EN 17694-2:2023

(Main)Hydrometry - Minimum performance requirements and test procedures for water monitoring equipment - Devices for the determination of flow - Part 2: Closed conduit instrumentation

Hydrometry - Minimum performance requirements and test procedures for water monitoring equipment - Devices for the determination of flow - Part 2: Closed conduit instrumentation

This document specifies general requirements, minimum performance requirements and test procedures for instrumentation used to measure either volumetric flow-rate and/or total volume passed of water in closed conduits. It covers all closed conduit instrument (CCI) technologies intended to operate in closed pressurized pipes and partially filled pipes. Requirements are expressed in volumetric units which may be converted to mass using the density of the water.

It is recognized that for some CCIs certain tests cannot be carried out.

The data obtained from the testing of CCIs in accordance with the requirements of the Measuring Instruments Directive [1] or EN ISO 4064-1 [2] can be used to meet, in part, the requirements specified in this document. However, for the avoidance of doubt, compliance with the requirements of this document does not equate to compliance with the requirements of the Measuring Instruments Directive or EN ISO 4064-1.

Hydrometrie - Mindestleistungsanforderungen und Prüfverfahren für Wasserüberwachungsgeräte - Geräte zur Bestimmung des Durchflusses - Teil 2: Messgeräte für geschlossene Rohrleitungen

Dieses Dokument legt allgemeine Anforderungen, Mindest-Leistungsanforderungen und Prüfverfahren für Messgeräte fest, die für die Messung des Volumenstroms und/oder des Gesamtdurchflussvolumens von Wasser in geschlossenen Rohrleitungen verwendet werden. Es deckt alle Technologien für Messgeräte für geschlossene Rohrleitungen (CCIs) ab, die für den Betrieb in geschlossenen Druckleitungen und teilgefüllten Rohren vorgesehen sind. Die Anforderungen werden als Volumeneinheiten angegeben, die anhand der Dichte des Wassers in eine Masse umgerechnet werden dürfen.

Es ist bekannt, dass bestimmte Prüfungen für einige CCIs nicht durchgeführt werden können.

Die bei der Prüfung von CCIs in Übereinstimmung mit den Anforderungen der Messgeräterichtlinie [1] oder den Anforderungen nach EN ISO 4064 1 [2] gewonnenen Daten können teilweise verwendet werden, um die Einhaltung der in diesem Dokument festgelegten Anforderungen nachzuweisen. Zur Klarstellung wird jedoch darauf hingewiesen, dass die Einhaltung der Anforderungen dieses Dokuments nicht mit der Einhaltung der Anforderungen der Messgeräterichtlinie oder der Anforderungen nach EN ISO 4064 1 gleichgesetzt werden kann.

Hydrométrie - Exigences minimales de performance et modes opératoires d'essai pour les équipements de surveillance de l'eau - Dispositifs de mesure de l'écoulement - Partie 2 : Instruments de mesure pour écoulements en conduite fermée

Le présent document spécifie les exigences générales, les exigences minimales de performance et les modes opératoires d'essai applicables aux instruments utilisés pour mesurer le débit volumétrique et/ou le volume total passé d'eau dans les conduites fermées. Il couvre toutes les technologies d'instruments de mesure pour écoulements en conduite fermée (CCI) destinées à fonctionner dans des tuyaux sous pression fermés et des tuyaux partiellement remplis. Les exigences sont exprimées en unités volumétriques qui peuvent être converties en masse à l'aide de la densité de l'eau.

Il est reconnu que certains essais ne peuvent pas être effectués sur certains CCI.

Les données obtenues à partir des essais des CCI conformément aux exigences de la Directive Instruments de mesure [1] ou de l'EN ISO 4064-1 [2] peuvent être utilisées pour répondre, en partie, aux exigences spécifiées dans le présent document. Toutefois, pour éviter tout doute, le respect des exigences du présent document n'équivaut pas au respect des exigences de la Directive Instruments de mesure ou de l'EN ISO 4064-1.

Hidrometrija - Minimalne zahteve za tehnične lastnosti in preskusni postopki za opremo za nadzor vode - Naprave za ugotavljanje pretoka - 2. del: Instrumenti za merjenje v zaprtem vodu

Ta evropski standard določa splošne zahteve, minimalne zahteve glede zmogljivosti in preskusne postopke za instrumente, ki se uporabljajo za merjenje stopnje volumetričnega pretoka in/ali celotne količine pretoka vode v umetno zaprtih vodih. Zajema vse tehnologije instrumentov za merjenje v zaprtem vodu (CCI), ki so namenjene za delovanje v zaprtih ceveh pod tlakom in delno napolnjenih ceveh.

Znano je, da nekaterih preskusov instrumentov za merjenje v zaprtem vodu ni mogoče izvesti.

Podatke, pridobljene pri preskušanju instrumentov za merjenje v zaprtem vodu v skladu z zahtevami Direktive o merilnih instrumentih [4] ali standarda ISO 4064-1 [5], je mogoče deloma uporabiti za izpolnjevanje zahtev, določenih v tem evropskem standardu. V izogib dvomom skladnost z zahtevami tega evropskega standarda ni enaka skladnosti z zahtevami Direktive o merilnih instrumentih ali standarda ISO 4064-1.

