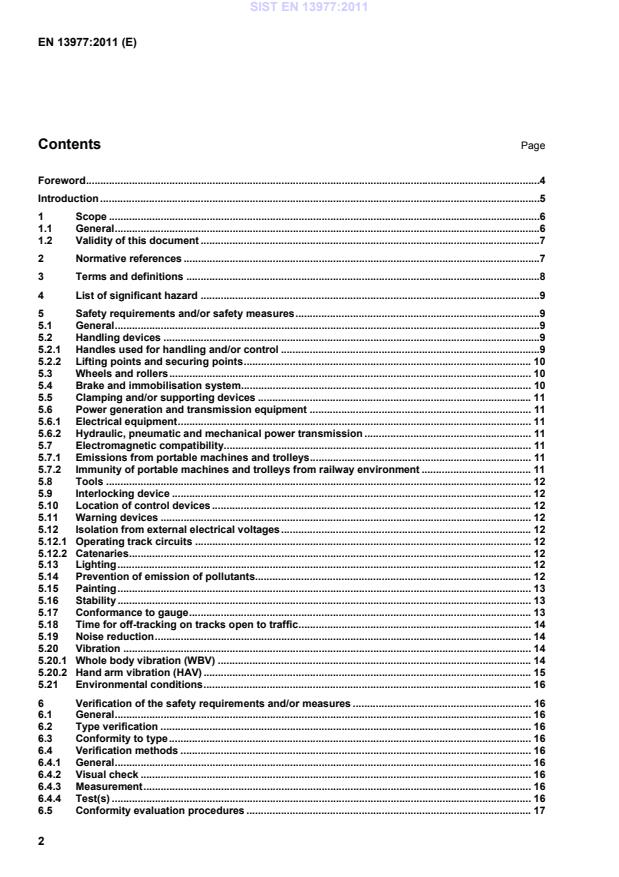

EN 13977:2011

(Main)Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance

Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance

1.1 General

This European Standard deals with the technical requirements to minimise the railway specific significant hazards of portable machines and trolleys intended for work on tracks as listed in Clause 4 which can arise during the commissioning, operation and maintenance of portable machines and trolleys when used as intended and under the conditions foreseen by the manufacturer. It does not deal with the performance of the machines, e.g. cutting, drilling, grinding.

This European Standard applies to portable machines and trolleys with rail wheels or rollers designed for work whilst on the track with nominal track gauges of 1 435 mm and 1 668 mm and clearance gauge as defined in Annex B including, e.g. cutting and drilling machines.

This European Standard does not apply to the additional hazards that may exist due to:

- the coupling together of trolleys;

- the towing or pushing of trolleys by other vehicles;

- the use of trolleys for the transportation of persons;

- self propelled rail wheeled machines, trolleys coupled to another towing vehicle;

- hazards due to laser systems.

Other special vehicles used on railway tracks are dealt with in other European Standards, see Annex H.

This European Standard does not apply to the following ):

- requirements for quality of the work or performance of the machine;

- regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer;

- portable machines used from railway vehicles.

This European Standard establishes the additional requirements for electromagnetic compatibility due to e.g. electronic components as well as for hazards due to vibration.

This European Standard does not establish the additional requirements for the following:

(....)

Bahnanwendungen - Oberbau - Sicherheitsanforderungen an tragbare Maschinen und Rollwagen für Bau und Instandhaltung

