IEC 61188-6-4:2019

(Main)Printed boards and printed board assemblies - Design and use - Part 6-4: Land pattern design - Generic requirements for dimensional drawings of surface mounted components (SMD) from the viewpoint of land pattern design

Printed boards and printed board assemblies - Design and use - Part 6-4: Land pattern design - Generic requirements for dimensional drawings of surface mounted components (SMD) from the viewpoint of land pattern design

IEC 61188-6-4:2019 specifies generic requirements for dimensional drawings of SMD from the viewpoint of land pattern design.

The purpose of this document is to prevent land pattern design issues caused by lack of information and/or misuse of the information from SMD outline drawing as well as to improve the utilization of IEC 61188 series. This document is applicable to the SMD of semiconductor devices and electrical components.

Cartes imprimées et cartes imprimées équipées - Conception et utilisation - Partie 6-4: Conception de la zone de report - Exigences génériques pour les dessins dimensionnels de composants montés en surface (CMS) du point de vue de la conception de la zone de report

L'IEC 61188-6-4:2019 spécifie les exigences génériques pour les dessins dimensionnels de CMS du point de vue de la conception de la zone de report. Le présent document a pour objet d'éviter les problèmes de conception de la zone de report causés par un manque d'informations et/ou une mauvaise utilisation des informations provenant des dessins d'encombrement de CMS, ainsi que d'améliorer l'utilisation de la série IEC 61188. Le présent document est applicable au CMS de dispositifs à semiconducteurs et de composants électriques.

General Information

- Status

- Published

- Publication Date

- 01-May-2019

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 12 - TC 91/WG 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 02-May-2019

- Completion Date

- 24-May-2019

Overview

IEC 61188-6-4:2019 is an international standard developed by the International Electrotechnical Commission (IEC) that establishes generic requirements for dimensional drawings of surface mounted components (SMD) from the perspective of land pattern design. It is part of the IEC 61188 series focused on the design and use of printed boards and printed board assemblies. This standard aims to prevent common land pattern design issues caused by incomplete or misused dimensional data in SMD outline drawings, thereby improving design consistency and reliability across the electronics manufacturing industry.

Applicable to a wide range of SMDs, including semiconductor devices and other electrical components, IEC 61188-6-4:2019 provides clear guidelines to support effective PCB layout and assembly processes through standardized land pattern design.

Key Topics

Dimensional Drawings for SMDs

The standard details the essential dimensional requirements and symbols for creating accurate outline drawings of surface mounted devices that inform land pattern layout.Solder Joint Fillet and Courtyard Design

Guidelines on solder joint fillet shapes and courtyard area dimensions ensure reliable soldering and component placement, minimizing manufacturing defects.Height and Bottom View Parameters

Defining height dimensions and bottom views of SMDs aids in avoiding interference issues and supports precise land pattern alignment.Terminal Type Specifications

Various terminal styles such as end-terminal, gull-wing, inward L-shaped ribbon, under-body L, bottom surface terminals, and flat lug terminals receive specific treatment to guide appropriate land pattern footprint design.Consistency and Coplanarity

The document emphasizes maintaining dimensional consistency across views and drawings, as well as ensuring coplanarity for optimum soldering outcomes.Dimensional Notation Standards

Uniform representation of component dimensions improves communication between component manufacturers, designers, and assembly engineers.

Applications

IEC 61188-6-4:2019 is essential for professionals involved in:

Printed Circuit Board (PCB) Design and Layout

Facilitates optimized land pattern layouts that enhance manufacturability and component reliability.Surface Mounted Device (SMD) Manufacturing

Helps manufacturers verify component footprints against standardized land pattern requirements, reducing returns and failures.Electronic Assembly Engineering

Provides assembly engineers with comprehensive data to ensure proper component placement and solder joint formation.Component Outline Drawing Creation

Assists component developers in producing dimensional drawings that fully support land pattern design compatibility.

Applications span industries including consumer electronics, automotive electronics, aerospace, telecommunications, and industrial controls, where robust PCB assembly is critical.

Related Standards

IEC 61188 Series

The IEC 61188 series covers broader aspects of printed boards and printed board assemblies design and usage.IPC Standards (e.g., IPC-7351)

Industry standards for surface mount land pattern design that complement IEC 61188-6-4 by providing detailed land pattern databases and guidelines.ISO/IEC Directives

IEC 61188-6-4 follows ISO/IEC Directives Part 2 which govern the preparation and presentation of international standards.

