ISO/TS 16949:2002

(Main)Quality management systems — Particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations

Quality management systems — Particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations

This Technical Specification, in conjunction with ISO 9001:2000, defines the quality management system requirements for the design and development, production and, when relevant, installation and service of automotive-related products. This Technical Specification is applicable to sites of the organization where customer-specified parts, for production and/or service, are manufactured. Supporting functions, whether on-site or remote (such as design centres, corporate headquarters and distribution centres), form part of the site audit as they support the site, but cannot obtain stand-alone certification to this Technical Specification. This Technical Specification can be applied throughout the automotive supply chain.

Systèmes de management de la qualité — Exigences particulières pour l'application de l'ISO 9001:2000 pour la production de série et de pièces de rechange dans l'industrie automobile

L'ISO/TS 16949, conjointement avec l'ISO 9001:2000, définit les exigences en matière de système de management de la qualité pour la conception, le développement, la production et, le cas échéant, l'utilisation, et les prestations de service associées aux produits du secteur automobile. L'ISO/TS 16949 est applicable aux «sites» de production des pièces de série et rechange des organismes où les produits spécifiés par le client sont fabriqués. Les «fonctions support» situées sur le site ou séparées, telles que les centres d'études et de conception, les sièges sociaux et les centres de distribution, font partie intégrante de l'audit du site, dès l'instant qu'ils contribuent à l'activité du site. Elles ne peuvent cependant pas obtenir de certification séparée selon l'ISO/TS 16949. L'ISO/TS 16949 peut être appliquée tout au long de la chaîne d'approvisionnement du secteur automobile.

Posebne zahteve za uporabo ISO 9001:2000 v organizacijah s serijsko proizvodnjo in proizvodnjo nadomestnih delov v avtomobilski industriji

General Information

- Status

- Withdrawn

- Publication Date

- 13-Mar-2002

- Withdrawal Date

- 13-Mar-2002

- Technical Committee

- ISO/TC 176 - Quality management and quality assurance

- Drafting Committee

- ISO/TC 176 - Quality management and quality assurance

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 12-Jun-2009

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 18-Dec-2008

- Effective Date

- 15-Apr-2008

ISO/TS 16949:2002 - Quality management systems -- Particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations

ISO/TS 16949:2002 - Systemes de management de la qualité -- Exigences particulieres pour l'application de l'ISO 9001:2000 pour la production de série et de pieces de rechange dans l'industrie automobile

ISO/TS 16949:2002 - Quality management systems -- Particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations

Get Certified

Connect with accredited certification bodies for this standard

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

Sponsored listings

Frequently Asked Questions

ISO/TS 16949:2002 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Quality management systems — Particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations". This standard covers: This Technical Specification, in conjunction with ISO 9001:2000, defines the quality management system requirements for the design and development, production and, when relevant, installation and service of automotive-related products. This Technical Specification is applicable to sites of the organization where customer-specified parts, for production and/or service, are manufactured. Supporting functions, whether on-site or remote (such as design centres, corporate headquarters and distribution centres), form part of the site audit as they support the site, but cannot obtain stand-alone certification to this Technical Specification. This Technical Specification can be applied throughout the automotive supply chain.

This Technical Specification, in conjunction with ISO 9001:2000, defines the quality management system requirements for the design and development, production and, when relevant, installation and service of automotive-related products. This Technical Specification is applicable to sites of the organization where customer-specified parts, for production and/or service, are manufactured. Supporting functions, whether on-site or remote (such as design centres, corporate headquarters and distribution centres), form part of the site audit as they support the site, but cannot obtain stand-alone certification to this Technical Specification. This Technical Specification can be applied throughout the automotive supply chain.

ISO/TS 16949:2002 is classified under the following ICS (International Classification for Standards) categories: 03.100.70 - Management systems; 03.120.10 - Quality management and quality assurance; 43.020 - Road vehicles in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TS 16949:2002 has the following relationships with other standards: It is inter standard links to ISO/TS 16949:2009, ISO/TS 16949:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TS 16949:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2002

Posebne zahteve za uporabo ISO 9001:2000 v organizacijah s serijsko proizvodnjo

in proizvodnjo nadomestnih delov v avtomobilski industriji

Quality management systems -- Particular requirements for the application of ISO

9001:2000 for automotive production and relevant service part organizations

Systèmes de management de la qualité -- Exigences particulières pour l'application de

l'ISO 9001:2000 pour la production de série et de pièces de rechange dans l'industrie

automobile

Ta slovenski standard je istoveten z: ISO/TS 16949:2002

ICS:

03.120.10 Vodenje in zagotavljanje Quality management and

kakovosti quality assurance

43.020 Cestna vozila na splošno Road vehicles in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL ISO/TS

SPECIFICATION 16949

Second edition

2002-03-01

Corrected version

2003-12-15

Quality management systems —

Particular requirements for the application

of ISO 9001:2000 for automotive production

and relevant service part organizations

Systèmes de management de la qualité —

Exigences particulières pour l'application de l'ISO 9001:2000 pour la

production de série et de pièces de rechange dans l'industrie automobile

Reference number

©

ISO 2002

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading

this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in

this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Printed in Switzerland

The content inside the boxed text of this document is ISO 9001:2000 text and is protected by the above copyright

statement.

The text outside the boxes has been originated by the International Automotive Task Force. Copyright for this text is

held by ANFIA, CCFA/FIEV, SMMT, VDA (see below) and the car manufacturers DaimlerChrysler, Ford Motor

Company, General Motors Corp.

Neither this Technical Specification nor any extract from it may be reproduced in a retrieval system or transmitted in

any form or by any means, electronic, photocopying, recording or otherwise without prior written permission being

secured.

Requests for permission to reproduce and/or translate non-boxed text should be addressed to one of the addresses

below:

International Automotive Oversight Bureau (IAOB/USA)

Associazione Nazionale Fra Industrie Automobilistiche (ANFIA/Italy)

Comité des Constructeurs Français d'Automobiles (CCFA/France)

Fédération des Industries des Équipements pour Véhicules (FIEV/France)

Society of Motor Manufacturers and Traders (SMMT/UK)

Verband der Automobilindustrie - Qualitätsmanagement Center (VDA-QMC/Germany)

