EN 14893:2006

(Main)LPG equipment and accessories - Transportable Liquefied Petroleum Gas (LPG) welded steel pressure drums with a capacity between 150 litres and 1 000 litres

LPG equipment and accessories - Transportable Liquefied Petroleum Gas (LPG) welded steel pressure drums with a capacity between 150 litres and 1 000 litres

This European Standard specifies the minimum requirements for the material, design, construction, workmanship, equipping, inspection and testing at manufacture of transportable, refillable welded steel pressure drums of volumes over 150 l up to and including 1 000 l for Liquefied Petroleum Gases (LPG).

Vertical and horizontal cylindrical receptacles are covered.

Flüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, geschweißte Druckfässer aus Stahl für Flüssiggas (LPG) mit einem Fassungsraum zwischen 150 Liter und 1 000 Liter

Diese Europäische Norm legt die Mindestanforderungen an Werkstoff, Gestaltung, Konstruktion, Ausführung, Ausrüstung und Prüfung fest, die bei der Herstellung von ortsbeweglichen, wiederbefüllbaren, geschweißten Druckfässern aus Stahl für Flüssiggas (LPG) mit einem Fassungsraum von 150 l bis einschließlich 1 000 l gelten.

Behandelt werden waagerechte und senkrechte Druckfässer.

Équipements pour GPL et leurs accessoires - Fûts à pression métalliques transportables pour GPL d'une capacité comprise entre 150 litres et 1 000 litres

La présente Norme européenne spécifie les exigences minimales relatives aux matériaux, à la conception, à la fabrication et à la qualité d’exécution, à l’inspection et aux essais en usine de fûts à gaz en acier soudé rechargeables, ayant un volume compris entre 150 l et 1 000 l, pour gaz de pétrole liquéfié (GPL) répertoriés.

Les récipients cylindriques verticaux et horizontaux sont couverts par la présente norme.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Premični varjeni jekleni tlačni sodi za utekočinjeni naftni plin (UNP) s prostornino med 150 in 1000 litri

General Information

- Status

- Withdrawn

- Publication Date

- 11-Jul-2006

- Withdrawal Date

- 20-May-2014

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Drafting Committee

- CEN/TC 286/WG 1 - Design and manufacture of LPG pressure vessels

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-May-2014

- Completion Date

- 21-May-2014

Relations

- Effective Date

- 08-Jun-2022

- Refers

EN ISO 5173:2023 - Destructive tests on welds in metallic materials - Bend tests (ISO 5173:2023) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 14893:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Transportable Liquefied Petroleum Gas (LPG) welded steel pressure drums with a capacity between 150 litres and 1 000 litres". This standard covers: This European Standard specifies the minimum requirements for the material, design, construction, workmanship, equipping, inspection and testing at manufacture of transportable, refillable welded steel pressure drums of volumes over 150 l up to and including 1 000 l for Liquefied Petroleum Gases (LPG). Vertical and horizontal cylindrical receptacles are covered.

This European Standard specifies the minimum requirements for the material, design, construction, workmanship, equipping, inspection and testing at manufacture of transportable, refillable welded steel pressure drums of volumes over 150 l up to and including 1 000 l for Liquefied Petroleum Gases (LPG). Vertical and horizontal cylindrical receptacles are covered.

EN 14893:2006 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14893:2006 has the following relationships with other standards: It is inter standard links to EN 14893:2014, EN ISO 5173:2023, EN ISO 17632:2015, EN ISO 14171:2016, EN 837-2:1997, EN 14894:2021, EN ISO 14732:2025, EN 10204:2004, EN ISO 9606-1:2017, EN ISO 15614-1:2017, EN ISO 17637:2016, EN 10028-5:2017, EN ISO 9016:2022, EN ISO 6520-1:2007, EN ISO 17639:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14893:2006 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14893:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.LPG equipment and accessories - Transportable Liquefied Petroleum Gas (LPG) welded steel pressure drums with a capacity between 150 litres and 1 000 litresÉquipements pour GPL et leurs accessoires - Futs a pression métalliques transportables pour GPL d'une capacité comprise entre 150 litres et 1 000 litresFlüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche, geschweißte Druckfässer aus Stahl für Flüssiggas (LPG) mit einem Fassungsraum zwischen 150 Liter und 1 000 LiterTa slovenski standard je istoveten z:EN 14893:2006SIST EN 14893:2007en23.020.30MHNOHQNHPressure vessels, gas cylindersICS:SLOVENSKI