Using IEC 61188-6-4 in conjunction with related standards promotes international harmonization and improved interoperability in electronics assembly processes.

Keywords: IEC 61188-6-4, land pattern design, surface mounted components, SMD, printed boards, dimensional drawings, solder joint fillet design, courtyard design, PCB design, electronics assembly, printed board assemblies, component footprint standardization, coplanarity, terminal types, semiconductor devices.

IEC 61188-6-4:2019 - Printed boards and printed board assemblies - Design and use - Part 6-4: Land pattern design - Generic requirements for dimensional drawings of surface mounted components (SMD) from the viewpoint of land pattern design

Frequently Asked Questions

IEC 61188-6-4:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Printed boards and printed board assemblies - Design and use - Part 6-4: Land pattern design - Generic requirements for dimensional drawings of surface mounted components (SMD) from the viewpoint of land pattern design". This standard covers: IEC 61188-6-4:2019 specifies generic requirements for dimensional drawings of SMD from the viewpoint of land pattern design. The purpose of this document is to prevent land pattern design issues caused by lack of information and/or misuse of the information from SMD outline drawing as well as to improve the utilization of IEC 61188 series. This document is applicable to the SMD of semiconductor devices and electrical components.

IEC 61188-6-4:2019 specifies generic requirements for dimensional drawings of SMD from the viewpoint of land pattern design. The purpose of this document is to prevent land pattern design issues caused by lack of information and/or misuse of the information from SMD outline drawing as well as to improve the utilization of IEC 61188 series. This document is applicable to the SMD of semiconductor devices and electrical components.

IEC 61188-6-4:2019 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61188-6-4:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61188-6-4 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Printed boards and printed board assemblies – Design and use –

Part 6-4: Land pattern design – Generic requirements for dimensional drawings

of surface mounted components (SMD) from the viewpoint of land pattern

design

Cartes imprimées et cartes imprimées équipées – Conception et utilisation –

Partie 6-4: Conception de la zone de report – Exigences génériques pour les

dessins dimensionnels de composants montés en surface (CMS) du point

de vue de la conception de la zone de report

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61188-6-4 ®

Edition 1.0 2019-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Printed boards and printed board assemblies – Design and use –

