IEC 61189-3-302:2025

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-302: Detection of plating defects in unpopulated circuit boards by computed tomography (CT)

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-302: Detection of plating defects in unpopulated circuit boards by computed tomography (CT)

IEC 61189-3-302:2025 describes a method for the detection of plating defects in unpopulated circuit boards using computed tomography (CT).

This document is applicable to non-destructive testing of metallized holes.

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres structures d’interconnexion et ensembles – Partie 3-302: Détection des défauts de métallisation dans les cartes de circuits imprimés nus par tomographie informatisée (TI)

L’IEC 61189-3-302:2025 décrit la méthode de détection des défauts de métallisation des cartes de circuits imprimés nus par tomographie informatisée (TI).

Le présent document s’applique aux essais non destructifs des trous métallisés.

General Information

- Status

- Published

- Publication Date

- 21-Oct-2025

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Oct-2025

- Completion Date

- 14-Nov-2025

Overview

IEC 61189-3-302:2025 specifies a standardized, non‑destructive test method for the detection of plating defects in unpopulated circuit boards using computed tomography (CT). Applicable to metallized holes (vias and through-holes), the standard defines the CT test principle, required equipment, test steps, image reconstruction and reporting requirements to reliably identify plating voids, fills and related defects.

Key technical topics and requirements

- Test principle: Cone‑beam X‑ray CT acquires multiple angular projections and uses reconstruction software to produce a 3D grayscale representation of the board interior. The minimum detectable defect is three times the device imaging resolution (3× pixel size).

- Equipment:

- X‑ray CT scanner with stable X‑ray source; select smaller focal size for smaller defects. Table examples link source focal size to spatial resolution (e.g., focus size 1 μm → spatial resolution ~0.5 μm).

- Detector system and imaging resolution definition (detector pixel size divided by magnification).

- Mechanical scanning system with minimum displacement steps ≤ 0.01 mm and angular rotation step ≤ 0.01°.

- Shielding facilities and appropriate software for reconstruction and visualization.

- Imaging parameters:

- Radiation penetration rate should exceed 20% (typically 20–70%).

- Parameter setup includes X‑ray source settings, scanning method, field of view, number of frames and scan time to optimize image quality.

- Analysis and reporting:

- 3D reconstruction, visualization, image analysis and data saving.

- Report items: device and sample information, sweep parameters and measurement results.

- Defect identification & statistics: Annexes provide typical images for plating voids, blind‑via filling defects, nodulation, folds and interlayer coincidence, plus void identification and statistical methods (void counts, void/board thickness ratios, filled hole void rate).

Practical applications and users

Who benefits:

- PCB manufacturers and contract electronics assembly (PCBA) houses performing quality control.

- Reliability engineers assessing interconnect integrity.

- Non‑destructive testing (NDT) labs and inspection service providers.

- X‑ray/CT equipment vendors and software developers validating system capabilities.

Typical uses:

- Detecting and quantifying plating voids, incomplete via fills, and internal anomalies without destroying boards.

- Process qualification, failure analysis, incoming inspection and supplier audits.

- Supporting corrective actions in plating and drilling processes by providing statistically robust defect metrics.

Related standards

- ISO 15708-3: Radiation methods for computed tomography - Operation and interpretation (normative reference).

- Other parts of the IEC 61189 series (test methods for electrical materials and printed boards).

Keywords: computed tomography, CT inspection, plating defects, unpopulated circuit boards, metallized holes, non‑destructive testing, X‑ray CT scanner, imaging resolution, void identification.

IEC 61189-3-302:2025 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-302: Detection of plating defects in unpopulated circuit boards by computed tomography (CT) Released:22. 10. 2025 Isbn:9782832707777

IEC 61189-3-302:2025 - Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres structures d’interconnexion et ensembles – Partie 3-302: Détection des défauts de métallisation dans les cartes de circuits imprimés nus par tomographie informatisée (TI) Released:22. 10. 2025 Isbn:9782832707777

IEC 61189-3-302:2025 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-302: Detection of plating defects in unpopulated circuit boards by computed tomography (CT) Released:22. 10. 2025 Isbn:9782832707777

Frequently Asked Questions

IEC 61189-3-302:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-302: Detection of plating defects in unpopulated circuit boards by computed tomography (CT)". This standard covers: IEC 61189-3-302:2025 describes a method for the detection of plating defects in unpopulated circuit boards using computed tomography (CT). This document is applicable to non-destructive testing of metallized holes.

IEC 61189-3-302:2025 describes a method for the detection of plating defects in unpopulated circuit boards using computed tomography (CT). This document is applicable to non-destructive testing of metallized holes.

IEC 61189-3-302:2025 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-3-302:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61189-3-302 ®

Edition 1.0 2025-10

INTERNATIONAL

STANDARD

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies -

Part 3-302: Detection of plating defects in unpopulated circuit boards by

computed tomography (CT)