1.1 Allgemeines Diese Europäische Norm behandelt die technischen Anforderungen, um die eisenbahnspezifischen, signifikanten Gefährdungen durch tragbare Maschinen und Rollwagen, vorgesehen für das Arbeiten auf Gleisen nach Abschnitt 4, zu begrenzen, die bei der Inbetriebnahme, dem Gebrauch und dem Instandhalten der tragbaren Maschinen und Rollwagen auftreten können, wenn sie wie vorgesehen eingesetzt und unter den vom Hersteller festgelegten Bedingungen betrieben werden. Es behandelt nicht die speziellen Funktionen der Maschinen, z. B. Schneiden, Bohren, Schleifen. Diese Europäische Norm gilt für tragbare Maschinen und Rollwagen mit Rädern oder Rollen, die für Arbeiten auf Eisenbahnanlagen mit Nennspurweiten von 1435 mm und 1668 mm und der Begrenzungslinie nach Anhang B1) konstruiert sind, z.B. Trenn- und Bohrmaschinen. Diese Europäische Norm gilt nicht für zusätzliche Gefahren, die durch - die Kupplung der Rollwagen untereinander; - das Ziehen oder Schieben der Rollwagen durch anderen Fahrzeugen; - den Einsatz der Rollwagen für den Personentransport; - selbstangetriebene schienengeführte Maschinen, Rollwagen, die mit anderen Maschinen gekuppelt sind; - Lasersysteme verursacht werden können. Andere spezielle Fahrzeuge für den Einsatz auf Eisenbahngleisen werden in anderen Europäischen Normen behandelt, siehe Anhang H. Diese Europäische Norm gilt nicht für: - Anforderungen in Bezug auf Arbeitsqualität oder -leistung der Maschine; - spezifische Anforderungen, die von jedem Eisenbahninfrastrukturbetreiber für den Einsatz der tragbaren Maschinen und Rollwagen aufgestellt werden und Gegenstand von Verhandlungen zwischen Hersteller und Betreiber sein müssen; - von Eisenbahnfahrzeugen aus eingesetzte tragbare Maschinen. Diese Europäische Norm legt die zusätzlichen Anforderungen der elektromagnetischen Kompatibilität z.B. aufgrund der elektrischen Komponenten wie auch die Gefährdungen durch Schwingung fest. (...)

Applications ferroviaires - Voie - Prescriptions de sécurité pour machines portables et lorries pour la construction et la maintenance

1.1 Généralités

La présente Norme européenne traite des prescriptions techniques pour minimiser les risques spécifiques au

ferroviaire et significatifs des machines portables et lorries destinés aux travaux sur les voies ferrées comme

mentionné à l’Article 4, qui peuvent se présenter lors de la mise en service, l’utilisation et l’entretien des

machines portables et lorries quand ils sont utilisés comme prévu et dans les conditions fixées par le

fabricant. La présente Norme européenne ne traite pas des performances des machines, par exemple sciage,

perçage, meulage.

La présente Norme européenne s'applique aux machines portables et lorries, équipés de roues ferroviaires ou

galets, et qui sont conçus pour les travaux sur les voies ferrées à écartement nominal de 1 435 mm et de

1 668 mm, avec gabarit autorisé tel que défini en Annexe B1, comprenant les perceuses et les machines à

découper.

La présente Norme européenne ne s’applique pas aux phénomènes dangereux additionnels pouvant

apparaître à cause de :

- l’accouplement ensemble des lorries ;

- la traction ou la pousse de lorries par d’autres véhicules ;

- l’utilisation de lorries pour transporter des personnes ;

- machines ferroviaires automotrices, lorries accouplés avec d’autres véhicules de traction ;

- risques occasionnés par des systèmes laser.

D’autres véhicules spéciaux utilisés sur les voies ferrées sont couverts par d’autres normes européennes, voir

Annexe H.

La présente Norme européenne ne s’applique pas :

- aux prescriptions relatives à la qualité du travail et aux performances de la machine ;

- aux dispositions réglementaires fixées par chaque gestionnaire d’infrastructure pour l’emploi des

machines portables et lorries, et qui doivent faire l’objet de négociations entre l’utilisateur et le fabricant ;

- aux machines portables utilisées à partir de véhicules ferroviaires.

Železniške naprave - Zgornji ustroj - Varnostne zahteve za prenosne stroje in lahko tirno mehanizacijo, ki se uporabljajo pri gradnji in vzdrževanju

Ta evropski standard obravnava tehnične zahteve za zmanjševanje velikih nevarnosti, značilnih za železnice, pri prenosnih strojih in lahki tirni mehanizaciji, ki se uporablja na zgornjem ustroju, kot je navedeno v točki 4, do katerih lahko pride med zagonom, obratovanjem in vzdrževanjem prenosnih strojev in lahke tirne mehanizacije, kadar se uporabljajo v skladu z namembnostjo in pod pogoji, kot jih je predvidel proizvajalec. Ne obravnava delovanja strojev, npr. rezanja, vrtanja, brušenja. Ta evropski standard velja za prenosne stroje in lahko tirno mehanizacijo z železniškimi kolesi ali valji, ki delujejo, medtem ko so na tirih z nazivnimi tirnimi širinami 1435 mm in 1668 mm ter obtirnim profilom, kot je opredeljen v dodatku B1, vključno s stroji za npr. rezanje in vrtanje. Druga posebna vozila, ki se uporabljajo na železniških tirnicah, obravnavajo drugi evropski standardi, glej dodatek H. Ta evropski standard vzpostavlja dodatne zahteve za elektromagnetno združljivost zaradi npr. elektronskih komponent in nevarnosti zaradi vibracij.

