IEC 60115-2:2023

(Main)Fixed resistors for use in electronic equipment - Part 2: Sectional specification: Low-power film resistors with leads for through-hole assembly on circuit boards (THT)

Fixed resistors for use in electronic equipment - Part 2: Sectional specification: Low-power film resistors with leads for through-hole assembly on circuit boards (THT)

IEC 60115-2:2023 is applicable to fixed low-power film resistors with termination leads for use in electronic equipment, which are typically assembled in through-hole technology (THT) on circuit boards.

These resistors are typically described according to types (different geometric shapes) and styles (different dimensions) and product technology. The resistive element of these resistors is typically protected by a conformal lacquer coating. These resistors have wire terminations and are primarily intended to be mounted on a circuit board in through-hole technique.

The object of this document is to state preferred ratings and characteristics and to select from IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and to give general performance requirements for this type of resistor.

This edition includes the following significant technical changes with respect to the previous edition:

the definitions of product technologies and product classification levels of the generic specification, IEC 60115‑1:2020, have been adopted;

the preferred dimensions given in Table 1 have been reviewed, and the legacy style RA_0922 has been removed;

a basis for the optional specification of the lead eccentricity of axial leaded resistors has been amended in 4.2;

the 'period-pulse high-voltage overload test' of IEC 60115‑1:2020, 8.3 has been adopted as default test method in 5.3.8, thereby replacing the legacy test 'periodic-pulse overload test' of IEC 60115‑1:2020, 8.4;

the revised solderability test of IEC 60115‑1:2020, 11.1 has been adopted in 5.3.19 and 5.3.20;

the combined solvent resistance test of IEC 60115‑1:2020, 11.3 has been adopted in 5.3.22;

the 'endurance at room temperature test' of IEC 60115‑1:2020, 7.2 (prior IEC 60115 2:2014, Annex C) has been adopted as an optional test in 5.4.1;

the 'single-pulse high-voltage overload test' of IEC 60115 1:2020, 8.2, applied with the pulse shape 10/700 in 5.3.7, is complemented with the optional alternative provided by the pulse shape 1,2/50 in 5.4.2;

climatic tests for 'operation at low temperature' of IEC 60115‑1:2020, 10.2, and for 'damp heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional tests in 5.4.4 and 5.4.5, respectively;

new guidance is provided in 6.2 on the presentation of stability requirements with their permissible absolute and relative deviations;

acceptance criteria for the visual examination have been added in 6.5 and in Annex B;

visual examination for the primary and proximity packaging has been added in 6.5.2 and in 7.2;

the periodical evaluation of termination platings has been added as a new topic of quality assessment in 9.8;

the revised test clause numbering of IEC 60115‑1:2020 has been applied;

a new Annex C has been added to summarize workmanship requirements for the assembly of leaded film resistors, e.g. as given in the prior IEC 61192 series of standards;

the informative Annex F (prior Annex B) on radial formed styles has been amended with details on a formed Z-bend style for surface-mount assembly.

Résistances fixes utilisées dans les équipements électroniques - Partie 2: Spécification intermédiaire: Résistances à broches à couche, à faible dissipation, pour assemblage par trous traversants sur cartes de circuit imprimé (carte THT)

L’IEC 60115-2:2023 s’applique aux résistances fixes à couche, à faible dissipation, équipées de broches de sortie, utilisées dans les équipements électroniques, et qui sont généralement assemblées sur les cartes de circuit imprimé au moyen de la technologie à trous traversants (THT).

Ces résistances sont généralement décrites selon des types (différentes formes géométriques), des modèles (différentes dimensions) et des technologies de produit. L’élément résistif de ces résistances est généralement protégé par un revêtement de vernis enrobant. Ces résistances comportent des fils de sortie et sont principalement destinées à être montées sur une carte de circuits avec la technique des trous traversants.

Le présent document a pour objet d’énoncer les caractéristiques assignées et les caractéristiques préférentielles, de choisir dans l’IEC 60115-1 les procédures d’assurance de la qualité et les méthodes d’essai et de mesure appropriées, et de fixer les exigences de performances générales pour ce type de résistance.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

a) adoption des définitions des technologies de produit et des niveaux de classification de produit de la spécification générique, IEC 60115-1:2020;

b) examen des dimensions préférentielles du Tableau 1, et suppression de l’ancien modèle RA_0922;

c) amendement en 4.2 d’une base pour la spécification facultative de l’excentricité des broches, pour les résistances à broches axiales;

d) intégration en 5.3.8, en tant que méthode d’essai par défaut, de l’"essai de surcharge haute tension à impulsions périodiques" donné dans l’IEC 60115‑1:2020, 8.3, entraînant le remplacement de l’ancien "essai de surcharge à impulsions périodiques" donné dans l’IEC 60115‑1:2020, 8.4;