Part 6-4: Land pattern design – Generic requirements for dimensional drawings

of surface mounted components (SMD) from the viewpoint of land pattern

design

Cartes imprimées et cartes imprimées équipées – Conception et utilisation –

Partie 6-4: Conception de la zone de report – Exigences génériques pour les

dessins dimensionnels de composants montés en surface (CMS) du point

de vue de la conception de la zone de report

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-6866-7

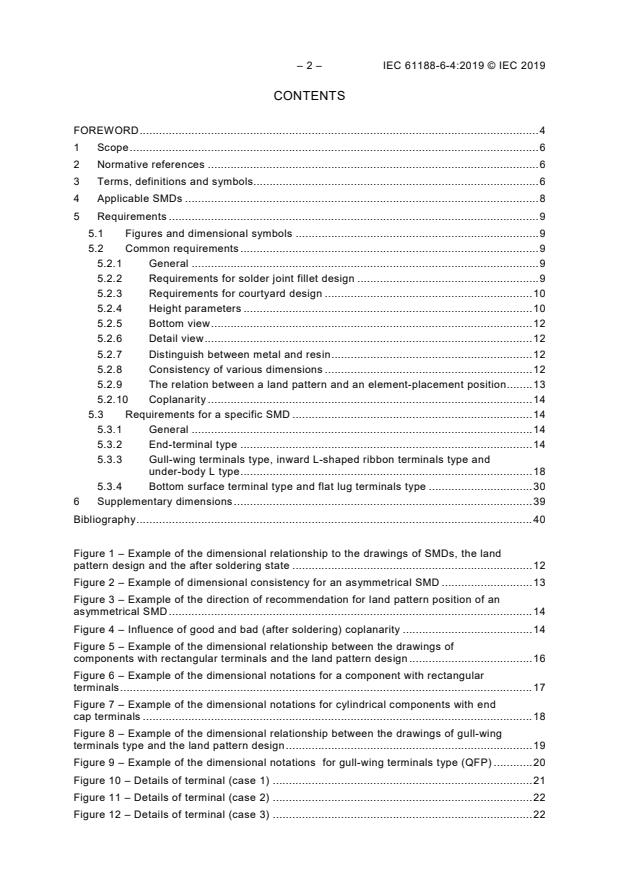

– 2 – IEC 61188-6-4:2019 © IEC 2019

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and symbols. 6

4 Applicable SMDs . 8

5 Requirements . 9

5.1 Figures and dimensional symbols . 9

5.2 Common requirements . 9

5.2.1 General . 9

5.2.2 Requirements for solder joint fillet design . 9

5.2.3 Requirements for courtyard design . 10

5.2.4 Height parameters . 10

5.2.5 Bottom view . 12

5.2.6 Detail view . 12

5.2.7 Distinguish between metal and resin . 12

5.2.8 Consistency of various dimensions . 12

5.2.9 The relation between a land pattern and an element-placement position . 13

5.2.10 Coplanarity . 14

5.3 Requirements for a specific SMD . 14

5.3.1 General . 14

5.3.2 End-terminal type . 14

5.3.3 Gull-wing terminals type, inward L-shaped ribbon terminals type and

under-body L type . 18

5.3.4 Bottom surface terminal type and flat lug terminals type . 30

6 Supplementary dimensions . 39

Bibliography . 40

Figure 1 – Example of the dimensional relationship to the drawings of SMDs, the land

pattern design and the after soldering state . 12

Figure 2 – Example of dimensional consistency for an asymmetrical SMD . 13

Figure 3 – Example of the direction of recommendation for land pattern position of an

asymmetrical SMD . 14

Figure 4 – Influence of good and bad (after soldering) coplanarity . 14

Figure 5 – Example of the dimensional relationship between the drawings of

components with rectangular terminals and the land pattern design . 16

Figure 6 – Example of the dimensional notations for a component with rectangular

terminals . 17

Figure 7 – Example of the dimensional notations for cylindrical components with end

cap terminals . 18

Figure 8 – Example of the dimensional relationship between the drawings of gull-wing

terminals type and the land pattern design . 19

Figure 9 – Example of the dimensional notations for gull-wing terminals type (QFP) . 20

Figure 10 – Details of terminal (case 1) . 21

Figure 11 – Details of terminal (case 2) . 22

Figure 12 – Details of terminal (case 3) . 22

Figure 13 – Details of terminal (case 4) . 23

Figure 14 – Details of terminal (case 5) . 23

Figure 15 – Example of the dimensional relationship between the drawings of inward

L-shaped ribbon terminals type and the land pattern design . 24

Figure 16 – Example of the dimensional notations for inward L-shaped ribbon terminals

type . 25

Figure 17 – Example of the dimensional notations for under-body L type . 26

Figure 18 – Terminal shape expansion drawing of under-body L type (capacitor) . 27

Figure 19 – Example of the dimensional notations for a connector . 28

Figure 20 – The cross-sectional a-a detail (terminal shape) of Figure 18, side view . 29

Figure 21 – Example of the drawing showing the moving range (lock lever open state) . 29

Figure 22 – Example of the upper surface cap constitution . 29

Figure 23 – Example of the dimensional relationship between the drawings of a BGA

and the land pattern design. 31

Figure 24 – Example of the dimensional notations for BGA . 32

Figure 25 – Example of details of solder balls (side view) . 33

Figure 26 – Example of the dimensional relationship between the drawings of QFN and

the land pattern design . 34

Figure 27 – Example of the dimensional notations for bottom surface terminals . 36

Figure 28 – Example of the dimensional relationship between the drawings of flat lug

terminals type and the land pattern design . 38

Figure 29 – Example of the dimensional notations for flat lug terminals type . 39

Figure 30 – Example of the recommended dimensions in the tray . 39

Table 1 – Reference symbols used in this document . 7

– 4 – IEC 61188-6-4:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PRINTED BOARDS AND PRINTED BOARD ASSEMBLIES –

DESIGN AND USE –

Part 6-4: Land pattern design – Generic requirements for dimensional

drawings of surface mounted components (SMD) from the viewpoint of

land pattern design

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61188-6-4 has been prepared by IEC technical committee 91:

Electronics assembly technology.

