SIST EN 13352:2012

(Main)Specification for the performance of automatic tank contents gauges

Specification for the performance of automatic tank contents gauges

This European Standard specifies the minimum performance requirements for various classes of automatic tank gauges which are limited to static tanks of shop fabricated manufacture both metallic and non metallic, underground and above ground which do not exceed 5 m in height.

It is applicable to gauges for fuels (products) which are flammable, having a flash point up to but not exceeding 100 C, stored at premises (e.g. filling stations) at which fuel is dispensed for use in vehicles and other forms of transportation. This European Standard applies to gauges suitable for use at ambient tempera¬tures and subject to normal operational pressure variations.

Gauging of liquefied gases are not covered by this standard.

This European Standard relates to the measurement of product level, measurement of product temperature and detection of the presence of free water. The detection of free water may be compromised for Alcohol blended fuels.

NOTE 1 This standard is not intended to cover safety functionalities (i.e. overfill prevention, leak detection, etc.). Further Standards apply.

NOTE 2 This standard is not intended to cover legal metrology requirements.

Anforderungen an automatische Tankinhaltsmessgeräte

Diese Europäische Norm legt Mindestanforderungen an unterschiedliche Klassen von automatischen Füll-standmessgeräten fest, die nur für den Einsatz in unter und oberirdisch aufgestellten, ortsfesten, werks-gefertigten Tanks gelten, die aus metallischen und nichtmetallischen Werkstoffen bestehen und nicht höher als 5 m sind.

Sie ist anzuwenden auf Füllstandmessgeräte für Kraftstoffe (Produkte), die brennbar sind, einen Flammpunkt bis einschließlich 100 °C haben und an Örtlichkeiten gelagert werden, in denen Kraftstoff für Kraftfahrzeuge und sonstige Transportmittel abgegeben wird (z. B. Tankstellen). Diese Europäische Norm gilt für Füllstand-messgeräte, die für den Einsatz bei Umgebungstemperaturen und normalen betriebsbedingten Druckverhält-nissen geeignet sind.

Die Füllstandmessung für Flüssiggase ist in dieser Norm nicht erfasst.

Die vorliegende Europäische Norm behandelt Messungen des Füllstandes und der Temperatur des Produkts sowie die Anzeige des Vorhandenseins von abgesetztem Wasser. Die Anzeige für abgesetztes Wasser kann für Kraftstoffe, die Alkohol als Blendkomponente enthalten, möglicherweise beeinträchtigt sein.

ANMERKUNG 1 In dieser Norm nicht erfasst werden Sicherheitsfunktionen (d. h. Überfüllsicherung, Leckageerkennung usw.). Dafür werden weitere Normen angewendet.

ANMERKUNG 2 In dieser Norm nicht erfasst werden Anforderungen des gesetzlichen Messwesens.

Spécification de performance des dispositifs mesureurs automatiques de niveau de réservoir

La présente Norme européenne spécifie les exigences minimales de performances pour différentes classes de dispositifs mesureurs automatiques de niveau de réservoir, ou jauges de niveau, qui se limitent aux réservoirs statiques, fabriqués en atelier, métalliques et non métalliques, enterrés et aériens, dont la hauteur ne dépasse pas 5 m.

Elle s'applique aux jauges pour combustibles (produits) inflammables, qui ont un point d'éclair d'au maximum 100 C, stockés sur des sites (des stations de remplissage par exemple) où le carburant est distribué pour la consommation de véhicules et autres moyens de transport. La présente Norme européenne s'applique aux jauges destinées à être utilisées à température ambiante et soumises à des variations de pression de fonctionnement normales.

Le jaugeage des gaz liquéfiés n'est pas couvert par la présente norme.

La présente Norme européenne concerne les mesurages de niveau et de température du produit et la détection de la présence d'eau. La détection de présence d'eau peut être compromise pour les mélanges de carburants et d’alcools.

NOTE 1 La présente norme n'est pas destinée à couvrir les fonctionnalités de sécurité (c'est-à-dire limitateur de remplissage, détection de fuite, etc.). Des normes complémentaires s’appliquent.

NOTE 2 La présente norme n'est pas destinée à couvrir les exigences de la métrologie légale.

Zahteve za avtomatske merilnike nivoja vsebine v rezervoarjih

Ta evropski standard določa minimalne zahteve za delovanje različnih razredov avtomatskih merilnikov za rezervoarje, ki so omejeni na tovarniško izdelane nepremične rezervoarje, kovinske in nekovinske, podzemne in nadzemne, katerih višina ne presega 5 m.

