ISO/TTA 1:1994

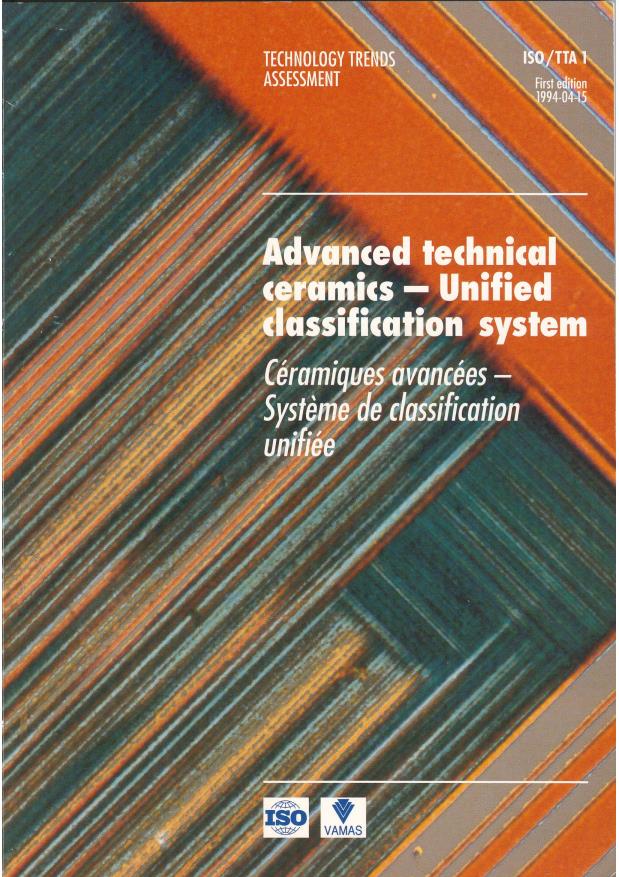

(Main)Advanced technical ceramics — Unified classification system

Advanced technical ceramics — Unified classification system

Céramiques avancées — Système de classification unifiée

General Information

- Status

- Withdrawn

- Publication Date

- 20-Apr-1994

- Withdrawal Date

- 20-Apr-1994

- Technical Committee

- ISO/TC 206 - Fine ceramics

- Drafting Committee

- ISO/TC 206 - Fine ceramics

- Parallel Committee

- VAMAS - Versailles Project on Advanced Materials and Standards

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 12-Jul-2017

- Completion Date

- 12-Feb-2026

Frequently Asked Questions

ISO/TTA 1:1994 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Advanced technical ceramics — Unified classification system". This standard covers: Advanced technical ceramics — Unified classification system

Advanced technical ceramics — Unified classification system

ISO/TTA 1:1994 is classified under the following ICS (International Classification for Standards) categories: 81.060.01 - Ceramics in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TTA 1:1994 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

lSO/l-l-A 1:1994(E)

Cover:

Photograph of a 0,2 mm x 0,2 mm square single crystal of the high tem-

perature superconductor Y Ba2CusO7.+ showing the orthogonal twin

structure characteristic of this material.

Photograph courtesy of Frank W. Gayle, Debra L. Kaiser and Leonard C.

Smith, Materials Science and Engineering Laboratory, National Institute of

Standards and Technology.

0 IS0 1994

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization Standardization

for

Case postale 56 l CH-12 11 Geneve 20 l Switzerland

Printed in Switzerland

ii

0 IS0 ISO/TTA 1:1994(E)

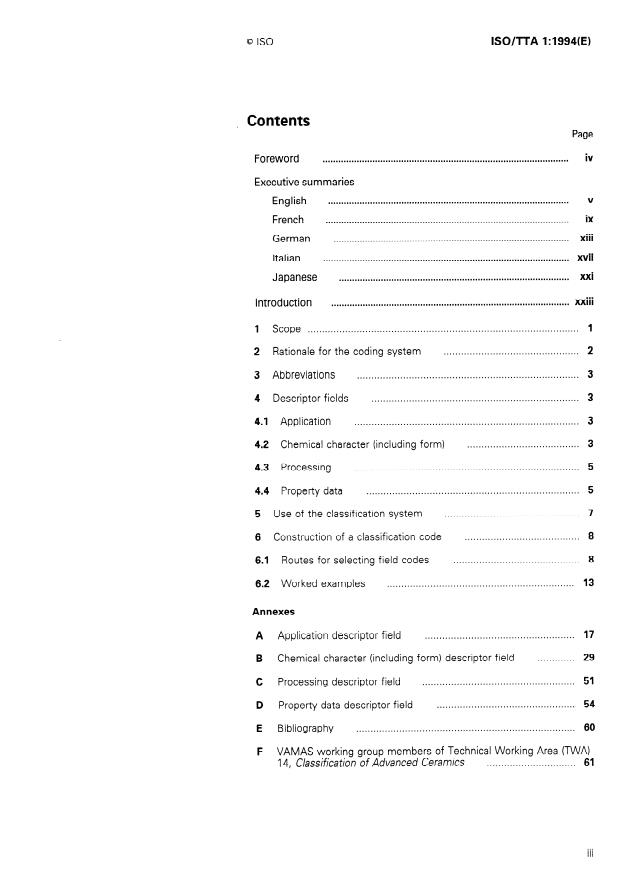

Contents

\

Page

iv

..............................................................................................