STANDARDSIST EN 14893:200701-januar-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14893July 2006ICS 23.020.30 English VersionLPG equipment and accessories - Transportable LiquefiedPetroleum Gas (LPG) welded steel pressure drums with acapacity between 150 litres and 1 000 litresÉquipements pour GPL et leurs accessoires - Fûts àpression métalliques transportables pour GPL d'unecapacité comprise entre 150 litres et 1 000 litresFlüssiggas-Geräte und Ausrüstungsteile - Ortsbewegliche,geschweißte Druckfässer aus Stahl für Flüssiggas (LPG)mit einem Fassungsraum zwischen 150 Liter und 1 000LiterThis European Standard was approved by CEN on 12 June 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14893:2006: E

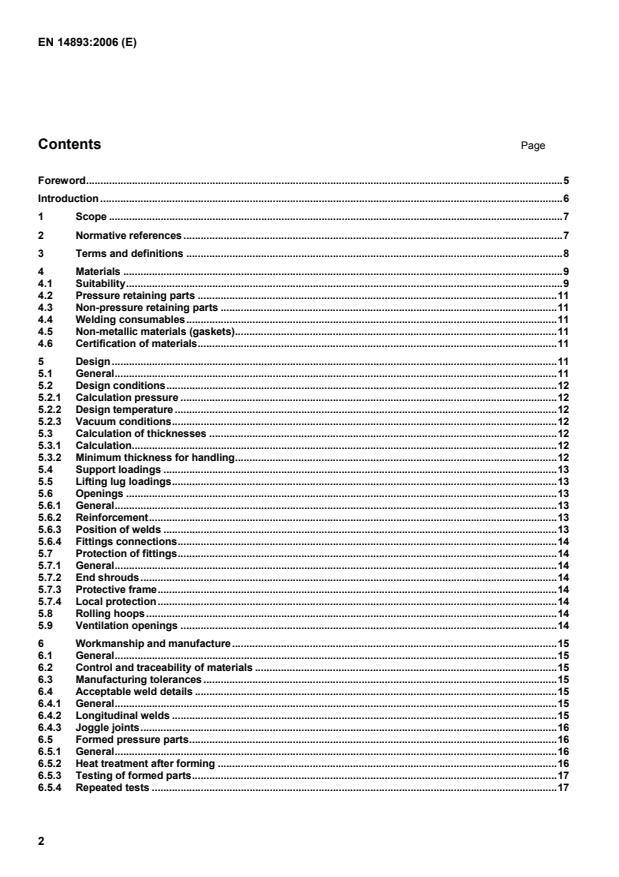

Guidance on selection of material grades.30 Annex B (normative)

Tolerances on drums.31 B.1 Mean external diameter.31

Hydraulic pressure test.34 C.1 Temporary fittings.34 C.2 Pressure gauges.34 C.3 Pressurising agent.34 C.4 Avoidance of shocks.34 C.5 Test procedure.34 Annex D (normative)

Imperfections.35 Annex E (normative)

Design formulae for drums.38 E.1 Allowable stresses.38 E.2 Design formulae.38 E.2.1 General.38 E.2.2 Cylindrical shell calculation.38 E.2.3 Torispherical end calculation.38 E.2.4 Ellipsoidal end calculation.39 E.2.5 Formulae for calculating C.40 E.3 Nozzle re-enforcement.41 E.3.1 General.41 E.3.2 Size of openings.41 E.3.3 Distance between openings or branches.42 E.3.4 Openings and branches.42 E.3.5 Cylindrical shells and dished ends with openings.42 E.3.6 Shell reinforcement.42 E.3.7 Extent of reinforcement.43 E.3.8 Elliptical openings.43 E.3.9 Welded branches.43 E.3.10 Compensating plates.43 E.3.11 Reinforcement — General.43 E.3.12 Reinforcement by pads.43 E.3.13 Reinforcement by branches.44 E.3.14 Branch connections normal to the drum wall.44 Annex F (informative)

Measurement of shell peaking.49 F.1 Profile gauge.49 F.2 Peaking survey.49 Annex G (informative)

Examples of welded joints.52 Bibliography.56

Therefore the standards listed in the normative references and covering basic requirements of the RID/ADR not addressed within the present standard are normative only when the standards themselves are referred to in the RID and/or in the technical annexes of the ADR. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Introduction This European Standard calls for the use of substances and procedures that may be injurious to health if adequate precautions are not taken. It refers only to technical suitability and does not absolve the user from legal obligations relating to health and safety at any stage. It has been assumed in the drafting of this European Standard that the execution of its provisions is entrusted to appropriately qualified and experienced people. NOTE The maximum capacity of drums is 1 000 l.

However the technical requirements of this standard can be applied for the safe design of receptacles larger than 1 000 l although these would not be classed as pressure drums under ADR.

1 Scope This European Standard specifies the minimum requirements for the material, design, construction, workmanship, equipping, inspection and testing at manufacture of transportable, refillable welded steel pressure drums of volumes over 150 l up to and including 1 000 l for Liquefied Petroleum Gases (LPG).