General Information

- Status

- Published

- Publication Date

- 08-Feb-2011

- Withdrawal Date

- 30-Aug-2011

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 5 - Track construction and maintenance machines

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Sep-2022

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 12-Feb-2011

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13977:2011 - published by CEN - specifies safety requirements for portable machines and trolleys used on railway track during construction and maintenance. The standard addresses railway‑specific significant hazards that can arise during commissioning, operation and maintenance when equipment is used as intended and under manufacturer‑foreseen conditions. It applies to rail‑wheeled or roller‑equipped portable machines and trolleys designed to work on the track for nominal gauges 1 435 mm and 1 668 mm, with clearance gauge defined in Annex B. EN 13977:2011 does not cover machine performance (cutting, drilling rates), self‑propelled vehicles, towing/coupling hazards, use for transporting persons, or laser‑related hazards.

Key Topics

EN 13977:2011 focuses on practical safety measures and verification, including:

- Handling and lifting - handles, lifting and securing points for safe manual handling and transport.

- Wheels, rollers and brakes - requirements for rail wheels, immobilisation and off‑tracking time on open tracks.

- Clamping/supporting devices - safe fixing and support while working on track.

- Power systems - electrical, hydraulic, pneumatic and mechanical power transmission safety.

- Electromagnetic compatibility (EMC) - emissions and immunity requirements for electronic components in the railway environment.

- Noise and vibration - noise test code (Annex G), whole‑body and hand‑arm vibration limits and assessment.

- Environmental and lighting - operational environmental conditions, prevention of pollutant emissions and lighting requirements.

- Information and marking - instruction handbook, assembly/use/maintenance instructions, markings, symbols and warnings.

- Verification & conformity - type verification, conformity to type, testing, measurement and declaration procedures (Annexes C–E).

Applications

EN 13977 is intended for:

- Manufacturers of portable machines and trolleys to design, test and document safe products for track work.

- Infrastructure managers and contractors specifying safety and procurement criteria for on‑track equipment.

- Safety engineers and compliance officers conducting risk assessments, type verification and conformity checks.

- Maintenance teams and trainers who need clear instructions, marking and PPE guidance for safe operation.

Practical use cases include safety design for cutting/drilling machines on tracks, verification of EMC and vibration performance, and producing compliant instruction handbooks and markings.

Related Standards

- EN ISO 12100 (general machinery safety principles) - EN 13977 is a type C standard and complements type A/B standards.

- Other CEN standards for special railway vehicles (see Annex H) and the Essential Requirements of EU Directive 2006/42/EC (Annex ZA).

Keywords: EN 13977:2011, portable machines and trolleys, railway track safety, track maintenance, EMC, vibration, conformity, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 13977:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance". This standard covers: 1.1 General This European Standard deals with the technical requirements to minimise the railway specific significant hazards of portable machines and trolleys intended for work on tracks as listed in Clause 4 which can arise during the commissioning, operation and maintenance of portable machines and trolleys when used as intended and under the conditions foreseen by the manufacturer. It does not deal with the performance of the machines, e.g. cutting, drilling, grinding. This European Standard applies to portable machines and trolleys with rail wheels or rollers designed for work whilst on the track with nominal track gauges of 1 435 mm and 1 668 mm and clearance gauge as defined in Annex B including, e.g. cutting and drilling machines. This European Standard does not apply to the additional hazards that may exist due to: - the coupling together of trolleys; - the towing or pushing of trolleys by other vehicles; - the use of trolleys for the transportation of persons; - self propelled rail wheeled machines, trolleys coupled to another towing vehicle; - hazards due to laser systems. Other special vehicles used on railway tracks are dealt with in other European Standards, see Annex H. This European Standard does not apply to the following ): - requirements for quality of the work or performance of the machine; - regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer; - portable machines used from railway vehicles. This European Standard establishes the additional requirements for electromagnetic compatibility due to e.g. electronic components as well as for hazards due to vibration. This European Standard does not establish the additional requirements for the following: (....)