Foreword

Executive summaries

V

English .

ix

French .

...

XIII

German .

xvii

Italian .

xxi

........................................................................................

Japanese

I.

XXIII

...........................................................................................

Introduction

..............................................................................................

1 Scope

...............................................

2 Rationale for the coding system

3 Abbreviations .

4 Descriptor fields .

............................... 3

4.1 Application .

.......................................

4.2 Chemical character (including form)

..............................................................................

4.3 Processing

..........................................................................

4.4 Property data

...............................................

5 Use of the classification system

........ 8

................................

6 Construction of a classification code

............................................

6.1 Routes for selecting field codes

.................................................................

6.2 Worked examples

Annexes

.................................................... 17

A Application descriptor field

............. 29

B Chemical character (including form) descriptor field

.....................................................

C Processing descriptor field

............................. 54

. . . .“.q.

D Property data descriptor field

.............................

E Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Working Area (TWA)

F VAMAS working group members of Technical

. . . 61

14, Classification of Advanced Ceramics

Q IS0

Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work

of preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(I EC) on all matters of electrotechnical standardization.

To respond to the need for global collaboration on standardization

questions at early stages of technological innovation, the IS0 Council,

following recommendations of the lSO/IEC Presidents’ Advisory Board on

Technological Trends, decided to establish a new series of IS0 publi-

cations named “Technology Trends Assessments” (ISO/TTA). These

publications are the results of either direct cooperation with prestandard-

ization organizations or ad hoc workshops of experts concerned with

standardization needs and trends in emerging fields.

Technology Trends Assessments are thus the result of prestandardization

work or research. As a condition of publication by ISO, ISO/TTAs shall not

conflict with existing International Standards or draft International Stan-

dards (DIS), but shall contain information that would normally form the

basis of standardization. IS0 has decided to publish such documents to

promote the harmonization of the objectives of ongoing prestandardization

work with those of new initiatives in the Research and Development en-

vironment. It is intended that these publications will contribute towards

rationalization of technological choice prior to market entry.

This Technology Trends Assessment, ISOnTA 1, has been developed by

the Versailles Project on Advanced Materials and Standards (VAMAS)

(see [I] and [2] for further information on this organization) and is pub-

lished under a Memorandum of Understanding concluded between IS0

and VAMAS. It reports the results of the Technical Working Area (TWA)

14 of VAMAS, which had the task of proposing a classification of advanced

technical ceramics and which retains the responsibility for the technical

content of this lSO/TTA. Users of this lSO/TTA who would like information

on the research project should refer to the full report of VAMAS

TWA 14 [3] which was prepared under the leadership of Dr S. Schneider,

Jr., from NIST, Gaithersburg, Maryland 20899-0001, USA. The IS0 Tech-

nical Board approved the publication of this classification as an lSO/TTA in

August 1993.

Whilst lSO/TTAs are not standards, it is hoped that they will be used as

a basis for standards development in future national and international

standardization processes. In the particular case of lSO/TTA 1, the publi-

cation has been brought to the attention of Technical Committee

lSO/TC 206, Fine ceramics, for use in its standardization work.

ISO/ll-A 1:1994(E)

EXECUTIVE SUMMARY

As a consequence of modern day technology needs, materials technologies have seen a

waning of commodity materials usage in parallel with a commensurate increased

demand for engineered materials that perform totally new functions or old functions in

much better ways. Accordingly, a wave of new products using advanced materials are

appearing with regularity on the marketplace. Among, these new materials types,

advanced ceramics have emerged as a premier class that has enabled current

technologies to be improved, and new technologies possible.

Advanced ceramics currently are market entities and have been for many years. With

more in the offing, estimates place world markets to be tens of billions of dollars by

year 2000. Even so, advanced ceramics have not been generally recognized as a

separate materials class, distinct from other types of ceramic materials. Currently

standardization systems are out of date and must be adjusted to factor in a coherent

way, advanced ceramics and other new material products along with the more

traditional materials. Otherwise every facet of science and technology and associated

parts of the economy, from the individual researchers and consumers, to

manufacturers, to whole industries, to the financial community, to governments and

nations, will devise their own set of advanced ceramic definitions, append various

labels and develop tabulation specifications that more often than not, conflict one to

another. This discordant process is already underway.

The standardization issue is complex, but one obvious first need is the development of

a classification system for advanced ceramics products that defines what they are,

what they are good for, and when statistics or other data are compiled, tells the level

of associated activity, element by element. In recognition of this need, the Versailles

Project on Advanced Materials and Standards (VAMAS) in 1988 established a new

project, Technical Work Area, Number 14 (TWA 14) on the classification of

advanced ceramics to provide the pre-standards foundation and building block guide

for an internationally acceptable system.

Three strategic objectives of TWA 14 set the

directions of the international effort:

1 . To identify and assess the issues inherent in developing a classification system

for advanced ceramics;

2 . To establish a classification structure suitable for international use in a

compendium of ways, including industrial economic statisticai indicators,

ISO/l-l-A 1:1994(E)

materials and property databases, and products, standards and literature

categorizations; and,

3 To develop mechanisms and international institutional links for system

.

implementation.

