SIST EN 14405:2017

(Main)Characterization of waste - Leaching behaviour test - Up-flow percolation test (under specified conditions)

Characterization of waste - Leaching behaviour test - Up-flow percolation test (under specified conditions)

This Standard is applicable to determine the leaching behaviour of inorganic constituents from granular waste (without or with size reduction. The waste body is subjected to percolation with water as a function of liquid to solid ratio under specified percolation conditions. The waste is leached under hydraulically dynamic conditions. The method is a once-through column leaching test and the test results establish the distinction between different release patterns, for instance wash-out and release under the influence of interaction with the matrix, when approaching local equilibrium between waste and leachant.

Charakterisierung von Abfällen - Untersuchung des Elutionsverfahrens - Perkolationsprüfung im Aufwärtsstrom (unter festgelegten Bedingungen)

Caractérisation des déchets - Essais de comportement à la lixiviation - Essai de percolation à écoulement ascendant (dans des conditions spécifiées)

La présente Norme européenne s’applique à la détermination du comportement à la lixiviation des

substances inorganiques et organiques non volatiles issues de déchets granulaires (avec ou sans réduction

granulométrique (voir en 7.2)). Le corps des déchets est soumis à une percolation à l’eau en fonction du

rapport liquide/solide, dans des conditions de percolation spécifiées. La lixiviation des déchets a lieu dans

des conditions hydrauliques dynamiques. La méthode est un essai de lixiviation en colonne mené en une fois.

Les résultats d’essai permettent de faire la distinction entre différents relargages types, tels que le lessivage

ou le relargage sous l’effet de l’interaction avec la matrice, à l’approche de l’équilibre local entre le déchet et

le lixiviant. Cette méthode d’essai produit des éluats qui peuvent ensuite être caractérisés par des méthodes

physiques, chimiques et écotoxicologiques selon des méthodes normalisées existantes.

NOTE 1 Les conditions de percolation spécifiées sont arbitraires et ne simulent pas nécessairement de scénario

spécifique.

NOTE 2 Les déchets présentant une conductivité hydraulique à saturation comprise entre 10-7 m/s et 10-8 m/s

peuvent être soumis à cet essai, mais il peut s’avérer difficile de maintenir le débit prescrit. Si un déchet présente une

conductivité hydraulique à saturation inférieure à 10-8 m/s, l’essai ne sera, de préférence, pas effectué (voir en C.5 pour

une définition de la « conductivité hydraulique »).

NOTE 3 D’une manière générale, ce mode opératoire ne s’applique pas aux matériaux subissant une biodégradation

ni à ceux qui réagissent avec le lixiviant et conduisent, par exemple, à des émissions gazeuses ou des dégagements de

chaleur excessifs.

NOTE 4 Ce mode opératoire s’applique aux matériaux présentant une solidification à l’intérieur de la colonne, si la

conductivité hydraulique finale est comprise dans la plage spécifiée (voir la NOTE 2).

NOTE 5 Il n’est pas toujours possible d’optimiser les conditions d’essai simultanément pour les substances

inorganiques et organiques non volatiles et les conditions d’essai optimales peuvent également varier au sein même

des groupes de substances organiques non volatiles. Les exigences d’essai applicables aux substances organiques non

volatiles sont généralement plus strictes que celles applicables aux constituants inorganiques. Les conditions d’essai

appropriées pour mesurer le relargage des substances organiques non volatiles seront généralement également

applicables aux substances inorganiques.

NOTE 6 Concernant les essais écotoxicologiques, des éluats représentant le relargage de substances inorganiques et

organiques non volatiles sont nécessaires. Dans la présente norme, les essais écotoxicologiques incluent également les

essais génotoxicologiques.

NOTE 7 Il n’existe actuellement aucune donnée de validation de l’essai aux substances organiques non volatiles.

Elles seront ajoutées au moment de la révision, dès qu’elles seront disponibles.

Karakterizacija odpadkov - Izluževalni preskusi - Preskus v koloni s tokom navzgor (pri določenih pogojih)

Ta standard se uporablja za določanje izluževanja anorganskih sestavin iz zrnatih odpadkov (z zmanjšanjem velikosti ali brez njega). Odpadki so izpostavljeni precejanju, pri čemer je voda funkcija razmerja tekoče/trdno pri določenih pogojih precejanja. Izluževanje odpadkov poteka pri hidravlično dinamičnih pogojih. Metoda je izluževanje z enkratnim pretokom skozi stolpec, rezultati pa določajo razliko med različnimi vzorci sproščanja, na primer izpiranje in sproščanje pod vplivom interakcije z matriko pri približevanju lokalnemu ravnovesju med odpadki in izluževalnim medijem.

General Information

- Status

- Published

- Public Enquiry End Date

- 04-Dec-2014

- Publication Date

- 07-Nov-2017

- Technical Committee

- KAT - Soil quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 31-Aug-2017

- Due Date

- 05-Nov-2017

- Completion Date

- 08-Nov-2017

- Directive

- 99/31/EC - Landfill of waste

Relations

- Effective Date

- 01-Dec-2017

Overview

EN 14405:2017 (CEN) defines an up-flow percolation test to characterize the leaching behaviour of inorganic and non‑volatile organic substances from granular waste. The standard describes a once‑through column leaching test in which water percolates upward through a packed sample under hydraulically dynamic conditions. Test results (eluates collected as a function of liquid-to-solid (L/S) ratio) are used to distinguish release patterns - for example rapid wash‑out versus matrix‑controlled release approaching local equilibrium.

Key topics and technical requirements

- Scope: Applies to granular waste with or without size reduction. Not suitable for strongly biological or highly reactive materials that produce excessive gas or heat.

- Test principle: Once‑through up‑flow column percolation; eluates collected at specified L/S ratios and analyzed.

- Hydraulic considerations: Intended for materials with saturated hydraulic conductivity typically above ~10‑8–10‑7 m/s; very low conductivity can make flow control difficult.

- Sample preparation & packing: Defined procedures for sample pretreatment, column packing, water saturation and equilibration to ensure reproducible hydraulics.

- Control parameters: Temperature control, flow rate, column dimensions and fraction collection strategy are specified to ensure comparability.

- Analytical endpoints: Produces eluates to be characterized by physical, chemical and ecotoxicological methods; inorganic constituents are validated, non‑volatile organic method validation is pending.

- Quality & reporting: Includes requirements for blank tests, calculation of results, performance characteristics (repeatability/reproducibility) and detailed test reporting.

Practical applications

- Environmental characterization of wastes for disposal, reuse or recycling decisions.

- Basic characterization supporting compliance programs and selection of appropriate follow‑up tests.

- Generating eluates for chemical or ecotoxicological assessment to evaluate potential environmental impacts (e.g., landfill leachate risk, secondary raw material assessment).

- Comparing release patterns between materials (e.g., construction & demolition waste, stabilised residues, granular industrial by‑products).

Who should use EN 14405:2017

- Environmental testing laboratories and accredited analysts performing leaching tests.

- Waste producers and recyclers conducting material characterization for treatment, reuse or acceptance.

- Regulators, landfill operators and consultants assessing leaching risk and compliance.

- Researchers developing leaching models or comparing laboratory and field release behaviour.

Related standards

- EN 12920 (complementary leaching test methods)

- EN 14346 (determination of dry matter)

- EN 14899 (sampling of waste materials)

- EU Landfill Directive guidance referenced for test hierarchy and application

EN 14405:2017 provides a standardized, reproducible method to evaluate leaching behaviour via up‑flow percolation testing, helping stakeholders quantify release patterns and make informed environmental management decisions.

Frequently Asked Questions

SIST EN 14405:2017 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Characterization of waste - Leaching behaviour test - Up-flow percolation test (under specified conditions)". This standard covers: This Standard is applicable to determine the leaching behaviour of inorganic constituents from granular waste (without or with size reduction. The waste body is subjected to percolation with water as a function of liquid to solid ratio under specified percolation conditions. The waste is leached under hydraulically dynamic conditions. The method is a once-through column leaching test and the test results establish the distinction between different release patterns, for instance wash-out and release under the influence of interaction with the matrix, when approaching local equilibrium between waste and leachant.

This Standard is applicable to determine the leaching behaviour of inorganic constituents from granular waste (without or with size reduction. The waste body is subjected to percolation with water as a function of liquid to solid ratio under specified percolation conditions. The waste is leached under hydraulically dynamic conditions. The method is a once-through column leaching test and the test results establish the distinction between different release patterns, for instance wash-out and release under the influence of interaction with the matrix, when approaching local equilibrium between waste and leachant.

SIST EN 14405:2017 is classified under the following ICS (International Classification for Standards) categories: 13.030.01 - Wastes in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14405:2017 has the following relationships with other standards: It is inter standard links to SIST-TS CEN/TS 14405:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14405:2017 is associated with the following European legislation: EU Directives/Regulations: 99/31/EC; Standardization Mandates: M/326. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14405:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Charakterisierung von Abfällen - Untersuchung des Elutionsverfahrens - Perkolationsprüfung im Aufwärtsstrom (unter festgelegten Bedingungen)Caractérisation des déchets - Essais de comportement à la lixiviation - Essai de percolation à écoulement ascendant (dans des conditions spécifiées)Characterization of waste - Leaching behaviour test - Up-flow percolation test (under specified conditions)13.030.01Odpadki na splošnoWastes in generalICS:Ta slovenski standard je istoveten z:EN 14405:2017SIST EN 14405:2017en,fr,de01-december-2017SIST EN 14405:2017SLOVENSKI

STANDARDSIST-TS CEN/TS 14405:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14405

March

t r s y English Version

Characterization of waste æ Leaching behaviour test æ UpæCaractérisation des déchets æ Essais de comportement à la lixiviation æ Essai de percolation à écoulement

Charakterisierung von Abfällen æ Untersuchung des Elutionsverfahrens æ Perkolationsprüfung im This European Standard was approved by CEN on

u February

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v v r wã t r s y ESIST EN 14405:2017

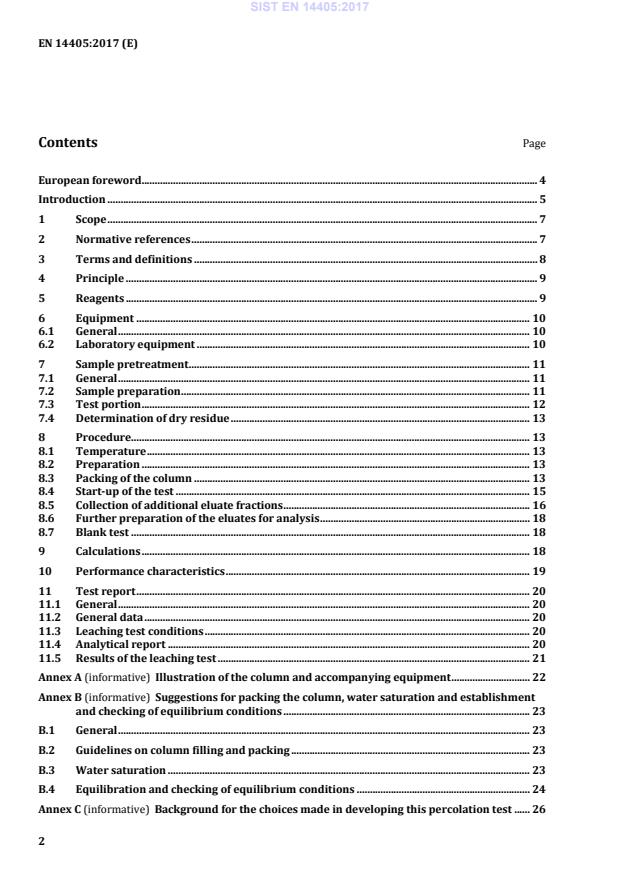

Illustration of the column and accompanying equipment . 22 Annex B (informative)

Suggestions for packing the column, water saturation and establishment and checking of equilibrium conditions . 23 B.1 General . 23 B.2 Guidelines on column filling and packing . 23 B.3 Water saturation . 23 B.4 Equilibration and checking of equilibrium conditions . 24 Annex C (informative)

Background for the choices made in developing this percolation test . 26 SIST EN 14405:2017

Repeatability and reproducibility data . 30 D.1 Materials used in the interlaboratory comparison study . 30 D.2 Interlaboratory comparison results . 30 Bibliography . 40

1 Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste. 2 Council Decision 2003/33/EC of 19 December 2002. SIST EN 14405:2017

< 4 mm Fraction

· 10 mm Column to be used (with required size-reduction) m/m)

Small column (without size reduction), or Wide column (without size reduction) 80 % (m/m) to 95 % (m/m) m/m) or Wide column (without size reduction) m/m) m/m) Wide column (without size reduction)