Uporablja se za merilnike za goriva (izdelke), ki so vnetljiva, imajo plamenišče do 100 °C in se shranjujejo na mestih (npr. bencinskih servisih), na katerih se gorivo toči za uporabo v vozilih in drugih prevoznih sredstvih. Ta evropski standard se uporablja za merilnike, ki so primerni za uporabo pri temperaturi okolja in so izpostavljeni običajnim spremembam delovnega tlaka.

Ta standard ne zajema merjenja utekočinjenih plinov.

Ta evropski standard se uporablja za merjenje ravni izdelka, merjenje temperature izdelka in odkrivanje prisotnosti vode. Zaznavanje proste vode za goriva, mešana z alkoholom, morda ni natančno.

Ta standard ne zajema zahtev zakonskega meroslovja.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Oct-2010

- Publication Date

- 18-Apr-2012

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Mar-2012

- Due Date

- 28-May-2012

- Completion Date

- 19-Apr-2012

Relations

- Effective Date

- 01-May-2012

Overview

EN 13352:2012 - Specification for the performance of automatic tank contents gauges - is a CEN European Standard that defines minimum performance requirements for automatic tank gauges (ATGs) used on static, shop-fabricated underground and above‑ground storage tanks up to 5 m height. It covers gauges for flammable fuels with flash points up to 100 °C (typical fuels dispensed at filling stations). The standard applies to devices measuring liquid level, product temperature, and free water detection, and addresses material compatibility with modern fuels (including ethanol blends and biodiesel). Liquefied gases and legal metrology or safety functions (e.g., overfill prevention, leak detection) are excluded.

Key Topics and Requirements

- Scope and applicability: static metallic and non‑metallic tanks, ambient temperature operation, normal pressure variations; excludes liquefied gases.

- Performance areas:

- Level measurement accuracy and repeatability; classification and designation of ATG performance.

- Temperature measurement requirements and temperature-category testing.

- Water detection capability and limitations (noting reduced reliability with alcohol-blended fuels).

- Materials and compatibility: tests and requirements for parts exposed to fuel vapors and direct fuel contact; explicit attention to compatibility with ethanol blends and biodiesel.

- Testing and conformity: test methods, sampling, MPE (maximum permitted error) tests for level and temperature, repeatability testing, test reporting.

- Information and labelling: essential information, indicator device requirements, manufacturer instructions, marking and labelling.

- Ancillary topics: installation guidance, environmental aspects, factory production control and surveillance (informative annexes).

Applications and Who Uses It

EN 13352:2012 is practical for:

- ATG manufacturers designing and certifying tank gauging equipment for fuel depots and service stations.

- System integrators and installers who fit gauges to underground and above‑ground tanks.

- Fuel retailers and site operators implementing inventory control, automatic reconciliation and basic gauging functions.

- Test laboratories and conformity assessors performing type testing, performance verification and documentation.

- Maintenance teams ensuring ongoing accuracy and compatibility with evolving fuel blends.

Typical use cases include continuous inventory monitoring, delivery acceptance checks, temperature-compensated level readings, and basic water-in-fuel detection at filling stations and commercial fuel storage sites.

Related Standards

EN 13352:2012 does not cover safety-specific functions (overfill prevention, leak detection) or legal metrology; users should reference relevant EN standards for safety systems and national metrology regulations when designing compliant installations.

Keywords: EN 13352:2012, automatic tank gauge, tank contents gauges, level measurement, water detection, fuel storage, filling stations, ethanol blends, biodiesel, CEN.

Frequently Asked Questions

SIST EN 13352:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Specification for the performance of automatic tank contents gauges". This standard covers: This European Standard specifies the minimum performance requirements for various classes of automatic tank gauges which are limited to static tanks of shop fabricated manufacture both metallic and non metallic, underground and above ground which do not exceed 5 m in height. It is applicable to gauges for fuels (products) which are flammable, having a flash point up to but not exceeding 100 C, stored at premises (e.g. filling stations) at which fuel is dispensed for use in vehicles and other forms of transportation. This European Standard applies to gauges suitable for use at ambient tempera¬tures and subject to normal operational pressure variations. Gauging of liquefied gases are not covered by this standard. This European Standard relates to the measurement of product level, measurement of product temperature and detection of the presence of free water. The detection of free water may be compromised for Alcohol blended fuels. NOTE 1 This standard is not intended to cover safety functionalities (i.e. overfill prevention, leak detection, etc.). Further Standards apply. NOTE 2 This standard is not intended to cover legal metrology requirements.

