EN 15002:2006

(Main)Characterization of waste - Preparation of test portions from the laboratory sample

Characterization of waste - Preparation of test portions from the laboratory sample

This European Standard is applicable for the preparation of representative test portions from the laboratory sample that has been taken according to the sampling plan (EN 14899), prior to physical and/or chemical analysis (e.g. preparation of eluates, extractions, digestion and/or analytical determinations) of solid and liquid samples and sludge. It is also applicable for the preparation of test portions from digests and eluates for the subsequent analyses.

This European Standard is intended to find the correct sequence of operations and treatments to be applied to the laboratory sample in order to obtain suitable test portions in compliance with the specific requirements defined in the corresponding analytical procedures.

Charakterisierung von Abfällen - Herstellung von Prüfmengen aus der Laboratoriumsprobe

Diese Europäische Norm ist anwendbar bei der Aufbereitung von repräsentativen Prüfmengen aus der Laboratoriumsprobe, die nach dem Probenahmeplan (prEN 14899) entnommen wurde, vor der physikalischen und/oder chemischen Analyse (z. B. Herstellung von Eluaten, Extraktionen, Aufschlüsse und/oder analytische Bestimmungen) von festen und flüssigen Proben sowie von Schlamm. Sie gilt auch für die Vorbereitung von Prüfmengen aus Aufschlüssen und Eluaten für die anschließende Analyse.

Diese Europäische Norm ist dafür vorgesehen, die richtige Reihenfolge von Arbeitsschritten und Behandlungen herauszufinden, die auf die Laboratoriumsproben anzuwenden sind, um geeignete Prüfmengen unter Beachtung der in den entsprechenden Analysenverfahren festgelegten spezifischen Anforderungen zu erhalten.

Caractérisation des déchets - Préparation de prises d'essai à partir de l'échantillon pour laboratoire

Karakterizacija odpadkov – Priprava preskusnih vzorcev iz laboratorijskega vzorca

General Information

- Status

- Withdrawn

- Publication Date

- 14-Feb-2006

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 292 - Characterization of waste

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Apr-2015

- Completion Date

- 11-Feb-2026

- Directive

- 99/31/EC - Landfill of waste

Relations

- Replaced By

EN 15002:2015 - Characterization of waste - Preparation of test portions from the laboratory sample - Effective Date

- 29-Apr-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 15002:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Characterization of waste - Preparation of test portions from the laboratory sample". This standard covers: This European Standard is applicable for the preparation of representative test portions from the laboratory sample that has been taken according to the sampling plan (EN 14899), prior to physical and/or chemical analysis (e.g. preparation of eluates, extractions, digestion and/or analytical determinations) of solid and liquid samples and sludge. It is also applicable for the preparation of test portions from digests and eluates for the subsequent analyses. This European Standard is intended to find the correct sequence of operations and treatments to be applied to the laboratory sample in order to obtain suitable test portions in compliance with the specific requirements defined in the corresponding analytical procedures.

This European Standard is applicable for the preparation of representative test portions from the laboratory sample that has been taken according to the sampling plan (EN 14899), prior to physical and/or chemical analysis (e.g. preparation of eluates, extractions, digestion and/or analytical determinations) of solid and liquid samples and sludge. It is also applicable for the preparation of test portions from digests and eluates for the subsequent analyses. This European Standard is intended to find the correct sequence of operations and treatments to be applied to the laboratory sample in order to obtain suitable test portions in compliance with the specific requirements defined in the corresponding analytical procedures.

EN 15002:2006 is classified under the following ICS (International Classification for Standards) categories: 13.030.01 - Wastes in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15002:2006 has the following relationships with other standards: It is inter standard links to EN 15002:2015, EN 14399-4:2005, EN 1994-1-1:2004/AC:2009, EN 13477-2:2010, EN ISO 15118-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15002:2006 is associated with the following European legislation: EU Directives/Regulations: 99/31/EC; Standardization Mandates: M/326. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15002:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2006

Karakterizacija odpadkov – Priprava preskusnih vzorcev iz laboratorijskega vzorca

Characterization of waste - Preparation of test portions from the laboratory sample

Charakterisierung von Abfällen - Herstellung von Prüfmengen aus der

Laboratoriumsprobe

Caractérisation des déchets - Préparation de prises d'essai a partir de l'échantillon pour

laboratoire

Ta slovenski standard je istoveten z: EN 15002:2006

ICS:

13.030.01 Odpadki na splošno Wastes in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 15002

NORME EUROPÉENNE

EUROPÄISCHE NORM

February 2006

ICS 13.030.01

English Version

Characterization of waste - Preparation of test portions from the

laboratory sample

Caractérisation des déchets - Préparation de prises d'essai Charakterisierung von Abfällen - Herstellung von

à partir de l'échantillon pour laboratoire Prüfmengen aus der Laboratoriumsprobe

This European Standard was approved by CEN on 30 December 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2006 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15002:2006: E

worldwide for CEN national Members.

