IEC 61340-4-7:2010

(Main)Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization

Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization

IEC 61340-4-7:2010 provides test methods and procedures for evaluating and selecting air ionization equipment and systems (ionizers). This standard establishes measurement techniques, under specified conditions, to determine offset voltage (ion balance) and discharge (charge neutralization) time for ionizers. This standard does not include measurements of electromagnetic interference (EMI), or uses of ionizers in connection with ordnance, flammables, explosive items or electrically initiated explosive devices.

Electrostatique - Partie 4-7: Méthodes d'essai normalisées pour des applications spécifiques - Ionisation

La CEI 61340-4-7:2010 fournit des méthodes et des modes opératoires d'essai pour évaluer et choisir le matériel et les systèmes d'ionisation de l'air (ioniseurs). Cette norme établit des techniques de mesure, dans des conditions spécifiées, pour déterminer la tension de décalage (équilibre ionique) et le temps de décharge (neutralisation des charges) pour les ioniseurs. La présente norme ne comporte pas de mesure d'interférences électromagnétiques (EMI) ou l'utilisation d'ioniseurs en relation avec des éléments pyrotechniques, inflammables, explosifs ou des dispositifs explosifs amorcés électriquement.

General Information

- Status

- Published

- Publication Date

- 13-Jan-2010

- Technical Committee

- TC 101 - Electrostatics

- Drafting Committee

- WG 5 - TC 101/WG 5

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 06-Jan-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 05-Sep-2023

Overview - IEC 61340-4-7:2010 (Ionization)

IEC 61340-4-7:2010 is an international test-method standard in the IEC 61340 electrostatics series that defines procedures for evaluating and selecting air ionization equipment (ionizers). The standard establishes measurement techniques - under specified conditions - to determine offset voltage (ion balance) and discharge (charge neutralization) time for ionizers. It is intended to produce reproducible performance data for manufacturers, users and test laboratories. Note: the standard does not cover electromagnetic interference (EMI) measurements or ionizer use with ordnance, flammables, explosives or electrically initiated explosive devices.

Key topics and technical requirements

- Measurement objectives

- Determine ion balance / offset voltage on an isolated conductive plate and charge decay / discharge time using a charged plate monitor (CPM).

- Test methods and instruments

- Procedures for using a charged plate monitor and related test equipment; Annex B provides a method to measure CPM capacitance.

- Ionizer categories covered

- Room ionization, laminar flow hood ionization (vertical and horizontal), worksurface/benchtop ionizers, and compressed gas ionizers (guns/nozzles).

- Performance considerations

- Test locations and set-ups for different ionizer types; Annex A (informative) discusses performance measurement of ionizers.

- Safety and regulatory items

- Safety requirements addressing personnel, electrical hazards, ozone, radioactive and X‑ray sources and installation practices. Normative references include ESD SP3.3 (periodic verification) and regulatory guidance for ozone and radiation where applicable.

- Standards provenance

- Text is based on ANSI/ESD STM3.1‑2006 and aligns with other parts of the IEC 61340 series.

Applications - who uses IEC 61340-4-7

- Ionizer manufacturers - to generate standardized performance data for product specs and datasheets.

- Quality assurance and test laboratories - to validate ionizer operation, repeatability and to perform acceptance testing.

- ESD control program managers and engineers - in electronics, cleanrooms and any environment where grounding is insufficient for neutralizing charges on insulators or isolated conductors.

- Procurement teams - to compare ionizers on measurable metrics such as offset voltage and discharge times.

Practical guidance in the standard encourages users to adapt test methods and to agree on performance specifications between user and manufacturer for each application, since environmental and item sensitivities vary.

Related standards and references

- IEC 61340 series (Electrostatics)

- ANSI/ESD STM3.1‑2006 (basis for this text)

- ESD SP3.3 (Periodic verification of air ionizers)

- Regulatory references for ozone, radiation and occupational exposure as cited in the normative references.

Keywords: IEC 61340-4-7, ionization standard, electrostatics, charged plate monitor, offset voltage, charge neutralization, ionizer testing, air ionization, ESD control.

IEC 61340-4-7:2010 - Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization Released:1/14/2010

IEC 61340-4-7:2010 - Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization Released:1/14/2010

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61340-4-7:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrostatics - Part 4-7: Standard test methods for specific applications - Ionization". This standard covers: IEC 61340-4-7:2010 provides test methods and procedures for evaluating and selecting air ionization equipment and systems (ionizers). This standard establishes measurement techniques, under specified conditions, to determine offset voltage (ion balance) and discharge (charge neutralization) time for ionizers. This standard does not include measurements of electromagnetic interference (EMI), or uses of ionizers in connection with ordnance, flammables, explosive items or electrically initiated explosive devices.