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

ii

– All rights reserved

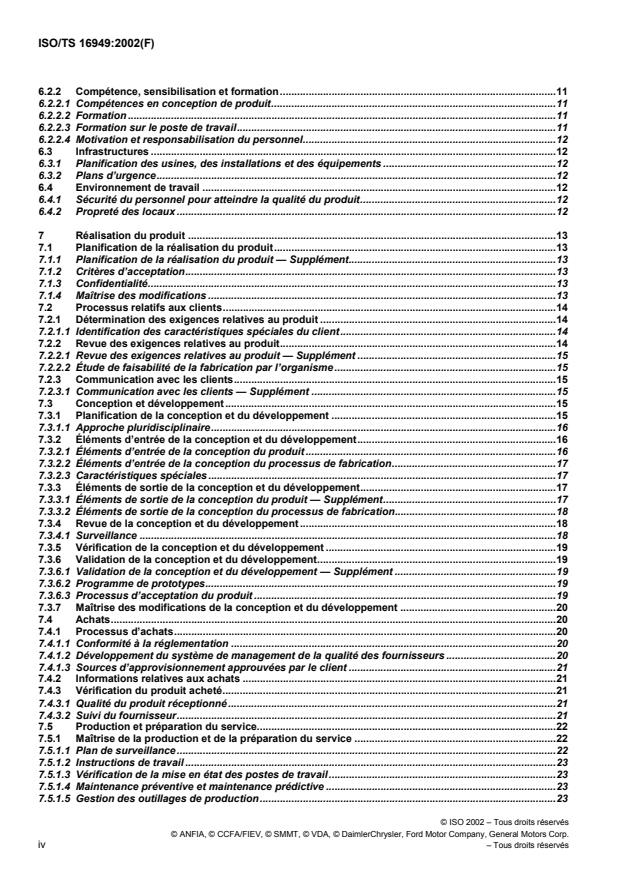

Contents

Page

Foreword vii

Remarks for certification viii

Introduction ix

0.1 General ix

0.2 Process approach ix

0.3 Relationship with ISO 9004 xi

0.3.1 IATF Guidance to ISO/TS 16949:2002 xi

0.4 Compatibility with other management systems xi

0.5 Goal of this Technical Specification xii

1 Scope 1

1.1 General 1

1.2 Application 1

2 Normative reference 2

3 Terms and definitions 2

3.1 Terms and definitions for the automotive industry 2

4 Quality management system 3

4.1 General requirements 3

4.1.1 General requirements — Supplemental 4

4.2 Documentation requirements 4

4.2.1 General 4

4.2.2 Quality manual 5

4.2.3 Control of documents 5

4.2.3.1 Engineering specifications 5

4.2.4 Control of records 6

4.2.4.1 Records retention 6

5 Management responsibility 6

5.1 Management commitment 6

5.1.1 Process efficiency 6

5.2 Customer focus 7

5.3 Quality policy 7

5.4 Planning 7

5.4.1 Quality objectives 7

5.4.1.1 Quality objectives — Supplemental 7

5.4.2 Quality management system planning 7

5.5 Responsibility, authority and communication 8

5.5.1 Responsibility and authority 8

5.5.1.1 Responsibility for quality 8

5.5.2 Management representative 8

5.5.2.1 Customer representative 8

5.5.3 Internal communication 8

5.6 Management review 9

5.6.1 General 9

5.6.1.1 Quality management system performance 9

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

iii

– All rights reserved

5.6.2 Review input 9

5.6.2.1 Review input — Supplemental 9

5.6.3 Review output 10

6 Resource management 10

6.1 Provision of resources 10

6.2 Human resources 10

6.2.1 General 10

6.2.2 Competence, awareness and training 10

6.2.2.1 Product design skills 11

6.2.2.2 Training 11

6.2.2.3 Training on the job 11

6.2.2.4 Employee motivation and empowerment 11

6.3 Infrastructure 11

6.3.1 Plant, facility and equipment planning 11

6.3.2 Contingency plans 12

6.4 Work environment 12

6.4.1 Personnel safety to achieve product quality 12

6.4.2 Cleanliness of premises 12

7 Product realization 12

7.1 Planning of product realization 12

7.1.1 Planning of product realization — Supplemental 13

7.1.2 Acceptance criteria 13

7.1.3 Confidentiality 13

7.1.4 Change control 13

7.2 Customer-related processes 13

7.2.1 Determination of requirements related to the product 13

7.2.1.1 Customer-designated special characteristics 14

7.2.2 Review of requirements related to the product 14

7.2.2.1 Review of requirements related to the product — Supplemental 14

7.2.2.2 Organization manufacturing feasibility 14

7.2.3 Customer communication 14

7.2.3.1 Customer communication — Supplemental 15

7.3 Design and development 15

7.3.1 Design and development planning 15

7.3.1.1 Multidisciplinary approach 15

7.3.2 Design and development inputs 15

7.3.2.1 Product design input 16

7.3.2.2 Manufacturing process design input 16

7.3.2.3 Special characteristics 16

7.3.3 Design and development outputs 16

7.3.3.1 Product design outputs — Supplemental 17

7.3.3.2 Manufacturing process design output 17

7.3.4 Design and development review 17

7.3.4.1 Monitoring 17

7.3.5 Design and development verification 18

7.3.6 Design and development validation 18

7.3.6.1 Design and development validation — Supplemental 18

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

iv

– All rights reserved

7.3.6.2 Prototype programme 18

7.3.6.3 Product approval process 18

7.3.7 Control of design and development changes 19

7.4 Purchasing 19

7.4.1 Purchasing process 19

7.4.1.1 Regulatory conformity 19

7.4.1.2 Supplier quality management system development 19

7.4.1.3 Customer-approved sources 19

7.4.2 Purchasing information 20

7.4.3 Verification of purchased product 20

7.4.3.1 Incoming product quality 20

7.4.3.2 Supplier monitoring 20

7.5 Production and service provision 21

7.5.1 Control of production and service provision 21

7.5.1.1 Control plan 21

7.5.1.2 Work instructions 21

7.5.1.3 Verification of job set-ups 21

7.5.1.4 Preventive and predictive maintenance 22

7.5.1.5 Management of production tooling 22

7.5.1.6 Production scheduling 22

7.5.1.7 Feedback of information from service 22

7.5.1.8 Service agreement with customer 22

7.5.2 Validation of processes for production and service provision 23

7.5.2.1 Validation of processes for production and service provision — Supplemental 23

7.5.3 Identification and traceability 23

7.5.3.1 Identification and traceability — Supplemental 23

7.5.4 Customer property 24

7.5.4.1 Customer-owned production tooling 24

7.5.5 Preservation of product 24

7.5.5.1 Storage and inventory 24

7.6 Control of monitoring and measuring devices 24

7.6.1 Measurement system analysis 25

7.6.2 Calibration/verification records 25

7.6.3 Laboratory requirements 25

7.6.3.1 Internal laboratory 25

7.6.3.2 External laboratory 25

8 Measurement, analysis and improvement 26

8.1 General 26

8.1.1 Identification of statistical tools 26

8.1.2 Knowledge of basic statistical concepts 26

8.2 Monitoring and measurement 26

8.2.1 Customer satisfaction 26

8.2.1.1 Customer satisfaction — Supplemental 26

8.2.2 Internal audit 27

8.2.2.1 Quality management system audit 27

8.2.2.2 Manufacturing process audit 27

8.2.2.3 Product audit 27

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

v

– All rights reserved

8.2.2.4 Internal audit plans 27

8.2.2.5 Internal auditor qualification 28

8.2.3 Monitoring and measurement of processes 28

8.2.3.1 Monitoring and measurement of manufacturing processes 28

8.2.4 Monitoring and measurement of product 29

8.2.4.1 Layout inspection and functional testing 29

8.2.4.2 Appearance items 29

8.3 Control of nonconforming product 29

8.3.1 Control of nonconforming product — Supplemental 30

8.3.2 Control of reworked product 30

8.3.3 Customer information 30

8.3.4 Customer waiver 30

8.4 Analysis of data 30

8.4.1 Analysis and use of data 31

8.5 Improvement 31

8.5.1 Continual improvement 31

8.5.1.1 Continual improvement of the organization 31

8.5.1.2 Manufacturing process improvement 31

8.5.2 Corrective action 31

8.5.2.1 Problem solving 32

8.5.2.2 Error-proofing 32

8.5.2.3 Corrective action impact 32

8.5.2.4 Rejected product test/analysis 32

8.5.3 Preventive action 32

Annex A (normative) Control plan 33

A.1 Phases of the control plan 33

A.2 Elements of the control plan 33

Bibliography 34

NOTE In this table of contents, ISO 9001:2000 headings are normal type face, IATF headings are in italics.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

vi

– All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International Standard

requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a technical

committee may decide to publish other types of normative document:

an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in an

ISO working group and is accepted for publication if it is approved by more than 50 % of the members of the

parent committee casting a vote;

an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting a

vote.