e) intégration en 5.3.19 et 5.3.20 de la révision de l’essai de brasabilité de l’IEC 60115‑1:2020, 11.1;

f) intégration en 5.3.22 de l’essai de résistance au solvant combiné de l’IEC 60115‑1:2020, 11.3;

g) intégration en 5.4.1, en tant qu’essai facultatif, de "l’essai d’endurance à la température ambiante" donné dans l’IEC 60115‑1:2020, 7.2 (figurant anciennement dans l’IEC 60115‑2:2014, Annexe C);

h) ajout de la forme d’ondes des impulsions 1,2/50 comme variante facultative en 5.4.2 à "l’essai de surcharge haute tension à une seule impulsion" donné dans l’IEC 60115‑1:2020, 8.2, appliqué avec la forme d’ondes des impulsions 10/700 spécifiée en 5.3.7;

i) intégration en tant qu’essais facultatifs des essais climatiques relatifs au "fonctionnement à basse température" de l’IEC 60115-1:2020, 10.2, et à "chaleur humide, essai continu, accéléré" de l’IEC 60115-1:2020, 10.5, respectivement en 5.4.4 et 5.4.5;

j) ajout de nouvelles recommandations en 6.2 sur la présentation des exigences de stabilité, ainsi que leurs écarts absolus et relatifs admis;

k) ajout de critères d’acceptation pour l’examen visuel en 6.5 et à l’Annexe B;

l) ajout d’un examen visuel pour l’emballage principal et l’emballage de proximité en 6.5.2 et en 7.2;

m) ajout de l’évaluation périodique des revêtements des sorties comme nouveau sujet de l’évaluation de la qualité en 9.8;

n) application de la numérotation corrigée des articles sur les essais de l’IEC 60115-1:2020;

o) ajout d’une nouvelle Annexe C pour synthétiser les exigences relatives à la qualité d’exécution pour l’assemblage de résistance à broches à couche, par exemple celles données dans l’ancienne série de normes IEC 61192;

p) amendement de l’Annexe F informative (anciennement Annexe B) sur les modèles à broches orientées radialement, en y intégrant des informations sur un modèle à courbure en Z, pour montage en surface.

General Information

- Status

- Published

- Publication Date

- 14-Feb-2023

- Technical Committee

- TC 40 - Capacitors and resistors for electronic equipment

- Drafting Committee

- MT 60115-2 - TC 40/MT 60115-2

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Feb-2023

- Completion Date

- 20-Mar-2023

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 60115-2:2023 (Low‑power film resistors, THT)

IEC 60115-2:2023 is the 4th edition sectional specification for fixed low-power film resistors with leads intended for through‑hole technology (THT) on printed circuit boards. It defines preferred ratings, characteristics, tests and measuring methods, and the applicable quality‑assessment procedures selected from the generic resistor standard IEC 60115‑1. The standard covers product types, styles (dimensions), product‑technology definitions, protective coatings (typically conformal lacquer), wire terminations and general performance requirements.

Key topics and technical requirements

- Product classification and technologies: Adopts definitions and classification levels from IEC 60115‑1:2020 for consistent product families and quality levels.

- Preferred styles and dimensions: Reviewed preferred outline dimensions; legacy style RA_0922 removed. Includes lead spacing, excessive coating length and lead eccentricity rules.

- Electrical and environmental characteristics: Rated dissipation, limiting element voltage, insulation voltage/resistance, temperature coefficient and temperature rise criteria.

- Tests and severities: Specifies mandatory and optional tests - resistance measurement, TCR, temperature rise, endurance (rated and optional room temperature endurance), short‑term and single/periodic‑pulse high‑voltage overload tests (period‑pulse HV overload adopted as default), ESD, vibration, rapid temperature change, damp heat and low‑temperature operation (optional).

- Solderability and solder‑heat resistance: Adopts revised solderability tests for lead‑free and SnPb solders, plus resistance to soldering heat.

- Solvent resistance and flammability: Includes combined solvent resistance and flammability verification.

- Visual and workmanship criteria: Adds acceptance criteria for visual examination, packing presentation, and Annex C summarizing workmanship requirements for leaded resistor assembly (lead forming, mounting, trimming).

- Quality assessment: Selects quality procedures (qualification, IECQ/QA/AC routes), introduces periodical evaluation of termination platings and certified test records.

Applications and who uses this standard

- Resistor manufacturers: product design, type approval, production testing and supplier specifications.

- Component engineers and PCB designers: selecting THT film resistors with validated electrical and thermal performance.

- Quality/Compliance teams and test labs: qualification testing, acceptance criteria and conformity certification (IECQ/CoC).

- Procurement and OEMs: specifying part detail requirements, ordering information, packaging and marking compliance.

Related standards

- IEC 60115‑1:2020 - Generic specification and test methods referenced throughout.