This European Standard specifies the minimum performance requirements for various classes of automatic tank gauges which are limited to static tanks of shop fabricated manufacture both metallic and non metallic, underground and above ground which do not exceed 5 m in height. It is applicable to gauges for fuels (products) which are flammable, having a flash point up to but not exceeding 100 C, stored at premises (e.g. filling stations) at which fuel is dispensed for use in vehicles and other forms of transportation. This European Standard applies to gauges suitable for use at ambient tempera¬tures and subject to normal operational pressure variations. Gauging of liquefied gases are not covered by this standard. This European Standard relates to the measurement of product level, measurement of product temperature and detection of the presence of free water. The detection of free water may be compromised for Alcohol blended fuels. NOTE 1 This standard is not intended to cover safety functionalities (i.e. overfill prevention, leak detection, etc.). Further Standards apply. NOTE 2 This standard is not intended to cover legal metrology requirements.

SIST EN 13352:2012 is classified under the following ICS (International Classification for Standards) categories: 43.060.40 - Fuel systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13352:2012 has the following relationships with other standards: It is inter standard links to SIST EN 13352:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13352:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

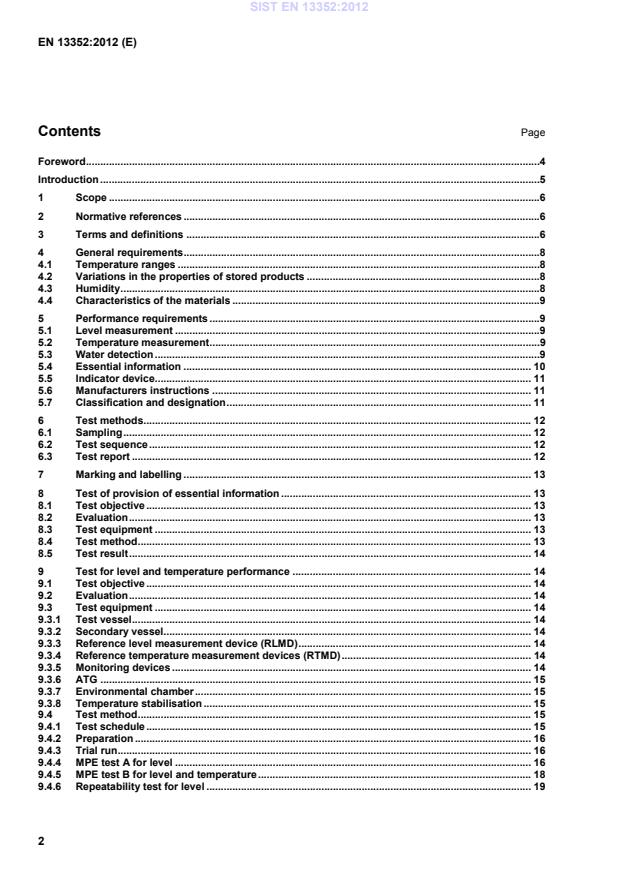

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zahteve za avtomatske merilnike nivoja vsebine v rezervoarjihAnforderungen an automatische TankinhaltsmessgeräteSpécification de performance des dispositifs mesureurs automatiques de niveau de réservoirSpecification for the performance of automatic tank contents gauges43.060.40Sistemi za gorivoFuel systemsICS:Ta slovenski standard je istoveten z:EN 13352:2012SIST EN 13352:2012en,fr,de01-maj-2012SIST EN 13352:2012SLOVENSKI

STANDARDSIST EN 13352:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13352

March 2012 ICS 75.180.30 Supersedes EN 13352:2002English Version

Specification for the performance of automatic tank contents gauges

Spécification de performance des jauges automatiques de niveau de réservoir

Anforderungen an automatische TankfüllstandmessgeräteThis European Standard was approved by CEN on 28 January 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13352:2012: ESIST EN 13352:2012

Evaluation of conformity. 31A.1 General . 31A.2 Initial type testing . 31A.3 Factory production control. 31A.4 Continuous surveillance . 32Annex B (informative)

Gauge sensors installation . 33B.1 General . 33B.2 Reference datum points . 33B.3 Safety . 34B.4 Ingress protection . 35Annex C (informative)

A-deviations . 36Annex D (informative)

Environmental Aspects . 37Annex E (normative)

Compatibility with fuels . 39E.1 Compatibility tests for materials . 39E.2 Test for parts exposed to fuels vapours . 39E.3 Test for parts in direct contact with fuels . 39Bibliography . 41 SIST EN 13352:2012