General Information

- Status

- Published

- Publication Date

- 09-May-2023

- Technical Committee

- CEN/TC 318 - Hydrometry

- Drafting Committee

- CEN/TC 318 - Hydrometry

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 10-May-2023

- Due Date

- 05-Aug-2022

- Completion Date

- 10-May-2023

Overview

EN 17694-2:2023 is a CEN hydrometry standard that defines minimum performance requirements and test procedures for instrumentation used to measure volumetric flow-rate and/or total volume of water in closed conduits (pressurised or partially filled pipes). Part 2 focuses specifically on closed conduit instrumentation (CCI) and is technology‑neutral - applicable to ultrasonic, electromagnetic, turbine, Coriolis and other CCI technologies where relevant. Requirements are expressed in volumetric units (with mass conversions possible using water density). The standard covers laboratory and field testing and clarifies that some CCIs cannot undergo certain tests.

Key topics and technical requirements

- Scope and intent: Defines general requirements, performance criteria and test methods for CCIs used in water monitoring (e.g., effluent discharges, wastewater, irrigation and transfer channels).

- Performance metrics: Evaluation of bias, repeatability and combined performance; statistical data evaluation methods (annexes provide worked examples).

- Test procedures:

- Laboratory tests (controlled conditions) and field tests (in situ performance and up-time).

- Specific checks such as loss of power, supply voltage, output impedance, response time and field error.

- Influence and environmental requirements: Effects of water temperature, ambient conditions, conduit material and size, sensor location, stray currents, bi‑directional flow and flow reversal.

- Data handling: Data retention and reporting requirements for test results and performance documentation.

- Installation influences & ancillary devices: Guidance on how installation and accessory devices affect measurement.

- Limitations: Testing under the Measuring Instruments Directive or EN ISO 4064-1 can partially satisfy some requirements, but compliance with EN 17694-2 is distinct from those legal metrology standards.

Applications and who uses it

- Manufacturers of closed conduit flow meters: to demonstrate product performance and prepare test plans.

- Test laboratories and calibration facilities: to carry out standardized lab and field tests and report results using the standard’s statistical methods.

- Water utilities, wastewater operators and environmental regulators: to specify procurement, acceptance testing and compliance monitoring of flow instrumentation.

- Consultants and system integrators: to design monitoring systems, evaluate meter selection and verify on-site performance. Practical benefits include consistent acceptance criteria, clearer procurement specifications and more reliable flow data for regulatory reporting and process control.

Related standards

- EN 17694-1 (Hydrometry - Part 1: Open channel instrumentation)

- EN ISO 4064-1 and the EU Measuring Instruments Directive (not interchangeable with EN 17694-2; some test data may be reused but separate compliance applies)

Keywords: EN 17694-2, hydrometry, closed conduit instrumentation, flow measurement, water monitoring equipment, performance requirements, test procedures, closed conduit instrument (CCI).

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

EN 17694-2:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Hydrometry - Minimum performance requirements and test procedures for water monitoring equipment - Devices for the determination of flow - Part 2: Closed conduit instrumentation". This standard covers: This document specifies general requirements, minimum performance requirements and test procedures for instrumentation used to measure either volumetric flow-rate and/or total volume passed of water in closed conduits. It covers all closed conduit instrument (CCI) technologies intended to operate in closed pressurized pipes and partially filled pipes. Requirements are expressed in volumetric units which may be converted to mass using the density of the water. It is recognized that for some CCIs certain tests cannot be carried out. The data obtained from the testing of CCIs in accordance with the requirements of the Measuring Instruments Directive [1] or EN ISO 4064-1 [2] can be used to meet, in part, the requirements specified in this document. However, for the avoidance of doubt, compliance with the requirements of this document does not equate to compliance with the requirements of the Measuring Instruments Directive or EN ISO 4064-1.

This document specifies general requirements, minimum performance requirements and test procedures for instrumentation used to measure either volumetric flow-rate and/or total volume passed of water in closed conduits. It covers all closed conduit instrument (CCI) technologies intended to operate in closed pressurized pipes and partially filled pipes. Requirements are expressed in volumetric units which may be converted to mass using the density of the water. It is recognized that for some CCIs certain tests cannot be carried out. The data obtained from the testing of CCIs in accordance with the requirements of the Measuring Instruments Directive [1] or EN ISO 4064-1 [2] can be used to meet, in part, the requirements specified in this document. However, for the avoidance of doubt, compliance with the requirements of this document does not equate to compliance with the requirements of the Measuring Instruments Directive or EN ISO 4064-1.

