EN 1010-1:2004

(Main)Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 1: Common requirements

Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 1: Common requirements

5

1.1 This document applies to

.printing machines for printing on paper and similar materials, including screen printing presses;

equipment used in the preparation of the printing process and additional equipment on printing machines

are also considered to be printing machines. This standard also covers machinery used for the handling

of paper, products, printing formes and inks (before and after the printing process) as well as machinery

for cleaning printing formes and checking the print quality (auxiliary printing machinery).

.paper converting machines, i. e. machines to process, convert or finish paper, board and similar materials

which are processed, converted or finished in a similar manner.

NOTE Similar substrates are, for example, board, corrugated board, plastic film, aluminium foil, sheet metal and

photographic paper.

1.2 This document deals with all common significant hazards relevant to printing and paper converting

machinery when they are used as intended and under the conditions foreseen by the manufacturer (see

clause 4). This part of the standard defines the common safety requirements for all kinds of printing and paper

converting machines and related common devices and shall be used in connection with another part of the

EN 1010 series. The specific requirements specified in Part 2 and following parts of EN 1010 take precedence

over the respective requirements in EN 1010-1.

NOTE In addition, where a machine is not covered by a specific part of this standard, Part 1 of EN 1010 may be used

to establish the approach for dealing with the relevant risks.

1.3 This document is not applicable to printing and paper converting machines which are manufactured

before the date of publication of this document by CEN..EN 1010-1:2004 (E)

Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Druck- und Papierverarbeitungsmaschinen - Teil 1: Gemeinsame Anforderungen

Diese Norm gilt: 1.1.1 für Druckmaschinen zum Drucken auf Papier und ähnlichn Stoffen (Rolle, Bogen, körperförmige Bedruckstoffe); als Druckmaschinen gelten auch Einrichtungen und Arbeitsmittel zur Druckformherstellung.

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines d'impression et de transformation du papier - Partie 1: Prescriptions communes

1.1 Le présent document s'applique aux :

machines d'impression, c'est-à-dire les machines imprimant sur papier ou matières similaires, y compris les machines d'impression sérigraphique ; le matériel utilisé pour la préparation du procédé d'impression et le matériel auxiliaire des machines d'impression sont également considérés au titre de machines d'impression. La présente norme s'applique également aux machines utilisées pour la manutention du papier, des produits, des formes d'impression ou des encres (avant et après le processus d'impression), de même qu'aux machines destinées au lavage des formes d'impression et au contrôle de la qualité d'impression (machines d'impression auxiliaires) ;

machines de transformation du papier qui préparent, transforment et finissent le papier, le carton et d'autres matières similaires qui sont préparées, transformées et finies de la même manière (machine de traitement du papier, machine de finition du papier).

NOTE Les matières similaires sont par exemple le carton et le carton ondulé, les films en matière plastique ou en aluminium, la tôle mince et le papier photographique.

1.2 Le présent document traite tous les phénomènes dangereux communs significatifs engendrés par les machines d'impression et de transformation du papier lorsqu'elles sont utilisées normalement et dans les conditions prévues par le constructeur (voir Article 4). La présente partie 1 de la norme définit les prescriptions de sécurité communes à tous les types de machines d'impression et de transformation du papier ainsi que leurs auxiliaires communs. Elle doit être utilisée avec une autre partie de la série de l'EN 1010. Les prescriptions spécifiques prescrites dans les parties 2 et suivantes de l'EN 1010 ont la priorité sur les prescriptions respectives de l'EN 1010-1.