> 5 % (m/m) Wide column ( Prepare a test sample according to EN 15002. Use a sample splitter or apply coning and quartering to split the laboratory sample as specified in EN 15002. The test shall be carried out preferably on a sample in the condition (particle size, moisture content) as it was delivered to the laboratory. If oversized material is to be size reduced (in accordance with Table 1), the entire oversized fraction shall be crushed according to EN 15002). On no account shall the material be finely ground. Non-crushable material (e.g. metallic parts such as nuts, bolts, scrap) in the sample shall be separated and the mass and the nature of the material shall be recorded. If the sample cannot be sieved or split or crushed because of its moisture content, it is allowed to dry the sample, but no further than is required for the sample preparation. The drying temperature shall not exceed

40 °C (see EN 15002). NOTE 2 Depending on the maximum particle size, the splitting can require size reduction of the coarser particles to comply with the rules of sampling. NOTE 3 Due to crushing and sieving, contamination of the sample can occur to an extent, which is affecting the release of some substances of concern, e.g. Co and W from tungsten carbide crushing equipment or Cr, Ni, Mo and V from stainless steel equipment. NOTE 4 Fibrous materials and plastics can often be size-reduced only after cryogenic treatment. NOTE 5 Drying may lead to oxidation and/or carbonation. If the material is fresh and has to be tested as a non oxidized / non carbonated material, the drying will preferably be conducted in an inert atmosphere. NOTE 6 Crushingá sieving and drying at

·

t w

¹C can lead to loss of semi-volatile components (inorganic and organic). In this case, particle size reduction and drying is best avoided. 7.3 Test portion At least two test portions shall be taken from the test sample. To fill the column completely, the quantity of one of the test portions shall be such that its volume after compaction is 0,6 l (in case a column with a diameter of 5 cm is used), or 2,4 l (in case a column with a diameter of 10 cm is used). A sample splitter shall be used or coning and quartering shall be applied to split the test sample and prepare the test portion(s) (see EN 15002). SIST EN 14405:2017

Key 1 layer of compacted waste 2 rammer drilled in the centre 3 column 4 rod for the manipulation of the rammer 5 guide 6 water inlet Figure 1 — Filling and packing of the column NOTE 1 In order to determine the proper mass for each layer, a preliminary test may be carried out. In that case, it is essential to put a 7 cm to 8 cm layer in the column, to pack it and to calculate the mass necessary to get a layer of approximately 6 cm. NOTE 2 If the column is not high enough to work according to the above mentioned packing procedure, a heightening device may be required. NOTE 3 It is difficult to pack some specific materials in the column in an appropriate way. Annex B gives guidelines on how to handle in that specific case. Fit the top section of the column, equipped with a filter plate or a layer of fine-grained chemically inert material (e.g. fine quartz sand) of approximately 1 cm and a pre-filter (see 6.2.6), to prevent entrainment of fine particles with the eluate. Fit the top section and pre-filter so that the liquid flow cannot bypass the filter and so that no open space (dead volume) is left above the material. NOTE 4 Care needs to be taken in positioning the pre-filter in place: the filter can tear. Weigh the column thus filled to an accuracy of 1 g. Determine the dry mass (m0) of the test portion in the column, in accordance with Formula 2. ()×=dr0100mwm (2) where m0 is the dry mass of the test portion in the column, in kg; m is the mass of the (moist) test portion in the column, in kg; wdr

is the dry residue, in %. Fit the outlet-hose to the top section of the column. SIST EN 14405:2017

(= L/S ratio times dry mass) a l Cumulative L/S ratio

l/kg dry matter 1 (0,1 ± 0,02) × m0 0,1 ± 0,02 2 (0,1 ± 0,02) × m0 0,2 ± 0,04 3 (0,3 ± 0,05) × m0 0,5 ± 0,08 4 (0,5 ± 0,1) × m0 1,0 ± 0,15 5 (1,0 ± 0,2) × m0 2,0 ± 0,3 6 (3,0 ± 0,2) × m0 5,0 ± 0,4 7 (5,0 ± 0,2) × m0 10,0 ± 0,1 a In the case of high salt loads (conductivity > 7 500 mS/m) the density of the eluate in the first few fractions is significantly more than 1 g/ml. In that case the volume of these fractions of eluate has to be measured and used for the calculations instead of the mass. The test itself is finished when the L/S ratio of 10 l/kg dry matter is reached. NOTE 4 For specific scenario’s (for example a landfill with top cover) it may be sufficient to know the leaching characteristics up to an L/S ratio of 2 l/kg dry matter. In that case the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...