EN 17694-2:2023 is classified under the following ICS (International Classification for Standards) categories: 07.060 - Geology. Meteorology. Hydrology; 17.120.10 - Flow in closed conduits; 17.120.20 - Flow in open channels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17694-2:2023 is associated with the following European legislation: EU Directives/Regulations: 2000/60/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 17694-2:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2023

Hidrometrija - Minimalne zahteve za tehnične lastnosti in preskusni postopki za

opremo za nadzor vode - Naprave za ugotavljanje pretoka - 2. del: Instrumenti za

merjenje v zaprtem vodu

Hydrometry - Minimum performance requirements and test procedures for water

monitoring equipment - Devices for the determination of flow - Part 2: Closed conduit

instrumentation

Hydrometrie - Leistungsanforderungen und Prüfverfahren für

Wasserüberwachungsgeräte - Geräte zur Bestimmung des Durchflusses - Teil 2:

Messgeräte für geschlossene Rohrleitungen

Hydrométrie - Exigences minimales de performance et modes opératoires d'essai pour

les équipements de surveillance de l'eau - Dispositifs de mesure de l'écoulement - Partie

2 : Instruments de mesure pour écoulements en conduite fermée

Ta slovenski standard je istoveten z: EN 17694-2:2023

ICS:

07.060 Geologija. Meteorologija. Geology. Meteorology.

Hidrologija Hydrology

17.120.10 Pretok v zaprtih vodih Flow in closed conduits

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17694-2

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2023

EUROPÄISCHE NORM

ICS 17.120.10

English Version

Hydrometry - Minimum performance requirements and

test procedures for water monitoring equipment - Devices

for the determination of flow - Part 2: Closed conduit

instrumentation

Hydrométrie - Exigences minimales de performance et Hydrometrie - Leistungsanforderungen und

modes opératoires d'essai pour les équipements de Prüfverfahren für Wasserüberwachungsgeräte - Geräte

surveillance de l'eau - Dispositifs de mesure de zur Bestimmung des Durchflusses - Teil 2: Messgeräte

l'écoulement - Partie 2 : Instruments de mesure pour für geschlossene Rohrleitungen

écoulements en conduite fermée

This European Standard was approved by CEN on 13 February 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17694-2:2023 E

worldwide for CEN national Members.