The text of this International Standard is based on the following documents:

FDIS Report on voting

91/1561/FDIS 91/1572/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61188 series, published under the general title Printed boards and

printed board assemblies – Design and use, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 61188-6-4:2019 © IEC 2019

PRINTED BOARDS AND PRINTED BOARD ASSEMBLIES –

DESIGN AND USE –

Part 6-4: Land pattern design – Generic requirements for dimensional

drawings of surface mounted components (SMD) from the viewpoint of

land pattern design

1 Scope

This part of IEC 61188 specifies generic requirements for dimensional drawings of SMD from

the viewpoint of land pattern design.

The purpose of this document is to prevent land pattern design issues caused by lack of

information and/or misuse of the information from SMD outline drawing as well as to improve

the utilization of IEC 61188 series.

This document is applicable to the SMD of semiconductor devices and electrical components.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 60194-2, Printed board design, manufacture and assembly – Vocabulary – Part 2:

Common usage in electronic technologies as well as printed board and electronic assembly

technologies

3 Terms, definitions and symbols

For the purposes of this document, the terms and definitions given in IEC 60194 and IEC

60194-2 apply, and the reference symbols are shown in Table 1.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

Table 1 – Reference symbols used in this document

Reference Definition

symbol

A

SMD height (from the mounting surface to the package upper surface)

A Stand-off height (distance from the mounting surface to the package bottom)

A Package height

A Standard heel height for terminal

A Terminal height

A Terminal height (thickness)

A SMD height (from the mounting surface to the package upper surface, maximum)

A SMD height from the mounting surface to the package top (excluding moving part)

A SMD height from the mounting surface to the package top (at the lock lever open state)

A SMD height from the mounting surface to the upper surface of cap

Øb Terminal diameter for ball

Øb Ball diameter

C, C , C Row spacing. Distance between land centers

1 2

CY Courtyard width

CY Courtyard length

D Package width

’

D Solder balls area width (distance between the centres of the ball of both ends)

E Package length

’

E Solder balls area length (distance between the centres of the ball of both ends)

E Position of auxiliary terminals

E Upper surface cap width

F , F Clearance between signal and center (GND) terminal

1 2

F Distance from package-end to terminal-end of signal terminal

F Distance between signal terminals at the package corners

G, G , G Distance between lands. Measured from inside edges

1 2

H SMD total width

D

H SMD total length

E

H Height from the tray stage to the package top

T

i Terminal inflection point

J Protrusion length of land over the component terminal

b

J Heel protrusion length

H

J Side protrusion length

S

J Toe protrusion length

T

k , k k Land pattern length

1 2, 4

k Distance between land patterns

K , K Terminal notch length (toe)

5 6

K , K Terminal notch height (heel)

7 8

L Terminal flat part length (mounting surface side)

L , L Length from the package end to a terminal tip

0 1

L Position of auxiliary terminals

L Auxiliary terminal pitch

L Package length at the lock lever open state

– 8 – IEC 61188-6-4:2019 © IEC 2019

Reference Definition

symbol

L Upper surface cap position

L Upper surface cap length

L , L , L Terminal length (mounting surface side),

P P1 P2

Projected terminal length (when part of the terminal is away from the mounting surface)

L Terminal length (upper side)

P0

ØM Diameter of auxiliary terminal

N Coplanarity to mounting surface

P Pitch

q Land pattern design parameter

R Terminal bend radius (inside)

R Terminal bend radius (outside)

S Distance between the terminals. Measured from inside edges

T Tray height from the tray stage to the surface that supports SMD

T

u , u Allowance for courtyard

1 2

ØW SMD diameter (terminal)

W W Terminal width

1, 2

W Bottom centre (GND) terminal length

W Bottom centre (GND) terminal width

W Groove width

G

W Position tolerance at terminal end

P

W Variation range of terminal tip outer position

V

X Land width

Y Land length

ØY Land diameter

Z Z Z Distance between lands. Measured from outside edges

, 1, 2

α, β (Datum symbols)

η Terminal horizontal angle formed by the groove centre line and the line form the egress to the tip

of the terminal

θ Terminal angle

4 Applicable SMDs

Applicable SMDs are as described below:

a) end-terminal type (components with rectangular or square terminal and cylindrical

components with end cap terminal);

NOTE 1 In IEC 61191-2, "toe" solder fillet height is specified but "heel" solder fillet height is not specified for

this type of SMD.

b) gull-wing terminals type (e.g. SOP, QFP), inward L-shaped ribbon terminals type and

under-body L type (e.g. vertical form aluminium electrolytic capacitor, connector);

NOTE 2 In IEC 61191-2, "heel" solder fillet height is required but "toe" solder fillet height is not required for

these SMD.

c) bottom surface terminal type (e.g. BGA, QFN and LGA) and flat lug terminals type.