ICS 31.180 ISBN 978-2-8327-0777-7

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

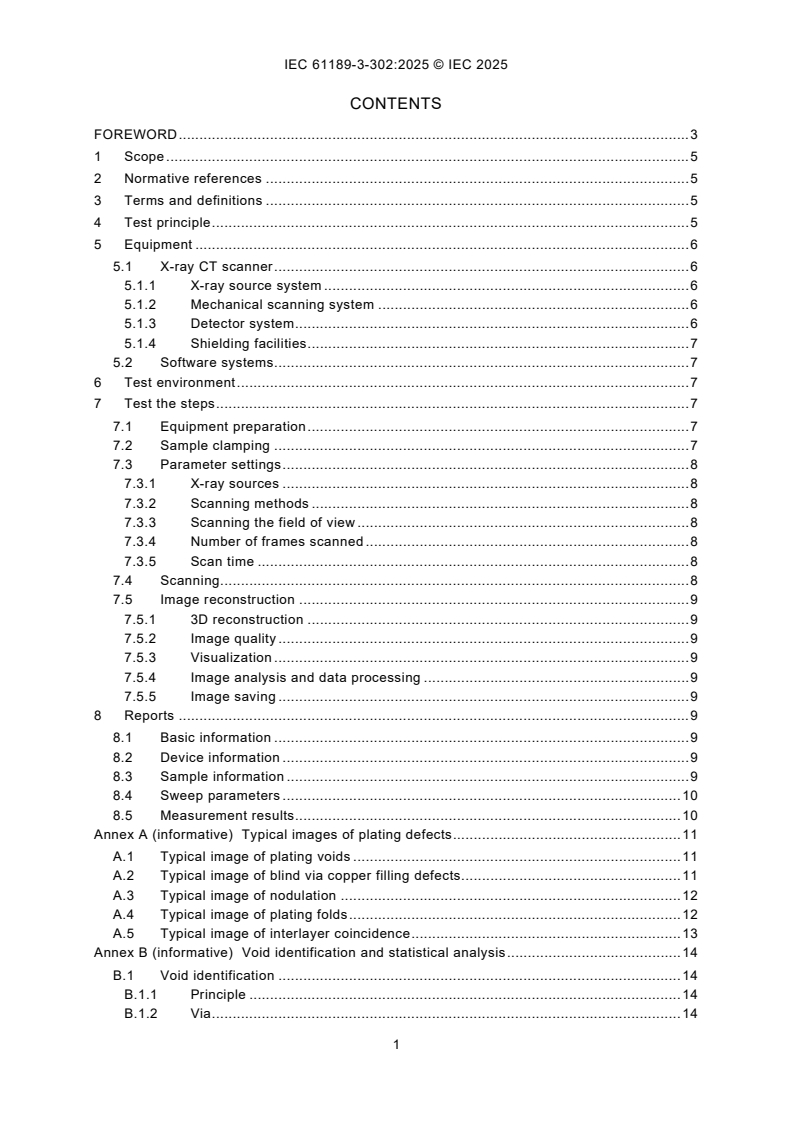

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Test principle . 5

5 Equipment . 6

5.1 X-ray CT scanner . 6

5.1.1 X-ray source system . 6

5.1.2 Mechanical scanning system . 6

5.1.3 Detector system . 6

5.1.4 Shielding facilities . 7

5.2 Software systems . 7

6 Test environment . 7

7 Test the steps . 7

7.1 Equipment preparation . 7

7.2 Sample clamping . 7

7.3 Parameter settings . 8

7.3.1 X-ray sources . 8

7.3.2 Scanning methods . 8

7.3.3 Scanning the field of view . 8

7.3.4 Number of frames scanned . 8

7.3.5 Scan time . 8

7.4 Scanning. 8

7.5 Image reconstruction . 9

7.5.1 3D reconstruction . 9

7.5.2 Image quality . 9

7.5.3 Visualization . 9

7.5.4 Image analysis and data processing . 9

7.5.5 Image saving . 9

8 Reports . 9

8.1 Basic information . 9

8.2 Device information . 9

8.3 Sample information . 9

8.4 Sweep parameters . 10

8.5 Measurement results . 10

Annex A (informative) Typical images of plating defects . 11

A.1 Typical image of plating voids . 11

A.2 Typical image of blind via copper filling defects. 11

A.3 Typical image of nodulation . 12

A.4 Typical image of plating folds . 12

A.5 Typical image of interlayer coincidence . 13

Annex B (informative) Void identification and statistical analysis . 14

B.1 Void identification . 14

B.1.1 Principle . 14

B.1.2 Via . 14

B.1.3 Fill hole . 15

B.2 Statistical analysis . 15

B.2.1 Number of voids . 15

B.2.2 Calculation of the maximum length of the voids/board thickness ratio . 15

B.2.3 Calculation of filled holes void rate . 16

Bibliography . 17

Figure 1 – Typical process of CT analysis . 5

Figure A.1 – Plating voids . 11

Figure A.2 – Blind via copper filling defects . 12

Figure A.3 – Plating nodulation . 12

Figure A.4 – Plating folds . 13

Figure A.5 – Interlayer coincidence . 13

Figure B.1 – Plating holes voids recognition image . 14

Figure B.2 – Identification of the void along the board thickness direction . 14

Figure B.3 – Fill holes voids recognition image . 15

Figure B.4 – Microvia void image . 15

Table 1 – Reference examples of focal size and spatial resolution correspondence for

source focus size . 6

Table 2 – Reference examples of the imaging resolution of the detector system

corresponding to the imaging field of view . 6

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Test methods for electrical materials, printed boards

and other interconnection structures and assemblies -

Part 3-302: Detection of plating defects in unpopulated

circuit boards by computed tomography (CT)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 61189-3-302 has been prepared by IEC technical committee 91: Electronics assembly

technology. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/2060/FDIS 91/2071/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

1 Scope

This part of IEC 61189 describes a method for the detection of plating defects in unpopulated

circuit boards using computed tomography (CT).

