EN 13977:2005+A1:2007

(Main)Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance

Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance

This document deals with the technical requirements to minimise the railway specific significant hazards of portable machines and trolleys used for work on tracks as listed in clause 4 and annex A which can arise during the commissioning, the operation and the maintenance of portable machines and trolleys when used as intended and under the conditions foreseen by the manufacturer. It does not deal with the general function of the machines (e.g. cutting, drilling, grinding).

This document applies to portable machines and portable trolleys designed for work on the track with nominal track gauges of 1 435 mm and 1 668 mm and clearance gauge as defined in annex B including cutting machines and those designed for working on wooden sleepers.

This document does not apply to portable trolleys coupled together, whether or not self propelled, and trolleys used for transporting personnel.

For portable machines and trolleys used on railway lines with a different clearance gauge to that defined in

annex B specific requirements concerning the clearance gauge may apply ).

This document does not apply to the following:

- requirements for quality of the work or performance of the machine;

- regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer;

- portable machines used from railway vehicles.

This document does not establish the additional requirements for the following:

- operation in severe conditions (e.g. extreme environmental conditions such as: freezing applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields);

- operation subject to special rules as potentially explosive atmospheres;

- electromagnetic compatibility, due to e.g. electronic components;

- hazards occurring during decommissioning and/or recycling;

- hazards due to vibration;

- hazards due to wind speed grea

Bahnanwendungen - Oberbau - Sicherheitsanforderungen an tragbare Maschinen und Rollwagen für Bau und Instandhaltung

Dieses Dokument behandelt die technischen Anforderungen, um die in Abschnitt 4 und Anhang A auf¬geführten spezifischen, signifikanten Gefährdungen für tragbare Maschinen und Rollwagen beim Arbeiten auf Gleisen zu begrenzen, die bei der Inbetriebnahme, dem Gebrauch und dem Instandhalten der tragbaren Maschinen und Rollwagen auftreten können, wenn sie wie vorgesehen eingesetzt und unter den vom Hersteller festgelegten Bedingungen betrieben werden. Sie behandelt nicht die generellen Funktionen der Maschinen, z. B. Schneiden, Bohren, Schleifen.

Dieses Dokument gilt für tragbare Maschinen und Rollwagen, die für Arbeiten auf Eisenbahnanlagen mit Nennspurweiten von 1435 mm und 1668 mm und der Begrenzungslinie nach Anhang B konstruiert wurden, einschließlich der Trennschleifmaschinen und der Maschinen, die speziell für das Bearbeiten der Holzschwellen im Gleis konzipiert wurden.

Dieses Dokument gilt nicht für gekuppelte tragbare Rollwagen mit oder ohne Eigenantrieb und auch nicht für den Personentransport.

Für tragbare Maschinen und Rollwagen für den Einsatz auf Eisenbahngleisen mit anderen Begrenzungslinien als sie in Anhang B definiert sind, können spezifische Anforderungen an die Begrenzungslinie ) gelten.

Dieses Dokument gilt nicht für:

Anforderungen in Bezug auf Arbeitsqualität oder leistung der Maschine;

spezifische Anforderungen, die von jedem Eisenbahninfrastrukturbetreiber für den Einsatz der tragbaren Maschinen und Rollwagen aufgestellt werden und Gegenstand von Verhandlungen zwischen Hersteller und Betreiber sein müssen;

von Eisenbahnfahrzeugen aus eingesetzte tragbare Maschinen.

Dieses Dokument behandelt nicht die folgenden zusätzlichen Anforderungen für:

schwierige Arbeitsbedingungen, z. B. Umgebungsbedingungen wie Eis, hohe Temperaturen, korrosive, tropische oder kontaminierte Umgebung, starkes magnetisches Feld;

besonderen Regeln unterworfenen Arbeiten, z. B. potentiell explosive Atmosphäre;

Applications ferroviaires - Voie - Prescriptions de sécurité pour machines et lorries portables pour la construction et la maintenance

1.1 Généralités

La présente Norme européenne traite des prescriptions techniques pour minimiser les risques spécifiques au ferroviaire et significatifs des machines et lorries portables utilisés pour les travaux sur les voies ferrées comme mentionné à l’Article 4 et en Annexe A, qui peuvent se présenter lors de la mise en service, l’utilisation et l’entretien des machines et lorries portables quand ils sont utilisés comme prévu et dans les conditions fixées par le fabricant.