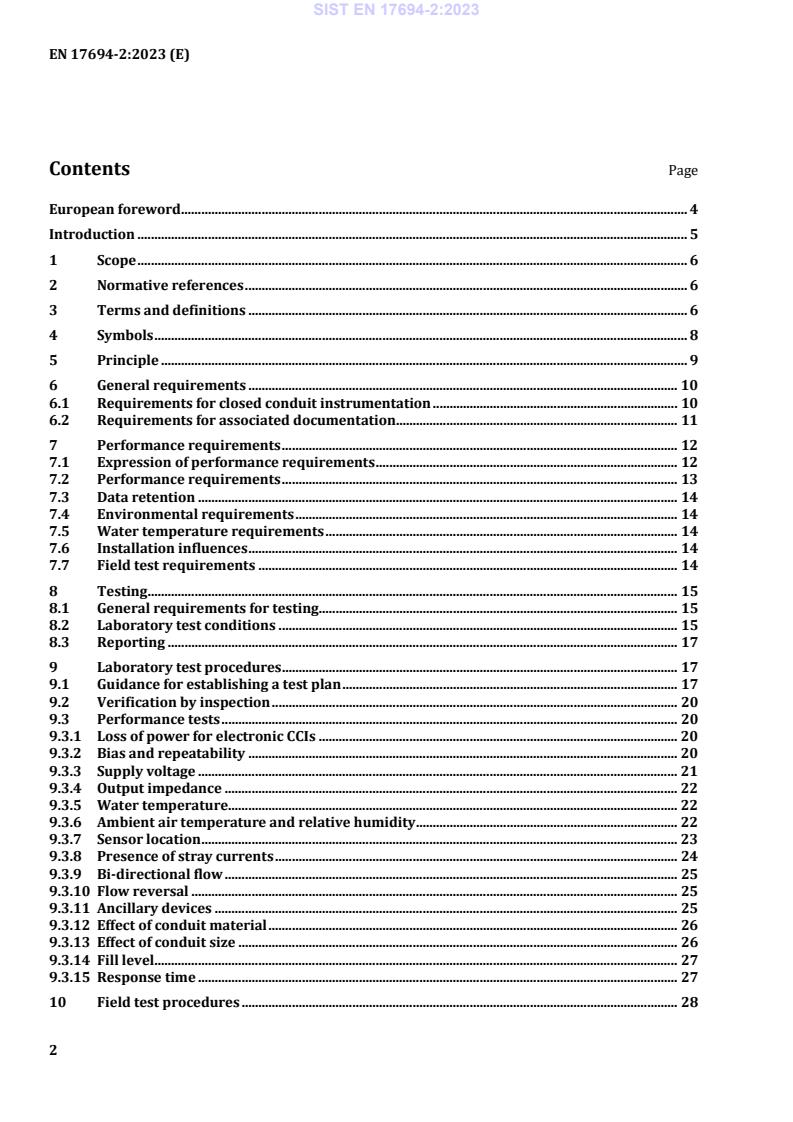

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Symbols . 8

5 Principle . 9

6 General requirements . 10

6.1 Requirements for closed conduit instrumentation . 10

6.2 Requirements for associated documentation . 11

7 Performance requirements . 12

7.1 Expression of performance requirements . 12

7.2 Performance requirements . 13

7.3 Data retention . 14

7.4 Environmental requirements . 14

7.5 Water temperature requirements . 14

7.6 Installation influences . 14

7.7 Field test requirements . 14

8 Testing . 15

8.1 General requirements for testing . 15

8.2 Laboratory test conditions . 15

8.3 Reporting . 17

9 Laboratory test procedures . 17

9.1 Guidance for establishing a test plan . 17

9.2 Verification by inspection . 20

9.3 Performance tests . 20

9.3.1 Loss of power for electronic CCIs . 20

9.3.2 Bias and repeatability . 20

9.3.3 Supply voltage . 21

9.3.4 Output impedance . 22

9.3.5 Water temperature . 22

9.3.6 Ambient air temperature and relative humidity . 22

9.3.7 Sensor location . 23

9.3.8 Presence of stray currents . 24

9.3.9 Bi-directional flow . 25

9.3.10 Flow reversal . 25

9.3.11 Ancillary devices . 25

9.3.12 Effect of conduit material . 26

9.3.13 Effect of conduit size . 26

9.3.14 Fill level. 27

9.3.15 Response time . 27

10 Field test procedures . 28

10.1 Objective of field test . 28

10.2 Field test plan . 28

10.3 Field test requirements . 28

10.4 Error under field test conditions . 29

10.5 Up-time . 29

10.6 Maintenance . 30

Annex A (normative) Evaluation of test data . 31

A.1 Introduction . 31

A.2 Bias. 31

A.3 Repeatability . 32

A.4 Effect of influence quantities . 32

A.5 Combined performance requirement . 32

A.6 Worked example . 34

A.6.1 Bias. 34

A.6.2 Repeatability . 35

A.6.3 Influence conditions . 35

A.7 Worked example — Field tests . 36

Annex B (informative) Reference methods . 40

B.1 Laboratory methods . 40

B.2 Field (in situ) methods . 40

Annex C (informative) Reference uncertainty and error calculations . 41

Annex D (informative) Example report format . 43

Bibliography . 46

European foreword

This document (EN 17694-2:2023) has been prepared by Technical Committee CEN/TC 318

“Hydrometry”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2023, and conflicting national standards shall

be withdrawn at the latest by November 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This standard is published in two parts:

— EN 17694-1, Hydrometry — Minimum performance requirements and test procedures for water

monitoring equipment — Devices for the determination of flow — Part 1: Open channel

instrumentation

— EN 17694-2, Hydrometry — Minimum performance requirements and test procedures for water

monitoring equipment — Devices for the determination of flow — Part 2: Closed conduit

instrumentation

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a product standard for instrumentation for the determination of the flow of waters in

closed conduits (e.g. effluent discharges from industrial installations, and wastewaters from sewage

treatment works, water irrigation channels and water transfer channels). A closed conduit instrument

(CCI) is a device that is normally fixed in position and used mainly to measure either volumetric flow-rate

and/or total volume passed. Certain CCI, e.g. Coriolis devices measure mass flow-rate and/or total mass

passed, from which volumetric flow may be derived, using the density of the water. This document

defines general requirements, minimum performance requirements, and test procedures. A CCI that is

shown, by means of the tests, to conform with the general requirements and performance requirements

is considered to be fit for purpose. However, this document does not cover the installation and on-going

use of a CCI, and also excludes instrumentation that is subject to separate legal control, for example, the

Measuring Instruments Directive.

The acronym “CCI” is used throughout this document except where it is necessary to be specific about the

particular type or component (e.g. sensor) of a device.

The general requirements and performance requirements specified in this document are intended to be

independent of measurement technology and applicable to all CCIs. The general requirements include

several features that are necessary to meet users’ applications and information that should be included

in associated documents.

The performance tests comprise testing carried out under laboratory and field conditions. They are

designed to determine, in a systematic and consistent way, the capability of CCI to make reliable

measurements. The testing focuses on key performance characteristics. Statistical procedures are defined

for evaluation of the test data.

Measurement ranges are not specified as part of the performance requirements though a minimum ratio

(maximum measured value: minimum measured value) is specified. It is for the manufacturer of the CCI

to decide on the measurement range over which the performance requirements are shown to be met by

the specified test procedures. Similarly, it is for the CCI manufacturer to decide on the intended uses

(applications) which will inform the design of the field trial.

Water monitoring equipment is widely used for compliance monitoring purposes under national and

European regulations.

1 Scope

This document specifies general requirements, minimum performance requirements and test procedures

for instrumentation used to measure either volumetric flow-rate and/or total volume passed of water in

closed conduits. It covers all closed conduit instrument (CCI) technologies intended to operate in closed

pressurized pipes and partially filled pipes. Requirements are expressed in volumetric units which may

be converted to mass using the density of the water.

It is recognized that for some CCIs certain tests cannot be carried out.

