EN 1247:2004

(Main)Foundry machinery - Safety requirements for ladles, pouring equipment, centrifugal casting machines, continuous and semi continous casting machines

Foundry machinery - Safety requirements for ladles, pouring equipment, centrifugal casting machines, continuous and semi continous casting machines

This document specifies requirements to be met by the manufacturer for the foreseeable significant hazards due to design, construction and installation, during commissioning, operation, maintenance, and decommissioning of the following machines and equipment which are used directly and indirectly for the manufacture of castings:

- Ladles;

- Pouring equipment;

- Centrifugal casting machines for production of tubes (only machines with horizontal or oblique axis of rotation);

- Continuous and semi continuous casting machines for non-ferrous metals.

This document specifies the safety requirements in addressing the following items:- controls; - protection against:

-mechanical hazards, movement of machines and material, ejection of parts, material, liquids and gases, implosion, structural instability;

- electric hazards;- explosion, fire, scalds, contact with hot parts (burns), gases and flames; - noise and vibration;- thermal radiation;- harmful by-products, poisoning, pollution of operators air;- impact;- deterioration of worker's health;- shearing;- crushing;- maintenance, provision for warning systems. It is assumed that

- normal operation of equipment falling within this scope may involve the intervention of personnel;

- machines are operated by skilled and adequately trained persons;

- machines are used with adequate workplace lighting conforming to local regulations, or to EN 12464-1.

This document does not specify the safety requirements for machines in combination and for ancillary plant, melting, holding, drying and/or heating equipment, crane installations, winches, conveyors or handling systems which could be an integral part of the above equipment, or ladles which are specific to steelworks or ladles forming part of a crane or ladles for pouring by a casting machine or vessels used for molten metal transport on public highway, or continuous or semi continuous casting equipment which is specific to steelworks, or ladles which are carried by hand.

Gießereimaschinen - Sicherheitsanforderungen für Pfannen, Gießeinrichtungen, Schleudergießmaschinen kontinuierliche und halbkontinuierliche Stranggießmaschinen

Diese Norm legt vom Hersteller zu beachtende Anforderungen für die vorhersehbaren signifikanten Gefährdungen aufgrund Konstruktion, Aufbau und Installation, während Inbetriebnahme, Betrieb, Wartung und Außerbetriebnahme der folgenden Maschinen und Einrichtungen, die direkt oder indirekt für die Herstellung von Gussteilen verwendet werden, fest:

Pfannen;

Gießeinrichtungen;

Schleudergießmaschinen zur Herstellung von Rohren (nur Maschinen mit horizontaler oder geneigter Rotationsachse);

kontinuierliche und halbkontinuierliche Stranggießmaschinen für NE-Metalle.

Diese Norm legt die Sicherheitsanforderungen bezüglich der folgenden Punkte fest:

Steuerungen;

Schutz gegen:

mechanische Gefährdungen, Bewegung von Maschinen und Material, Herausschleudern von Teilen, Material, Flüssigkeiten und Gase, Implosion, bauliche Instabilität;

elektrische Gefährdungen;

Explosion, Feuer, Verbrühungen, Berührung heißer Teile (Verbrennungen), Gase und Flammen;

Lärm und Schwingungen;

thermische Strahlung;

gesundheitsschädliche Nebenprodukte, Vergiftung, Verschmutzung der Atemluft des Bedieners;

Stoß;

Beeinträchtigung der Gesundheit des Arbeiters;

Scheren;

Quetschen;

Wartung, Bereitstellung von Warnsystemen.

Es wird vorausgesetzt, dass

der normale Betrieb der Ausrüstung, die unter diesen Anwendungsbereich fällt, den Eingriff von Personal einschließen kann;

die Maschinen von kompetenten und entsprechend geschulten Mitarbeitern betrieben werden;

die Maschinen bei entsprechender Arbeitsplatzbeleuchtung gemäß lokaler Bestimmungen oder gemäß EN 12464-1 genutzt werden.

Die vorliegende Norm legt keine Sicherheitsanforderungen fest für verkettete Maschinen und Zusatzeinrichtungen, Anlagen zum Schmelzen, Warmhalten, Trocknen und/oder Heizen, Krananlagen, Winden, Förderer oder Handhabungssysteme, die Bestandteil der oben genannten Ausrüstung sein können, oder stahlwerkspezifische Pfannen oder Pfannen als Teil eines Krans oder Pfannen einer Gießmaschine oder Behälte

Machines de fonderie - Prescriptions de sécurité concernant les poches, les matériels de coulée, les machines à couler par centrifugation, les machines à couler en continu ou en semi-continu

La présente norme européenne définit les risques significatifs prévisibles causés par la conception, la construction et l'installation, pendant la mise en service, le fonctionnement et la maintenance des machines et installations utilisées pour la fabrication des pièces moulées en moules perdus ou en coquilles, à savoir: - poches, - matériels de coulée, - machines à couler par centrifugation, - machines à couler en continu ou en semi-continu. Elle précise les exigences spécifiques de sécurité que doit respecter le fabricant pour éviter ces risques.