NOTE 3 These SMDs have characteristics different from a) or b).

5 Requirements

5.1 Figures and dimensional symbols

The figures shown in this document are indicated as examples of typical SMDs. However, it is

not the purpose to specify the rule of drawings (such as how to pull out a dimension line and

dimensional symbols to be used).

The dimensional symbols in this document are used to show the various cases in order to

indicate common requirements for land pattern designs. This document is not intended to

integrate dimensional symbols.

NOTE The dimensional symbols used in this document are referring to existing International Standards and

industry standards. It is difficult to integrate the dimensional symbols because the definitions of the dimensional

symbols are different between these standards. For this reason, the dimensional symbols in this document can

differ depending on the figure. The dimensional symbols in this document give priority to coordination with land

pattern shape notation given by the IEC 61188-5 series. As a result, the notation for some SMDs can differ from

the industry standards.

5.2 Common requirements

5.2.1 General

The common requirements for dimensional drawings of SMDs from the viewpoint of land

pattern design are described in 5.2.2 to 5.2.10.

To explain a basic relation between dimensional drawings of SMDs and land pattern design, a

representative case is shown in Figure 1 (gull-wing terminals type; 4-pin S-terminals). The

quoted reference symbols in 5.2.2 to 5.2.10 are based on Figure 1.

5.2.2 Requirements for solder joint fillet design

To design a land that is a part of the land pattern and makes a solder joint to each terminal of

the SMD, the dimensional drawing of the SMD shall have the terminal's dimensions (L and

P

W in Figure 1) and the dimensions that specify the location of the terminal (H and P in

1 E

Figure 1). Each dimension should be indicated by a nominal value with its tolerances.

The reasons are as shown below:

a) As a principle, each terminal of the SMD will have its own land.

Land width (X) and land length (Y) are given by the following formulas:

XW+×2 J

1S

YJ= ++L J

T PH

where

X is the land width [mm];

Y is the land length [mm];

is the terminal width [mm];

W

L is the terminal length [mm];

P

J is the toe protrusion length [mm];

T

J is the heel protrusion length [mm];

H

J is the side protrusion length [mm].

S

=

– 10 – IEC 61188-6-4:2019 © IEC 2019

b) As a principle, the location of each land is decided based on the dimensions, such as H

E

and P in Figure 1a), which indicate the physical relationship of the soldering terminals of

the SMD.

5.2.3 Requirements for courtyard design

The outermost dimensions of the SMD shall be given (e.g. H , E, D and A in Figure 1). This is

E

because the courtyard is designed by taking into account the outermost shape after mounting

the SMD on the land pattern.

NOTE The courtyard, which is a monopolization area for the SMD on a PCB, is designed based on the shape of

the mount state (when the SMD is located on the lands), to prevent mechanical interferences at the time of

mounting or assembly. If solder paste openings are outside the maximum extent of the package outline, plus

terminals plus lands, the courtyard can be designed based on the outermost shape including solder paste openings.

In addition, the courtyard is sometimes designed in consideration of reworkability, electrical insulation, stability of

optical inspection, and the like. Therefore, three-dimensional information is required for the courtyard design.

5.2.4 Height parameters

The height of the soldering terminal, A in Figure 1a), shall be given in dimensional drawings

of the SMD to determine the land pattern design.

NOTE Generally, the height of soldering terminal is used for the solder joint fillet design to estimate the

necessary amount of solder. The height of the SMD is used for spatial design of the PCB assembly, and also used

for defining the mounting machine parameters, such as the floating height of the vacuum adsorption nozzle.

Figure 1 (1 of 2)

– 12 – IEC 61188-6-4:2019 © IEC 2019

Key

H SMD total length

E

E Package length

D Package width

W Terminal width

P Pitch

A SMD height (from the mounting surface to the package upper surface)

A Terminal height (thickness)

L Terminal length

P

J Toe protrusion length

T

J Heel protrusion length

H

J Side protrusion length

S

X Land width

Y Land length

G Distance between lands. Measured from inside edges

C

Row spacing. Distance between land centers

Z Distance between lands. Measured from outside edges

CY Courtyard width

CY Courtyard length

u , u Allowance for courtyard

1 2

Sample image: gull-wing terminals type; 4-pin S-terminals.

NOTE In Figure 1e), the area enclosed by dashed lines is the courtyard.

Figure 1 – Example of the dimensional relationship to the drawings of SMDs,

the land pattern design and the after soldering state (2 of 2)

5.2.5 Bottom view

In the case of a 2D drawing, a figure of the bottom (attachment side) view should be given in

addition to a top view, a side view, and a front view based on trigonometry. If the shape of the

SMD can be recognized from the figure of the top view and the side view only, the figures of

the front view and the bottom view may be omitted.

NOTE The examples of SMDs shown in Figure 6 and Figure 9 omit the figures of their front and bottom

(attachment side) views.

5.2.6 Detail view

If an SMD has a terminal with complicated shape, an additional detail view should be given. If

the SMD shape is asymmetrical, the figure showing the relation of the position of the body

and terminals shall be given.

5.2.7 Distinguish between metal and resin

In any 2D drawing or 3D data, the conductive metal part and the insulated resin part shall be

clearly distinguished, at least for the bottom and the side of the SMD.

5.2.8 Consistency of various dimensions

The nominal dimension for any part shall be fixed in one value for land pattern design. For

this purpose, the following conditions shall be met:

a) In a 2D drawing and 3D data, the dimension of the SMD shall be given by the nominal

value and its tolerances. However, in the case of a 2D drawing, when the nominal value

can be considered as the centre value of the maximum value and the minimum value, the

nominal value may be omitted.

b) In a 2D drawing for the SMD that has two or more soldering terminals, the dimension of

soldering terminals, other metal parts and each soldering terminal distance shall be given

in addition to an SMD outline. However, such distance can be given as a reference value.

c) The sum of each part's dimensions shall be consistent with the nominal value of the total

width or the total length of the SMD.

With these conditions, even if an asymmetrical SMD, the arrangement of the spatial

relationship of all the parts is possible. The example of a case where the sum of each part's

dimensions is consistent with the nominal value of the total length H is shown in Figure 2.

E

Top view Side view Bottom view

EXAMPLE:

The total length of the SMD is equal to the sum of the length of the parts in the top view and in the bottom view.

H= L+ EL+ = L+ S+ L

E 0 1 P0 P1

where

H is the SMD total length [mm];

E

E is the package length [mm];

L is the length from the package end to a terminal tip [mm];

L is the length from the package end to a terminal tip [mm];

L is the terminal length [mm];

P0

L

is the terminal length [mm];

P1

S is the distance between the terminals measured from inside edges [mm].

Figure 2 – Example of dimensional consistency for an asymmetrical SMD

5.2.9 The relation between a land pattern and an element-placement position

When a recommended land pattern along with the outline drawing of an SMD is shown, the

information that shows the geometrical relation between a recommended land pattern and the

position of the mounted SMD shall be given.

For an asymmetric SMD, draw the common centre line for the outline drawing of the SMD and

the recommended land pattern so that the SMD's position on the land pattern can be clearly

recognized (refer to Figure 3).

– 14 – IEC 61188-6-4:2019 © IEC 2019

Bottom view Recommended land pattern

Key

L

Terminal length;

P0

L Terminal length;

P1

S Distance between the terminals. Measured from inside edges

k , k k Land pattern length

1 2, 4

k Distance between land patterns

Figure 3 – Example of the direction of recommendation

for land pattern position of an asymmetrical SMD

5.2.10 Coplanarity

If the SMD has three or more soldering terminals or the body of the SMD seats on the

mounting surface regardless of the number of soldering terminals, an acceptable value of the

float height variation (coplanarity) from the mounting surface to a soldering terminal shall be

given.