This document is applicable to non-destructive testing of metallized holes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

ISO 15708-3, Non-destructive testing - Radiation methods for computed tomography - Part 3:

Operation and interpretation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

– IEC Electropedia: available at https://www.electropedia.org/

– ISO Online browsing platform: available at https://www.iso.org/obp

3.1

imaging resolution

value of the physical size of the detector's pixels divided by the magnification ratio which is the

ratio of the distance between the detector and the ray source to the distance between the

sample centre and the ray source

4 Test principle

The principle of computer tomography (CT) analysis of the plating defects in the metallization

holes of the circuit board consists in using the cone beam X-rays emitted by the X-ray source

to obtain multiple X-ray projecti

...

IEC 61189-3-302 ®

Edition 1.0 2025-10

NORME

INTERNATIONALE

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres

structures d’interconnexion et ensembles -

Partie 3-302: Détection des défauts de métallisation dans les cartes de circuits

imprimés nus par tomographie informatisée (TI)

ICS 31.180 ISBN 978-2-8327-0777-7

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications gratuitement tous les aperçus des publications, symboles

IEC en utilisant différents critères (numéro de référence, graphiques et le glossaire. Avec un abonnement, vous aurez

texte, comité d’études, …). Elle donne aussi des toujours accès à un contenu à jour adapté à vos besoins.

informations sur les projets et les publications remplacées

ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au

IEC Just Published - webstore.iec.ch/justpublished monde, avec plus de 22 500 articles terminologiques en

Restez informé sur les nouvelles publications IEC. Just anglais et en français, ainsi que les termes équivalents

dans 25 langues additionnelles. Egalement appelé

Published détaille les nouvelles publications parues.

Disponible en ligne et une fois par mois par email. Vocabulaire Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-

nous: sales@iec.ch.

SOMMAIRE

AVANT-PROPOS . 3

1 Domaine d’application . 5

2 Références normatives . 5

3 Termes et définitions . 5

4 Principe d’essai . 5

5 Appareil . 6

5.1 Scanneur TI à rayons X . 6

5.1.1 Système source de rayons X . 6

5.1.2 Dispositif de balayage mécanique . 6

5.1.3 Système de détection . 6

5.1.4 Installations de protection . 7

5.2 Systèmes logiciels . 7

6 Environnement d’essai . 7

7 Essai des étapes . 7

7.1 Préparation de l’équipement . 7

7.2 Serrage de l’échantillon . 8

7.3 Paramétrage . 8

7.3.1 Sources de rayons X . 8

7.3.2 Méthodes de balayage . 8

7.3.3 Balayage du champ de vision . 8

7.3.4 Nombre de trames balayées . 8

7.3.5 Temps de balayage . 9

7.4 Balayage. 9

7.5 Reconstruction d’image . 9

7.5.1 Reconstruction 3D . 9

7.5.2 Qualité d’image . 9

7.5.3 Visualisation . 9

7.5.4 Analyse d’images et traitement des données . 9

7.5.5 Enregistrement de l’image . 10

8 Rapports. 10

8.1 Informations de base . 10

8.2 Informations sur le dispositif . 10

8.3 Informations sur l’échantillon . 10

8.4 Paramètres de balayage . 10

8.5 Résultat des mesures . 10

Annexe A (informative) Images types de défauts de métallisation . 11

A.1 Images types des vides de métallisation . 11

A.2 Image type de défauts de remplissage du cuivre du trou de liaison borgne . 11

A.3 Image type de nodulation . 12

A.4 Images types des plis de métallisation . 12

A.5 Image type de coïncidence entre couches . 13

Annexe B (informative) Identification des vides et analyse statistique . 14

B.1 Identification des vides . 14

B.1.1 Principe . 14

B.1.2 Trou de liaison . 14

B.1.3 Trou de remplissage . 15

B.2 Analyse statistique . 16

B.2.1 Nombre de vides . 16

B.2.2 Calcul de la longueur maximale du rapport vides/épaisseur de la carte . 16

B.2.3 Taux de vide calculé des trous remplis . 16

Bibliographie . 17

Figure 1 – Processus classique d’une analyse TI . 5

Figure A.1 – Vides de métallisation . 11

Figure A.2 – Défauts de remplissage du cuivre du trou de liaison borgne . 12

Figure A.3 – Nodulation de métallisation . 12

Figure A.4 – Plis de métallisation . 13

Figure A.5 – Coïncidence entre couches . 13

Figure B.1 – Image de reconnaissance des vides de trous de métallisation . 14

Figure B.2 – Identification du vide dans le sens de l’épaisseur de la carte . 15

Figure B.3 – Image de reconnaissance des vides de trous de remplissage . 15

Figure B.4 – Image du vide de microtrou de liaison empilé . 15

Tableau 1 – Exemples de référence de la correspondance entre la taille de foyer et

la résolution spatiale pour la taille de foyer source . 6

Tableau 2 – Exemples de référence de la résolution d’imagerie du système de

détection correspondant au champ de vision d’imagerie . 6

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

Méthodes d’essai pour les matériaux électriques, les cartes imprimées

et autres structures d’interconnexion et ensembles –

Partie 3-302: Détection des défauts de métallisation dans les cartes de

circuits imprimés nus par tomographie informatisée (TI)

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (IEC) est une organisation mondiale de normalisation composée

de l’ensemble des comités électrotechniques nationaux (Comités nationaux de l’IEC). L’IEC a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l’électricité et de l’électronique. À cet effet, l’IEC – entre autres activités – publie des Normes internationales,

des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au public (PAS) et des

Guides (ci-après dénommés "Publication(s) de l’IEC"). Leur élaboration est confiée à des comités d’études, aux

travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les organisations

internationales, gouvernementales et non gouvernementales, en liaison avec l’IEC, participent également aux

travaux. L’IEC collabore étroitement avec l’Organisation Internationale de Normalisation (ISO), selon des

conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de l’IEC concernant les questions techniques représentent, dans la mesure du

possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de l’IEC intéressés

sont représentés dans chaque comité d’études.

