EN 10217-6:2019

(Main)Welded steel tubes for pressure purposes - Technical delivery conditions - Part 6: Submerged arc welded non-alloy steel tubes with specified low temperature properties

Welded steel tubes for pressure purposes - Technical delivery conditions - Part 6: Submerged arc welded non-alloy steel tubes with specified low temperature properties

This document specifies the technical delivery conditions for two test categories of submerged arc longitudinally (SAWL) or helically (SAWH) welded tubes of circular cross section, with specified low temperature properties, made from non-alloy quality steel.

NOTE 1 These tube grades are intended to support the essential requirements of EU Directive 2014/68/EU in respect of pressure equipment with specified low temperature properties (see Table 5), covered under all relevant Categories as set out in Article 13 of that Directive.

NOTE 2 Once this standard is published in the Official Journal of the European Union (OJEU), presumption of conformity to the Essential Safety Requirements (ESR) of Directive 2014/68/EU is limited to the technical data for the materials in this standard and does not presume adequacy of the material for a specific item of pressure equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

Geschweißte Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen - Teil 6: Unterpulvergeschweißte Rohre aus unlegierten Stählen mit festgelegten Eigenschaften bei tiefen Temperaturen

Dieses Dokument legt die technischen Lieferbedingungen für unterpulvergeschweißte Rohre mit Längsnaht (SAWL) und Spiralnaht (SAWH) mit kreisförmigem Querschnitt aus unlegierten Stählen mit festgelegten Eigenschaften bei tiefen Temperaturen in zwei Prüfkategorien fest.

ANMERKUNG 1 Die Rohrgüten sind vorgesehen zur Unterstützung der grundlegenden Anforderungen der EU-Richtlinie 2014/68/EU bezüglich Druckgeräten mit festgelegten Eigenschaften bei tiefen Temperaturen (siehe Tabelle 5) und sie decken alle festgelegten Kategorien nach Artikel 13 der Richtlinie ab.

ANMERKUNG 2 Nach Veröffentlichung dieser Norm im EU-Amtsblatt (ABl.) ist die Annahme ihrer Konformität mit den grundlegenden Sicherheitsanforderungen (ESR) der Richtlinie 2014/68/EU auf die technischen Daten von Werkstoffen in dieser Norm beschränkt, und es darf nicht angenommen werden, dass damit die Eignung des Werkstoffs für ein bestimmtes Ausrüstungsteil festgestellt ist. Folglich müssen die in dieser Werkstoffnorm angegebenen technischen Parameter im Hinblick auf die konstruktiven Anforderungen dieses bestimmten Ausrüstungsteils ermittelt werden, um damit zu verifizieren, dass den ESR der Druckgeräterichtlinie entsprochen wird. Dies muss durch den Ausleger oder den Hersteller der Druckgeräte geschehen, der auch den nachfolgenden Herstellungsprozess berücksichtigen muss, der die Eigenschaften des Grundmaterials verändern kann.

Tubes soudés en acier pour service sous pression- Conditions techniques de livraison - Partie 6: Tubes soudés à l'arc sous flux en acier non allié avec caractéristiques spécifiées à basse température

Le présent document spécifie les conditions techniques de livraison de deux catégories d’essai de tubes soudés à l’arc immergé longitudinal (SAWL) ou hélicoïdal (SAWH), à section circulaire, avec caractéristiques spécifiées à basse température, fabriqués en aciers de qualité non alliés.

NOTE 1 Ces nuances sont destinées à remplir les exigences essentielles de la directive 2014/68/UE de l'UE sur les équipements sous pression avec caractéristiques spécifiées à basse température (voir le Tableau 5), concernant toutes les catégories pertinentes comme exposé dans l’Article 13 de cette directive.

NOTE 2 Dès lors que la présente Norme européenne est publiée dans le Journal Officiel de l’Union européenne (JOUE), la présomption de conformité avec les exigences essentielles de sécurité (ESR) de la Directive 2014/68/UE se limite aux données techniques des matériaux spécifiées dans la présente Norme européenne et ne suppose pas l’adéquation des matériaux avec un appareil en particulier. Par conséquent, l’évaluation des données techniques spécifiées dans la présente norme de matériaux par rapport aux exigences de conception d’un équipement spécifique, pour vérifier que les exigences essentielles de sécurité (ESRs) de la Directive sur les équipements sous pression soient satisfaites, doit être effectuée par le concepteur ou le fabricant de l’équipement sous pression, en tenant aussi compte de toutes les procédures ultérieures de fabrication qui peuvent affecter les propriétés du matériau de base.

Varjene jeklene cevi za tlačne posode - Tehnični dobavni pogoji - 6. del: Obločno pod praškom varjene nelegirane jeklene cevi s specificiranimi lastnostmi za delo pri nizkih temperaturah

Ta del standarda EN 10217 določa tehnične dobavne pogoje v dveh preskusnih kategorijah za obločno pod praškom varjene cevi s krožnim prerezom iz nelegiranega jekla in specificiranimi lastnostmi za delo pri nizkih temperaturah.