Depending on the degree of the coplanarity, the land pattern design may be modified in

accordance with the process conditions of soldering, such as the amount of solder paste. The

example of an effect of the coplanarity is shown in Figure 4. When the coplanarity is bad, it is

difficult to check the fillet by visual inspection after soldering.

a) The fillet at the case of good coplanarity b) The fillet at the case of bad coplanarity

Figure 4 – Influence of good and bad (after soldering) coplanarity

5.3 Requirements for a specific SMD

5.3.1 General

For a specific SMD, the portion that should be observed is outlined in 5.3.2 to 5.3.4.

5.3.2 End-terminal type

5.3.2.1 Components with rectangular or square terminals

Figure 5 shows the relationship between the land pattern design and part dimensions

necessary for land pattern design, and the land pattern design image for components with

rectangular or square terminals.

Figure 5 (1 of 2)

– 16 – IEC 61188-6-4:2019 © IEC 2019

Key

H SMD total length

E

W Terminal width

A SMD height (from the mounting surface to the package upper surface)

L Terminal length (mounting surface side)

P

S Distance between the terminals. Measured from inside edges

J Toe protrusion length

T

J Heel protrusion length

H

J Side protrusion length

S

X Land width

Y Land length

G Distance between lands. Measured from inside edges

C Row spacing. Distance between land centers

Z Distance between lands. Measured from outside edges

CY Courtyard width

CY Courtyard length

u , u Allowance for courtyard

1 2

NOTE In Figure 5e), the area surrounded by dashed lines is the courtyard.

Figure 5 – Example of the dimensional relationship between the drawings of

components with rectangular terminals and the land pattern design (2 of 2)

The dimensional notations for the components with rectangular or square terminals shall

satisfy the following requirements. The example is shown in Figure 6.

a) If the terminal length of the upper side L differs from that of the mounting surface side,

P0

the terminal length of the mounting surface side L shall be given.

P

b) If the terminal length of the mounting surface side L of one side differs from that of

P

another side, the length of both sides shall be given.

SMDs with rectangular or square-end terminations are likely to cause the "tombstone

phenomenon" at reflow soldering. Therefore, consideration of terminal length is necessary for

prevention.

SOURCE: IEC 61188-5-2 with modification

Key

H SMD total length

E

W Terminal width

A SMD height (from the mounting surface to the package upper surface)

L Terminal length (upper side)

P0

L Terminal length (mounting surface side)

P

S

Distance between the terminals. Measured from inside edges

Figure 6 – Example of the dimensional notations for a component

with rectangular terminals

5.3.2.2 Cylindrical components with end cap terminals

The dimensional notations for the cylindrical components with end cap terminals shall satisfy

the following requirement. The example is shown in Figure 7.

a) If the terminal length L of one side differs from that of another side, the length of both

P

sides shall be given.

SMDs with cylindrical end cap terminations are likely to cause the "tombstone phenomenon"

at reflow soldering. Therefore, consideration of terminal length is necessary for prevention.

– 18 – IEC 61188-6-4:2019 © IEC 2019

SOURCE: IEC 61188-5-2 with modification.

Key

H SMD total length

E

φW SMD diameter (terminal)

L Terminal length

P

S Distance between the terminals. Measured from inside edges

Figure 7 – Example of the dimensional notations

for cylindrical components with end cap terminals

5.3.3 Gull-wing terminals type, inward L-shaped ribbon terminals type and under-

body L type

5.3.3.1 Gull-wing terminals type (including SOP, QFP and mini-mould of gull-wing

terminals type)

5.3.3.1.1 General

The details of the terminal type shall be given in addition to the whole SMD drawing.

Figure 8 shows the relationship between land pattern design and the part dimensions

necessary for land pattern design, and the land pattern design image for the gull-wing

terminals type.

And the example of details of the terminal type is shown in Figure 9.

Furthermore, because detailed definition of the terminal length L is necessary, so the main

P

cases of the description method are shown in 5.3.3.1.2.

Key

W Terminal width

P Pitch

L Terminal length

P

J Toe protrusion length

T

J Heel protrusion length

H

J Side protrusion length

s

X Land width

Y Land length

G, G , G Distance between lands, measured from inside edges

1 2

C Row spacing, distance between land centres

Z , Z Distance between lands, measured from outside edges

1 2

CY Courtyard width

CY Courtyard length

u , u Allowance for courtyard

1 2

NOTE In Figure 8e), the area surrounded by dot lines is courtyard.