3) Les Publications de l’IEC se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de l’IEC. Tous les efforts raisonnables sont entrepris afin que l’IEC

s’assure de l’exactitude du contenu technique de ses publications; l’IEC ne peut pas être tenue responsable de

l’éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d’encourager l’uniformité internationale, les Comités nationaux de l’IEC s’engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de l’IEC dans leurs publications nationales

et régionales. Toutes divergences entre toutes Publications de l’IEC et toutes publications nationales ou

régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) L’IEC elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d’évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de l’IEC. L’IEC n’est responsable d’aucun des services effectués par les organismes de certification

indépendants.

6) Tous les utilisateurs doivent s’assurer qu’ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à l’IEC, à ses administrateurs, employés, auxiliaires ou mandataires,

y compris ses experts particuliers et les membres de ses comités d’études et des Comités nationaux de l’IEC,

pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre dommage de quelque

nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais de justice) et les dépenses

découlant de la publication ou de l’utilisation de cette Publication de l’IEC ou de toute autre Publication de l’IEC,

ou au crédit qui lui est accordé.

8) L’attention est attirée sur les références normatives citées dans cette publication. L’utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’IEC attire l’attention sur le fait que la mise en application du présent document peut entraîner l’utilisation d’un

ou de plusieurs brevets. L’IEC ne prend pas position quant à la preuve, à la validité et à l’applicabilité de tout

droit de brevet revendiqué à cet égard. À la date de publication du présent document, l’IEC n’avait pas reçu

notification qu’un ou plusieurs brevets pouvaient être nécessaires à sa mise en application. Toutefois, il y a lieu

d’avertir les responsables de la mise en application du présent document que des informations plus récentes

sont susceptibles de figurer dans la base de données de brevets, disponible à l’adresse https://patents.iec.ch.

L’IEC ne saurait être tenue pour responsable de ne pas avoir identifié de tels droits de brevet.

L’IEC 61189-3-302 a été établie par le comité d’études 91 de l’IEC: Techniques d’assemblage

des composants électroniques. Il s’agit d’une Norme internationale.

Le texte de cette Norme internationale est issu des documents suivants:

Projet Rapport de vote

91/2060/FDIS 91/2071/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à son approbation.

La langue employée pour l’élaboration de cette Norme internationale est l’anglais.

Ce document a été rédigé selon les Directives ISO/IEC, Partie 2, il a été développé selon les

Directives ISO/IEC, Partie 1 et les Directives ISO/IEC, Supplément IEC, disponibles sous

www.iec.ch/members_experts/refdocs. Les principaux types de documents développés par

l’IEC sont décrits plus en détail sous www.iec.ch/publications.

Une liste de toutes les parties de la série IEC 61189, publiées sous le titre général Méthodes

d’essai pour les matériaux électriques, les cartes imprimées et autres structures

d’interconnexion et ensembles, se trouve sur le site web de l’IEC.

Le comité a décidé que le contenu de ce document ne sera pas modifié avant la date de stabilité

indiquée sur le site web de l’IEC sous webstore.iec.ch dans les données relatives au document

recherché. À cette date, le document sera

– reconduit,

– supprimé, ou

– révisé.

1 Domaine d’application

La présente partie de l’IEC 61189 décrit la méthode de détection des défauts de métallisation

des cartes de circuits imprimés nus par tomographie informatisée (TI).

Le présent document s’applique aux essais non destructifs des trous métallisés.

2 Références normatives

Les documents suivants sont cités dans le texte de sorte qu’ils constituent, pour tout ou partie

de leur contenu, des exigences du présent document. Pour les références datées, seule

l’édition citée s’applique. Pour les références non datées, la dernière édition du document de

référence s’applique (y compris les éventuels amendements).

ISO 15708-3, Essais non destructifs - Méthodes par rayonnements pour la tomographie

informatisée - Partie 3: Fonctionnement et interprétation

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s’appliquent.

L’ISO et l’IEC tiennent à jour des bases de données terminologiques destinées à être utilisées

en normalisation, consultables aux adresses suivantes:

– IEC Electropedia: disponible à l’adresse https://www.electropedia.org/

– ISO Online browsing platform: disponible à l’adresse https://www.iso.org/obp

3.1

résolution d’imagerie

valeur de la taille physique des pixels du détecteur divisée par le facteur de multiplication, qui

est le rapport de la distance entre le détecteur et la source de rayonnement sur la distance

entre le centre de l’échantillon et la source de rayonnement

4 Principe d’essai

Le principe de l’analyse par tomographie informatisée (TI) des défauts de métallisation dans

les trous de la carte de circuits imprimés consiste à utiliser les rayons X à faisceau conique

émis par la source, afin d’obtenir plusieurs projections de rayons X selon différents angles de

l’échantillon, avec un paramètre de reconstruction spécifique en utilisant le logiciel dédié, à

reconstruire la structure tridimensionnelle de l’échantillon réel de l’image de projection, à

afficher les trous de l’échantillon en échelle de gris, et à obtenir la structure des défauts de

métallisation et les nombres associés. Avec cette méthode, le défaut minimal détectable est

égal à trois fois la taille de pixel de la résolution d’imagerie du dispositif. Le processus classique

est présenté à la Figure 1.