Livarski stroji – Varnostne zahteve za livne ponve, opremo za vlivanje, stroje za centrifugalno vlivanje ter stroje za kontinuirno in polkontinuirno vlivanje

General Information

- Status

- Withdrawn

- Publication Date

- 10-Aug-2004

- Withdrawal Date

- 13-Jul-2010

- Technical Committee

- CEN/TC 202 - Foundry machinery

- Drafting Committee

- CEN/TC 202/WG 3 - Other pouring and casting processes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Jul-2010

- Completion Date

- 14-Jul-2010

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 24-Apr-2010

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 1247:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Foundry machinery - Safety requirements for ladles, pouring equipment, centrifugal casting machines, continuous and semi continous casting machines". This standard covers: This document specifies requirements to be met by the manufacturer for the foreseeable significant hazards due to design, construction and installation, during commissioning, operation, maintenance, and decommissioning of the following machines and equipment which are used directly and indirectly for the manufacture of castings: - Ladles; - Pouring equipment; - Centrifugal casting machines for production of tubes (only machines with horizontal or oblique axis of rotation); - Continuous and semi continuous casting machines for non-ferrous metals. This document specifies the safety requirements in addressing the following items:- controls; - protection against: -mechanical hazards, movement of machines and material, ejection of parts, material, liquids and gases, implosion, structural instability; - electric hazards;- explosion, fire, scalds, contact with hot parts (burns), gases and flames; - noise and vibration;- thermal radiation;- harmful by-products, poisoning, pollution of operators air;- impact;- deterioration of worker's health;- shearing;- crushing;- maintenance, provision for warning systems. It is assumed that - normal operation of equipment falling within this scope may involve the intervention of personnel; - machines are operated by skilled and adequately trained persons; - machines are used with adequate workplace lighting conforming to local regulations, or to EN 12464-1. This document does not specify the safety requirements for machines in combination and for ancillary plant, melting, holding, drying and/or heating equipment, crane installations, winches, conveyors or handling systems which could be an integral part of the above equipment, or ladles which are specific to steelworks or ladles forming part of a crane or ladles for pouring by a casting machine or vessels used for molten metal transport on public highway, or continuous or semi continuous casting equipment which is specific to steelworks, or ladles which are carried by hand.

This document specifies requirements to be met by the manufacturer for the foreseeable significant hazards due to design, construction and installation, during commissioning, operation, maintenance, and decommissioning of the following machines and equipment which are used directly and indirectly for the manufacture of castings: - Ladles; - Pouring equipment; - Centrifugal casting machines for production of tubes (only machines with horizontal or oblique axis of rotation); - Continuous and semi continuous casting machines for non-ferrous metals. This document specifies the safety requirements in addressing the following items:- controls; - protection against: -mechanical hazards, movement of machines and material, ejection of parts, material, liquids and gases, implosion, structural instability; - electric hazards;- explosion, fire, scalds, contact with hot parts (burns), gases and flames; - noise and vibration;- thermal radiation;- harmful by-products, poisoning, pollution of operators air;- impact;- deterioration of worker's health;- shearing;- crushing;- maintenance, provision for warning systems. It is assumed that - normal operation of equipment falling within this scope may involve the intervention of personnel; - machines are operated by skilled and adequately trained persons; - machines are used with adequate workplace lighting conforming to local regulations, or to EN 12464-1. This document does not specify the safety requirements for machines in combination and for ancillary plant, melting, holding, drying and/or heating equipment, crane installations, winches, conveyors or handling systems which could be an integral part of the above equipment, or ladles which are specific to steelworks or ladles forming part of a crane or ladles for pouring by a casting machine or vessels used for molten metal transport on public highway, or continuous or semi continuous casting equipment which is specific to steelworks, or ladles which are carried by hand.

EN 1247:2004 is classified under the following ICS (International Classification for Standards) categories: 25.120.30 - Moulding equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1247:2004 has the following relationships with other standards: It is inter standard links to EN 1247:2004+A1:2010, EN 13757-1:2002, EN 1247:2004/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1247:2004 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1247:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2004

Livarski stroji – Varnostne zahteve za livne ponve, opremo za vlivanje, stroje za

centrifugalno vlivanje ter stroje za kontinuirno in polkontinuirno vlivanje

Foundry machinery - Safety requirements for ladles, pouring equipment, centrifugal

casting machines, continuous and semi continous casting machines

Gießereimaschinen - Sicherheitsanforderungen für Pfannen, Gießeinrichtungen,

Schleudergießmaschinen kontinuierliche und halbkontinuierliche Stranggießmaschinen

Machines de fonderie - Prescriptions de sécurité concernant les poches, les matériels de

coulée, les machines a couler par centrifugation, les machines a couler en continu ou en

semi-continu

Ta slovenski standard je istoveten z: EN 1247:2004

ICS:

25.120.30 Livarska oprema Moulding equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 1247

NORME EUROPÉENNE

EUROPÄISCHE NORM

August 2004

ICS 25.120.30

English version

Foundry machinery - Safety requirements for ladles, pouring

equipment, centrifugal casting machines, continuous and semi

continous casting machines

Machines de fonderie - Prescriptions de sécurité Gießereimaschinen - Sicherheitsanforderungen für

concernant les poches, les matériels de coulée, les Gießpfannen, Gießeinrichtungen,

machines à couler par centrifugation, les machines à couler Schleudergießmaschinen, kontinuierliche und

en continu ou en semi-continu halbkontinuierliche Stranggießmaschinen

This European Standard was approved by CEN on 17 December 2003.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1247:2004: E

worldwide for CEN national Members.