The objectives were achieved through a work plan that included: an assessment of

existing classifications systems and terminology; a worldwide survey of the

classification practices and preferences of industry; and, an international workshop to

develop a detailed technical basis for the preferred industrial scheme. These, and

associated work activities culminated in the development of a full range classification

system for advanced technical ceramics, having the following features:

l

Defines “advanced technical ceramics” for classification purposes asi “a highly

engineered, high performance, predominately non-metallic, inorganic, ceramic

This definition encompasses a

material having specific functional attributes”.

diverse range of materials and product classes separated along physical

applications like mechanical, thermal, electrical, etc., but excludes commodity

products, such as building materials and refractories.

Identifies and lists 500 different product types as advanced technical ceramics;

Establishes a comprehensive classification system for advanced technical

ceramics that is capable of expansion to accommodate new products or the

inclusion of other ceramic classes;

*

Provides a non-hierarchical, matrix-type scheme of classification that is

accessible by a number of entry and retrieval routes to build relational

databases; and,

Provides a machine readable coding system built upon four independent

descriptor fields and corresponding subdivisions that may be sequenced in any

Each descriptor field is separately

order to match the users preference.

identified by a unique initial code letter:

A for application,

C for chemical character and product form,

P for processing and

D for property data.

vi

lSO/ll-A 1:1994(E)

The unique code letters act as field separators in long coding strings. Detailed listings

are provided for complete coding by subdivision categories of each of the independent

descriptor fields.

Overall the utility of the classification system is multi-fold. Its use is advantageous at

the company level for purposes involving assembly of design and materials property

Industry can use the system for

databases, or tabulation of inventories, or invoicing.

gathering and sorting trend data on market behavior or R&D expenditures, or for

literature categorization. At the government level, the system can be used for

gathering national and international economic data, or other vital statistics, or: for

determining demographics of the field.

This page intentionally left blank

ISO/TI-A 1:1994(E)

RESUME

Les besoins de la technologie moderne ont entrame une diminution de l’usage des

materiaux de commodites et parallelement, une augmentation de la demande pour des

materiaux de specialites capables d’assurer des fonctions completement nouvelles ou

de remplir des fonctions traditionnelles d’une man&e beaucoup plus efficace. Ainsi,

de nouveaux produits utilisant ces materiaux avances apparaissent regulierement sur le

marche. Parmi ces classes de nouveaux materiaux, les ceramiques avancees se

signalent comme la premiere generation qui a permis l’amelioration des technologies

actuelles et l’emergence de nouvelles technologies.

Les ceramiques avancees sont devenus des produits industriels et ce depuis plusieurs

an&es. Les estimations placent le marche mondial de ces produits a plusieurs

milliards de dollars a l’horizon de l’an 2000, et ce nest qu’un debut ! Malgre cela, les

ceramiques avancees n’ont pas ete generalement reconnues comme constituant une

classe a part de materiaux, distincte des autres types de materiaux ceramiques. A

l’heure actuelle, les systemes de normalisation sont perimes et doivent etre refondus

pour classer d’une man&e coherente les ceramiques avancees et d’autres nouveaux

materiaux ainsi que des materiaux plus traditionnels. Si cette tache n’est pas me&e a

bien, chaque domaine de la science et de technologie et les acteurs economiques qui

lui sont associes, des chercheurs et des consommateurs aux producteurs en passant par

l’industrie toute entiere, la communaute financiere, les gouvernements et les etats, tous

vont mettre sur pied leur propre dictionnaire des ceramiques avancees, donner des

noms varies et des specifications de codage qui trop souvent entreront en conflit l’une

avec l’autre. Ce processus dit de la “Tour de Babel” a deja commence.

Le probleme de la standardisation est complexe, mais l’un des premiers et des plus

evidents besoins est le developpement d’un systeme de classification pour les

ceramiques avancees qui definit ce qu’elles sont ; a quoi elles sont bonnes ; et quand

des statistiques ou d’autres donnees auront ete rassemblees, donnera le niveau

d’activite qui leur est associe, element par element. Prenant conscience de ce besoin,

le projet “Versailles Avanced Materials and Standards (VAMAS)“, crea en 1988 une

nouvelle commission “Technical Work Area” numero 14 (TWA 14) sur la

classification des ceramiques avancees pour jeter les bases d’une pre-standardisation et

rediger un guide des elements constitutifs d’un systeme de classification acceptable a

l’echelon international. Les 3 objectifs strategiques du TWA 14 montrent bien les axes

de l’effort international :

1 .

Identifier et evaluer les problemes inherents a la creation d’un systeme de

classification des ceramiques avancees. -

ix

lSO/TTA 1:1994(E)

. Etablir un schema de classification permettant un usage international, pour des

: des bases de donnees economiques et industrielles ;

usages diversifies tels que

des tables des materiaux des produits existants et de leurs proprietes ; un

classement des standards et de la litterature scientifique ; etc. .

3 . Developper les mecanismes et les liens institutionnels internationaux necessaires

a l’epanouissement du systeme.

