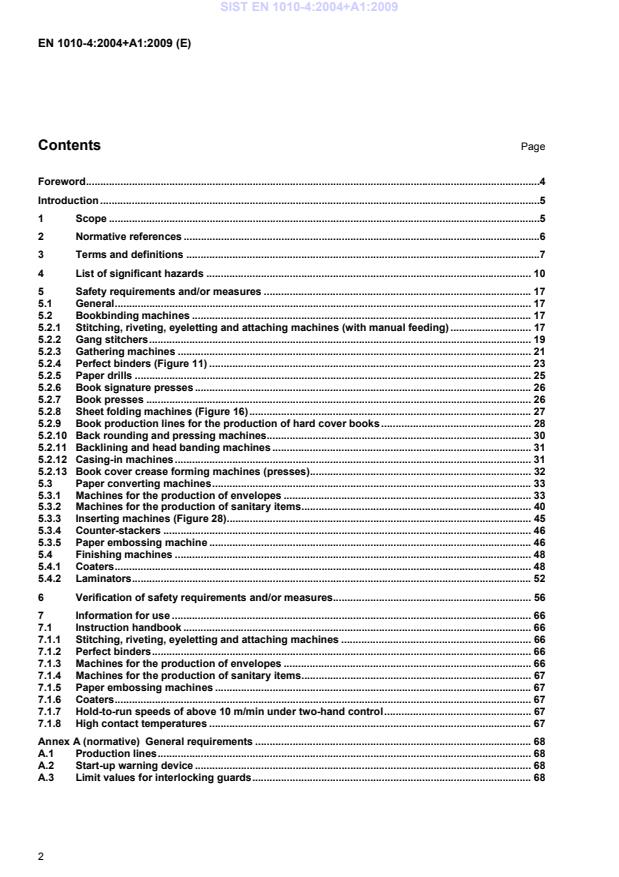

EN 1010-4:2004+A1:2009

(Main)Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 4: Bookbinding, paper converting and finishing machines

Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 4: Bookbinding, paper converting and finishing machines

This document applies to

- bookbinding machines:

- stitching, riveting, eyeletting and attaching machines;

- gang stitchers;

- gathering machines;

- perfect binders;

- paper drills;

- book signature presses;

- book presses;

- sheet folding machines;

- book production lines for the production of books with hard covers;

- back rounding and pressing machines;

- backlining and head banding machines;

- casing-in machines;

- book cover crease forming machines.

- paper converting machines:

- machines for the production of envelopes;

- machines for the production of sanitary items;

- inserting machines;

- counter-stackers;

- paper embossing machines.

- paper finishing machines:

- coaters;

- laminators.

This document shall be used together with EN 1010-1:2004+A1. Both parts together identify all significant hazards relevant to bookbinding, paper converting and paper finishing machines when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). The specific requirements in EN 1010 4 take precedence over respective requirements in EN 1010-1:2004+A1.

This document does not deal with risks generated by noise emitted from the machines. These issues are covered basically in EN 1010-1:2004+A1. However, for machines like sheet folding machines and machines for the production of envelopes and sanitary items, some specific proposals for noise reduction measures are given.

This document is not applicable to bookbinding, paper converting and finishing machines manufactured before the date of publication of this document by CEN.

Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Druck- und Papierverarbeitungsmaschinen - Teil 4: Buchbinderei-, Papierverarbeitungs- und Papierveredelungsmaschinen

Dieses Dokument gilt für:

- Buchbindereimaschinen:

- Heft-, Niet-, Öse- und Ansetzmaschinen;

- Sammelhefter;

- Zusammentragmaschinen;

- Klebebinder;

- Papierbohrmaschinen;

- Bündelpressen;

- Bücherpressen;

- Bogenfalzmaschinen;

- Buchfertigungsstraßen;

- Buchrückenrunde- und Abpressmaschinen;

- Buchblockhinterklebe- und Kapitalmaschinen;

- Bucheinhängemaschinen;

- Falzeinbrennmaschinen.

- Papierverarbeitungsmaschinen:

- Briefumschlag-, Versandtaschenmaschinen;

- Hygieneartikelmaschinen;

- Einsteckmaschinen;

- Kreuzleger;

- Papierprägemaschinen.

- Papierveredelungsmaschinen:

- Beschichtungsmaschinen;

- Kaschiermaschinen.

Dieses Dokument ist gemeinsam mit !EN 1010-1:2004+A1" anzuwenden. Beide Teile zusammen behandeln alle signifikanten Gefährdungen, die auf die Buchbinderei-, Papierverarbeitungs- und Papier-veredelungsmaschinen zutreffen, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden (siehe Abschnitt 4). Die spezifischen Anforderungen in EN 1010-4 haben Vorrang vor entspre¬chenden Anforderungen in der !EN 1010-1:2004+A1".