General Information

- Status

- Published

- Publication Date

- 16-Apr-2019

- Withdrawal Date

- 30-Oct-2019

- Technical Committee

- ECISS/TC 110 - Steel tubes, and iron and steel fittings

- Drafting Committee

- ECISS/TC 29/SC 1 - Tubes for pressure purposes

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Dec-2024

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 24-Apr-2019

- Effective Date

- 24-Apr-2019

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10217-6:2019 (CEN) specifies the technical delivery conditions for submerged arc welded non‑alloy steel tubes with specified low temperature properties for pressure purposes. It covers two test categories of submerged arc longitudinally (SAWL) and helically (SAWH) welded tubes of circular cross‑section made from non‑alloy quality steel. The standard supports the essential requirements of the EU Pressure Equipment Directive (2014/68/EU) for materials with low temperature performance, while noting that conformity to the Directive for a specific pressure item still requires assessment by the equipment designer or manufacturer.

Key topics and requirements

The standard defines mandatory content and verification measures for manufacturers, including:

- Classification and designation of tube types (SAWL / SAWH) and test categories.

- Information to be supplied by the purchaser (order data and options).

- Manufacturing process controls (steelmaking, tube manufacture, NDT personnel requirements).

- Material requirements such as chemical composition and product analysis.

- Mechanical properties and sampling rules for tensile, transverse tensile and impact testing.

- Weld quality and internal soundness requirements, including non‑destructive testing of weld seams and laminations.

- Dimensional tolerances, straightness, end preparation, lengths and mass.

- Inspection and sampling procedures, verification of test methods and frequency of tests.

- Marking, protection and inspection documentation required on delivery.

- Normative annexes for welding procedure qualification and an informative Annex ZA relating the standard to 2014/68/EU.

Practical applications and users

EN 10217-6:2019 is used where welded steel tubes are specified for pressure equipment that must perform reliably at low temperatures. Typical applications include:

- Pressure vessels, heat exchangers and piping systems operating in cold climates or cryogenic conditions.

- Industry sectors: oil & gas, petrochemical, power generation, maritime and industrial refrigeration.

- Project stakeholders who rely on the standard:

- Tube manufacturers and welders (process control and welding procedure qualification).

- Pressure equipment designers and manufacturers (material selection and conformity assessment).

- Procurement engineers and quality / inspection teams (ordering, inspection and acceptance).

- Notified bodies and certification agencies assessing PED compliance for material data.

Related standards

- EN 10217 (other parts): covers welded tubes for room and elevated temperature properties, alloy steels and stainless steels.

- EN 10216: Seamless steel tubes for pressure purposes.

- Annex ZA in EN 10217-6 links material provisions to 2014/68/EU (PED) for regulatory context.

Keywords: EN 10217-6:2019, welded steel tubes, submerged arc welded, SAWL, SAWH, low temperature properties, pressure equipment, pressure vessels, CEN, PED 2014/68/EU.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 10217-6:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Welded steel tubes for pressure purposes - Technical delivery conditions - Part 6: Submerged arc welded non-alloy steel tubes with specified low temperature properties". This standard covers: This document specifies the technical delivery conditions for two test categories of submerged arc longitudinally (SAWL) or helically (SAWH) welded tubes of circular cross section, with specified low temperature properties, made from non-alloy quality steel. NOTE 1 These tube grades are intended to support the essential requirements of EU Directive 2014/68/EU in respect of pressure equipment with specified low temperature properties (see Table 5), covered under all relevant Categories as set out in Article 13 of that Directive. NOTE 2 Once this standard is published in the Official Journal of the European Union (OJEU), presumption of conformity to the Essential Safety Requirements (ESR) of Directive 2014/68/EU is limited to the technical data for the materials in this standard and does not presume adequacy of the material for a specific item of pressure equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

This document specifies the technical delivery conditions for two test categories of submerged arc longitudinally (SAWL) or helically (SAWH) welded tubes of circular cross section, with specified low temperature properties, made from non-alloy quality steel. NOTE 1 These tube grades are intended to support the essential requirements of EU Directive 2014/68/EU in respect of pressure equipment with specified low temperature properties (see Table 5), covered under all relevant Categories as set out in Article 13 of that Directive. NOTE 2 Once this standard is published in the Official Journal of the European Union (OJEU), presumption of conformity to the Essential Safety Requirements (ESR) of Directive 2014/68/EU is limited to the technical data for the materials in this standard and does not presume adequacy of the material for a specific item of pressure equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

