IEC 60115-4:2022

(Main)Fixed resistors for use in electronic equipment - Part 4: Sectional specification: Power resistors for through hole assembly on circuit boards (THT) or for assembly on chassis

Fixed resistors for use in electronic equipment - Part 4: Sectional specification: Power resistors for through hole assembly on circuit boards (THT) or for assembly on chassis

IEC 60115-4:2022 relates to resistors having a rated dissipation typically greater than 1 W up to and including 1 000 W for use in electronic equipment. This document is applicable to fixed power resistors with a maximum surface temperature (MET) higher than the preferred upper category temperature (UCT) of 200 °C.

NOTE Heat sink resistors, i.e. resistors which in their operation depend on being mounted on a dedicated heat sink, owing to their special temperature conditions, are covered by a special sectional specification (under consideration at the time of publication).

These resistors are typically described according to types (different geometric shapes) and styles (different dimensions), and product technology.

The object of this document is to define preferred ratings and characteristics and to select from IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and to give general performance requirements for this type of resistor.

NOTE SMD resistors are covered by IEC 60115-8, regardless of their dissipation.

This edition includes the following significant technical changes with respect to the previous edition:

the definitions of product technologies and product classification levels of the generic specification, IEC 60115-1:2020, have been adopted;

a basis for the optional specification of the lead eccentricity of axial leaded resistors has been amended in 4.2;

the 'period-pulse high-voltage overload test' of IEC 60115-1:2020, 8.3 has been adopted as default test method in 5.3.9, thereby replacing the legacy test 'periodic-pulse overload test of IEC 60115-1:2020, 8.4;

the revised solderability test of IEC 60115-1:2020, 11.1 has been adopted in 5.3.22 and 5.3.23;

the combined solvent resistance test of IEC 60115-1:2020, 11.3 has been adopted in 5.3.25;

the 'endurance at room temperature test' of IEC 60115-1:2020, 7.2 has been reworked and adopted in 5.3.5;

the 'single-pulse high-voltage overload test' of IEC 60115-1:2020, 8.2, applied with the pulse shape 10/700 in 5.3.8, is complemented with the optional alternative provided by the pulse shape 1,2/50 in 5.4.1.

climatic tests for 'operation at low temperature' of IEC 60115 1:2020, 10.2, and for 'damp heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional tests in 5.4.5. and 5.4.6, respectively;

inclusion of an optional flammability test as 5.4.8;

new guidance is provided in 6.2 on the presentation of stability requirements with their permissible absolute and relative deviations;

acceptance criteria for the visual inspection have been added in 6.5 and in Annex B;

visual inspection for the primary and proximity packaging has been added in 6.5.3 and in 7.2;

the periodical evaluation of termination platings has been added as a new topic of quality assessment in 9.8;

the revised test clause numbering of IEC 60115-1:2020 has been applied;

a new Annex C has been added to summarize workmanship requirements for the assembly of leaded power resistors, e.g. as given in the prior IEC 61192 series of standards;

the informative Annex F on radial formed styles has been amended with details on a formed Z-bend style for surface-mount assembly;

furthermore, the informative Annex X has been ad

Résistances fixes utilisées dans les équipements électroniques - Partie 4: Spécification intermédiaire: Résistances de puissance pour assemblage par trous traversants sur cartes de circuit imprimé (carte THT) ou pour assemblage sur châssis

L’IEC 60115-4:2022 couvre les résistances ayant un pouvoir de dissipation assignée généralement supérieur à 1 W et pouvant atteindre 1 000 W, qui sont utilisées dans les équipements électroniques. Le présent document s’applique aux résistances de puissance fixes, dont la température de surface maximale (qui correspond à la MET) est supérieure à la température maximale de catégorie (UCT) préférentielle de 200 °C.

NOTE Les résistances à radiateur, c’est-à-dire les résistances dont le fonctionnement impose qu’elles soient montées sur un radiateur réservé, en raison de leurs conditions de température particulières, sont couvertes par une spécification intermédiaire qui leur est réservée (à l’étude à la date de publication du présent document).

Ces résistances sont généralement décrites selon des types (différentes formes géométriques), des modèles (différentes dimensions) et des technologies de produit.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

a) adoption des définitions des technologies de produit et des niveaux de classification des produits de la spécification générique, IEC 60115-1:2020;

b) amendement en 4.2 d’une base pour la spécification facultative de l’excentricité des broches, pour les résistances à broches axiales;

c) intégration en 5.3.9, en tant que méthode d’essai par défaut, de l’"essai de surcharge haute tension à impulsions périodiques" donné dans l’IEC 60115‑1:2020, 8.3, entraînant le d) remplacement de l’ancien "essai de surcharge à impulsions périodiques" donné dans l’IEC 60115-1:2020, 8.4;

d) intégration en 5.3.22 et 5.3.23 de la révision de l’essai de brasabilité de l’IEC 60115-1:2020, 11.1;

e) intégration en 5.3.25 de l’essai de résistance au solvant combiné de l’IEC 60115-1:2020, 11.3;

f) refonte et intégration en 5.3.5 de l’essai d’endurance à température ambiante de l’IEC 60115-1:2020, 7.2;

g) ajout de la forme d’ondes des impulsions 1,2/50, spécifiée en 5.4.1, comme variante facultative en 5.3.8 à l’"essai de surcharge haute tension à une seule impulsion" donné dans l’IEC 60115-1:2020, 8.2, appliqué avec la forme d’ondes des impulsions 10/700;

h) intégration en tant qu’essais facultatifs des essais climatiques relatifs au "fonctionnement à basse température" de l’IEC 60115-1:2020, 10.2, et à "chaleur humide, essai continu, accéléré" de l’IEC 60115-1:2020, 10.5, respectivement en 5.4.5 et 5.4.6;

i) ajout d’un essai facultatif d’inflammabilité en 5.4.8;

j) ajout de nouvelles recommandations en 6.2 sur la présentation des exigences de stabilité, ainsi que leurs écarts absolus et relatifs admis;

k) ajout de critères d’acceptation pour l’examen visuel en 6.5 et à l’Annexe B;

l) ajout d’un examen visuel pour l’emballage principal et l’emballage de proximité en 6.5.3 et en 7.2;

m) ajout de l’évaluation périodique des revêtements des sorties comme nouveau sujet de l’évaluation de la qualité en 9.8;

n) application de la numérotation corrigée des articles sur les essais de l’IEC 60115-1:2020;

o) ajout d’une nouvelle Annexe C pour synthétiser les exigences relatives à la qualité d’exécution pour l’assemblage de résistance de puissance à broches, par exemple celles données dans l’ancienne série de normes IEC 61192;

p) amendement de l’Annexe F informative sur les modèles à broches orientées radialement, en y intégrant des informations sur un modèle à courbure en Z, pour montage en surface;

q) ajout de l’Annexe X informative pour présenter les références croisées des éléments qui composent l’édition précédente du présent document.