IEC 61340-4-7:2010 provides test methods and procedures for evaluating and selecting air ionization equipment and systems (ionizers). This standard establishes measurement techniques, under specified conditions, to determine offset voltage (ion balance) and discharge (charge neutralization) time for ionizers. This standard does not include measurements of electromagnetic interference (EMI), or uses of ionizers in connection with ordnance, flammables, explosive items or electrically initiated explosive devices.

IEC 61340-4-7:2010 is classified under the following ICS (International Classification for Standards) categories: 17.200.99 - Other standards related to thermodynamics; 19.040 - Environmental testing; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61340-4-7:2010 has the following relationships with other standards: It is inter standard links to EN 61340-2-1:2015, EN 61340-5-1:2016, IEC 61340-4-7:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61340-4-7:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61340-4-7 ®

Edition 1.0 2010-01

INTERNATIONAL

STANDARD

Electrostatics –

Part 4-7: Standard test methods for specific applications – Ionization

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61340-4-7 ®

Edition 1.0 2010-01

INTERNATIONAL

STANDARD

Electrostatics –

Part 4-7: Standard test methods for specific applications – Ionization

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

U

ICS 17.200.99; 29.020 ISBN 978-2-88910-504-5

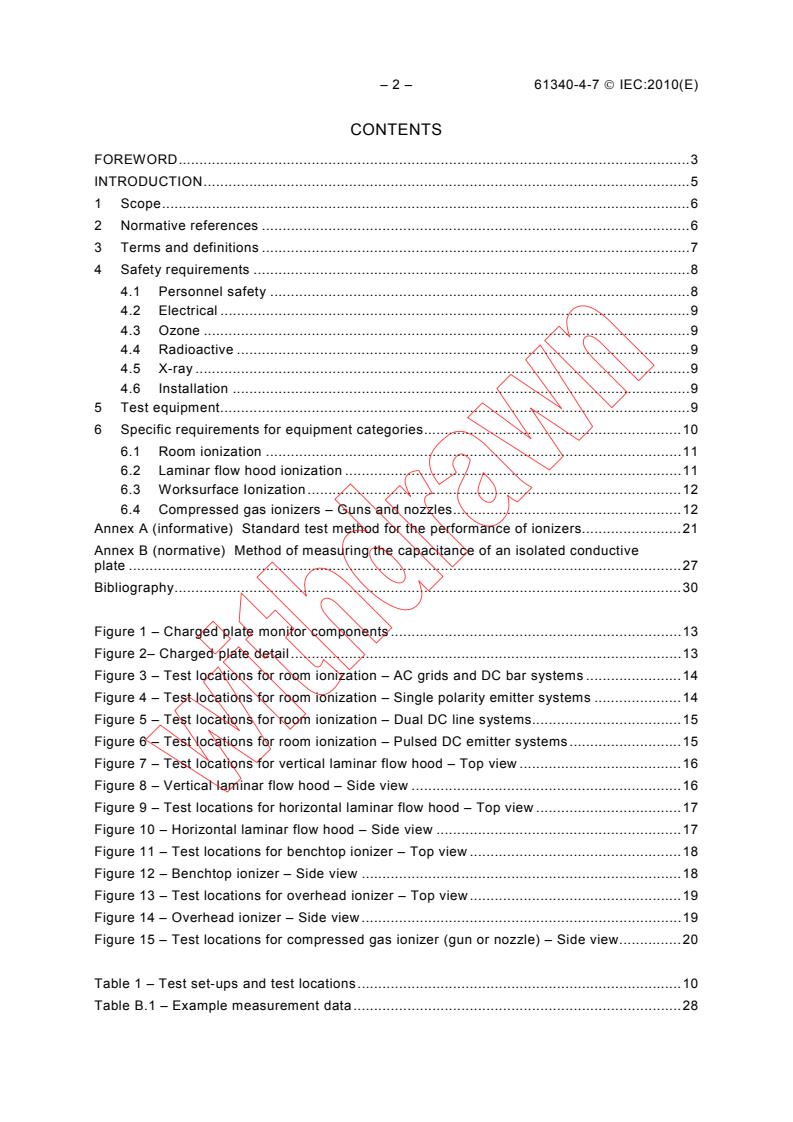

– 2 – 61340-4-7 © IEC:2010(E)