EN 10217-6:2019 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10217-6:2019 has the following relationships with other standards: It is inter standard links to EN 10217-6:2002, EN 10217-6:2002/A1:2005, ISO 11484:2009, EN ISO 10893-7:2011, EN 10020:2000, EN 10027-2:2015, EN ISO 4885:2018, EN 10168:2004, EN 10021:2006, EN ISO 10893-9:2011, EN ISO 2566-1:1999, EN ISO 10893-6:2011, EN ISO 6892-1:2016, EN 10204:2004, EN ISO 10893-11:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10217-6:2019 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10217-6:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST EN 10217-6:2003

SIST EN 10217-6:2003/A1:2005

Varjene jeklene cevi za tlačne posode - Tehnični dobavni pogoji - 6. del: Obločno

pod praškom varjene nelegirane jeklene cevi s specificiranimi lastnostmi za delo

pri nizkih temperaturah

Welded steel tubes for pressure purposes - Technical delivery conditions - Part 6:

Submerged arc welded non-alloy steel tubes with specified low temperature properties

Geschweißte Stahlrohre für Druckbeanspruchungen - Technische Lieferbedingungen -

Teil 6: Unterpulvergeschweißte Rohre aus unlegierten Stählen mit festgelegten

Eigenschaften bei tiefen Temperaturen

Tubes soudés en acier pour service sous pression - Conditions techniques de livraison -

Partie 6 : Tubes soudés à l'arc immergé en acier non allié avec caractéristiques

spécifiées à basse température

Ta slovenski standard je istoveten z: EN 10217-6:2019

ICS:

23.020.32 Tlačne posode Pressure vessels

77.140.75 Jeklene cevi in cevni profili Steel pipes and tubes for

za posebne namene specific use

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 10217-6

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 23.040.10; 77.140.75 Supersedes EN 10217-6:2002

English Version

Welded steel tubes for pressure purposes - Technical

delivery conditions - Part 6: Submerged arc welded non-

alloy steel tubes with specified low temperature

properties

Tubes soudés en acier pour service sous pression- Geschweißte Stahlrohre für Druckbeanspruchungen -

Conditions techniques de livraison - Partie 6: Tubes Technische Lieferbedingungen - Teil 6:

soudés à l'arc sous flux en aciers non allié avec Unterpulvergeschweißte Rohre aus unlegierten

caractéristiques spécifiées à basse température Stählen mit festgelegten Eigenschaften bei tiefen

Temperaturen

This European Standard was approved by CEN on 25 February 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 10217-6:2019 E

worldwide for CEN national Members.