General Information

- Status

- Published

- Publication Date

- 28-Nov-2022

- Technical Committee

- TC 40 - Capacitors and resistors for electronic equipment

- Drafting Committee

- MT 60115-4 - TC 40/MT 60115-4

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Nov-2022

- Completion Date

- 27-Dec-2022

Overview

IEC 60115-4:2022 is the IEC sectional specification for fixed power resistors intended for through‑hole assembly on printed circuit boards (THT) or for assembly on chassis. It covers resistors with rated dissipation typically greater than 1 W up to and including 1 000 W, and specifically those with a maximum surface temperature (MET) above the preferred upper category temperature (UCT) of 200 °C. The standard defines preferred ratings and characteristics, selects applicable tests and measuring methods from IEC 60115‑1, and sets general performance and quality assessment requirements for high‑power fixed resistors.

Key topics and technical requirements

- Product types and styles: axial, radial, vertical, tubular, ceramic‑housed, metal‑housed wire‑wound and other geometric shapes and styles for THT or chassis mounting.

- Product technologies: metal film, metal glaze, metal oxide, wire‑wound, metal strip and other specified technologies.

- Ratings and limits: rated dissipation (P), limiting element voltage (Umax), insulation voltage and insulation resistance for power resistors.

- Temperature and stability: temperature coefficient of resistance (TCR), temperature rise, endurance at rated and room temperatures, and UCT‑based tests.

- Electrical overload tests: single‑pulse high‑voltage overload test (pulse shape 10/700 ms adopted; 1.2/50 ms optional) and periodic‑pulse high‑voltage overload test adopted as default.

- Reliability and environmental tests: solderability (lead‑free and SnPb revisions adopted), combined solvent resistance, climatic tests (optional low‑temperature and damp‑heat), vibration, shock, rapid temperature change, and optional flammability and ESD tests.

- Quality and inspection: visual inspection acceptance criteria, packaging and marking requirements, periodic evaluation of termination platings, workmanship guidance (new Annex C), and updated quality assessment procedures.

Practical applications and who uses this standard

IEC 60115‑4 is essential for:

- Resistor manufacturers specifying design, materials and test regimes for high‑power fixed resistors (THT and chassis mounted).

- Electronic component engineers and designers selecting power resistors for power supplies, motor drives, audio amplifiers, power conversion, load banks and industrial electronics.

- Test laboratories and QA teams implementing conformity testing, endurance and environmental verification per IEC methods.

- Purchasing and compliance teams defining procurement specifications and supplier conformance clauses.

- PCB and chassis assembly engineers needing guidance on mounting, solderability and mechanical robustness for through‑hole power resistors.

Related standards

- IEC 60115‑1 (generic specification and test procedures) - referenced heavily for test methods and classifications.

- IEC 60115‑8 - covers SMD resistors (regardless of dissipation).

- Prior workmanship guidance: IEC 61192 series (informative history referenced).

Keywords: IEC 60115‑4, power resistors, fixed resistors, THT, through‑hole resistors, chassis assembly, rated dissipation, temperature coefficient, solderability, high‑voltage overload test, wire‑wound, metal oxide.

Buy Documents

IEC 60115-4:2022 - Fixed resistors for use in electronic equipment - Part 4: Sectional specification: Power resistors for through hole assembly on circuit boards (THT) or for assembly on chassis Released:11/29/2022 Isbn:9782832260883

IEC 60115-4:2022 - Fixed resistors for use in electronic equipment - Part 4: Sectional specification: Power resistors for through hole assembly on circuit boards (THT) or for assembly on chassis Released:11/29/2022 Isbn:9782832298589

Frequently Asked Questions

IEC 60115-4:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fixed resistors for use in electronic equipment - Part 4: Sectional specification: Power resistors for through hole assembly on circuit boards (THT) or for assembly on chassis". This standard covers: IEC 60115-4:2022 relates to resistors having a rated dissipation typically greater than 1 W up to and including 1 000 W for use in electronic equipment. This document is applicable to fixed power resistors with a maximum surface temperature (MET) higher than the preferred upper category temperature (UCT) of 200 °C. NOTE Heat sink resistors, i.e. resistors which in their operation depend on being mounted on a dedicated heat sink, owing to their special temperature conditions, are covered by a special sectional specification (under consideration at the time of publication). These resistors are typically described according to types (different geometric shapes) and styles (different dimensions), and product technology. The object of this document is to define preferred ratings and characteristics and to select from IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and to give general performance requirements for this type of resistor. NOTE SMD resistors are covered by IEC 60115-8, regardless of their dissipation. This edition includes the following significant technical changes with respect to the previous edition: the definitions of product technologies and product classification levels of the generic specification, IEC 60115-1:2020, have been adopted; a basis for the optional specification of the lead eccentricity of axial leaded resistors has been amended in 4.2; the 'period-pulse high-voltage overload test' of IEC 60115-1:2020, 8.3 has been adopted as default test method in 5.3.9, thereby replacing the legacy test 'periodic-pulse overload test of IEC 60115-1:2020, 8.4; the revised solderability test of IEC 60115-1:2020, 11.1 has been adopted in 5.3.22 and 5.3.23; the combined solvent resistance test of IEC 60115-1:2020, 11.3 has been adopted in 5.3.25; the 'endurance at room temperature test' of IEC 60115-1:2020, 7.2 has been reworked and adopted in 5.3.5; the 'single-pulse high-voltage overload test' of IEC 60115-1:2020, 8.2, applied with the pulse shape 10/700 in 5.3.8, is complemented with the optional alternative provided by the pulse shape 1,2/50 in 5.4.1. climatic tests for 'operation at low temperature' of IEC 60115 1:2020, 10.2, and for 'damp heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional tests in 5.4.5. and 5.4.6, respectively; inclusion of an optional flammability test as 5.4.8; new guidance is provided in 6.2 on the presentation of stability requirements with their permissible absolute and relative deviations; acceptance criteria for the visual inspection have been added in 6.5 and in Annex B; visual inspection for the primary and proximity packaging has been added in 6.5.3 and in 7.2; the periodical evaluation of termination platings has been added as a new topic of quality assessment in 9.8; the revised test clause numbering of IEC 60115-1:2020 has been applied; a new Annex C has been added to summarize workmanship requirements for the assembly of leaded power resistors, e.g. as given in the prior IEC 61192 series of standards; the informative Annex F on radial formed styles has been amended with details on a formed Z-bend style for surface-mount assembly; furthermore, the informative Annex X has been ad