La présente Norme européenne ne traite pas des fonctions générales des machines (par exemple sciage, perçage, meulage).

La présente Norme européenne s'applique aux machines et lorries portables conçus pour les travaux sur les voies ferrées à écartement nominal de 1 435 mm et de 1 668 mm, avec gabarit autorisé tel que défini en Annexe B, comprenant les tronçonneuses à rail et les machines conçues spécifiquement pour le travail des traverses en bois.

La présente Norme européenne ne s’applique pas aux lorries portables accouplés ensembles, automoteurs ou non, et aux lorries destinés au transport du personnel.

Des règles spécifiques ) de gabarit peuvent s’appliquer aux machines et lorries portables utilisés sur des lignes à gabarit autres que celui défini en Annexe B.

La présente Norme européenne ne s’applique pas :

aux prescriptions relatives à la qualité du travail et aux performances de la machine ;

aux dispositions réglementaires fixées par chaque gestionnaire d’infrastructure pour l’emploi des machines et lorries portables, et qui doivent faire l’objet de négociations entre l’utilisateur et le fabricant ;

aux machines portables utilisées à partir de véhicules ferroviaires.

La présente Norme européenne ne comporte pas d’exigences additionnelles pour les cas suivants :

— conditions sévères de travail (par exemple conditions extrêmes d’environnement telles que gel, haute température, atmosphère corrosive, tropicale ou contaminante, fort champ magnétique) ;

— conditions soumises

Železniške naprave - Zgornji ustroj - Varnostne zahteve za prenosne stroje in lahko tirno mehanizacijo, ki se uporabljajo pri gradnji in vzdrževanju

General Information

- Status

- Withdrawn

- Publication Date

- 03-Jul-2007

- Withdrawal Date

- 08-Feb-2011

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 5 - Track construction and maintenance machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Feb-2011

- Completion Date

- 09-Feb-2011

- Directive

- Not Harmonized93/38/EEC - Procurement procedures of entities operating in the water, energy, transport and telecommunications sectors

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 12-Feb-2011

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 13977:2005+A1:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance". This standard covers: This document deals with the technical requirements to minimise the railway specific significant hazards of portable machines and trolleys used for work on tracks as listed in clause 4 and annex A which can arise during the commissioning, the operation and the maintenance of portable machines and trolleys when used as intended and under the conditions foreseen by the manufacturer. It does not deal with the general function of the machines (e.g. cutting, drilling, grinding). This document applies to portable machines and portable trolleys designed for work on the track with nominal track gauges of 1 435 mm and 1 668 mm and clearance gauge as defined in annex B including cutting machines and those designed for working on wooden sleepers. This document does not apply to portable trolleys coupled together, whether or not self propelled, and trolleys used for transporting personnel. For portable machines and trolleys used on railway lines with a different clearance gauge to that defined in annex B specific requirements concerning the clearance gauge may apply ). This document does not apply to the following: - requirements for quality of the work or performance of the machine; - regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer; - portable machines used from railway vehicles. This document does not establish the additional requirements for the following: - operation in severe conditions (e.g. extreme environmental conditions such as: freezing applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields); - operation subject to special rules as potentially explosive atmospheres; - electromagnetic compatibility, due to e.g. electronic components; - hazards occurring during decommissioning and/or recycling; - hazards due to vibration; - hazards due to wind speed grea

This document deals with the technical requirements to minimise the railway specific significant hazards of portable machines and trolleys used for work on tracks as listed in clause 4 and annex A which can arise during the commissioning, the operation and the maintenance of portable machines and trolleys when used as intended and under the conditions foreseen by the manufacturer. It does not deal with the general function of the machines (e.g. cutting, drilling, grinding). This document applies to portable machines and portable trolleys designed for work on the track with nominal track gauges of 1 435 mm and 1 668 mm and clearance gauge as defined in annex B including cutting machines and those designed for working on wooden sleepers. This document does not apply to portable trolleys coupled together, whether or not self propelled, and trolleys used for transporting personnel. For portable machines and trolleys used on railway lines with a different clearance gauge to that defined in annex B specific requirements concerning the clearance gauge may apply ). This document does not apply to the following: - requirements for quality of the work or performance of the machine; - regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer; - portable machines used from railway vehicles. This document does not establish the additional requirements for the following: - operation in severe conditions (e.g. extreme environmental conditions such as: freezing applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields); - operation subject to special rules as potentially explosive atmospheres; - electromagnetic compatibility, due to e.g. electronic components; - hazards occurring during decommissioning and/or recycling; - hazards due to vibration; - hazards due to wind speed grea

