EN 1034-4:2005+A1:2009

(Main)Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 4: Pulpers and their loading facilities

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 4: Pulpers and their loading facilities

This European Standard applies to pulpers and their loading facilities intended for use in paper making and shall be used together with EN 1034-1:2000+A1:2009. It deals with all significant hazards, hazardous situations and hazard events relevant to pulpers and their loading facilities, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4).

This European Standard is not applicable to pulpers and their loading facilities that have been manufactured before the date of publication of this standard.

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 4: Stofflöser und deren Beschickungseinrichtungen

Diese Europäische Norm gilt für Stofflöser und deren Beschickungseinrichtungen, die zur Verwendung bei der

Papierherstellung bestimmt sind, und muss in Verbindung mit !EN 1034-1:2000+A1:2010" angewendet

werden. Sie behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse,

die auf Stofflöser und deren Beschickungseinrichtungen zutreffen, wenn sie bestimmungsgemäß und

entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden (siehe Abschnitt 4).

Diese Europäische Norm gilt nicht für Stofflöser und deren Beschickungseinrichtungen, die hergestellt

wurden, bevor CEN diese Norm veröffentlichte.

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 4: Triturateurs et leurs dispositifs d'alimentation

La présente Norme européenne s’applique aux triturateurs et à leurs systèmes d’alimentation destinés à la fabrication

du papier et doit être utilisée conjointement avec l’!EN 1034-1:2000+A1:2010". Elle traite tous les phénomènes

dangereux significatifs, les situations et les événements dangereux engendrés par les triturateurs et leurs systèmes

d’alimentation lorsqu’ils sont utilisés normalement et dans les conditions prévues par le constructeur (voir Article 4).

La présente Norme européenne n’est pas applicable aux triturateurs et à leurs systèmes d’alimentation qui ont été

fabriqués avant la date de publication de cette norme par le CEN.

Varnost strojev - Varnostne zahteve za načrtovanje in konstrukcijo strojev in opreme za izdelavo papirja - 4. del: Razpuščevalniki in pripadajoče naprave za polnjenje

Ta evropski standard velja za razpuščevalnike in pripadajoče naprave za polnjenje, namenjene uporabi pri izdelavi papirja, in se uporablja skupaj z EN 1034-1:2000+A1:2010. Obravnava vse velike nevarnosti, nevarne situacije in primere, pomembne za razpuščevalnike in pripadajoče naprave, kadar se uporabljajo v skladu z namembnostjo in pod pogoji, kot jih je predvidel proizvajalec (glej Klavzulo 4). Ta evropski standard ne velja za razpuščevalnike in pripadajoče naprave za polnjenje, ki so bili narejeni pred objavo tega standarda.

General Information

- Status

- Withdrawn

- Publication Date

- 01-Dec-2009

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 198 - Printing and paper machinery - Safety

- Drafting Committee

- CEN/TC 198/WG 2 - Paper Machinery

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-Nov-2021

- Completion Date

- 21-Jan-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 24-Oct-2009

- Effective Date

- 24-Nov-2021

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 547-3:1996+A1:2008 - Safety of machinery - Human body measurements - Part 3: Anthropometric data - Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 1034-4:2005+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 4: Pulpers and their loading facilities". This standard covers: This European Standard applies to pulpers and their loading facilities intended for use in paper making and shall be used together with EN 1034-1:2000+A1:2009. It deals with all significant hazards, hazardous situations and hazard events relevant to pulpers and their loading facilities, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard is not applicable to pulpers and their loading facilities that have been manufactured before the date of publication of this standard.

This European Standard applies to pulpers and their loading facilities intended for use in paper making and shall be used together with EN 1034-1:2000+A1:2009. It deals with all significant hazards, hazardous situations and hazard events relevant to pulpers and their loading facilities, when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This European Standard is not applicable to pulpers and their loading facilities that have been manufactured before the date of publication of this standard.

EN 1034-4:2005+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1034-4:2005+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1034-4:2005, EN 1034-4:2021, EN 619:2002, EN 418:1992, EN 13023:2003, EN ISO 12100-2:2003, EN 741:2000, EN 1088:1995, EN 1050:1996, EN 294:1992, EN 983:1996, EN 626-1:1994, EN 954-1:1996, EN 349:1993, EN 547-3:1996+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1034-4:2005+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1034-4:2005+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SROQMHQMHSicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 4: Stofflöser und deren BeschickungseinrichtungenSécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 4: Triturateurs et leurs dispositifs d'alimentationSafety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 4: Pulpers and their loading facilities85.100Oprema za papirno industrijoEquipment for the paper industry21.020Characteristics and design of machines, apparatus, equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1034-4:2005+A1:2009SIST EN 1034-4:2006+A1:2010en,fr01-februar-2010SIST EN 1034-4:2006+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1034-4:2005+A1

December 2009 ICS 85.100 Supersedes EN 1034-4:2005English Version

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 4: Pulpers and their loading facilities

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 4: Triturateurs et leurs dispositifs d'alimentation

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen an Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 4: Stofflöser und deren Beschickungseinrichtungen This European Standard was approved by CEN on 20 October 2005 and includes Amendment 1 approved by CEN on 17 November 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1034-4:2005+A1:2009: ESIST EN 1034-4:2006+A1:2010

Relationship of this European Standard with the Essential Requirements of EU Directive 98/37/EC . 19Annex ZB (informative)