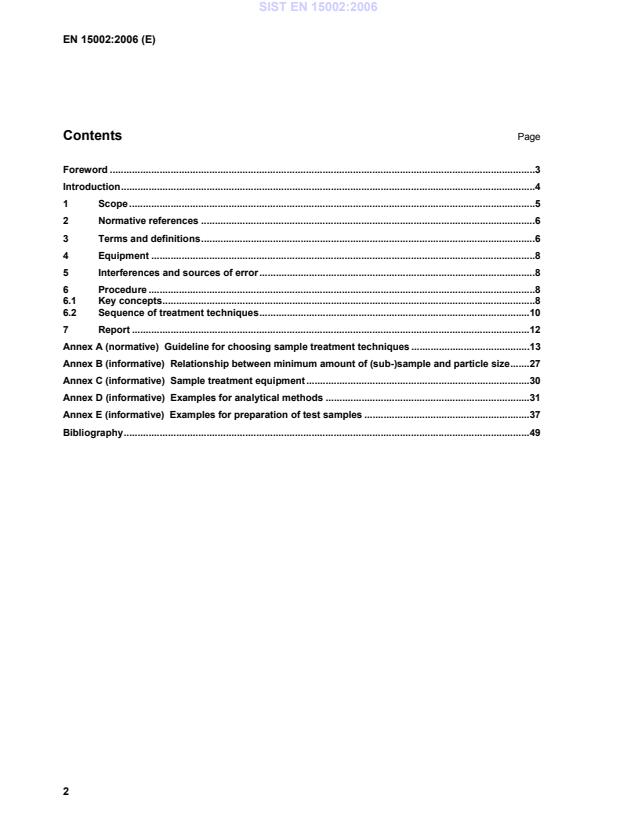

Contents Page

Foreword .3

Introduction.4

1 Scope .5

2 Normative references .6

3 Terms and definitions.6

4 Equipment .8

5 Interferences and sources of error.8

6 Procedure .8

6.1 Key concepts.8

6.2 Sequence of treatment techniques.10

7 Report .12

Annex A (normative) Guideline for choosing sample treatment techniques .13

Annex B (informative) Relationship between minimum amount of (sub-)sample and particle size.27

Annex C (informative) Sample treatment equipment.30

Annex D (informative) Examples for analytical methods .31

Annex E (informative) Examples for preparation of test samples .37

Bibliography.49

Foreword

This European Standard (EN 15002:2006) has been prepared by Technical Committee CEN/TC 292

“Characterisation of waste”, the secretariat of which is held by NEN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by August 2006, and conflicting national standards shall be withdrawn at

the latest by August 2006.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden,

Switzerland and United Kingdom.

Introduction

In laboratory praxis, very often different analytical procedures have to be applied to the laboratory sample that

has been taken according to the sampling plan. For this purpose subsampling has to be applied in a way, that

the different test portions are representative for the original laboratory sample with respect to the compounds

of interest and the specific analytical procedures. The representativity of the laboratory sample and of the test

portions is of major importance to guarantee the quality and accuracy of analytical results. The representativity

of the laboratory sample is specified by the sampling plan. This European Standard specifies the correct

sequence of operations to ensure the representativity of the test portions.

Safety remarks

Anyone dealing with waste and sludge analysis has to be aware of the typical risks of that kind of material

irrespective of the parameter to be determined. Waste and sludge samples may contain hazardous (e.g. toxic,

reactive, flammable and infectious) substances, which can be liable to biological and/or chemical reaction.

Consequently it is recommended that these samples should be handled with special care. The gases that may

be produced by microbiological or chemical activity are potentially flammable and will pressurise sealed

bottles. Bursting bottles are likely to result in hazardous shrapnel, dust and/or aerosol. National regulations

should be followed with respect to all hazards associated with this method.

1 Scope

This European Standard is applicable for the preparation of representative test portions from the laboratory

sample that has been taken according to the sampling plan (EN 14899), prior to physical and/or chemical

analysis (e.g. preparation of eluates, extractions, digestion and/or analytical determinations) of solid and liquid

samples and sludge. It is also applicable for the preparation of test portions from digests and eluates for the

subsequent analyses.

This European Standard is intended to find the correct sequence of operations and treatments to be applied to

the laboratory sample in order to obtain suitable test portions in compliance with the specific requirements

defined in the corresponding analytical procedures.