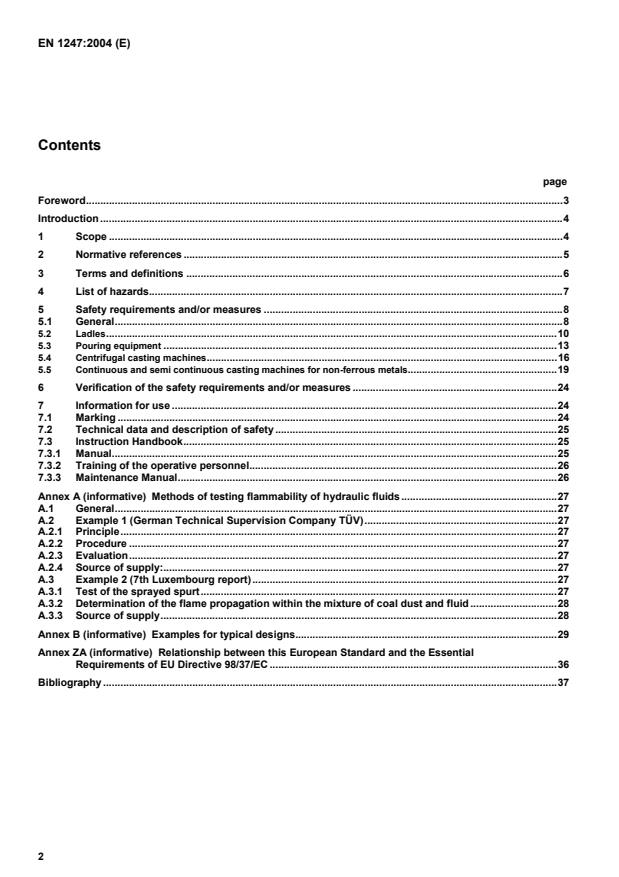

Contents

page

Foreword.3

Introduction .4

1 Scope .4

2 Normative references .5

3 Terms and definitions .6

4 List of hazards.7

5 Safety requirements and/or measures .8

5.1 General.8

5.2 Ladles.10

5.3 Pouring equipment .13

5.4 Centrifugal casting machines.16

5.5 Continuous and semi continuous casting machines for non-ferrous metals.19

6 Verification of the safety requirements and/or measures .24

7 Information for use .24

7.1 Marking .24

7.2 Technical data and description of safety .25

7.3 Instruction Handbook.25

7.3.1 Manual.25

7.3.2 Training of the operative personnel.26

7.3.3 Maintenance Manual.26

Annex A (informative) Methods of testing flammability of hydraulic fluids.27

A.1 General.27

A.2 Example 1 (German Technical Supervision Company TÜV).27

A.2.1 Principle.27

A.2.2 Procedure .27

A.2.3 Evaluation.27

A.2.4 Source of supply:.27

A.3 Example 2 (7th Luxembourg report).27

A.3.1 Test of the sprayed spurt.27

A.3.2 Determination of the flame propagation within the mixture of coal dust and fluid .28

A.3.3 Source of supply.28

Annex B (informative) Examples for typical designs.29

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 98/37/EC .36

Bibliography .37

Foreword

This document (EN 1247:2004) has been prepared by Technical Committee CEN/TC 202 “Safety requirements of

foundry machinery”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by February 2005, and conflicting national standards shall be withdrawn at the latest

by February 2005.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following

countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Cyprus, Denmark,

Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

Introduction

This document is a type C standard as stated in EN 1070.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are

indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or type B standards, the

provisions of this type C standard take precedence over the provisions of the other standards, for machines that

have been designed and built according to the provisions of this type C standard.

This document covers: the equipment concerned, the hazards and hazardous situation as well as all events during

construction, operation and maintenance normally foreseeable.

1 Scope

This document specifies requirements to be met by the manufacturer for the foreseeable significant hazards due to

design, construction and installation, during commissioning, operation, maintenance, and decommissioning of the

following machines and equipment which are used directly and indirectly for the manufacture of castings:

Ladles;

Pouring equipment;

Centrifugal casting machines for production of tubes (only machines with horizontal or oblique axis of rotation);

Continuous and semi continuous casting machines for non-ferrous metals.

This document specifies the safety requirements in addressing the following items:

controls;

protection against:

mechanical hazards, movement of machines and material, ejection of parts, material, liquids and gases,

implosion, structural instability;

electric hazards;

explosion, fire, scalds, contact with hot parts (burns), gases and flames;

noise and vibration;

thermal radiation;

harmful by-products, poisoning, pollution of operators air;

impact;

deterioration of worker’s health;

shearing;

crushing;

maintenance, provision for warning systems.