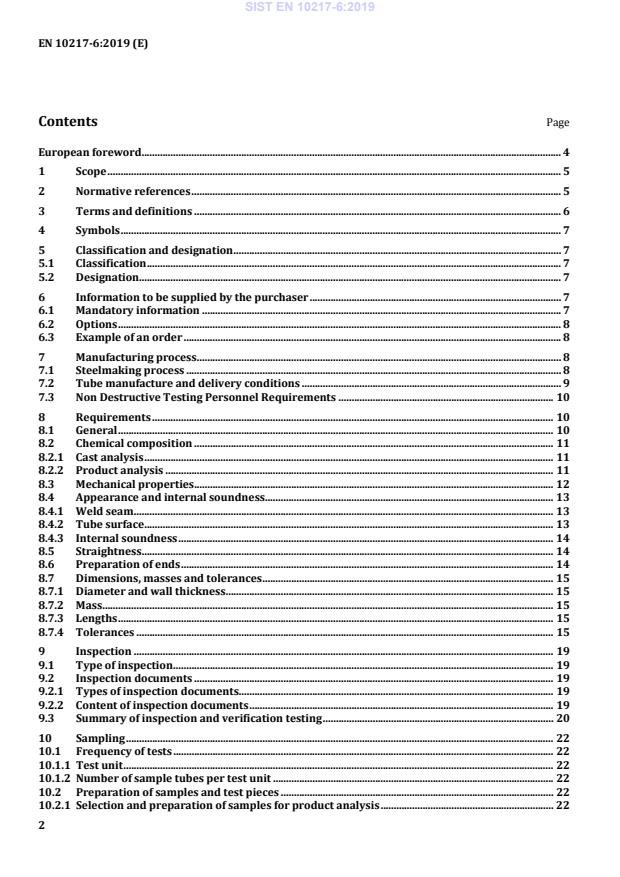

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols . 7

5 Classification and designation . 7

5.1 Classification . 7

5.2 Designation. 7

6 Information to be supplied by the purchaser . 7

6.1 Mandatory information . 7

6.2 Options . 8

6.3 Example of an order . 8

7 Manufacturing process . 8

7.1 Steelmaking process . 8

7.2 Tube manufacture and delivery conditions . 9

7.3 Non Destructive Testing Personnel Requirements . 10

8 Requirements . 10

8.1 General . 10

8.2 Chemical composition . 11

8.2.1 Cast analysis . 11

8.2.2 Product analysis . 11

8.3 Mechanical properties . 12

8.4 Appearance and internal soundness. 13

8.4.1 Weld seam . 13

8.4.2 Tube surface . 13

8.4.3 Internal soundness . 14

8.5 Straightness . 14

8.6 Preparation of ends . 14

8.7 Dimensions, masses and tolerances . 15

8.7.1 Diameter and wall thickness . 15

8.7.2 Mass . 15

8.7.3 Lengths . 15

8.7.4 Tolerances . 15

9 Inspection . 19

9.1 Type of inspection . 19

9.2 Inspection documents . 19

9.2.1 Types of inspection documents. 19

9.2.2 Content of inspection documents . 19

9.3 Summary of inspection and verification testing . 20

10 Sampling . 22

10.1 Frequency of tests . 22

10.1.1 Test unit . 22

10.1.2 Number of sample tubes per test unit . 22

10.2 Preparation of samples and test pieces . 22

10.2.1 Selection and preparation of samples for product analysis . 22

10.2.2 Location, orientation and preparation of samples and test pieces for mechanical tests . 22

11 Verification of test methods . 24

11.1 Chemical analysis . 24

11.2 Tensile test on the tube body . 24

11.3 Transverse tensile test on the weld . 24

11.4 Weld bend test . 24

11.5 Impact test . 24

11.6 Hydrostatic leak tightness test . 25

11.7 Dimensional inspection . 25

11.8 Visual examination . 26

11.9 Non-Destructive Testing . 26

11.9.1 Non-Destructive Testing of the weld seam . 26

11.9.2 Non-Destructive Testing for the detection of laminations for tubes of test category 2 . 26

11.9.3 Supply of strip end welds in SAWH tubes . 27

11.10 Retests, sorting and reprocessing . 27

12 Marking . 27

12.1 Marking to be applied . 27

12.2 Additional marking . 27

13 Protection . 27

Annex A (normative) Qualification of welding procedure. 28

A.1 General . 28

A.2 Welding procedure specification . 28

A.3 Preparation of sample tube and sample assessment . 30

A.4 Inspection and testing of the weld. 30

A.5 Weld test pieces. 31

A.6 Test methods . 31

A.7 Test acceptance levels. 32

A.8 Range of use of qualified procedures . 34

A.9 Qualification record . 34

Annex B (informative) Technical changes from the previous edition . 35

B.1 Introduction . 35

B.2 Technical changes . 35

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of 2014/68/EU . 37

Bibliography . 38

European foreword

This document (EN 10217-6:2019) has been prepared by Technical Committee CEN/TC 459 “ECISS -

European Committee for Iron and Steel Standardization” , the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by October 2019, and conflicting national standards shall be withdrawn

at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 10217-6:2002.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2014/68/EU.

For relationship with EU Directive 2014/68/EU (formerly 97/23/EC), see informative Annex ZA, which is an

integral part of this document.

This European Standard consists of the following parts, under the general title Welded steel tubes for

pressure purposes – Technical delivery conditions:

Part 1: Electric welded and submerged arc welded non-alloy steel tubes with specified room temperature

properties

Part 2: Electric welded non-alloy and alloy steel tubes with specified elevated temperature properties

Part 3: Electric welded and submerged arc welded alloy fine grain steel tubes with specified room, elevated

and low temperature properties

Part 4: Electric welded non-alloy steel tubes with specified low temperature properties

Part 5: Submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties

Part 6: Submerged arc welded non-alloy steel tubes with specified low temperature properties

Part 7: Stainless steel tubes

Another European Standard series covering tubes for pressure purposes is:

EN 10216, Seamless steel tubes for pressure purposes.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Through its subcommittee SC 10 “Steel tubes, and iron and steel fittings” (secretariat: UNI)

1 Scope

This document specifies the technical delivery conditions for two test categories of submerged arc

longitudinally (SAWL) or helically (SAWH) welded tubes of circular cross section, with specified low

temperature properties, made from non-alloy quality steel.

NOTE 1 These tube grades are intended to support the essential requirements of EU Directive 2014/68/EU in

respect of pressure equipment with specified low temperature properties (see Table 5), covered under all relevant

Categories as set out in Article 13 of that Directive.

NOTE 2 Once this standard is published in the Official Journal of the European Union (OJEU), presumption of

conformity to the Essential Safety Requirements (ESR) of Directive 2014/68/EU is limited to the technical data for the

materials in this standard and does not presume adequacy of the material for a specific item of pressure equipment.