An ISO/PAS or ISO/TS is reviewed after three years with a view to deciding whether it should be confirmed for a

further three years, revised to become an International Standard, or withdrawn. In the case of a confirmed ISO/PAS

or ISO/TS, it is reviewed again after six years at which time it has to be either transposed into an International

Standard or withdrawn.

Manufacturers Association, Inc. (JAMA), with support from ISO/TC 176, Quality management and quality assurance.

This second edition of ISO/TS 16949 cancels and replaces the first edition (ISO/TS 16949:1999), which has been

technically revised.

Boxed text is original ISO 9001:2000 text. The sector-specific supplemental requirements are outside the boxes.

In this Technical Specification, the word “shall” indicates a requirement. The word “should” indicates a

recommendation. Paragraphs marked “NOTE” are for guidance in understanding or clarifying the associated

requirement.

Where the term “such as” is used, any suggestions given are for guidance only.

Annex A forms a normative part of this Technical Specification.

This corrected version of ISO/TS 16949:2002 incorporates the following corrections:

e-mail address of IAOB corrected on page viii;

year of publication corrected in 0.3.1;

the term “supplier” replaced by “the organization's” in Note to 7.6.3.1;

“agree with” replaced by “approve” in last paragraph of 8.3.4.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

vii

– All rights reserved

Remarks for certification

The certification to this Technical Specification, including customer-specific requirements if any, is recognized by

the customer members of IATF when achieved according to the IATF certification scheme (see the “Rules for

achieving IATF recognition”).

Details can be obtained at the addresses of the local oversight bodies of IATF cited below:

Associazione Nazionale Fra Industrie Automobilistiche (ANFIA)

Web site: www.anfia.it e-mail: anfia@anfia.it

International Automotive Oversight Bureau (IAOB)

Web site: www.iaob.org e-mail: quality@aiag.org

Fédération des Industries des Équipements pour Véhicules (FIEV)

Comité des Constructeurs Français d'Automobiles (CCFA)

Web site: www.iatf-france.com e-mail: iatf@iatf-france.com

Society of Motor Manufacturers and Traders Ltd. (SMMT Ltd.)

Web site: www.smmt.co.uk e-mail: quality@smmt.co.uk

Verband der Automobilindustrie Qualitätsmanagement Center (VDA-QMC)

Web site: www.vda-qmc.de e-mail: info@vda-qmc.de

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

viii

– All rights reserved

Introduction

0.1 General

ISO 9001:2000, Quality management systems — Requirements

Introduction

0.1 General

The adoption of a quality management system should be a strategic decision of an organization. The design and

implementation of an organization's quality management system is influenced by varying needs, particular

objectives, the products provided, the processes employed and the size and structure of the organization. It is not

the intent of this International Standard to imply uniformity in the structure of quality management systems or

uniformity of documentation.

The quality management system requirements specified in this International Standard are complementary to

requirements for products. Information marked “NOTE” is for guidance in understanding or clarifying the

associated requirement.

This International Standard can be used by internal and external parties, including certification bodies, to assess

the organization's ability to meet customer, regulatory and the organization's own requirements.

The quality management principles stated in ISO 9000 and ISO 9004 have been taken into consideration during

the development of this International Standard.

0.2 Process approach

ISO 9001:2000, Quality management systems — Requirements

0.2 Process approach

This International Standard promotes the adoption of a process approach when developing, implementing and

improving the effectiveness of a quality management system, to enhance customer satisfaction by meeting

customer requirements.

For an organization to function effectively, it has to identify and manage numerous linked activities. An activity

using resources, and managed in order to enable the transformation of inputs into outputs, can be considered as a

process. Often the output from one process directly forms the input to the next.

The application of a system of processes within an organization, together with the identification and interactions of

these processes, and their management, can be referred to as the “process approach”.

An advantage of the process approach is the ongoing control that it provides over the linkage between the

individual processes within the system of processes, as well as over their combination and interaction.

When used within a quality management system, such an approach emphasizes the importance of

a) understanding and meeting requirements,

b) the need to consider processes in terms of added value,

c) obtaining results of process performance and effectiveness, and

d) continual improvement of processes based on objective measurement.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

ix

– All rights reserved

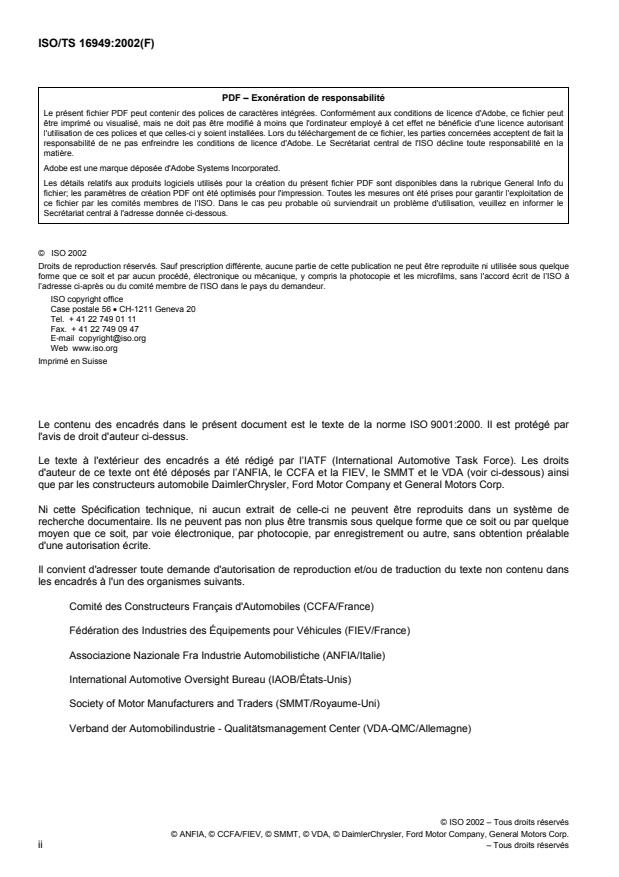

The model of a process-based quality management system shown in Figure 1 illustrates the process linkages

presented in clauses 4 to 8. This illustration shows that customers play a significant role in defining requirements

as inputs. Monitoring of customer satisfaction requires the evaluation of information relating to customer

perception as to whether the organization has met the customer requirements. The model shown in Figure 1

covers all the requirements of this International Standard, but does not show processes at a detailed level.

NOTE In addition, the methodology known as “Plan-Do-Check-Act” (PDCA) can be applied to all processes. PDCA can be

briefly described as follows.

Plan: establish the objectives and processes necessary to deliver results in accordance with customer requirements and

the organization's policies.