Dieses Dokument befasst sich nicht mit Risiken, die durch Lärm entstehen, der von den Maschinen erzeugt wird. Dies ist grundlegend in !EN 1010-1:2004+A1" behandelt. Jedoch gibt es für Falzmaschinen, Briefumschlag- und Versandtaschenmaschinen und Hygieneartikelmaschinen Anforderungen bezüglich Lärmminderung.

Dieses Dokument gilt nicht für Buchbinderei-, Papierverarbeitungs- und Papierveredelungsmaschinen, die hergestellt wurden, bevor CEN dieses Dokument veröffentlichte.

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines d'impression et de transformation du papier - Partie 4 : Machines à relier les livres, machines de transformation et de finition du papier

Le présent document s'applique aux :

- machines à relier les livres :

- brocheuses à fil métallique, riveteuses, machines à poser les œillets et machines à agrafer ;

- encarteuses-piqueuses ;

- assembleuses ;

- machines à relier par collage ;

- perceuses/foreuses ;

- presseurs de cahiers ;

- presses à livres ;

- plieuses de feuilles ;

- lignes de production de livres à couverture rigide ;

- machines à arrondir les dos et à presser ;

- machines à coller la mousseline et le tranchefile ;

- machines à emboîter dans les couvertures ;

- machines à repincer ;

- machines de transformation du papier :

- machines à fabriquer les enveloppes et les pochettes ;

- machines à fabriquer les articles sanitaires ;

- machines à insérer les encarts ;

- machines d'empilage ;

- gaufreuses ;

- machines de finition du papier :

- machines d'enduction ;

- machines de contre-collage.

Le présent document doit être appliqué conjointement avec l’EN 1010-1:2004+A1. Ces deux normes traitent tous les phénomènes dangereux significatifs engendrés par les machines d'impression et de transformation du papier lorsqu'elles sont utilisées normalement et dans les conditions prévues par le constructeur (voir article 4). Les spécifications de la partie 4 de l'EN 1010:2001 ont la priorité sur les spécifications de la partie 1.

Le présent document ne traite pas les risques engendrés par le bruit émis par les machines à l'exception des plieuses de feuilles, des machines à fabriquer les enveloppes et les pochettes et des machines à fabriquer les articles sanitaires. Il existe pour ces machines des exigences relatives aux mesures de réduction du bruit. Ceci est traité fondamentalement dans l’EN 1010-1:2004+A1.

Ce document n’est pas applicable aux machines à relier les livres et machines de transformation et de finition du papier qui ont été fabriquées avant la date de publication de ce document par le CEN.

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo tiskarskih strojev in strojev za obdelavo papirja - 4. del: Stroji za vezavo knjig, obdelavo in izdelavo papirja

General Information

- Status

- Withdrawn

- Publication Date

- 13-Oct-2009

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 198 - Printing and paper machinery - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Dec-2023

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 22-Aug-2009

- Effective Date

- 28-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 1539:2000 - Dryers and ovens, in which flammable substances are released - Safety requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1010-4:2004+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 4: Bookbinding, paper converting and finishing machines". This standard covers: This document applies to - bookbinding machines: - stitching, riveting, eyeletting and attaching machines; - gang stitchers; - gathering machines; - perfect binders; - paper drills; - book signature presses; - book presses; - sheet folding machines; - book production lines for the production of books with hard covers; - back rounding and pressing machines; - backlining and head banding machines; - casing-in machines; - book cover crease forming machines. - paper converting machines: - machines for the production of envelopes; - machines for the production of sanitary items; - inserting machines; - counter-stackers; - paper embossing machines. - paper finishing machines: - coaters; - laminators. This document shall be used together with EN 1010-1:2004+A1. Both parts together identify all significant hazards relevant to bookbinding, paper converting and paper finishing machines when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). The specific requirements in EN 1010 4 take precedence over respective requirements in EN 1010-1:2004+A1. This document does not deal with risks generated by noise emitted from the machines. These issues are covered basically in EN 1010-1:2004+A1. However, for machines like sheet folding machines and machines for the production of envelopes and sanitary items, some specific proposals for noise reduction measures are given. This document is not applicable to bookbinding, paper converting and finishing machines manufactured before the date of publication of this document by CEN.