The data obtained from the testing of CCIs in accordance with the requirements of the Measuring

Instruments Directive [1] or EN ISO 4064-1 [2] can be used to meet, in part, the requirements specified

in this document. However, for the avoidance of doubt, compliance with the requirements of this

document does not equate to compliance with the requirements of the Measuring Instruments Directive

or EN ISO 4064-1.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

combined performance requirement

combination of individual performance requirements

3.2

conduit

pipe through which water is flowing

3.3

closed conduit instrument

CCI

device(s) which measures the flow-rate or totalized volume of water passing along a conduit or computes

such quantities from measurements of one or more properties which have a defined relationship with

the flow-rate

Note 1 to entry: A closed conduit instrument can, for example, include a complete flow-metering system, such as: a

flow sensor and transmitter, a mechanical CCI including any ancillary device required to derive an electronic output,

a velocity-area CCI comprising a water velocity sensor with a water level sensor and associated electronics, or a

non-standardized primary device with a differential pressure sensor and associated electronics.

3.4

determinand

property that is required to be measured

3.5

expanded uncertainty

expanded measurement uncertainty

U

product of a combined measurement uncertainty and a factor larger than the number one

Note 1 to entry: The factor depends upon the type of probability distribution of the output quantity in a

measurement model and on the selected coverage probability.

Note 2 to entry: The term “factor” in this definition refers to a coverage factor.

Note 3 to entry: Expanded measurement uncertainty is termed “overall uncertainty” in paragraph 5 of

Recommendation INC-1 (1980) (see the GUM) and simply “uncertainty” in IEC documents.

[ISO/IEC Guide 99:2007, 2.35 plus notes] [3]

3.6

flow-rate

q

volume of water passing through the CCI per unit time

3.7

influence quantity

quantity, generally external to the CCI, which may affect the performance of the equipment

3.8

insertion sensor

sensor designed to be inserted into a pipe through a tapping or other fitting, or mounted internally within

a pipe, in direct contact with the water and connected to a transmitter mounted externally to the pipe

3.9

measurement range

range over which the CCI conforms within the performance requirements specified in this document

Note to 1 entry: The measurement range is defined from a minimum non-zero value to a maximum value.

3.10

non-invasive sensor

sensor for application to a pipe which attaches to the outside of a pipe and requires no tapping, drilling

or cutting of the pipe to install, for example clamp-on ultrasonic transducers

3.11

percentage error

error in measurement expressed as a percentage of the true or actual value

Note 1 to entry: In this document, the true or actual value is the reference value and percentage error is calculated

using the following equation: percentage error = 100 × (measured value – reference value)/reference value.

3.12

performance requirement

one of the quantities (described by values, tolerances, range) that defines a CCI’s performance

3.13

rated operating conditions

minimum to maximum values of any environmental, fluid or electrical parameter within which a CCI is

designed to operate without adjustment, within the performance requirements specified in this

document

3.14

reference conditions

specified set of values (including tolerances) of influence variables, delivering representative values of

performance requirements

3.15

reference method

method to be used to obtain the determinand value to a stated uncertainty, against which the readings

from the CCI under test can be compared

3.16

repeatability

ability of a CCI to provide closely similar indications for repeated applications of the same determinand

under the same conditions of measurement

3.17

sensor

transducer consisting of one or more components from which is derived an electrical or mechanical

output related to a property from which the flow-rate may be computed

3.18

totalized volume

total volume of water which has been measured by the CCI over a period of time which commenced when

the totalizer was set to zero

4 Symbols

For the purposes of this document the following symbols apply.

b bias

S repeatability

R

X errors due to variations in supply voltage

V

X errors due to variations in output impedance

O

X errors due to variations in water temperature

FT

errors due to variations in ambient air temperature

X

T

X errors due to variations in relative humidity

RH

X errors due to variations in sensor location

SL

X errors due to variations in stray currents

SC

U combined performance requirement

C

5 Principle

This document sets general requirements, minimum performance requirements and test procedures for

a CCI that is to be used for determining the flow of water in closed conduits.

The general requirements are based on experience of users’ needs when operating a CCI in a range of

applications. Many are consistent with general requirements specified in EN ISO 4064-1.

The minimum performance requirements specify limit values in terms of percentage error for

measurement bias, repeatability, a range of environmental and sensor operational parameters, and for a

combination of all of these values. A CCI that can be demonstrated by the specified tests to conform with

the performance requirements is judged to be fit for purpose.

For the majority of applications where a CCI is used, the required parameter is volumetric flow-rate.

In Table 2 the combined performance requirement is less than the sum of the specified individual

performance values combined in quadrature. This allows for some differences in the performance of a

CCI with respect to the individual requirements within an overall combined performance requirement.

The laboratory performance tests are designed to show whether a CCI can conform with the applicable

performance requirements under a range of environmental and sensor operational conditions.

Laboratory testing is used to determine the performance characteristics in a systematic and consistent

way in a controlled environment. Several of the laboratory tests correspond to tests specified in

EN ISO 4064-2 [4] and ISO 12242 [5]. For CCI that are tested to demonstrate conformity with

EN ISO 4064-1 and ISO 12242 the test data can also be used for the purposes of this document thereby

minimizing the amount of testing.