IEC 60115-4:2022 relates to resistors having a rated dissipation typically greater than 1 W up to and including 1 000 W for use in electronic equipment. This document is applicable to fixed power resistors with a maximum surface temperature (MET) higher than the preferred upper category temperature (UCT) of 200 °C. NOTE Heat sink resistors, i.e. resistors which in their operation depend on being mounted on a dedicated heat sink, owing to their special temperature conditions, are covered by a special sectional specification (under consideration at the time of publication). These resistors are typically described according to types (different geometric shapes) and styles (different dimensions), and product technology. The object of this document is to define preferred ratings and characteristics and to select from IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and to give general performance requirements for this type of resistor. NOTE SMD resistors are covered by IEC 60115-8, regardless of their dissipation. This edition includes the following significant technical changes with respect to the previous edition: the definitions of product technologies and product classification levels of the generic specification, IEC 60115-1:2020, have been adopted; a basis for the optional specification of the lead eccentricity of axial leaded resistors has been amended in 4.2; the 'period-pulse high-voltage overload test' of IEC 60115-1:2020, 8.3 has been adopted as default test method in 5.3.9, thereby replacing the legacy test 'periodic-pulse overload test of IEC 60115-1:2020, 8.4; the revised solderability test of IEC 60115-1:2020, 11.1 has been adopted in 5.3.22 and 5.3.23; the combined solvent resistance test of IEC 60115-1:2020, 11.3 has been adopted in 5.3.25; the 'endurance at room temperature test' of IEC 60115-1:2020, 7.2 has been reworked and adopted in 5.3.5; the 'single-pulse high-voltage overload test' of IEC 60115-1:2020, 8.2, applied with the pulse shape 10/700 in 5.3.8, is complemented with the optional alternative provided by the pulse shape 1,2/50 in 5.4.1. climatic tests for 'operation at low temperature' of IEC 60115 1:2020, 10.2, and for 'damp heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional tests in 5.4.5. and 5.4.6, respectively; inclusion of an optional flammability test as 5.4.8; new guidance is provided in 6.2 on the presentation of stability requirements with their permissible absolute and relative deviations; acceptance criteria for the visual inspection have been added in 6.5 and in Annex B; visual inspection for the primary and proximity packaging has been added in 6.5.3 and in 7.2; the periodical evaluation of termination platings has been added as a new topic of quality assessment in 9.8; the revised test clause numbering of IEC 60115-1:2020 has been applied; a new Annex C has been added to summarize workmanship requirements for the assembly of leaded power resistors, e.g. as given in the prior IEC 61192 series of standards; the informative Annex F on radial formed styles has been amended with details on a formed Z-bend style for surface-mount assembly; furthermore, the informative Annex X has been ad

IEC 60115-4:2022 is classified under the following ICS (International Classification for Standards) categories: 31.040.10 - Fixed resistors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60115-4:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60115-4 ®

Edition 3.0 2022-11

INTERNATIONAL

STANDARD

colour

inside

Fixed resistors for use in electronic equipment –

Part 4: Sectional specification: Power resistors for through hole assembly on

circuit boards (THT) or for assembly on chassis

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60115-4 ®

Edition 3.0 2022-11

INTERNATIONAL

STANDARD

colour

inside

Fixed resistors for use in electronic equipment –

Part 4: Sectional specification: Power resistors for through hole assembly on

circuit boards (THT) or for assembly on chassis

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.040.10 ISBN 978-2-8322-6088-3