EN 13977:2005+A1:2007 is classified under the following ICS (International Classification for Standards) categories: 45.120 - Equipment for railway/cableway construction and maintenance. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13977:2005+A1:2007 has the following relationships with other standards: It is inter standard links to EN 13977:2005, EN 13977:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13977:2005+A1:2007 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC, 98/37/EC; Standardization Mandates: M/024, M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13977:2005+A1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenanceŽelezniške naprave - Zgornji ustroj - Varnostne zahteve za prenosne stroje in lahko tirno mehanizacijo, ki se uporabljajo pri gradnji in vzdrževanjuApplications ferroviaires - Voie - Prescriptions de sécurité pour machines et lorries portables pour la construction et la maintenanceBahnanwendungen - Oberbau - Sicherheitsanforderungen an tragbare Maschinen und Rollwagen für Bau und InstandhaltungTa slovenski standard je istoveten z:EN 13977:2005+A1:2007SIST EN 13977:2005+A1:2007en,fr,de45.120åLþQLFEquipment for railway/cableway construction and maintenanceICS:SLOVENSKI

STANDARDSIST EN 13977:2005+A1:200701-september-2007

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13977:2005+A1

July 2007 ICS 45.120 Remplace l’EN 13977:2005English Version

Railway applications - Track - Safety requirements for portable machines and trolleys for construction and maintenance

Applications ferroviaires - Voie - Prescriptions de sécurité pour machines et lorries portables pour la construction et la maintenance

Bahnanwendungen - Oberbau - Sicherheitsanforderungen an tragbare Maschinen und Rollwagen für Bau und Instandhaltung This European Standard was approved by CEN on 20 August 2004 and includes Amendment 1 approved by CEN on 26 May 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2007 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13977:2005+A1:2007: E

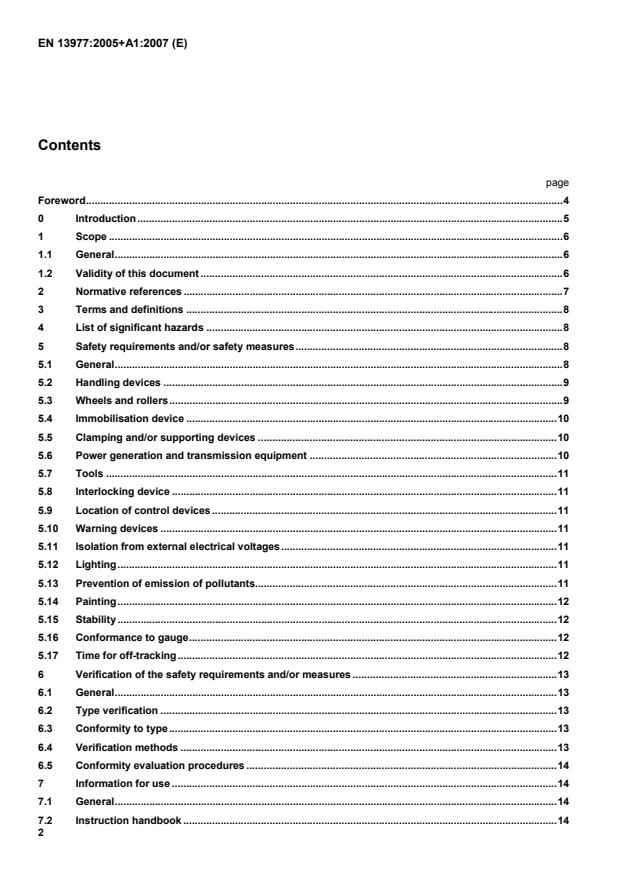

List of significant hazards.19 Annex B (normative)