Consequently, the assessment of the technical data stated in this material standard against the design requirements of

this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied, needs to be

done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent

manufacturing processes which may affect properties of the base materials.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 10020, Definition and classification of grades of steel

EN 10021:2006, General technical delivery conditions for steel products

EN 10027-1, Designation systems for steels — Part 1: Steel names

EN 10027-2, Designation systems for steels — Part 2: Numerical system

EN 10168:2004, Steel products — Inspection documents — List of information and description

EN 10204:2004, Metallic products — Types of inspection documents

EN 10220, Seamless and welded steel tubes — Dimensions and masses per unit length

CEN/TR 10261, Iron and steel — European standards for the determination of chemical composition

EN 10266, Steel tubes, fittings and structural hollow sections — Symbols and definitions of terms for use in

product standards

EN ISO 148-1:2016, Metallic materials — Charpy pendulum impact test — Part 1: Test method (ISO 148-

1:2016)

EN ISO 377:2017, Steel and steel products — Location and preparation of samples and test pieces for

mechanical testing (ISO 377:2017)

EN ISO 2566-1:1999, Steel — Conversion of elongation values — Part 1: Carbon and low alloy steels (ISO 2566-

1:1984)

EN ISO 4885, Ferrous materials — Heat treatments — Vocabulary (ISO 4885)

EN ISO 5173:2010, Destructive tests on welds in metallic materials — Bend tests (ISO 5173:2009)

EN ISO 6892-1:2016, Metallic materials — Tensile testing — Part 1: Method of test at room temperature (ISO

6892-1:2016)

EN ISO 10893-6:2011, Non-destructive testing of steel tubes — Part 6: Radiographic testing of the weld seam

of welded steel tubes for the detection of imperfections (ISO 10893-6:2011)

EN ISO 10893-7:2011, Non-destructive testing of steel tubes — Part 7: Digital radiographic testing of the weld

seam of welded steel tubes for the detection of imperfections (ISO 10893-7:2011)

EN ISO 10893-8:2011, Non-destructive testing of steel tubes — Part 8: Automated ultrasonic testing of

seamless and welded steel tubes for the detection of laminar imperfections (ISO 10893-8:2011)

EN ISO 10893-9:2011, Non-destructive testing of steel tubes — Part 9: Automated ultrasonic testing for the

detection of laminar imperfections in strip/plate used for the manufacture of welded steel tubes (ISO 10893-

9:2011)

EN ISO 10893-11:2011, Non-destructive testing of steel tubes — Part 11: Automated ultrasonic testing of the

weld seam of welded steel tubes for the detection of longitudinal and/or transverse imperfections (ISO 10893-

11:2011)

EN ISO 14174:2012, Welding consumables — Fluxes for submerged arc welding and electroslag welding —

Classification (ISO 14174:2012)

EN ISO 14284, Steel and iron — Sampling and preparation of samples for the determination of chemical

composition (ISO 14284)

EN ISO 17639:2013, Destructive tests on welds in metallic materials — Macroscopic and microscopic

examination of welds (ISO 17639:2003)

ISO 11484:2009, Steel products — Employer’s qualification system for non-destructive testing (NDT) personnel

3 Terms and definitions

For the purpose of this document, the definitions given in EN 10020, EN 10021, EN 10266, EN ISO 4885 and

the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

test category

classification that indicates the extent and level of inspection and testing

3.2

employer

organisation for which a person works on a regular basis

Note 1 to entry: The employer may be either the tube manufacturer or a third party organization providing services,

such as Non-Destructive Testing (NDT).

3.3

SAW

submerged-arc welded tube

tubular product having one or two longitudinal seams, or one helical seam, produced using the submerged-

arc welding process

3.4

SAWH

submerged-arc helical welded tube

tubular product having one helical weld seam produced using the submerged-arc welding process

3.5

SAWL

submerged-arc longitudinal welded tube

tubular product having one or two longitudinal weld seams produced using the submerged-arc welding

process

4 Symbols

For the purposes of this document, the symbols given in EN 10266 apply.

5 Classification and designation

5.1 Classification

In accordance with the classification system in EN 10020, the steel grades given in Tables 2 and 4 are

classified as non-alloy quality steels.

5.2 Designation

5.2.1 For the tubes covered by this document the steel designation consists of:

— the number of this European Standard, e.g. EN 10217-6;

plus either:

— the steel name in accordance with EN 10027-1;

or:

— the steel number allocated in accordance with EN 10027-2.

5.2.2 The steel name is designated by

— the capital letter P for pressure purposes;

— the indication of the specified minimum yield strength expressed in MPa, (see Table 4);

— the symbol of the delivery condition for the steel grade concerned (see Table 1);

— the symbol L for low temperature.

6 Information to be supplied by the purchaser

6.1 Mandatory information

The following information shall be supplied by the purchaser at the time of enquiry and order:

a) the quantity (mass, total length or number of tubes of set length);

b) the term ‘tube’ and tube type, SAWL or SAWH;

c) the dimensions (outside diameter D, wall thickness T) (see Table 6);

d) the random length range (see 8.7.3);

e) for tubes with a D/T > 100, out of roundness limits (see 8.7.4.6);

f) the designation of the steel grade in accordance with this document (see 5.2);

g) the test category (see 9.3).

6.2 Options

A number of options are specified in document and these are listed below. In the event that the purchaser

does not indicate his wish to implement any of these options at the time of enquiry and order, the tubes shall

be supplied in accordance with the basic specification (see 6.1).