1.1 General This European Standard deals with the technical requirements to minimise the railway specific significant hazards of portable machines and trolleys intended for work on tracks as listed in Clause 4 which can arise during the commissioning, operation and maintenance of portable machines and trolleys when used as intended and under the conditions foreseen by the manufacturer. It does not deal with the performance of the machines, e.g. cutting, drilling, grinding. This European Standard applies to portable machines and trolleys with rail wheels or rollers designed for work whilst on the track with nominal track gauges of 1 435 mm and 1 668 mm and clearance gauge as defined in Annex B including, e.g. cutting and drilling machines. This European Standard does not apply to the additional hazards that may exist due to: - the coupling together of trolleys; - the towing or pushing of trolleys by other vehicles; - the use of trolleys for the transportation of persons; - self propelled rail wheeled machines, trolleys coupled to another towing vehicle; - hazards due to laser systems. Other special vehicles used on railway tracks are dealt with in other European Standards, see Annex H. This European Standard does not apply to the following ): - requirements for quality of the work or performance of the machine; - regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer; - portable machines used from railway vehicles. This European Standard establishes the additional requirements for electromagnetic compatibility due to e.g. electronic components as well as for hazards due to vibration. This European Standard does not establish the additional requirements for the following: (....)

EN 13977:2011 is classified under the following ICS (International Classification for Standards) categories: 45.120 - Equipment for railway/cableway construction and maintenance; 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13977:2011 has the following relationships with other standards: It is inter standard links to EN 13977:2005+A1:2007, EN 50121-3-1:2006, ISO 3864-1:2002, ISO 6405-2:1993, EN 15746-1:2010, EN 28662-1:1992, EN 13715:2020, EN 15273-2:2025, EN 614-1:2006+A1:2009, EN ISO 4414:2010, EN ISO 7731:2008, EN 1837:2020, EN ISO 15744:2008, EN ISO 3744:2009, EN ISO 11202:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13977:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 93/38/EEC, 98/37/EC; Standardization Mandates: M/024, M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13977:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Železniške naprave - Zgornji ustroj - Varnostne zahteve za prenosne stroje in lahko tirno mehanizacijo, ki se uporabljajo pri gradnji in vzdrževanjuBahnanwendungen - Oberbau - Sicherheitsanforderungen an tragbare Maschinen und Rollwagen für Bau und InstandhaltungApplications ferroviaires - Voie - Prescriptions de sécurité pour machines portables et lorries pour la construction et la maintenanceRailway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance45.120åLþQLFEquipment for railway/cableway construction and maintenanceICS:Ta slovenski standard je istoveten z:EN 13977:2011SIST EN 13977:2011en,fr,de01-september-2011SIST EN 13977:2011SLOVENSKI

STANDARDSIST EN 13977:2005+A1:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13977

February 2011 ICS 45.120; 93.100 Supersedes EN 13977:2005+A1:2007English Version

Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance

Applications ferroviaires - Voie - Prescriptions de sécurité pour machines portables et lorries pour la construction et la maintenance

Bahnanwendungen - Oberbau - Sicherheitsanforderungen an tragbare Maschinen und Rollwagen für Bau und Instandhaltung This European Standard was approved by CEN on 24 December 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13977:2011: ESIST EN 13977:2011

List of significant hazards . 22Annex B (normative)

Clearance gauge for portable machines and trolleys . 24Annex C (normative)

Type verification . 27C.1Identification . 27C.2Technical documents . 27C.3Conformance check to EN 13977:2011 . 27Annex D (normative)

Portable machine and trolley marking . 30Annex E (normative)

Conformity to type verification . 31E.1Identification . 31E.2Conformance check to EN 13977:2011 . 31E.3Declaration of conformity to type . 33Annex F (informative)

Special conditions . 34Annex G (normative)

Noise test code for portable machines and trolleys for construction and maintenance – Grade of accuracy 2 and 3 . 35G.1Scope . 35G.2Terms and definitions . 35G.3Determination of the emission sound pressure level at the workstation or other specified positions . 35G.4Sound power level determination . 35G.5Installation and mounting conditions . 35G.6Operating conditions . 36G.7Measurement uncertainties . 37G.8Recordings . 37G.9Information to be reported. 37G.10Declaration and verification of noise emission values . 38Annex H (informative)

Structure of European Standards for track construction and maintenance machines . 40Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 42Bibliography . 43 SIST EN 13977:2011

When the provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard.