NOTE En outre, la partie 1 de l'EN 1010 peut être appliquée dans les cas où une machine n'entre pas dans le domaine d'application d'une partie spécifique de la présente norme et si un phén

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo tiskarskih strojev in strojev za obdelavo papirja - 1. del: Splošne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 07-Dec-2004

- Withdrawal Date

- 07-Dec-2010

- Technical Committee

- CEN/TC 198 - Printing and paper machinery - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 08-Dec-2010

- Completion Date

- 08-Dec-2010

- Directive

- Not Harmonized94/9/EC - Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX)OJ Ref: C 300, C 300, C 300, C 300, C 300, C 300, C 300, C OJ Date: 30-Nov-2005

Not Harmonized98/37/EC - MachineryOJ Ref: C 336, C 57, C 336, C 57, C 336, C 57, C 336, C 57 OJ Date: 09-Mar-2006

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1010-1:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 1: Common requirements". This standard covers: 5 1.1 This document applies to .printing machines for printing on paper and similar materials, including screen printing presses; equipment used in the preparation of the printing process and additional equipment on printing machines are also considered to be printing machines. This standard also covers machinery used for the handling of paper, products, printing formes and inks (before and after the printing process) as well as machinery for cleaning printing formes and checking the print quality (auxiliary printing machinery). .paper converting machines, i. e. machines to process, convert or finish paper, board and similar materials which are processed, converted or finished in a similar manner. NOTE Similar substrates are, for example, board, corrugated board, plastic film, aluminium foil, sheet metal and photographic paper. 1.2 This document deals with all common significant hazards relevant to printing and paper converting machinery when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of printing and paper converting machines and related common devices and shall be used in connection with another part of the EN 1010 series. The specific requirements specified in Part 2 and following parts of EN 1010 take precedence over the respective requirements in EN 1010-1. NOTE In addition, where a machine is not covered by a specific part of this standard, Part 1 of EN 1010 may be used to establish the approach for dealing with the relevant risks. 1.3 This document is not applicable to printing and paper converting machines which are manufactured before the date of publication of this document by CEN..EN 1010-1:2004 (E)

5 1.1 This document applies to .printing machines for printing on paper and similar materials, including screen printing presses; equipment used in the preparation of the printing process and additional equipment on printing machines are also considered to be printing machines. This standard also covers machinery used for the handling of paper, products, printing formes and inks (before and after the printing process) as well as machinery for cleaning printing formes and checking the print quality (auxiliary printing machinery). .paper converting machines, i. e. machines to process, convert or finish paper, board and similar materials which are processed, converted or finished in a similar manner. NOTE Similar substrates are, for example, board, corrugated board, plastic film, aluminium foil, sheet metal and photographic paper. 1.2 This document deals with all common significant hazards relevant to printing and paper converting machinery when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of printing and paper converting machines and related common devices and shall be used in connection with another part of the EN 1010 series. The specific requirements specified in Part 2 and following parts of EN 1010 take precedence over the respective requirements in EN 1010-1. NOTE In addition, where a machine is not covered by a specific part of this standard, Part 1 of EN 1010 may be used to establish the approach for dealing with the relevant risks. 1.3 This document is not applicable to printing and paper converting machines which are manufactured before the date of publication of this document by CEN..EN 1010-1:2004 (E)

EN 1010-1:2004 is classified under the following ICS (International Classification for Standards) categories: 37.100.10 - Reproduction equipment; 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1010-1:2004 has the following relationships with other standards: It is inter standard links to EN 1010-1:2004+A1:2010, EN 1010-2:2006+A1:2010, EN 1010-3:2002+A1:2009, EN 1010-4:2004+A1:2009, EN 1010-5:2005, EN 1010-1:2004/FprA1; is excused to EN 1010-5:2005, EN 1010-2:2006, EN 1010-3:2002, EN 1010-4:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1010-1:2004 is associated with the following European legislation: EU Directives/Regulations: 94/9/EC, 98/37/EC; Standardization Mandates: M/BC/CEN/88/13, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1010-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 1: Common requirementsSécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines d'impression et de transformation du papier - Partie 1: Prescriptions communesSicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Druck- und Papierverarbeitungsmaschinen - Teil 1: Gemeinsame Anforderungen85.100Oprema za papirno industrijoEquipment for the paper industry37.100.10Reprodukcijska opremaReproduction equipmentICS:SIST EN 1010-1:2005enTa slovenski standard je istoveten z:EN 1010-1:200401-april-2005SIST EN 1010-1:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1010-1December 2004ICS 37.100.10; 85.100English versionSafety of machinery - Safety requirements for the design andconstruction of printing and paper converting machines - Part 1:Common requirementsSécurité des machines - Prescriptions de sécurité pour laconception et la construction de machines d'impression etde transformation du papier - Partie 1: PrescriptionscommunesSicherheit von Maschinen - Sicherheitsanforderungen anKonstruktion und Bau von Druck- undPapierverarbeitungsmaschinen - Teil 1: GemeinsameAnforderungenThis European Standard was approved by CEN on 7 June 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1010-1:2004: E