1) Tube manufacturing route (see 7.3.2);

2) Restriction on copper and tin content (see Table 2);

3) Product analysis (see 8.2.2);

4) Special end preparation (see 8.6);

5) Exact lengths (see 8.7.3);

6) Inspection document 3.2 in place of the standard 3.1 Inspection Certificate (see 9.2.1);

7) Verification of the tensile strength of the weld in the transverse direction for tubes with D ≤ 508 mm

(see Table 11).

8) Agreement of a different test pressure for hydrostatic leak-tightness test (see 11.6);

9) Wall thickness measurement away from the ends (see 11.7);

10) Non Destructive Testing method for the inspection of weld seam (see 11.9.1);

11) Additional marking (see 12.2);

12) Protection (see Clause 13).

6.3 Example of an order

500 m of SAWL tube with an outside diameter of 508 mm, a wall thickness of 4,5 mm in accordance with

EN 10217-6, made of steel grade P265NL, test category 1, in 9 m random lengths, with a 3.2 inspection

certificate in accordance with EN 10204:

500 m – SAWL - Tube - 508 × 4,5 - EN 10217–6 — P265NL - TC 1 - 9m - Option 6: 3.2

7 Manufacturing process

7.1 Steelmaking process

The steelmaking process is at the discretion of the manufacturer with the exception that the open hearth

(Siemens-Martin) process shall not be employed unless in combination with a secondary steelmaking or

ladle refining process.

Steels shall be fully killed and contain nitrogen binding elements, details of which shall be reported.

NOTE This excludes the use of rimming, balanced or semi-killed steel.

7.2 Tube manufacture and delivery conditions

7.2.1 The tubes shall be manufactured by a SAW process and in accordance with one of the routes as

specified in Table 1.

Unless Option 1 is specified the manufacturing route is at the discretion of the manufacturer.

Option 1: The manufacturing route from Table 1 is specified by the purchaser.

The submerged arc weld shall be made using at least one weld run on the inside and one weld run on the

outside of the tube.

The strip used for the manufacture of the SAWH tubes shall have a width of not less than 0,8 times or more

than 3,0 times the outside diameter of the tube.

The finished tubes shall not include the welds used to join together the strip or plate prior to forming, except

for SAWH tubes to test category 1, where this is permitted only when the welding procedure for the weld

joining the strip or plate has been qualified in accordance with Annex A and has also been subjected to the

same inspection and testing regime as the helical pipe welds and base material to test category 2 (see

11.9.3).

7.2.2 Submerged arc welding shall be carried out by qualified personnel in accordance with documented

procedures. For tubes to be used in pressure equipment under European legislation, manufacturers shall

employ an established procedure for the approval of welding operatives.

7.2.3 The welding procedure for SAW tubes shall be qualified in accordance with Annex A.

7.2.4 The delivery condition of tubes covered by this document are shown in Table 1.

Table 1 — Tube manufacturing process, route and delivery condition

Route Manufacturing process Manufacturing route

N° Acceptable

delivery

(according

Forming

Process Symbols Starting material

a

to condition

operation

Part 1)

4b Hot rolled plate or strip NP

Submerged arc SAW

welded

- SAWL

— longitudinal

Normalized rolled plate

- SAWH

Cold formed and

c

5a

As welded

seam

or strip

welded

or

–– helical seam

Full body normalized

6a

plate or strip

7a Hot rolled plate or strip

Normalized

Normalized rolled plate

8a

formed and c

or strip

As welded

b

welded

Full body normalized

9a

plate or strip

a

As welded = no subsequent heat treatment; NP = tube full body normalized;

b

Only applicable to SAWL tubes;

c

Stress relieving treatment on the weld is permissible.

7.3 Non Destructive Testing Personnel Requirements

7.3.1 All NDT activities shall be carried out by qualified and competent level 1, 2 and/or 3 personnel,

authorized to carry out this work by the employer.

7.3.2 The qualification for levels 1 and 2 personnel shall be in accordance with ISO 11484 or, at least, an

equivalent to it.

7.3.3 It is recommended for the level 3 personnel to be suitably certified in accordance with EN ISO 9712

or, at least, an equivalent to it.

7.3.4 The operating authorization issued by the employer shall be in accordance with a written procedure.

7.3.5 All NDT operations shall be authorised by a level 3 NDT technician approved by the employer.

NOTE The definition of levels 1, 2 and 3 can be found in appropriate standards, e.g. EN ISO 9712 and ISO 11484.

8 Requirements

8.1 General

The tubes shall conform to the requirements of this document when supplied in a delivery condition in

accordance with Table 1 and inspected in accordance with the specified requirements in Table 11.

Tubes shall be suitable for hot and cold bending.

In addition, the general technical delivery requirements specified in EN 10021 shall apply.

8.2 Chemical composition

8.2.1 Cast analysis

The cast analysis reported by the steel producer shall apply and conform to the requirements of Table 2.