It is assumed that

normal operation of equipment falling within this scope may involve the intervention of personnel;

machines are operated by skilled and adequately trained persons;

machines are used with adequate workplace lighting conforming to local regulations, or to EN 12464-1.

This document does not specify the safety requirements for machines in combination and for ancillary plant,

melting, holding, drying and/or heating equipment, crane installations, winches, conveyors or handling systems

which could be an integral part of the above equipment, or ladles which are specific to steelworks or ladles forming

part of a crane or ladles for pouring by a casting machine or vessels used for molten metal transport on public

highway, or continuous or semi continuous casting equipment which is specific to steelworks, or ladles which are

carried by hand.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body.

EN 418:1992, Safety of machinery — Emergency stop equipment functional aspects — Principles for design.

EN 626-1:1994, Safety of machinery — Reduction of risks to health from hazardous substances emitted by

machinery — Part 1: Principles and specifications for machinery manufacturers.

EN 626-2:1996, Safety of machinery — Reduction of risks to health from hazardous substances emitted by

machinery — Part 2: Methodology leading to verification procedures.

EN 746-2:1997, Industrial thermoprocessing equipment — Part 2: Safety requirements for combustion and fuel

handling systems.

EN 953:1997, Safety of machinery — Guards — General requirements for the design and construction of fixed and

movable guards.

EN 954-1:1996, Safety of machinery — Safety related parts of control systems — Part 1: General principles for

design.

EN 1037:1995, Safety of machinery — Prevention of unexpected start-up.

EN 1070:1998, Safety of machinery — Terminology.

EN 1088:1995, Safety of machinery — Interlocking devices associated with guards — Principles for design and

selection.

EN 1265:1999, Noise test codes for foundry machines and equipment.

EN 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

(IEC 60204-1:1997).

EN 60519-1:1993, Safety in electroheat installations; Part 1: General requirements (IEC 60519-1:1984).

EN 61310-1:1995, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual,

auditory and tactile signals (IEC 61310-1:1995).

EN 61310-2:1995, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for marking

(IEC 61310-2:1995).

EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment

(ISO 4871:1996).

EN ISO 11688-1/AC:1998, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995).

EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic

terminology, methodology (ISO 12100-1:2003).

EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical

principles and specifications (ISO 12100-2:2003).

EN ISO 14122-1:2001, Safety of machinery — Permanent means of access to machinery — Part 1: Choice of a

fixed means of access between two levels (ISO 14122-1:2001).

EN ISO 14122-2:2001, Safety of machinery — Permanent means of access to machinery — Part 2: Working

platforms and walkways (ISO 14122-2:2001).

EN ISO 14122-3:2001, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2001).

prEN ISO 14122-4:2002, Safety of Machinery — Permanent means of access to machinery — Part 4: Fixed

ladders (ISO/DIS 14122-4:1996).

ISO 7745:1989, Hydraulic fluid power — fire-resistant (FR) fluids — Guidelines for use.

CENELEC R044-001, 1999, Safety of machinery — Guidance and recommendations for the avoidance of hazards

due to static electricity.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1070:1998 and the following apply.

3.1

Ladle

tiltable vessel with or without hanger with or without refractory lining designed to contain, transport and discharge

molten material (see Annex B, Figures B.1 and B.2).

NOTE The tilting movement is often achieved by power driven tilting drives. Sometimes ladles are bottom discharging. In

this case discharging is achieved by moving a stopper rod (see Annex B, Figure B.2) or a hydraulically or pneumatically driven

bottom slide gate nozzle. Ladles are usually transported by hoists and have their own hanger which is integral to the ladle.

Sometimes ladles are transported by floor based trucks or fork lift trucks.

3.2

tundish

refractory lined vessel with a discharge at its bottom which may be interposed between the ladle and the mould in

teeming

3.3

pouring equipment

mechanically or electrically driven device (see Annex B, Figure B.6) which stores and delivers molten metal to the

mould as part of an automatic or semi automatic integrated casting plant

NOTE: This equipment consists of a vessel, heated or unheated, with or without a metering device, for delivery of molten

metal to the mould by gravity, or by applying air or inert gas pressure or vacuum onto the surface of the molten metal in the

vessel. Heated vessels are also called furnaces.

3.4

centrifugal casting machine

machine to manufacture tubes by centrifugal means. The axis of the tube coincides with the axis of rotation and

where the thickness of the tube is determined by the dimensions of the mould and the amount of metal cast (see

Annex B, Figure B.7). The said axis may be horizontal or oblique (vertical axis of rotation is excluded, see Clause

1)

3.5

continuous and semi continuous casting machine

machine which provides a regular or intermittent supply of liquid metal (for this document: non-ferrous metal only,

see Clause 1) to a mould, from where the solidified product leaves under gravity or by powered means

Depending upon the direction in which the bar leaves the tundish distinction is made between vertical and

horizontal casting. Additionally, distinction is made between continuous and semi continuous casting as to whether

the bar is cast without interruption and cut with a flying saw or is stopped after reaching a determined length and is

then completely removed from the equipment.

In the non-ferrous metals sector the semi continuous casting process is mainly used.