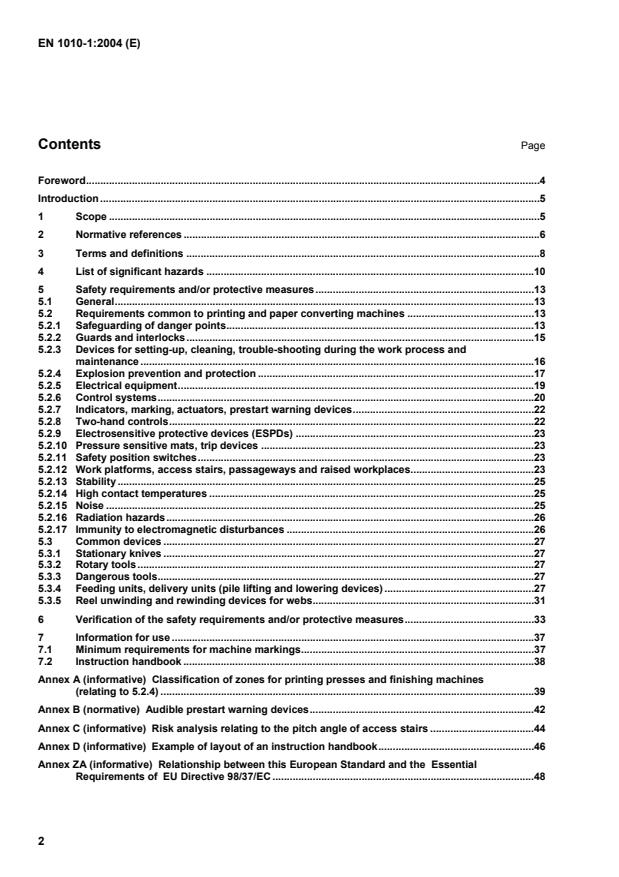

Classification of zones for printing presses and finishing machines

(relating to 5.2.4).39 Annex B (normative)

Audible prestart warning devices.42 Annex C (informative)

Risk analysis relating to the pitch angle of access stairs.44 Annex D (informative)

Example of layout of an instruction handbook.46 Annex ZA (informative)

Relationship between this European Standard and the

Essential Requirements of

EU Directive 98/37/EC.48

Relationship between this

European

Standard and the Essential Requirements

of EU Directive 94/9/EC.49 Bibliography.51

Common requirements Part 2

Printing and varnishing machines including pre-press machinery Part 3

Cutting machines Part 4

Bookbinding, paper converting and finishing machines Part 5

Machines for the production of corrugated board and machines for the conversion of flat and corrugated board. 1 Scope 1.1 This document applies to printing machines for printing on paper and similar materials, including screen printing presses; equipment used in the preparation of the printing process and additional equipment on printing machines are also considered to be printing machines. This standard also covers machinery used for the handling of paper, products, printing formes and inks (before and after the printing process) as well as machinery for cleaning printing formes and checking the print quality (auxiliary printing machinery). paper converting machines, i. e. machines to process, convert or finish paper, board and similar materials which are processed, converted or finished in a similar manner. NOTE Similar substrates are, for example, board, corrugated board, plastic film, aluminium foil, sheet metal and photographic paper. 1.2 This document deals with all common significant hazards relevant to printing and paper converting machinery when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of printing and paper converting machines and related common devices and shall be used in connection with another part of the EN 1010 series. The specific requirements specified in Part 2 and following parts of EN 1010 take precedence over the respective requirements in EN 1010-1. NOTE In addition, where a machine is not covered by a specific part of this standard, Part 1 of EN 1010 may be used to establish the approach for dealing with the relevant risks. 1.3 This document is not applicable to printing and paper converting machines which are manufactured before the date of publication of this document by CEN.