2 Normative references

The following referenced documents are indispensable for the application of this European Standard. For

dated references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 11465:1993, Soil quality – Determination of dry matter and water content on a mass basis – Gravimetric

method

ISO 14507:2003, Soil quality — Pretreatment of samples for determination of organic contaminants

3 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1

sample

portion of material selected from a larger quantity of material

3.2

laboratory sample

sample sent to or received by the laboratory

NOTE 1 When the laboratory sample is further prepared (reduced) by subdividing, mixing, grinding, or by combinations

of these operations, the result is the test sample. When no preparation of the laboratory sample is required, the laboratory

sample is the test sample. A test portion is removed from the test sample for the performance of the test or for analysis.

NOTE 2 The laboratory sample is the final sample from the point of view of sample collection but it is the initial sample

from the point of view of the laboratory.

NOTE 3 Several laboratory samples may be prepared and sent to different laboratories or to the same laboratory for

different purposes. When sent to the same laboratory, the set is generally considered as a single laboratory sample and is

documented as a single sample.

3.3

test sample; analytical sample

sample, prepared from the laboratory sample, from which test portions are removed for testing or analysis

3.4

test portion; analytical portion

quantity of material of proper size, for measurement of the concentration or other properties of interest,

removed from the test sample

NOTE The test portion may be taken from the laboratory sample directly if no preparation of sample is required (e. g.

with liquids or samples of proper homogeneity, size and fineness), but usually it is taken from the prepared test sample.

3.5

sub-sample

sample obtained by procedures in which the items of interest are randomly distributed in parts of equal or

unequal size

NOTE A sub-sample may be:

a) portion of the sample obtained by selection or division;

b) the final sample of multistage sample-preparation.

3.6

fraction

sample obtained by procedures from the laboratory sample where the properties of interest may be unequally

distributed

NOTE A fraction may consist of metal pieces, stones etc.

3.7

volatile organic compounds

organic compound having a boiling point below 300 °C (at a pressure of 101 kPa)

NOTE This includes volatile aromatic and volatile halogenated hydrocarbons as determined in accordance with

ISO 15009. Some mono- and dichlorophenols, for instance, and naphthalene also belong to this group.

3.8

moderately volatile organic compounds

organic compound having a boiling point above 300 °C (at a pressure of 101 kPa)

NOTE This definition includes:

a) mineral oil;

b) most polycyclic aromatic hydrocarbons (PAH) (see ISO 13877);

c) polychlorobiphenyls (PCB) (see ISO 10382);

d) organochlorine pesticides (see ISO 10382).

3.9

moderately volatile compounds

sum of moderately volatile organic compounds and volatile inorganic compounds (e.g. mercury, arsenic

cadmium, thallium) that can be lost during sample preparation (e.g. heating)

3.10

homogenisation

process of combining of components, particles or layers into a more homogeneous state of the original

samples (in the case of composite samples) or pre-treated fractions of samples in order to ensure equal

distribution of substances in and properties of the sample

3.11

phase separation; fraction separation

process of dividing components, particles or layers if homogenisation of the sample is practically not

applicable and/or the analysis of different fractions or phases are appropriate

3.12

drying

process of removing water from a sample

NOTE For the purpose of test portion preparation, it may be useful to remove just the amount of water that could

interfere with other processes involved (e.g. during crushing or milling). In order to minimise the alteration of the sample

during test portion preparation, removing the total amount of water present in the sample is not necessarily needed.

3.13

particle size reduction

mechanical friction of the sample by milling, grinding, crushing or cutting

3.14

sub-sampling

process of selecting one or more sub-samples from a sample

4 Equipment

For the purpose of preparation of test portions from the laboratory samples appropriate equipment has to be

chosen depending on the procedures selected according to Annex A.

In the selection of the type of treatment techniques, one should keep in mind that each of them has some

potential impact on analytical results, because it can introduce contamination or alter the physical-chemical

properties of the sample.

All glassware and devices that come in contact with the sample shall be made out of a suitable material,

chemically compatible with the sample, selected in order to minimize contamination of samples (e.g. plastic

materials for inorganic elemental analysis, quartz or glass for volatile and organic analytes). Care shall be

taken to ensure a good cleaning, in order to avoid cross-contamination of samples.

An informative list of appropriate equipment for the sample treatment procedures is given in Annex C.

5 Interferences and sources of error

The (sub)-sample shall be re-homogenised after any operation that may have resulted in segregation of

different sized particles.

Care should be taken to avoid loss of material and contamination of the sample via the air, by dust, by the use

of the apparatus (e.g. from the ambient laboratory atmosphere or between samples stored or processed close

to one another).