Figure 1 – Processus classique d’une analyse TI

5 Appareil

5.1 Scanneur TI à rayons X

5.1.1 Système source de rayons X

Pour une source de rayons X pouvant émettre de manière stable des rayons X, si la taille du

défaut de la cible est plus petite, il convient d’utiliser un système source de rayons X avec une

taille de foyer plus petite. La résolution spatiale la plus élevée de l’imagerie aux

...

IEC 61189-3-302 ®

Edition 1.0 2025-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies -

Part 3-302: Detection of plating defects in unpopulated circuit boards by

computed tomography (CT)

Méthodes d’essai pour les matériaux électriques, les cartes imprimées et autres

structures d’interconnexion et ensembles -

Partie 3-302: Détection des défauts de métallisation dans les cartes de circuits

imprimés nus par tomographie informatisée (TI)

ICS 31.180 ISBN 978-2-8327-0777-7

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications gratuitement tous les aperçus des publications, symboles

IEC en utilisant différents critères (numéro de référence, graphiques et le glossaire. Avec un abonnement, vous aurez

texte, comité d’études, …). Elle donne aussi des toujours accès à un contenu à jour adapté à vos besoins.

informations sur les projets et les publications remplacées

ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au

IEC Just Published - webstore.iec.ch/justpublished monde, avec plus de 22 500 articles terminologiques en

Restez informé sur les nouvelles publications IEC. Just anglais et en français, ainsi que les termes équivalents

Published détaille les nouvelles publications parues. dans 25 langues additionnelles. Egalement appelé

Disponible en ligne et une fois par mois par email. Vocabulaire Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-

nous: sales@iec.ch.

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Test principle . 5

5 Equipment . 6

5.1 X-ray CT scanner . 6

5.1.1 X-ray source system . 6

5.1.2 Mechanical scanning system . 6

5.1.3 Detector system . 6

5.1.4 Shielding facilities . 7

5.2 Software systems . 7

6 Test environment . 7

7 Test the steps . 7

7.1 Equipment preparation . 7

7.2 Sample clamping . 7

7.3 Parameter settings . 8

7.3.1 X-ray sources . 8

7.3.2 Scanning methods . 8

7.3.3 Scanning the field of view . 8

7.3.4 Number of frames scanned . 8

7.3.5 Scan time . 8

7.4 Scanning. 8

7.5 Image reconstruction . 9

7.5.1 3D reconstruction . 9

7.5.2 Image quality . 9

7.5.3 Visualization . 9

7.5.4 Image analysis and data processing . 9

7.5.5 Image saving . 9

8 Reports . 9

8.1 Basic information . 9

8.2 Device information . 9

8.3 Sample information . 9

8.4 Sweep parameters . 10

8.5 Measurement results . 10

Annex A (informative) Typical images of plating defects . 11

A.1 Typical image of plating voids . 11

A.2 Typical image of blind via copper filling defects. 11

A.3 Typical image of nodulation . 12

A.4 Typical image of plating folds . 12

A.5 Typical image of interlayer coincidence . 13

Annex B (informative) Void identification and statistical analysis . 14

B.1 Void identification . 14

B.1.1 Principle . 14

B.1.2 Via . 14

B.1.3 Fill hole . 15

B.2 Statistical analysis . 15

B.2.1 Number of voids . 15

B.2.2 Calculation of the maximum length of the voids/board thickness ratio . 15

B.2.3 Calculation of filled holes void rate . 16

Bibliography . 17

Figure 1 – Typical process of CT analysis . 5

Figure A.1 – Plating voids . 11

Figure A.2 – Blind via copper filling defects . 12

Figure A.3 – Plating nodulation . 12

Figure A.4 – Plating folds . 13

Figure A.5 – Interlayer coincidence . 13

Figure B.1 – Plating holes voids recognition image . 14

Figure B.2 – Identification of the void along the board thickness direction . 14

Figure B.3 – Fill holes voids recognition image . 15

Figure B.4 – Microvia void image . 15

Table 1 – Reference examples of focal size and spatial resolution correspondence for

source focus size . 6

Table 2 – Reference examples of the imaging resolution of the detector system

corresponding to the imaging field of view . 6

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Test methods for electrical materials, printed boards

and other interconnection structures and assemblies -

Part 3-302: Detection of plating defects in unpopulated

circuit boards by computed tomography (CT)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 61189-3-302 has been prepared by IEC technical committee 91: Electronics assembly

technology. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

91/2060/FDIS 91/2071/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61189 series, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

1 Scope

This part of IEC 61189 describes a method for the detection of plating defects in unpopulated

circuit boards using computed tomography (CT).