1.4 This document does not apply to: winder-slitters and sheeters in paper finishing (sheeters with unwinders) (see EN 1034-1:2000, EN 1034-3:2000, prEN 1034-5:2001); office-type collating machines equipped with friction feeders; mail processing machines; machines used for filling packages (such as machines for shaping, filling, and closing the package), textile printing presses 2 Normative references The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any amendments) applies. EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs. EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body. EN 418:1992, Safety of machinery — Emergency stop equipment, functional aspects — Principles for design. EN 563:1994, Safety of machinery — Temperatures of touchable surfaces — Ergonomics data to establish temperature limit values for hot surfaces. EN 574:1996, Safety of machinery — Two-hand control devices — Functional aspects — Principles for design. EN 953:1997, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards. EN 954-1:1996, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design. EN 999:1998, Safety of machinery — The positioning of protective equipment in respect of approach speeds of parts for the human body. EN 1037:1995, Safety of machinery — Prevention of unexpected start-up. EN 1050:1996, Safety of machinery — Principles for risk assessment. EN 1070:1998, Safety of machinery — Terminology. EN 1088:1995, Safety of machinery — Interlocking devices associated with guards — Principles for design and selection. EN 1127-1:1997, Explosive atmospheres — Explosion prevention and protection — Part 1: Basic concepts and methodology. EN 1760-1:1997:1997, Safety of machinery — Pressure sensitive devices — Part 1: General principles for the design and testing of pressure sensitive mats and pressure sensitive floors.

Basic terminology, methodology (ISO 12100-1:2003). EN ISO 12100-2:2003, Safety of machinery - Basic concepts, general principles for design - Part 2:

Technical principles (ISO 12100-2:2003). EN ISO 14122-1:2001, Safety of machinery — Permanent means of access to machines and industrial plants — Part 1: Choice of a fixed means of access between two levels (ISO 14122-1:2001). EN ISO 14122-2:2001, Safety of machinery — Means of permanent access to machines and industrial plants — Part 2: Working platforms and gangways (ISO 14122-2:2001). EN ISO 14122-3:2001, Safety of machinery — Means of permanent access to machines and industrial plants — Part 3: Stairways, stepladders and guard-rails (ISO 14122-3:2001). EN ISO 14122-4:1996, Safety of machinery — Means of permanent access to machines and industrial plants — Part 4: Fixed ladders (ISO 14122-4:2004). EN 50014:1999, Electrical apparatus for potentially explosive

atmospheres — General requirement. EN 50015:1998, Electrical apparatus for potentially explosive atmospheres — Oil immersion "o". EN 50016:1995, Electrical apparatus for potentially explosive atmospheres — Pressurized apparatus "p". EN 50017:1998, Electrical apparatus for potentially explosive atmospheres — Powder filling "q". EN 50018:2000, Electrical apparatus for potentially explosive atmospheres — Flameproof enclosures "d". EN 50019:2000, Electrical apparatus for potentially explosive atmospheres — Increased safety "e". EN 50020:1994, Electrical apparatus for potentially explosive atmospheres — Intrinsic safety "i". EN 50039:1980, Electrical apparatus for potentially explosive atmospheres — Intrinsic safety "i". EN 50281-1-2:1999, Electrical apparatus for use in the presence of

combustible dust — Part 1-2: Electrical apparatus

protected by enclosures; selection, installation

and maintenance.

atmospheres - Part 14: Electrical installations in

hazardous areas (other than mines). EN 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

EN 60825-1:1994, Safety of laser products — Part 1: Equipment classification, requirements and user's guide. EN 61000-6-2:2001 Electromagnetic compatibility (EMC) — Part 6-2: Generic

standards; Immunity for industrial environment. EN 61010-1:2001, Safety requirements for electrical equipment for measurement, control and laboratory use — Part 1: General requirements (IEC 61010-1:2001). EN 61310-1:1995, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, auditory and tactile signals. EN 61310-2:1995, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for marking. EN 61496-1:1997, Safety of machinery — Electrosensitive protective equipment — Part 1: General requirements and tests. IEC 61496-2:1997, Safety of machinery — Electrosensitive protective equipment — Part 2: Particular require-ments for equipment using active opto-electronic protective devices. CLC R 044-001:1999, Safety of machinery: „Guidance and recommendations for the avoidance of hazards due to static electricity. 3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 1070:1998 and the following apply. 3.1 danger points danger points are defined locations in the danger zone of machines where persons can be injured by movements of

— parts of machines;

— tools of machines or parts of tools;

— workpieces or parts of workpieces or

— materials being processed.