- IEC 61192 (prior series) - Earlier workmanship guidance referenced and consolidated into Annex C.

- IEC webstore and IEC electropedia provide access to the full normative text and related documents.

Keywords: IEC 60115-2:2023, low-power film resistors, THT, through-hole resistors, fixed resistors, solderability, high-voltage overload test, quality assessment.

Frequently Asked Questions

IEC 60115-2:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fixed resistors for use in electronic equipment - Part 2: Sectional specification: Low-power film resistors with leads for through-hole assembly on circuit boards (THT)". This standard covers: IEC 60115-2:2023 is applicable to fixed low-power film resistors with termination leads for use in electronic equipment, which are typically assembled in through-hole technology (THT) on circuit boards. These resistors are typically described according to types (different geometric shapes) and styles (different dimensions) and product technology. The resistive element of these resistors is typically protected by a conformal lacquer coating. These resistors have wire terminations and are primarily intended to be mounted on a circuit board in through-hole technique. The object of this document is to state preferred ratings and characteristics and to select from IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and to give general performance requirements for this type of resistor. This edition includes the following significant technical changes with respect to the previous edition: the definitions of product technologies and product classification levels of the generic specification, IEC 60115‑1:2020, have been adopted; the preferred dimensions given in Table 1 have been reviewed, and the legacy style RA_0922 has been removed; a basis for the optional specification of the lead eccentricity of axial leaded resistors has been amended in 4.2; the 'period-pulse high-voltage overload test' of IEC 60115‑1:2020, 8.3 has been adopted as default test method in 5.3.8, thereby replacing the legacy test 'periodic-pulse overload test' of IEC 60115‑1:2020, 8.4; the revised solderability test of IEC 60115‑1:2020, 11.1 has been adopted in 5.3.19 and 5.3.20; the combined solvent resistance test of IEC 60115‑1:2020, 11.3 has been adopted in 5.3.22; the 'endurance at room temperature test' of IEC 60115‑1:2020, 7.2 (prior IEC 60115 2:2014, Annex C) has been adopted as an optional test in 5.4.1; the 'single-pulse high-voltage overload test' of IEC 60115 1:2020, 8.2, applied with the pulse shape 10/700 in 5.3.7, is complemented with the optional alternative provided by the pulse shape 1,2/50 in 5.4.2; climatic tests for 'operation at low temperature' of IEC 60115‑1:2020, 10.2, and for 'damp heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional tests in 5.4.4 and 5.4.5, respectively; new guidance is provided in 6.2 on the presentation of stability requirements with their permissible absolute and relative deviations; acceptance criteria for the visual examination have been added in 6.5 and in Annex B; visual examination for the primary and proximity packaging has been added in 6.5.2 and in 7.2; the periodical evaluation of termination platings has been added as a new topic of quality assessment in 9.8; the revised test clause numbering of IEC 60115‑1:2020 has been applied; a new Annex C has been added to summarize workmanship requirements for the assembly of leaded film resistors, e.g. as given in the prior IEC 61192 series of standards; the informative Annex F (prior Annex B) on radial formed styles has been amended with details on a formed Z-bend style for surface-mount assembly.

IEC 60115-2:2023 is applicable to fixed low-power film resistors with termination leads for use in electronic equipment, which are typically assembled in through-hole technology (THT) on circuit boards. These resistors are typically described according to types (different geometric shapes) and styles (different dimensions) and product technology. The resistive element of these resistors is typically protected by a conformal lacquer coating. These resistors have wire terminations and are primarily intended to be mounted on a circuit board in through-hole technique. The object of this document is to state preferred ratings and characteristics and to select from IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and to give general performance requirements for this type of resistor. This edition includes the following significant technical changes with respect to the previous edition: the definitions of product technologies and product classification levels of the generic specification, IEC 60115‑1:2020, have been adopted; the preferred dimensions given in Table 1 have been reviewed, and the legacy style RA_0922 has been removed; a basis for the optional specification of the lead eccentricity of axial leaded resistors has been amended in 4.2; the 'period-pulse high-voltage overload test' of IEC 60115‑1:2020, 8.3 has been adopted as default test method in 5.3.8, thereby replacing the legacy test 'periodic-pulse overload test' of IEC 60115‑1:2020, 8.4; the revised solderability test of IEC 60115‑1:2020, 11.1 has been adopted in 5.3.19 and 5.3.20; the combined solvent resistance test of IEC 60115‑1:2020, 11.3 has been adopted in 5.3.22; the 'endurance at room temperature test' of IEC 60115‑1:2020, 7.2 (prior IEC 60115 2:2014, Annex C) has been adopted as an optional test in 5.4.1; the 'single-pulse high-voltage overload test' of IEC 60115 1:2020, 8.2, applied with the pulse shape 10/700 in 5.3.7, is complemented with the optional alternative provided by the pulse shape 1,2/50 in 5.4.2; climatic tests for 'operation at low temperature' of IEC 60115‑1:2020, 10.2, and for 'damp heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional tests in 5.4.4 and 5.4.5, respectively; new guidance is provided in 6.2 on the presentation of stability requirements with their permissible absolute and relative deviations; acceptance criteria for the visual examination have been added in 6.5 and in Annex B; visual examination for the primary and proximity packaging has been added in 6.5.2 and in 7.2; the periodical evaluation of termination platings has been added as a new topic of quality assessment in 9.8; the revised test clause numbering of IEC 60115‑1:2020 has been applied; a new Annex C has been added to summarize workmanship requirements for the assembly of leaded film resistors, e.g. as given in the prior IEC 61192 series of standards; the informative Annex F (prior Annex B) on radial formed styles has been amended with details on a formed Z-bend style for surface-mount assembly.