Vertical and horizontal cylindrical receptacles are covered. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 287-1, Qualification test of welders - Fusion welding - Part 1: Steels EN 462-3, Non-destructive testing — Image quality of radiographs — Part 3: Image quality classes for ferrous metals EN 473, Non-destructive testing – Qualification and certification of NDT personnel - General principles. EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment EN 571-1, Non destructive testing - Penetrant testing - Part 1: General principles EN 756, Welding consumables - Solid wires, solid wire-flux and tubular cored electrode-flux combinations for submerged arc welding of non alloy and fine grain steels - Classification EN 758, Welding consumables - Tubular cored electrodes for metal arc welding with and without a gas shield of non alloy and fine grain steels - Classification EN 837-2, Pressure gauges - Part 2: Selection and installation recommendations for pressure gauges EN 875, Destructive tests on welds in metallic materials - Impact tests - Test specimen location, notch orientation and examination EN 876, Destructive tests on welds in metallic materials - Longitudinal tensile test on weld metal in fusion welded joints EN 895, Destructive tests on welds in metallic materials - Transverse tensile test EN 910, Destructive tests on welds in metallic materials - Bend tests EN 970, Non-destructive examination of fusion welds — Visual examination EN 1092-1, Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, PN designated – Part 1: Steel flanges EN 1290, Non-destructive examination of welds - Magnetic particle examination of welds EN 1321, Destructive tests on welds in metallic materials - Macroscopic and microscopic examination of welds EN 1418, Welding personnel – Approval testing of welding operators for fusion welding and resistance weld setters for fully mechanised and automatic welding of metallic materials EN 1435, Non-destructive examination of welds - Radiographic examination of welded joints

The materials of construction shall be suitable for operating within the envisaged temperature range.

If the drum could be subjected to more severe ambient or product temperatures, the design temperature range shall be –40 °C to +50 °C. Guidance on selection of material grades is given in Annex A. Steels shall be grouped in accordance with Table 1

Steels with a specified minimum yield strength ReH < 460 N/mm² a and with analysis in % : C < 0,25 Si < 0,60 Mn < 1,70 Mo < 0,70b S < 0,045 P < 0,045 Cu < 0,40 b Ni < 0,5b Cr < 0,3 (0,4 for castings)b Nb < 0,05 V < 0,12b Ti < 0,05 1.1 Steels with a specified minimum yield strength ReH < 275 N/mm² 1.2 Steels with a specified minimum yield strength 275 N/mm² < ReH < 360 N/mm² 1 1.3 Normalised fine grain steels with a specified minimum yield strength ReH >

360 N/mm²

Thermomechanically treated fine grain steels and cast steels with a specified minimum yield strength ReH > 360N/mm² 2.1 Thermomechanically treated fine grain steels and cast steels with a specified minimum yield strength 360 N/mm² < ReH < 460 N/mm² 2 2.2 Thermomechanically treated fine grain steels and cast steels with a specified minimum yield strength ReH > 460 N/mm² a

In accordance with the specification of the steel product standards, ReH may be replaced by Rp0,2. b

A higher value is accepted provided that Cr + Mo + Ni + Cu + V < 0,75 %. NOTE This table is an extract from CEN ISO/TR 15608:2005

If additional impact testing is required, it shall be carried out in accordance with EN 10045-1 to achieve the impact values specified in 7.8.

All materials shall conform to 7.8.

Steels in sub-group 2.2 shall have a carbon equivalent limited to 0,43%, maximum, when calculated in accordance with EN 10028-5. 4.3 Non-pressure retaining parts All materials used for non-pressure retaining parts shall be compatible with the material of pressure retaining parts. Their capability to be used at low temperature shall be established: by testing in accordance with EN 10045-1 to meet the impact requirements in 7.8, or

by reference to a recognised pressure vessel standard or specification : e.g. EN 13445. 4.4 Welding consumables Welding consumables shall be such that they are capable of giving consistent welds with properties at least equal to those specified for the parent materials of the finished drum.

They shall be selected from EN ISO 2560, EN 756, EN 758, or EN 1668 as appropriate.

Suitability of the chosen consumables shall be demonstrated in accordance with 6.6.3. 4.5 Non-metallic materials (gaskets) All non-metallic materials in contact with LPG shall be compatible with LPG and shall not distort or harden.

They shall also comply with the appropriate requirements of EN 549 including resistance to ozone (where gasket/seal is exposed to atmosphere). 4.6 Certification of materials Pressure retaining parts and non-pressure retaining parts directly welded to the drum shall be provided with material manufacturers’ certificates conforming to EN 10204 certificate type 3.1.

Other parts shall have certificates conforming to EN 10204 certificate type 2.2.