Do: implement the processes.

Check: monitor and measure processes and product against policies, objectives and requirements for the product and

report the results.

Act: take actions to continually improve process performance.

Figure 1 — Model of a process-based quality management system

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

x

– All rights reserved

0.3 Relationship with ISO 9004

ISO 9001:2000, Quality management systems — Requirements

0.3 Relationship with ISO 9004

The present editions of ISO 9001 and ISO 9004 have been developed as a consistent pair of quality management

system standards which have been designed to complement each other, but can also be used independently.

Although the two International Standards have different scopes, they have similar structures in order to assist their

application as a consistent pair.

ISO 9001 specifies requirements for a quality management system that can be used for internal application by

organizations, or for certification, or for contractual purposes. It focuses on the effectiveness of the quality

management system in meeting customer requirements.

ISO 9004 gives guidance on a wider range of objectives of a quality management system than does ISO 9001,

particularly for the continual improvement of an organization's overall performance and efficiency, as well as its

effectiveness. ISO 9004 is recommended as a guide for organizations whose top management wishes to move

beyond the requirements of ISO 9001, in pursuit of continual improvement of performance. However, it is not

intended for certification or for contractual purposes.

NOTE The knowledge and use of the eight quality management principles referred to in ISO 9000:2000 and ISO 9004:2000

should be demonstrated and cascaded through the organization by top management.

0.3.1 IATF Guidance to ISO/TS 16949:2002

“IATF Guidance to ISO/TS 16949:2002” is a document containing recommended automotive industry practices,

examples, illustrations and explanations, and provides assistance in the application to conform to the requirements

of this Technical Specification.

This IATF Guidance document is not intended for certification or for contractual purposes

0.4 Compatibility with other management systems

ISO 9001:2000, Quality management systems — Requirements

0.4 Compatibility with other management systems

This International Standard has been aligned with ISO 14001:1996 in order to enhance the compatibility of the two

standards for the benefit of the user community.

This International Standard does not include requirements specific to other management systems, such as those

particular to environmental management, occupational health and safety management, financial management or

risk management. However, this International Standard enables an organization to align or integrate its own

quality management system with related management system requirements. It is possible for an organization to

adapt its existing management system(s) in order to establish a quality management system that complies with

the requirements of this International Standard.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

xi

– All rights reserved

0.5 Goal of this Technical Specification

The goal of this Technical Specification is the development of a quality management system that provides for

continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain.

This Technical Specification, coupled with applicable customer-specific requirements, defines the fundamental

quality management system requirements for those subscribing to this document.

This Technical Specification is intended to avoid multiple certification audits and provide a common approach to a

quality management system for automotive production, and relevant service part organizations.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

xii

– All rights reserved

TECHNICAL SPECIFICATION ISO/TS 16949:2002(E)

Quality management systems ------ Particular requirements for the

application of ISO 9001:2000 for automotive production and

relevant service part organizations

1 Scope

1.1 General

ISO 9001:2000, Quality management systems — Requirements

1 Scope

1.1 General

This International Standard specifies requirements for a quality management system where an organization

a) needs to demonstrate its ability to consistently provide product that meets customer and applicable regulatory

requirements, and

b) aims to enhance customer satisfaction through the effective application of the system, including processes for

continual improvement of the system and the assurance of conformity to customer and applicable regulatory

requirements.

NOTE In this International Standard, the term “product” applies only to the product intended for, or required by, a customer.

This Technical Specification, in conjunction with ISO 9001:2000, defines the quality management system

requirements for the design and development, production and, when relevant, installation and service of

automotive-related products.

This Technical Specification is applicable to sites of the organization where customer-specified parts, for production

and/or service, are manufactured.

Supporting functions, whether on-site or remote (such as design centres, corporate headquarters and distribution

centres), form part of the site audit as they support the site, but cannot obtain stand-alone certification to this

Technical Specification.

This Technical Specification can be applied throughout the automotive supply chain.

1.2 Application

ISO 9001:2000, Quality management systems — Requirements

1.2 Application

All requirements of this International Standard are generic and are intended to be applicable to all organizations,

regardless of type, size and product provided.

Where any requirement(s) of this International Standard cannot be applied due to the nature of an organization

and its product, this can be considered for exclusion.

Where exclusions are made, claims of conformity to this International Standard are not acceptable unless these

exclusions are limited to requirements within clause 7, and such exclusions do not affect the organization's ability,

or responsibility, to provide product that meets customer and applicable regulatory requirements.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

The only permitted exclusions for this Technical Specification relate to 7.3 where the organization is not

responsible for product design and development.

Permitted exclusions do not include manufacturing process design.

2 Normative reference

The following normative document contains provisions, which, through reference in this text, constitute provisions of

this Technical Specification. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this Technical Specification are encouraged to

investigate the possibility of applying the most recent edition of the normative document indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 9000:2000, Quality management systems — Fundamentals and vocabulary

3 Terms and definitions

ISO 9001:2000, Quality management systems — Requirements

3 Terms and definitions

For the purposes of this International Standard, the terms and definitions given in ISO 9000 apply.

The following terms, used in this edition of ISO 9001 to describe the supply chain, have been changed to reflect

the vocabulary currently used:

———— ————

supplier X organization X customer

The term “organization” replaces the term “supplier” used in ISO 9001:1994, and refers to the unit to which this

International Standard applies. Also, the term “supplier” now replaces the term “subcontractor”.

Throughout the text of this International Standard, wherever the term “product” occurs, it can also mean “service”.

3.1 Terms and definitions for the automotive industry

For the purposes of this Technical Specification, the terms and definitions given in ISO 9000:2000 and the following

apply.

3.1.1

control plan

documented description of the systems and processes required for controlling product (see annex A)

3.1.2

design responsible organization

organization with authority to establish a new, or change an existing, product specification

NOTE This responsibility includes testing and verification of design performance within the customer’s specified application.

3.1.3

error proofing

product and manufacturing process design and development to prevent manufacture of nonconforming products

3.1.4

laboratory

facility for inspection, test or calibration that may include, but is not limited to, chemical, metallurgical, dimensional,

physical, electrical or reliability testing

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

3.1.5

laboratory scope

controlled document containing

specific tests, evaluations and calibrations that a laboratory is qualified to perform,

list of the equipment which it uses to perform the above, and

list of methods and standards to which it performs the above

3.1.6

manufacturing

process of making or fabricating

production materials,

production or service parts,

assemblies, or

heat treating, welding, painting, plating or other finishing services

3.1.7

predictive maintenance

activities based on process data aimed at the avoidance of maintenance problems by prediction of likely failure

modes

3.1.8

preventive maintenance

planned action to eliminate causes of equipment failure and unscheduled interruptions to production, as an output

of the manufacturing process design

3.1.9

premium freight

extra costs or charges incurred additional to contracted delivery

NOTE This can be caused by method, quantity, unscheduled or late deliveries, etc.