Clearance gauge for portable machines and trolleys.21 Annex C (normative)

Type verification.23 Annex D (informative)

Declaration of type verification.26 Annex E (normative)

Portable machine and trolley marking.27 Annex F (normative)

Conformity to type verification.28 Annex G (informative)

Special conditions.31 Annex H (informative)

Rail cutting off machines.32 Annex I (normative)

!!!!Noise reduction.33 Annex J (normative)

Noise test code for portable machines and trolleys for construction and maintenance – Grade of accuracy 2 and 3.34 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.39 Bibliography.40

annex B specific requirements concerning the clearance gauge may apply1). This document does not apply to the following: requirements for quality of the work or performance of the machine; regulations defined by each infrastructure controller for portable machine and trolley operation which shall be the subject of negotiation between the user and the manufacturer; portable machines used from railway vehicles. This document does not establish the additional requirements for the following: operation in severe conditions (e.g. extreme environmental conditions such as: freezing applications, high temperatures, corrosive environment, tropical environment, contaminating environments, strong magnetic fields); operation subject to special rules as potentially explosive atmospheres; electromagnetic compatibility, due to e.g. electronic components; hazards occurring during decommissioning and/or recycling; hazards due to vibration; hazards due to wind speed greater than 35 m/s; hazards due to natural causes e.g. earthquake, lightning, flooding etc. noise. NOTE Noise of machines which are dealt with by this document is regarded as a significant hazard. Noiseis not covered by this document but will be dealt with in an Amendment to the first edition of this standard. This Amendment will give: clauses dealing with noise emission according to EN 1746. a noise test code using as a basis for preparation the designation of noise-emission according to the requirements of the Machinery-Directive

98/37/EC, annex I, clause 1.7.4f. 1.2 Validity of this document This document applies to portable machines and trolleys that are ordered after the date of publication of this standard.

1) E.g. the specific rules of the infrastructure manager.

EN 982, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics EN 983, Safety of machinery — Safety requirements for fluid power systems and their components — Pneumatics EN 1050:1996, Safety of machinery — Principles for risk assessment EN 1837, Safety of machinery — Integral lighting of machines !EN 13674-1, Railway applications – Track – Rail – Part 1: Vignole railway rails 46 kg/m and above" EN 60204-1, !Safety of machinery - Electrical equipment of machines - Part 1: General requirements (IEC 60204-1:2005, modified) " !EN ISO 3744:1995, Acoustics – Determination of sound power levels of noise sources using sound pressure – Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994) EN ISO 3746:1995, Acoustics – Determination of sound power levels of noise sources using sound pressure – Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:1995) EN ISO 4871:1996, Acoustics – Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) !EN ISO 7731, Ergonomics - Danger signals for public and work areas - Auditory danger signals (ISO 7731:2003) " EN ISO 9614-2:1996, Acoustics – Determination of sound power levels of noise sources using sound intensity – Part 2: Measurement by scanning (ISO 9614-2:1996) EN ISO 11202:1995, Acoustics – Noise emitted by machinery and equipment – Measurement of emission sound pressure levels at a work station and at other specified positions – Survey method in situ (ISO 11202:1995) EN ISO 11204:1995, Acoustics – Noise emitted by machinery and equipment – Measurement of emission sound pressure levels at a work station and at other specified positions – Method requiring environmental corrections (ISO 11204:1995) EN ISO 11688-1:1998, Acoustics – Recommended practice for the design of low-noise machinery and equipment – Part 1: Planning (ISO/TR 11688-1:1995) EN ISO 12001:1996, Acoustics – Noise emitted by machinery and equipment – Rules for the drafting and presentation of a noise test code (ISO 12001:1996)" EN ISO 12100-1:2003, Safety of machinery – Basic concepts, general principles for design – Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery – Basic concepts, general principles for design – Part 2: Technical principles (ISO 12100-2:2003) !EN ISO 15744:2002, Hand-held non-electric power tools – Noise measurement code – Engineering method (grade 2) (ISO 15744:2002)" ISO 3864-1:2002, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety signs in workplaces and public areas

