ISO 16111:2018

(Main)Transportable gas storage devices — Hydrogen absorbed in reversible metal hydride

Transportable gas storage devices — Hydrogen absorbed in reversible metal hydride

This document defines the requirements applicable to the material, design, construction, and testing of transportable hydrogen gas storage systems, referred to as "metal hydride assemblies" (MH assemblies) which utilize shells not exceeding 150 l internal volume and having a maximum developed pressure (MDP) not exceeding 25 MPa. This document is applicable to refillable storage MH assemblies where hydrogen is the only transferred media. It is not applicable to storage MH assemblies intended to be used as fixed fuel-storage onboard hydrogen fuelled vehicles.

Appareils de stockage de gaz transportables — Hydrogène absorbé dans un hydrure métallique réversible

General Information

- Status

- Published

- Publication Date

- 15-Aug-2018

- Technical Committee

- ISO/TC 197 - Hydrogen technologies

- Drafting Committee

- ISO/TC 197 - Hydrogen technologies

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 17-Apr-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Revises

ISO 16111:2008 - Transportable gas storage devices — Hydrogen absorbed in reversible metal hydride - Effective Date

- 05-Nov-2015

Overview

ISO 16111:2018 specifies requirements for transportable hydrogen gas storage devices that use hydrogen absorbed in reversible metal hydride (MH) materials. The standard applies to refillable metal hydride assemblies (MH assemblies) with shells up to 150 L internal volume and a maximum developed pressure (MDP) not exceeding 25 MPa, where hydrogen is the only media transferred. It excludes fixed onboard fuel-storage systems for hydrogen‑fuelled vehicles.

Keywords: ISO 16111, hydrogen storage, metal hydride, transportable gas storage, MH assemblies, refillable hydrogen storage, hydrogen transport safety.

Key technical topics and requirements

ISO 16111 covers the full lifecycle of transportable MH assemblies, focusing on safety, design and verification:

- Service conditions

- Definitions of MDP (maximum developed pressure), rated charging pressure (RCP), rated capacity, operating and service temperature ranges, environmental conditions and service life.

- Design considerations

- Material selection and external surface compatibility with hydrogen service.

- Shell design requirements (including distinctions for very small volumes) and design strength.

- Overpressure and fire protection, with pressure relief device (PRD) considerations.

- Loading of hydrogen‑absorbing alloys, valves (integral and removable shut‑off), particulate containment and options for actively cooled assemblies.

- Inspection and testing

- Type/qualification tests such as fire tests, drop/impact tests, leak tests, hydrogen cycling and strain measurement, thermal cycling, and burst tests for small-volume assemblies.

- Batch and routine tests including burst testing, MDP checks for hydride batches and certification paperwork.

- Marking, labelling and documentation

- Product marking, hazard labelling (including temperature warnings), safety data sheets and user/operating manuals with initial fill and refill procedures.

- Annexes

- Material compatibility, environmental tests and model certificates are provided as informative and normative annexes.

Practical applications and users

ISO 16111 is intended for organizations developing, manufacturing, testing, certifying or procuring transportable hydride‑based hydrogen storage devices, including:

- Hydrogen cartridge and fuel cell cartridge manufacturers

- Suppliers of refillable hydrogen storage cylinders and portable hydrogen supplies

- Test laboratories and conformity assessment bodies performing type and batch testing

- Safety engineers, system integrators and procurement teams in hydrogen supply chains

Use of ISO 16111 helps ensure safe, consistent and certified performance of metal hydride hydrogen containers for portable and refillable applications.

Related standards

- ISO 11119 series (referenced for shell design guidance)

- Other ISO/TC 197 hydrogen technologies standards are relevant for system-level integration and hydrogen quality requirements.

Adopting ISO 16111 supports compliance with international best practice for transportable metal hydride hydrogen storage and improves safety, traceability and market acceptance.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

ISO 16111:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Transportable gas storage devices — Hydrogen absorbed in reversible metal hydride". This standard covers: This document defines the requirements applicable to the material, design, construction, and testing of transportable hydrogen gas storage systems, referred to as "metal hydride assemblies" (MH assemblies) which utilize shells not exceeding 150 l internal volume and having a maximum developed pressure (MDP) not exceeding 25 MPa. This document is applicable to refillable storage MH assemblies where hydrogen is the only transferred media. It is not applicable to storage MH assemblies intended to be used as fixed fuel-storage onboard hydrogen fuelled vehicles.