Ces objectifs furent atteints grace a un plan de travail qui inclut une evaluation des

systemes de classification et des terminologies existantes et une recherche mondiale

des pratiques en mat&e de classification et des preferences de l’industrie, suivie d’un

seminaire international pour mettre sur pied les bases techniques detaillees du schema

ayant la preference des industriels. De tout cela et du travail qui lui a ete associe

emergea un systeme de classification complet des ceramiques avancees ayant les

caracteristiaues suivantes :

A

11 definit pour les besoins de la classification les “ceramiques avancees” comme

des ” materiaux ceramiques, de conception evoluee, a hautes performances,

inorganiques a dominante non metallique et presentant des attributs fonctionnels

specifiques”. Cette definition englobe des types de materiaux et de produits

assez divers qui sont classes selon leurs applications physiques comme la

mecanique, la thermique, l’industrie Clectrique etc. ., mais exclut les produits

de commodites comme les materiaux de construction et les refractaires.

11 ident.ifie et liste en tern1 s que ceramiques techniques avancees 500 types de

produits differents.

11 etablit un vaste systeme de classification pour les ceramiques techniques

avancees qui est susceptib e de recevoir des extensions et d’inclure de nouveaux

produits voire meme de nouveaux types de ceramiques.

11 apporte un systeme de classification non-hierarchique de type matriciel qui est

accessible par plusieurs entrees et permet done de construire des bases de

donnees relationnelles.

11 propose un systeme de codage lisible par une machine, bati autour de 4

champs de descripteurs independants, eux-memes sous-divises, qui peuvent etre

sequences dans un ordre quelconque selon la preference de l’utilisateur. Chaque

champ de descripteurs est identifie separement par une unique lettre initiale de

code.

ISO/TT’A 1:1994(E)

A pour les Applications.

C pour la nature Chimique et le type du produit.

P pour le Procede de fabrication.

D pour les Don&s sur les proprietes.

Ces lettres de code servent a &parer les champs dans les longues chai‘nes de codage.

Des listes detaillees sont fournies pour un codage complet par sous-categories pour

chacun des champs de descripteurs independants.

Les usages que l’on peut faire de ce systeme de classification sont multiples. Son

utilisation au niveau d’une entreprise est interessante pour rassembler des bases de

donnees sur la conception et les proprietes des materiaux, pour la tabulation des

inventaires, ou pour la facturation. L’industrie peut utiliser le systeme pour collecter

et trier des don&es sur le comportement du marche, les depenses R & D ou pour les

classement de la documentation scientifique. Au niveau gouvernemental, les systeme

pourra etre utilise pour collecter des donnees economiques a l’echelon national et

international, ou d’autres statistiques strategiques, ou encore pour determiner

l’evolution demographique du domaine.

XI

This page intentionally left blank

ISO/lTA 1:1994(E)

AUS-LICHE ZUSAMMENF’ASSUNG

Die modernen technologischen Erfordernisse fiihren zu einer Minderung im Gebrauch

der Massenwerkstoffe bei einem gleichzeitigen Anstieg des Bedarfs an

maf3geschneiderten Werkstoffen, die vollstandig neue Funktionen oder alte Funktionen

auf vie1 bessere Weise erfiillen. Dementsprechend erscheint regelmsig eine Welle

neuer Produkte im Handel, bei denen Hochleistungswerkstoffe eingesetzt werden.

Unter diesen neuen Werkstofftypen hat sich die Technische Hochleistungskeramik als

ein Werkstoff erster Giite herausgestellt, hat die Verbesserung der gegenwgrtigen

Technologien zugelassen und neue Technologien ermdglicht.

Die Technische Hochleistungskeramik ist seit Jahren eine MarktgrdRe, und das

Leistungspotential ist noch nicht ausgeschopft. So wird der Weltmarkt im Jahr 2000

auf mehrere 10 Milliarden Dollar geschgtzt. Trotzdem wurde Technische

Hochleistungskeramik nicht als eine getrennte Werkstoffklasse, die sich von anderem

keramischen Material unterscheidet, allgemein anerkannt. Heutige

Standardisierungssysteme sind veraltet. Sie miissen schliissig der Tatsache

entsprechend weiterentwickelt werden, da0 Technische Hochleistungskeramik und

andere neue Werkstoffprodukte zusammen mit den mehr traditionellen Werkstoffen

iibereinstimmend klassifiziert sind. Anderenfalls wiirde jede Facette in Wissenschaft

und Technologie, die jeweiligen Bereiche der Wirtschaft, vom einzelnen

Wissenschaftler und Verbraucher zu den Herstellern und ganzen Industrien, zur

Finanzwelt, den Regierungen und Nationen ihr eigenes System zur Kennzeichnung und

Klassifikation Keramischer Werkstoffe entwickeln, eigene Bezeichnungen einfiihren

und Listenspezifikationen entwickeln, die eher haufig als gar nicht zueinander im

Widerspruch stehen. Dieser auseinanderlaufende Prozen ist bereits im Gange.

Die Standardisierungsfrage ist komplex, aber eine erste offensichtliche Notwendigkeit

ist die Entwicklung eines Klassifikationssystems fur Produkte aus Technischer

Hochleistungskeramik, das Stuck fur Stuck bestimmt, woffir sie sind, wozu sie dienen

und, falls Statistiken oder andere Datensammlungen erstellt werden, das den Grad der

damit verbundenen Bearbeitung mitteilt. In der Erkenntnis dieses Erfordernisses

erstellte das Versailles Project on Advanced Materials and Standards (VAMAS) im ’

Jahr 1988 ein neues Projekt, die Technische Arbeitsgruppe Nr. 14 (TWA 14) zur

Klassifizierung van Technischer Hochleistungskeramik, urn eine pranormative

Grundlage zu schaffen und einen Rahmen zu erstellen fur ein international

annehmbares System. Drei strategische Ziele von TWA 14 kennzeichneten die

Zielrichtung der internationalen Bemiihungen:

. . .