20 mm and 30 mm and the grip opening shall have a minimum length of 250 mm and a minimum width of 50 mm. The handles shall be positioned so that they are inside the vertical limits of the gauge indicated in annex B with the operator in the work position intended by the manufacturer (see 7.4.10). When such handles are also used for control purposes they shall, when used for handling, be in the stop position. If more than one person is recommended for putting the machine or trolley on or off the track the number of people necessary shall be indicated on the portable machine or trolley as appropriate (see 7.6). 5.2.2 Additional handle, lifting points and securing points If the portable machine or portable trolley weighs more than 25 kg, or it is not designed to be lifted by one person, then an additional handle and a lifting point shall be provided suitable for the weight, for maintaining the equilibrium of the machine and for preventing spillage of liquids (e.g. fuel, lubricants). For transport in vehicles points to secure the machine shall be provided. 5.3 Wheels and rollers The wheels and rollers used for moving and guidance of machines or trolleys on rail(s) shall: be arranged and in sufficient numbers to ensure the stability of the machine on the track (see 5.15); be shaped and of the correct width to ensure good guidance on the rails and to take account of gauges between 1 430 mm and 1 470 mm with a 1 435 mm nominal gauge, and gauges 1 665 mm and 1 698 mm with a 1 668 mm nominal gauge; not damage the electrical connections to the rails (see annex G); not damage signalling equipment (see annex G); allow the free running on rail through switches and crossings, level crossings and other installations. Where this is not achievable the handbook (see 7.2) shall make an indication of this limitation.

Machines

Trolleys

Dry rail Damp rail Dry rail Damp rail 0 < i < 15 3 5 6 10 15 < i < 25 4 6 8 12 25 < i < 40 5 7 10 14

5.5 Clamping and/or supporting devices If portable machines and trolleys are fitted with clamping and/or supporting devices they shall: be able to resist vibrations and forces generated by the work of the machine. They shall not cause: permanent deformation of these devices; reduction of the stability of the track; damage to the rails, sleepers, or track fastenings. 5.6 Power generation and transmission equipment 5.6.1 Electrical equipment Electrical equipment and the degree of electrical protection shall meet the requirements of EN 60204-1. Portable machines shall use voltages less than 500 V AC or 750 V DC. In order to avoid shorting track circuits, any flexible cables shall not have external metallic covering. 5.6.2 Hydraulic, pneumatic and mechanical power transmission If a portable machine is fed by exterior hydraulic, pneumatic or mechanical power transmission, risks according to EN 982 and EN 983 shall be taken into consideration. In order to avoid shorting of track circuits, the flexible pipes shall not be covered by metallic protection.

> 1,25. If portable machines are equipped with stands, these shall be adapted to the size, mass and use of the machine in order that its stability is assured. 5.16 Conformance to gauge The reference gauge given in annex B is the UIC gauge. For infrastructures with different gauges the corresponding applicable gauge shall be used. When moving or rotating about their vertical axis, portable machines equipped with running gear and trolleys the design shall ensure conformance to the envelope defined in annex B consisting of: UIC 505-1 gauge (position 1); the upper horizontal limit (position 2); low gauge contour (position 3). Conformance to the above shall take into account all cumulative wear on all components of the machine or of the trolley. In all cases guards, either movable or fixed, shall not exceed the gauge as defined in annex B with the exception of the low contour (position 3). If there is a need to leave a machine on a line open to traffic, then the machine design shall be such that it is contained below the “low” contours of the running gauge of position 3. Where a machine or trolley design necessitates exceedance of the clearance gauge as defined in annex B there shall be an indication in the instruction handbook indicating the need to apply further railway specific operational measures. 5.17 Time for off-tracking Portable machines and trolleys, which are used on tracks open to traffic and which present an obstruction to the passage of trains shall be designed in such a way that the time necessary for off-tracking is the shortest possible but shall not exceed 15 s.

the components; assembly phases; any fixing positions and fixing methods to ensure stability during assembly; electric, hydraulic and pneumatic connections; any special equipment for assembly.