This document defines the requirements applicable to the material, design, construction, and testing of transportable hydrogen gas storage systems, referred to as "metal hydride assemblies" (MH assemblies) which utilize shells not exceeding 150 l internal volume and having a maximum developed pressure (MDP) not exceeding 25 MPa. This document is applicable to refillable storage MH assemblies where hydrogen is the only transferred media. It is not applicable to storage MH assemblies intended to be used as fixed fuel-storage onboard hydrogen fuelled vehicles.

ISO 16111:2018 is classified under the following ICS (International Classification for Standards) categories: 71.100.20 - Gases for industrial application. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 16111:2018 has the following relationships with other standards: It is inter standard links to EN ISO 22734-1:2025, ISO 16111:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 16111:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16111

Second edition

2018-08

Transportable gas storage devices —

Hydrogen absorbed in reversible

metal hydride

Appareils de stockage de gaz transportables — Hydrogène absorbé

dans un hydrure métallique réversible

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

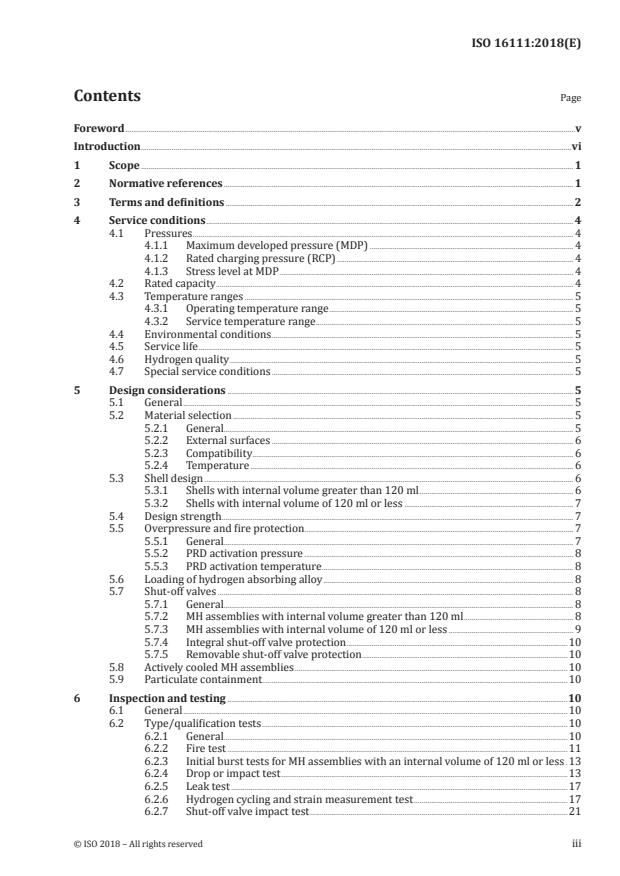

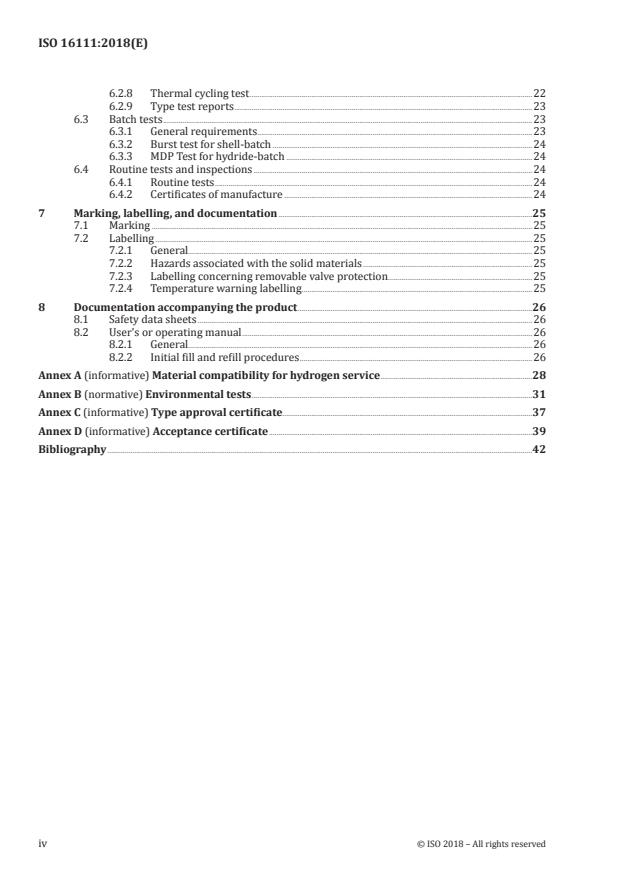

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Service conditions . 4

4.1 Pressures . 4

4.1.1 Maximum developed pressure (MDP) . 4

4.1.2 Rated charging pressure (RCP) . 4

4.1.3 Stress level at MDP . 4

4.2 Rated capacity . 4

4.3 Temperature ranges . 5

4.3.1 Operating temperature range . 5

4.3.2 Service temperature range . 5

4.4 Environmental conditions . 5

4.5 Service life . 5

4.6 Hydrogen quality . 5

4.7 Special service conditions . 5

5 Design considerations . 5

5.1 General . 5

5.2 Material selection . 5

5.2.1 General. 5

5.2.2 External surfaces . 6

5.2.3 Compatibility . 6

5.2.4 Temperature . 6

5.3 Shell design . 6

5.3.1 Shells with internal volume greater than 120 ml . 6

5.3.2 Shells with internal volume of 120 ml or less . 7

5.4 Design strength . 7

5.5 Overpressure and fire protection. 7

5.5.1 General. 7

5.5.2 PRD activation pressure . 8

5.5.3 PRD activation temperature . 8

5.6 Loading of hydrogen absorbing alloy . 8

5.7 Shut-off valves . 8

5.7.1 General. 8

5.7.2 MH assemblies with internal volume greater than 120 ml . 8