NOTE Danger points can exist, for example, on gear, chain and worm drives, V-belt, flat belt, cord and rope drives, pulling and supporting elements on continuous conveyors, spoke wheels and fly wheels, shafts and shaft ends, rollers, slides, push rods and similar parts, tools and clamping devices. Particular points of danger are: crushing and shearing points; trapping points;

a) two counter-rotating rollers, powered or non-powered; b) one rotating roller and an adjacent fixed part of the machine; c) rollers rotating and conveyer belts in the same direction, but with different peripheral speeds or surface properties (friction); d) guide roller and driving belt, conveyor belt and possibly the web (see Figure 1). Inrunning nips also exist on non-powered riding rollers (guide rollers) which are driven by the movement of the web. This hazard may depend on a number of factors, e.g. type and strength of material, wrapping angle, web speed, inertia. - Figure 1 — Examples of inrunning nips 3.3 integrated pile lifting and lowering devices devices integrated into sheet and blank feeders or deliveries for lifting and lowering the sheet pile 3.4 format size maximum size of blanks (maximum length times maximum width) that can be printed or converted by the machine 3.5 routine and regular access access to a danger point required for production reasons after each tool closing movement 3.6 web-type materials webs of paper, board, foil or similar material which is to be handled or processed

clauses in Significant hazards Danger zone this standard EN ISO 12100-1: 2003 EN 1050: 1996 Annex A Mechanical hazards crushing shearing cutting or severing entanglement drawing-in trapping impacts Production area: – between rollers, cylinders, drums – short linear movements

– wheels for floor travel – revolving handwheels – crushing hazards with parts of building – guards – accessible danger zone – make-ready, cleaning, maintenance operations and trouble

shooting (hold-to-run) – safe threading of web-type material – impact hazards in passageways, access ways – stationary knives

– rotary tools – transport of hazardous tools – on feeding and delivery units (pile lifting and lowering devices)

– unwinding and rewinding units for web-type material

5.2.1.1, 5.2.1.2 5.2.1.3 5.2.1.4 5.2.1.5 5.2.1.6 5.2.2 5.2.3.1 5.2.3.2, 5.2.3.3, 5.2.3.4

5.2.3.5 5.2.12.1.4

5.3.1 5.3.2 5.3.3 5.3.4.3 to 5.3.4.10 5.3.5 4.2.1 1 Mechanical hazards generated by: Mass and stability, Mass and velocity – stability – movable machines – feeding units, delivery units

5.2.13.1 5.2.13.2 5.3.4.1, 5.3.4.2, 5.3.4.11, 7.2.5 4.2 1 Slipping, tripping, falling Work platforms, access stairs, passageways, steps, floor coverings 5.2.12

4.2.3 19 Electrical hazards Direct or indirect contact Thermal radiation (burns) – electrical equipment (equipment made live under electrical fault conditions) – supply disconnection device, stop category

– rectifier drives – degree of protection – measuring devices 5.2.5.1, 5.2.5.7

5.2.5.2, 5.2.5.3

5.2.5.4 5.2.5.5 5.2.5.8 4.3 2 Thermal hazards Burns due to possible contact Hot machine parts 5.2.14, 7.2.4 4.4 3 Hazards generated by noise Hearing damage Interference with speech communication Accidents due to interference with the perception of acoustic signals Stress All machines 5.2.15, 7.2.4

4.5 4 Hazards generated by radiation UV-radiation, laser Machines with laser and UV-light 5.2.16, 7 4.7 6

clauses in Significant hazards Danger zone this standard EN ISO 12100-1: 2003 EN 1050: 1996 Annex A Hazards from explosion – machinery using flammable liquids or dusts 5.2.4, 7.2.4