5 Design 5.1 General Drums shall be designed such that they are either; capable of being rolled (see 5.8), or prevented from rolling by the provision of support and lifting arrangements or a protective frame to permit safe handling by mechanical means, transport and use. Drums shall be an assembly of a cylindrical shell and 2 ellipsoidal or torispherical dished ends.

Dished ends convex to pressure (inwardly dished ends) are not permitted. Dished ends shall be made from one piece of plate.

Where necessary to reduce stress concentrations, attachments to the drum shall be welded using a backing plate.

A fully detailed, dimensional drawing shall be produced. 5.2 Design conditions 5.2.1 Calculation pressure The drum shall be designed for a calculation pressure not less than the test pressure of 30 bar. 5.2.2 Design temperature Generally the design temperature range shall be –20 °C to 50 °C.

However, where temperatures lower than –20 °C are envisaged, the manufacturer shall demonstrate that the material from which the pressure containing parts of drum are constructed shall have properties suitable for a range of temperatures –40 °C to 50 °C in accordance with a recognised pressure vessel standard or specification. e.g. EN 13445-2.

5.2.3 Vacuum conditions The drum shall be designed to withstand a minimum internal pressure of 0,1 bar absolute. NOTE 1 This requirement can be demonstrated by meeting the requirements of a recognised pressure vessel standard such as EN 13445-3. NOTE 2 This requirement ensures that the drum will withstand vacuum conditions generated by the product during operation or by normal maintenance. 5.3 Calculation of thicknesses 5.3.1 Calculation Drum thicknesses shall be calculated in accordance with Annex E. 5.3.2 Minimum thickness for handling 5.3.2.1 The thicknesses of the shell and ends calculated from pressure considerations (see 5.2) shall be increased if they are less than the value calculated from the following formula: 5052,oh,=TDe Where:

eh is the minimum thickness of cylindrical shell or dished end to satisfy handling criteria

In no case shall the thickness be less than 2,5 mm. If the materials used for shell and ends are different, the calculation shall be carried out for each component using the appropriate properties. 5.4 Support loadings The drum and supports, if any, shall be designed to withstand the greater of the following;

1) static load when the drum is filled with water. 2) maximum operating mass of the drum subject to 2g acceleration acting vertically down and horizontally, and 1g acting vertically up. Where g is the acceleration due to gravity. This shall be demonstrated by experimental testing or calculation in accordance with a recognised pressure vessel standard or specification, e.g. EN 13445-3. Under the forces defined above, the stresses in the drum and its fastenings shall not exceed the following: a) for general membrane stress in the shell, remote from the supports – the normal design stress as defined in E.1; b) for stresses local to the supports, determined either by experimental analysis or calculation/special analysis – the limits specified in accordance with a recognised pressure vessel standard or specification. e.g. EN 13445-3. 5.5 Lifting lug loadings The lifting lugs shall be designed to accept the maximum loads anticipated during construction and handling in service, applying an acceleration of 2g vertically downwards and an assumed sling angle of 45º.

This shall be demonstrated by experimental testing or calculation in accordance with a recognised pressure vessel standard or specification, e.g. EN 13445-3.

Stress limits as specified in 5.4 apply.

5.6 Openings 5.6.1 General Drums shall be provided with the minimum number of openings required to satisfy the need for fittings to meet service requirements. Openings shall be positioned and/or grouped in such a way that their fittings can be protected as required by 5.7.

For drums not fixed into a protective framework, the openings shall be located in the ends only. 5.6.2 Reinforcement Each opening shall be reinforced by a boss, pad or compensating plate attached by welding and designed in accordance with Annex E. 5.6.3 Position of welds The welds of opening reinforcements shall be clear of longitudinal and circumferential welds and welds of other opening reinforcements by a minimum of 40 mm between the weld edges.

The shrouds shall be attached to the receptacle by welding for at least 50 % of their circumference.

Shrouds shall have holes or cutaways large enough to allow for drainage. 5.7.3 Protective frame Where fitted, the protective frame shall be designed to allow a safe handling of the assembly by mechanical means e.g. crane, forklift truck, 3 points system. The frame shall be a welded steel structure and shall be designed to protect the fittings against damage leading to leakage in service.

This shall be demonstrated by the drop test specified in 12.4 The drum shall be totally or partly inserted and fixed in the frame by adequate means in a vertical or horizontal position. 5.7.4 Local protection In addition to the general protection specified in 5.7.1, 5.7.2 and 5.7.3, fittings shall be provided with local protection against unauthorised access. 5.8 Rolling hoops Horizontal drums which are capable of being rolled (i.e. not fitted with saddle supports or inside a frame) shall be provided with two rolling hoops to protect the pressure envelope from damage during rolling. Where the hoops are fitted to the pressure retaining part of the drum they shall be attached by continuous fillet welds on both sides of the hoop.

The minimum leg length of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...