5.7.3 MH assemblies with internal volume of 120 ml or less . 9

5.7.4 Integral shut-off valve protection .10

5.7.5 Removable shut-off valve protection .10

5.8 Actively cooled MH assemblies .10

5.9 Particulate containment.10

6 Inspection and testing .10

6.1 General .10

6.2 Type/qualification tests .10

6.2.1 General.10

6.2.2 Fire test .11

6.2.3 Initial burst tests for MH assemblies with an internal volume of 120 ml or less .13

6.2.4 Drop or impact test .13

6.2.5 Leak test .17

6.2.6 Hydrogen cycling and strain measurement test .17

6.2.7 Shut-off valve impact test .21

6.2.8 Thermal cycling test .22

6.2.9 Type test reports .23

6.3 Batch tests .23

6.3.1 General requirements .23

6.3.2 Burst test for shell-batch .24

6.3.3 MDP Test for hydride-batch .24

6.4 Routine tests and inspections .24

6.4.1 Routine tests .24

6.4.2 Certificates of manufacture .24

7 Marking, labelling, and documentation .25

7.1 Marking .25

7.2 Labelling .25

7.2.1 General.25

7.2.2 Hazards associated with the solid materials .25

7.2.3 Labelling concerning removable valve protection .25

7.2.4 Temperature warning labelling .25

8 Documentation accompanying the product .26

8.1 Safety data sheets .26

8.2 User's or operating manual .26

8.2.1 General.26

8.2.2 Initial fill and refill procedures .26

Annex A (informative) Material compatibility for hydrogen service .28

Annex B (normative) Environmental tests .31

Annex C (informative) Type approval certificate .37

Annex D (informative) Acceptance certificate .39

Bibliography .42

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by ISO/TC 197, Hydrogen technologies.

This second edition cancels and replaces the first edition (ISO 16111:2008), which has been technically

revised.

The following clauses have been modified with respect to the previous edition: 2; 3.4; 3.5; 3.9; 3.10;

3.11; 3.12; 3.13; 3.14; 3.15; 3.16; 3.17; 3.18; 3.19; 3.20; 3.21; 3.22; 4.1; 4.3; 5.2.1; 5.3; 5.5; 5.8; 6.2; 6.3; 7.2;

8.1 and Annex D.

The main changes compared to the previous edition concern the following:

— service temperature conditions have been described in further detail (4.3.2);

— shell design has been extended to ISO 11119-3 standard reference (5.3);

— drop test conditions have been modified (6.2.4);

— acceptance criteria have been modified for leak testing (6.2.5);

— hydrogen cycling conditions have been modified (6.2.6);

— new warning labelling has been proposed (7.2);

— information in safety data sheets has been updated (8.1).

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

As the utilization of gaseous hydrogen evolves from the chemical industry into various emerging

applications, such as fuel for fuel cells and internal combustion engines and other specialty hydrogen

applications, the importance of new and improved storage techniques has become essential. One of

these techniques employs the absorption of hydrogen into specially formulated alloys. The material

can be stored and transported in a solid form, and the hydrogen later released and used under specific

thermodynamic conditions. This document describes the service conditions, design criteria, type tests,

batch tests and routine tests for transportable hydride-based hydrogen storage systems, referred to as

“metal hydride assemblies” (MH assemblies). Types of MH assemblies may serve as: fuel cell cartridges;

hydrogen fuel storage containers; high-purity hydrogen supplies as well as other uses.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 16111:2018(E)

Transportable gas storage devices — Hydrogen absorbed

in reversible metal hydride

1 Scope

This document defines the requirements applicable to the material, design, construction, and testing of

transportable hydrogen gas storage systems, referred to as “metal hydride assemblies” (MH assemblies)

which utilize shells not exceeding 150 l internal volume and having a maximum developed pressure

(MDP) not exceeding 25 MPa.

This document is applicable to refillable storage MH assemblies where hydrogen is the only transferred

media. It is not applicable to storage MH assemblies intended to be used as fixed fuel-storage onboard

hydrogen fuelled vehicles.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 7225, Gas cylinders — Precautionary labels

ISO 7866, Gas cylinders — Refillable seamless aluminium alloy gas cylinders — Design, construction

and testing

ISO 9809-1, Gas cylinders — Refillable seamless steel gas cylinders — Design, construction and testing —

Part 1: Quenched and tempered steel cylinders with tensile strength less than 1 100 MPa

ISO 9809-2, Gas cylinders — Refillable seamless steel gas cylinders — Design, construction and testing —

Part 2: Quenched and tempered steel cylinders with tensile strength greater than or equal to 1 100 MPa

ISO 9809-3, Gas cylinders — Refillable seamless steel gas cylinders — Design, construction and testing —

Part 3: Normalized steel cylinders

ISO 10297:2014, Gas cylinders — Cylinder valves — Specification and type testing

ISO 11114-1, Gas cylinders — Compatibility of cylinder and valve materials with gas contents — Part 1:

Metallic materials

ISO 11114-2, Gas cylinders — Compatibility of cylinder and valve materials with gas contents — Part 2:

Non-metallic materials

ISO 11114-4, Transportable gas cylinders — Compatibility of cylinder and valve materials with gas

contents — Part 4: Test methods for selecting steels resistant to hydrogen embrittlement

ISO 11119-1, Gas cylinders — Refillable composite gas cylinders and tubes — Design, construction and

testing — Part 1: Hoop wrapped fibre reinforced composite gas cylinders and tubes up to 450 l

ISO 11119-2:2012, Gas cylinders — Refillable composite gas cylinders and tubes — Design, construction

and testing — Part 2: Fully wrapped fibre reinforced composite gas cylinders and tubes up to 450 l with

load-sharing metal liners

ISO 11119-3, Gas cylinders — Refillable composite gas cylinders and tubes — Design, construction and

testing — Part 3: Fully wrapped fibre reinforced composite gas cylinders and tubes up to 450L with non-

load-sharing metallic or non-metallic liners

ISO 14246, Gas cylinders — Cylinder valves — Manufacturing tests and examinations

ISO 14687 (all parts), Hydrogen fuel — Product specification

ISO 16528-1, Boilers and pressure vessels — Part 1: Performance requirements

UN Recommendations on the Transport of Dangerous Goods: Model Regulations

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

absorbed, adj.

taken and held through the formation of chemical bonds within the bulk of the material

3.2

burst pressure

highest pressure reached in an MH assembly during a burst test

3.3

design stress limit

total stress loading allowed on the shell wall

Note 1 to entry: In MH assemblies, the shell design takes into account the gas pressure plus other stresses, such

as pressure exerted by expansion of the hydrogen absorbing alloy.

3.4

fuel cartridge

MH assembly, which stores hydrogen for use as a fuel in a fuel cell through a valve(s) that controls the

discharge of fuel into the fuel cell

3.5

full flow capacity pressure

gas pressure at which the pressure relief device is fully open to have the maximum gas flow

3.6

hydrogen absorbing alloy

material capable of reacting with hydrogen gas to form a reversible metal hydride

3.7

internal component

structure, matrix, material or device contained within the shell (excluding hydrogen gas, hydrogen

absorbing alloy and metal hydride)

Note 1 to entry: Internal components may be used for purposes such as heat transfer, preventing movement of

the hydrogen absorbing alloy/metal hydride and/or to prevent excessive stress on the shell walls due to hydride

expansion.

3.8

internal volume

water capacity of the shell

2 © ISO 2018 – All rights reserved

3.9

maximum developed pressure

MDP

highest gas gauge pressure developed internally to an MH assembly at rated capacity and equilibrium

under normal service conditions or normal operating conditions, whichever is greater

Note 1 to entry: The MDP term was specifically selected for MH assemblies to avoid confusion with the maximum

allowable working pressure (MAWP) and the service pressure used in other ISO International Standards.

3.10

metal hydride

solid material formed by reaction between hydrogen and hydrogen absorbing alloy

3.11

metal hydride assembly

MH assembly

single complete hydrogen storage system, including shell, metal hydride, pressure relief device (PRD),

shut-off valve, other appurtenances and internal components

Note 1 to entry: The MH assembly extends only to, and including, the first shut-off valve.

Note 2 to entry: A fuel cell cartridge is a type of MH assembly.

3.12

normal operating conditions

range of pressures, MH assembly external shell temperatures, hydrogen flow rates, hydrogen quality,

etc., specified for all use and filling operations

3.13

normal service conditions

range of pressures and environmental temperatures, specified for transportation and storage

conditions

3.14

pressure relief device

PRD

device intended to prevent the rupture of an MH assembly in the event of overpressure or exposure to fire

Note 1 to entry: A pressure relief device may be “pressure-activated”, set to activate at a certain pressure.

Alternatively, a pressure relief device may be “thermally-activated”, set to activate at a certain temperature. A

pressure relief device may also be both “pressure-activated” and “thermally-activated”.

3.15

pressure relief valve

PRV

reseatable pressure relief device (PRD)

3.16

rated capacity

maximum quantity of hydrogen deliverable under specified conditions

3.17

rated charging pressure

RCP

maximum pressure to be applied to the MH assembly for refilling

Note 1 to entry: The RCP is not necessarily equal to the equilibrium plateau pressure of the hydrogen

absorbing alloy.

3.18

reversible metal hydride

metal hydride for which there exists an equilibrium condition where the hydrogen absorbing alloy,

hydrogen gas and the metal hydride co-exist

Note 1 to entry: Changes in pressure or temperature will shift the equilibrium favouring the formation or

decomposition of the metal hydride with respect to the hydrogen absorbing alloy and hydrogen gas.

3.19

rupture

structural failure of a shell resulting in the sudden release of stored energy

3.20

shell

enclosure of any shape (cylindrical, prismatic, cubic, etc.) designed to contain the hydrogen gas, metal

hydride and other internal components of the MH assembly

Note 1 to entry: A shell may be a gas cylinder, a pressure vessel or other type of container.

3.21

stress level at MDP

sum of all the stresses on the shell wall caused by the metal hydride at rated capacity, hydrogen gas at

MDP and any other applicable mechanical loadings

3.22

test pressure

required pressure applied during a pressure test for qualification

4 Service conditions

4.1 Pressures

4.1.1 Maximum developed pressure (MDP)

The MDP shall be determined by the manufacturer from the metal hydride's temperature–pressure

characteristics. In no case shall the MDP exceed 0,8 times the test pressure of the shell. The MDP shall

not exceed 25 MPa.

4.1.2 Rated charging pressure (RCP)

The RCP shall be specified by the manufacturer in order to prevent charging at a pressure that could

result in the shell wall stress exceeding the design stress limit.

4.1.3 Stress level at MDP

The stress level at MDP shall be determined by the manufacturer from the hydrogen absorbing alloy's

packing and expansion properties, the MDP within the MH assembly, and other applicable mechanical

loadings.

4.2 Rated capacity

The manufacturer shall state the rated capacity of the MH assembly by units of mass of hydrogen.

4 © ISO 2018 – All rights reserved

4.3 Temperature ranges

4.3.1 Operating temperature range

The minimum and maximum MH assembly temperature for normal operating conditions shall be

specified by the manufacturer.

4.3.2 Service temperature range

The minimum and maximum ambient shell temperatures for normal service conditions shall be a

minimum of −40 °C and a maximum of +65 °C. If the maximum and minimum shell temperatures are to

be different from those specified, they shall be identified by the manufacturer.

4.4 Environmental conditions

The MH assemblies are expected to be exposed to a number of environmental conditions over their

service life, such as vibration and shock, varying humidity levels, and corrosive environments. The

manufacturer shall specify the environmental conditions for which the MH assembly was designed.

4.5 Service life

The service life for the MH assemblies shall be specified by the manufacturer on the basis of use under

service conditions specified herein. The service life shall not exceed that specified by the standard to

which the shell is designed according to 5.3.

4.6 Hydrogen quality

The minimum quality of the hydrogen gas that shall be used to fill an MH assembly shall be specified by

the manufacturer according to ISO 14687 (all parts) or as appropriate.

If the quality of the hydrogen gas is considered a critical issue to avoid performance degradation of the

MH assembly, the manufacturer may consider including the information on the product label.

4.7 Special service conditions

Any additional service conditions that shall be met for the safe operation, handling and usage of the MH

assembly shall be specified by the manufacturer.

5 Design considerations

5.1 General

The MH assembly shall be designed and constructed to prevent leakage of free hydrogen gas or metal

hydride particles under normal service and operating conditions.

5.2 Material selection

5.2.1 General

The MH assembly components shall be made of materials that are suitable for the range of conditions

expected over the life of the MH assembly. Components that are in contact with gaseous hydrogen and/

or metal hydride material shall be sufficiently resistant to their chemical and physical action under

normal service or operating conditions to maintain operational and pressure containment integrity.

Hydrogen absorbing alloys and/or metal hydride materials that are classified as Type I explosive

materials according to the UN Recommendations on the Transport of Dangerous Goods shall not be

used in an MH assembly.

5.2.2 External surfaces

The MH assembly shell, shut-off valve, PRDs and other components shall be resistant to the environmental

conditions specified in 4.4. Resistance to these environmental conditions may be provided by using

materials inherently resistant to the environment or by applying resistant coatings to the components.

Exterior protection may be provided by using a surface finish giving adequate corrosion protection

(e.g. metal sprayed on aluminium or anodizing) or a protective coating (e.g. organic coating or paint).

If an exterior coating is part of the design, the coating shall be evaluated using the applicable test

methods specified in Annex B. Any coatings applied to MH assemblies shall be such that the application

process does not adversely affect the mechanical properties of the shell or performance and operation

of other components. The coatings shall be designed to facilitate subsequent in-service inspection and

the manufacturer shall provide guidance on coating treatment during such inspections to ensure the

continued integrity of the MH assembly.

5.2.3 Compatibility

The compatibility of MH assembly materials with process fluids and solids, specifically embrittlement

due to the exposure to hydrogen, shall be considered. Guidance on compatibility of materials with

gases is given in ISO 11114-1 and ISO 11114-2. Materials necessary for the pressure containment and

structural integrity of the MH assembly and its internal and external components shall be resistant

to hydrogen embrittlement, hydrogen attack and reactivity with contained materials and maintain

their integrity for the service life of the MH assembly. Recognized test methods, such as those

specified in ISO 11114-4, shall be used to select metallic materials resistant to hydrogen embrittlement

where required for pressure or structural integrity. Consideration shall be given to the impact that

temperature may have on hydrogen embrittlement.

Consideration shall be given to all of the chemical species that may be present during the charged,

partially charged and discharged states and their potential reactivity with the MH assembly material.

The MH assembly materials shall be selected so as the combination does not endanger the MH assembly

integrity.

NOTE The susceptibility to hydrogen embrittlement of some commonly used metals is summarized in ISO/

TR 15916. Additional guidance regarding hydrogen compatibility is found in Annex A.

5.2.4 Temperature

The MH assembly materials shall be suitable for the service and operating temperature range specified

in 4.3.1 and 4.3.2.

5.3 Shell design

5.3.1 Shells with internal volume greater than 120 ml

The MH assembly shell shall be designed and tested according to ISO 7866, ISO 9809-1, ISO 9809-3,

ISO 11119-1, ISO 11119-2, ISO 11119-3 or for design or shape shell not covered by the previous standards

the manufacturer shall prove their performance in accordance to ISO 16528-1. Shells designed and

tested in accordance with ISO 9809-1 shall have a tensile strength less than 950 MPa. Shells designed

and tested in accordance with ISO 11119-1 or ISO 11119-2 that use seamless steel liners conforming to

ISO 9809-2 or to ISO 9809-1 shall have a tensile strength less than 950 MPa. Shells designed with proof

of performance according to ISO 16528-1 are considered as pressure vessels.

The shell shall not exceed 150 l internal volume, and the MDP shall not exceed 25 MPa. The maximum

combined stresses for the loads described in 5.4 as well as the operating and service temperature

6 © ISO 2018 – All rights reserved

ranges for the MH assembly shall not exceed the limits prescribed by the standard to which the shell is

designed.

NOTE An equivalent gas pressure calculated to be equal to the stress level at MDP can be used as the design

hydraulic test pressure for determining minimum shell wall thickness.

5.3.2 Shells with internal volume of 120 ml or less

For MH assemblies with an internal volume of 120 ml or less, the shell design shall be deemed to be

appropriate if the shell meets 5.3.1 or the MH assembly meets the following design and test criteria:

a) the pressure in the MH assembly shall not exceed 5 MPa at 55 °C when the MH assembly is filled to

its rated capacity; and

b) the MH assembly design shall withstand as required by 6.2.3, without leaking or bursting, a

minimum shell burst pressure of 2 times the pressure in the MH assembly at 55 °C when filled to

rated capacity, or 1,6 times the pressure in the MH assembly at the maximum service temperature

when filled to rated capacity, or 200 kPa more than the MDP of the assembly at 55 °C when filled to

rated capacity, whichever is greater.

5.4 Design strength

The shell design shall take into account the stress level at 1,25 times MDP. Consideration of components

contributing to the stress level at MDP shall include but not be limited to:

— 1,25 × MDP;

— thermal stress, including dissimilar rates of thermal expansion and contraction;

— weight of internals in any possible MH assembly orientation;

— shock and vibration loading;

— maximum stress due to hydrogen absorbing alloy expansion;

— other mechanical loadings.

To verify that the design stress limit is not exceeded, the MH assembly design shall be subjected to the

hydrogen cycling and strain measurement test described in 6.2.6.

NOTE The process of introducing and subsequently removing hydrogen in the hydrogen absorbing alloy

typically causes it to expand and contract. In turn, this can result in large stresses inside the alloy's particles

that cause them to fragment into smaller particles, a phenomenon known as decrepitation. After several charge/

discharge cycles, the average particle size can have significantly decreased. Stresses on the MH assembly walls

can be derived from expansion of the hydrogen absorbing alloy during hydrogenation and from changes in

the packing configuration due to decrepitation over the service life of the MH assembly. The magnitude of the

expansion/contraction phenomena varies greatly as a function of the hydrogen absorbing alloy used.

5.5 Overpressure and fire protection

5.5.1 General

The MH assembly shall be protected with one or more PRDs of the non-reclosing type, such as thermally

activated PRD, rupture disks and diaphragms, or of the re-sealable type, such as spring-loaded PRVs.

The MH assembly and any added component (e.g. insulation or protective material) shall collectively

pass the fire test specified in 6.2.2. The PRD shall conform to the requirements of 5.5.2 and 5.5.3 and

the additional requirements of the competent authority of country of use, as applicable.

For MH assemblies with an internal volume of 120 ml or less, other means may be used to protect from

overpressurization, such as venting through a feature integral to the shell. MH assemblies that use an

alternative means of relieving pressure shall meet the acceptance criteria of the fire test specified in 6.2.2.

Re-sealable PRV is not recommended for MH assembly having composite or aluminium shell. For these

MH assemblies the manufacturer shall use other type of overpressure and fire protection.

5.5.2 PRD activation pressure

The pressure of actuation of pressure-activated PRDs shall be specified by the manufacturer and shall

be greater than the MDP but less than 1,25 times the MDP. In no case shall the pressure of actuation of

a pressure-activated PRD exceed the test pressure of the shell. For PRVs, the full flow capacity pressure

shall also be specified, and shall not exceed the test pressure of the shell.

5.5.3 PRD activation temperature

The temperature at which any thermally activated PRD is set to activate shall be specified by the

manufacturer and correspond to an equilibrium pressure inside the MH assembly of less than

1,25 times the MDP. In no case shall the temperature of actuation of a temperature-activated PRD result

in an equilibrium pressure inside the MH assembly that exceeds the test pressure of the shell. The PRD

shall have a pressure rating greater than the MDP at all temperatures less than or equal to 10 °C above

the maximum service temperature or operating temperature (whichever is higher). In no case shall the

PRD activate at a temperature lower than the maximum service or operating temperature.