Statistical procedures are defined for evaluation of the laboratory test data to produce the individual

performance characteristic measurement uncertainties, u, and the combined performance characteristic

measurement uncertainty, U . They are based on the ISO/IEC Guide 98-3 [6]. The measured errors arising

C

from the tests for each performance tests are converted to standard uncertainties, taking into account

the distribution of errors. To obtain the combined performance characteristic, the individual

uncertainties are combined using a root sum of squares, as described in the GUM, with due account taken

of the contribution of each component through the use of sensitivity coefficients. To determine sensitivity

coefficients, it is necessary to know the functions by which each component contributes to overall error.

In the case of CCI testing this will rarely be known. Hence, for the purposes of this document, the

sensitivity coefficients are all taken as 1.

The combined performance characteristic, U , is expressed as an expanded uncertainty. The expanded

C

uncertainty, (U), is obtained by multiplying the standard uncertainty by a coverage factor. The coverage

factor is determined by the confidence level. This document uses a 95 % confidence with a coverage

factor assumed to be 2.

The field trial is used to demonstrate that the performance of a CCI can be maintained under operational

conditions and to determine the CCI’s up-time.

6 General requirements

6.1 Requirements for closed conduit instrumentation

A CCI shall have:

a) a unique designation that unambiguously identifies the CCI (e.g. model, serial number);

b) a means of protection against inadvertent or unauthorized access to the control functions (e.g.

password, physical locks, etc);

c) an output signal and/or display scaled in metric units (the units of measurement shall be displayed

on the indicating device);

d) one or more output signals and/or a means of displaying the measured determinand and/or either

the totalized volume and/or volumetric flow-rate. If the CCI does not incorporate a local display, it

shall be possible for an authorized person to obtain the current reading by communicating with the

CCI on site using a portable device, such as a laptop, tablet or smart phone. Communication with a

portable device to display a reading shall not interrupt the measurement and shall not allow the user

to defeat access security features;

e) a means of displaying its operating status, for example, normal operation, stand-by, maintenance

mode or malfunction;

f) a means to return to normal operating mode from maintenance, service or programming mode if no

user interactions have been detected after a defined time period;

g) an audible or visual method of indicating loss of power supply (applies only to CCI operating from an

external power supply), e.g. a relay that fails open;

h) an audible or visual method of indicating when the power supply voltage is below its normal

operating limit (applies only to CCIs operating from a battery);

i) a means for preventing unauthorized resetting of the total recorded volume for abstraction metering

and/or effluent discharge monitoring; a symbol, incorporated into the indication device to show the

flow direction, for bi-directional CCI;

NOTE A pointer rotating clockwise with increasing flow and counter-clockwise with reverse flow is acceptable,

but reliance on an increasing or decreasing total is not.

j) a clear physical marking of the direction of forward flow (in the case of a bi-directional CCI this should

be the direction of flow which gives an increase in the total flow recorded. For a CCI which has been

wet calibrated, this should be the direction of flow in which the CCI has been calibrated);

k) a means to subtract from the indicated volume or to record separately the reverse flow volume, for

a bi-directional CCI;

l) an upstream strainer or filter to protect the CCI, where recommended by the manufacturer;

-1 -1

m) a minimum rated operating range for water conductivity between 50 μS cm to 1200 μS cm for an

electro-magnetic device;

n) a means for displaying the firmware and software versions installed.

6.2 Requirements for associated documentation

The following information shall be incorporated into the associated documentation:

a) operating instructions which cover the full functionality and measurement principle of the CCI. These

instructions shall make clear if they are applicable to specific versions of software or firmware;

b) generic guidance on the time period over which the CCI can operate continuously without requiring

manual adjustment or intervention;

NOTE 1 Automatic routines for cleaning, maintenance or recalibration can be used to maintain performance

within the required limits between manual interventions. It is up to the user to ensure that a suitable regime is

adopted for an individual application.

c) a statement of the types of primary device, where applicable, for which the CCI can compute flow-

rate without the input of data other than the type and dimensions of the primary device and a zero

datum;

d) a statement of whether the CCI is designed to measure flow in both forward and reverse directions;

e) a statement defining minimum up and downstream straight lengths of conduit of uniform section

adjacent to the sensor required to meet the performance requirements of this document;

f) a statement of any limitations on the material of conduit into or onto which the CCI’s sensor can be

installed;

g) a statement of any limitations on the conduit dimensions or shape (including wall thickness or pipe

schedule if appropriate), into or onto which the CCI’s sensor can be installed. If multiple sensors are

required, for example in a large conduit, the number and spacing of those sensors shall be stated;

h) for non-contact velocity sensors, a statement of the minimum and maximum separation distances

from the sensor face to the water surface;

i) a statement of the minimum measurable water depth under free surface conditions (the maximum

measurable water depth is assumed to be full bore), for CCIs intended to operate in partially filled

pipes. The manufacturer shall also state whether the CCI can maintain performance within the

requirements of this document under surcharged conditions. A CCI that can only operate in partially

filled pipe with free surface conditions should be tested in accordance with EN 17694-1 [7];

j) a statement, where appropriate, of the rated operating conditions for water pressure;

k) a statement of the quality (e.g. contaminants, salinity) nature and quantity of particulate or other

material that the CCI can pass whilst maintaining its performance within the limits of this document.