4.8 7.2 Hazards generated by neglect of ergonomic principles in machine design

Unhealthy body postures

Unsuitable construction, place or identification of actuators – design of actuators and displays – safety access, workplaces, catwalks, passageways

– footsteps, handles – balance of weight – avoidance of irritating reflection

5.2.7 Annex B 5.2.12.1.1, 5.2.12.1.3,

5.2.12.1.4, 5.2.12.1.5

5.2.12.2 5.2.2.5 5.2.2.6 4.9 8 Failure, malfunction of control system

Faults or failures in safety circuits malfunction of software – machinery with safety circuits

– conductor identification – separation of chucking cones 5.2.6 5.2.8 to 5.2.11

5.2.5.6 5.3.5.4

10 External effects on electrical devices Iimmunity to electromagnetic disturbances 5.2.17

10.3

5 Safety requirements and/or protective measures 5.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant, which are not dealt with by this document (e. g. sharp edges of the machine frame). 5.2 Requirements common to printing and paper converting machines 5.2.1 Safeguarding of danger points 5.2.1.1 Inrunning nips on cylinders, rollers, drums, rolls and similar parts shall be safeguarded by guards or by applying the safety distances specified in EN 349:1993. On guide rollers, the safety distance specified for the arm is considered to be sufficient where risk assessment has determined that whole-body or head access cannot be expected. Guards shall be designed as follows: a) as guards without openings or with openings for feeding the material (for example sheets, blanks, webs, work pieces). The safety distances shall be established in relation to the width of the opening in accordance with EN 294:1992 (see Figure 2).

These guards shall be interlocked with the dangerous movements in accordance with 5.2.2 or they shall be fixed to the machine. When the interlocking guard is open, one of the measures set out in 5.2.3 shall become effective.

Figure 2 — Safeguarding of inrunning nips b) on smooth-surface rollers or cylinders as fixed nip bars extending across the entire working width, designed in suitable sections. The clearance between the bar and the respective machine part, for example, cylinders, rollers with a smooth surface etc., shall not exceed 6 mm (see Figure 3).

Figure 3 — Safeguarding an inrunning nip by means of a fixed nip bar 5.2.1.2 The use of trip devices for safeguarding inrunning nips shall be permitted only if the condition defined in 5.2.10.2 is satisfied. 5.2.1.3 Linear movements are considered to be sufficiently safe if the maximum distance between moving part and fixed part does not exceed 4 mm.

Figure 4 — Example of a linear movement on a plate clamping device 5.2.1.4 On machines which travel under power, the crushing points between wheels and floor shall be safeguarded. Safeguarding of crushing points is achieved, for example, by providing foot guards fixed such that there is a distance of no more than 15 mm between the runway and the lower edge of the guard. 5.2.1.5 Handwheels and cranks shall be so designed that they do not automatically rotate when the machine operates at production speed. This is achieved, for example, where handwheels and cranks are decoupled by pressure springs during the production run. 5.2.1.6 Where machines with movable parts are used in the workroom, the instruction handbook shall require users to erect machines in such a way that the hazard of crushing of persons between movable machine parts and the building is prevented. 5.2.2 Guards and interlocks

5.2.2.1 Guards shall satisfy the requirements of EN 953:1997. Interlocking shall satisfy the requirements of clauses 5 and 6 of EN 1088:1995. Stopping times vary with the type of machine used, but should be as short as possible. For interlocking, see 5.2.11 (safety position switches with approach reaction) and 5.2.6 (control systems). 5.2.2.2 For fence-type enclosures, the safety distances according to EN 294:1992 apply. A further requirement is that the distance between the floor and lower edge of the fence does not exceed 200 mm and between the floor and upper edge is at least 1,4 m. 5.2.2.3 Guards and access doors in enclosures which are opened or removed frequently in the production process or for setting-up operations shall be interlocked with the hazardous movements. Guards which do not have to be opened frequently shall be fixed in such a way that their removal necessitates the use of tools. These guards may also be interlocked with the hazardous movements.

5.2.3.1 Where accessible danger zones cannot be observed from positions from which hazardous movements can be started, one of the following requirements shall be satisfied: where accessible danger zones are safeguarded by a fence-type enclosure, it shall not be possible for the person(s) within the enclosure to close the interlocking access gate or an additional control device shall be provided outside the enclosure in such a position that it cannot be actuated from the inside. Any hazardous movement shall be permitted only after the access door has been closed and the control device been actuated; where accessible danger zones are safeguarded by means of ESPDs, an additional control element shall be provided outside the danger zone that cannot be reached from any position in the danger zone. Provisions shall be made that the hazardous movement can only be started after the person has actuated the additional control element. 5.2.3.2 When the interlocking guard is opened or removed or if a person has entered the danger zone and there are danger points unprotected, it shall only be possible to start a machine by means of

a) Hold-to-run control devices

Any two-hand control device shall satisfy the requirements defined in 5.2.8. The stopping path shall be as short as technically feasible.

Starting the machine in the hold-to-run mode after opening an interlocking guard may be done without operating a selector switch, if production operation during hold-to-run control is positively prevented by the interlocking device. A selector switch is required for machines which allow two modes of hold-to-run control (hold-to-run control with one actuator and two-hand control). b) Manual operation Devices which allow manual operation of the machine or parts of the machine shall be designed so that persons are not exposed to danger.

5.2.3.3 From the place of operation of the hold-to-run control, it shall be possible to observe the danger points and danger zones. 5.2.3.4 Where hold-to-run controls are being used for safeguarding a danger point, starting the machine in the hold-to-run mode after opening the interlocking guard shall only be possible when other interlocking guards outside the area that can be observed by the operator are closed. 5.2.3.5 Safe threading of the web-type material shall be ensured. On power-driven web threading devices, access to danger points shall be prevented by guards.

Access to danger points is considered prevented if, for example,

on rope-type threading devices, the inrunning nips between threading rope and idler pulley are safeguarded. Safeguarding may include the provision, on the outside of the pulleys, of a fixed disc, the radius of which is at least 120 mm larger than that of the pulley, on power-driven bar-type threading devices with transport chains, the inrunning nips between chains and chain wheels are provided with guards filling the inrunning nips as far as possible, threading is carried out under hold-to-run control with speed limitation. 5.2.4 Explosion prevention and protection 5.2.4.1 All electrical and non-electrical equipment and components intended for use in potentially explosive atmospheres shall be designed and constructed according to good engineering practice and conform to the required categories for group II equipment to ensure avoidance of any ignition source as specified in 5.3 of EN 1127-1:1997. To classify the category of the equipment, it shall be subjected to an ignition hazard assessment in accordance with 5.2 of EN 13463-1:2001. 5.2.4.2 Explosion prevention and protection is not required for machinery where there are no flammable liquids with a flash point below 55 °C being used and no flammable liquids are sprayed or heated to a temperature above flash point under operating conditions. All other machinery shall be designed to satisfy the requirements specified in EN 1127-1:1997 for the zones described in Annex A.

5.2.4.3.3 Group II category ID, 2D or 3D equipment for installation in a particular zone shall be selected according to EN 50281-1-2:1999.

5.2.4.4 Non-electrical equipment 5.2.4.4.1 All non-electrical equipment, intended for use in a potentially explosive atmosphere caused by gas, vapour, mist or dust, shall comply with the requirements of EN 13463-1:2001 and EN 13463-5:2003 and, where relevant, the European Standards to be applied for the specific type of ignition protection. 5.2.4.4.2 Group II category 1G or ID equipment, for installation in zone 0 or 20 respectively, shall not contain any effective ignition source during expected malfunctions or rare malfunctions. 5.2.4.4.3 Group II category 2G or 2D equipment, for installation in zone 1 or 21 respectively, shall not contain any effective ignition source during normal operation or expected malfunction. 5.2.4.4.4 Group II category 3G or 3D equipment, for installation in zone 2 or 21 respectively, shall not contain any effective ignition source during normal operation. 5.2.4.5 The surface temperature of all parts of category 1 and 2 non-electrical equipment likely to come into contact with potentially explosive atmospheres and the temperature of the potentially explosive atmosphere shall not exceed 80 % of the ignition temperature in °C of the gases or vapours. The temperature of all surfaces which can come into contact with dust clouds shall not exceed 2/3 of the minimum ignition temperature in °C of the dust cloud. 5.2.4.6 On surfaces where the deposition of potentially glowing dust cannot be positively prevented, the surface temperature of all parts of non-electrical equipment shall not exceed the minimum ignition temperature of the dust layer reduced by 75 K.