This document applies to - bookbinding machines: - stitching, riveting, eyeletting and attaching machines; - gang stitchers; - gathering machines; - perfect binders; - paper drills; - book signature presses; - book presses; - sheet folding machines; - book production lines for the production of books with hard covers; - back rounding and pressing machines; - backlining and head banding machines; - casing-in machines; - book cover crease forming machines. - paper converting machines: - machines for the production of envelopes; - machines for the production of sanitary items; - inserting machines; - counter-stackers; - paper embossing machines. - paper finishing machines: - coaters; - laminators. This document shall be used together with EN 1010-1:2004+A1. Both parts together identify all significant hazards relevant to bookbinding, paper converting and paper finishing machines when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). The specific requirements in EN 1010 4 take precedence over respective requirements in EN 1010-1:2004+A1. This document does not deal with risks generated by noise emitted from the machines. These issues are covered basically in EN 1010-1:2004+A1. However, for machines like sheet folding machines and machines for the production of envelopes and sanitary items, some specific proposals for noise reduction measures are given. This document is not applicable to bookbinding, paper converting and finishing machines manufactured before the date of publication of this document by CEN.

EN 1010-4:2004+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 37.100.10 - Reproduction equipment; 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1010-4:2004+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1010-4:2004/FprA1, EN 1010-4:2004, EN ISO 12643-4:2023, EN ISO 12643-3:2023, EN 61000-6-4:2001, EN 292-2:1991/A1:1995, EN 13023:2003+A1:2010, EN 1050:1996, EN 1010-1:2004, EN 954-1:1996, EN ISO 4871:2009, EN 292-2:1991, EN 1010-3:2002, EN 1539:2000, EN 626-2:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1010-4:2004+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1010-4:2004+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Druck- und Papierverarbeitungsmaschinen - Teil 4: Buchbinderei, Papierverarbeitungs- und PapierveredelungsmaschinenSécurité des machines - Exigences de sécurité pour la conception et la construction de machines d'impressions et de transformation du papier - Partie 4: Machines à relier les livres, machines de transformation et de finition du papierSafety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 4: Bookbinding, paper converting and finishing machines85.100Oprema za papirno industrijoEquipment for the paper industry37.100.10Reprodukcijska opremaReproduction equipmentICS:Ta slovenski standard je istoveten z:EN 1010-4:2004+A1:2009SIST EN 1010-4:2004+A1:2009en01-december-2009SIST EN 1010-4:2004+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1010-4:2004+A1

October 2009 ICS 37.100.10; 85.100 Supersedes En 1010-4:2004English Version

Safety of machinery - Safety requirements for the design and construction of printing and paper converting machines - Part 4: Bookbinding, paper converting and finishing machines

Sécurité des machines - Exigences de sécurité pour la conception et la construction de machines d'impressions et de transformation du papier - Partie 4: Machines à relier les livres, machines de transformation et de finition du papier Sicherheit von Maschinen - Sicherheitsanforderungen an Konstruktion und Bau von Druck- und Papierverarbeitungsmaschinen - Teil 4: Buchbinderei, Papierverarbeitungs- und Papierveredelungsmaschinen This European Standard was approved by CEN on 21 November 2003 and includes Amendment 1 approved by CEN on 15 September 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1010-4:2004+A1:2009: ESIST EN 1010-4:2004+A1:2009

General requirements . 68A.1Production lines . 68A.2Start-up warning device . 68A.3Limit values for interlocking guards . 68SIST EN 1010-4:2004+A1:2009

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""" . 69Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 70SIST EN 1010-4:2004+A1:2009

Common requirements Part 2 Printing and varnishing machines including pre-press machinery Part 3 Cutting machines Part 4 Bookbinding, paper converting and finishing machines Part 5 Machines for the production of corrugated board and machines for the conversion of flat and corrugated board 1 Scope This document applies to bookbinding machines: stitching, riveting, eyeletting and attaching machines; gang stitchers; gathering machines; perfect binders; paper drills; book signature presses; book presses; sheet folding machines; book production lines for the production of books with hard covers; back rounding and pressing machines; SIST EN 1010-4:2004+A1:2009

This document is not applicable to bookbinding, paper converting and finishing machines manufactured before the date of publication of this document by CEN. 2 Normative references This European Standard incorporates by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments). EN 292-1:1991, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology. EN 292-2:1991+A1:1995, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles and specifications. EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs. EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body. SIST EN 1010-4:2004+A1:2009

EN 626-1:1994, Safety of machinery — Reduction of risks to health from hazardous substances emitted by machinery — Part 1: Principles and specifications for machinery manufacturers. EN 626-2:1996, Safety of machinery — Reduction of risks to health from hazardous substances emitted by machinery — Part 2: Methodology leading to verification procedures. EN 954-1:1996, Safety of machinery — Safety related parts of control systems. Part 1: General principles for design.

!EN 1010-1:2004+A1, Safety of machinery — Safety requirements for the design and construction of printing and paper converting machines — Part 1: Common requirements." prEN 1010-2:2003, Safety of machinery — Safety requirements for the design and construction of printing and paper converting machines — Part 2: Printing and varnishing machines including pre-press machinery. EN 1010-3:2002, Safety of machinery — Safety requirements for the design and construction of printing and paper converting machines — Part 3: Cutting machines. EN 1050:1996, Safety of machinery — Principles for risk assessment. EN 1070 :1998, Safety of machinery — Terminology. EN 1539:2000, Dryers and ovens in which flammable substances are released — Safety requirements. prEN 13023, Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment — Accuracy categories 2 and 3.