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

4 Safety requirements .8

4.1 Personnel safety .8

4.2 Electrical .9

4.3 Ozone .9

4.4 Radioactive .9

4.5 X-ray .9

4.6 Installation .9

5 Test equipment.9

6 Specific requirements for equipment categories.10

6.1 Room ionization .11

6.2 Laminar flow hood ionization .11

6.3 Worksurface Ionization .12

6.4 Compressed gas ionizers – Guns and nozzles.12

Annex A (informative) Standard test method for the performance of ionizers.21

Annex B (normative) Method of measuring the capacitance of an isolated conductive

plate .27

Bibliography.30

Figure 1 – Charged plate monitor components .13

Figure 2– Charged plate detail.13

Figure 3 – Test locations for room ionization – AC grids and DC bar systems .14

Figure 4 – Test locations for room ionization – Single polarity emitter systems .14

Figure 5 – Test locations for room ionization – Dual DC line systems.15

Figure 6 – Test locations for room ionization – Pulsed DC emitter systems.15

Figure 7 – Test locations for vertical laminar flow hood – Top view .16

Figure 8 – Vertical laminar flow hood – Side view .16

Figure 9 – Test locations for horizontal laminar flow hood – Top view .17

Figure 10 – Horizontal laminar flow hood – Side view .17

Figure 11 – Test locations for benchtop ionizer – Top view .18

Figure 12 – Benchtop ionizer – Side view .18

Figure 13 – Test locations for overhead ionizer – Top view.19

Figure 14 – Overhead ionizer – Side view .19

Figure 15 – Test locations for compressed gas ionizer (gun or nozzle) – Side view.20

Table 1 – Test set-ups and test locations.10

Table B.1 – Example measurement data.28

61340-4-7 © IEC:2010(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 4-7: Standard test methods for specific applications –

Ionization

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61340-4-7 has been prepared by IEC technical committee 101:

Electrostatics.

The text of this standard is based on ANSI/ESD STM3.1-2006. It was submitted to the

National Committees for voting under the Fast Track Procedure.

The text of this standard is also based on the following documents:

FDIS Report on voting

101/292/FDIS 101/299/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 61340-4-7 © IEC:2010(E)

A list of all parts in the IEC 61340 series, under the general title Electrostatics, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

61340-4-7 © IEC:2010(E) – 5 –

INTRODUCTION

Grounding is the primary method used to limit static charge fwhen protecting electrostatic

discharge-susceptible items in the work environment. However, grounding methods are not

effective in removing static charges from the surfaces of non-conductive (insulative) or

isolated conductive materials. Air ionization techniques may be employed to reduce these

charges as the active parameters in charge neutralization are the conductivities of the air for

each polarity. It would be appropriate to measure either the conductivities themselves or the

ion concentrations for each polarity as this would determine the ability of the ionized air to

neutralize a charge in a given location. Annex A provides information on performance of

ionizers.

In practice, these measurements are difficult to make. A more feasible way of evaluating the

ability of an ionizer to neutralize a static charge is to directly measure the rate of charge

decay. Charges to be neutralized may be located on insulators as well as on isolated

conductors. It is difficult to charge an insulator reliably and repeatably. Charge neutralization

is more easily evaluated by measuring the rate of decay of the voltage of an isolated

conductive plate. The measurement of this decay should not interfere with or change the

nature of the actual decay. Four practical methods of air ionization are addressed in this

standard test method:

a) radioactive emission;

b) high-voltage corona from a.c. electric fields;

c) high-voltage corona from d.c. electric fields;

d) soft X-ray emission.

This part of IEC 61340 provides test methods and procedures that can be used when

evaluating ionization equipment. The objective of the test methods is to generate meaningful,

reproducible data. The test methods are not meant to be a recommendation for any particular

ionizer configuration. The wide variety of ionizers, and the environments within which they are

used, will often require test methods different from those described in this part of IEC 61340.

Users of this standard should be prepared to adapt the test methods as required to produce

meaningful data in their own application of ionizers.

Similarly, the test conditions chosen in this part of IEC 61340 do not represent a

recommendation for acceptable ionizer performance. There is a wide range of item

sensitivities to static charge. There is also a wide range of environmental conditions affecting

the operation of ionizers. Performance specifications should be agreed upon between the

user and manufacturer of the ionizer in each application. Users of this standard test method

should be prepared to establish reasonable performance requirements for their own

application of ionizers.

Annex B has been provided in order to provide a method for measuring capacitance of the

charged plate.