IEC 60115-2:2023 is classified under the following ICS (International Classification for Standards) categories: 31.040.10 - Fixed resistors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60115-2:2023 has the following relationships with other standards: It is inter standard links to IEC 60115-2:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60115-2:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60115-2 ®

Edition 4.0 2023-02

INTERNATIONAL

STANDARD

Fixed resistors for use in electronic equipment –

Part 2: Sectional specification: Low-power film resistors with leads for through-

hole assembly on circuit boards (THT)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60115-2 ®

Edition 4.0 2023-02

INTERNATIONAL

STANDARD

Fixed resistors for use in electronic equipment –

Part 2: Sectional specification: Low-power film resistors with leads for through-

hole assembly on circuit boards (THT)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.040.10 ISBN 978-2-8322-6467-6

– 2 – IEC 60115-2:2023 © IEC 2023

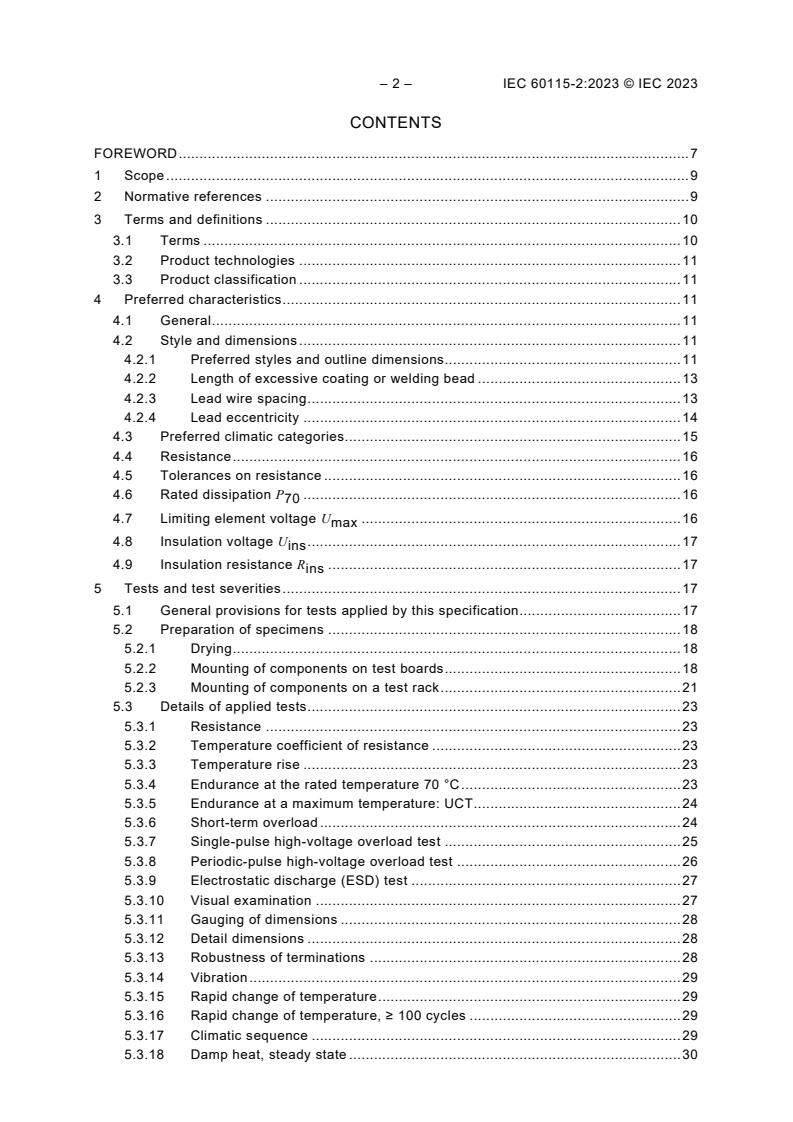

CONTENTS

FOREWORD . 7

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 10

3.1 Terms . 10

3.2 Product technologies . 11

3.3 Product classification . 11

4 Preferred characteristics . 11

4.1 General . 11

4.2 Style and dimensions . 11

4.2.1 Preferred styles and outline dimensions. 11

4.2.2 Length of excessive coating or welding bead . 13

4.2.3 Lead wire spacing . 13

4.2.4 Lead eccentricity . 14

4.3 Preferred climatic categories . 15

4.4 Resistance . 16

4.5 Tolerances on resistance . 16

4.6 Rated dissipation P . 16

4.7 Limiting element voltage U . 16

max

4.8 Insulation voltage U . 17

ins

4.9 Insulation resistance R . 17

ins

5 Tests and test severities . 17

5.1 General provisions for tests applied by this specification . 17

5.2 Preparation of specimens . 18

5.2.1 Drying . 18

5.2.2 Mounting of components on test boards . 18

5.2.3 Mounting of components on a test rack . 21

5.3 Details of applied tests . 23

5.3.1 Resistance . 23

5.3.2 Temperature coefficient of resistance . 23

5.3.3 Temperature rise . 23

5.3.4 Endurance at the rated temperature 70 °C . 23

5.3.5 Endurance at a maximum temperature: UCT . 24

5.3.6 Short-term overload . 24

5.3.7 Single-pulse high-voltage overload test . 25

5.3.8 Periodic-pulse high-voltage overload test . 26

5.3.9 Electrostatic discharge (ESD) test . 27

5.3.10 Visual examination . 27

5.3.11 Gauging of dimensions . 28

5.3.12 Detail dimensions . 28

5.3.13 Robustness of terminations . 28

5.3.14 Vibration . 29

5.3.15 Rapid change of temperature . 29

5.3.16 Rapid change of temperature, ≥ 100 cycles . 29

5.3.17 Climatic sequence . 29

5.3.18 Damp heat, steady state . 30

5.3.19 Solderability, with lead-free solder . 30

5.3.20 Solderability, with SnPb solder . 31

5.3.21 Resistance to soldering heat . 32

5.3.22 Solvent resistance . 32

5.3.23 Insulation resistance . 32

5.3.24 Voltage proof . 32

5.3.25 Flammability . 33

5.4 Optional and/or additional tests . 33

5.4.1 Endurance at room temperature . 33

5.4.2 Single-pulse high-voltage overload test . 34

5.4.3 Periodic-pulse overload test . 34

5.4.4 Operation at low temperature. 35

5.4.5 Damp heat, steady state, accelerated . 35