Three types of contamination could occur from the apparatus:

abrasion;

cross-contamination;

chemical release.

It is recommended to perform treatment of waste material in a separate room used only for this purpose,

especially crushing or sieving.

If the sample has a dust-like consistency or contains (semi)-volatile compounds, part of it may be lost and this

may alter its physical-chemical properties.

6 Procedure

6.1 Key concepts

Preparation of the test portion can be a complex process, because of a number of factors: sample type and its

physical state, amount of laboratory sample, type and number of determinations to be carried out etc. The

prepared test portions shall satisfy the following requirements at the same time:

each test portion shall be as representative as possible of the laboratory sample;

the amount and the physical state (e.g. particle size) of each test portion have to comply with the

requirements of the respective analytical technique;

for each test portion, no losses of and no contamination with respective analytes of interest should

occur.

The preparation of the test portions from the laboratory sample, that has been taken according to the sampling

plan, is related to the requested analytical determinations. This means that, if needed, contact has to be

established among all involved parties such as the sampler, the customer and the analytical laboratory to

achieve the requirements of the standards to be used for the requested determinations.

The preparation of test portions in the laboratory will frequently involve a sequence of operations such as

homogenisation, phase separation, drying, reducing particle size and sub sampling. Specific forms of these

operations are described in A.2 to A.6, respectively. A number of decisions on the specific order of these

operations for a particular laboratory sample have to be made. In some cases, the sequence of operations to

be applied is rather straightforward, but in more complicated cases (e.g. when several determinations with

different requirements have to be performed) it can be critical to choose the right sequence of such operations.

For soil samples more specific procedures are described in ISO 11464 for inorganic parameters or in ISO

14507 for organic parameters.

In order to define the operations to be applied to a laboratory sample to produce one or more representative

test portions, three main steps have to be considered:

Definition of analytical requirements

First, the requirements of analytical procedures of interest shall be defined:

what methods shall be used;

how many test portions are necessary;

quantity and properties of the test portions necessary for each analytical procedure;

preservation requirements (e.g. time frame, temperature, addition of reagents).

NOTE 1 Indicative amounts of test portions and specific requirements of the analytical methods involved are

given in Annex D. It is recommended to prepare at least five times the amounts needed as test portions for the

tests.

Definition of sequence of operations

Then, the sequence of operations shall be defined according to the flow sheet (Figure 1), based on

the properties of the laboratory sample and the requirements of the analytical procedures: each

single operation of this sequence has to be considered like an independent module; available

modules are:

phase/fraction separation;

drying;

particle size reduction;

homogenisation;

sub-sampling.

NOTE 2 For practical reasons it is recommended to group the parameters in a way that test samples with

similar requirements can be prepared for several parameters. The same test sample may be used for different

parameters if it fulfils the necessary requirements.

Frequently, different determinations have to be performed on the laboratory samples. In those cases,

modules have to be combined and/or repeated to obtain sub-samples, finally resulting in different test

portions. In order to define the actual sequence of operations to be applied to a given sample, the

flow sheet (Figure 1) shall be used.

Choice of appropriate procedures

According to the requirements of the respective analytical techniques and the properties of the

sample the appropriate sample treatment technique has to be chosen within each module by

following the instructions of Annex A. Instructions are given in this annex in which case a particular

operation is appropriate to use.

6.2 Sequence of treatment techniques

The flow sheet in Figure 1 describes the procedure to enable decisions on the specific order of treatment

operations for a particular laboratory sample in order to yield in representative test portions. It shall be applied

on the starting laboratory sample and repeated on all sample fractions or sub-samples subsequently obtained

during the preparation, in an iterative cycle until all analytical requirements are fulfilled.

If volatile compounds or moderately volatile compounds are parameters of interest this should be considered

in the sampling plan and may result in separate samples. In case of a single laboratory sample special care

has to be taken in order to avoid losses of the volatile compounds during homogenisation and/or reduction of

particle size. A preliminary sub-sampling without any homogenisation step may be necessary (see A.2.4,

A.6.4) if the representativity of the remaining sample is not substantially altered.

NOTE In special cases sub-sampling without a drying step will not lead to representative sub-samples.

Sampling Plan

Definition of analytical

requirements

Laboratory sample,

sub-sample or sample fraction

Fractions to be further treated as

Assess required characteristics

separate sample(s); results may be

of test portion(s)

combined, if applicable

Phase/fraction

Y

Phase/fraction

separation required?

separation (A.3)

(A.3.1)

N

Y

Drying allowed and

Drying (A.4)

required? (A.4.1)

N

Particle size

Y

Particle size

reduction required and

reduction (A.5)

applicable? (A.5.1)

N

Y

Homogenisation possible?

Homogenisation (A.2)

(A.2.1)

Sub-sampling (A.6)

N

For

One or more

Y

each sub-sample:

test portions

compliance with requirements?

for analysis

N

One or more sub-samples, not yet

complying with requirements

specified in respective analytical

standards, to be further treated

Figure 1 — Flow sheet – sequence of operations

7 Report

The work carried out by the testing laboratory shall be covered by a report which accurately, clearly and

unambiguously presents all relevant information.

Each report shall include at least the following information:

a) name, address and location of any laboratory involved in the preparation of the test portions;

b) unique identification of report (such as serial number) and of each page and total number of pages of the

report;

c) description and identification of the laboratory sample;

d) date of receipt of laboratory sample;

e) reference to this European Standard, i.e. EN 15002;

f) reference to the sampling report; if a sampling report is not available, precise reference shall be made to

the company or persons responsible for the sampling;

g) whole sequence and operating conditions (procedures and apparatuses) actually applied to the laboratory

sample for preparation of test portions;

h) any details not specified in this European Standard or which are optional, and any other factors which

may have affected the results.

For the subsequent performance of the analyses the dates of the preparation of the test portions shall be

available.

Annex A

(normative)

Guideline for choosing sample treatment techniques

A.1 General

The preparation of test samples from a laboratory sample will frequently involve a sequence of operations

such as homogenisation, phase separation, drying, particle size reduction and sub-sampling. Specific forms of

these operations are described in this annex.

The sample treatment techniques prescribed in the analytical standards have to be fulfilled in any case.

A.2 Homogenisation

A.2.1 General information

Before each operation that implies sub-sampling, a homogenisation step is required, in order to guarantee that

all sub-samples or sample fractions have the same properties and composition. The homogenisation

technique to be used is chosen depending on the properties of the sample.

In many cases before homogenisation particle size reduction may be necessary.

If homogenisation of a sample is too difficult or even practically impossible (e.g. if the sample contains pieces

of plastic or metal), its phases shall be separated and treated as they were different samples (see A.3

phase/fraction separation).

A.2.2 Solid samples

A.2.2.1 Manual homogenisation

When to use it

Generally usable;

in cases when mechanical homogenisation could lead to loss of volatile compounds of interest.

When not to use it

For samples that form layers because of the presence of particles of different density;

for samples with particles of such a large size that homogenisation can not be reached by manual mixing.

Procedure

Mix the sample with appropriate tool (e.g. shovel, scoop, pestle and mortar). If there is a risk of losses of

volatile substances the manual homogenisation has to be done very carefully.

A.2.2.2 Mechanical homogenisation

When to use it

Generally usable especially in cases when manual homogenisation is not suitable;

in cases of large sample sizes;

for solid samples containing particles of nearly the same density (e.g. for materials that don't form "layers"

after shaking).

When not to use it

For samples that form layers because of the presence of particles of different density; in this case, if

homogenisation is not possible separate and treat each layer as a different sample (see A.3

phase/fraction separation);

when the apparatus may heat the sample and loss of volatile analytes can occur during this process; in

this case, a manual homogenisation shall be performed.

Procedure

Operate according to the manufactures instructions.

NOTE For small sample sizes it may be also possible to use a ball-mill without balls for homogenisation.

A.2.3 Liquid samples

A.2.3.1 Manual homogenisation

When to use it

For liquid single-phase and visually homogeneous samples (with no visible particles).

When not to use it

For liquid samples where particles or emulsions can be visually identified, including sludge and slurries.

Procedure

Stir with appropriate tool or shake the closed bottle.

A.2.3.2 Mechanical homogenisation

When to use it

For liquid samples, possibly containing small particles like sludge or slurry, that don not settle or form

layers within minutes;

for liquid samples, containing more than one layer when emulsions may be formed.

When not to use it

For liquid samples containing particles that are too large to be homogenised and/or settle within minutes

after homogenisation, forming layers. In this case, homogenisation is not possible, separate and treat

each phase as a different sample (see A.3 phase/fraction separation);

for liquid samples, containing more than one layer when phase separation occurs instantaneously.

Procedure

Different types of mechanical mixers (impeller, magnetic stirrer, propeller, ultrasonic, emulsifier etc.) can be

used, depending on the properties of the sample. The sub-sample shall be taken out as quickly as possible

just after the homogenisation, in order to avoid settling or phase separation.

A.2.4 Homogenisation in case of volatile compounds

If volatile compounds of interest are expected in the sample homogenisation has to be done very carefully and

quickly to avoid losses. If losses cannot be avoided during homogenisation process it may be a solution to

take several non-homogenised sub-samples for analyses of volatile compounds and calculate the statistical

mean as an estimate of the total content. This step should not lead to major alterations of the composition and

the representativity of the remaining sample. A possible procedure for volatile organic compounds is given in

ISO 14507:2003, 8.2.

NOTE The sampling plan should consider the presence of volatile compounds.

A.3 Phase/fraction separation

A.3.1 General information

For heterogeneous and multi-phase samples, depending on their nature and on the determinations of interest,

one or more techniques of phase separation can be applied to obtain two or more different sub-samples that

are to be analysed separately. For samples consisting of different fractions, separation of some fractions may

be necessary (e.g. nuts, bolts, stones). For this reason, the weight of each separated phase (sub-sample)

shall be directly or indirectly measured after the separation, in order to allow a final weighed combination of

different phases analysis results.

The test report shall clearly state the technique(s) used for phase separation, the weight and analytical results

related to all sub-samples obtained from phase separation, as well as the “weighted” results.

A.3.2 Solid – liquid separation

Depending on the nature of the sample and the analytical techniques to be used, one or more of the following

separation techniques can be applied.

A.3.2.1 Settling

When to use it

In every case, provided that complete separation of the two phases can be reached in appropriate time

without alterations of analytes of interest.

NOTE 1 Settling with appropriate cooling may be the method of choice, if volatile compounds are to be analysed in

the sample.

When not to use it

When the properties of the sample don’t allow a good separation of the phases in a reasonable time;

if it is necessary to recover the maximum amount possible of liquid phase, or when it’s necessary to

obtain a solid phase that is as dry as possible, because normally a certain amount of water is still present

in the settled phase;

when biological or chemical alterations are expected during settling time.

NOTE 2 A reasonable time could be a maximum time of two hours.

Procedure

Let the bottles stand undisturbed until the phases can be separated with an appropriate technique.

A.3.2.2 Filtration

When to use it

When other solid-liquid separation techniques fail or are practically not applicable;

when the separation should be performed in short time;

when the liquid phase shall be separated as quantitatively as possible;

when prescribed by the analytical method (e.g. DOC, AOX).

When not to use it

When the properties of the sample don’t allow a good filtration in a reasonable time;

when it can alter the properties of interest of the sample;

in case of adsorption to the filter of analytes of interest.

NOTE A reasonable time could be a maximum time of one hour.

Don’t use vacuum techniques when volatile compounds of interest are supposed to be in the sample.

Procedure

Filter the sample with appropriate filtration technique and equipment.

Depending on the type of sample and the analytes of interest the appropriate technique (e.g. pressure

filtration, atmospheric pressure filtration, vacuum filtration), the appropriate filter material (e.g. glass-fibre,

paper filter, membrane filter) and porosity of the filter have to be chosen. Information on the appropriate

technique and filter material shall be taken from the corresponding analytical standards.

A.3.2.3 Centrifugation

When to use it

When other solid-liquid separation techniques fail or are practically not applicable: for example, when

settling takes too long and filtration could lead to chemical alterations or adsorption.

When not to use it

When the properties of the sample don’t allow a good separation in a reasonable time;

when loss of volatile compounds is to be considered.

NOTE 1 A reasonable time could be a maximum time of 30 min.

NOTE 2 Appropriate cooling may diminish the loss of volatile compounds.

Procedure

Apply proper centrifugation conditions. If the first centrifugation does not lead to a good phase separation,

centrifugation can be applied for longer time and/or higher acceleration; if centrifugation appears to be not

enough effective, filtration can be applied on the whole sample or just on the liquid suspension that is still

present after centrifugation.

A.3.3 Liquid – liquid separation

A.3.3.1 Separation with separating funnel

When to use it

In most cases, provided that complete separation of the two phases can be reached in appropriate time

without alterations of analytes of interest.

When not to use it

When losses e.g. by adsorption may occur;

when phases do not separate in reasonable time.

NOTE 1 A reasonable time could be a maximum time of two hours.

Procedure

Fill into a separating funnel and let separate the phases.

NOTE 2 In some cases addition of salts or acids may accelerate the separation process provided that no interference

with any analytes of interest will occur.

A.3.3.2 Centrifugation

When to use it

When other liquid-liquid separation techniques fail or are practically not applicable.

When not to use it

When the properties of the sample don’t allow a good separation;

when loss of volatile compounds is to be considered.

NOTE Appropriate cooling may diminish the loss of volatile compounds.

Procedure

Apply proper centrifugation conditions. If the first centrifugation does not lead to a good phase separation,

centrifugation can be applied for longer time and/or higher acceleration.

A.3.4 Solid – solid separation; separation into different fractions

In cases when the sample is constituted by different macroscopic phases, a separation of such phases can be

performed, especially if this can make subsequent particle size reduction, homogenisation and sub-sampling

easier. In cases of visible heterogeneity of separable fractions (e.g. metal pieces, stones) the separation of

different fractions may be necessary.

A.3.4.1 Manual separation

When to use it

When several fractions, e.g. bolts, nuts, stones, can be distinguished.

When not to use it

When contamination or losses of analytes of interest may occur.

Procedure

Manually select macroscopic pieces of different nature and store them in separate containers, either by hand

(with protective gloves) or by using appropriate tools (e.g. tweezers, magnet).

A.3.4.2 Sieving

When to use it

When separation of fractions of different particle size is necessary;

for checking the grain size of the sample or the particle size distribution.

When not to use it

When contamination or losses of analytes of interest may occur.

Procedure

Sieve the sample by shaking either by hand or apparatus through sieves with appropriate mesh size and

material.

A.4 Drying

A.4.1 General information

Depending on the nature of the sample and the specific requirements of the test portion, a drying step might

be needed during sample treatment for test sample preparation. For the purpose of this European Standard,

drying is just used to remove the amount of water that could interfere with test sample preparation (e.g. during

crushing or milling). For the determination of water content a separate sub-sample may be necessary.

Drying is very likely to introduce analytical errors for volatile compounds, and should be avoided when not

strictly required. If a (sub-)sample for volatile compounds determination is to be dried, the actual drying

technique shall be selected in order to minimise losses of volatile compounds. The test report shall clearly

state the technique(s) used for drying, along with the weight of sub-sample(s) before and after each drying

step.

It is likely that a certain drying technique is not applicable for all requested determinations. In such cases,

different sub-samples shall be dried in different ways, choosing the appropriate sequence of techniques for

each one.

The drying time will depend on the technique chosen, the thickness of the layer of the sample, the nature of

the sample, moisture content of the sample and of the air and the rate of ventilation.

The “grade of dryness” that shall be reached with the drying step depends on the subsequent treatments to be

applied to the sample. Typically, it is not necessary to wait until constant weight: e.g. the sample shall be just

dried enough to make crushing, grinding etc. possible.

A.4.2 Procedures

A.4.2.1 Air drying at room temperature

When to use it

In every case where drying can be reached in appropriate time without alterations of analytes of interest;

if loss of volatile compounds of interest does not occur at room temperature.

When not to use it

When time is critical, and the properties of the sample don’t allow a good drying in a reasonable time at

room temperature, and a higher temperature drying step can be safely applied;

when degradation may occur, e.g. due to light, biological activity;

when contamination or reactions with air may occur.

NOTE A reasonable time could be a maximum time of one week.

Procedure

Spread the sample on the trays in a thin layer and allow it to get dry enough. Care shall be taken in order to

minimise possible contamination e.g. by dust and exposition to direct sunlight or light sources. The use of a

desiccator may accelerate the drying process for small amounts of (sub-)samples.

A.4.2.2 Oven drying at 40 °C

When to use it

If loss of volatile compounds of interest does not occur at 40 °C;

when time is critical, and the properties of the sample don’t allow a good drying in a reasonable time at

room temperature.

When not to use it

When the properties of the sample don’t allow a good drying in a reasonable time at this temperature, and

a higher temperature drying step can be safely applied;

when losses of volatile compounds of interest is suspected even at this temperature.

NOTE A reasonable time could be a maximum time of one week.

Procedure

Spread the sample on the trays in a thin layer and allow it to get dry in the oven at 40 °C. Air renewal may

accelerate the drying process, provided that it does not cause loss of dust-like particles.

NOTE Oven drying at other temperatures may be used if they fit with analytical procedures to be applied.

A.4.2.3 Oven drying at 105 °C

When to use it

In cases when loss of volatile analytes is not likely to occur at 105 °C;

on sub-sample for which volatile compounds are not of interest.

When not to use it

When losses of volatile compounds of interest is suspected at this temperature;

in cases auto-ignition can be expected.

NOTE 1 A reasonable time could be a maximum time of one day.

NOTE 2 Losses of most organic compounds and even some inorganic constituents may occur.

Procedure

Spread the sample on the trays in a thin layer and allow it to get dry in the oven at 105 °C. Air renewal may

accelerate the drying process, provided that it does not cause loss of dust-like particles.

A.4.2.4 Freeze-drying

When to use it

In cases when loss of volatile analytes is likely to occur with other procedures.