Figure 8 – Example of the dimensional relationship between the drawings

of gull-wing terminals type and the land pattern design

– 20 – IEC 61188-6-4:2019 © IEC 2019

SOURCE IEC 60191-6-1 with modification.

Key

H SMD total length

E

E Package length

H

SMD total width

D

D Package width

W Terminal width

Pitch

P

A SMD height (from the mounting surface to the package upper surface)

A

Stand-off height (distance from the mounting surface to the package bottom)

A Package height

A Standard heel height for terminal

A Terminal height (thickness)

N Coplanarity to mounting surface

L

Length from package edge to terminal tip

L Terminal length

P

L Terminal flat part length (mounting surface side)

θ Terminal angle

Figure 9 – Example of the dimensional notations

for gull-wing terminals type (QFP)

5.3.3.1.2 Details of the view of the terminal

5.3.3.1.2.1 General

Examples of details of terminal drawing and the requirements for case 1 to case 5 are shown

in 5.3.3.1.2.2 to 5.3.3.1.2.6.

5.3.3.1.2.2 Case 1

is equal to the length from the terminal tip to the point where the

The terminal length L

P

terminal under-surface height is 0,25 mm from the mounting surface (standard heel height for

terminal A ).

The end point of L shall be given with A , and the nominal value and tolerance of the

P 3

terminal angle θ should be given.

The example of details of terminal is shown in Figure 10.

Key

A (0,25mm) Standard heel height for terminal (0,25 mm)

L Projected terminal length

P

A Terminal thickness

θ

Terminal angle

Figure 10 – Details of terminal (case 1)

5.3.3.1.2.3 Case 2

The terminal length L is equal to the terminal tip to the point where the terminal under-

P

surface height is 0,1 mm from the mounting surface.

The end point of L shall be given, and the nominal value and tolerance of the terminal angle

P

θ should be given.

The example of details of the terminal is shown in Figure 11.

– 22 – IEC 61188-6-4:2019 © IEC 2019

Key

L Terminal length (The length from the terminal to the point where the terminal under-surface

P

height is 0,1 mm from the mounting surface.)

A Terminal height (thickness)

θ Terminal angle

Figure 11 – Details of terminal (case 2)

5.3.3.1.2.4 Case 3

L is equal to the length of the flat part of the terminal (under-surface of terminal is flat and

level to the mounting surface).

The end point of L shall be given, and the bend radius R should be given.

An example of details of the terminal is shown in Figure 12.

The bend radius R may be the inside bend radius, centre bend radius, or outside bend radius.

If the bend radius is not specified, the following value should be used as an inside bend

radius (refer to IPC-A-610F):

RA (A< 0,8 mm)

5 5

RA1,5 × (0,8 mm ≤≤A 1,2 mm)

RA2 × ()1,2 mm < A

Key

L

Terminal flat part length (mounting surface side)

A Terminal thickness

R Terminal bending radius (inside)

Figure 12 – Details of terminal (case 3)

5.3.3.1.2.5 Case 4

The terminal length L is equal to the length from the terminal tip to the point where the

P

terminal under-surface height from the mounting surface is identical to the terminal thickness.

=

=

=

The end point of L shall be given, and the nominal value and tolerance of the terminal angle

P

θ should be given.

An example of details of the terminal is shown in Figure 13.

Key

L Terminal length

P

A Terminal thickness

θ Terminal angle

Figure 13 – Details of terminal (case 4)

5.3.3.1.2.6 Case 5

The terminal length L is equal to the length from the terminal tip to the terminal inflection

P

point.

The end point of L shall be given and the nominal value and tolerance of the terminal angle θ

P

should be given. An example of details of the terminal is shown in Figure 14.

Key

i Terminal inflection point

L Terminal length

P

A Terminal height (thickness)

θ Terminal angle

Figure 14 – Details of terminal (case 5)

5.3.3.2 Inward L-shaped ribbon terminals type

Figure 15 shows the relationship between land pattern design and the part dimensions

necessary for land pattern design, and the land pattern design image for the inward L-shaped

ribbon terminals type.

– 24 – IEC 61188-6-4:2019 © IEC 2019

Key

H SMD total length

E

D Package width

W Terminal width

L Terminal length

P

S Distance between the terminals. Measured from inside edges

J Toe protrusion length

T

J Heel protrusion length

H

J Side protrusion length

S

X Land width

Y Land length

e Row spacing. D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...