XIII

1 . Bestimmung und Bewertung der Fragen im Zusammenhang mit der

Entwicklung eines Klassifikationssystems fur Technische Hochleistungskeramik

2 . Erstellung einer Klassifikationsstruktur, die zum internationalen Gebrauch

in einer vielftiligen Weise einschliefilich industrieller, wirtschaftlicher,

statistischer Indikatoren, Werkstoff- und Werkstoffeigenschaftsdatenbanken,

Produkt-, Normen-und Literatur-Einordnung geeignet ist

3 .

Entwicklung von Mechanismen und internationalen institutionalisierten

Verbindungen fiir die Einfiihrung des Systems.

Die Ziele wurden durch einen Arbeitsplan erreicht, der die folgenden Elemente

einschlok Bewertung der existierenden Klassifikationssysteme und Terminologie; eine

weltweite Ubersicht der Klassifikationspraxis und Prioritaten der Industrie sowie einen

internationalen Workshop zur Entwicklung einer detaillierten technischen Grundlage

fur das von der Industrie bevorzugte Schema. Diese und die daraus folgenden

Arbeiten gipfelten in der Entwicklung eines umfassenden Klassifikationssystems fur

Technische Hochleistungskeramik, das durch die folgenden Elemente gekennzeichnet

ist:

Q

Es bezeichnet “Technische Hochleistungskeramik” zum Zweck der

Klassifikation als “eine hochentwickelte Hochleistungskeramik, die iiberwiegend

nichtmetallisch anorganisch ist und spezifische funktionale Eigenschaften

aufweist”. Diese Definition schlieRt eine Vielzahl von Werkstoffen und

Produktklassen ein, diedurch physikalische Anwendungen, wie mechanisch,

thermisch, elektrisch usw., gegliedert sind, aber schlieBt Massenprodukte wie

Baumaterial und Feuerfestmaterial aus.

Es benennt und fiihrt 500 verschiedene Produkttypen als Technische

Hochleistungskeramik auf.

Es erstellt ein zusammengeftites Klassifikationssystem fur Technische

Hochleistungskeramik, das erweiterbar ist, urn neue Produkte oder andere

Keramikklassen zu berficksichtigen bzw . einzuschlienen.

Es stellt ein nichthierarchisches Klassifikationsschema im Matrixformat dar,

das iiber eine Vielzahl von Zugangs- und Abfragewegen zuggnglich ist und eine

relationale Datenbank bildet.

xiv

ISO/lTA 1:1994(E)

l

Es stellt ein maschinenlesbares Codiersystem zur Verfiigung, das auf vier

unabhangigen Beschreibungsfeldern und zugehdrigen weiteren

Unterteilungen basiert, das in beliebiger Reihenfolge angeordnet werden kann,

so da.8 der Prioritat des Anwenders entsprochen wird. Jedes Descriptorfeld ist

einzeln durch einen einzigen Schliisselbuchstaben gekennzeichnet:

A fiir Anwendung

C fur chemischen Charakter und Produktform

P fur Verarbeitung und

D fur Eigenschaftsdaten.

Die einzelnen Codierungsbuchstaben trennen die einzelnen Felder in langen

Codierfolgen. Es werden dataillierte Listen zur vollstandigen Codierung durch

Untergruppenbildung fur jedes der unabhangigen Descriptorfelder aufgefiihrt.

Das Klassifikationssystem erweist sich als vielfaltig verwendbar. In den Unternehmen

kann es vorteilhaft zu Zwecken der Herstellung, der Konstruktion und fiir

Werkstoffeigenschaftsdatenbanken, zur Erstellung von Listen zur Lagerhaltung oder

Buchhaltung eingesetzt werden. Die Wirtschaft kann das System zur Sammlung und

Gliederung von Trenddaten zum Marktverhalten oder fiir Forschungs- und

Entwicklungs-Ausgaben oder zur Literaturordnung verwenden. Auf Regierungsebene

kann das System zur Sammlung nationaler und internationaler Wirtschaftsdaten, fur

andere wesentliche Statistiken und fur die Bestimmung des demographischen Umfeldes

eingesetzt werden.

xv

This page intentionally left blank

lSO/-lTA 1:1994(E)

SOMMARIO

A seguito delle variate necessita’ delle tecnologie moderne, si assiste oggi a un decline

dell’ impiego dei materiali di largo consume al quale corrisponde un aumento della

domanda di materiali ingegneristici capaci di offtire funzioni totalmente nuove oppure

di svolgere funzioni tradizionali ma in modo notevolmente migliore. Di conseguenza,

vengono introdotti sul mercato con consistente flusso un insieme di nuovi prodotti

basati sull’ impiego di nuovi materiali.

Tra questi tipi di nuovi materiali, le ceramiche

avanzate si sono proposte come una classe tra le piu’ interessanti in quanto hanno

consentito il miglioramento di tecnologie tradizionali e reso possibili nuove tecnologie.