3.1.10

remote location

location that supports sites and at which non-production processes occur

3.1.11

site

location at which value-added manufacturing processes occur

3.1.12

special characteristic

product characteristic or manufacturing process parameter which can affect safety or compliance with regulations,

fit, function, performance or subsequent processing of product

4 Quality management system

4.1 General requirements

ISO 9001:2000, Quality management systems — Requirements

4 Quality management system

4.1 General requirements

The organization shall establish, document, implement and maintain a quality management system and continually

improve its effectiveness in accordance with the requirements of this International Standard.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

The organization shall

a) identify the processes needed for the quality management system and their application throughout the

organization (see 1.2),

b) determine the sequence and interaction of these processes,

c) determine criteria and methods needed to ensure that both the operation and control of these processes are

effective,

d) ensure the availability of resources and information necessary to support the operation and monitoring of these

processes,

e) monitor, measure and analyse these processes, and

f) implement actions necessary to achieve planned results and continual improvement of these processes.

These processes shall be managed by the organization in accordance with the requirements of this International

Standard.

Where an organization chooses to outsource any process that affects product conformity with requirements, the

organization shall ensure control over such processes. Control of such outsourced processes shall be identified

within the quality management system.

NOTE Processes needed for the quality management system referred to above should include processes for management

activities, provision of resources, product realization and measurement.

4.1.1 General requirements — Supplemental

Ensuring control over outsourced processes shall not absolve the organization of the responsibility of conformity to

all customer requirements.

NOTE See also 7.4.1 and 7.4.1.3.

4.2 Documentation requirements

4.2.1 General

ISO 9001:2000, Quality management systems — Requirements

4.2 Documentation requirements

4.2.1 General

The quality management system documentation shall include

a) documented statements of a quality policy and quality objectives,

b) a quality manual,

c) documented procedures required by this International Standard,

d) documents needed by the organization to ensure the effective planning, operation and control of its processes,

and

e) records required by this International Standard (see 4.2.4).

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

NOTE 1 Where the term “documented procedure” appears within this International Standard, this means that the procedure

is established, documented, implemented and maintained.

NOTE 2 The extent of the quality management system documentation can differ from one organization to another due to

a) the size of organization and type of activities,

b) the complexity of processes and their interactions, and

c) the competence of personnel.

NOTE 3 The documentation can be in any form or type of medium.

4.2.2 Quality manual

ISO 9001:2000, Quality management system — Requirements

4.2.2 Quality manual

The organization shall establish and maintain a quality manual that includes

a) the scope of the quality management system, including details of and justification for any exclusions (see 1.2),

b) the documented procedures established for the quality management system, or reference to them, and

c) a description of the interaction between the processes of the quality management system.

4.2.3 Control of documents

ISO 9001:2000, Quality management system — Requirements

4.2.3 Control of documents

Documents required by the quality management system shall be controlled. Records are a special type of

document and shall be controlled according to the requirements given in 4.2.4.

A documented procedure shall be established to define the controls needed

a) to approve documents for adequacy prior to issue,

b) to review and update as necessary and re-approve documents,

c) to ensure that changes and the current revision status of documents are identified,

d) to ensure that relevant versions of applicable documents are available at points of use,

e) to ensure that documents remain legible and readily identifiable,

f) to ensure that documents of external origin are identified and their distribution controlled, and

g) to prevent the unintended use of obsolete documents, and to apply suitable identification to them if they are

retained for any purpose.

4.2.3.1 Engineering specifications

The organization shall have a process to assure the timely review, distribution and implementation of all customer

engineering standards/specifications and changes based on customer-required schedule. Timely review should be

as soon as possible, and shall not exceed two working weeks.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

The organization shall maintain a record of the date on which each change is implemented in production.

Implementation shall include updated documents.

NOTE A change in these standards/specifications requires an updated record of customer production part approval when

these specifications are referenced on the design record or if they affect documents of production part approval process, such

as control plan, FMEAs, etc.

4.2.4 Control of records

ISO 9001:2000, Quality management system — Requirements

4.2.4 Control of records

Records shall be established and maintained to provide evidence of conformity to requirements and of the

effective operation of the quality management system. Records shall remain legible, readily identifiable and

retrievable. A documented procedure shall be established to define the controls needed for the identification,

storage, protection, retrieval, retention time and disposition of records.

NOTE 1 “Disposition” above includes disposal.

NOTE 2 “Records” also include customer-specified records.

4.2.4.1 Records retention

The control of records shall satisfy regulatory and customer requirements.

5 Management responsibility

5.1 Management commitment

ISO 9001:2000, Quality management systems — Requirements

5 Management responsibility

5.1 Management commitment

Top management shall provide evidence of its commitment to the development and implementation of the quality

management system and continually improving its effectiveness by

a) communicating to the organization the importance of meeting customer as well as statutory and regulatory

requirements,

b) establishing the quality policy,

c) ensuring that quality objectives are established,

d) conducting management reviews, and

e) ensuring the availability of resources.

5.1.1 Process efficiency

Top management shall review the product realization processes and the support processes to assure their

effectiveness and efficiency.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

5.2 Customer focus

ISO 9001:2000, Quality management systems — Requirements

5.2 Customer focus

Top management shall ensure that customer requirements are determined and are met with the aim of enhancing

customer satisfaction (see 7.2.1 and 8.2.1).

5.3 Quality policy

ISO 9001:2000, Quality management systems — Requirements

5.3 Quality policy

Top management shall ensure that the quality policy

a) is appropriate to the purpose of the organization,

b) includes a commitment to comply with requirements and continually improve the effectiveness of the quality

management system,

c) provides a framework for establishing and reviewing quality objectives,

d) is communicated and understood within the organization, and

e) is reviewed for continuing suitability.

5.4 Planning

5.4.1 Quality objectives

ISO 9001:2000, Quality management systems — Requirements

5.4 Planning

5.4.1 Quality objectives

Top management shall ensure that quality objectives, including those needed to meet requirements for product

[see 7.1 a)] are established at relevant functions and levels within the organization. The quality objectives shall be

measurable and consistent with the quality policy.

5.4.1.1 Quality objectives — Supplemental

Top management shall define quality objectives and measurements that shall be included in the business plan and

used to deploy the quality policy.

NOTE Quality objectives should address customer expectations and be achievable within a defined time period.

5.4.2 Quality management system planning

ISO 9001:2000, Quality management systems — Requirements

5.4.2 Quality management system planning

Top management shall ensure that

a) the planning of the quality management system is carried out in order to meet the requirements given in 4.1, as

well as the quality objectives, and

b) the integrity of the quality management system is maintained when changes to the quality management system

are planned and implemented.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

5.5 Responsibility, authority and communication

5.5.1 Responsibility and authority

ISO 9001:2000, Quality management systems — Requirements

5.5 Responsibility, authority and communication

5.5.1 Responsibility and authority

Top management shall ensure that the responsibilities and authorities are defined and communicated within the

organization.

5.5.1.1 Responsibility for quality

Managers with responsibility and authority for corrective action shall be promptly informed of products or processes

which do not conform to requirements.

Personnel responsible for product quality shall have the authority to stop production to correct quality problems.

Production operations across all shifts shall be staffed with personnel in charge of, or delegated responsibility for,

ensuring product quality.

5.5.2 Management representative

ISO 9001:2000, Quality management systems — Requirements

5.5.2 Management representative

Top management shall appoint a member of management who, irrespective of other responsibilities, shall have

responsibility and authority that includes

a) ensuring that processes needed for the quality management system are established, implemented and

maintained,

b) reporting to top management on the performance of the quality management system and any need for

improvement, and

c) ensuring the promotion of awareness of customer requirements throughout the organization.