This standard is not intended to cover legal metrology requirements. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 228, Automotive fuels — Unleaded petrol — Requirements and test methods EN 590:2009+A1:2010, Automotive fuels — Diesel — Requirements and test methods EN 14214, Automotive fuels — Fatty acid methyl esters (FAME) for diesel engines — Requirements and test methods EN 15376, Automotive fuels — Ethanol as a blending component for petrol — Requirements and test methods EN 60296, Fluids for electrotechnical applications — Unused mineral insulating oils for transformers and switchgear (IEC 60296) EN ISO/IEC 17025:2005, General requirements for the competence of testing and calibration laboratories (ISO/IEC 17025:2005) 3 Terms and definitions For the purposes of this European Standard, the following terms and definitions apply. 3.1 automatic tank gauge (ATG) device capable, as a minimum, of providing a measurement of the level of liquid contained in a storage tank without the need for manual access into the tank 3.2 ullage product quantity which can safely be delivered into the tank without running the risk of exceeding the maximum safe filling capacity SIST EN 13352:2012

NOTE The temperature category are intended to cover Over-ground, Underground, Indoor and Protected environments. 4.2 Variations in the properties of stored products The performance requirements for ATGs according to 5.1 and 5.2 shall be satisfied when using one or more of the following test liquids: Type 1 Diesel according to EN 590:2009+A1:2010; Type 2 Transformer oil according to EN 60296. NOTE 1 The above test liquids have defined ranges of variations in their physical properties. NOTE 2 The above test liquids cover also the characteristics of gasoline and bio-fuels (including bio-diesel and ethanol-gasoline blends) for level and temperature measurements only. 4.3 Humidity For all classes of gauging system, the performance shall be unaffected by humidity, i.e. the gauge sensors shall operate in conditions of 95 % non-condensing humidity. SIST EN 13352:2012

The method of type testing for level measurement is given in Clause 9. 5.2 Temperature measurement Where average product temperature measurement is provided, the performance requirements for temperature measurement according to Table 3 shall be satisfied. Table 3 — Temperature measurement performance requirements Class

Maximum permissible error

° C A ± 1,0 B ± 2,0 C Not prescribed

The method of type testing for temperature measurement is given in Clause 9. 5.3 Water detection Where water detection is provided, this facility shall: 5.3.1 Detect a minimum free water level of 30 mm when the probe has been installed on the bottom of the tank. SIST EN 13352:2012

The correct provision of essential information shall be verified through the type approval test procedure described in Clause 8. NOTE 1 With a multiple tank system, a single indicator device for the gauge sensors can be provided in which case it should be capable of being switched between tanks or should switch automatically between tanks and should then indicate clearly to which tank the information shown refers. NOTE 2 To achieve accurate volume measurement, an accurate tank capacity table is required. Suggested methods for generating tank capacity tables are referenced in Annex B (informative). SIST EN 13352:2012

b) c) {A}

{O}

{B}

{P} [W] {C}

{U}

Items bracketed { } are required. One option from each classification shall be given. Items bracketed [

] are optional. For example, a sensor achieving class of performance B, over the temperature range of category U and capable of water detection would be designated BUW. These designations shall not be affixed other than to sensors within the range of tank sizes specified by manufacturer for which approval has been obtained. 5.7.2 Indicator devices (where separate from the sensor) shall be designated according to the following classifications as established by the relevant test methods: a) measurement performance (class A, B or C in accordance with Table2 and Table 3); b) the temperature range over which this class of performance is achieved (category O or I according to 4.1). These classifications shall be designated each by a single letter according to the following syntax: SIST EN 13352:2012

Items bracketed { } are required. One option from each classification shall be given. For example, an indicator unit achieving class of performance B, over the temperature range of category I would be designated BI. 6 Test methods 6.1 Sampling The gauging system to be tested shall consist of one sample of the ATG including gauge sensors which cover the longest gauge sensor length for which they will obtain approval. 6.2 Test sequence Prior to testing, the manufacturer shall state the class of measurement performance against which the gauging system is to be assessed. For each gauge sensor contained in the gauging system to be tested, the manufacturer shall also state the temperature category, the measuring range and whether water detection is provided. For each indicator device (if separate from the gauge sensors) the manufacturer shall also state the relevant temperature category. The device under test shall be the subject of three tests, the test parameter bands in each case being selected according to the relevant ranges as stated by the manufacturer. These tests shall be conducted in the following order: test for the provision of essential information, according to Clause 8. test for level and temperature measurement performance, according to Clause 9. test for water detection capability, according to Clause 10, if relevant. 6.3 Test report The results of the three tests according to 6.2 shall be compiled into a test report in accordance with 5.10 of EN ISO/IEC 17025:2005. This report shall include at least the following information: a) identification of the ATG and details of the length of the sensor tested, stating the approval apply to all sensor lengths up to the length of the sensor tested; b) date of manufacture of the product; c) dates for the beginning and end of each test; d) reference to this standard and the test methods used; e) any variants of any test method; f) the class of measurement performance assessed; SIST EN 13352:2012

9.4.2 Preparation The gauge sensor under test shall be mounted in the test vessel in accordance with the manufacturer’s installation instructions. The manufacturer’s installation materials should be used whenever possible. The gauge sensor under test is connected to the indicator device under test, which is situated in ambient laboratory conditions. Power shall then be applied to the ATG and the ATG shall be commissioned in accordance with the manufacturer’s instructions. After installation and commissioning, the test vessel shall be filled with the test liquid to its maximum level. Three consecutive level readings are taken from the RLMD and the ATG’s level reading is set equal to that of the RLMD. The environmental monitoring devices shall be installed in the vicinity of the ATG’s components such that the environmental conditions can be monitored. The monitors are used throughout the duration of the tests to ensure that all tests are conducted within a temperature range of +15 °C to +35 °C, humidity range of 25 % to 75 % non condensing and a pressure range of 860 mbar to 1 060 mbar. 9.4.3 Trial run The purpose of the trial run is to establish that the ATG is operating correctly. With the ATG under test fully operational, the test vessel is filled with the test liquid to a level of 60 % of the ATG’s measuring range. The product level test vessel is then left to stabilise until the reading of the RLMD is stable to within 1/3 of the level-MPE under test. After stabilisation, three consecutive level readings are taken from both the RLMD and ATG. The sets of readings for the RLMD and ATG are individually averaged. The average level reading for the ATG, when compared to the averaged level reading of the RLMD, shall be within the band of the maximum permissible error ATG for the class in question plus the maximum permissible error of the RLMD. The test vessel shall be then further left to stabilise at room temperature. After stabilisation, three consecutive temperature readings shall be taken from both the RTMD and ATG. The sets of readings for the RTMD and ATG are individually averaged. The average temperature reading for the ATG, when compared to the averaged temperature reading of the RTMD, shall be within the band of the maximum permissible error ATG for the class in question plus the maximum permissible error of the RTMD. 9.4.4 MPE test A for level 9.4.4.1 General

The measuring range of the ATG, as specified by the manufacturer, is divided into 12 bands according to Table 6. SIST EN 13352:2012

Table 6 — Definition of level measurement bands Band Range Band no. 1 010+ % of the ATG’s measuring range Band no. 2 5 % to 10 % of the ATG’s measuring range Band no. 3 11 % to 20 % of the ATG’s measuring range Band no. 4 21 % to 30 % of the ATG’s measuring range Band no. 5 31 % to 40 % of the ATG’s measuring range Band no. 6 41 % to 50 % of the ATG’s measuring range Band no. 7 51 % to 60 % of the ATG’s measuring range Band no. 8 61 % to 70 % of the ATG’s measuring range Band no. 9 71 % to 80 % of the ATG’s measuring range Band no. 10 81 % to 90 % of the ATG’s measuring range Band no. 11 91 % to 95 % of the ATG’s measuring range Band no. 12 10010+ % of the ATG’s measuring range

Two measurements shall be performed at a test level randomly selected within each band. One measurement is performed when filling the tank, the other is performed when emptying the tank. The test consists of one filling/emptying cycle during which the test liquid is kept at a room temperature and stable within (± 1) °C. Individual sensor temperatures will be recorded throughout the test to ensure that stratification does not exceed 3 K. The level measurements shall be made using the following procedure: 9.4.4.2 Filling The first part of a cycle shall consist of the recording of the environmental parameters as measured by the environmental monitors. Also the test liquid used for the cycle shall be recorded plus the average product temperature as measured by the RTMD. Starting with an empty tank, pump the test liquid into the test vessel until a level within band no. 1 is reached. The test vessel shall be then left to stabilise until the reading of the RLMD is stable to within one third of the MPE under test. If the reading of the ATG is not stable within the MPE under test, during 1 min, the device has failed the test. If the level is stable, record three consecutive level readings of both the ATG and the RLMD. Average the three readings for the ATG and record it as LF1. Average the three readings for the RLMD and record it as RF1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...