When welding tubes produced in accordance with this document, account should be taken of the fact that

the behaviour of the steel during and after welding is dependent not only on the steel analysis, but also on

the welding process, including heat input, any applied heat treatment and the conditions of preparing for

and carrying out the welding.

a

Table 2 — Chemical composition (cast analysis) in % by mass

Al

c

Steel grade C Si Mn P S Cr Mo Ni Nb Ti V

Cu

b

tot

Steel Steel max

max. max. max. max. max. max. min. max. max. max. max.

name number .

0,40

P215N 0,02 0,01

1.0451 0,15 0,35 to 0,025 0,30 0,08 0,30 0,020 0,30 0,03 0,02

L 0 0

1,20

0,60

P265N 0,02 0,01

1.0453 0,20 0,40 to 0,025 0,30 0,08 0,30 0,020 0,30 0,03 0,02

L 0 0

1,40

a

Elements not quoted in this table shall not be intentionally added to the steel without the agreement of the purchaser, except

for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of

undesirable elements from scrap or other materials used in the steel making process, which would have a negative impact on the

mechanical properties, ageing and the suitability of the material;

b

For Al/N ratios ≥ 2, if nitrogen is fixed by niobium, titanium or vanadium, details of which shall be reported, this

requirement does not apply except that when using titanium, the steel producer shall verify that (Al+Ti/2) ≥ 0,020 %;

c

Option 2: In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an

agreed specified maximum tin content shall apply.

8.2.2 Product analysis

Unless Option 3 is specified, only the cast analysis shall be reported.

Option 3: A product analysis for the tubes shall be supplied.

Table 3 specifies the permissible deviations of the product analysis from the specified limits on cast analysis

given in Table 2.

Table 3 — Permissible deviations of the product analysis from specified limits on cast analysis given

in Table 2

Limiting value for the cast

Permissible deviation of the

analysis in accordance with

product analysis

Element

Table 2

% by mass

% by mass

C ≤ 0,20 + 0,02

Si ≤ 0,40 + 0,05

Mn ≤ 1,40 + 0,10

P ≤ 0,025 + 0,005

S ≤ 0,020 + 0,005

Al ≥ 0,020 - 0,005

Cr ≤ 0,30 + 0,05

Cu ≤ 0,30 + 0,05

Mo ≤ 0,08 + 0,02

Nb ≤ 0,010 + 0,005

Ni ≤ 0,30 + 0,05

Ti ≤ 0,03 + 0,01

V ≤ 0,02 + 0,01

8.3 Mechanical properties

The mechanical properties of the tubes, in a specified delivery condition from Table 1, shall conform to the

requirements of Table 4, Table 5 and 11.4, irrespective of whether the test results are actually verified or not

(see Table 11 for a summary of the inspection and verification testing required).

Table 4 —Tensile properties

Steel grade Tensile properties at room temperature

Upper yield Tensile a

Elongation

strength

strength or proof

A min.

Steel

strength

%

Steel name

Number

R or R min. R

eH p0,2 m

MPa MPa l t

b 1.0451 215 360 to 480 25 23

P215NL

c 1.0453 265 410 to 570 24 22

P265NL

a

l = longitudinal, t = transverse

b

Applies for specified wall thickness T ≤ 10 mm.

c

Applies for specified wall thickness T ≤ 25 mm.

Table 5 —Impact properties

Minimum average absorbed

a

energy

Steel grade

b

KV2 J

at a temperature of °C

- 40 - 20 + 20

Steel name Steel number

l t l t l t

c

1.0451 40 - 45 - 55 -

P215NL

d

1.0453 40 27 45 30 50 35

P265NL

a

l = longitudinal t = transverse

b

KV = impact values obtained using a 2 mm radius striker in

accordance with EN ISO 148-1.

c

Applies for specified wall thickness T ≤ 10 mm.

d

Applies for specified wall thickness T ≤ 25 mm.

8.4 Appearance and internal soundness

8.4.1 Weld seam

The weld area shall be free from cracks, lack of fusion and lack of penetration. Repairs to the weld seam shall

be permitted if done in accordance with an agreed documented procedure.

NOTE For strip and plate alignment (radial offset) and tolerances in the weld region, see 8.7.4.3 and 8.7.4.4.

8.4.2 Tube surface

8.4.2.1 The tubes shall be free from external and internal surface defects that can be detected by visual

examination of the surfaces that are accessible without the use of special equipment.

8.4.2.2 The internal and external surface finish of the tubes shall be typical of the manufacturing process

and, where applicable, the heat treatment employed. Normally the finish and surface condition shall be such

that any surface imperfections requiring dressing can be identified.

8.4.2.3 It shall be permissible to dress only by grinding or machining surface imperfections provided

that after doing so, the wall thickness in the dressed area is not less than the specified minimum wall

thickness. All dressed areas shall blend smoothly into the contour of the tube

8.4.2.4 Any surface imperfection, which is demonstrated to be deeper than 5 % of the wall thickness T or

3 mm, whichever is the smaller, shall be dressed.