If a minimum level of particulate is required for operation of the CCI, this too shall be stated;

l) a statement of any specific requirements relating to the location or shielding of components

necessary to maintain performance within the limits of this document under varying environmental

conditions;

m) a statement, for electronic CCI, of the rated operating conditions for the power supply;

n) a statement, for electronic CCI, of the rated operating conditions for the signal load impedance on the

analogue output, if present. This shall include any resistive effects of cabling and terminations;

o) a statement of the rated operating conditions for water temperature, ambient temperature and

humidity as appropriate;

NOTE 2 The influence of ambient temperature and relative humidity on the performance of a CCI is tested

(see 7.4 and 9.3.6) over the rated environmental operating conditions.

p) the minimum rated operating range for water conductivity for an electromagnetic CCI;

q) a register table or other appropriate instructions for digital (bus) outputs, to ensure the user is able

to read the correct value(s).

7 Performance requirements

7.1 Expression of performance requirements

Specific requirements are expressed as bias (b), variations in error (X), standard deviation (u) or

expanded uncertainty (U) as shown in Table 1. Not all requirements will apply to every CCI.

Annex A describes in detail how the values are calculated for each requirement.

Table 1 — Expression of performance requirements

Requirement Symbol Expression of requirement

Bias b The mean of the errors measured at each

test point (see Annex A)

Repeatability S The standard deviation of the errors

R

measured at each test point (see Annex A)

Output impedance X

O

Supply voltage

X

V

Ambient air X

T The value to be reported for each individual

temperature

performance requirement, and to be used in

the calculation of the combined

Relative humidity X

RH

performance characteristic, shall be the

Incident light X maximum value obtained (see Annex A).

LX

Direct solar radiation X

SR

Water temperature X

FT

Sensor location X

SL

Stray currents X

SC

Combined performance U An expanded uncertainty obtained by

C

requirement combining uncertainties derived from the

measured errors for the individual

performance requirements. It is expressed

at a 95 % confidence with a coverage factor

taken to be 2 (see Annex A).

7.2 Performance requirements

7.2.1 A CCI shall be capable of meeting the performance requirements of this document over a

measurement ratio of at least 20:1 (maximum measured value: minimum measured value). The minimum

measured value shall be a non-zero value.

7.2.2 Table 2 shows the maximum value for each performance requirement for a CCI as determined by

the tests specified in Clauses 9 and 10. A CCI shall conform with each performance requirement and the

combined performance requirement.

Table 2 — Performance requirements for CCIs

Performance requirement Symbol Test % error

Bias b 9.3.2 ±1,5

a

9.3.2 ±5

Lower limit value for mean error

Repeatability S 9.3.2 1

R

Supply voltage X 9.3.3 0,5

V

Output impedance X 9.3.4 0,5

O

Water temperature X 9.3.5 0,5

FT

Ambient air temperature X 9.3.6 0,5

T

Relative humidity X 9.3.6 0,5

RH

Sensor location X 9.3.7 0,5

SL

Stray currents X 9.3.8 0,5

SC

b

U 2

Combined performance requirement

C

c

- 9.3.15 30 s

Maximum response time

Warm up - 9.2 To be reported

a

The lower limit value for mean error is only applicable from the minimum value to the minimum value plus

10 % of the measurement range.

b

The combined performance requirement is less than the sum of the specified individual performance values

combined in quadrature. This allows for some differences in performance of CCIs with respect to the

individual requirements within an overall combined performance requirement.

c

The response time of a CCI will be assessed over a variation in flow-rate of at least 20 % of the measurement

range.

7.2.3 A bi-directional CCI shall meet the requirements for bias and repeatability for both forward and

reverse flows. See test 9.3.9.

7.2.4 The bias and repeatability of a CCI not designed to measure reverse flow shall meet the

requirements for bias and repeatability following an accidental short-term reversal of flow. See test

9.3.10.

7.2.5 A mechanical CCI shall meet the requirements for bias and repeatability with and without any

ancillary device used to derive an electronic output. See test 9.3.11.

7.3 Data retention

7.3.1 All pre-set data, including calibration and alarm set points and adjustments, shall be retained for

a minimum period of 30 days after disconnection of the power supply.

7.3.2 The totalized volume shall be retained for a minimum period of 30 days after disconnection of the

power supply.

NOTE National regulations can require significantly longer times.

7.4 Environmental requirements

NOTE See test 9.3.6.

A CCI shall meet the performance requirements detailed in Table 2 over its rated ambient temperature

and relative humidity ranges (see 6.2 o)). For CCIs that are used in external locations or in locations where

humidity may be high, the minimum rated operating conditions for an CCI with respect to ambient

temperature should be −10 ° to +50 °C and for humidity 5 % to 95 % including condensation.