– 2 – IEC 60115-4:2022 © IEC 2022

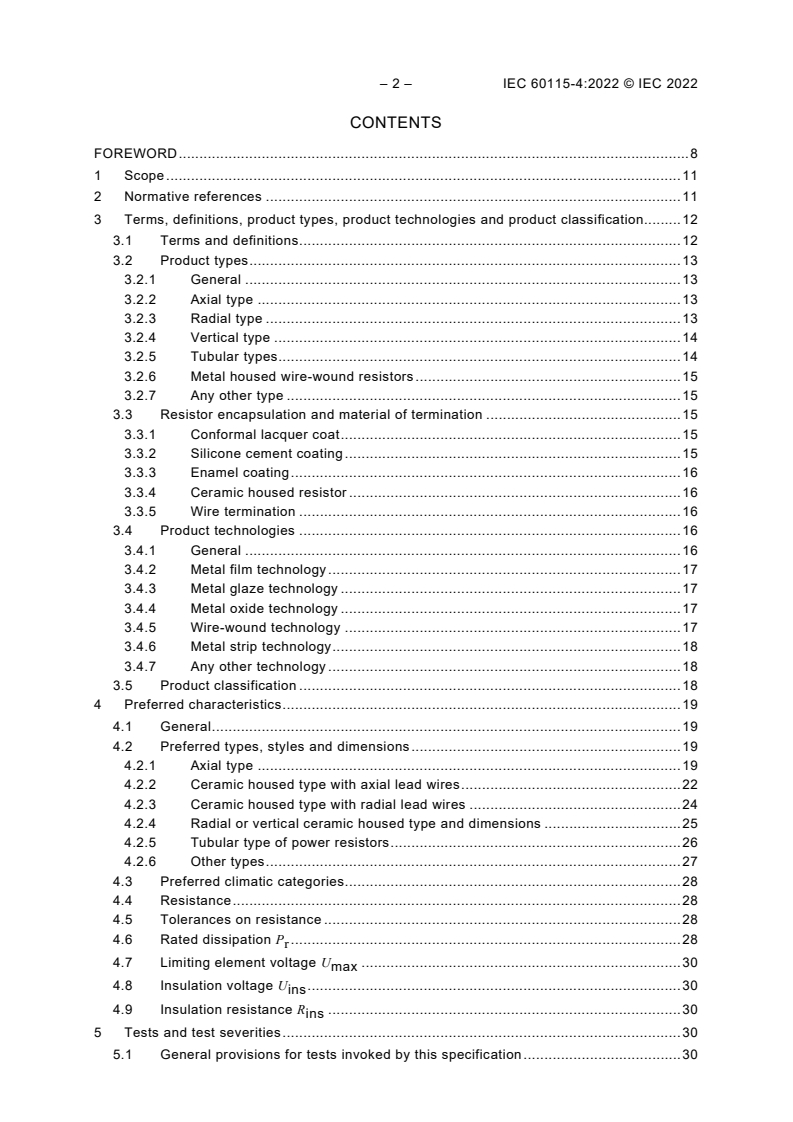

CONTENTS

FOREWORD . 8

1 Scope . 11

2 Normative references . 11

3 Terms, definitions, product types, product technologies and product classification. 12

3.1 Terms and definitions . 12

3.2 Product types . 13

3.2.1 General . 13

3.2.2 Axial type . 13

3.2.3 Radial type . 13

3.2.4 Vertical type . 14

3.2.5 Tubular types . 14

3.2.6 Metal housed wire-wound resistors . 15

3.2.7 Any other type . 15

3.3 Resistor encapsulation and material of termination . 15

3.3.1 Conformal lacquer coat . 15

3.3.2 Silicone cement coating . 15

3.3.3 Enamel coating . 16

3.3.4 Ceramic housed resistor . 16

3.3.5 Wire termination . 16

3.4 Product technologies . 16

3.4.1 General . 16

3.4.2 Metal film technology . 17

3.4.3 Metal glaze technology . 17

3.4.4 Metal oxide technology . 17

3.4.5 Wire-wound technology . 17

3.4.6 Metal strip technology . 17

3.4.7 Any other technology . 18

3.5 Product classification . 18

4 Preferred characteristics . 18

4.1 General . 18

4.2 Preferred types, styles and dimensions . 18

4.2.1 Axial type . 18

4.2.2 Ceramic housed type with axial lead wires . 22

4.2.3 Ceramic housed type with radial lead wires . 23

4.2.4 Radial or vertical ceramic housed type and dimensions . 25

4.2.5 Tubular type of power resistors . 26

4.2.6 Other types . 27

4.3 Preferred climatic categories . 27

4.4 Resistance . 28

4.5 Tolerances on resistance . 28

4.6 Rated dissipation P . 28

r

4.7 Limiting element voltage U . 30

max

4.8 Insulation voltage U . 30

ins

4.9 Insulation resistance R . 30

ins

5 Tests and test severities . 30

5.1 General provisions for tests invoked by this specification . 30

5.2 Preparation of specimen . 31

5.2.1 Drying . 31

5.2.2 Mounting of power resistors on test boards . 31

5.2.3 Mounting of power resistors on test racks . 32

5.2.4 Specification of test boards/ racks for any other type of high-power

resistors . 34

5.3 Details of applicable tests . 34

5.3.1 Resistance . 34

5.3.2 Temperature coefficient of resistance . 34

5.3.3 Temperature rise . 35

5.3.4 Endurance at the rated temperature 70 °C . 35

5.3.5 Endurance at room temperature . 36

5.3.6 Endurance at a maximum temperature: UCT with category dissipation . 37

5.3.7 Short-term overload . 37

5.3.8 Single-pulse high-voltage overload test . 38

5.3.9 Periodic-pulse high-voltage overload test . 38

5.3.10 Visual examination . 40

5.3.11 Gauging of dimensions . 40

5.3.12 Detail dimensions . 41

5.3.13 Robustness of the resistor body . 41

5.3.14 Robustness of terminations . 41

5.3.15 Bump . 42

5.3.16 Shock . 42

5.3.17 Vibration . 42

5.3.18 Rapid change of temperature . 43

5.3.19 Rapid change of temperature, ≥ 100 cycles . 43

5.3.20 Climatic sequence . 43

5.3.21 Damp heat, steady state . 44

5.3.22 Solderability, with lead-free solder . 45

5.3.23 Solderability, with SnPb solder . 46

5.3.24 Resistance to soldering heat . 46

5.3.25 Solvent resistance . 47

5.3.26 Insulation resistance . 47

5.3.27 Voltage proof . 47

5.4 Optional and/or additional tests . 48

5.4.1 Single-pulse high-voltage overload test . 48

5.4.2 Periodic-pulse overload test . 48

5.4.3 Electrostatic discharge (ESD) . 49

5.4.4 Robustness of threaded stud or screw terminations . 49

5.4.5 Operation at low temperature. 50

5.4.6 Damp heat, steady state, accelerated . 50

5.4.7 Accidental overload test. 51

5.4.8 Flammability . 51

6 Performance requirements. 52

6.1 General . 52

6.2 Limits for change of resistance at test . 52

6.3 Temperature coefficient of resistance . 54

6.4 Temperature rise . 54

6.5 Visual inspection . 55

– 4 – IEC 60115-4:2022 © IEC 2022

6.5.1 General visual criteria . 55

6.5.2 Visual criteria after tests . 55

6.5.3 Visual criteria for the packaging . 55

6.6 Solderability . 55

6.7 Insulation resistance . 56

6.8 Flammability . 56

6.9 Accidental overload test . 56

7 Marking, packaging and ordering information . 56

7.1 Marking of the component . 56

7.2 Packaging . 56

7.3 Marking of the packaging . 57

7.4 Ordering information . 57

8 Detail specifications . 57

8.1 General . 57

8.2 Information to be specified in a detail specification . 58

8.2.1 Outline drawing or illustration . 58

8.2.2 Type, style, and dimensions . 58

8.2.3 Climatic category . 58

8.2.4 Resistance range . 58

8.2.5 Tolerances on rated resistance . 58

8.2.6 Rated dissipation P . 58

8.2.7 Limiting element voltage U . 59

max

8.2.8 Insulation voltage U . 59

ins

8.2.9 Insulation resistance R . 59

ins

8.2.10 Tests and test severities . 59

8.2.11 Limits of resistance change after testing . 59

8.2.12 Temperature coefficient of resistance . 59

8.2.13 Marking . 59

8.2.14 Ordering information . 59

8.2.15 Mounting . 59

8.2.16 Storage. 60

8.2.17 Transportation . 60

8.2.18 Additional information . 60

8.2.19 Quality assessment procedures . 60

9 Quality assessment procedures . 60

9.1 General . 60

9.2 Definitions. 60

9.2.1 Primary stage of manufacture . 60

9.2.2 Structurally similar components . 60

9.2.3 Assessment level EZ . 61

9.3 Formation of inspection lots . 61

9.4 Approved component (IECQ AC) procedures . 62

9.5 Qualification approval (QA) procedures . 62

9.5.1 General . 62

9.5.2 Qualification approval . 62

9.5.3 Quality conformance inspection . 62

9.6 Capability certification (IECQ AC-C) procedures . 63

9.7 Technology certification (IECQ-AC-TC) procedures . 63

9.8 Periodical evaluation of termination platings . 63

9.9 Delayed delivery . 63

9.10 Certified test records. 63

9.11 Certificate of conformity (CoC) . 63

Annex A (normative) Symbols and abbreviated terms . 74

A.1 Symbols . 74

A.2 Abbreviated terms . 77

Annex B (normative) Visual inspection acceptance criteria. 79

B.1 General . 79

B.2 Acceptance criteria for a general visual inspection of body of specimens . 79

B.3 Acceptance criteria for a general visual inspection of the terminals . 79

B.4 Acceptance criteria for a general visual inspection of specimen after test . 79

Annex C (normative) Workmanship requirements for the assembly of power resistors. 80

C.1 General . 80

C.2 Lead forming . 80

C.2.1 General . 80

C.2.2 Means for support of mounting height . 81

C.3 Mounting . 82

C.3.1 General . 82

C.3.2 Lateral mounting . 83

C.3.3 Upright mounting . 84

C.4 Lead trimming . 85

Annex D (informative) Zero ohm resistors (jumpers) . 87

Annex E (informative) Guide on the application of optional and/or additional tests . 88