3.6

metering

monitoring the amount of liquid metal

3.7

breakthrough

refractory lining of the pouring equipment is penetrated by molten metal

3.8

stripping/ejection of castings

removal of the centrifugal casting from the mould after solidification

3.9

self-locking gear

a gearbox meets the requirements for self-locking, if the following test gives evidence: the ladle is bottom-placed

and removed from the hook; the hanger is moved to a inclined position at approx. 45 degree . The hanger shall be

kept in this position by the gearbox. This requirement for self-locking applies for vibration-less conditions only

3.10

refractories

material being resistant to high temperatures with a high refractoriness under load for the bricking up and lining of

pouring equipment and ladles

4 List of hazards

Hazardous situations are those where the risk of being injured through hazardous movements (e. g., squeeze or

shear points) or sources of hazard exists (e. g., hazardous materials, conduction and radiation of heat, ejection of

molten or very hot metal, explosion, ignition of hydraulic or lubrication fluids, unexpected discharge of molten

metal).

A parameter for the level of safety measures to be applied is the risk of accident to be expected, the extent of which

depends upon the highest foreseeable degree of severity and effect as well as the probability of an injury, e. g.,

exposure to risk (frequency of intervention or access or duration of stay in a danger zone). Movable safeguards or

facilities with guarding functions in danger zones with fixed cycle intervention or access (e. g., during filling with

molten metal or periodical manual cleaning or trouble shooting) require a special degree of safety against

unexpected start up or dangerous movements, as well as against hazardous sources and failure of relevant

safeguards and control systems.

An assessment of the foreseeable risks arising from the intended use of the equipment was carried out when this

document was prepared.

This assessment formed the basis for determining

a) potentially hazardous situations having significant risks;

b) the safety requirements and/or measures which shall be incorporated into the machinery/equipment;

c) any information describing the intended uses which shall be communicated to the user.

The significant hazards and hazardous situations identified are listed in columns 1 and 2 of Clause 5, Table 1.

Before using this document it is important to carry out a risk assessment of the machine in question to check that

the machine has the same hazards identified in Clause 5. For hazards not covered by this document the principles

contained in EN ISO 12100-1 and EN ISO 12100-2 shall be applied.

5 Safety requirements and/or measures

5.1 General

5.1.1 Machines conforming to this document shall comply with the safety requirements and/or measures set out

in this Clause together with those set out in Clause 7. Relevant hazards identified in the risk assessment carried

out by the manufacturer but not dealt with in this document shall be reduced by applying the principles of EN ISO

12100-2.

For hazards which are to be reduced by the application of a B document such as, e. g., EN 294, EN 418,

EN 563/A1/AC the risk assessment carried out by the manufacturer shall establish the requirements of the B

standard which are to be applied. This specific risk assessment shall be part of the general risk assessment of the

machine.

5.1.2 Where the means of reducing the risk is by the physical arrangement or positioning of the installed

machines, the manufacturer shall include in the Information for use a reference to the reduction means to be

provided, and to any limiting value of the requirement, and, if appropriate, to the means of verification.

5.1.3 Where the means of reducing the risk is by a safe system of working, the manufacturer shall include in the

Information for use details of the system and of the elements of information required by the operating personnel.

This shall include arrangements to run a machine for essential operating reasons or in special mode with safety

devices suspended or temporarily modified.

5.1.4 It is recognised that a general hazard exists of exposure to high temperature surfaces which may be

touched and which is not practicable to eliminate. The manufacturers information for use shall contain guidance to

the user on the preventative measures to be used in connection with contact to hot surfaces and the need to

provide the operator(s) with PPE as appropriate.

5.1.5 Access to a danger zone is required for any reason during normal operation, e. g., commissioning, setting

up, production, maintenance, decommissioning (see 5.2.3 of EN ISO 12100-2:2003). The safety related control

system of the machines and equipment shall be in accordance with the appropriate category given in EN 954-1, at

least category 3, except for hydraulic equipment which shall be at least category 1.

If access to machines and equipment specified in this document is required for repairs, the measures outlined in

5.5.4 of EN ISO 12100-2:2003, shall apply, where all movements shall be made safe.

5.1.6 Required guards and enclosures shall be made in such a way that injuries caused by metal eruptions are

prevented.

5.1.7 Table 1 is a comprehensive presentation of significant hazards, the safety requirements to reduce risks,

and the means of verifying their presence:

Column 1 identifies the significant hazards;

Column 2 identifies the situations that give rise to the hazards;

Column 3 identifies the risk reduction measures to be applied for the significant hazards and hazardous

situations. They shall be provided in a cumulative manner if not otherwise stated;

NOTE When implementing safety requirements and/or measures it has to be considered that different hazards may appear

at the same time.

Column 4 identifies the method to be used to demonstrate conformity; the abbreviations V, F, M and D are

defined as follows:

V: Visual inspection verifies the required features of the components.

F: A functional check/test verifies that the features provided perform their function in such a

way that the requirement is met. If a functional check is necessary, the manufacturer shall

give details in the instruction handbook (see 7.3).

M: Measurement verifies that requirements are met, to the specified limits.

D: Drawings and/or calculations verify that the design characteristics of the components

provided meet the requirements.

Verification may involve more than one method.

Table 1 — Safety requirements and/or measures

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

5.2 Ladles

5.2.1 Discharge of molten metal or

Fire, burns slag due to unexpected tilting

in case of:

manual tilting

Locking device for ladles tilted by hand. D, F (see

Clause 6)

A self-locking gear shall be installed by the

manufacturer which is fitted to the forces

under operation such that tilting movements

are under the control of the operator at all

operations. Tilting test shall be carried out

with inclined hanger (see 3.9).

motorised tilting

The tilting movement shall be activated only F

when energised through a hold-to-run

control device, placed where its operator

has a full and unrestricted view of the ladle

and the receiver vessel/container.

centre of gravity above The manufacturer shall ensure that the D

trunnion axis, e. g., by centre of gravity is always below the

modification of nominal trunnion axis at all operating conditions. He

capacity by the user (e. g., shall advise the user in the Information for

use of smaller linings) use that

any modification shall maintain this

condition and

the conditions due to gearing and

maximum operating load shall be

given.

Loss of self-locking of gear in Lubricants shall not prevent the self-locking

case of gear ladles that are of ladle gears.

tilted by hand.

Information for use shall include advice that

the gear function shall be checked before

every shift (see 7.3.1).

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

Insufficient connection

between

trunnion and ladle Ladle trunnions shall be inserted con- V, D

(centre band) centrically into the centre band and

positively fixed by welding (see Annex B,

Figure B.1).

vessel and bottom

Ladle bottoms shall be dished or V, D

strengthened with gusset plates (see

Annex B, figures B.3, B.4 and B.5).

Using qualified welders and certificated V, D

procedures (see EN 287-1, EN 719,

EN 729-1).

Worm wheel of the ladle gear Safety device shall be fixed by mechanical V, D

without mechanical safety means, e. g., key and not rely on friction.

device.

Breakage of gear parts. Ladle gearing shall be designed to V, D

withstand the calculated and foreseen

dynamic loads during lifting and

transportation.

Information for use shall include advice that V

impacts to the gear shall be prevented (see

7.3.1).

Breakthrough of the ladle and Information for use shall include advice that V

unexpected discharge of the ladle shall only be used after refractory

molten metal. material has been applied in accordance

with the refractory manufacturer’s instruc-

tions.

Unexpected discharge from a The stopper rod equipment (see Annex B, D, F (see

bottom pouring ladle caused Figure B.2) shall be designed to prevent Clause 6)

by unintended actuation of the unintended or accidental actuation, e. g., by

stopper rod equipment. a mechanical locking device.

Information for use shall include advice V, D

about the need to inspect and renew the

stopper at necessary intervals.

5.2.2 Moisture existing in the lining Vents shall be provided for certain types of V

Explosion, of the ladle. linings.

burns

Information for use shall include a note that

the lining shall be heated and the moisture

shall be removed in accordance with the

refractory manufacturer's instructions

(see 7.3.1).

Bottom pouring ladles Information for use should advise the user

that pouring zones and ladle filling areas in

which bottom pouring ladles are used

should have provisions to accommodate

molten metal leakage (e. g., sand pits, pit

moulds).

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

5.2.3 Unexpected upset of hanger Ladles shall be provided with devices to V, D

Impact, burns or ladle. prevent ladle turning during transport and

filling, e. g., by a locking pin or mechanical

latch.

NOTE Hazards due to ladles directly lifted

by cranes or casting machines are not covered

by this document.

Hoisted ladle falling caused by The manufacturer shall design the hoist- D

break, tear out and wear of ladle such that at a minimum there is no

parts of the ladle and hanger. permanent deformation with stress of

20,000 cycles at 2x the intended max.

operating load.

If necessary protection of hanger against V, D

radiant heat shall be provided, e. g., by a

heat shield (see Annex B, Figure B.1).

The manufacturer and welders shall be

certified for welding conditions on this

equipment (see EN 287-1, EN 719 and

EN 729-1).

Welding that requires special treatment

shall be done prior to the final heat

treatment if appropriate.

Information for use shall provide

instructions that

before each use there shall be visual

inspections for apparent deficiencies

such as missing parts, corrosion,

deformation and points of visible

overheating of the material and in

particular the self-locking of the gear

and

at regular intervals there shall be

inspections of all stressed components

of the assembly by qualified personnel

for

cracks, wear, corrosion,

deformation, distortion,

missing parts,

points of visible overheating and

loss of self-locking of the gear.

Stressed components are:

hangers and hanger connections,

supporting arms of hanger, tilt

gear parts and supporting parts of

the ladle exposed to radiation or

direct heat;

hanger connections and gear

fittings stressed by mechanical

vibrations during transport;

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

strengthening bands of ladle

walls and bottom that may be

weakened by corrosion and

trunnions.

Detection for cracks shall be performed by M

a proven non-destructive test method, e. g.,

magnetic particle inspection process,

ultrasonic or equivalent methods. The

results of the tests shall be recorded.

5.2.4 Transport by industrial truck If the ladle is intended to be transported by V, D

Burns, impact (not on public highway). industrial truck it shall be fitted with the

means for lifting by industrial truck and the

Ladles slipping from the forks

manufacturer shall include information in

of an industrial truck.

the Information for use suitable industrial

truck facilities and methods of operation.

5.2.5 If liquid metal is treated with The space for treatment ladles shall be V, D

Burns, fumes magnesium there is a risk of enclosed during treatment to prevent

spattering and/or delayed spattering of liquid metal.

reactions.

Information for use shall include information

to provide means to remove toxic or

reaction fumes and

how to protect area open to personnel

against spattering of liquid metal, e. g.,

by shields and

to provide PPE.

5.3 Pouring equipment

NOTE Hazards and safety requirements of plant and equipment for liquid phase treatment are given in

prEN 746-6:1994.

5.3.1 Unintended tilting during tilting Provide by design:

Lack of stability or in a tilt stop position due to

hold-to-run control device. The tilting

any cause.

movement shall be activated only

when energised through a hold-to-run

control device, placed where its

operator has a full and unrestricted

view of the ladle and the receiver

vessel/container and

controlled non-return valves or direc- D

tional valves (directly attached at the

hydraulic cylinder) which turn off inde-

pendently in case of pressure drop or

mechanically operated jacks (by hand, D

hydraulics, spring or gravity) and

device for manual re-tilting and D

control system to provide means due

to malfunction (see 5.3.12)

5.3.2 During tilting or movement of Design safety distances, grids, guards, trip V, D

Crushing, equipment. devices

shearing

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

5.3.3 Metal eruptions caused by:

Burns

excess pressure in the Pressure limitation and display for minimum V, D

vessel or metal level heel level of the vessel (see Annex B,

below the minimum heel Figure B.6)

level required to maintain

Fixed guards (see EN 953) V, D

the siphon effect or

damaged siphon Covers or lids on filling gate and pouring V, D

refractories losing the spout and

siphon effect or

cracks in the refractories.

Protective walls and roofing over operators V, D

desk.

Information for use shall provide

information about PPE, warning signs

(see EN 61310-1; -2) and fault alarms.

instructions that equipment shall only

be used in accordance with the

refractory manufacturers' instructions

(see 7.3.2).

cooling water coming into Monitoring (preferably automatic) of D

contact with liquid metal; refractory lining in case of electric heated

pouring equipment;

leakage of liquid metal

Protection of cooling pipes and hoses and V, D

into moist furnace pit;

use of equipment with Where applicable, any furnace pit has to be V, D

refractory lining not fully

designed such that water can flow off freely

dried. in case of damaged pipes and hoses and

that no ground water can enter (see 7.3.2);

Information for use shall include a note that

the lining shall be heated and the moisture

shall be removed in accordance with the

refractory manufacturer's instructions

(see 7.3.2).

Information for use shall indicate the need

for PPE (see 7.3.2).

Overfilling of the pouring Provide means such as automatic pressure V, D

equipment causes flow out of relief if maximum permissible level in the

molten metal. pouring spout or pressure limit value inside

or the pouring equipment has been

exceeded.

Design to include provisions to re-tilt the V, D

pouring equipment to the neutral position, if

necessary by manual means or auxiliary

means.

5.3.4 If burner flame extinguishes See 5.2.6, 5.3.6 and 5.4.6 of

Fire or explo- the fuel may enter the vessel EN 746-2:1997.

sions or burns and suddenly ignite.

Ejection of molten material Design of equipment to prevent uncon- D

from the vessel. trolled release of treatment gases.

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

Information for use shall contain

instructions on training of personnel

(see 7.3.2) and shall indicate the need for

personal protective clothing (see 7.3.1).

When producing spheroidal Guard close to the pipes and valves where V, D

graphite cast iron, magnesium flammable gases could escape from the

vapour ignites in air when it equipment.

discharges.

Uncontrolled release and igni- Pipework and hoses for hydraulic fluids V, D

tion of hydraulic fluids. shall be protected against mechanical and

thermal damage by the use of covers,

shielding etc. and fixing means such as

ducts and channels and

Hydraulic equipment shall be suitable for

use with fire resistant hydraulic fluids (see

ISO 7745 and Annex A).

Information for use shall include advice,

that hydraulic fluids which contain poly-

chlorinated bi phenyls (P.C.B.) and poly-

chlorinated tri phenyls (P.C.T.) shall not be

used (see 7.3.1).

5.3.5 When there is cooling water Provide standby emergency cooling in case D

Burns and failure, formation of vapour in there is cooling water failure.

scalds cooling pipes and hoses can

NOTE This provision should be made by

cause explosion danger.

agreement between the manufacturer and the user.

5.3.6 When there is a generation of Design of equipment to prevent these D

Explosions explosive dusts or gases in a generations.

confined space, heat caused

Provide explosion reliefs where applicable. D

by, e. g., welding or hot gases

can create an explosion when

Information for use shall indicate the need

escaping, or a furnace door is for a control procedure to prevent this

opened.

situation, e. g., work permits for danger

zones for preventative maintenance

(see 7.3.3) or repairs.

5.3.7 Burns by contact or close Information for use shall indicate the need

Thermal proximity to hot parts during, for:

radiation e. g.,

Protective screens;

deslagging;

Warning signs (see EN 60310-1; -2);

changing the stopper

Wearing personal protective clothing

rod, or metal level control

when potentially exposed and

electrode;

Protection of operators work place, if

pouring spout replace-

applicable.

ment;

maintenance;

opening the slag door;

opening the cover;

inductor replacement.

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

5.3.8 Glare causing: Design of equipment to prevent this

V

Light radiation condition.

disorientation;

Information for use shall indicate the need

defective vision.

for:

Warning notices in danger zones (see

EN 60310-1; -2);

Using antiglare glasses where appli-

cable (see 7.3.2).

5.3.9 Deliberate or accidental use of Adequate exhaust ventilation shall be V, D

Inhalation, potentially harmful operational provided, or operating manual shall include

ingestion of process materials, e. g., the need for its provision and maintenance

harmful dusts chloride, fluoride, cadmium, (see 7.3.2, EN 626-1:1994 and EN 626-2).

and fumes lead, nickel.

5.3.10 Intended or unintended ac- According to EN 1037 and EN 954-1 the D

Crushing, tuation of machine move- control system shall ensure that automatic

shearing, ments. restart is prevented and re-actuation of the

cutting or start control is always required to initiate

Unexpected movements or

severing, en- powered movement following, e. g., any

failure of the normal retaining

tanglement, change of mode, selection of optional

or drive system whether

drawing, function, a system re-set, guard interlock

mechanical, electrical,

trapping, interruption, restoration of adequate

hydraulic or pneumatic.

impact, friction, pressure or voltage or correction of a

or burns Cooling water failure system failing.

5.3.11 Direct contact or indirect con- See 10.1, 10.2, 10.3, 10.4, 11 and 12 of D

Electrical shock tact with live parts. EN 60519-1:1993

Heat radiation or excessive See 13 of EN 60519-1:1993

temperature causes failure of

electric isolation.

Inadequate connections and

conductors.

Adjacent metallic parts under

the effect of induced currents

5.3.12 Impossibility of stopping the Emergency stop device(s) in accordance

Malfunction tilting in the best possible with EN 418.

condition

Stop category 1 (9.2.2 of EN 60204-1:1997)

shall be provided for the tilting movement of

a pouring vessel to prevent flow-out of

molten metal in tilting position.

Emergency switching off device:

Push-button operated switches shall be

used (see 10.8.2 of EN 60204-1:1997).

5.3.13 Electrostatic discharge 6.2 and 7.2.6 of CENELEC R044-001,1999

Electrical

shock, fire

5.4 Centrifugal casting machines

5.4.1 Stripping/ejection of castings. Design of the machine:

Crushing,

Control panel shall be remote from danger D

impact

zone;

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

standards AND/OR specific measures cation

Provision of interlocking guards with guard

V, D

locking conforming to EN 1088 (see

Annex B, Figure B.7).

Disintegration of parts of the Strength of the die and die-locking. D

die due to centrifugal force,

Information for use shall provide

e. g., die-lockings.

instructions of intended use, e. g.,

speed limits (rpm) corresponding to

the strength of the die and

pressure limits.

Uncontrolled over-speed of Limiting of the speed (rpm) by proximity D

the drive (electronic switches.

controlled)

Mechanical rail guided cross Design equipment to prevent trapping of D

transport of castings. persons so that movements of the equip-

ment do not cause danger.

Dies moving along pouring Provide safety distances by location of V, D, M

spouts and approaching end parts, according EN 349.

stops.

Ejection or falling of the die Design to prevent ejection or falling of die

D

from the bearing rollers. (see Annex B, Figure B.8), e. g.

fixed guides;

restraining pieces.

5.4.2 Machine integrated controlled The tilting movement shall be activated only D

Burns, impact, tilting of the ladle, manually when energised through a hold-to-run

crushing initiated. control device, placed where its operator

has a full and unrestricted view of the ladle

and the receiver vessel/container.

5.4.3 Discharge of molten metal Centrifugally applied die-lockings shall be D

Burns due to designed to prevent them loosening during

casting operation. Die-lockings that are

disintegration of parts

actuated pneumatically, hydraulically or

(see also 5.4.1);

electro-mechanically shall be designed in

such a way that unlocking cannot occur

unintended loosening of

die-lockings during before the solidification of the liquid metal.

rotation of the die;

The emergency stop device for the die D, F (see

unintended machine stop rotation movement (see 5.4.9) shall Clause 6)

correspond to 9.2.2 of EN 60204-1:1997,

category 1, and EN 418.

Shifting of movable and slew- It shall be possible to fix pouring spouts V, D, F

able pouring spouts. positively prior to start of casting operation, (see

e. g., by locking clamps. Clause 6)

Ejecting metal during rotation Coverings to protect against burns caused V, D

of the die. by ejection of molten metal shall be

included and conformed to fixed guard (see

5.3.2.1 of EN ISO 12100-2:2003 and

EN 953) with an inserted movable guard

(see 5.3.2.3 of EN ISO 12100-2:2003,

EN 953 and EN 1088).

Table 1 (continued)

Column 1 Column 2 Column 3 Column 4

Hazard Hazardous situation Safety measures according to the mentioned Verifi-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...