NOTE The responsibility of a management representative can include liaison with external parties on matters relating to the

quality management system.

5.5.2.1 Customer representative

Top management shall designate personnel with responsibility and authority to ensure that customer requirements

are addressed. This includes selection of special characteristics, setting quality objectives and related training,

corrective and preventive actions, product design and development.

5.5.3 Internal communication

ISO 9001:2000, Quality management systems — Requirements

5.5.3 Internal communication

Top management shall ensure that appropriate communication processes are established within the organization

and that communication takes place regarding the effectiveness of the quality management system.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

5.6 Management review

5.6.1 General

ISO 9001:2000, Quality management systems — Requirements

5.6 Management review

5.6.1 General

Top management shall review the organization's quality management system, at planned intervals, to ensure its

continuing suitability, adequacy and effectiveness. This review shall include assessing opportunities for

improvement and the need for changes to the quality management system, including the quality policy and quality

objectives.

Records from management reviews shall be maintained (see 4.2.4).

5.6.1.1 Quality management system performance

These reviews shall include all requirements of the quality management system and its performance trends as an

essential part of the continual improvement proc

...

TECHNICAL ISO/TS

SPECIFICATION 16949

Second edition

2002-03-01

Corrected version

2003-12-15

Quality management systems —

Particular requirements for the application

of ISO 9001:2000 for automotive production

and relevant service part organizations

Systèmes de management de la qualité —

Exigences particulières pour l'application de l'ISO 9001:2000 pour la

production de série et de pièces de rechange dans l'industrie automobile

Reference number

©

ISO 2002

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading

this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in

this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Printed in Switzerland

The content inside the boxed text of this document is ISO 9001:2000 text and is protected by the above copyright

statement.

The text outside the boxes has been originated by the International Automotive Task Force. Copyright for this text is

held by ANFIA, CCFA/FIEV, SMMT, VDA (see below) and the car manufacturers DaimlerChrysler, Ford Motor

Company, General Motors Corp.

Neither this Technical Specification nor any extract from it may be reproduced in a retrieval system or transmitted in

any form or by any means, electronic, photocopying, recording or otherwise without prior written permission being

secured.

Requests for permission to reproduce and/or translate non-boxed text should be addressed to one of the addresses

below:

International Automotive Oversight Bureau (IAOB/USA)

Associazione Nazionale Fra Industrie Automobilistiche (ANFIA/Italy)

Comité des Constructeurs Français d'Automobiles (CCFA/France)

Fédération des Industries des Équipements pour Véhicules (FIEV/France)

Society of Motor Manufacturers and Traders (SMMT/UK)

Verband der Automobilindustrie - Qualitätsmanagement Center (VDA-QMC/Germany)