Le ceramiche avanzate sono attualmente, e lo sono gia’ da vari anni, un interessante

segment0 di mercato. Confidando su aspettative di ulteriore consolidamento ed

estensione degli impieghi, si stima the il mercato mondiale nel 2000 possa

raggiungere decine di miliardi di dollari. Nonostante queste premesse, le ceramiche

avanzate non sono state in generale considerate come una classe separata di materiali,

distinta cioe’ dagli atri tipi di materiali ceramici. Attualmente i sistemi di normazione

sono arretrati e necessitano di correzioni onde renderli idonei a descrivere in modo

coerente le ceramiche avanzate a gli altri prodotti a base di nuovi materiali, rispetto ai

materiali piu’ tradizionali. In case contrario, ciascuna realta’ operativa della scienza e

della tecnologia e delle componenti economiche a queste associate, dai singoli

ricercatori ai consumatori, ai produttori, all’ industria utlizzatrice, alla comunita’

finanziaria, ai governi e alle nazioni, vorranno darsi proprie definizioni di ceramica

avanzata, proprie etichette, proprie specifiche the, piu’ spesso the non, saranno in

conflitto tra di loro. Quest0 process0 di scarsa sintonia e’ gia’ in atto.

11 problema della normazione e’ complesso, ma una prima ovvia necessita’ e’ di

procedere allo sviluppo di un sistema di classificazione per i prodotti the usano

ceramiche avanzate il quale definisca cosa esse siano e a quali fini esse siano idonee, e

the una volta completato sia capace di fornire le informazioni di dettaglio per ciascun

suo elemento. Sulla base della predetta esigenza, nel 1988 il VAMAS (Versailles

Project on Advanced Materials and Standards) ha attivato un nuovo progetto TWA 14

(Technical Working Area, Number 14) indirizzato specificamente alla classificazione

delle ceramiche avanzate al fine di offrire le basi di pre-normazione e una guida a

blocchi per un sistema fruibile a live110 internazionale.

L’attivita’ de1 TWA 14 e’ stata indirizzata su tre obbiettivi strategici:

1 .

Identificare e valutare le problematiche inerenti alla messa a punto di una

~

classifkazione per le ceramiche avanzate;

I

xvii

lSO/TTA I :1994(E)

2 . Creare una struttura di classificazione appropriata all’ uso internazionale e

fruibile per una molteplicita’ di funzioni quali indicatori statistici

industriali/economici, banche dati per materiali/proprieta’ /prodotti,

categorizzazione di norme e dati bibliografici, etc.

Sviluppare un meccanismo di collegamenti istituzionali internazionali per

3 .

implementare il sistema.

I suddetti obblettivi sono stati conseguiti attraverso un piano di lavoro the

comprendeva; una valutazione dei sistemi di classificazione e della terminologia

esistenti; una rassegna a live110 mondiale delle modalita’ seguite dall’ industria nella

classificazione e relativi orientamenti preferenziali; un “workshop” internazionale

inteso a individuare e realizzare una dettagliata base tecnica per lo schema di

Le suddette attivita’, e quelle loro associate,

classificazione preferito dall’ industria.

sono culminate nello sviluppo di un sistema di classificazione onnicomprensivo per le

ceramiche tecniche avanzate, the presenta le seguenti caratteristiche:

D&in&e, a scope di classificazione, le “ceramiche tecniche avanzate” come un

“mater& ceramic0 altamente ingegnerizzato, di alte prestazioni, inorganic0 ed

essenzialmente non metallico, avente specifici attributi funzionali” ;

Identifica ed elenca, come ceramiche tecniche avanzate, 500 differenti tipi di

prodotto;

Stabilisce un sistema complete di classificazione per le ceramiche tecniche

avanzate suscettibile di essere esteso per accogliere nuovi prodotti o altre classi

di ceramici;

Fornisce uno schema di classificazione a base matriciale, non gerarchico

fruibile me&ante varie chiavi di access0 e procedure iterative per costruire

banche dati;

Fornisce un sistema codificato e informatizzato costruito con quattro campi

descrittori indipendenti, e corrispondenti suddivisioni, the possono essere

sequenzate in qualsiasi ordine al fine di soddisfare le preferenze dell’

utilizzatore. Ciascun campo descrittore viene identificato da una lettera:

A per l’impiego (Application)

C per la chimica e la forma de1 prodotto (Chemistry)

P per la tecnologia di fabbricazione (Processing)

D per le proprieta’ (Data)

*.

XVIII

lSO/lTA 1:1994(E)

Le singole lettere de1 codice hanno anche la funzione di separare i campi, nel case di

Vengono forniti dettagliati elenchi per una codifkazione

codici molto lunghi.

completa delle categoric in cui viene suddiviso ciascun campo descrittore.

Nell’insieme, il sistema di classificazione elaborato si presenta di grande utilita’ sotto

vari aspetti. 11 suo impiego e’ vantaggioso a live110 di azienda per scopi the

coinvolgano la progettazione, banche dati sui materiali, tabulazione di inventari,

fatturazione. L’industria puo’ utilizzare il sistema per ottenere e selezionare dati di

tendenza de1 mercato o sugli investimenti di R&S, o per la categorizzazione di

informazioni bibliografiche. A live110 governativo il sistema puo’ essere impiegato

per acquisire dati economici nazionali e internazionali, e altre statistiche di grande

interesse, o per studi demografici de1 settore.

xix

This page intentionally left blank

ISO/=ITA 1:1994(E)

xxi

lSO/TTA 1:1994(E)

0 IS0

Introduction

An international survey and workshop on the classification of advanced

ceramics [3] found that most respondents defined advanced technical

ceramics as

highly engineered, high pe rformance, predominantly non-metallic, in-

0 rganic, ceramic ma terials h aving spec fit functional attributes”.