See prEN 50281-1-3:2002. 5.2.4.7 Brakes and clutches shall be designed such that they cannot be a source of ignition in accordance with EN 13463-5:2003. 5.2.4.8 Undesirable electrostatic discharges shall be avoided by earthing and interconnecting all the metallic components. Note Further information on this topic is given in the CENELEC report R044-001 "Safety of machinery - Guidance and recommendations for the avoidance of hazards due to static electricity". 5.2.4.9 Hoses and pipes used for exhausting flammable dusts and other flammable materials (paper, plastic etc.) shall be conductive and electrostatically grounded (resistance less than 106 ). Respective reference shall be made in the instruction handbook.

Key 1 Drive motor 2 Agitator 3 Top view Figure 5 — Distance between drive motor and agitator (lantern) 5.2.4.12 The electric drive motor on recirculating pumps on supply tank for inks, coating substances, impregnating material or glues shall be protected in accordance with EN 50018:2000 with regard to ignition protection. Where protective motor switches are mounted on the pump, EN 50019:2000 is sufficient. 5.2.5 Electrical equipment

5.2.5.1 All electrical equipment shall be designed such that electrical hazards (for example electric shock, burns) according to EN 60204-1:1997 are prevented. The requirements of EN 60204-1:1997 shall be fulfilled, taking into account the following additional requirements. 5.2.5.2 Machines shall be provided with a supply disconnecting device in accordance with 5.3.2 a) or c) of EN

60204-1:1997. The device shall be provided with a means to be locked in the OFF position. Where the operation of the emergency stop control devices causes galvanic disconnection from the power supply by undervoltage tripping, a circuit-breaker in accordance with 5.3.2 c) of EN 60204-1:1997 is required. Where circuits as specified in 5.3.5 of EN 60204-1:1997 are not disconnected by the supply disconnecting device, such circuits shall be provided with their own disconnecting device. See also 5.2.7.5. 5.2.5.3 Emergency stop devices shall be designed in accordance with 9.2.5.4.2 of EN 60204-1:1997 either as a category 0 stop or as a category 1 stop. On machines where inrunning nips are safeguarded by trip bars according to 5.2.10, the emergency stop shall function as a category 1 stop. See also 5.2.6.1.2. 5.2.5.4 On rectifier drives, the actuation of an emergency stop control device may, as a deviation from 9.2.5.4 of EN 60204-1:1997, cause stopping of the drive as a category 2 stop according to 9.2.2 of

EN 60204-1:1997 if

14.2.4 of EN 60204-1:1997; securing conductors in position, for example by using comb-type wire fixing in such a way that any confusion of conductors when changing electric components is safely prevented; or another adequate method. 5.2.5.7 All electrical equipment shall be designed such that it will withstand the testing specified in 19.2 to 19.6 of EN 60204-1:1997. Voltage tests as specified in 19.4 of EN 60204-1:1997 are not required for electronic control circuits provided by computer systems or electronic control components. 5.2.5.8 Measuring devices which are part of machines shall comply with EN 61010-1:2001. 5.2.6 Control systems 5.2.6.1 Control requirements for machines which do not require routine and regular access to danger points. 5.2.6.1.1 In the hydraulic/pneumatic control system, the safety-related parts shall satisfy at least category 1 (6.2.2) of EN 954-1:1996. In the electric/electronic control system, the safety-related parts shall satisfy at least category 3 (6.2.4) of EN 954-1:1996. Only single main contactors may be provided. The minimum requirement is that faults in the auxiliary relays and auxiliary contactors in the control circuit shall be detected and hazardous

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...