This document is applicable to non-destructive testing of metallized holes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

ISO 15708-3, Non-destructive testing - Radiation methods for computed tomography - Part 3:

Operation and interpretation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

– IEC Electropedia: available at https://www.electropedia.org/

– ISO Online browsing platform: available at https://www.iso.org/obp

3.1

imaging resolution

value of the physical size of the detector's pixels divided by the magnification ratio which is the

ratio of the distance between the detector and the ray source to the distance between the

sample centre and the ray source

4 Test principle

The principle of computer tomography (CT) analysis of the plating defects in the metallization

holes of the circuit board consists in using the cone beam X-rays emitted by the X-ray source

to obtain multiple X-ray projections from different angles of the sample, with a specific

reconstruction algorithm, using the reconstruction software, to reconstruct the three-

dimensional structure of the actual sample of the projection image, to display the holes in the

sample in grayscale, and obtain the plating defects structure and related numbers. With this

method the minimum detectable defect is three times the pixel size of the device's imaging

resolution. The typical process is shown in Figure 1.

Figure 1 – Typical process of CT analysis

5 Equipment

5.1 X-ray CT scanner

5.1.1 X-ray source system

For an X-ray source that can stably emit X-rays, if the size of the target defect is smaller, then

an X-ray source system with a smaller focal size should be used.The highest spatial resolution

of X-ray imaging is about half the focal point size of the source, and in order to obtain a clear

image of the internal structure, the appropriate X-ray source system is selected according to

Table 1. In addition, the radiation penetration rate of the circuit board should reach more than

20 %, generally between 20 % and 70 %.

Table 1 – Reference examples of focal size and spatial resolution

correspondence for source focus size

a

Spatial resolution (minimum defect size)

Focus size

μm

μm

1 0,5

5 2,5

10 5

a

The focus size is a nominal value provided by the manufacturer of the X-ray tube,

but the actual focus size can be larger.

5.1.2 Mechanical scanning system

The minimum step of the mechanical displacement and vertical and horizontal movement of the

scanning system should be less than or equal to 0,01 mm, and the minimum step of the vertical

axial rotation angle should be less than or equal to 0,01°.

5.1.3 Detector system

X-rays can be received and imaged, and scanned images can be converted into digital signals

and stored in memory. The number of pixels of the detector is usually between 2 000 ~ 4 000,

and the product of the imaging resolution (image pixel size) and the number of pixels is the

imaging field of view. There are two ways to expand the imaging field of view, one is to reduce

the imaging resolution, and the second is to scan and stitch through multiple scans. The

appropriate detector system can be selected according to Table 2. To obtain a sufficiently clear

image of the internal structure of the plated through hole, an imaging resolution of the detector

system as low as possible is recommended.

Table 2 – Reference examples of the imaging resolution of the detector system

corresponding to the imaging field of view

a

Imaging resolution

Imaging field of view

(image pixel size)

μm

μm

0,5 1 000 ~ 2 000

2,5 5 000 ~ 10 000

5 10 000 ~ 20 000

10 20 000 ~ 40 000

30 60 000 ~ 120 000

a

The board size is scanned only once.

For X-ray detectors, there is an important relationship between the imaging resolution and the

pixel resolution. The imaging resolution is assumed to be the value that corresponds to the

sensor manufacturer's technical data. It should be noted that different values can be specified.

Imaging resolution refers to the ability of the system to display fine details in the image. It is

often measured by the modulation transfer function (MTF), which describes how well different

spatial frequencies are transmitted through the system. Pixel resolution, on the other hand,

refers to the number of pixels used to create the image. A higher number of pixels means more

detail. However, the actual image resolution also depends on other factors such as the signal-

to-noise ratio of the detector and the image processing.

5.1.4 Shielding facilities

Shielding facilities should effectively shield radiation leakage to meet safety requirements.

There should be a radiation alarm light that can be used to warn when the radiation source is

turned on. There should be a door interlocking device to prevent misoperation. When the X-ray

source is turned on and operating, the X-ray intensity at each point at 100 mm from the outer

surface of the instrument should be less than 1 μSv/h.

NOTE The limit value of "1 μSv/h" is derived from IAEA Safety Standards Series No. GSR Part 3, Radiation

Protection and Safety of Radiation Sources: International Basic Safety Standards.

5.2 Software systems

The software system should have the following features:

a) it can adjust and control the X-ray source power, detector exposure time, ray source, sample

stage and detector position, sample scanning angle, etc., set the scanning mode, scan and

can store the projection image;

b) it can perform image reconstruction, image processing, artifact removal, image

enhancement and other functions of the projected image according to a specific algorithm;

c) it can analyze 3D models, with functions such as threshold segmentation, dimensional

measurement,statistical analysis.

6 Test environment

Environmental conditions shall comply with the provisions of ISO 15708-3.

7 Test the steps

7.1 Equipment preparation

According to the equipment operating specifications, perform pre-boot safety checks, turn on

the CT scanner, and adjust or preheat the X-ray source system. After the warm-up is completed,

the device self-test is carried out, including connecting the ray source, connecting the detector,

connecting the controller, and returning the motion controller to zero. Offset (darkfield)

correction and gain (lightfield) correction are performed. If necessary, make bad pixel

corrections.

7.2 Sample clamping

Select the appropriate fixture according to the size and shape of the sample to ensure that the

inspection area of the circuit board is within the effective detection field of view, and the area

to be inspected is as close as possible to the centre axis of the turntable. According to the

requirements of the material composition and detection accuracy of the circuit board, auxiliary

detection devices can be added appropriately. For example, when the number of copper layers

on the circuit board is large and the resin is relatively small, a layer of filter can be attached to

the ray outlet to improve resolution and reduce image artifacts.