only authorised personnel shall start, operate or interfere with the normal working of the equipment; specification of any personal protective equipment needed for the operation of the equipment and the hazards which it is designed to protect against; stopping modes, in particular means of operation of normal and emergency-stopping devices shall be made known to all appropriate personnel. Areas giving access to them shall be kept clear of obstacles. Their proper working shall be periodically checked; cleaning requirements; if an emergency switch is fitted it shall not be used for normal stopping; all restarting operations on equipment which has been inoperative because of an emergency or accidental stoppage shall be preceded by an inspection aiming at: determining the cause of the emergency or accidental stoppage; repairing the fault; details of a restarting procedure to be followed after an emergency or accidental stoppage; the user shall be careful to use the machine in the normal way avoiding over-loading; the user shall not modify the design or configuration of the equipment without consulting the manufacturer. !The instruction handbook shall include the noise emission declaration according to Annex J." 7.4.2 Restriction of use The instruction handbook shall indicate the restrictions of use of the portable machine or trolley according to the requirements of this document e.g. • if the machine cannot negotiate switches, crossings, level crossings and other installations; • if special conditions apply when the machine is working in track circuited areas; • if special conditions apply in the presence of live conductor rails (see 7.4.3); • cannot be immobilised on gradient steeper than 40 ‰ and therefore special measurements shall be fixed by the infrastructure controller. 7.4.3 Use in the vicinity of conductor rails The instruction handbook shall clearly indicate that the portable machine or trolley can only be used on a live conductor rail system with the approval of the infrastructure controller. In this case the manual shall give the following information: distances between the portable machine or trolley and the conductor rails; where the machine is powered by an external supply (e.g. electric, hydraulic, pneumatic), information on the safety measures to be met;

inspection, adjustment, maintenance and cleaning of moving parts and safety devices shall be carried out regularly in a safe manner according to the manufacturer's instructions; inspection and adjustment in motion shall only be carried out with guards in position; maintenance of safeguards, safety signs, information signs and lighting. 7.4.13 Instructions for training Where the training of the machine operator has been deemed necessary a programme of this training shall be included in the instruction handbook.

2) For machines and their related products intended to be put on the market in EEA, CE-marking as defined in the applicable European Directive(s).

(normative)

List of significant hazards This list is based on EN 1050:1996, annex A and includes those hazards which are considered significant to the working conditions of the portable machines and trolleys which are the subject of this document. The other hazards are not dealt with in this document. Table A.1 List of significant hazards From EN 1050:1996, annex A Number Hazards EN 13977 Hazards, hazardous situations and hazardous events 1 Mechanical hazards due to machine parts or workpieces, e.g.:

b)

relative location;

e)

inadequacy of mechanical strength; 5.2, 5.3, 5.4, 5.5, 5.6.2, 5.7, 5.8, 5.9, 5.16, 5.17, 7.3, 7.4.8, 7.4.9, 7.4.10, 7.4.11, 7.4.12 1.1 Crushing hazard 5.2, 5.3, 5.4, 5.8, 5.17, 7.4.2, 7.4.8, 7.4.9, 7.4.10, 7.4.11 1.4 Entanglement hazard 5.8, 5.9, 7.4.12 2 Electrical hazard due to:

2.1 Contact of persons with live parts (direct contact) 5.6.1, 7.4.2, 7.4.3 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 5.6.1, 7.4.2, 7.4.3 2.3 Approach to live parts under high voltage (Catenary, conductor rail, return conductors) 5.11, 7.4.2, 7.4.3 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery

7.2 Hazards from contact with or inhalation of harmful fluids, gases, mists, fumes and dusts 5.2.2, 5.14, 7.4.6, 7.4.5 8 Hazards generated by neglecting ergonomic principles in machinery design as, e.g. hazards from:

8.4 Inadequate local lighting 5.12 8.7 Inadequate design, location or identification of manual controls 5.2.1, 5.2.2, 5.9, 5.17, 7.4.10 15 Errors of fitting 7.3 16 Break-up during operation 5.5, 5.6.2, 5.8, 7.4.12

Table A.1 (continued) From EN 1050:1996, annex A Number Hazards EN 13977 Additional hazards, hazardous situations and hazardous events due to mobility 18 Loss of stability / overturning of machinery 5.2.2, 5.3, 5.4, 5.16, 7.4.2, 7.4.8, 7.4.9, 7.4.11 20 Relating to the travelling function 5.4, 5.5 20.3 Movement

without all parts in a safe position 7.4.12 20.6 Insufficient ability of the machine to be slowed down, stopped or i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...