7.5 Water temperature requirements

NOTE See test 9.3.5.

The minimum rated operating conditions for water temperature shall be +0,1 °C to +30 °C. A CCI shall

meet the performance requirements for water temperature detailed in Table 2 over its rated water

temperature range (see 6.2 o)).

7.6 Installation influences

7.6.1 General

NOTE See tests 9.3.12 and 9.3.13.

7.6.2 CCIs with insertion electromagnetic sensors shall meet the bias, repeatability and combined

performance requirements detailed in Table 2 when installed in plastic or metal conduits.

7.6.3 CCIs with non-invasive ultrasonic sensors shall meet the bias, repeatability and combined

performance requirements detailed in Table 2 when installed on pipes constructed from plastic and

metal materials including lined pipes.

7.6.4 CCIs with insertion or non-invasive sensors shall meet the bias, repeatability and combined

performance requirements detailed Table 2 when installed in conduits within the manufacturer’s

specified size range.

7.6.5 CCIs for partially filled pipes sensors shall meet the bias, repeatability and combined performance

requirements detailed in Table 2 under both free surface and surcharged flow conditions.

7.7 Field test requirements

7.7.1 General

NOTE See Clause 10.

7.7.2 During the field test, the errors calculated from a minimum of 24 reference measurements shall

be less than or equal to the value of the combined performance requirement detailed in Table 2, in at least

90 % of the paired readings taken.

7.7.3 During the field test the CCI shall have an up-time greater than 95 %.

8 Testing

8.1 General requirements for testing

The tests defined in Clauses 9 and 10 are designed to demonstrate that a CCI conforms with the

performance requirements defined in Clause 7. CCI testing shall be carried out by laboratories that apply

quality management system practices in accordance with EN ISO/IEC 17025 [8] or other equivalent

standards accepted at international level to ensure that the results of testing are acceptable.

The reference methods, simulated inputs or secondary standards for CCI testing listed at Annex B shall

be used as appropriate. The use of simulated inputs or secondary standards shall be recorded and

justified in the test report.

The uncertainty of the reference method shall be included in the calculation of the results for all tests

except where the uncertainty of the reference method is no more than 1/5 of the performance

requirement being tested. Further information is given at Annex C.

Fewer measurements than required by an individual test can be made if this can be justified, e.g. where a

pattern of low variability is supported by statistical analysis. If this approach is adopted it shall be

recorded and justified in the test report.

The CCI shall be maintained, cleaned or recalibrated in line with manufacturer’s instructions prior to any

test, but adjustments shall not be carried out during the course of the test.

Any self-cleaning mechanisms or other automatic maintenance functions shall be disabled during any

laboratory test unless these are part of the normal measurement cycle or the test procedure states

otherwise.

Insertion sensors should be cleaned between tests by rinsing with demineralized water.

Readings shall be allowed to stabilize after any change in an influence quantity or determinand value.

Data from tests shall be processed in accordance with the calculation methods detailed in Annex A.

8.2 Laboratory test conditions

The number of test points depends on the range of the CCI. The measurement range (R) is calculated as:

R = Q / Q

upper lower

where

Q to Q are the minimum and maximum measured values over which the CCI is to be tested.

lower upper

This is equivalent to the R value as defined in EN ISO 4064-1, where Q = Q3 and Q = Q1

upper lower

Q shall be a non-zero value.

lower

For CCIs to be tested over a water velocity range, R shall be calculated using the minimum and maximum

velocities for which certification is sought and a fixed nominal liquid depth or conduit size.

The number and distribution of test points shall be chosen from Table 3.

Table 3 — Test point values

R

Limits of

Test point 20 – 39 40 – 199 200 – 629 630 +

determinand value

1A 1,05 Qlower ± 5 % Y One of One of One of

1B 1,68 Q ± 5 % Y these these these

lower

2A 4 Q ± 5 % - Y Y Y

lower

2B 16 Q ± 5 % - - Y

lower

One of these

2C 0,05 Q ± 5 % - - Y

upper

2 0,2 Q ± 5 % Y Y Y Y

upper

3 0,35 Q ± 5 % Y Y Y Y

upper

4 0,75 Q ± 5 % Y Y Y Y

upper

5 0,975 Q ± 2,5 % Y Y Y Y

upper

In Table 3, test points 1A, 1B, 3, 4 and 5 are designed to correspond to the test points required by

EN ISO 4064-2 where Q corresponds to Q1 and Q corresponds to Q3.

lower upper

Table 4 gives the reference conditions for possible influence quantities. Tests shall be carried out with all

influence quantities at their reference values, including tolerances, unless where specifically varied in any

one test.

Table 4 — Reference conditions

Influence quantity Reference value Tolerance

Ambient air temperature Shall not vary > ± 2,5 °C during

the conduct of each test

Ambient humidity at 20°C non-condensing -

Incident light Existing local light level -

Water temperature Shall not vary > ± 2,5 °C during

the conduct of each test

Water pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...