– 6 – 61340-4-7 © IEC:2010(E)

ELECTROSTATICS –

Part 4-7: Standard test methods for specific applications –

Ionization

1 Scope

This part of IEC 61340 provides test methods and procedures for evaluating and selecting air

ionization equipment and systems (ionizers).

This standard establishes measurement techniques, under specified conditions, to determine

offset voltage (ion balance) and discharge (charge neutralization) time for ionizers.

This standard does not include measurements of electromagnetic interference (EMI), or uses

of ionizers in connection with ordnance, flammables, explosive items or electrically initiated

explosive devices.

As contained in this standard, the test methods and test conditions may be used by

manufacturers of ionizers to provide performance data describing their products. Users of

ionizers are urged to modify the test methods and test conditions for their specific application

in order to qualify ionizers for use, or to make periodic verifications of ionizer performance

(refer to ESD SP3.3). The user will need to decide the extent of the data required for each

application.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

ESD ADV1.0, Glossary of terms

ESD SP3.3, Standard practice for protection of electrostatic discharge susceptible items –

Periodic verification of air ionizers

29 CFR 1910.1000, Ozone, (OSHA) Air contaminants

29 CFR 1910.95, (OSHA) Occupational noise exposure

29 CFR 1910.242 (b), (OSHA) Compressed air used for cleaning

10 CFR 20, (NRC) Standards for protection against radiation

21 CFR 1020, (FDA) Performance standards for ionizing radiation emitting products

___________

ESD Association, 7900 Turin Road, Bldg. 3, Rome, NY 13440-2069, 315-339-6937, www.esda.org

CFR (Code of Federal Regulations) U.S. Government printing office, 732 N. Capitol Street NW, Washington,

DC 20401, 866-512-1800, http://bookstore.gpo.gov

61340-4-7 © IEC:2010(E) – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions, in addition to those

specified in the ESD association glossary of terms, shall apply.

3.1

air conductivity

ability of air to conduct (pass) an electric current under the influence of an electric field

3.2

air Ions

molecular clusters of about ten molecules (water, impurities, etc.) bound by polarization

forces to a singly charged oxygen or nitrogen molecule

3.3

charge decay

decrease and/or neutralization of a net electrostatic charge

3.4

charge induction

redistribution of charge in an isolated conductor when placed in an electric field (e.g. from a

charged body)

NOTE Momentary grounding of such a conductor would result in its gaining a net charge.

3.5

charged plate monitor

CPM

instrument used to measure the charge neutralization properties of ionization equipment

3.6

compressed gas ionizer

ionization devices that can be used to neutralize charged surfaces and/or remove surface

particles with pressurized gas

NOTE This type of ionizer may be used to ionize the gas within production equipment.

3.7

corona

production of positive and negative ions by a very localized high electric field

NOTE The field is normally established by applying a high voltage to a conductor in the shape of a sharp point or

wire.

3.8

decay rate

decrease of charge or voltage per unit time

3.9

discharge time

time necessary for a voltage (due to an electrostatic charge) to decay from an initial value to

some arbitrarily chosen final value

3.10

emitter

conducting sharp object, usually a needle or wire, which will cause a corona discharge when

kept at a high potential

– 8 – 61340-4-7 © IEC:2010(E)

3.11

horizontal laminar flow

non-turbulent airflow in a horizontal direction

3.12

ion balance

(see offset voltage)

3.13

ionizer

device that is designed to generate positive and/or negative air ions

3.14

isolated conductor

non-grounded conductor

3.15

laminar flow hood ionization

these devices or systems provide local area ionization coverage in vertical or horizontal

laminar flow hoods or benches

3.16

offset voltage

observed voltage on the isolated conductive plate of a charged plate monitor (CPM) that has

been placed in an ionized environment

3.17

peak offset voltage

for pulsed ionizers, the maximum value of the offset voltage for each polarity, as the ionizer

cycles between positive and negative ion outputs

3.18

room ionization

ionization systems that provide large area coverage with air ions

3.19

worksurface ionization (formerly tabletop ionization)

ionization devices or systems used to control static charges at a workstation

NOTE This type includes benchtop ionizers, overhead worksurface ionizers and laminar flow hood ionizers.

3.20

vertical laminar flow

non-turbulent airflow in a vertical direction

4 Safety requirements

In addition to the safety issues mentioned in this clause, there may be local, state, national

and international safety standards or regulations that affect the operation of ionizers. Users of

this standard test method should determine if such requirements will apply to their installation

of ionizers.