6 Performance requirements. 36

6.1 General . 36

6.2 Limits for change of resistance at tests . 36

6.3 Temperature coefficient of resistance . 39

6.4 Temperature rise . 39

6.5 Visual examination . 40

6.5.1 General visual criteria . 40

6.5.2 Visual criteria after tests . 40

6.5.3 Visual criteria for the packaging . 40

6.6 Solderability . 40

6.7 Insulation resistance . 41

6.8 Flammability . 41

7 Marking, packaging and ordering information . 41

7.1 Marking of the component . 41

7.2 Packaging . 41

7.3 Marking of the packaging . 41

7.4 Ordering information . 42

8 Detail specifications . 42

8.1 General . 42

8.2 Information to be specified in a detail specification . 42

8.2.1 Outline drawing or illustration . 42

8.2.2 Style and dimensions . 42

8.2.3 Climatic category . 43

8.2.4 Resistance range . 43

8.2.5 Tolerances on resistance . 43

8.2.6 Rated dissipation P . 43

8.2.7 Limiting element voltage U . 43

max

8.2.8 Insulation voltage U . 43

ins

8.2.9 Insulation resistance R . 43

ins

8.2.10 Test severities . 44

8.2.11 Limits of resistance change after testing . 44

8.2.12 Temperature coefficient of resistance . 44

8.2.13 Marking . 44

8.2.14 Ordering information . 44

8.2.15 Mounting . 44

– 4 – IEC 60115-2:2023 © IEC 2023

8.2.16 Storage. 44

8.2.17 Transportation . 44

8.2.18 Additional information . 44

8.2.19 Quality assessment procedures . 44

8.2.20 0 Ω resistors . 44

9 Quality assessment procedures . 45

9.1 General . 45

9.2 Definitions. 45

9.2.1 Primary stage of manufacture . 45

9.2.2 Structurally similar components . 45

9.2.3 Assessment level EZ . 45

9.3 Formation of inspection lots . 45

9.4 Approved component (IECQ AC) procedures . 46

9.5 Qualification approval (QA) procedures . 46

9.5.1 General . 46

9.5.2 Qualification approval . 47

9.5.3 Quality conformance inspection . 47

9.6 Capability certification (IECQ AC-C) procedures . 47

9.7 Technology certification (IECQ-AC-TC) procedures . 47

9.8 Periodical evaluation of termination plating . 47

9.9 Delayed delivery . 47

9.10 Certified test records. 48

9.11 Certificate of conformity (CoC) . 48

Annex A (normative) Symbols and abbreviated terms . 58

A.1 Symbols . 58

A.2 Abbreviated terms . 61

Annex B (normative) Visual examination acceptance criteria . 63

B.1 General . 63

B.2 Criteria for general visual inspection of specimens . 63

B.3 Criteria for visual inspection of specimens after tests . 63

Annex C (normative) Workmanship requirements for the assembly of leaded film

resistors . 64

C.1 General . 64

C.2 Lead forming . 64

C.2.1 General . 64

C.2.2 Means for support of mounting height . 65

C.3 Mounting . 66

C.3.1 General . 66

C.3.2 Lateral mounting . 67

C.3.3 Upright mounting . 68

C.4 Lead trimming . 69

Annex D (normative) Zero Ohm resistors (jumpers). 71

D.1 General . 71

D.2 Preferred characteristics . 71

D.3 Tests and test severities . 71

D.4 Performance requirements . 72

D.5 Marking, packaging and ordering information . 72

D.6 Detail specification . 73

D.7 Quality assessment procedures . 73

Annex E (informative) Guide on the application of optional and additional tests . 74

E.1 General . 74

E.2 Endurance at room temperature . 74

E.3 Single-pulse high-voltage overload test . 75

E.4 Periodic- pulse overload test . 76

