errors of indication at each flow rate shall be within a span of 0,2 %.5.2.3 Linearity5.2.3.1 RequirementsFor the test flow rates from 0,25 × Qmax to Qmax at each test pressure the differences between the highestand the lowest error of indication shall not exceed the values specified in Table 7.Table 7 — Allowable differences between the highest and lowest error of indication at each testpressurePressureSize< 4 bar> 4 bar< DN 1001,0 %0,5 %> DN 1001,0 %0,3 %5.2.3.2TestIn order to determine if the linearity requirement is fulfilled the value of the errors found at each flow rateaccording to 5.2.1.2 shall be taken.5.2.4 Endurance5.2.4.1 RequirementsMeters shall retain the accuracy of their metrological characteristics, within defined limits, over theirexpected life. To prove this the meters shall undergo an endurance test.The difference in error of indication between the start and end of the test shall be less than one third ofthe maximum permissible error given in Table 4.5.2.4.2 TestOne to six sample meters of each type irrespective of size shall be used for the endurance test.Meters shall be tested with their indicating devices fitted.The duration of the test shall be such that each meter measures a volume corresponding to 1 000 h ofoperation of the meter at the maximum flow rate; the test shall be completed within 2 months.For a meter type intended for operation in a pressure range below or equal to 4 bar the test shall becarried out with a gas at a

pressure of 4 bar or its maximum working pressure whichever is the lower.For a meter type intended for operation in a pressure range extended above 4 bar, the test shall becarried out with a gas at a minimum pressure of 8 bar or at its maximum working pressure whichever islower.SIST EN 12261:2004

than one third of the maximum permissible error limits for the flow rates above and below Qt.b) A sample meter shall be subjected to the endurance test specified in 5.2.4 in each position.NOTEDifferent sample meters may be used for each test position.5.2.6 Temporary overload5.2.6.1 RequirementsThe meter shall be designed to be capable of occasionally running 20 % above the maximum flow ratewithin the range of pressure and temperature for which it is rated without influence on the error ofindication of the meter.5.2.6.2 TestThe meter shall run at a flow rate of 1,2 × Qmax for a time period of 1 h. The test shall be carried out at thesame pressures as the error of indication test in 5.2.1.After this 1 hour test, the error of indication in the flow rate range from 0,25 × Qmax to Qmax shall remainwithin the span specified for the stability test in 5.2.2.5.2.7 Temperature range5.2.7.1 RequirementsThe working temperature ranges over which the meter is designed to perform within the standardperformance specification shall be stated by the manufacturer.This temperature range shall be at least from –1 °C to +40 °C.SIST EN 12261:2004

rates Qmin or 0,05 × Qmax, whichever is greater, and at0,40 × Qmax.Two sample meters of each type, the size of which does not exceed DN 150, shall be used for the test.The test shall be carried out at atmospheric conditions (± 100 mbar).5.2.8 Installation conditions5.2.8.1 RequirementsIn order to assess the sensitivity of the meter performance to upstream installation conditions, each typeof meter shall be subjected to the standard tests described in annex B „Perturbation testing“.The errors of indication obtained during disturbed flow conditions downstream of the pertubation unitsshall not differ by more than one third of the maximum permissible error limits given in Table 4, from theerror of indication obtained with an undisturbed upstream flow condition as obtained in 5.2.1.Any additional pipe inlet lengths and/or flow conditioners necessary to meet this requirement shall bespecified by the manufacturer. These components together with the meter consitute a “meter package”.SIST EN 12261:2004

affect theresults of the tests.The test shall be carried out with a suitable gas, e.g. air or nitrogen. The gas shall be free of oil, greaseand moisture.The test method to be used shall provide the level of sensitivity suitable for detecting a level of leakage of0,1× DN × mm3 × s-1 at ambient pressure and temperature conditions.If the leakage test is run after the hydrostatic test (see 6.2.2.3) water could become trapped and sealpotential leaks , therefore the meter shall be dried before assembling the mechanism and the leak test iscarried out.The completely assembled gas containing parts shall be pneumatically tested for external leakage at aminimum internal pressure of 1,1 times of the maximum working pressure with a minimum of 0,5 bar. Thepressure shall be increased slowly up to the test pressure. The rate of pressure increase shall not exceed0,350 bar×s-1 unless specified otherwise by the manufacturer.The test pressure shall be maintained for a minimum of 3 min.NOTEThe manufacturer of the meter may carry out an additional test at a pressure close to that at which themeter is designated to operate.After the test the pressure shall be released at a rate not greater than that during pressurization.6.2.4 Bending and torsional moment6.2.4.1 RequirementsThe manufacturers installation instructions shall specify the level of protection required with regard tobending and torsional moment.When tested as specified in 6.2.4.2,

the performance of the meter shall not be significantly affected, andthe meter shall remain leak tight in accordance with 6.2.3.6.2.4.2 Type testTests for determining the strength of the meter shall be performed with a device according to Figure 1. Itconsists of a lever arm of predetermined length to which a force in addition to the weight of the meter canbe applied in a perpendicular plane for performing torsional and bending moment tests. The moment maybe applied to the inlet or the outlet flange of the meter. The opposite end of the meter shall be supportedas shown in Figure 1.NOTEFigure 1 does not show the reference meter rig, or instruments for checking leakage.SIST EN 12261:2004

mmstriking the centre of the window and falling normal to its plane.6.2.6 Transportation and storage6.2.6.1 RequirementsThe meter connections shall be fitted with suitable covers to prevent the entry of foreign matter duringtransportation and storage.The meter packing shall be prepared in such a way as to minimize the possibility of damage to the meterduring transportation. For meters with DN 100 connections and above,

provision shall be made to securethe meter in a stable position during transportation.SIST EN 12261:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...