7.3 Parameter settings

7.3.1 X-ray sources

According to the size and material composition of the circuit board, the energy (such as tube

voltage and tube power) and other parameters of the X-ray source are reasonably selected. If

the number of copper layers that make up the circuit board is small or the thickness of the

copper layer is small (e.g. less than 6 layers or the total thickness of copper foil is less than

230 μm), the X-ray source can easily penetrate and the X-ray source can be selected at a lower

voltage (e.g.130 kV). If the upper limit is exceeded, it is recommended to choose a higher

voltage (e.g.150 kV). To meet the detection of metallized holes plating defects of unpopulated

circuit boards, the resolution is usually 1 μm, and the scanning power is selected as 4 W ~ 5 W.

7.3.2 Scanning methods

According to the size of the circuit board, detection accuracy and detection efficiency

requirements, select the appropriate scanning method. Usually, the sample is first detected by

2D fluoroscopy, and then the CT scan target area is determined; adjust the relative position of

the ray source, detector and sample so that it is located in the centre of the field of view, while

ensuring that the resolution and field of view meet the detection requirements, and then carry

out three-dimensional inspection.

7.3.3 Scanning the field of view

According to the needs of the circuit board detection, the size of the target scanning area is

determined, and the image of the target area of the circuit board is about 2/3 of the whole CT

image compared to the diameter of the field of view.

7.3.4 Number of frames scanned

Combined with the requirements of detection efficiency, image quality and analysis, select the

number of scanned frames (such as 360, 720, 1 080, 1 440, 1 800, etc.). Generally, to meet the

resolution of 1 μm, it is recommended to choose 1 080 and above frame numbers.

7.3.5 Scan time

The scanning time is determined by the number of frames acquired, the sampling time per frame,

and other factors. The smaller the number of frames acquired, the shorter the time required,

but a number of frames which is too small will affect the quality of the reconstructed image, and

the specific sampling frame setting should take into account the size, resolution requirements

and image recognition algorithm capabilities of the circuit board to be measured. Scanning time

which is too short can lead to too low signal-to-noise ratio and thus affect image quality, and

the specific scanning time setting should take into account the thickness of the circuit board to

be measured, the dose rate of the ray source and other factors.

7.4 Scanning

Load the circuit board to be inspected, close the screen door, set the scanning parameters,

operate the control system to move the sample to the centre of the field of view, start the X-ray

source, observe the X-ray source parameters (tube voltage, tube current, etc.), determine the

dose stability and then carry out the detection scan. After the scan, wait for the current and

voltage values to drop to 0 before opening the screen door to take the sample.

7.5 Image reconstruction

7.5.1 3D reconstruction

The scanned projected image is reconstructed in three dimensions according to the

reconstruction algorithm. Additional corrections and processing should be performed during the

reconstruction process, such as noise reduction, removal of common artifacts, correction of

beam hardening, etc.

7.5.2 Image quality

CT images should have good spatial resolution, contrast, and signal-to-noise ratio, and there

should be no image artifacts or edge hardening that affect the judgment.

7.5.3 Visualization

Rely on visualization software to process all images and data. Import the reconstructed 3D raw

image data in the visualization software and perform 2D or 3D visualization operations

according to the inspection requirements. 2D visualization examines data in segments along a

defined axis, while 3D visualization renders a three-dimensional effect of a two-dimensional

image overlay.

7.5.4 Image analysis and data processing

For the purpose of detection, according to the pixel value, shape, size, gray scale and other

conditions of the detailed features on the image, the image analysis software with dimension

measurement, CT value statistical analysis, signal-to-noise ratio analysis and other functions

is used to analyze the image. Complete the automatic identification and positioning of plating

defects such as voids, copper filling defects, rough plating, plating nodulation, plating folds,

plating separation, poor coincidence between layers, etc. Typical images of defects are shown

in Annex A.

The identification of plated voids, as well as the calculation method of the thickness ratio of the

length of the plating void to the board and the void rate of copper filling are shown in Annex B.

NOTE The finished image is the product of the evaluation algorithms of the machine manufacturer's software. These

internal algorithms for evaluation cannot be influenced by the user. Thus, different results can be obtained when

analysing the same sample on different equipment. This is particularly of importance if there are artifacts in the image

that are similar to actual effects. Thus, the physical context of the effect is taken into account to judge, whether a

result can be realistic or not.

7.5.5 Image saving

The image and analysis results are output and saved in a standard format; the integrity of the

original data of the image should be maintained.

8 Reports

8.1 Basic information

The report includes the laboratory name, report number, analyst, auditor, report time.

8.2 Device information

The device information includes the device model, basic parameters, applicable standards.

8.3 Sample information

The sample information includes the circuit board type, number of layers, structure.

8.4 Sweep parameters

The sweep parameters include the scan mode, X-ray source parameters, detector exposure

time, number of scanned frames, resolution, etc.

8.5 Measurement results

The measurement results include the hole wall/void image, number of voids, maximum void

length/plate thickness ratio, coating thickness, plating nodulation, plating folds, plating

separation, and through-hole copper filling defects.

Annex A

(informative)

Typical images of plating defects

A.1 Typical image of plating voids

A typical image of plating voids is shown in Figure A.1.

Figure A.1 – Plating voids

A.2 Typical image of blind via copper filling defects

A typical image of blind via copper filling defects is shown in Figure A.2.

NOTE The picture shows blind via copper filling defects. Voids are completely encapsulated and the total volume

exceeds 25 % of the volume of the filled via.

Figure A.2 – Blind via copper filling defects

A.3 Typical image of nodulation

A typical image of nodulation is shown in Figure A.3.

a) Side view 1 b) Side view 2

Figure A.3 – Plating nodulation

A.4 Typical image of plating folds

A typical image of plating folds is shown in Figure A.4.