E.5 Operation at low temperature . 76

E.6 Damp heat, steady state, accelerated . 77

Annex F (informative) Radial formed types. 79

F.1 General . 79

F.1.1 Applicability of this annex . 79

F.1.2 Denomination of radial formed types . 79

F.1.3 Coated lead wires . 81

F.1.4 Means for support of mounting height . 81

F.1.5 Means for retention . 82

F.2 Radial formed types for through-hole assembly . 82

F.2.1 Radial formed type with lateral body position . 82

F.2.2 Radial formed type with upright body position . 84

F.3 Radial formed types for surface-mount assembly . 87

F.4 Packaging . 88

F.4.1 Packaging of resistors formed for through-hole assembly . 88

F.4.2 Packaging of resistors formed for surface-mount assembly . 89

F.5 Quality assessment . 89

F.5.1 General . 89

F.5.2 Quality assessment of formed resistors . 89

F.5.3 Forming of finished resistors of assessed quality . 90

F.5.4 Special inspection requirements . 90

Annex X (informative) Cross-references for the prior revision of this specification . 91

Bibliography . 94

Figure 1 – Illustration of a typical axial leaded resistor . 10

Figure 2 – Illustrations of typical radial leaded resistors . 10

Figure 3 – Shape and dimension of axial leaded resistors . 12

Figure 4 – Alternative methods for specification of the length of excessive protective

coating on axial leaded resistors . 13

Figure 5 – Lead-wire spacing of axial leaded resistors with bent leads . 14

Figure 6 – Specification of the lead eccentricity of axial leaded resistors . 15

Figure 7 – Derating curve . 16

Figure 8 – Basic layout for mechanical, environmental and electrical tests . 19

Figure 9 – Assembly of specimens to the test board . 20

Figure 10 – Mounting of axial leaded specimens on a rack, top view . 22

Figure 11 – Examples of specimen lead fixation devices . 23

Figure C.1 – Lead forming dimensions . 64

Figure C.2 – Examples of mounting height support . 66

Figure C.3 – Clearance between coating and solder . 67

Figure C.4 – Lateral mounting . 67

– 6 – IEC 60115-2:2023 © IEC 2023

Figure C.5 – Upright mounting . 68

Figure C.6 – Lead protrusion . 69

Figure C.7 – Lead end distortion . 70

Figure F.1 – Production flow and different scopes of quality assurance . 80

Figure F.2 – Shape and dimensions of radial formed resistor for lateral body position . 82

Figure F.3 – Shape and dimensions of radial formed resistor for lateral body position

with kinked lead wires . 83

Figure F.4 – Shape and dimensions of radial formed resistor for upright body position. 84

Figure F.5 – Shape and dimensions of radial formed resistor for upright body position

and wide spacing . 85

Figure F.6 – Shape and dimensions of radial formed resistor for upright body position

and wide spacing, with kinked lead wire . 85

Figure F.7 – Shape and dimensions of radial formed resistor for surface-mount

assembly (Z-bend) . 87

Figure F.8 – Land pattern dimensions for surface-mount assembly . 88

Table 1 – Preferred styles of axial leaded resistors . 12

Table 2 – Test board dimensions . 20

Table 3 – Preferred aggravated overload conditions . 27

Table 4 – Limits for the change of resistance at tests . 38

Table 5 – Permitted change of resistance due to the variation of temperature . 39