Technical characteristics, deviations or special national conditions may be the subject of special requirements of the infrastructure manager controller and/or negotiation between the user and the manufacturer, see Annex F.

regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer;

portable machines used from railway vehicles. This European Standard establishes the additional requirements for electromagnetic compatibility due to e.g. electronic components as well as for hazards due to vibration. This European Standard does not establish the additional requirements for the following: operation in severe conditions, e.g. extreme environmental conditions such as: high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields; operation subject to special rules such as potentially explosive atmospheres; hazards occurring during decommissioning and/or recycling; hazards due to wind speed; hazards due to natural causes, e.g. earthquake, lightning, flooding, etc.

1) For portable machines and trolleys used on railway lines with a different clearance gauge to that defined in Annex B, special requirements concerning the clearance gauge are permitted to be applied. SIST EN 13977:2011

(ISO 7731:2003) EN ISO 9614-2:1996, Acoustics Determination of sound power levels of noise sources using sound intensity Part 2: Measurement by scanning (ISO 9614-2:1996) EN ISO 11202:2010, Acoustics Noise emitted by machinery and equipment Determination of emission sound pressure levels at a work station and at other specified positions applying approximate environmental corrections (ISO 11202:2010) EN ISO 11204:2010, Acoustics Noise emitted by machinery and equipment Determination of emission sound pressure levels at a work station and at other specified positions applying accurate environmental corrections (ISO 11204:2010) EN ISO 11688-1:2009, Acoustics Recommended practice for the design of low-noise machinery and equipment Part 1: Planning (ISO/TR 11688-1:1995) EN ISO 12001:2009, Acoustics Noise emitted by machinery and equipment Rules for the drafting and presentation of a noise test code (ISO 12001:1996) EN ISO 12100-1:2003, Safety of machinery Basic concepts, general principles for design Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery Basic concepts, general principles for design Part 2: Technical principles (ISO 12100-2:2003) EN ISO 14121-1:2007, Safety of machinery Risk assessment Part 1: Principles (ISO 14121-1:2007) EN ISO 15744:2008, Hand-held non-electric power tools Noise measurement code Engineering method (grade 2) (ISO 15744:2002) ISO 3864-1, Graphical symbols Safety colours and safety signs Part 1: Design principles for safety signs in workplaces and public areas ISO 3864-2, Graphical symbols Safety colours and safety signs Part 2: Design principles for product safety labels ISO 6405-1, Earth-moving machinery Symbols for operator controls and other displays Part 1: Common symbols ISO 6405-2, Earth-moving machinery Symbols for operator controls and other displays Part 2: Specific symbols for machines, equipment and accessories 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following apply. 3.1 portable machine machine designed or adapted to be manually propelled along the track with wheels or rollers which is not designed to operate track signalling systems SIST EN 13977:2011

For the application of type B standards EN 60204-1, EN 982, EN 983 and EN ISO 7731, the manufacturer shall carry out a risk assessment where choice is necessary. This specific risk assessment is part of the general risk assessment relating to the hazards not covered by the present document.

5.2 Handling devices 5.2.1 Handles used for handling and/or control Portable machines and trolleys shall be ergonomically designed according to the requirements of EN 614-1 and EN 614-2 so that they are able to be lifted. Where practicable this shall be by manual handling. Where fitted handles used for handling and/or control shall be sufficient for the weight of the portable machine or trolley and allow removal of the portable machine or trolley from the track. Handles for lifting are to be positioned to ensure reasonable sharing of the weight. The weight permitted per person shall not exceed 20 kg when the load is shared by more than one person or 25 kg for a single person lift. Handles for control shall be ergonomically designed and located at a reasonable height for the operating position. SIST EN 13977:2011