E.1 General . 88

E.2 Endurance at room temperature . 88

E.3 Single-pulse high-voltage overload test . 89

E.4 Periodic-pulse overload test . 90

E.5 Operation at low temperature . 91

E.6 Damp heat, steady state, accelerated . 92

E.7 Accidental overload test . 93

E.8 Flammability test . 94

E.9 Electrostatic discharge test (ESD) . 95

E.10 Robustness of threaded stud or screw terminations . 96

Annex F (informative) Radial formed types from axial styles . 98

F.1 General . 98

F.1.1 Applicability of this annex . 98

F.1.2 Denomination of radial formed styles . 98

F.1.3 Coated lead wires . 100

F.1.4 Means for support of mounting height . 100

F.1.5 Means for retention . 101

F.2 Radial formed types for through hole assembly . 101

F.2.1 Radial formed style with lateral body position . 101

F.2.2 Radial formed style with upright body position . 103

F.3 Radial formed types for surface-mount assembly . 105

F.4 Packaging . 106

F.4.1 Packaging of resistors formed for through-hole assembly . 106

F.4.2 Packaging of resistors formed for surface-mount assembly . 107

– 6 – IEC 60115-4:2022 © IEC 2022

F.5 Quality assessment . 107

F.5.1 General . 107

F.5.2 Quality assessment of formed resistors . 107

F.5.3 Forming of finished resistors of assessed quality . 108

F.5.4 Special inspection requirements . 108

Annex X (informative) Cross references for the prior revision of this specification . 109

Bibliography . 112

Figure 1 – Illustrations of typical axial leaded power resistors . 13

Figure 2 – Illustrations of typical radial leaded power resistors . 13

Figure 3 – Illustrations of typical vertical leaded power resistors with punched

terminals . 14

Figure 4 – Illustrations of typical tubular type power resistors . 14

Figure 5 – Illustrations of typical metal housed power resistors . 15

Figure 6 – Shape and dimensions of cylindrical axial leaded resistors . 19

Figure 7 – Alternative methods for specification of the length of excessive protective

coating or welding beads on axial leaded resistors . 20

Figure 8 – Lead-wire spacing of axial leaded resistors with bent leads . 21

Figure 9 – Specification of the lead eccentricity of axial leaded resistors . 22

Figure 10 – Shape and dimensions of axial leaded ceramic housed resistors . 22

Figure 11 – Shape and dimensions of radial type ceramic resistors . 24

Figure 12 – Shape and dimensions of radial leaded ceramic resistors . 25

Figure 13 – Shape and dimensions of tubular resistors . 26

Figure 14 – Typical derating curve for MET > UCT . 29

Figure 15 – Typical derating curve for power wire-wound resistors . 29

Figure 16 – Assembly of specimen to the test board . 32

Figure 17 – Mounting of axial leaded specimens on a rack, top view . 33

Figure 18 – Examples of specimen lead fixation devices . 34

Figure C.1 – Lead forming dimensions . 80

Figure C.2 – Examples of mounting height support . 82

Figure C.3 – Clearance between coating and solder . 83

Figure C.4 – Lateral mounting . 83

Figure C.5 – Upright mounting . 84

Figure C.6 – Lead protrusion . 85

Figure C.7 – Lead end distortion . 86

Figure F.1 – Production flow and different scopes of quality assurance . 99

Figure F.2 – Shape and dimensions of radial formed resistor for lateral body position . 101

Figure F.3 – Shape and dimensions of radial formed resistor for lateral body position

with kinked lead wires . 101

Figure F.4 – Shape and dimensions of radial formed resistor for upright body position. 103

Figure F.5 – Shape and dimensions of radial formed resistor for upright body position

and wide spacing . 103

Figure F.6 – Shape and dimensions of radial formed resistor for upright body position

and wide spacing, with kinked lead wire . 104

Figure F.7 – Shape and dimensions of radial formed resistor for surface-mount

assembly (Z-bend) . 105

Figure F.8 – Land pattern dimensions for surface-mount assembly . 106

Table 1 – Examples of preferred styles of cylindrical axial leaded power resistors . 19

Table 2 – Examples of preferred styles of axial leaded ceramic housed resistors . 23

Table 3 – Examples of preferred styles of radial type ceramic resistors. 24

Table 4 – Preferred styles of radial or vertical mount ceramic resistors . 26

Table 5 – Example of preferred styles of tubular types of power resistors . 27

Table 6 – Preferred alternative overload conditions . 40

Table 7 – Limits for resistance variations at tests . 53

Table 8 – Permitted change of resistance due to the temperature coefficient of

resistance . 54

Table 9 – Test schedule for the qualification approval of power resistors . 64

Table 10 – Test schedule for quality conformance inspection of power resistors . 69

Table C.1 – Lead bend radius . 81

Table C.2 – Recommended circuit board bore diameters . 82

Table C.3 – Clearance of lateral mounted resistors . 84

Table E.1 – Implementation of the test endurance at room temperature . 89

Table E.2 – Implementation of the single-pulse high-voltage overload test . 90

Table E.3 – Implementation of the periodic-pulse overload test . 91

Table E.4 – Implementation of the operation at low temperature test . 92

Table E.5 – Implementation of the test damp heat, steady state, accelerated . 93

Table E.6 – Implementation of the test accidental overload test . 94

Table E.7 – Implementation of the test flammability . 95

Table E.8 – Implementation of the test Electrostatic discharge (ESD) . 96

Table E.9 – Implementation of the test Robustness of threaded stud or screw

terminations . 97

Table F.1 – Feasible lead-wire spacing of radial formed resistor for

lateral body position . 102

Table F.2 – Feasible lead-wire spacing of radial formed resistor for

upright body position . 105

Table X.1 – Cross reference for references to clauses . 110

Table X.2 – Cross reference for references to figures . 111

Table X.3 – Cross reference for references to tables . 111

– 8 – IEC 60115-4:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 4: Sectional specification: Power resistors for through hole

assembly on circuit boards (THT) or for assembly on chassis

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60115-4 has been prepared by IEC technical committee 40: Capacitors and resistors for

electronic equipment. It is an International Standard.