Table 6 – Test schedule for the qualification approval . 48

Table 7 – Test schedule for the quality conformance inspections . 53

Table C.1 – Lead bend radius . 65

Table C.2 – Recommended circuit board bore diameters . 66

Table C.3 – Clearance of lateral mounted resistors . 68

Table E.1 – Implementation of the test endurance at room temperature . 74

Table E.2 – Implementation of the single-pulse high-voltage overload test . 75

Table E.3 – Implementation of the periodic-pulse overload test . 76

Table E.4 – Implementation of the operation at low temperature test . 77

Table E.5 – Implementation of the test damp heat, steady state, accelerated . 78

Table F.1 – Feasible lead-wire spacing of radial formed resistor for lateral body

position . 84

Table F.2 – Feasible lead-wire spacing of radial formed resistor for upright body

position . 87

Table X.1 – Cross reference for references to clauses . 91

Table X.2 – Cross reference for references to figures . 93

Table X.3 – Cross reference for references to table . 93

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 2: Sectional specification: Low-power film resistors with leads

for through-hole assembly on circuit boards (THT)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60115-2 has been prepared by IEC technical committee 40: Capacitors and resistors for

electronic equipment. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2014. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the definitions of product technologies and product classification levels of the generic

specification, IEC 60115‑1:2020, have been adopted;

b) the preferred dimensions given in Table 1 have been reviewed, and the legacy style

RA_0922 has been removed;

c) a basis for the optional specification of the lead eccentricity of axial leaded resistors has

been amended in 4.2;

– 8 – IEC 60115-2:2023 © IEC 2023

d) the 'period-pulse high-voltage overload test' of IEC 60115‑1:2020, 8.3 has been adopted as

default test method in 5.3.8, thereby replacing the legacy test 'periodic-pulse overload test'

of IEC 60115‑1:2020, 8.4;

e) the revised solderability test of IEC 60115‑1:2020, 11.1 has been adopted in 5.3.19 and 5.3.20;

f) the combined solvent resistance test of IEC 60115‑1:2020, 11.3 has been adopted in 5.3.22;

g) the 'endurance at room temperature test' of IEC 60115‑1:2020, 7.2 (prior IEC 60115 2:2014,

Annex C) has been adopted as an optional test in 5.4.1;

h) the 'single-pulse high-voltage overload test' of IEC 60115 1:2020, 8.2, applied with the pulse

shape 10/700 in 5.3.7, is complemented with the optional alternative provided by the pulse

shape 1,2/50 in 5.4.2;

i) climatic tests for 'operation at low temperature' of IEC 60115‑1:2020, 10.2, and for 'damp

heat, steady state, accelerated' of IEC 60115‑1:2020, 10.5, have been adopted as optional

tests in 5.4.4 and 5.4.5, respectively;

j) new guidance is provided in 6.2 on the presentation of stability requirements with their

permissible absolute and relative deviations;

k) acceptance criteria for the visual examination have been added in 6.5 and in Annex B;

l) visual examination for the primary and proximity packaging has been added in 6.5.2 and in 7.2;

m) the periodical evaluation of termination platings has been added as a new topic of quality

assessment in 9.8;

n) the revised test clause numbering of IEC 60115‑1:2020 has been applied;

o) a new Annex C has been added to summarize workmanship requirements for the assembly

of leaded film resistors, e.g. as given in the prior IEC 61192 series of standards;

p) the informative Annex F (prior Annex B) on radial formed styles has been amended with

details on a formed Z-bend style for surface-mount assembly.

The text of this International Standard is based on the following documents:

Draft Report on voting

40/2943/CDV 40/3001/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

A list of all parts in the IEC 60115 series, published under the general title Fixed resistors for

use in electronic equipment, can be found on the IEC website.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

FIXED RESISTORS FOR USE IN ELECTRONIC EQUIPMENT –

Part 2: Sectional specification: Low-power film resistors with leads

for through-hole assembly on circuit boards (THT)

1 Scope

This part of IEC 60115 is applicable to fixed low-power film resistors with termination leads for

use in electronic equipment, which are typically assembled in through-hole technology (THT)

on circuit boards.

These resistors are typically described according to types (different geometric shapes) and

styles (different dimensions) and product technology. The resistive element of these resistors

is typically protected by a conformal lacquer coating. These resistors have wire terminations

and are primarily intended to be mounted on a circuit board in through-hole technique.