Figure A.4 – Plating folds

A.5 Typical image of interlayer coincidence

A typical image of interlayer coincidence is shown in Figure A.5.

a) 2D illustration of the defect b) 3D cross-section of the defect

Figure A.5 – Interlayer coincidence

Annex B

(informative)

Void identification and statistical analysis

B.1 Void identification

B.1.1 Principle

The plating and voids of metallized holes are identified according to the grayscale boundary

values.

B.1.2 Via

An example of through-hole hole identification is shown in Figure B.1.

Figure B.1 – Plating holes voids recognition image

For through-hole, the hole identification should contain the following information: whether the

hole is located at the interface of the inner conductor, whether the hole is a circular hole, and

the maximum size of the hole along the plate thickness direction. The schematic diagram of

identifying the hole along the plate thickness direction is shown in Figure B.2.

b) Identify voids along the board thickness

a) 3D illustration of the defect

direction

Figure B.2 – Identification of the void along the board thickness direction

B.1.3 Fill hole

An example of filling holes identification is shown in Figure B.3.

Figure B.3 – Fill holes voids recognition image

For plating fill holes, the volume of the holes should be identified. A schematic diagram of the

identification of hole-filled holes in electroplating is shown in Figure B.4.

a) 3D illustration of the defect b) 2D cross-section of the defect

Figure B.4 – Microvia void image

B.2 Statistical analysis

B.2.1 Number of voids

Count the number of voids present in the walls of metallized holes.

NOTE A plating thickness below the specified value is considered a void for inspection. The voids in this document

do not contain cases where copper plating thickness is less than the specified value and is considered a void.

B.2.2 Calculation of the maximum length of the voids/board thickness ratio

Calculate the ratio of the maximum size of the identified void to the board thickness, as shown

in Formula (B.1):

P = L /L × 100 %

(B.1)

1 void board thickness

where:

P is the maximum length of the voids/board thickness ratio;

L is the maximum length of the voids;

void

L is the board thickness.

board thickness

B.2.3 Calculation of filled holes void rate

Calculate the filled holes void rate, as shown in Formula (B.2):

P = V /V × 100 %

(B.2)

2 void total

where:

P is the filled holes void rate;

V is the void volume;

void

V is the entire hole volume.

total

NOTE When the relative deviation of the void rate calculated by the same specimen is more than 10 %, the image

and acquisition data will be reconstructed.

Bibliography

IEC 60194-1:2021, Printed board design, manufacture and assembly - Vocabulary - Part 1:

Common usage in printed board and electronic assembly technologies

IEC 60194-2:2025, Printed board design, manufacture and assembly - Vocabulary - Part 2:

Common usage in electronic technologies as well as printed board and electronic assembly

technologies

ISO 15708-1:2024, Non-destructive testing - Radiation methods for computed tomography -

Part 1: Vocabulary

IAEA, Safety Standards Series No. GSR Part 3, Radiation Protection and Safety of Radiation

Sources: International Basic Safety Standards

___________

SOMMAIRE

AVANT-PROPOS . 3

1 Domaine d’application . 5

2 Références normatives . 5

3 Termes et définitions . 5

4 Principe d’essai . 5

5 Appareil . 6

5.1 Scanneur TI à rayons X . 6

5.1.1 Système source de rayons X . 6

5.1.2 Dispositif de balayage mécanique . 6

5.1.3 Système de détection . 6

5.1.4 Installations de protection . 7

5.2 Systèmes logiciels . 7

6 Environnement d’essai . 7

7 Essai des étapes . 7

7.1 Préparation de l’équipement . 7

7.2 Serrage de l’échantillon . 8

7.3 Paramétrage . 8

7.3.1 Sources de rayons X . 8

7.3.2 Méthodes de balayage . 8

7.3.3 Balayage du champ de vision . 8

7.3.4 Nombre de trames balayées . 8

7.3.5 Temps de balayage . 9

7.4 Balayage. 9

7.5 Reconstruction d’image . 9

7.5.1 Reconstruction 3D . 9

7.5.2 Qualité d’image . 9

7.5.3 Visualisation . 9

7.5.4 Analyse d’images et traitement des données . 9

7.5.5 Enregistrement de l’image . 10

8 Rapports. 10

8.1 Informations de base . 10

8.2 Informations sur le dispositif . 10

8.3 Informations sur l’échantillon . 10

8.4 Paramètres de balayage . 10

8.5 Résultat des mesures . 10

Annexe A (informative) Images types de défauts de métallisation . 11

A.1 Images types des vides de métallisation . 11

A.2 Image type de défauts de remplissage du cuivre du trou de liaison borgne . 11

A.3 Image type de nodulation . 12

A.4 Images types des plis de métallisation . 12

A.5 Image type de coïncidence entre couches . 13

Annexe B (informative) Identification des vides et analyse statistique . 14

B.1 Identification des vides . 14

B.1.1 Principe . 14

B.1.2 Trou de liaison . 14

B.1.3 Trou de remplissage . 15

B.2 Analyse statistique . 16

B.2.1 Nombre de vides . 16

B.2.2 Calcul de la longueur maximale du rapport vides/épaisseur de la carte . 16

B.2.3 Taux de vide calculé des trous remplis . 16

Bibliographie . 17

Figure 1 – Processus classique d’une analyse TI .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...