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

ii

– All rights reserved

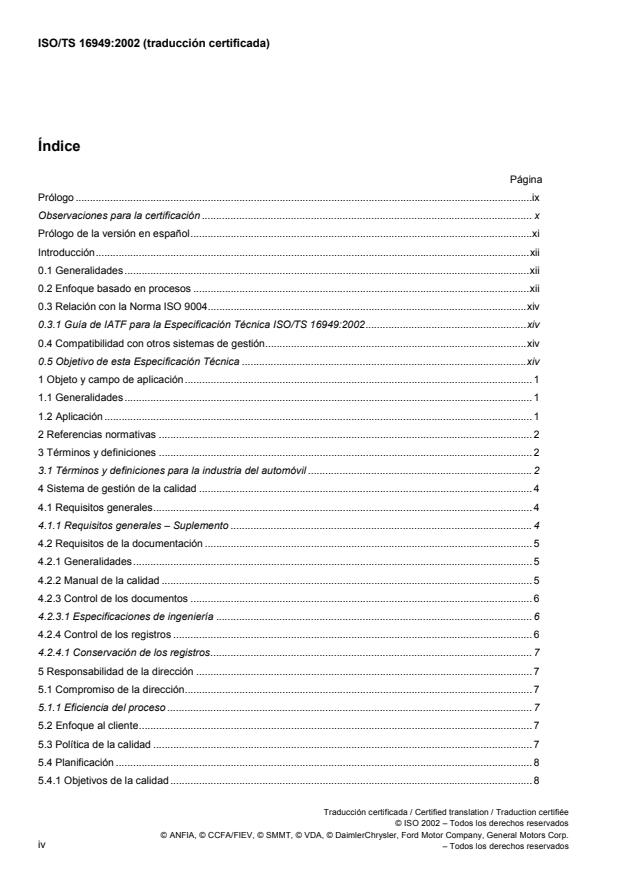

Contents

Page

Foreword vii

Remarks for certification viii

Introduction ix

0.1 General ix

0.2 Process approach ix

0.3 Relationship with ISO 9004 xi

0.3.1 IATF Guidance to ISO/TS 16949:2002 xi

0.4 Compatibility with other management systems xi

0.5 Goal of this Technical Specification xii

1 Scope 1

1.1 General 1

1.2 Application 1

2 Normative reference 2

3 Terms and definitions 2

3.1 Terms and definitions for the automotive industry 2

4 Quality management system 3

4.1 General requirements 3

4.1.1 General requirements — Supplemental 4

4.2 Documentation requirements 4

4.2.1 General 4

4.2.2 Quality manual 5

4.2.3 Control of documents 5

4.2.3.1 Engineering specifications 5

4.2.4 Control of records 6

4.2.4.1 Records retention 6

5 Management responsibility 6

5.1 Management commitment 6

5.1.1 Process efficiency 6

5.2 Customer focus 7

5.3 Quality policy 7

5.4 Planning 7

5.4.1 Quality objectives 7

5.4.1.1 Quality objectives — Supplemental 7

5.4.2 Quality management system planning 7

5.5 Responsibility, authority and communication 8

5.5.1 Responsibility and authority 8

5.5.1.1 Responsibility for quality 8

5.5.2 Management representative 8

5.5.2.1 Customer representative 8

5.5.3 Internal communication 8

5.6 Management review 9

5.6.1 General 9

5.6.1.1 Quality management system performance 9

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

iii

– All rights reserved

5.6.2 Review input 9

5.6.2.1 Review input — Supplemental 9

5.6.3 Review output 10

6 Resource management 10

6.1 Provision of resources 10

6.2 Human resources 10

6.2.1 General 10

6.2.2 Competence, awareness and training 10

6.2.2.1 Product design skills 11

6.2.2.2 Training 11

6.2.2.3 Training on the job 11

6.2.2.4 Employee motivation and empowerment 11

6.3 Infrastructure 11

6.3.1 Plant, facility and equipment planning 11

6.3.2 Contingency plans 12

6.4 Work environment 12

6.4.1 Personnel safety to achieve product quality 12

6.4.2 Cleanliness of premises 12

7 Product realization 12

7.1 Planning of product realization 12

7.1.1 Planning of product realization — Supplemental 13

7.1.2 Acceptance criteria 13

7.1.3 Confidentiality 13

7.1.4 Change control 13

7.2 Customer-related processes 13

7.2.1 Determination of requirements related to the product 13

7.2.1.1 Customer-designated special characteristics 14

7.2.2 Review of requirements related to the product 14

7.2.2.1 Review of requirements related to the product — Supplemental 14

7.2.2.2 Organization manufacturing feasibility 14

7.2.3 Customer communication 14

7.2.3.1 Customer communication — Supplemental 15

7.3 Design and development 15

7.3.1 Design and development planning 15

7.3.1.1 Multidisciplinary approach 15

7.3.2 Design and development inputs 15

7.3.2.1 Product design input 16

7.3.2.2 Manufacturing process design input 16

7.3.2.3 Special characteristics 16

7.3.3 Design and development outputs 16

7.3.3.1 Product design outputs — Supplemental 17

7.3.3.2 Manufacturing process design output 17

7.3.4 Design and development review 17

7.3.4.1 Monitoring 17

7.3.5 Design and development verification 18

7.3.6 Design and development validation 18

7.3.6.1 Design and development validation — Supplemental 18

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

iv

– All rights reserved

7.3.6.2 Prototype programme 18

7.3.6.3 Product approval process 18

7.3.7 Control of design and development changes 19

7.4 Purchasing 19

7.4.1 Purchasing process 19

7.4.1.1 Regulatory conformity 19

7.4.1.2 Supplier quality management system development 19

7.4.1.3 Customer-approved sources 19

7.4.2 Purchasing information 20

7.4.3 Verification of purchased product 20

7.4.3.1 Incoming product quality 20

7.4.3.2 Supplier monitoring 20

7.5 Production and service provision 21

7.5.1 Control of production and service provision 21

7.5.1.1 Control plan 21

7.5.1.2 Work instructions 21

7.5.1.3 Verification of job set-ups 21

7.5.1.4 Preventive and predictive maintenance 22

7.5.1.5 Management of production tooling 22

7.5.1.6 Production scheduling 22

7.5.1.7 Feedback of information from service 22

7.5.1.8 Service agreement with customer 22

7.5.2 Validation of processes for production and service provision 23

7.5.2.1 Validation of processes for production and service provision — Supplemental 23

7.5.3 Identification and traceability 23

7.5.3.1 Identification and traceability — Supplemental 23

7.5.4 Customer property 24

7.5.4.1 Customer-owned production tooling 24

7.5.5 Preservation of product 24

7.5.5.1 Storage and inventory 24

7.6 Control of monitoring and measuring devices 24

7.6.1 Measurement system analysis 25

7.6.2 Calibration/verification records 25

7.6.3 Laboratory requirements 25

7.6.3.1 Internal laboratory 25

7.6.3.2 External laboratory 25

8 Measurement, analysis and improvement 26

8.1 General 26

8.1.1 Identification of statistical tools 26

8.1.2 Knowledge of basic statistical concepts 26

8.2 Monitoring and measurement 26

8.2.1 Customer satisfaction 26

8.2.1.1 Customer satisfaction — Supplemental 26

8.2.2 Internal audit 27

8.2.2.1 Quality management system audit 27

8.2.2.2 Manufacturing process audit 27

8.2.2.3 Product audit 27

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

v

– All rights reserved

8.2.2.4 Internal audit plans 27

8.2.2.5 Internal auditor qualification 28

8.2.3 Monitoring and measurement of processes 28

8.2.3.1 Monitoring and measurement of manufacturing processes 28

8.2.4 Monitoring and measurement of product 29

8.2.4.1 Layout inspection and functional testing 29

8.2.4.2 Appearance items 29

8.3 Control of nonconforming product 29

8.3.1 Control of nonconforming product — Supplemental 30

8.3.2 Control of reworked product 30

8.3.3 Customer information 30

8.3.4 Customer waiver 30

8.4 Analysis of data 30

8.4.1 Analysis and use of data 31

8.5 Improvement 31

8.5.1 Continual improvement 31

8.5.1.1 Continual improvement of the organization 31

8.5.1.2 Manufacturing process improvement 31

8.5.2 Corrective action 31

8.5.2.1 Problem solving 32

8.5.2.2 Error-proofing 32

8.5.2.3 Corrective action impact 32

8.5.2.4 Rejected product test/analysis 32

8.5.3 Preventive action 32

Annex A (normative) Control plan 33

A.1 Phases of the control plan 33

A.2 Elements of the control plan 33

Bibliography 34

NOTE In this table of contents, ISO 9001:2000 headings are normal type face, IATF headings are in italics.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

vi

– All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International Standard

requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a technical

committee may decide to publish other types of normative document:

an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in an

ISO working group and is accepted for publication if it is approved by more than 50 % of the members of the

parent committee casting a vote;

an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting a

vote.

An ISO/PAS or ISO/TS is reviewed after three years with a view to deciding whether it should be confirmed for a

further three years, revised to become an International Standard, or withdrawn. In the case of a confirmed ISO/PAS

or ISO/TS, it is reviewed again after six years at which time it has to be either transposed into an International

Standard or withdrawn.

Manufacturers Association, Inc. (JAMA), with support from ISO/TC 176, Quality management and quality assurance.

This second edition of ISO/TS 16949 cancels and replaces the first edition (ISO/TS 16949:1999), which has been

technically revised.

Boxed text is original ISO 9001:2000 text. The sector-specific supplemental requirements are outside the boxes.

In this Technical Specification, the word “shall” indicates a requirement. The word “should” indicates a

recommendation. Paragraphs marked “NOTE” are for guidance in understanding or clarifying the associated

requirement.

Where the term “such as” is used, any suggestions given are for guidance only.

Annex A forms a normative part of this Technical Specification.

This corrected version of ISO/TS 16949:2002 incorporates the following corrections:

e-mail address of IAOB corrected on page viii;

year of publication corrected in 0.3.1;

the term “supplier” replaced by “the organization's” in Note to 7.6.3.1;

“agree with” replaced by “approve” in last paragraph of 8.3.4.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

vii

– All rights reserved

Remarks for certification

The certification to this Technical Specification, including customer-specific requirements if any, is recognized by

the customer members of IATF when achieved according to the IATF certification scheme (see the “Rules for

achieving IATF recognition”).

Details can be obtained at the addresses of the local oversight bodies of IATF cited below:

Associazione Nazionale Fra Industrie Automobilistiche (ANFIA)

Web site: www.anfia.it e-mail: anfia@anfia.it

International Automotive Oversight Bureau (IAOB)

Web site: www.iaob.org e-mail: quality@aiag.org

Fédération des Industries des Équipements pour Véhicules (FIEV)

Comité des Constructeurs Français d'Automobiles (CCFA)

Web site: www.iatf-france.com e-mail: iatf@iatf-france.com

Society of Motor Manufacturers and Traders Ltd. (SMMT Ltd.)

Web site: www.smmt.co.uk e-mail: quality@smmt.co.uk

Verband der Automobilindustrie Qualitätsmanagement Center (VDA-QMC)

Web site: www.vda-qmc.de e-mail: info@vda-qmc.de

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

viii

– All rights reserved

Introduction

0.1 General

ISO 9001:2000, Quality management systems — Requirements

Introduction

0.1 General

The adoption of a quality management system should be a strategic decision of an organization. The design and

implementation of an organization's quality management system is influenced by varying needs, particular

objectives, the products provided, the processes employed and the size and structure of the organization. It is not

the intent of this International Standard to imply uniformity in the structure of quality management systems or

uniformity of documentation.