EN 61000-6-4:2002, Electromagnetic compatibility (EMC) — Generic standards — Part 6-4: Emission standard for industrial environment (IEC 61000-6-4:1997). EN ISO 4871, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996). 3 Terms and definitions For the purposes of this European Standard, the definitions given in EN 1070:1998 and !EN 1010-1:2004+A1" and the following apply. 3.1 stitching, riveting, eyeletting and attaching machines powered machines using tools for connecting material by means of metallic items or positively fixing metallic items to material 3.2 gang stitchers machines for stitching folded sheets of paper where individual folded sheets are removed by feeding grippers and the open sheets are stacked on top of each other on a transport chain for subsequent back stitching (see Figure 1) SIST EN 1010-4:2004+A1:2009

Key A1 to A4 Feeding grippers Figure 1 — Principle of a gang stitcher 3.3 gathering machines machines for gathering folded sheets of paper where individual sheets are removed by feeding grippers and are stacked in the correct order on a transport chain (see Figure 2)

Key A1 to A4 Feeding grippers Figure 2 — Principle of a gathering machine 3.4 perfect binders machines for the automatic production of brochures (soft cover) or book signatures (hard cover) where gathered folded sheets or single sheets are bound to form book or brochure signatures by applying glue on the pre-processed book back and where book or brochure signatures are inserted into covers by gluing the cover on the back and/or sides 3.5 paper drills machines to drill holes into piles of paper 3.6 book signature presses presses used for pressing book signatures: blocks are fed and aligned manually, pressing is power-operated SIST EN 1010-4:2004+A1:2009

machines for the automatic production of books where book signatures consisting of gathered folded sheets or single sheets are put together and trimmed and provided with hard or flexible book covers 3.10 back rounding and pressing machines machines for rounding book signature backs and completing the forming process by pressing the back 3.11 Back-lining and head banding machines machines for the automatic production of books with rounded or flat book back where book signatures are glued, gauzed, back-lined and head banded 3.12 casing-in machines machines for the production of books (hard cover) where rounded or flat book signatures are cased into hard or flexible book covers by gluing the end papers on the front and on the back of the book signatures to the inner sides of the book covers 3.13 book cover crease forming machines (presses) machines for the production of books (hard cover) where, following the process of gluing book signatures to book covers, book cover creases are formed under heat and pressure and the books are pressed over the entire surface 3.14 machines for the production of envelopes machines for the production of envelopes and other kinds of paper bags 3.15 machines for the production of sanitary items machines for the production of sanitary items from paper, tissue and non-woven fabric such as, for example, paper handkerchiefs, paper napkins, tampons etc. 3.16 inserting machines machines (for example attached to web-fed rotary printing presses) where printed matter such as leaflets and magazines are inserted at a predetermined position into other printed products, for example newspapers or magazines

Key A feeder of main product,

B1 to B3 feeder of material to be inserted Figure 3 — Principle of an inserting machine 3.17 counter-stackers machines for cross-wise stacking of piles of leaflets, books, magazines or newspapers 3.18 paper embossing machines machines for forming paper surfaces by using embossing cylinders 3.19 paper finishing machines machines used for applying liquid or solid coating material on substrates made of paper or similar materials such as board and corrugated boards, plastic film, tinfoil, metal sheets and photo paper. Examples of paper finishing machines are coaters and laminators 3.19.1 coaters type of paper finishing machine applying a liquid substance (for example glue, varnish, ink) of a predetermined thickness onto a substrate. For dosing the substance applied, a doctor blade (scraper) or the gap between two rollers (dosing gap) is used 3.19.2 laminators type of paper finishing machine applying a solid material (for example foil, paper) onto a substrate 4 List of significant hazards 4.1 Insofar as they are dealt with in this standard, this clause contains all the significant hazards (noise is dealt with basically in !EN 1010-1:2004+A1"), that have been identified by the risk assessment process as being significant for this type of machinery and require action to eliminate or reduce the risk. When carrying out the risk assessment, the machine designer shall check whether the list of hazards in Table 1 is complete and applicable with respect to the particular machine. 4.2 It is of great importance that the user of this standard, i.e. the designer or manufacturer, takes into account the following basic aspects in accordance with EN 1050: the intended use of the machine including setting up (making ready), cleaning and maintenance, including foreseeable misuse; SIST EN 1010-4:2004+A1:2009

impacts

Machines with guards in open position

Interfaces between individual machines

Stitching, riveting, eyeletting and attaching machines - between tools

Gang stitchers - feeder - stitching section

- drawing-in zone on thickness control - transport chain - starting with guards open - trimmer

Gathering machines - feeder - hand-feeder, transport chain - gathering device (transport device) - starting with guards open

5.1.2

5.1.5, Annex A.1

5.2.1.1 to 5.2.1.3

5.2.2.1 to 5.2.2.3 5.2.2.4 5.2.2.5 5.2.2.7 5.2.2.8, 7.1.7 5.2.2.10

5.2.3.1 to 5.2.3.3 5.2.3.4 5.2.3.5 5.2.3.7 4.2.1 5.2.2.3

5.2.8

5.3.4.8, 5.2.6.1.5

5.3.4.8 5.2.10.2

Perfect binders - book clamps - gluing rollers - cover feeder - delivery unit - starting with guards open - milling head cutters

Paper drills - drill - drill/clamp jaws

5.2.4.1 5.2.4.2 5.2.4.8 5.2.4.9 5.2.4.11, 7.1.2.2 5.2.4.12, 7.1.2.1

5.2.5.1 5.2.5.2

5.3.4.8

Book signature presses - clamping plate/material

Book presses - pressing plates - pressing plates/machine enclosure

Sheet folding machines - drawing-in zones of folding rollers - cutting, creasing, perforating unit - folding knife - starting with guards open

Book production lines - feed opening - preheater, transport device - pressing section - glue section - gauze section - head banding section - book cover magazine - cover bending section - casing-in section - starting with guards open

5.2.6

5.2.7.1, 5.2.7.2 5.2.7.3

5.2.8.1 5.2.8.2 5.2.8.3 5.2.8.4

5.2.9.1 5.2.9.2 5.2.9.3 5.2.9.4 5.2.9.6 5.2.9.7 5.2.9.8 5.2.9.9 5.2.9.10 5.2.9.11, 7.1.7

5.2.10.2

5.2.1.1 b) 5.3.4.8

Back rounding and pressing machines - drawing-in zones of belts, transport chains, feed opening - tipping section - preheater -

pre-forming, back rounding, pressing sections

Backlining and head banding machines - feed opening, belt feeding - glue section, glue rollers - gauze section - head banding section - pressing section

Casing-in machines - transport finger - book cover feeder - cover bending section - forming section

5.2.10.1

5.2.10.2 5.2.10.3 5.2.10.5

5.2.11.1 5.2.11.2 5.2.11.4 5.2.11.5 5.2.11.6

5.2.12.1 5.2.12.2 5.2.12.3 5.2.12.4

5.3.4.8

- casing-in, gluing section - pressing section - delivery unit, delivery opening

5.2.12.6 5.2.12.7 5.2.12.8

Book cover crease forming machine - feed and delivery openings - tipping section, transport devices - pressing section - starting with guards open

Machines for the production of envelopes - reel unwinding unit - feeder - printing unit - longitudinal and cross scoring - form cutting section - guide rollers - window cutting section - window material conveying section - scraper gluing unit - separating cutting unit

- bottom flap folding section - transport rolls - staggering wheel

- roller gluing unit

- hot air dryers - separation roller before aligner section - aligner section - seal flap folding section - separating disc delivery - starting with guards locked open

Machines for the production of sanitary items - reel unwinding unit - smoothing and embossing section - longitudinal cutting section

5.2.13.1 5.2.13.2 5.2.13.3 5.2.13.5, 7.1.7

5.3.1.1 5.3.1.2 5.3.1.3.1, 5.3.1.3.2 5.3.1.4.1, 5.3.1.4.2 5.3.1.5 5.3.1.6.1, 5.3.1.6.2 5.3.1.7 5.3.1.8.1to 5.3.1.8.4 5.3.1.9.1, 5.3.1.9.2 5.3.1.10.1 to 5.3.1.10.3 5.3.1.11.1, 5.3.1.11.2 5.3.1.12.1, 5.3.1.12.2 5.3.1.13.1, 5.3.1.13.2, 7.1.3.1 5.3.1.14.1to 5.3.1.14.4, 7.1.3.3 5.3.1.15.1, 5.3.1.15.2 5.3.1.16 5.3.1.17 5.3.1.18 5.3.1.19.1, 5.3.1.19.2 5.3.1.20.1, 7.1.7, 5.3.1.20.2, 7.1.4.1

5.3.2.1.1 to 5.3.2.1.4 5.3.2.2.1, 5.3.2.2.2 5.3.2.3

5.3.5 5.3.4.8 5.2.1.1 5.3.2.1

5.2.1.1 5.2.1.1

5.2.1.1 5.2.1.1 b)

5.2.1.1

5.2.1.1 5.2.1.1

5.2.3.4

5.3.5.1 5.2.1.1 5.3.2 SIST EN 1010-4:2004+A1:2009

- longitudinal folding section - waste suction devices on cutting devices - counting and transfer section - product checking section - delivery unit - starting with guards open

Inserting machines - feeder - transport device/drive elements - starting with guards open

5.3.2.4 5.3.2.5 5.3.2.6 5.3.2.7 5.3.2.8.1, 7.1.4.2 5.3.2.9.1, 7.1.7, 5.3.2.9.2, 7.1.4.1

5.3.3.1, 5.3.3.2 5.3.3.3 5.3.3.5, 7.1.5

5.2.1.1

5.3.4.8

Counter-stackers - drawing-in zones of belts - waste separator - turntable - delivery units - stored energy (pneumatic system)

Paper embossing machines - danger zones of web threading device - reel unwinding, rewinding units - guide rollers - stretch roller - drawing-in zone of embossing roller/counter roller - movement of counter roller - rotary knives

5.3.4.1 5.3.4.2 5.3.4.3 5.3.4.4 5.3.4.5

5.3.5.2 5.3.5.3 5.3.5.4 5.3.5.5

5.3.5.6 5.3.5.7, 7.1.5 5.3.5.9

5.2.3.5 5.3.5 5.2.1.1

5.2.3.2 a) 2)

Coaters - danger zones of web threading device

- reel unwinding, rewinding units - guide rollers - dosing gap - coating unit - engagement and disengagement

of rollers

5.4.1.2 5.4.1.3 5.4.1.4 5.4.1.5 5.4.1.8 5.4.1.9

5.3.5

- drawing-in zones of belts - continuous flow dryers

- entire machine

Foil laminators - reel unwinding, rewinding units - manual feeding - guide rollers - engagement and disengagement of laminating rollers - drawing-in zones of laminating rollers - cutting unit

Laminators with glue application - danger zones of web threading device - reel unwinding, rewinding units - feeder, delivery unit - drawing-in zones of belts - guide rollers - tear-resistant material web - rotary knife - transport rolls - glue unit - laminating rollers 5.4.1.10 5.4.1.13.2, 5.4.1.13.5, 5.4.1.13.6, 7.1.6.3

5.4.2.1.1 5.4.2.1.2 5.4.2.1.3, 5.4.2.1.4 5.4.2.1.5

5.4.2.1.6 5.4.2.1.8

5.4.2.2.2 5.4.2.2.3 5.4.2.2.4 5.4.2.2.5 5.4.2.2.6 5.4.2.2.7 5.4.2.2.8 5.4.2.2.9 5.4.2.2.10 5.4.2.2.11, 5.4.2.2.12

5.3.5

5.2.1.1

5.2.1.1

5.3.5 5.3.4

5.2.1.1

5.3.2

5.2.3.2 a) 2)

- sheeter - pressing belt - package stop, conveyor belt - turning belt

5.4.2.2.13 5.4.2.2.14, 5.4.2.2.15 5.4.2.2.16 5.4.2.2.17

5.2.1.1 a)

Avoiding direct or pending hazardous situations Gang stitchers Gathering machine Perfect binders Sheet folding machines Book production lines Back rounding and pressing machines Backlining and head banding machines Casing-in machines Book cover crease forming machines Machines for the production of envelopes Machines for the production of sanitary items Inserting machines Counter-stackers Paper embossing machines Coaters Foil laminators Laminators with glue application 5.2.2.6, 5.2.2.9 5.2.3.6, 5.2.3.8 5.2.4.10,5.2.4.13 5.2.8.6 5.2.9.12, 5.2.9.13 5.2.10.6 5.2.11.7 5.2.12.9 5.2.13.6 5.3.1.21, 5.3.1.23

5.3.2.11, 5.3.2.12

5.3.3.4, 5.3.3.6 5.3.4.6 5.3.5.1, 5.3.5.10 5.4.1.1, 5.4.1.15 5.4.2.1.9 5.4.2.2.19

5.2.7.2 5.2.7.2

5.2.7.2

5.2.7.2

5.2.7.2

5.2.7.2 5.2.7.2

Electrical hazards Direct or indirect contact

Electrical equipment of all machines 5.1.3

4.3 5.2.5 Thermal hazards Burns due to possible contact Perfect binders - hotmelt glue reservoirs