The object of this document is to state preferred ratings and characteristics and to select from

IEC 60115-1 the appropriate quality assessment procedures, tests and measuring methods and

to give general performance requirements for this type of resistor.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60062:2016, Marking codes for resistors and capacitors

IEC 60063:2015, Preferred number series for resistors and capacitors

IEC 60068-1:2013, Environmental testing – Part 1: General and guidance

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-20:2021, Environmental testing – Part 2-20: Tests – Test Ta and Tb – Test

methods for solderability and resistance to soldering heat of devices with leads

IEC 60115-1:2020, Fixed resistors for use in electronic equipment – Part 1: Generic

specification

IEC 60286-1, Packaging of components for automatic handling – Part 1: Tape packaging of

components with axial leads on continuous tapes

IEC 60294:2012, Measurement of the dimensions of a cylindrical component with axial

terminations

IEC 60301, Preferred diameters of wire terminations of capacitors and resistors

IEC 61193-2:2007, Quality assessment systems – Part 2: Selection and use of sampling plans

for inspection of electronic components and packages

– 10 – IEC 60115-2:2023 © IEC 2023

3 Terms and definitions

3.1 Terms

For the purposes of this document, the terms and definitions given in IEC 60115‑1:2020, 3.1,

as well as the following, apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

axial type

physical design of a component with leads extending to both sides along the longitudinal axis

of the components body

Note 1 to entry: Figure 1 shows an illustration of a typical axial leaded resistor.

Figure 1 – Illustration of a typical axial leaded resistor

3.1.2

radial type

physical design of a component with leads extending to one side along the longitudinal or along

the diagonal axis of the component body

Note 1 to entry: The single direction of the leads may originate from inside the component body or by forming one

or both leads outside of the component body, see Figure 2.

a) Radial leaded b) Radial formed type, c) Radial formed type,

resistor upright body position lateral body position

Figure 2 – Illustrations of typical radial leaded resistors

Note 2 to entry: See Annex F for information on radial formed types.

3.1.3

insulated resistor

resistor that is declared as being insulated by the relevant specification, which in order to

support this has a specified insulating voltage and insulation resistance, and which is assessed

for these properties with the suitable tests of this specification

Note 1 to entry: The mere existence of a protection of the resistive element, e.g. by means of a lacquer coating,

does not constitute an insulation unless the insulating properties have been assessed properly.

Note 2 to entry: Typical tests for the assessment of insulating properties are endurance, climatic sequence and

damp heat steady state tests.

[SOURCE: IEC 60115-1:2020, 3.1.7, modified – Note 3 to entry omitted.]

3.2 Product technologies

The definitions of product technologies intend to provide the reader with a guidance on the

variety of technologies used for the making of resistors, and to aid their identification.

For the purposes of this document, the following product technologies as described in

IEC 60115‑1:2020, 3.2 apply:

– metal film technology,

– metal glaze technology,

– metal oxide technology,

– carbon film technology.

3.3 Product classification

The introduction of a product classification permits the user to select performance requirements

according to the conditions of the intended end-use application.

For the purposes of this document, the following product classification levels as defined in

IEC 60115‑1:2020, 3.4 apply:

– Level G – general electronic equipment

– Level P – high-performance electronic equipment

– Level R – high-performance and high-reliable electronic equipment

4 Preferred characteristics

4.1 General

The values given in detail specifications shall be selected from the values given in 4.2 to 4.9.

4.2 Style and dimensions

4.2.1 Preferred styles and outline dimensions

The shape and dimensions of axial leaded resistors are shown in Figure 3, with preferred styles

and their respective dimensions given in Table 1. Style designators of axial leaded film resistors

begin with RA.

– 12 – IEC 60115-2:2023 © IEC 2023

Table 1 – Preferred styles of axial leaded resistors

Dimensions

a c b d e

Style Body diameter D Body length L Lead diameter d Lead length l

min

mm mm mm mm

+1,0

2 4

RA_0204 0,5 21

−0,7 −1,0

+0,5 +0,5

RA_0207 2 7 0,6 21

0 −2,0

+0,5 +0,5

RA_0309 3 9 0,7 21

−0,5 −2,5

+0,5 +0,5

4 11

RA_0411 0,7 21

−1,0 −3,5

+0,5 +0,5

RA_0414 4 14 0,8 21

−1,0 −4,0

+0,5 +0,5

6 17

RA_0617 0,8 21

−1,0 −4,0

a

The style reference starts with the characters RA, representing Resistor, Axial.

The style reference is completed by a third character for the product technology, as given in 3.2:

M = metal film; G = metal glaze; C = carbon film; X = metal oxide.

The numerals indicate the dimensions of the resistor body, using 2 digits for the diameter D, followed by

2 digits for the length L, both given in tenths of millimetres.

Examples for complete style references are RAM0204, RAX0414.

b

The body length of the resistor L shall be gauged as described in 5.3.11.

c

The body diameter of the resistor D shall be gauged as described in 5.3.11.

d

Nominal diameter of the lead wires d, with permissible tolerances in accordance with IEC 60301.

e

The minimum lead length l applies only to the free lead length in tape packaging in accordance with

min

IEC 60286‑1.

Figure 3 – Shape and dimension of axial leaded resistors

The detail specification shall present a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...