Due to the MDP definition, an equilibrium pressure less than 1,25 times the MDP is in accordance with

4.1.1 and 5.4, which respectively refer to the MDP assessment and the shell design. As an immediate

consequence, the pressure inside the MH assembly cannot exceed the test pressure of the shell at the

temperature of actuation.

5.6 Loading of hydrogen absorbing alloy

Procedures and verification testing shall be put in place to ensure the consistent loading of the hydrogen

absorbing alloy/metal hydride in the MH assembly.

5.7 Shut-off valves

5.7.1 General

The MH assembly shall incorporate a shut-off valve that shall be capable of being closed when the

MH assembly is disconnected from the refill or gas-consuming equipment. The shut-off valve may be

manually actuated, such as by a handwheel, or automatically actuated.

All MH assemblies shall provide a means of shut-off valve protection that complies with 5.7.4 or 5.7.5.

The shut-off valve selection shall include verification that the shut-off valve seal is maintained with

vacuum conditions within the MH assembly.

NOTE Due to the temperature/pressure characteristics of metal hydrides, the development of sub-ambient

pressures is possible within MH assemblies.

5.7.2 MH assemblies with internal volume greater than 120 ml

Shut-off valves shall comply with ISO 10297, or equivalent, with the following adjustment:

a) 3 times MDP shall be used as the resistance pressure for the valve.

b) Valve test pressure, p , shall be equal to 1,5 times the MDP.

vt

c) Gas pressure for endurance test shall be equal to 0,5 times the MDP.

In addition, the shut-off valve shall meet all requirements and tests prescribed in this document.

8 © ISO 2018 – All rights reserved

Alternatively, if the shut-off valve cannot demonstrate full compliance to ISO 10297 or equivalent, the

shut-off valve construction and performance shall meet all the requirements and tests prescribed in

this document as well as the following requirements:

— the material requirements of ISO 10297:2014, 4.3;

— the test requirements of ISO 10297:2014, 6.1 to 6.8, as they apply to the tests prescribed below with

the exception the valve test pressure, p , shall be equal to 1,5 times the MDP;

vt

— the hydraulic pressure test of ISO 10297:2014, 6.9, with the exception that 3 times the MDP shall be

used as the test pressure;

— the leak tightness test of ISO 10297:2014, 6.11, where p shall be equal to 1,5 times the MDP;

vt

— the endurance test of ISO 10297:2014, 6.12, using a gas pressure equal to 0,5 times the MDP. When

the shut-off valve does not incorporate a handwheel, the forces and torques used in the endurance

test shall be representative of those used in service to open and close the valve member. Prior to

and following the endurance test, the shut-off valve shall be tested for leakage from an internal and

external leakage perspective at a test pressure of 1,5 times MDP at minimum and maximum service

temperature. Leakage rates less than or equal to 6 standard cm /h (standard conditions of 0 °C and

101,325 kPa absolute) shall be acceptable.

The minimum rated pressure of the shut-off valve shall be at least equal to 1,5 times MDP.

In addition, the shut-off valve manufacturer shall demonstrate that the shut-off valve is subjected to the

requirements of ISO 14246.

5.7.3 MH assemblies with internal volume of 120 ml or less

For MH assemblies with an internal volume of 120 ml or less, the shut-off valve construction and

performance shall meet all requirements and tests prescribed in this document as well as the following

requirements:

— the material requirements of ISO 10297:2014, 4.3;

— the test requirements of ISO 10297:2014, 6.1 to 6.8, as they apply to the tests prescribed below with

the exception that the valve test pressure, p , shall be equal to 1,5 times the MDP;

vt

— the hydraulic pressure test of ISO 10297:2014, 6.9, with the exception that the test pressure shall be

in accordance with 5.3.2 b) and the test may be performed pneumatically;

— the leak tightness test of ISO 10297:2014, 6.11, where p shall be equal to 1,5 times the MDP. Valve

vt

closure may be determined using torque, compression or other suitable means and the test gas shall

be helium;

— the endurance test of ISO 10297:2014, 6.12, using a gas pressure equal to 0,5 times the MDP and

minimum number of 100 cycles. When the shut-off valve does not incorporate a handwheel, the

forces and torques used in the endurance test shall be representative of those used in service

to open and close the valve member. Prior to and following the endurance test, a shut-off valve

shall be tested for leakage from an internal and external lea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...