The quality management system requirements specified in this International Standard are complementary to

requirements for products. Information marked “NOTE” is for guidance in understanding or clarifying the

associated requirement.

This International Standard can be used by internal and external parties, including certification bodies, to assess

the organization's ability to meet customer, regulatory and the organization's own requirements.

The quality management principles stated in ISO 9000 and ISO 9004 have been taken into consideration during

the development of this International Standard.

0.2 Process approach

ISO 9001:2000, Quality management systems — Requirements

0.2 Process approach

This International Standard promotes the adoption of a process approach when developing, implementing and

improving the effectiveness of a quality management system, to enhance customer satisfaction by meeting

customer requirements.

For an organization to function effectively, it has to identify and manage numerous linked activities. An activity

using resources, and managed in order to enable the transformation of inputs into outputs, can be considered as a

process. Often the output from one process directly forms the input to the next.

The application of a system of processes within an organization, together with the identification and interactions of

these processes, and their management, can be referred to as the “process approach”.

An advantage of the process approach is the ongoing control that it provides over the linkage between the

individual processes within the system of processes, as well as over their combination and interaction.

When used within a quality management system, such an approach emphasizes the importance of

a) understanding and meeting requirements,

b) the need to consider processes in terms of added value,

c) obtaining results of process performance and effectiveness, and

d) continual improvement of processes based on objective measurement.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

ix

– All rights reserved

The model of a process-based quality management system shown in Figure 1 illustrates the process linkages

presented in clauses 4 to 8. This illustration shows that customers play a significant role in defining requirements

as inputs. Monitoring of customer satisfaction requires the evaluation of information relating to customer

perception as to whether the organization has met the customer requirements. The model shown in Figure 1

covers all the requirements of this International Standard, but does not show processes at a detailed level.

NOTE In addition, the methodology known as “Plan-Do-Check-Act” (PDCA) can be applied to all processes. PDCA can be

briefly described as follows.

Plan: establish the objectives and processes necessary to deliver results in accordance with customer requirements and

the organization's policies.

Do: implement the processes.

Check: monitor and measure processes and product against policies, objectives and requirements for the product and

report the results.

Act: take actions to continually improve process performance.

Figure 1 — Model of a process-based quality management system

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

x

– All rights reserved

0.3 Relationship with ISO 9004

ISO 9001:2000, Quality management systems — Requirements

0.3 Relationship with ISO 9004

The present editions of ISO 9001 and ISO 9004 have been developed as a consistent pair of quality management

system standards which have been designed to complement each other, but can also be used independently.

Although the two International Standards have different scopes, they have similar structures in order to assist their

application as a consistent pair.

ISO 9001 specifies requirements for a quality management system that can be used for internal application by

organizations, or for certification, or for contractual purposes. It focuses on the effectiveness of the quality

management system in meeting customer requirements.

ISO 9004 gives guidance on a wider range of objectives of a quality management system than does ISO 9001,

particularly for the continual improvement of an organization's overall performance and efficiency, as well as its

effectiveness. ISO 9004 is recommended as a guide for organizations whose top management wishes to move

beyond the requirements of ISO 9001, in pursuit of continual improvement of performance. However, it is not

intended for certification or for contractual purposes.

NOTE The knowledge and use of the eight quality management principles referred to in ISO 9000:2000 and ISO 9004:2000

should be demonstrated and cascaded through the organization by top management.

0.3.1 IATF Guidance to ISO/TS 16949:2002

“IATF Guidance to ISO/TS 16949:2002” is a document containing recommended automotive industry practices,

examples, illustrations and explanations, and provides assistance in the application to conform to the requirements

of this Technical Specification.

This IATF Guidance document is not intended for certification or for contractual purposes

0.4 Compatibility with other management systems

ISO 9001:2000, Quality management systems — Requirements

0.4 Compatibility with other management systems

This International Standard has been aligned with ISO 14001:1996 in order to enhance the compatibility of the two

standards for the benefit of the user community.

This International Standard does not include requirements specific to other management systems, such as those

particular to environmental management, occupational health and safety management, financial management or

risk management. However, this International Standard enables an organization to align or integrate its own

quality management system with related management system requirements. It is possible for an organization to

adapt its existing management system(s) in order to establish a quality management system that complies with

the requirements of this International Standard.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

xi

– All rights reserved

0.5 Goal of this Technical Specification

The goal of this Technical Specification is the development of a quality management system that provides for

continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain.

This Technical Specification, coupled with applicable customer-specific requirements, defines the fundamental

quality management system requirements for those subscribing to this document.

This Technical Specification is intended to avoid multiple certification audits and provide a common approach to a

quality management system for automotive production, and relevant service part organizations.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

xii

– All rights reserved

TECHNICAL SPECIFICATION ISO/TS 16949:2002(E)

Quality management systems ------ Particular requirements for the

application of ISO 9001:2000 for automotive production and

relevant service part organizations

1 Scope

1.1 General

ISO 9001:2000, Quality management systems — Requirements

1 Scope

1.1 General

This International Standard specifies requirements for a quality management system where an organization

a) needs to demonstrate its ability to consistently provide product that meets customer and applicable regulatory

requirements, and

b) aims to enhance customer satisfaction through the effective application of the system, including processes for

continual improvement of the system and the assurance of conformity to customer and applicable regulatory

requirements.

NOTE In this International Standard, the term “product” applies only to the product intended for, or required by, a customer.

This Technical Specification, in conjunction with ISO 9001:2000, defines the quality management system

requirements for the design and development, production and, when relevant, installation and service of

automotive-related products.

This Technical Specification is applicable to sites of the organization where customer-specified parts, for production

and/or service, are manufactured.

Supporting functions, whether on-site or remote (such as design centres, corporate headquarters and distribution

centres), form part of the site audit as they support the site, but cannot obtain stand-alone certification to this

Technical Specification.

This Technical Specification can be applied throughout the automotive supply chain.

1.2 Application

ISO 9001:2000, Quality management systems — Requirements

1.2 Application

All requirements of this International Standard are generic and are intended to be applicable to all organizations,

regardless of type, size and product provided.

Where any requirement(s) of this International Standard cannot be applied due to the nature of an organization

and its product, this can be considered for exclusion.

Where exclusions are made, claims of conformity to this International Standard are not acceptable unless these

exclusions are limited to requirements within clause 7, and such exclusions do not affect the organization's ability,

or responsibility, to provide product that meets customer and applicable regulatory requirements.

© ANFIA, © CCFA/FIEV, © SMMT, © VDA, © DaimlerChrysler, Ford Motor Company, General Motors Corp.

– All rights reserved

The only permitted exclusions for this Technical Specification relate to 7.3 where the organization is not

responsible for product design and development.

Permitted exclusions do not include manufacturing process design.

2 Normative reference

The following normative document contains provisions, which, through reference in this text, constitute provisions of

this Technical Specification. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this Technical Specification are encouraged to

investigate the possibility of applying the most recent edition of the normative document indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 9000:2000, Quality management systems — Fundamentals and vocabulary

3 Terms and definitions

ISO 9001:2000, Quality management systems — Requirements

3 Terms and definitions

For the purposes of this International Standard, the terms and definitions given in ISO 9000 apply.

The following terms, used in this edition of ISO 9001 to describe the supply chain, have been changed to reflect

the vocabulary currently used: