IEC 60115-1:2020

(Main)Fixed resistors for use in electronic equipment - Part 1: Generic specification

Fixed resistors for use in electronic equipment - Part 1: Generic specification

IEC 60115-1:2020 is a generic specification and is applicable to fixed resistors for use in electronic equipment. It establishes standard terms, inspection procedures and methods of test for use in sectional and detail specifications of electronic components for quality assessment or any other purpose.

This edition contains the following significant technical changes with respect to the previous edition:

this 5th edition employs a new document structure, where the tests of prior Clause 4 are given in Clauses 6 to 12 now, with an informative Annex X providing cross-references for references to the prior revision of this standard;

the terms and definitions have been revised and amended, supplemented by a new section on resistor technologies and a new section on product classification levels;

a new Subclause 4.7 on recommendations for permissible substitutions has been added;

the provisions for packaging, storage and transportation in Subclauses 4.8, 4.9 and 4.10 have been completely revised;

a new Subclause 5.3 on default tolerances for the most common test parameters has been added;

the generic method of measuring resistance, now Sublause 5.6, has been separated from the test for compliance with a prescribed resistance value in 6.1, as a revision of the prior 4.5;

the test for the temperature coefficient of resistance of Subclause 6.2 is a revision of the prior test 4.8, variation of resistance with temperature, where the special concessions for resistors below 10 Ω have been waived;

the test methods for endurance testing of Subclauses 7.1 to 7.3 (prior 4.25.1 to 4.25.3) have been completely revised;

the single‑pulse high‑voltage overload test of Subclause 8.2 (prior 4.27) has been completely revised, and now offers adjustable severities for the 1,2/50 and for the 10/700 pulse shape for the benefit of detail specifications with improved significance;

the periodic-pulse high-voltage overload test of Subclause 8.3 (prior 4.28) has been revised and a corrected table of severities provided;

the period-pulse overload test of Subclause 8.4 (prior 4.39) has been deprecated and streamlined to only offer the severity historically applied in subordinate specifications;

the Subclauses 9.1 on visual inspection, 9.2 on the gauging of dimensions, and 9.3 on the assessment of detail dimensions (all parts of prior 4.4) have been completely revised;

the tests for robustness of terminations (prior 4.16) have been revised and separated into tests for the robustness of solderable terminations, Subclause 9.5, and tests for the robustness of threaded stud or screw terminations, Subclause 9.6;

the bump test of Subclause 9.9 (prior 4.20) and the shock test of Subclause 9.10 (prior 4.21) have been revised to reflect the merged relevant test standard IEC 60068-2-29;

the dry heat and cold test of the climatic sequence of Subclause 10.3 (prior 4.23) have been revised to reflect the changes of the relevant test standards IEC 60068‑2‑2 and IEC 60068‑2‑1;

the accelerated damp heat, steady state test of Subclause 10.5 (prior 4.37) has been amended with an option for a reduced number of bias voltages;

the corrosion test of Subclause 10.6 has been completely revised in order to employ the better suitable test method of IEC 60068-2-52 instead of the prior used IEC 60068-2-11;

the whisker growth test of Subclause 10.7 has been revised to reflect the changes of the new revision of the test methods of IEC 60068-2-82;

the test methods for solderability of Subclause 11.1 (prior 4.17) and for resistance to soldering heat of Subclause 11.2 (prior 4.18) have been completely revised to incorporate the necessary option for the variety of lead-bearing and lead-free solder alloys and respective process conditions;

the solvent resistance test of Subclause 11.3 combines the prior tests 4.29, component solvent resistance, and 4.30, solvent resistance of marking, in one test;

the accidental overload test of Subclause 12.3 (prior 4.26) has been completely r

Résistances fixes utilisées dans les équipements électroniques - Partie 1: Spécification générique

L'IEC 60115-1:2020 est une spécification générique et s'applique aux résistances fixes utilisées dans les équipements électroniques. Elle définit les termes normalisés, les procédures d'examen et les méthodes d'essai utilisés dans les spécifications intermédiaires et particulières des composants électroniques dans le cadre de l'assurance qualité, ainsi qu'à d'autres fins.

Cette édition contient les modifications techniques majeures suivantes par rapport à l'édition précédente:

cette 5e édition s'appuie sur une nouvelle structure de document, dans laquelle les essais du précédent Article 4 sont désormais présentés de l'Article 6 à l'Article 12, avec une Annexe X informative donnant des références croisées vers la version précédente de la présente norme;

les termes et définitions ont été révisés et amendés, complétés par une nouvelle section relative aux technologies en matière de résistance et une nouvelle section relative aux niveaux de classification des produits;

un nouveau Paragraphe 4.7 relatif aux recommandations en matière de remplacements admis a été ajouté;

les dispositions en matière d'emballage, de stockage et de transport de 4.8, 4.9 et 4.10 ont été intégralement révisées;

un nouveau Paragraphe 5.3 relatif aux tolérances par défaut pour la plupart des paramètres d'essai habituels a été ajouté;

la méthode générique de résistance de mesure (5.6 désormais) a été séparée de l'essai pour des raisons de conformité avec une valeur de résistance spécifiée en 6.1, en révision du précédent 4.5;

l'essai de coefficient de température de résistance de 6.2 est une révision du précédent essai de 4.8 (Variation de la résistance avec la température), des concessions particulières sur les résistances inférieures à 10 Ω ayant été consenties;

les méthodes d'essai d'endurance de 7.1 à 7.3 (précédemment 4.25.1 à 4.25.3) ont été intégralement révisées;

l'essai de surcharge haute tension à une seule impulsion de 8.2 (précédemment 4.27) a été intégralement révisé. Il propose désormais des sévérités pour la forme d'onde des impulsions 1,2/50 et la forme d'onde des impulsions 10/700 au profit de spécifications particulières avec signification améliorée;

l'essai de surcharge haute tension à impulsions périodiques de 8.3 (précédemment 4.28) a été révisé et un tableau corrigé des sévérités est fourni;

l'essai de surcharge à impulsions périodiques de 8.4 (précédemment 4.39) a été déconseillé et simplifié pour ne présenter que la sévérité historiquement appliquée dans les spécifications subordonnées;

le Paragraphe 9.1 relatif à l'examen visuel, le Paragraphe 9.2 relatif au calibrage des dimensions et le Paragraphe 9.3 relatif à l'évaluation des dimensions détaillées (toutes les parties de l'ancien 4.4) ont été intégralement révisés;

les essais de robustesse des sorties (précédemment 4.16) ont été révisés et divisés en essais de robustesse des bornes soudables (9.5) et essais de robustesse des bornes à tiges filetées ou à vis (9.6);

l'essai de secousses de 9.9 (précédemment 4.20) et l'essai de choc de 9.10 (précédemment 4.21) ont été révisés pour refléter la norme d'essai pertinente fusionnée IEC 60068-2-29;

l'essai de chaleur sèche et à froid de la séquence climatique de 10.3 (précédemment 4.23) a été révisé pour refléter les modifications apportées aux normes d'essai pertinentes IEC 60068‑2‑2 et IEC 60068‑2‑1;

l'essai continu accéléré de chaleur humide de 10.5 (précédemment 4.37) a été amendé avec une option pour un nombre réduit de tensions de polarisation;

l'essai de corrosion de 10.6 a été intégralement révisé afin d'utiliser la meilleure méthode d'essai adaptée de l'IEC 60068-2-52 en lieu et place de la précédente norme IEC 60068-2-11;

l'essai sur le développement des trichites de 10.7 a été révisé pour refléter les modifications de la nouvelle révision des méthodes d'essai de l'IEC 60068-2-82;

les méthodes d'essai de brasabilité de 11.1 (précédemment 4.17) et de résistance à la chaleur de brasage de 11.2 (précédemment 4.1

General Information

- Status

- Published

- Publication Date

- 17-Mar-2020

- Technical Committee

- TC 40 - Capacitors and resistors for electronic equipment

- Drafting Committee

- MT 60115-1 - TC 40/MT 60115-1

- Current Stage

- PPUB - Publication issued

- Start Date

- 18-Mar-2020

- Completion Date

- 13-Mar-2020

Relations

- Revises

IEC 60115-1:2008 - Fixed resistors for use in electronic equipment - Part 1: Generic specification - Effective Date

- 05-Sep-2023

Overview

IEC 60115-1:2020 is the international standard published by the International Electrotechnical Commission (IEC) specifying generic requirements for fixed resistors used in electronic equipment. This 5th edition standard establishes a comprehensive framework for terminology, inspection procedures, and testing methods essential for quality assessment and compliance of fixed resistors in various electronic applications.

This revision features significant updates including a reorganized document structure, new sections on resistor technologies and product classification levels, updated procedures for packaging, storage, and transportation, as well as modernized testing protocols. These enhancements ensure that IEC 60115-1:2020 reflects current industry practices and technological advancements in resistor manufacturing and testing.

Key Topics

Standardized Terminology and Classifications

- Revised terms and definitions for fixed resistor technologies

- Clear product classification levels to assist manufacturers and users in component identification

Measurement and Test Methods

- Detailed specifications for measuring resistance, temperature coefficient, inductance, voltage coefficient, and non-linearity

- Endurance tests categorizing performance under rated and extreme operating conditions

- Electrical overload tests including single-pulse and periodic-pulse high-voltage overloads for rigorous evaluation

- Mechanical tests like visual inspection, dimensional gauging, robustness of body and terminations, shock, bump, and vibration assessments

- Environmental and climatic testing such as rapid temperature change, damp heat, corrosion, whisker growth, and hydrogen sulfide resistance

Packaging, Storage, and Transportation

- Revised guidelines to maintain resistor quality during handling and shipment

- Conditions for packaging integrity and storage environment to prevent damage or performance degradation

Quality Assessment Procedures

- Standard rules for preparing detail specifications for fixed resistors used within the IEC qualification system (IECQ)

- Certified test records and failure rate evaluation methods to ensure reliable component performance

Applications

IEC 60115-1:2020 is crucial for manufacturers, testers, and users of fixed resistors in electronic equipment, enabling them to:

- Ensure consistent quality and reliability of fixed resistors across diverse applications including consumer electronics, industrial machinery, telecommunications, automotive electronics, and aerospace systems

- Facilitate standardized testing and inspection processes that support compliance with international quality and safety regulations

- Improve design accuracy by providing comprehensive test data on electrical, mechanical, and environmental performance parameters

- Assist procurement and quality control teams in vendor qualification and product acceptance based on uniform standards

- Support engineers and designers in selecting resistors with the appropriate tolerance, temperature coefficient, and durability characteristics for specific applications

Related Standards

IEC 60115-1:2020 works in conjunction with several related standards to offer comprehensive guidance on resistor specifications and component performance:

- IEC 60068 series – Environmental testing standards referenced for climatic and mechanical tests

- IEC 60115-2 – Sectional specifications covering product-specific features and tests for particular resistor types

- IECQ system standards – For quality assurance and certification processes within the electronics supply chain

- IEC 60068-2-29, IEC 60068-2-2, IEC 60068-2-1, IEC 60068-2-52 – Standards referenced for shock, dry heat, cold, and corrosion testing adapted in IEC 60115-1

Keywords: IEC 60115-1:2020, fixed resistors, resistor testing, electronic components, resistor standards, resistor quality assessment, resistor packaging, resistor endurance tests, electrical overload, resistor classification, environmental testing, IEC standards

Frequently Asked Questions

IEC 60115-1:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fixed resistors for use in electronic equipment - Part 1: Generic specification". This standard covers: IEC 60115-1:2020 is a generic specification and is applicable to fixed resistors for use in electronic equipment. It establishes standard terms, inspection procedures and methods of test for use in sectional and detail specifications of electronic components for quality assessment or any other purpose. This edition contains the following significant technical changes with respect to the previous edition: this 5th edition employs a new document structure, where the tests of prior Clause 4 are given in Clauses 6 to 12 now, with an informative Annex X providing cross-references for references to the prior revision of this standard; the terms and definitions have been revised and amended, supplemented by a new section on resistor technologies and a new section on product classification levels; a new Subclause 4.7 on recommendations for permissible substitutions has been added; the provisions for packaging, storage and transportation in Subclauses 4.8, 4.9 and 4.10 have been completely revised; a new Subclause 5.3 on default tolerances for the most common test parameters has been added; the generic method of measuring resistance, now Sublause 5.6, has been separated from the test for compliance with a prescribed resistance value in 6.1, as a revision of the prior 4.5; the test for the temperature coefficient of resistance of Subclause 6.2 is a revision of the prior test 4.8, variation of resistance with temperature, where the special concessions for resistors below 10 Ω have been waived; the test methods for endurance testing of Subclauses 7.1 to 7.3 (prior 4.25.1 to 4.25.3) have been completely revised; the single‑pulse high‑voltage overload test of Subclause 8.2 (prior 4.27) has been completely revised, and now offers adjustable severities for the 1,2/50 and for the 10/700 pulse shape for the benefit of detail specifications with improved significance; the periodic-pulse high-voltage overload test of Subclause 8.3 (prior 4.28) has been revised and a corrected table of severities provided; the period-pulse overload test of Subclause 8.4 (prior 4.39) has been deprecated and streamlined to only offer the severity historically applied in subordinate specifications; the Subclauses 9.1 on visual inspection, 9.2 on the gauging of dimensions, and 9.3 on the assessment of detail dimensions (all parts of prior 4.4) have been completely revised; the tests for robustness of terminations (prior 4.16) have been revised and separated into tests for the robustness of solderable terminations, Subclause 9.5, and tests for the robustness of threaded stud or screw terminations, Subclause 9.6; the bump test of Subclause 9.9 (prior 4.20) and the shock test of Subclause 9.10 (prior 4.21) have been revised to reflect the merged relevant test standard IEC 60068-2-29; the dry heat and cold test of the climatic sequence of Subclause 10.3 (prior 4.23) have been revised to reflect the changes of the relevant test standards IEC 60068‑2‑2 and IEC 60068‑2‑1; the accelerated damp heat, steady state test of Subclause 10.5 (prior 4.37) has been amended with an option for a reduced number of bias voltages; the corrosion test of Subclause 10.6 has been completely revised in order to employ the better suitable test method of IEC 60068-2-52 instead of the prior used IEC 60068-2-11; the whisker growth test of Subclause 10.7 has been revised to reflect the changes of the new revision of the test methods of IEC 60068-2-82; the test methods for solderability of Subclause 11.1 (prior 4.17) and for resistance to soldering heat of Subclause 11.2 (prior 4.18) have been completely revised to incorporate the necessary option for the variety of lead-bearing and lead-free solder alloys and respective process conditions; the solvent resistance test of Subclause 11.3 combines the prior tests 4.29, component solvent resistance, and 4.30, solvent resistance of marking, in one test; the accidental overload test of Subclause 12.3 (prior 4.26) has been completely r

IEC 60115-1:2020 is a generic specification and is applicable to fixed resistors for use in electronic equipment. It establishes standard terms, inspection procedures and methods of test for use in sectional and detail specifications of electronic components for quality assessment or any other purpose. This edition contains the following significant technical changes with respect to the previous edition: this 5th edition employs a new document structure, where the tests of prior Clause 4 are given in Clauses 6 to 12 now, with an informative Annex X providing cross-references for references to the prior revision of this standard; the terms and definitions have been revised and amended, supplemented by a new section on resistor technologies and a new section on product classification levels; a new Subclause 4.7 on recommendations for permissible substitutions has been added; the provisions for packaging, storage and transportation in Subclauses 4.8, 4.9 and 4.10 have been completely revised; a new Subclause 5.3 on default tolerances for the most common test parameters has been added; the generic method of measuring resistance, now Sublause 5.6, has been separated from the test for compliance with a prescribed resistance value in 6.1, as a revision of the prior 4.5; the test for the temperature coefficient of resistance of Subclause 6.2 is a revision of the prior test 4.8, variation of resistance with temperature, where the special concessions for resistors below 10 Ω have been waived; the test methods for endurance testing of Subclauses 7.1 to 7.3 (prior 4.25.1 to 4.25.3) have been completely revised; the single‑pulse high‑voltage overload test of Subclause 8.2 (prior 4.27) has been completely revised, and now offers adjustable severities for the 1,2/50 and for the 10/700 pulse shape for the benefit of detail specifications with improved significance; the periodic-pulse high-voltage overload test of Subclause 8.3 (prior 4.28) has been revised and a corrected table of severities provided; the period-pulse overload test of Subclause 8.4 (prior 4.39) has been deprecated and streamlined to only offer the severity historically applied in subordinate specifications; the Subclauses 9.1 on visual inspection, 9.2 on the gauging of dimensions, and 9.3 on the assessment of detail dimensions (all parts of prior 4.4) have been completely revised; the tests for robustness of terminations (prior 4.16) have been revised and separated into tests for the robustness of solderable terminations, Subclause 9.5, and tests for the robustness of threaded stud or screw terminations, Subclause 9.6; the bump test of Subclause 9.9 (prior 4.20) and the shock test of Subclause 9.10 (prior 4.21) have been revised to reflect the merged relevant test standard IEC 60068-2-29; the dry heat and cold test of the climatic sequence of Subclause 10.3 (prior 4.23) have been revised to reflect the changes of the relevant test standards IEC 60068‑2‑2 and IEC 60068‑2‑1; the accelerated damp heat, steady state test of Subclause 10.5 (prior 4.37) has been amended with an option for a reduced number of bias voltages; the corrosion test of Subclause 10.6 has been completely revised in order to employ the better suitable test method of IEC 60068-2-52 instead of the prior used IEC 60068-2-11; the whisker growth test of Subclause 10.7 has been revised to reflect the changes of the new revision of the test methods of IEC 60068-2-82; the test methods for solderability of Subclause 11.1 (prior 4.17) and for resistance to soldering heat of Subclause 11.2 (prior 4.18) have been completely revised to incorporate the necessary option for the variety of lead-bearing and lead-free solder alloys and respective process conditions; the solvent resistance test of Subclause 11.3 combines the prior tests 4.29, component solvent resistance, and 4.30, solvent resistance of marking, in one test; the accidental overload test of Subclause 12.3 (prior 4.26) has been completely r

IEC 60115-1:2020 is classified under the following ICS (International Classification for Standards) categories: 31.040.10 - Fixed resistors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60115-1:2020 has the following relationships with other standards: It is inter standard links to IEC 60115-1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60115-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60115-1 ®

Edition 5.0 2020-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fixed resistors for use in electronic equipment –

Part 1: Generic specification

Résistances fixes utilisées dans les équipements électroniques –

Partie 1: Spécification générique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60115-1 ®

Edition 5.0 2020-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fixed resistors for use in electronic equipment –

Part 1: Generic specification

Résistances fixes utilisées dans les équipements électroniques –

Partie 1: Spécification générique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.040.10 ISBN 978-2-8322-7904-5

– 2 – IEC 60115-1:2020 © IEC 2020

CONTENTS

FOREWORD . 6

INTRODUCTION . 9

1 Scope . 11

2 Normative references . 11

3 Terms, definitions, product technologies and product classifications . 13

3.1 Terms and definitions . 13

3.2 Product technologies . 20

3.3 Resistor encapsulations . 23

3.4 Product classification . 24

4 General requirements . 25

4.1 Units and symbols. 25

4.2 Preferred values . 25

4.3 Coding . 26

4.4 Marking of the resistors. 26

4.5 Marking of the packaging . 26

4.6 Ordering designation . 27

4.7 Permissible substitutions . 27

4.8 Packaging . 28

4.9 Storage . 29

4.10 Transportation . 29

5 General provisions for measurements and test methods . 30

5.1 General . 30

5.2 Standard atmospheric conditions . 30

5.3 Tolerances on test severity parameters . 32

5.4 Drying . 33

5.5 Mounting of specimens . 33

5.6 Measurement of resistance . 35

6 Electrical measurements and tests . 37

6.1 Resistance . 37

6.2 Temperature coefficient of resistance . 39

6.3 Inductance . 42

6.4 Voltage coefficient of resistance . 44

6.5 Non-linearity . 45

6.6 Current noise . 46

6.7 Temperature rise . 47

7 Endurance tests . 48

7.1 Endurance at the rated temperature 70 °C . 48

7.2 Endurance at room temperature . 50

7.3 Endurance at a maximum temperature . 55

8 Electrical overload tests. 59

8.1 Short-term overload . 59

8.2 Single-pulse high-voltage overload test . 61

8.3 Periodic-pulse high-voltage overload test . 66

8.4 Periodic-pulse overload test . 68

8.5 Electrostatic discharge . 70

9 Mechanical measurements and tests . 71

9.1 Visual examination . 71

9.2 Gauging of dimensions . 72

9.3 Detail dimensions . 73

9.4 Robustness of the resistor body . 74

9.5 Robustness of terminations . 75

9.6 Robustness of threaded stud or screw terminations . 78

9.7 Shear test . 79

9.8 Substrate bending test . 81

9.9 Bump . 83

9.10 Shock . 84

9.11 Vibration . 85

10 Environmental and climatic tests . 87

10.1 Rapid change of temperature . 87

10.2 Operation at low temperature . 88

10.3 Climatic sequence. 89

10.4 Damp heat, steady state . 92

10.5 Damp heat, steady state, accelerated . 95

10.6 Corrosion . 97

10.7 Whisker growth test . 99

10.8 Hydrogen sulphide test . 100

11 Tests related to component assembly . 101

11.1 Solderability . 101

11.2 Resistance to soldering heat . 105

11.3 Solvent resistance . 107

12 Tests related to safety . 109

12.1 Insulation resistance . 109

12.2 Voltage proof . 114

12.3 Accidental overload test . 115

12.4 Flammability . 120

13 Quality assessment procedures . 121

Annex A (normative) Symbols and abbreviated terms . 123

A.1 Symbols . 123

A.2 Abbreviated terms . 126

Annex B (normative) Rules for the preparation of detail specifications for resistors

and capacitors for electronic equipment for use within the IECQ system . 129

Annex C (informative) Example of a certified test record . 130

Annex Q (informative) Quality assessment procedures . 132

Q.1 General . 132

Q.2 IECQ Approved Component (IECQ AC) procedures . 136

Q.3 IECQ Qualification Approval (QA) procedures . 137

Q.4 IECQ Approved Component – Capability Certification (IECQ AC-C)

procedures . 138

Q.5 IECQ Approved Component – Technology Certification (IECQ AC-TC)

procedure . 140

Annex R (informative) Failure rate level evaluation, determination and qualification . 143

R.1 General . 143

R.2 Certification and determination of a failure rate level . 144

– 4 – IEC 60115-1:2020 © IEC 2020

R.3 Non-conformances . 146

R.4 Extension of a qualification to a higher failure rate level . 146

R.5 Maintenance of a failure rate level . 146

R.6 Deliveries . 147

R.7 Determination of a component failure rate . 148

Annex X (informative) Cross-references for references to the prior revision of this

document . 151

Bibliography . 155

Figure 1 – Hierarchical system of specifications . 10

Figure 2 – Voltage and dissipation on a resistor below and above its critical resistance . 14

Figure 3 – Standard measurement points on a leaded resistor . 36

Figure 4 – Standard measurement points on an SMD resistor . 36

Figure 5 – Measurement points on an assembled SMD resistor . 37

Figure 6 – Permissible resistance range due to tolerance . 38

Figure 7 – Permissible resistance range due to tolerance and TCR . 39

Figure 8 – Variation of resistance with temperature (example) . 39

Figure 9 – Test circuit for measurement of the inductance . 43

Figure 10 – Exponential voltage rise caused by inductance . 44

Figure 11 – Standard derating curve for the rated dissipation P . 49

Figure 12 – Derating curve with specification of a suitable test dissipation . 53

Figure 13 – Derating curve without specification of a suitable test dissipation . 53