This definition describes a diverse range of materials and product classes

usually distinguished by their primary physical application, e.g. mechanical,

thermal, electrical, etc.

The principle behind the system proposed in this lSO/TTA was established

in meetings of the Versailles Project on Advanced Materials and Standards

(VAMAS), Technical Working Area (TWA) 14, and the task of the consult-

ants was to establish the terminology and a means of coding it [3]. [See

annex F for a list of the VAMAS working group members of Technical

Working Area (TWA) 14, Classification of Advanced Ceramics.]

The primary objective of this ISOnTA is thus to propose a classification

system for advanced technical ceramics which can form the basis for a

multi-level database (to be defined elsewhere). A further objective is to

define categories within the classification in order to define fully an ad-

vanced technical ceramic component or product which is encompassed

by the following descriptor fields:

Application

Chemistry

Form

Processing

Properties

These descriptor fields were identified by the international survey [3] as

being the most important fields in the identification and categorization of

advanced technical ceramics. The fields Application and Chemistry were

found to be of primary importance, whereas the others were recognized

as being important if a more rigorous identification or description was re-

quired.

. . .

XXIII

Q IS0

xxiv

TECHNOLOGY TRENDS ASSESSMENT o IS0 ISO/TTA 1:1994(E)

Advanced technical ceramics

- Unified classification

system

1 Scope

This lSO/TTA proposes a unified classification system for advanced technical ceramics, intended to meet the fol-

lowing objectives.

- It should provide a comprehensive description of materials, products and applications of advanced technical

ceramics.

- It should be able to accommodate new materials and products as they become available.

- It should be accessible via the following four descriptor fields, either individually or in combination:

Application

Chemical character (including form)

Processing

Property data

- Its coding system should be machine readable, thereby providing a means of sorting data within the descriptor

fields.

- Its coding system should be such that it can be simplified by truncation and elimination of redundant characters

or, where only limited information is required, by limitation of the number of descriptor fields.

- The coding system should be simple to use and employ characters and strings which are both easy to recog-

nize and relate to classification information.

The term “advanced technical ceramics” covers a wide range of materials (some having complex chemistry) which

may be used in diverse applications. For the purposes of this ISODTA it is assumed that advanced technical cer-

amics include materials in the following forms:

monolithic ceramics

powders

composite ceramics

fibres

glasses

glass ceramics

coatings

porous materials

and, in addition to the readily recognized “ceramic” materials, halides and single crystals.

0 IS0

ISO/lTA 1:1994(E)

Specifically excluded from the classification system are the following:

elemental carbon, except for speci ic ceramic forms such as diamond, vitreous carbon and chemical vapour

deposited (CVD) graphite;

it forms an integral component of or precursor for an advanced technical

elemental silicon, other than when

ceramic;

elemental germanium and other elemental or compound semi-metallic substances;

traditional ceramics based on clay, including

whitewares (e.g. tableware and fine porcelain),

sanitary wares,

floor and wall tiles, and

building ceramics (e.g. bricks and pipes);

unshape.d and shaped refractories and bulk glasses for tonnage applications.

The mode of use of the classification system will be determined by the objective behind its use. It is not the

purpose of this ISOnTA to define how the system should be used, but examples are given of how it might be

used. It is intended that the user can define the coding combination and the level of detail to suit his particular

purpose.

2 Rationale for the coding system

It is clear that for a multicomponent classification system such as that proposed, the associated coding system is

vital in ensuring that the system is workable. The coding system should also be comprehensive enough to en-

compass and describe adequately the wide range of data covered by the classification.

Since a funda mental 0 bjective is to provide a means of c lassifyi any combinatio n of descrip tor fields in any se-

quence priate to user ne eds, each field is identified by a u niq ue upper case I ette r code:

appro

Application

Chemical character (including form)

Processing

property Data

These letters do not appear in any other part of the coding system and hence can be used uniquely to identify a

given descriptor field and hence the sequence in which the fields are used need not be fixed. The letters also act

as field separators in long coding strings -

the presence of one of the letters indicating that what follows (i.e.

until the next descriptor field letter occurs) relates to that descriptor field.

In addition, it is envisaged that for most users only a limited number of descriptor fields will be relevant. An ex-

ample of the use of the classification system by limited descriptor use may be the user seeking statistical infor-

mation on product manufacture or sales where only application and/or chemical character will be of interest A

more detailed outline of the likely use of this form of classification system is given in table I.

One of the findings of the questionnaire on this topic [3] was the relative importance (or perceived usefulness)

of the application and chemical character descriptors, and it is clear that the use of the classification system by

these two descriptors should be as convenient as possible.

0 IS0

3 Abbreviations

CVD chemical vapour deposition

I

rllP hot isostatically pressed

PSZ partially stabilized zirconia

PVD physical vapour deposition

TZP tetragonal zirconia polycrystals

4 Descriptor fields

4.1 Application

This field is identified by the upper case letter A.

Information in co ntained in a three-digit code corresponding to a particular application. A full list of ap-

this field is

numbers IS given In annex A .

plications and correspondi

ng

The coding format for this descriptor is

where ytytyt is the number corresponding to the particular application.

In the list in annex A, applications are separated into, initially, a hierarchical series of areas by the principal func-

tions of the product as defined by

- electrical insulation;

- electronic/ionic conduction;

- mechanical functions, including wear, at or near ambient temperature;

- thermal and thermomechanical functions, where dimensional stability at raised temperature, heat insulation,

heat conduction or resistance to thermal shock are the principal functions, and where additionally mechanical

loads may be applied;

- nuclear functions, where the component plays either an active or a passive nuclear role;

- optical functions, where the component plays a functional role as an optical element in reflection, refraction,

transmission or absorption of electromagnetic radiation;

- chemical functions, including biomedical, where the component is employed for handling melts, chemicals,

solutions or atmospheres because of its resistance to attack by them, and in the case of biomedical materials,

a degree of biocompatibility;

- magnetic functions, where the component possesses properties allowing a functional magnetic role.

The first digit of the three-digit code is given by the principal physical function as above. The subsequent digits

are non-hierarchical, and follow the listing in annex A. To aid the identification of codes, an alphabetical index of

applications is given in A.3.

4.2 Chemical character (including form)

4.2.1 General

This field contains information relating to chemical character and form, and is identified by the upper case

letter C.

0 IS0

lSO/TTA 1:1994(E)

Owing to the relatively complex chemistry and the likelihood of the presence of a number of compounds and

forms, this part of the coding system is required to be particularly versatile. It is proposed that the chemical

character code should contain at least three essential items of information:

a) descriptor field identifier (C);

b) overall form of the item expressed as one or two upper case letters, i.e. powder, fibre, rigid ceramic body, etc;

c) numerical identification of the chemical formula (of the major constituent at least) or material type.

Subsequent coding items may be included to identify the purity of the major component, and the form and

chemistry of minor constituents. In these cases the form descriptors also act as separators between related

compounds.

4.2.2 Options for numerical codes

The complexity of the chemistry associated with advanced technical ceramics places a heavy responsibility on the

numerical coding system used to describe it. A number of options are suggested to accommodate the user’s

preference to describe a product’s chemical character (i.e. chemical formula or generic material type, and purity

or compositional range).

4.2.2.1 Options for denoting chemical formula or generic material type

The options are based on a four-digit code to denote chemical formula or material type. A list of code numbers

and associated definitions are given in annex B.

4.2.2.2 Options for the definition of chemical purity or compositional range

NOTE 1 Identification of an option as option 1 or option 2 does not infer or rank order of priority.

4.2.2.2.1 Option 1

The addition of a fifth digit, following the four-digit chemical character code, indicating the quantity of the material

defined by the preceding four-digit code. The fifth digit would indicate the mass fraction as follows:

1 < 1 %

2 > 1 % < 10%

3 > 10 % < 30 %

50 %

4 > 30 % <

5 > 50 % < 70 %

6 > 70 % < 90 %

7 > 90 % < 99 %

8 > 99 %

If the value is undefined or undefinable then the digit may be omitted.

4.2.2.2.2 Option 2

The addition of the purity or mass fraction in parentheses (.) following the four-digit code. The use of this option

is governed by the following set of rules.

a) The sole presence of a number within the parentheses indicates the percentage of the material present For

single-constituent strings, this figure would define the purity level; for multiple items, i.e. where the chemical

character is described in the long form, this would denote the composition.

0 IS0

lSO/TTA 1:1994(E

b) The presence within the parentheses of the symbol < or > followed by a number indicates the maximum o

minimum content of the constituent, e.g.

(< 90) indicates maximum content 90 %;

(> 99,99) indicates minimum content 99,99 % (probably used to signify purity).

The presence within the parentheses of two numbers separated by a hyphen (-) indicates a range of compo-

d

sition, e.g.

(95-98,5) indicates that the material contains between 95 % and 98,5 % of the constituent in question.

4.2.3 Coding principle

In simple form a chemical character code would have the following appearance:

CFBnnnn

where FB identifies the material as fibre blanket and nnnn defines its composition.

A chemical character coding could, however, have the appearance

CEExxxx7MFyyyy2MBzz~zl (option I)

which indicates that the material is a powder (diameter < 100 pm) of a compound XXX.X(> 90 % G 99 %) physically

mixed (MF) with a chemical compound (MB) of yyyy(> 1 % < IO %) and ZZZZ(< 1 %), or

CEExx.xx(~ 90)MFyyyy(O,5-4,5)MBzzzz(0,5) (option 2)

Form descriptors (single letters or pairs of letters) and the numeric codes for individual compounds are given in

annex B.

4.3 Processing

This field is identified by the upper case letter P.

The information contained in this part of the coding system relates to the processes to which the product has been

subjected and hence may contain several independent items. To accommodate this, the coding system comprises

a series of strings comprising the following elements:

Pmm

where mm is a number relating to a process stage defined in the list in annex C.

The process coding for a ceramic body might have the appearance

indicating that the powder used was prepared by chemical precipitation (7) and then spray dried (I 2) prior to

isostatic pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...