5.5 Clamping and/or supporting devices If portable machines and trolleys are fitted with clamping and/or supporting devices they shall: be able to resist vibrations and forces generated by the work of the machine; be fit for purpose and not suffer permanent deformation during use. They shall be designed not to cause: reduction of the stability of the track; damage to the infrastructure. 5.6 Power generation and transmission equipment 5.6.1 Electrical equipment Electrical equipment and the degree of electrical protection shall meet the requirements of EN 60204-1. Portable machines shall use voltages less than 500 V AC or less than 750 V DC. In order to avoid inadvertent operation or damage to track circuits, any flexible cables shall not have external metallic covering. 5.6.2 Hydraulic, pneumatic and mechanical power transmission If a portable machine is fed by exterior hydraulic, pneumatic or mechanical power transmission, risks according to EN 982 and EN 983 shall be taken into consideration. In order to avoid inadvertent operation or damage to track circuits, flexible pipes shall not be covered by metallic protection. 5.7 Electromagnetic compatibility 5.7.1 Emissions from portable machines and trolleys Portable machines and trolleys shall meet the requirements of EN 13309 or EN 50121-3-1:2006, Clause 6. Any electrical component that is added to a machine that has already been tested and a certificate of emissions provided shall either be assessed as an additional component for its potential to affect railway signals, or the whole machine shall be reassessed. 5.7.2 Immunity of portable machines and trolleys from railway environment Manufacturers shall assess the component parts of portable machines and trolleys for their susceptibility and immunity to electro-magnetic induced currents. Each electrical or electronic circuit box shall be assessed for the effect they would have if the currents were induced. Any electrical or electronic circuit which the manufacturer considers vulnerable to electro-magnetic compatibility shall comply with the requirements according to EN 50121-3-2:2006, Clause 8, Tables 7, 8 and 9, or equivalent. SIST EN 13977:2011

When a portable machine or trolley is not permitted for use with an adjacent line open to traffic, this shall be stated in the instruction handbook, see 7.2. 5.11 Warning devices Warning equipment if fitted to portable machines or trolleys shall be designed and manufactured according to EN ISO 7731 and be clearly distinguishable from other railway specific signals and audible above the peak sound pressure level as measured in Annex G. 5.12 Isolation from external electrical voltages 5.12.1 Operating track circuits Portable machines and trolleys having contact with both rails (rollers, clamps, etc.), or on the same line of rail shall always have an electrical resistance between the points of contact of ≥ 1 MΩ. The resistance measurement shall be taken under a 500 V DC tension. 5.12.2 Catenaries Portable machines and trolleys in working configuration for use under live catenary shall not have parts above rail level greater than that shown in EN 15746-1:2010, Table A.1, line 9. 5.13 Lighting The portable machine or trolley lighting shall be sufficient to permit the intended task to be carried out correctly and safely and shall ensure a luminance level of at least 50 lx and meet the requirements of EN 1837. Dazzling of, e.g. train drivers or workers on the site, shall be prevented by appropriate measures. The position of the lights shall not cause confusion with railway signalling. 5.14 Prevention of emission of pollutants Effective measures shall be taken to prevent or reduce leakage or development of dust, smoke, steam gas and other particles. Wherever practicable, portable machines or trolleys shall use biodegradable lubricants. SIST EN 13977:2011

NOTE EN ISO 11688-2:2000 gives further information on noise generation mechanisms in machinery. The major sound sources of portable machines and trolleys for construction and maintenance are: the power generation and transmission equipment; the tools working on the rails, fastening systems, sleepers or ballast; the cooling system (if fitted). Established measures for noise reduction are: capsulated power generation and transmission equipment, capsulated cooling system; exhaust mufflers; silencers for tools. 5.20 Vibration 5.20.1 Whole body vibration (WBV) 5.20.1.1 Measurement and degree of uncertainty of WBV Manufacturers shall either state the highest rms value of weighted acceleration to which the whole body is subjected to by the machine, if it exceeds 0,5 m/s2 or state that it is less than 0,5 m/s2 when this is correct. The manufacturer shall also state the degree of uncertainty of each vibration measurement. The degree of uncertainty can either be determined by compliance with the recommendation given in EN 12096:1997, Annex D or through an analysis of test methods and measurements where the production run is sufficiently large to give measurements from at least 10 machines. 5.20.1.2 WBV measurement Measurements shall be taken at locations where personnel can either stand or sit. For standing locations the measurement shall be taken on the floor and for seated locations the measurement shall be taken on the seat cushion, there is no requirement for measurements on the seat back support. Measurements shall be made using tri-axial accelerometers, in accordance with the requirements of EN 1032. Only the largest of the three readings needs to be used in the assessment process. SIST EN 13977:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...