When not to use it

When another simpler drying technique can be safely applied;

when vacuum can lead to loss of analytes of interest.

Procedure

Operate according to the freeze-drier manufacturer’s instructions.

A.4.2.5 Chemical drying

This procedure is only applicable to sub-samples for determination of organic compounds. Chemical drying is

a process where water free inorganic salts (e.g. sodium sulphate and magnesium silicate) are added to the

sample in order to bind its water.

When to use it

In cases when loss of volatile analytes is likely to occur.

When not to use it

When another simpler drying technique can be safely applied;

when the addition of salts can lead to alterations of analytes or properties of interest;

for samples with high water content (e.g. sludges).

Procedure

Mix thoroughly the weighed (sub-)sample with the weighed chosen salt mixture preferably in a cool

environment and closed bottle. An adequate drying time should be ensured (e.g. 12 h to 16 h). The amount of

salts added shall be taken into account in the calculations of concentrations. A procedure for drying samples

containing volatile organic compounds is given in ISO 14507:2003, 8.3.

A.5 Particle size reduction

A.5.1 General information

In order to achieve a homogeneous and representative test portion, one or more particle-size reduction steps

might be needed. The choice of the technique to be used depends strongly on the nature of the sample and

on the particle size needed.

Typically, particle-size reduction is a multi-step operation that implies the use of a sequence of different

techniques; in some cases, it might be necessary to repeat a step until the sample reaches the requested

particle size.

Particle-size reduction is a critical step in sample preparation because of potential loss of volatile compounds

due to heating, because of loss of dust-like material and because of contamination coming from the

equipment itself or from other samples. Care shall be taken in selecting the appropriate equipment and

keeping it clean.

The test report shall clearly state the technique(s) and operating conditions used for particle-size reduction.

Non-crushable fractions shall be separated (according to A.3.4), weighed and, if needed, analysed as

separate sub-samples.

A.5.2 Procedures

A.5.2.1 Crushing/grinding

When to use it

When representative sub-samples cannot be taken because of large particle size;

when the particle size of the sample is larger than the allowed inlet particle size for the milling or grinding

equipment;

when the analytical requirements demand a particle size in the mm order of magnitude.

When not to use it

When not applicable because of the nature of the sample (e.g. soft materials, paste-like materials);

when contamination or losses of compounds of interest may occur by the equipment.

Procedure

Break large pieces of the sample with a hammer and/or crush the sample with appropriate apparatus (e.g.

shredder, jaw-crusher) according to the manufacturer’s instructions to the desired particle size. Pieces that are

not crushable can be cut with other kinds of manual or mechanical devices and recombined afterwards.

A.5.2.2 Freeze crushing

When to use it

When moderately volatile organic compounds are the compounds of interest and particle size reduction is

necessary;

when the sample has a plastic or paste-like consistency;

when representative sub-samples cannot be taken because of large particle size;

when the particle size of the sample is larger than the allowed inlet particle size for the milling or grinding

equipment;

when the analytical requirements demand a particle size in the mm order of magnitude.

When not to use it

When contamination or losses of compounds of interest may occur by the equipment.

Procedure

Wrap the sample in a polyethylene container. Fill a Dewar vessel with sufficient liquid nitrogen and immerse

the wrapped sample in the liquid nitrogen. Allow the container to stand until the liquid nitrogen no longer boils

vigorously. Cool for approximately 10 min. After complete cooling, retrieve the container from the liquid

nitrogen and break large pieces of the sample with a hammer and/or crush the sample with appropriate

apparatus (e.g. shredder, jaw-crusher) according to the manufacturer’s instructions to the desired particle size.

A.5.2.3 Milling

When to use it

When representative sub-samples cannot be taken because of large particle size;

when the requested particle size is less than 1 mm.

When not to use it

When the initial particle size is too coarse: a crushing step is required in these cases;

when losses of volatile compounds or contamination with compounds of interest may occur by the

equipment;

when not applicable, because of the nature of the sample (e.g. soft materials, paste-like materials).

Procedure

Mill the sample according to the mill’s manufacturers instructions until it reaches the desired particle size; in

order to prevent losses of volatile analytes, care shall be taken to avoid excessive heating of the sample

during milling: a sequence of short and low-speed millings is to be preferred to a long and/or high-speed

treatment; it is necessary to let the equipment cool down between each milling operation and the subsequent

one. The use of a freeze-head mill can minimise the loss of volatile compounds, if this is suspected.

NOTE If the sample has a plastic or paste-like consistency, freezing it down to low temperatures (e.g. –20 °C to

–30 °C) can make it ea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...