Figure 14 – Derating curve for UCT ≥ MET . 57

Figure 15 – Derating curve for UCT < MET . 57

Figure 16 – Parameters of an open-circuit lightning impulse voltage . 62

Figure 17 – Circuit for generation of 1,2/50 pulses . 63

Figure 18 – Circuit for generation of 10/700 pulses . 64

Figure 19 – Testing of resistor body robustness . 75

Figure 20 – Shear test for SMD resistors . 80

Figure 21 – Substrate bending test for SMD resistors . 82

Figure 22 – V-block fixture . 110

Figure 23 – Foil method applied to a resistor specimen . 111

Figure 24 – Mounting method applied to a resistor specimen . 111

Figure 25 – Parallel clamp fixture for rectangular SMD resistors . 112

Figure 26 – V-clamp test fixture for cylindrical SMD resistors . 113

Figure 27 – Gauze fixture for axial cylindrical specimens . 117

Figure 28 – Gauze fixture dimensions for cylindrical specimens . 118

Figure 29 – Gauze fixture dimensions for non-cylindrical specimens . 119

Table 1 – Reference atmospheric conditions . 30

Table 2 – Referee atmospheric conditions . 31

Table 3 – Standard atmospheric conditions for testing . 31

Table 4 – Controlled atmospheric conditions for recovery . 32

Table 5 – Default tolerances on temperature specifications. 32

Table 6 – Default tolerances on voltage specifications . 32

Table 7 – Default tolerances on duration specifications . 33

Table 8 – Specimen drying procedures . 33

Table 9 – Voltages for resistance measurement . 35

Table 10 – Sequence of temperatures and measurements . 40

Table 11 – Severities for the single-pulse high-voltage overload test . 65

Table 12 – Severities for the periodic-pulse high-voltage overload test . 68

Table 13 – Tensile test force for wire terminations . 76

Table 14 – Test torque for threaded studs, screws and integral mounting devices . 78

Table 15 – Recommended parameters for the substrate bending test . 81

Table 16 – Recommended parameters for the bump test . 84

Table 17 – Recommended parameters for the shock test . 85

Table 18 – Recommended parameters for the vibration test . 86

Table 19 – Recommended parameters for the rapid change of temperature test . 88

Table 20 – Number of additional damp heat cycles . 91

Table 21 – Severity parameters for the damp heat, steady state test . 93

Table 22 – Bias voltage for the damp heat, steady state test . 94

Table 23 – Severity parameters for the accelerated damp heat, steady state test . 96

Table 24 – Grouped DC bias voltages for < 25 % deviation . 97

Table 25 – Recommended parameters for the corrosion test . 98

Table 26 – Test methods and parameters for the whisker growth test . 100

Table 27 – Selection of accelerated ageing methods of IEC 60068-2-20 . 101

Table 28 – Process temperatures for selected solder alloy examples . 102

Table 29 – Solderability test parameters for SMD resistors . 103

Table 30 – Solderability test parameters for resistors with wire or tag terminations . 104

Table 31 – Resistance to soldering heat test parameters for SMD resistors . 106

Table 32 – RSH test parameters for resistors with wire or tag terminations . 106

Table 33 – Recommended parameters for the solvent resistance test . 109

Table 34 – Insulation resistance measuring voltage . 114

Table 35 – Recommended parameters for the accidental overload test . 120

Table R.1 – Requirements for the qualification of a failure rate level . 145

Table R.2 – Requirements for the maintenance of a failure rate level qualification . 147

Table R.3 – Environmental factor π for determination of the component failure rate . 150

E

Table R.4 – Quality factor π for determination of the component failure rate . 150

Q

Table X.1 – Cross-references for references to clauses (1 of 3) . 151

Table X.2 – Cross-references for references to figures . 153

Table X.3 – Cross reference for references to tables . 154

– 6 – IEC 60115-1:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 1: Generic specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60115-1 has been prepared by IEC technical committee 40:

Capacitors and resistors for electronic equipment.

This fifth edition cancels and replaces the fourth edition published in 2008. This edition

constitutes a technical revision.

This edition contains the following significant technical changes with respect to the previous

edition:

th

a) this 5 edition employs a new document structure, where the tests of prior Clause 4 are

given in Clauses 6 to 12 now, with an informative Annex X providing cross-references for

references to the prior revision of this standard;

b) the terms and definitions have been revised and amended, supplemented by a new

section on resistor technologies and a new section on product classification levels;

c) a new Subclause 4.7 on recommendations for permissible substitutions has been added;

d) the provisions for packaging, storage and transportation in Subclauses 4.8, 4.9 and 4.10

have been completely revised;

e) a new Subclause 5.3 on default tolerances for the most common test parameters has been

added;

f) the generic method of measuring resistance, now Sublause 5.6, has been separated from

the test for compliance with a prescribed resistance value in 6.1, as a revision of the prior

4.5;

g) the test for the temperature coefficient of resistance of Subclause 6.2 is a revision of the

prior test 4.8, variation of resistance with temperature, where the special concessions for

resistors below 10 Ω have been waived;

h) the test methods for endurance testing of Subclauses 7.1 to 7.3 (prior 4.25.1 to 4.25.3)

have been completely revised;

i) the single-pulse high-voltage overload test of Subclause 8.2 (prior 4.27) has been

completely revised, and now offers adjustable severities for the 1,2/50 and for the 10/700

pulse shape for the benefit of detail specifications with improved significance;

j) the periodic-pulse high-voltage overload test of Subclause 8.3 (prior 4.28) has been

revised and a corrected table of severities provided;

k) the period-pulse overload test of Subclause 8.4 (prior 4.39) has been deprecated and

streamlined to only offer the severity historically applied in subordinate specifications;

l) the Subclauses 9.1 on visual inspection, 9.2 on the gauging of dimensions, and 9.3 on the

assessment of detail dimensions (all parts of prior 4.4) have been completely revised;

m) the tests for robustness of terminations (prior 4.16) have been revised and separated into

tests for the robustness of solderable terminations, Subclause 9.5, and tests for the

robustness of threaded stud or screw terminations, Subclause 9.6;

n) the bump test of Subclause 9.9 (prior 4.20) and the shock test of Subclause 9.10 (prior

4.21) have been revised to reflect the merged relevant test standard IEC 60068-2-29;

o) the dry heat and cold test of the climatic sequence of Subclause 10.3 (prior 4.23) have

been revised to reflect the changes of the relevant test standards IEC 60068-2-2 and

IEC 60068-2-1;

p) the accelerated damp heat, steady state test of Subclause 10.5 (prior 4.37) has been

amended with an option for a reduced number of bias voltages;

q) the corrosion test of Subclause 10.6 has been completely revised in order to employ the

better suitable test method of IEC 60068-2-52 instead of the prior used IEC 60068-2-11;

r) the whisker growth test of Subclause 10.7 has been revised to reflect the changes of the

new revision of the test methods of IEC 60068-2-82;

s) the test methods for solderability of Subclause 11.1 (prior 4.17) and for resistance to

soldering heat of Subclause 11.2 (prior 4.18) have been completely revised to incorporate

the necessary option for the variety of lead-bearing and lead-free solder alloys and

respective process conditions;

t) the solvent resistance test of Subclause 11.3 combines the prior tests 4.29, component

solvent resistance, and 4.30, solvent resistance of marking, in one test;

u) the accidental overload test of Subclause 12.3 (prior 4.26) has been completely revised;

v) the Annex Q on quality assessment procedures has been completely revised;

w) a new Annex R on failure rate evaluation, determination and qualification has been added.

The text of this International Standard is based on the following documents:

FDIS Report on voting

40/2717/FDIS 40/2733/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

– 8 – IEC 60115-1:2020 © IEC 2020

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60115 series, under the general title Fixed resistors for use in

electronic equipment, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

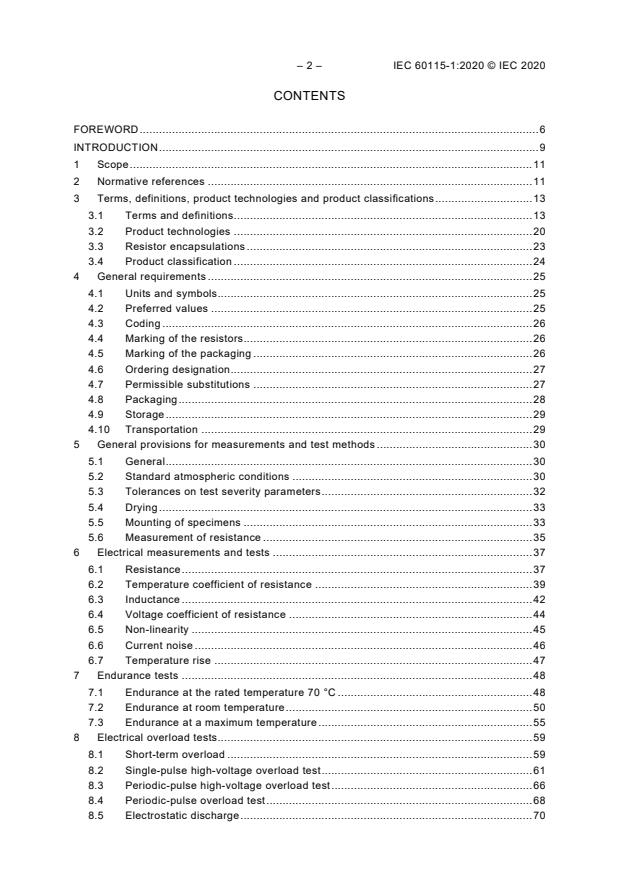

INTRODUCTION

The specification system for fixed resistors for use in electronic equipment is structured in a

hierarchical system as shown in Figure 1, consisting of the following specification types.

Generic specification

The generic specification covers all subjects mainly common to the family of fixed resistors for

use in electronic equipment, such as terminology, methods of measurement and tests. Where

the individual subjects require the prescription conditions or parameters specific to the

particular sub-family or type of fixed resistor, such prescriptions are required to be given by

one of the subordinate specifications.

For the scope of fixed resistors, the numeric reference to the generic specification is

IEC 60115-1.

Sectional specification

Sectional specifications cover all subjects additional to those given in the generic

specification, which are specific to a defined sub-group of fixed resistors. These subjects

normally are preferred values for dimensions and characteristics, additional test methods and

relevant prescriptions for test methods given in the generic specification, prescriptions for

sampling and for the preparation of specimen, recommended test severities and preferred

acceptance criteria. The sectional specification also outlines the structure and scope of the

test schedules which are to be applied in all subordinate detail specifications.

For the scope of fixed resistors, the numeric references to the sectional specifications reach

from IEC 60115-2 for leaded fixed low power film resistors to currently IEC 60115-9 for fixed

surface mount resistor networks with individually measurable resistors. The variety of

sectional specifications may be adapted to the portfolio of different technologies of fixed

resistors.

Detail specification

Detail specifications give directly, or by making reference to other documents, all information

necessary to completely describe a given type and range of fixed resistors, including

prescriptions of all values for dimensions and characteristics. They also give all information

required for the quality assessment of the covered type and range of fixed resistors within a

suitable quality assessment system, including prescriptions for all applied test severities and

acceptance criteria, and the completed test schedules.

Detail specifications can be either specifications within the IEC system, another specification

system linked to IEC, or specified by the manufacturer or user. For the scope of fixed

resistors, the numeric references to detail specifications are e.g. IEC 60115-2-101; if related

to the sectional specification, IEC 60115-2; and if related to the ancillary blank detail

specification, IEC 60115-2-1.

Blank detail specification

The hierarchical system of specifications is supplemented by one or more blank detail

specification to a sectional specification, which are used to ensure a uniform presentation of

detail specifications. The blank detail specifications provide the specification writer with a

template on the layout to be adopted and on the information to be given and with guidance for

the preparation of detail specifications in line with the requirements of the superior generic or

sectional specifications. Blank detail specifications are not considered as relevant

specifications since they do not themselves describe any particular component.

– 10 – IEC 60115-1:2020 © IEC 2020

The presence of an established hierarchical specification system with blank detail

specifications permits the preparation of detail specifications even outside of the relevant IEC

technical committee.

For the scope of fixed resistors, the numeric references to blank detail specifications are e.g.

IEC 60115-2-1: if related to the sectional specification, IEC 60115-2.

Relevant specification

In this system the term "relevant specification" addresses subordinate specifications

containing specific requirements, where applicable.

Any generic or sectional specification may use abstract and universal references to

subordinate specifications of either hierarchical level by use of the expression "relevant

specification".

Key

1 Indicates the range of "Relevant specifications" to the superior generic specification, where applicable.

2 Indicates the range of "Relevant specifications" to the superior sectional specification, where applicable.

Figure 1 – Hierarchical system of specifications

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 1: Generic specification

1 Scope

This part of IEC 60115 is a generic specification and is applicable to fixed resistors for use in

electronic equipment.

It establishes standard terms, inspection procedures and methods of test for use in sectional

and detail specifications of electronic components for quality assessment or any other

purpose.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60027 (all parts), Letter symbols to be used in electrical technology

IEC 60050 (all parts), International Electrotechnical Vocabulary (IEV) (available at

www.electropedia.org)

IEC 60062, Marking codes for resistors and capacitors

IEC 60063, Preferred number series for resistors and capacitors

IEC 60068-1:2013, Environmental testing – Part 1: General and guidance

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Tests A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Tests B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-13, Basic environmental testing procedures – Part 2-13: Tests – Test M: Low air

pressure

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-21:2006, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27:2008, Environmental testing – Part 2-27: Tests – Test Ea and guidance:

Shock

– 12 – IEC 60115-1:2020 © IEC 2020

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-45:1980, Basic environmental testing procedures - Part 2-45: Tests - Test XA

and guidance: Immersion in cleaning solvents

IEC 60068-2-45:1980/AMD1:1993

IEC 60068-2-47, Environmental testing – Part 2-47: Test – Mounting of specimens for

vibration, impact and similar dynamic tests

IEC 60068-2-52, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium

chloride solution)

IEC 60068-2-58, Environmental testing – Part 2-58: Tests – Test Td: Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-67, Environmental testing – Part 2-67: Tests – Test Cy: Damp heat, steady state,

accelerated test primarily intended for components

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60068-2-82:2019, Environmental testing – Part 2-82: Tests – Test XW1: Whisker test

methods for components and parts used in electronic assemblies

IEC 60195:2016, Method of measurement of current noise generated in fixed resistors

IEC 60286 (all parts), Packaging of components for automatic handling

IEC 60294, Measurement of the dimensions of a cylindrical component with axial terminations

IEC 60440:2012, Method of measurement of non-linearity in resistors

IEC 60617, Graphical symbols for diagrams (available at http://www.graphical-

symbols.info/equipment)

IEC 60695-11-5, Fire hazard testing – Part 11-5: Test flames – Needle-flame test method –

Apparatus, confirmatory test arrangement and guidance

IEC 61191 (all parts), Printed board assemblies

IEC 61193-2, Quality assessment systems – Part 2: Selection and use of sampling plans for

inspection of electronic components and packages

IEC 61340-3-1, Electrostatics – Part 3-1: Methods for simulation of electrostatic effects –

Human body model (HBM) electrostatic discharge test waveforms

IEC 61760-1, Surface mounting technology – Part 1: Standard method for the specification of

surface mounting components (SMDs)

IEC 61760-2, Surface mounting technology – Part 2: Transportation and storage conditions of

surface mounting devices (SMD) – Application guide

IEC 62090, Product package labels for electronic components using bar code and two-

dimensional symbologies

IEC 62812:2019, Low resistance measurements – Methods and guidance

IEC 80000 (all parts), Quantities and units

IECQ 03-1:2018, IEC Quality Assessment System for Electronic Components (IECQ System)

– Rules of procedure – Part 1: General Requirements for all IECQ Schemes

ISO 80000 (all parts), Quantities and units

3 Terms, definitions, product technologies and product classifications

NOTE A list of used symbols and abbreviated terms is provided in Annex A.

3.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...