This third edition cancels and replaces the second edition published in 1982 and

Amendment 1:1993. This edition constitutes a technical revision and includes test conditions

and requirements for lead-free soldering and assessment procedures meeting the requirements

of a "zero defect" approach.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the definitions of product technologies and product classification levels of the generic

specification, IEC 60115-1:2020, have been adopted;

b) a basis for the optional specification of the lead eccentricity of axial leaded resistors has

been amended in 4.2;

c) the 'period-pulse high-voltage overload test' of IEC 60115-1:2020, 8.3 has been adopted as

default test method in 5.3.9, thereby replacing the legacy test 'periodic-pulse overload test

of IEC 60115-1:2020, 8.4;

d) the revised solderability test of IEC 60115-1:2020, 11.1 has been adopted in 5.3.22 and

5.3.23;

e) the combined solvent resistance test of IEC 60115-1:2020, 11.3 has been adopted in 5.3.25;

f) the 'endurance at room temperature test' of IEC 60115-1:2020, 7.2 has been reworked and

adopted in 5.3.5;

g) the 'single-pulse high-voltage overload test' of IEC 60115-1:2020, 8.2, applied with the pulse

shape 10/700 in 5.3.8, is complemented with the optional alternative provided by the pulse

shape 1,2/50 in 5.4.1.

h) climatic tests for 'operation at low temperature' of IEC 60115 1:2020, 10.2, and for 'damp

heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional

tests in 5.4.5. and 5.4.6, respectively;

i) inclusion of an optional flammability test as 5.4.8;

j) new guidance is provided in 6.2 on the presentation of stability requirements with their

permissible absolute and relative deviations;

k) acceptance criteria for the visual inspection have been added in 6.5 and in Annex B;

l) visual inspection for the primary and proximity packaging has been added in 6.5.3 and in

7.2;

m) the periodical evaluation of termination platings has been added as a new topic of quality

assessment in 9.8;

n) the revised test clause numbering of IEC 60115-1:2020 has been applied;

o) a new Annex C has been added to summarize workmanship requirements for the assembly

of leaded power resistors, e.g. as given in the prior IEC 61192 series of standards;

p) the informative Annex F on radial formed styles has been amended with details on a formed

Z-bend style for surface-mount assembly;

q) furthermore, the informative Annex X has been added to show the cross-references to the

prior edition of this document.

The text of this International Standard is based on the following documents:

Draft Report on voting

40/2920/CDV 40/2963/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

A list of all parts in the IEC 60115 series, published under the general title Fixed resistors for

use in electronic equipment, can be found on the IEC website.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

– 10 – IEC 60115-4:2022 © IEC 2022

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 4: Sectional specification: Power resistors for through hole

assembly on circuit boards (THT) or for assembly on chassis

1 Scope

This part of IEC 60115 relates to resistors having a rated dissipation typically greater than 1 W

up to and including 1 000 W for use in electronic equipment. This document is applicable to

fixed power resistors with a maximum surface temperature (MET) higher than the preferred

upper category temperature (UCT) of 200 °C.

NOTE Heat sink resistors, i.e. resistors which in their operation depend on being mounted on a dedicated heat sink,

owing to their special temperature conditions, are covered by a special sectional specification (under consideration

at the time of publication).

These resistors are typically described according to types (different geometric shapes) and

styles (different dimensions), and product technology.

The resistive element of these resistors is typically

– protected by a conformal lacquer coating, or

– cement coating, or

– vitreous enamel, or

– a ceramic body, or

– any other housing, which is to be described in the relevant specification.

The electrical connection of these resistors is typically achieved by means of

– axial leads for through hole assembly (THT), or

– vertical or radial leads or punched terminals, or

– ferrules or lugs for chassis mount, or

– push on terminals, or

– screw terminals, or

– any other termination, which is to be described in the relevant specification.

In special cases, a heat sink can be applicable but not mandatory.

The object of this document is to define preferred ratings and characteristics and to select from

IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and

to give general performance requirements for this type of resistor.

NOTE SMD resistors are covered by IEC 60115-8, regardless of their dissipation.

2 Normative references

The following doc

...

IEC 60115-4 ®

Edition 3.0 2022-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fixed resistors for use in electronic equipment –

Part 4: Sectional specification: Power resistors for through hole assembly on

circuit boards (THT) or for assembly on chassis

Résistances fixes utilisées dans les équipements électroniques –

Partie 4: Spécification intermédiaire: Résistances de puissance pour

assemblage par trous traversants sur cartes de circuit imprimé (carte THT) ou

pour assemblage sur châssis

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60115-4 ®

Edition 3.0 2022-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fixed resistors for use in electronic equipment –

Part 4: Sectional specification: Power resistors for through hole assembly on

circuit boards (THT) or for assembly on chassis

Résistances fixes utilisées dans les équipements électroniques –

Partie 4: Spécification intermédiaire: Résistances de puissance pour

assemblage par trous traversants sur cartes de circuit imprimé (carte THT) ou

pour assemblage sur châssis

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.040.10 ISBN 978-2-8322-9858-9