Book production lines

- preheating section

Back rounding and pressing machines - preheater

5.2.4.6

5.2.9.2, 7.1.8

5.2.10.4, 7.1.8 4.4

5.2.14

Backlining and head banding machines - hotmelt

Casing-in machines - heated forming section

5.2.11.3, 7.1.8

5.2.12.5, 7.1.8

5.2.14

Book cover crease forming machines (press) - heated crease forming rails

Machines for the production of envelopes - hot air nozzles, hot parts of machine

Paper embossing machines - heated embossing roller

Coaters - hot liquid material

5.2.13.4, 7.1.8

5.3.1.15.3

5.3.5.8, 7.1.8

5.4.1.6

5.2.14

5.2.14

- continuous flow dryer

Foil laminators - heated laminating rollers 5.4.1.13.4

5.4.2.1.7

5.2.14

5.2.14

Machines for the production of envelopes

Machines for the production of sanitary items 5.2.8.5

5.3.1.22

5.3.2.10 4.5

Hazards generated by radiation UV radiation, laser

Perfect binders - radiation dryers (UV- HF-dryers)

5.2.4.7 4.7

5.2.16.2 Hazards from fire and explosion Machines for the production of sanitary items

Coaters

Laminators with glue application

5.3.2.5

5.4.1.11, 5.4.1.13.1, 7.1.6.2, 5.4.1.13.3

5.4.2.2.18 4.8

5.2.4 Hazards from substances and materials used for processing, machine operation or which are emitted during the process Hazards resulting from contact with or inhalation of harmful fluids, gases, fumes, dusts

Perfect binders - polyurethane hotmelt

Book production lines - hotmelt

Coaters - hazardous substances

5.2.4.3 to 5.2.4.5, 7.1.2.3

5.2.9.5

5.4.1.7, 7.1.6.1 4.8

Hazards generated by neglect of ergonomic principles in machine design unhealthy body postures

Stitching, riveting, eyeletting and attaching machines - adjustments

Book production lines - glue replenishment

5.2.1.2

5.2.9.4 4.9 8 Failure, malfunction of control system Faults or failures in safety circuits Control systems of all machines

Stitching, riveting, eyeletting, attaching machines

Gathering machines

Perfect binders Paper drills

5.1.4

5.2.1.1, 5.2.1.4

5.2.3.1, 5.2.3.4

5.2.4.8 5.2.5.2

5.2.6.1

5.2.6

5.2.6.1.5, 5.2.10.1 5.2.6.1.5 5.2.8

Machines for the production of sanitary items Water jet knives Inserting machines, residual pile monitoring 5.3.2.8.2

5.3.3.1

5.2.6.2.1

5.2.6.1.5 SIST EN 1010-4:2004+A1:2009

Figure 4) shall be avoided or safeguarded. This requirement is satisfied by observing a maximum distance of 4 mm between the tools in the open position

or ensuring that the closing force of the movable tool is less than 50 N and a higher closing force is allowed to become effective only after it has been ensured by means of a sensing device that there is no part of a human body present between the two tools. The sensing device may, for example, function on the basis of the difference in electrical resistance between the workpiece and parts of the body or the difference in thickness. Control systems shall comply at least with category B of EN 954-1:1996. Danger zones are safeguarded if guards are provided with apertures and safety distances in accordance with Table 4 of EN 294:1992 or the machine can only be started by two-hand control. A device shall be provided for supporting and fixing the product to be processed. Two-hand controls shall comply with the requirements specified in 5.2.8 of !EN 1010-1:2004+A1". 5.2.1.2 On flat and saddle stitching machines (see Figures 4 and 5) and on combined flat and saddle stitching machines, adjustable guards are required for operational reasons. Where power-operated movable guards are used, the requirements of 5.2.2.4 of !EN 1010-1:2004+A1" shall be satisfied.

Instructions that describe the safe adjustment of the guards in a clear and easily understandable form shall be provided on the machine. This requirement is satisfied by labels provided with sketches and dimensional data, for example, for identifying the guard adjustment required for a specific stitching thickness. The required information on this in the instruction handbook is given in 7.1.1.

Key 1 Upper tool

2 Guard Figure 4 — Flat stitching

Key 1 Upper edge of saddle

2 Guard 3 Workpiece Figure 5 — Saddle stitching 5.2.1.3 For machines that can only be started by two-hand control, 5.2.8 of !EN 1010-1:2004+A1" shall apply. A workpiece support is required.

If the shape or size of the workpiece requires the operator to use both hands to hold the workpiece outside the danger zone or if the workpiece needs to be held outside the danger zone with one hand, a hold-to-run control shall be provided for starting the machine instead of the two-hand control. 5.2.1.4 Safety-related control circuits shall comply with 5.2.6 of !EN 1010-1:2004+A1". SIST EN 1010-4:2004+A1:2009

Key

1 Transport chain 2 Feeder 3 Thickness control

4 Stitching unit,

5 Trimmer (three-knife trimmer) Figure 6 — Gang stitcher

Key

1 Manual feeding

2 Bottom of feeder 3 Transport chain Figure 7 — Feeder 5.2.2.5 Where a drawing-in zone exists in the calliper roll used for thickness control (see Figure 8), one of the following requirements shall be applied: maximum clamping force of 50 N or displacement of at least 20 mm or guard. 5.2.2.6 Gang stitchers shall be provided with a start-up warning device according to 5.2.7.2 of !EN 1010-1:2004+A1".

Key 1 Folded sheets

2 Drawing-in zone of calliper roll

3 Gripper Figure 8 — Calliper roll for thickness control

5.2.2.7 A safety distance of at least 25 mm is required between transport chain grippers and fixed machine parts. 5.2.2.8 Starting the machine with the interlocking guards in the open position and with a hold-to-run speed higher than 10 m/min shall be possible only by means of two-hand control and only if SIST EN 1010-4:2004+A1:2009

a selector switch for this kind of operation is provided and the hold-to-run speed is the slowest speed possible under procedural requirements. For further information in the instruction handbook, see 7.1.7. 5.2.2.9 An emergency stop system shall be provided with emergency stop buttons located on each main control panel. In the area of the feeders, emergency stop buttons shall be provided at 5 m intervals. 5.2.2.10 The three-knife trimmer shall be safeguarded according to 5.5 of prEN 1010-3:2002.

When the interlocking guard is opened, it shall only be possible to start the trimmer by means of two-hand controls. Operation of the two-hand control shall allow only a single stroke of the knives. 5.2.3 Gathering machines 5.2.3.1 With manual feeding of the feeders, the danger zones of the separating elements of the feeder shall be safeguarded in accordance with 5.3.4.8 of !EN 1010-1:2004+A1" and the residual pile monitoring device shall be provided in accordance with 5.2.6.1.5 of !EN 1010-1:2004+A1". 5.2.3.2 For feeding sections that are not used and cannot be stopped, blanking boards of maximum format size shall be provided to safeguard the danger zones at the separating elements instead of the blanks. Such boards shall ensure that the machine is not stopped by the residual pile monitoring system. 5.2.3.3 With automatic feeding of the feeding hopper, tunnel-type guards with a safety distance of 550 mm from the nearest danger zone shall be provided instead of the measures required in 5.2.2.1.

Key

1 Manual feeding

2 Tunnel 3 Feeder 4 Gathering device (transport device)

5 Direction of following machine Figure 9 — Gathering machine (plan view) 5.2.3.4 For safeguarding the danger zones on the manual feeding unit, a minimum distance of 25 mm is required between the transport chain and fixed machine parts. Where the minimum distance cannot be adhered to, trip bars shall be used for safeguarding. The requirements of 5.2.10.1 (category 3) and 5.2.10.2 of !EN 1010-1:2004+A1" shall be met.

Danger zones that can be reached from the manual feeding section in the following feeder shall be safeguarded by fixed or tunnel-type guards interlocked with the hazardous movement of a minimum length of 300 mm (see Figure 9, item 2). 5.2.3.5 Danger zones on the gathering device (transport device) (see Figure 9, item 4) shall be safeguarded by fixed guards or by guards interlocked with the hazardous movement. 5.2.3.6 Gathering machines shall be provided with a start-up warning device in accordance with 5.2.7.2 of !EN 1010-1:2004+A1". 5.2.3.7 Starting the machine with the interlocking guards in the open position and with a speed higher than 10 m/min shall be possible only by means of two-hand control and only if zones with restricted view and mutual interlocking as described in 5.2.3.4 of !EN 1010-1:2004+A1" are provided and

a selector switch for this kind of operation is provided and the hold-to-run speed is the slowest speed possible under procedural requirements. For further information in the instruction handbook, see 7.1.7. 5.2.3.8 An emergency stop system shall be provided with emergency stop buttons located at least on each main control panel. In the area of the feeders, emergency stop buttons shall be provided at 5 m intervals. SIST EN 1010-4:2004+A1:2009

Key 1 Book clamps open

2 Book clamps closed 3 Book signature Figure 10 — Book clamps 5.2.4.2 The danger zones existing in the gluing unit (glue rollers, glue applicators) and the danger zones between book backs and/or between book clamps and glue rollers and fixed machine parts shall be protected by fixed guards or by guards interlocked with the hazardous movement.

Key

1 Milling unit 2 Gluing unit 3 Cover feeder 4 Pressing unit 5 Book clamps 6 Delivery Figure 11 —

Perfect binder (plan view) 5.2.4.3 The glue pans for hotmelt shall be provided with temperature control and with limit temperature monitoring. Any hotmelt vapour shall be extracted from the perfect binder and from outside the machine for premelters where tight covers cannot be provided. 5.2.4.4 Perfect binders using polyurethane hotmelt glues for binding shall be designed so that there are no hazardous concentrations of isocyanates emitted from the machine over the entire process (preheating, processing, cleaning). These requirements are met if the isocyanate vapours and isocyanate aerosols are extracted. SIST EN 1010-4:2004+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...