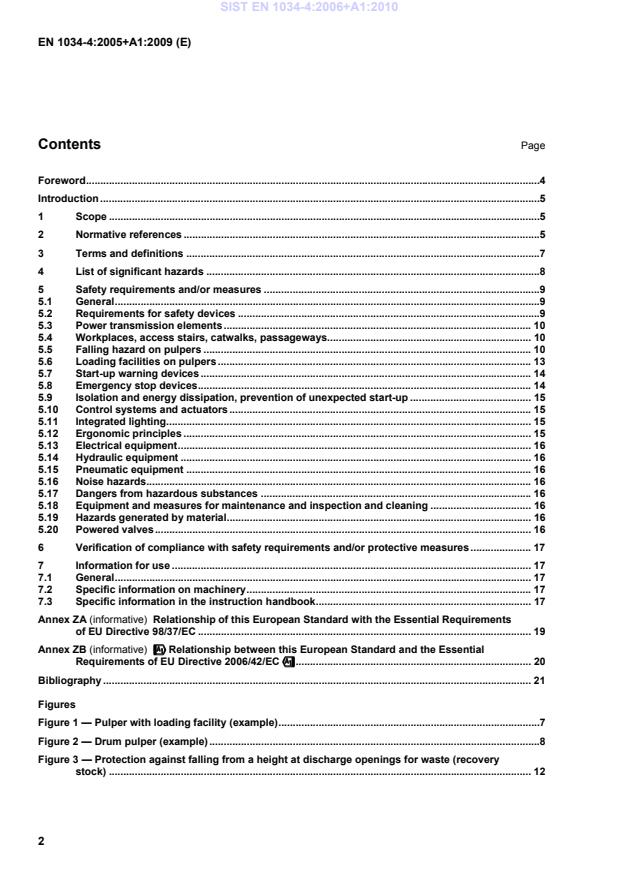

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 20Bibliography . 21Figures Figure 1 — Pulper with loading facility (example) .7 Figure 2 — Drum pulper (example) .8 Figure 3 — Protection against falling from a height at discharge openings for waste (recovery stock) . 12 SIST EN 1034-4:2006+A1:2010

3.2 rotor pulper pulper consisting of a tank and a power-driven rotor to break down the charged raw material using water. The principle of a rotor pulper is illustrated in Figure 1

3.3 drum pulper pulper consisting of a horizontal drum rotating round its horizontal axis in which raw material is dissolved with the addition of water. The principle of a drum pulper is illustrated in Figure 2

3.4 loading facility machinery such as continuous conveyor, lifting device or a combination of these machines intended to charge pulpers with the raw material to be dissolved such as pulp, waste paper or recovery stock

3.5 feeding conveyor continuous conveyor as part of the loading facility defined in 3.4 onto which the raw material to be dissolved is loaded by means of fork lifts, mechanical shovels or lifting tools, see Figure 1

3.6 charging conveyor continuous conveyor as part of the loading facility defined in 3.4, forwarding the raw material to be dissolved into the pulper, see Figure 1

Key

1 Drive 4 Tank

7 Manhole 2 Discharging pump

5 Rotor

8 Charging conveyor 3 Charging pump

6 Trash discharge gate

9 Feeding conveyor

Figure 1 — Pulper with loading facility (example) SIST EN 1034-4:2006+A1:2010

Key 1 Loading opening for raw material and water 2 Water supply 3 Exit of dissolved material

NOTE Safety devices are not shown Figure 2 — Drum pulper (example) 4 List of significant hazards This clause contains all the significant hazards that, as far as they are dealt with in this standard, are identified by risk assessment in accordance with EN 1050 as significant for this type of machinery and require action to eliminate or reduce the risk. When carrying out the risk assessment, the machine designer has to check whether the list of hazards in Table 1 is complete and applicable with respect to his particular machine.

Crushing hazard

5.5; 5.20 5.1; 5.3 Entanglement hazard 5.2; 5.3; 5.19 5.2 Drawing-in or trapping hazard

5.2; 5.3; 5.4.2 5.1; 5.4 High-pressure fluid ejection hazard 5.14; 5.15 5.24 Ejection of parts

5.19 5.2 Slip, trip and fall hazards in relationship with machines

5.4; 5.5; 5.6; 5.18 5.5 Electrical hazards caused by, for example:

Electrical contact (direct or indirect) 5.13 5.23; 5.8 External influences on electrical equipment 5.13 5.23 Hazards generated by noise, resulting in

Hearing loss (deafness), other physiological disorders

5.16 5.15 Hazards generated by materials and substances processed, used or exhausted by machines

Hazards resulting from contact with or inhalation of harmful

fluids, gases, mists, fumes and dusts; lack of oxygen 5.17; 5.18 5.16 Hazards generated by neglecting ergonomic principles in machine design

Unhealthy postures or excessive efforts 5.6.2; 5.12

5.22 Inadequate consideration of human hand-arm or foot-leg anatomy 5.12; 5.18 5.22 Inadequate area lighting 5.11 5.18 Hazards caused by failure of energy supply and other functional disorders, for example:

Failure of energy supply

5.9; 5.13 5.8 Malfunction of control system

5.7; 5.8; 5.10.1 5.14 Hazards caused by unexpected start up 5.7; 5.9; 5.10.2 5.6; 5.8 Combination of hazards 5.18

5.6; 5.9; 5.10 Emergency measures 5.8 5.1.3; 5.7; 5.18; 5.19

5 Safety requirements and/or measures 5.1 General Machinery shall comply with the safety requirements and/or measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for relevant but not significant hazards that are not dealt with by this document, e. g. avoidance of sharp edges. 5.2 Requirements for safety devices 5.2.1 The requirements of 5.1 of !EN 1034-1:2000+A1:2010" shall be satisfied. 5.2.2 The instruction handbook shall contain instructions for checking the safety devices. SIST EN 1034-4:2006+A1:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...