– 2 – IEC 60115-4:2022 © IEC 2022

CONTENTS

FOREWORD . 8

1 Scope . 11

2 Normative references . 11

3 Terms, definitions, product types, product technologies and product classification. 12

3.1 Terms and definitions . 12

3.2 Product types . 13

3.2.1 General . 13

3.2.2 Axial type . 13

3.2.3 Radial type . 13

3.2.4 Vertical type . 14

3.2.5 Tubular types . 14

3.2.6 Metal housed wire-wound resistors . 15

3.2.7 Any other type . 15

3.3 Resistor encapsulation and material of termination . 15

3.3.1 Conformal lacquer coat . 15

3.3.2 Silicone cement coating . 15

3.3.3 Enamel coating . 16

3.3.4 Ceramic housed resistor . 16

3.3.5 Wire termination . 16

3.4 Product technologies . 16

3.4.1 General . 16

3.4.2 Metal film technology . 17

3.4.3 Metal glaze technology . 17

3.4.4 Metal oxide technology . 17

3.4.5 Wire-wound technology . 17

3.4.6 Metal strip technology . 18

3.4.7 Any other technology . 18

3.5 Product classification . 18

4 Preferred characteristics . 19

4.1 General . 19

4.2 Preferred types, styles and dimensions . 19

4.2.1 Axial type . 19

4.2.2 Ceramic housed type with axial lead wires . 22

4.2.3 Ceramic housed type with radial lead wires . 24

4.2.4 Radial or vertical ceramic housed type and dimensions . 25

4.2.5 Tubular type of power resistors . 26

4.2.6 Other types . 27

4.3 Preferred climatic categories . 28

4.4 Resistance . 28

4.5 Tolerances on resistance . 28

4.6 Rated dissipation P . 28

r

4.7 Limiting element voltage U . 30

max

4.8 Insulation voltage U . 30

ins

4.9 Insulation resistance R . 30

ins

5 Tests and test severities . 30

5.1 General provisions for tests invoked by this specification . 30

5.2 Preparation of specimen . 31

5.2.1 Drying . 31

5.2.2 Mounting of power resistors on test boards . 31

5.2.3 Mounting of power resistors on test racks . 32

5.2.4 Specification of test boards/ racks for any other type of high-power

resistors . 34

5.3 Details of applicable tests . 34

5.3.1 Resistance . 34

5.3.2 Temperature coefficient of resistance . 34

5.3.3 Temperature rise . 35

5.3.4 Endurance at the rated temperature 70 °C . 35

5.3.5 Endurance at room temperature . 36

5.3.6 Endurance at a maximum temperature: UCT with category dissipation . 37

5.3.7 Short-term overload . 37

5.3.8 Single-pulse high-voltage overload test . 38

5.3.9 Periodic-pulse high-voltage overload test . 38

5.3.10 Visual examination . 40

5.3.11 Gauging of dimensions . 40

5.3.12 Detail dimensions . 41

5.3.13 Robustness of the resistor body . 41

5.3.14 Robustness of terminations . 41

5.3.15 Bump . 42

5.3.16 Shock . 42

5.3.17 Vibration . 42

5.3.18 Rapid change of temperature . 43

5.3.19 Rapid change of temperature, ≥ 100 cycles . 43

5.3.20 Climatic sequence . 43

5.3.21 Damp heat, steady state . 45

5.3.22 Solderability, with lead-free solder . 45

5.3.23 Solderability, with SnPb solder . 46

5.3.24 Resistance to soldering heat . 46

5.3.25 Solvent resistance . 47

5.3.26 Insulation resistance . 47

5.3.27 Voltage proof . 47

5.4 Optional and/or additional tests . 48

5.4.1 Single-pulse high-voltage overload test . 48

5.4.2 Periodic-pulse overload test . 48

5.4.3 Electrostatic discharge (ESD) . 49

5.4.4 Robustness of threaded stud or screw terminations . 50

5.4.5 Operation at low temperature. 50

5.4.6 Damp heat, steady state, accelerated . 50

5.4.7 Accidental overload test. 51

5.4.8 Flammability . 51

6 Performance requirements. 52

6.1 General . 52

6.2 Limits for change of resistance at test . 52

6.3 Temperature coefficient of resistance . 55

6.4 Temperature rise . 55

6.5 Visual inspection . 56

– 4 – IEC 60115-4:2022 © IEC 2022

6.5.1 General visual criteria . 56

6.5.2 Visual criteria after tests . 56

6.5.3 Visual criteria for the packaging . 56

6.6 Solderability . 56

6.7 Insulation resistance . 57

6.8 Flammability . 57

6.9 Accidental overload test . 57

7 Marking, packaging and ordering information . 57

7.1 Marking of the component . 57

7.2 Packaging . 57

7.3 Marking of the packaging . 58

7.4 Ordering information . 58

8 Detail specifications . 58

8.1 General . 58

8.2 Information to be specified in a detail specification . 59

8.2.1 Outline drawing or illustration . 59

8.2.2 Type, style, and dimensions . 59

8.2.3 Climatic category . 59

8.2.4 Resistance range . 59

8.2.5 Tolerances on rated resistance . 59

8.2.6 Rated dissipation P . 59

8.2.7 Limiting element voltage U . 60

max

8.2.8 Insulation voltage U . 60

ins

8.2.9 Insulation resistance R . 60

ins

8.2.10 Tests and test severities . 60

8.2.11 Limits of resistance change after testing . 60

8.2.12 Temperature coefficient of resistance . 60

8.2.13 Marking . 60

8.2.14 Ordering information . 60

8.2.15 Mounting . 60

8.2.16 Storage. 61

8.2.17 Transportation . 61

8.2.18 Additional information . 61

8.2.19 Quality assessment procedures . 61

9 Quality assessment procedures . 61

9.1 General . 61

9.2 Definitions. 61

9.2.1 Primary stage of manufacture . 61

9.2.2 Structurally similar components . 61

9.2.3 Assessment level EZ . 62

9.3 Formation of inspection lots . 62

9.4 Approved component (IECQ AC) procedures . 63

9.5 Qualification approval (QA) procedures . 63

9.5.1 General . 63

9.5.2 Qualification approval . 63

9.5.3 Quality conformance inspection . 63

9.6 Capability certification (IECQ AC-C) procedures . 64

9.7 Technology certification (IECQ-AC-TC) procedures . 64

9.8 Periodical evaluation of termination platings . 64

9.9 Delayed delivery . 64

9.10 Certified test records. 64

9.11 Certificate of conformity (CoC) . 64

Annex A (normative) Symbols and abbreviated terms . 75

A.1 Symbols . 75

A.2 Abbreviated terms . 78

Annex B (normative) Visual inspection acceptance criteria. 80

B.1 General . 80

B.2 Acceptance criteria for a general visual inspection of body of specimens . 80

B.3 Acceptance criteria for a general visual inspection of the terminals . 80

B.4 Acceptance criteria for a general visual inspection of specimen after test . 80

Annex C (normative) Workmanship requirements for the assembly of power resistors. 81

C.1 General . 81

C.2 Lead forming . 81

C.2.1 General . 81

C.2.2 Means for support of mounting height . 82

C.3 Mounting . 83

C.3.1 General . 83

C.3.2 Lateral mounting . 84

C.3.3 Upright mounting . 85

C.4 Lead trimming . 86

Annex D (informative) Zero ohm resistors (jumpers) . 88

Annex E (informative) Guide on the application of optional and/or additional tests . 89

E.1 General . 89

E.2 Endurance at room temperature . 89

E.3 Single-pulse high-voltage overload test . 90

E.4 Periodic-pulse overload test . 91

E.5 Operation at low temperature . 92

E.6 Damp heat, steady state, accelerated . 93

E.7 Accidental overload test . 94

E.8 Flammability test . 95

E.9 Electrostatic discharge test (ESD) . 96

E.10 Robustness of threaded stud or screw terminations . 97

Annex F (informative) Radial formed types from axial styles . 99

F.1 General . 99

F.1.1 Applicability of this annex . 99

F.1.2 Denomination of radial formed styles . 99

F.1.3 Coated lead wires . 101

F.1.4 Means for support of mounting height . 101

F.1.5 Means for retention . 102

F.2 Radial formed types for through hole assembly . 102

F.2.1 Radial formed style with lateral body position . 102

F.2.2 Radial formed style with upright body position . 104

F.3 Radial formed types for surface-mount assembly . 106

F.4 Packaging . 107

F.4.1 Packaging of resistors formed for through-hole assembly . 107

F.4.2 Packaging of resistors formed for surface-mount assembly . 108

– 6 – IEC 60115-4:2022 © IEC 2022

F.5 Quality assessment . 108

F.5.1 General . 108

F.5.2 Quality assessment of formed resistors . 108

F.5.3 Forming of finished resistors of assessed quality . 109

F.5.4 Special inspection requirements . 109

Annex X (informative) Cross references for the prior revision of this specification . 111

Bibliography . 114

Figure 1 – Illustrations of typical axial leaded power resistors . 13

Figure 2 – Illustrations of typical radial leaded power resistors . 13

Figure 3 – Illustrations of typical vertical leaded power resistors with punched

terminals . 14

Figure 4 – Illustrations of typical tubular type power resistors . 14

Figure 5 – Illustrations of typical metal housed power resistors . 15

Figure 6 – Shape and dimensions of cylindrical axial leaded resistors . 19

Figure 7 – Alternative methods for specification of the length of excessive protective

coating or welding beads on axial leaded resistors . 21

Figure 8 – Lead-wire spacing of axial leaded resistors with bent leads . 21

Figure 9 – Specification of the lead eccentricity of axial leaded resistors . 22

Figure 10 – Shape and dimensions of axial leaded ceramic housed resistors . 23

Figure 11 – Shape and dimensions of radial type ceramic resistors . 24

Figure 12 – Shape and dimensions of radial leaded ceramic resistors . 25

Figure 13 – Shape and dimensions of tubular resistors . 26

Figure 14 – Typical derating curve for MET > UCT . 29

Figure 15 – Typical derating curve for power wire-wound resistors . 29

Figure 16 – Assembly of specimen to the test board . 32

Figure 17 – Mounting of axial leaded specimens on a rack, top view . 33

Figure 18 – Examples of specimen lead fixation devices . 34

Figure C.1 – Lead forming dimensions . 81

Figure C.2 – Examples of mounting height support . 83

Figure C.3 – Clearance between coating and solder . 84

Figure C.4 – Lateral mounting . 84

Figure C.5 – Upright mounting . 85

Figure C.6 – Lead protrusion . 86

Figure C.7 – Lead end distortion . 87

Figure F.1 – Production flow and different scopes of quality assurance . 100

Figure F.2 – Shape and dimensions of radial formed resistor for lateral body position . 102

Figure F.3 – Shape and dimensions of radial formed resistor for lateral body position

with kinked lead wires . 102

Figure F.4 – Shape and dimensions of radial formed resistor for upright body position. 104

Figure F.5 – Shape and dimensions of radial formed resistor for upright body position

and wide spacing . 104

Figure F.6 – Shape and dimensions of radial formed resistor for upright body position

and wide spacing, with kinked lead wire . 105

Figure F.7 – Shape and dimensions of radial formed resistor for surface-mount

assembly (Z-bend) . 106

Figure F.8 – Land pattern dimensions for surface-mount assembly . 107

Table 1 – Examples of preferred styles of cylindrical axial leaded power resistors . 20

Table 2 – Examples of preferred styles of axial leaded ceramic housed resistors . 23

Table 3 – Examples of preferred styles of radial type ceramic resistors. 24

Table 4 – Preferred styles of radial or vertical mount ceramic resistors . 26

Table 5 – Example of preferred styles of tubular types of power resistors . 27

Table 6 – Preferred alternative overload conditions . 40

Table 7 – Limits for resistance variations at tests . 54

Table 8 – Permitted change of resistance due to the temperature coefficient of

resistance . 55

Table 9 – Test schedule for the qualification approval of power resistors . 65

Table 10 – Test schedule for quality conformance inspection of power resistors . 70

Table C.1 – Lead bend radius . 82

Table C.2 – Recommended circuit board bore diameters . 83

Table C.3 – Clearance of lateral mounted resistors . 85

Table E.1 – Implementation of the test endurance at room temperature . 90

Table E.2 – Implementation of the single-pulse high-voltage overload test . 91

Table E.3 – Implementation of the periodic-pulse overload test . 92

Table E.4 – Implementation of the operation at low temperature test . 93

Table E.5 – Implementation of the test damp heat, steady state, accelerated . 94

Table E.6 – Implementation of the test accidental overload test . 95

Table E.7 – Implementation of the test flammability . 96

Table E.8 – Implementation of the test Electrostatic discharge (ESD) . 97

Table E.9 – Implementation of the test Robustness of threaded stud or screw

terminations . 98

Table F.1 – Feasible lead-wire spacing of radial formed resistor for

lateral body position . 103

Table F.2 – Feasible lead-wire spacing of radial formed resistor for

upright body position . 106

Table X.1 – Cross reference for references to clauses . 112

Table X.2 – Cross reference for references to figures . 113

Table X.3 – Cross reference for references to tables . 113

– 8 – IEC 60115-4:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 4: Sectional specification: Power resistors for through hole

assembly on circuit boards (THT) or for assembly on chassis

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60115-4 has been prepared by IEC technical committee 40: Capacitors and resistors for

electronic equipment. It is an International Standard.

This third edition cancels and replaces the second edition published in 1982 and

Amendment 1:1993. This edition constitutes a technical revision and includes test conditions

and requirements for lead-free soldering and assessment procedures meeting the requirements

of a "zero defect" approach.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the definitions of product technologies and product classification levels of the generic

specification, IEC 60115-1:2020, have been adopted;

b) a basis for the optional specification of the lead eccentricity of axial leaded resistors has

been amended in 4.2;

c) the 'period-pulse high-voltage overload test' of IEC 60115-1:2020, 8.3 has been adopted as

default test method in 5.3.9, thereby replacing the legacy test 'periodic-pulse overload test

of IEC 60115-1:2020, 8.4;

d) the revised solderability test of IEC 60115-1:2020, 11.1 has been adopted in 5.3.22 and

5.3.23;

e) the combined solvent resistance test of IEC 60115-1:2020, 11.3 has been adopted in 5.3.25;

f) the 'endurance at room temperature test' of IEC 60115-1:2020, 7.2 has been reworked and

adopted in 5.3.5;

g) the 'single-pulse high-voltage overload test' of IEC 60115-1:2020, 8.2, applied with the pulse

shape 10/700 in 5.3.8, is complemented with the optional alternative provided by the pulse

shape 1,2/50 in 5.4.1.

h) climatic tests for 'operation at low temperature' of IEC 60115 1:2020, 10.2, and for 'damp

heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional

tests in 5.4.5. and 5.4.6, respectively;

i) inclusion of an optional flammability test as 5.4.8;

j) new guidance is provided in 6.2 on the presentation of stability requirements with their

permissible absolute and relative deviations;

k) acceptance criteria for the visual inspection have been added in 6.5 and in Annex B;

l) visual inspection for the primary and proximity packaging has been added in 6.5.3 and in

7.2;

m) the periodical evaluation of termination platings has been added as a new topic of quality

assessment in 9.8;

n) the revised test clause numbering of IEC 60115-1:2020 has been applied;

o) a new Annex C has been added to summarize workmanship requirements for the assembly

of leaded power resistors, e.g. as given in the prior IEC 61192 series of standards;

p) the informative Annex F on radial formed styles has been amended with details on a formed

Z-bend style for surface-mount assembly;

q) furthermore, the informative Annex X has been added to show the cross-references to the

prior edition of this document.

The text of this International Standard is based on the following documents:

Draft Report on voting

40/2920/CDV 40/2963/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

A list of all parts in the IEC 60115 series, published under the general title Fixed resistors for

use in electronic equipment, can be found on the IEC website

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...