8.4.2.5 Surface imperfections which extend below the specified minimum wall thickness shall be

considered defects and tubes containing these shall be deemed not to conform with this document and shall

be rejected.

8.4.3 Internal soundness

8.4.3.1 Leak tightness

The tubes shall be assessed for leak tightness by a hydrostatic test (see 11.6).

8.4.3.2 Non-Destructive Testing

The full length of the weld seam of SAWL and SAWH tubes to test categories 1 and 2 shall be subjected to

Non-Destructive Testing for the detection of imperfections in accordance with 11.9.1.

Additionally the edges of the plate or strip, the body and the ends of tubes supplied to test category 2 shall be

subjected to Non-Destructive Testing for the detection of laminar imperfections in accordance with 11.9.2.

8.5 Straightness

The deviation from straightness of any tube length L shall not exceed 0,001 5 L. Deviations from straightness

over any one metre length shall not exceed 3 mm.

8.6 Preparation of ends

Unless Option 4 is specified, tubes shall be delivered with square cut ends free from excessive burrs.

Option 4: The tubes shall be delivered with bevelled ends (see Figure 1). The bevel shall have an angle α of 30°

+°5

with a root face C of 1,6 mm ± 0,8 mm. Bevelling is applicable for specified wall thicknesses ≥ 3,2 mm, except

0°

that for wall thickness T ≥ than 20 mm, an agreed alternative bevel may be specified.

Key

D outside diameter

α bevel angle

C root face of bevelled end

Figure 1 — Tube end bevel

8.7 Dimensions, masses and tolerances

8.7.1 Diameter and wall thickness

Tubes shall be delivered by outside diameter D and wall thickness T.

Preferred outside diameters D and wall thicknesses T have been selected from EN 10220 and are given in

Table 6.

NOTE Dimensions other than those in Table 6 may be agreed.

8.7.2 Mass

For the mass per unit length the provision of EN 10220 applies.

8.7.3 Lengths

Unless option 5 is specified, the tubes shall be delivered in random lengths. The delivery range shall be

agreed at the time of enquiry and order.

Option 5: The tubes shall be delivered in exact lengths, the length to be specified at the time of enquiry and

order. For tolerances see 8.7.4.5.

8.7.4 Tolerances

8.7.4.1 Tolerances on diameter and thickness

The diameter and the wall thickness of the tubes shall be within the tolerance limits given in Table 7.

Table 6 — Preferred dimensions

Dimensions in millimetres

Outside diameter D Wall thickness T

a

Series

1 2 3 4 4,5 5 5,6 6,3 7,1 8 8,8 10 11 12,5 14,2 16 17,5 20 22,2 25

406,4

a

series 1 = diameters for which all the accessories needed for the construction of piping systems are

standardised;

series 2 = diameters for which not all the accessories are standardised;

series 3 = diameters for special applications for which very few standardised accessories exist.

Table 7 — Tolerances on outside diameter and on wall thickness

Dimensions in millimetres

a

Tolerance on wall thickness

Outside

Tolerance on

Diameter

outside diameter

D T ≤ 5 5 < T ≤ 40

±0,75 % or ± 6 ±10 % or ± 0,3 ±8 % or ± 2

≥ 406,4

whichever is the lower whichever is the greater whichever is the lower

a

The plus tolerance excludes the weld area (see 8.7.4.2).

8.7.4.2 Height of the weld seam

The height of the external and internal weld seam shall be within the limits indicated in Table 8.

Table 8 — Maximum height of the weld seam

Dimensions in millimetres

Maximum height of the

Wall thickness

outside and inside weld

T

seam

T ≤ 12,5 3

T > 12,5 4

8.7.4.3 Radial offset of plate or strip edges at the weld

The radial offset of the abutting plate or strip edges, see Figure 2, shall be within the limits indicated in

Table 9.

Key

1, 4 outside/inside diameter radial offset

2, 3 outside/inside height of the weld seam

Figure 2 — Radial offset of the abutting plate or strip edges

Table 9 — Maximum radial offset of the abutting plate or strip edges

Dimension in millimetres

Wall thickness

Maximum radial offset

T

T ≤ 12,5 1,6

T > 12,5 0,125 T with a max. of 3,2

8.7.4.4 Misalignment of the weld seam

Misalignment of the weld seams, see Figure 3, shall be acceptable provided complete penetration and

complete fusion are achieved.

Key

1 misalignment

Figure 3 — Example showing the possible misalignment of the weld seams

8.7.4.5 Tolerances on exact length

The tolerances for exact lengths shall be as given in Table 10.

Table 10 — Tolerances on exact length

Dimensions in millimetres

Length range

Tolerance

L

+ 25

L ≤ 6 000

+ 50

6 000 < L ≤ 12 000

+ By agreement

L > 12 000

8.7.4.6 Out of roundness

The out-of-roundne

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...