4.1 Personnel safety

4.1.1 The procedures and equipment described in this part of IEC 61340 may expose

personnel to hazardous electrical conditions. Users of this standard, therefore, are

responsible for selecting equipment that complies with applicable laws, regulatory codes and

61340-4-7 © IEC:2010(E) – 9 –

both external and internal policy. Users are also cautioned that this standard cannot replace

or supersede any requirements for personnel safety.

Ground fault circuit interrupters (GFCI) and other safety protection should be considered

wherever personnel may come into contact with electrical sources.

Electrical hazard reduction practices should be exercised and proper grounding instructions

for the equipment must be followed.

4.2 Electrical

In the case of high-voltage ionizers with exposed emitters, the corona points or wires should

be peak current limited to applicable safety requirements for the installation.

4.3 Ozone

The OSHA limit, as defined by 29 CFR 1910.1000, shall not be exceeded. If ozone-sensitive

components are in the vicinity of an ionizer, the manufacturer should provide information

and/or evaluation suggestions for the situation.

4.4 Radioactive

The manufacturer is required to obtain a license from the Nuclear Regulatory Commission

(NRC) or the NRC agreement state in which the equipment is manufactured. The

manufacturer and user shall meet all requirements of 10 CFR 20 and any other applicable

government regulations.

4.5 X-ray

The manufacturer and user shall meet all requirements of 21 CFR 1020 and any other

applicable government regulations. Typically, state and local government agencies will require

the device to be registered at its use location. X-ray devices should be installed in such a way

that prevents accidental exposure to personnel. Typically this will include some type of

enclosure for the X-ray device and electrical interlocking to turn the X-ray device off when the

enclosure is opened.

4.6 Installation

Installation should conform to applicable electrical, mechanical and safety codes, as well as

individual facility standards. Some equipment, such as compressed gas guns and nozzles

may have to meet other requirements such as 29 CFR 1910.95 for noise exposure and

29 CFR 1910.242 for personnel safety with compressed gas devices. Installation techniques

should also be applicable to the particular environment in which the ionizer is to be installed

(e.g., cleanrooms).

5 Test equipment

5.1 The instrument recommended in this standard to make performance measurements on

air ionization equipment is the CPM (refer to Figure 1). The conductive plate shall be 15 cm

by 15 cm (6“ by 6“) with a minimum capacitance of 15 pF when mounted in the test fixture

without electrical hook-ups. The total capacitance of the test circuit, with plate, shall be 20 pF

± 2 pF (refer to Annex B). The instrument recommended by this standard test method may

also be used for the periodic verification of air ionizers (refer to ESD SP3.3).

5.2 There shall be no objects, grounded or otherwise, closer than dimension "A" of the

conductive plate except the supporting insulators or plate voltage contacts, as shown in

Figure 2 (refer to Annex B).

– 10 – 61340-4-7 © IEC:2010(E)

5.3 The isolated conductive plate, when charged to the desired test voltage, shall not

discharge more than 10 % of the test voltage within 5 min, in the absence of ionization.

5.4 The voltage on the plate shall be monitored in such a way that the system conforms to

5.1, 5.2 and 5.3. The response time of the monitoring device shall be sufficient to accurately

measure changing plate voltages.

5.5 The voltage source used to charge the plate should be current limited so as to meet

the requirements of 4.1.

6 Specific requirements for equipment categories

For the types of ionization equipment listed in 6.1, 6.2, 6.3 and 6.4, the following specific

requirements apply:

a) Discharge time test – The conductive plate of the test fixture shall be charged to an initial

test voltage and allowed to discharge to 10 % of the initial test voltage. The time required

shall be monitored and recorded for both polarities of initial charge. This time is referred to

as the discharge time (refer to 5.1 and Figure 1).

b) Offset voltage test – The conductive plate shall be momentarily grounded to remove any

residual charges and to verify zero of the monitoring device. The plate is then monitored

within the ionized environment, per the procedure described for each equipment category.

The resulting observed voltage is referred to as the offset voltage.

c) Locations – The discharge time and offset voltage should be measured for each test

location described in the test location figures (see Table 1).

d) Same conditions – Discharge time and offset voltage shall be measured under the same

conditions without any equipment adjustments. If ionizers from different categories are to

be compared, the same test voltages shall be used for all tests.

e) Peak offset voltage – In the case of pulsed ionizers, offset voltage should be measured

and reported in peak values using the test equipment described in 5.1.

f) Other parameters – Application specific parameters such as humidity, temperature, air

velocity, etc., should be recorded.

Table 1 – Test set-ups and test locations

Offset voltage

Equipment Figure Number of test Charged plate

measurement

category references locations initial voltage

time interval

Room ionization

Grids, AC 3 2 (1 to 5) min 1 000

Bars, pulsed and DC 3 2 (1 to 5) min 1 000

Single polarity emitter 4 3 (1 to 5) min 1 000

Dual DC Line 5 3 (1 to 5) min 1 000

Pulsed DC emitter 6 2 (1 to 5) min 1 000

Laminar flow hood

Vertical 7 and 8 8 (1 to 5) min 1 000

Horizontal 9 and 10 6 (1 to 5) min 1 000

Worksurface ionization

Benchtop 11 and 12 12 (1 to 5) min 1 000

Overhead 13 and 14 12 (1 to 5) min 1 000

Compressed gas ionization

Guns and nozzles 15 1 10 s to 1 min 1 000

61340-4-7 © IEC:2010(E) – 11 –

6.1 Room ionization

6.1.1 The area around the charged plate monitor should be cleared for a horizontal distance

of 60“ in all directions. The ionization system should be operated for a minimum of 30 min to

stabilize conditions in the test area.

6.1.2 During the test, the test technician should be grounded and stand outside the 60“

cleared area.

6.1.3 Discharge time from a 1 000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.1.4 The air velocity at the test location should be recorded.

6.1.5 Measurements should be taken with the charged plate monitor at a distance of 60“

from the ionizer under test. Since installed ionizer heights may vary, a consistent

measurement height should be selected for the evaluation of different systems. This height

and the ionizer mounting height shall be recorded in the test results.

6.1.6 The minimum number of test locations is determined by the type of system. (See

Table 1 and refer to Figures 3 through 6.)

6.1.7 Discharge time as described in Clause 6, point a), should be measured at each test

location.

6.1.8 Offset voltage as described in Clause 6, points b) and e) should be determined at

each test location. Offset voltage shall be measured after a period of at least 1 mkin to allow

the reading to stabilize (5 min maximum).

6.2 Laminar flow hood ionization

6.2.1 The test should be performed on a surface that does not contain obstructions to

airflow. Unless otherwise specified, the test surface should be static dissipative or conductive

and properly grounded.

6.2.2 The test technician should be properly grounded.

6.2.3 Discharge time from a 1 000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.2.4 The air velocity at test location TP4, as shown in Figures 7 or 9, should be recorded.

6.2.5 For a vertical laminar flow hood, the test set-up is shown in Figures 7 and 8. Data

should be taken at test positions TP1 through TP8 as shown in Figure 7.

6.2.6 For a horizontal laminar flow hood, the test set-up is shown in Figures 9 and 10. Data

should be taken at test positions TP1 through TP6 as shown in Figure 9.

6.2.7 Discharge time as described in Clause 6, point a), should be measured at each test

location.

6.2.8 Offset voltage as described in Clause 6, points b) and e) should be determined at

each test location. Offset voltage shall be measured after a period of at least 1 min, or as

necessary to allow the reading to stabilize (5 min maximum).

– 12 – 61340-4-7 © IEC:2010(E)

6.3 Worksurface Ionization

6.3.1 The test should be performed on a surface that does not contain obstructions to

airflow. Unless otherwise specified the test surface should be static dissipative or conductive

and properly grounded.

6.3.2 The test technician should be properly grounded.

6.3.3 Discharge time from a 1,000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.3.4 The unit should be measured with the heater off, if so equipped. The unit should be

tested with any filters in place if so equipped. Measurements should be made at both

minimum and maximum airflows for units with variable airflow. The air velocity should be

measured and included in the test results. End users should test ionizers with the same

configuration of operating heaters and filters that they intend to use.

6.3.5 For benchtop units, the ionizer should be placed as shown in Figures 11 and 12.

Airflow should be directed at test location TP2 and measured at test locations TP2 and TP5.

The charged plate monitor shall face the ionizer. Measurements with the charged plate

monitor should be made at test locations TP1 through TP12 as shown in Figure 11.

6.3.6 For overhead units, the ionizer should be placed as shown in Figures 13 and 14.

Airflow should be measured at test locations TP5 and TP8. Measurements with the charged

plate monitor should be made at test locations TP1 through TP12 as shown in Figure 13.

6.3.7 Discharge time as described in Clause 6, point a), should be measured at each test

location.

6.3.8 Offset voltage as described in Clause 6, points b) and e) should be determined at

each test location. Offset voltage shall be measured after a period of at least 1 min, or as

necessary to allow the reading to stabilize (5 min maximum).

6.4 Compressed

...

IEC 61340-4-7 ®

Edition 1.0 2010-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrostatics –

Part 4-7: Standard test methods for specific applications – Ionization

Électrostatique –

Partie 4-7: Méthodes d'essai normalisées pour des applications spécifiques –

Ionisation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61340-4-7 ®

Edition 1.0 2010-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrostatics –

Part 4-7: Standard test methods for specific applications – Ionization

Électrostatique –

Partie 4-7: Méthodes d'essai normalisées pour des applications spécifiques –

Ionisation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

U

CODE PRIX

ICS 17.200.99; 29.020 ISBN 978-2-88912-463-3

– 2 – 61340-4-7 IEC:2010

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Safety requirements . 8

4.1 Personnel safety . 8

4.2 Electrical . 9

4.3 Ozone . 9

4.4 Radioactive . 9

4.5 X-ray . 9

4.6 Installation . 9

5 Test equipment . 9

6 Specific requirements for equipment categories . 10

6.1 Room ionization . 11

6.2 Laminar flow hood ionization . 11

6.3 Worksurface Ionization . 12

6.4 Compressed gas ionizers – Guns and nozzles . 12

Annex A (informative) Standard test method for the performance of ionizers. 21

Annex B (normative) Method of measuring the capacitance of an isolated conductive

plate . 27

Bibliography . 30

Figure 1 – Charged plate monitor components . 13

Figure 2– Charged plate detail . 13

Figure 3 – Test locations for room ionization – AC grids and DC bar systems . 14

Figure 4 – Test locations for room ionization – Single polarity emitter systems . 14

Figure 5 – Test locations for room ionization – Dual DC line systems . 15

Figure 6 – Test locations for room ionization – Pulsed DC emitter systems . 15

Figure 7 – Test locations for vertical laminar flow hood – Top view . 16

Figure 8 – Vertical laminar flow hood – Side view . 16

Figure 9 – Test locations for horizontal laminar flow hood – Top view . 17

Figure 10 – Horizontal laminar flow hood – Side view . 17

Figure 11 – Test locations for benchtop ionizer – Top view . 18

Figure 12 – Benchtop ionizer – Side view . 18

Figure 13 – Test locations for overhead ionizer – Top view . 19

Figure 14 – Overhead ionizer – Side view . 19

Figure 15 – Test locations for compressed gas ionizer (gun or nozzle) – Side view . 20

Table 1 – Test set-ups and test locations . 10

Table B.1 – Example measurement data . 28

61340-4-7 IEC:2010 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 4-7: Standard test methods for specific applications –

Ionization

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61340-4-7 has been prepared by IEC technical committee 101:

Electrostatics.

The text of this standard is based on ANSI/ESD STM3.1-2006. It was submitted to the

National Committees for voting under the Fast Track Procedure.

This bilingual version (2011-04) replaces the English version.

The text of this standard is also based on the following documents:

FDIS Report on voting

101/292/FDIS 101/299/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 4 – 61340-4-7 IEC:2010

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61340 series, under the general title Electrostatics, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61340-4-7 IEC:2010 – 5 –

INTRODUCTION

Grounding is the primary method used to limit static charge fwhen protecting electrostatic

discharge-susceptible items in the work environment. However, grounding methods are not

effective in removing static charges from the surfaces of non-conductive (insulative) or

isolated conductive materials. Air ionization techniques may be employed to reduce these

charges as the active parameters in charge neutralization are the conductivities of the air for

each polarity. It would be appropriate to measure either the conductivities themselves or the

ion concentrations for each polarity as this would determine the ability of the ionized air to

neutralize a charge in a given location. Annex A provides information on performance of

ionizers.

In practice, these measurements are difficult to make. A more feasible way of evaluating the

ability of an ionizer to neutralize a static charge is to directly measure the rate of charge

decay. Charges to be neutralized may be located on insulators as well as on isolated

conductors. It is difficult to charge an insulator reliably and repeatably. Charge neutralization

is more easily evaluated by measuring the rate of decay of the voltage of an isolated

conductive plate. The measurement of this decay should not interfere with or change the

nature of the actual decay. Four practical methods of air ionization are addressed in this

standard test method:

a) radioactive emission;

b) high-voltage corona from a.c. electric fields;

c) high-voltage corona from d.c. electric fields;

d) soft X-ray emission.

This part of IEC 61340 provides test methods and procedures that can be used when

evaluating ionization equipment. The objective of the test methods is to generate meaningful,

reproducible data. The test methods are not meant to be a recommendation for any particular

ionizer configuration. The wide variety of ionizers, and the environments within which they are

used, will often require test methods different from those described in this part of IEC 61340.

Users of this standard should be prepared to adapt the test methods as required to produce

meaningful data in their own application of ionizers.

Similarly, the test conditions chosen in this part of IEC 61340 do not represent a

recommendation for acceptable ionizer performance. There is a wide range of item

sensitivities to static charge. There is also a wide range of environmental conditions affecting

the operation of ionizers. Performance specifications should be agreed upon between the

user and manufacturer of the ionizer in each application. Users of this standard test method

should be prepared to establish reasonable performance requirements for their own

application of ionizers.

Annex B has been provided in order to provide a method for measuring capacitance of the

charged plate.

– 6 – 61340-4-7 IEC:2010

ELECTROSTATICS –

Part 4-7: Standard test methods for specific applications –

Ionization

1 Scope

This part of IEC 61340 provides test methods and procedures for evaluating and selecting air

ionization equipment and systems (ionizers).

This standard establishes measurement techniques, under specified conditions, to determine

offset voltage (ion balance) and discharge (charge neutralization) time for ionizers.

This standard does not include measurements of electromagnetic interference (EMI), or uses

of ionizers in connection with ordnance, flammables, explosive items or electrically initiated

explosive devices.

As contained in this standard, the test methods and test conditions may be used by

manufacturers of ionizers to provide performance data describing their products. Users of

ionizers are urged to modify the test methods and test conditions for their specific application

in order to qualify ionizers for use, or to make periodic verifications of ionizer performance

(refer to ESD SP3.3). The user will need to decide the extent of the data required for each

application.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

ESD ADV1.0, Glossary of terms

ESD SP3.3, Standard practice for protection of electrostatic discharge susceptible items –

Periodic verification of air ionizers

29 CFR 1910.1000, Ozone, (OSHA) Air contaminants

29 CFR 1910.95, (OSHA) Occupational noise exposure

29 CFR 1910.242 (b), (OSHA) Compressed air used for cleaning

10 CFR 20, (NRC) Standards for protection against radiation

21 CFR 1020, (FDA) Performance standards for ionizing radiation emitting products

___________

ESD Association, 7900 Turin Road, Bldg. 3, Rome, NY 13440-2069, 315-339-6937, www.esda.org

CFR (Code of Federal Regulations) U.S. Government printing office, 732 N. Capitol Street NW, Washington,

DC 20401, 866-512-1800, http://bookstore.gpo.gov

61340-4-7 IEC:2010 – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions, in addition to those

specified in the ESD association glossary of terms, apply.

3.1

air conductivity

ability of air to conduct (pass) an electric current under the influence of an electric field

3.2

air Ions

molecular clusters of about ten molecules (water, impurities, etc.) bound by polarization

forces to a singly charged oxygen or nitrogen molecule

3.3

charge decay

decrease and/or neutralization of a net electrostatic charge

3.4

charge induction

redistribution of charge in an isolated conductor when placed in an electric field (e.g. from a

charged body)

NOTE Momentary grounding of such a conductor would result in its gaining a net charge.

3.5

charged plate monitor

CPM

instrument used to measure the charge neutralization properties of ionization equipment

3.6

compressed gas ionizer

ionization devices that can be used to neutralize charged surfaces and/or remove surface

particles with pressurized gas

NOTE This type of ionizer may be used to ionize the gas within production equipment.

3.7

corona

production of positive and negative ions by a very localized high electric field

NOTE The field is normally established by applying a high voltage to a conductor in the shape of a sharp point or

wire.

3.8

decay rate

decrease of charge or voltage per unit time

3.9

discharge time

time necessary for a voltage (due to an electrostatic charge) to decay from an initial value to

some arbitrarily chosen final value

3.10

emitter

conducting sharp object, usually a needle or wire, which will cause a corona discharge when

kept at a high potential

– 8 – 61340-4-7 IEC:2010

3.11

horizontal laminar flow

non-turbulent airflow in a horizontal direction

3.12

ion balance

(see offset voltage)

3.13

ionizer

device that is designed to generate positive and/or negative air ions

3.14

isolated conductor

non-grounded conductor

3.15

laminar flow hood ionization

these devices or systems provide local area ionization coverage in vertical or horizontal

laminar flow hoods or benches

3.16

offset voltage

observed voltage on the isolated conductive plate of a charged plate monitor (CPM) that has

been placed in an ionized environment

3.17

peak offset voltage

for pulsed ionizers, the maximum value of the offset voltage for each polarity, as the ionizer

cycles between positive and negative ion outputs

3.18

room ionization

ionization systems that provide large area coverage with air ions

3.19

worksurface ionization (formerly tabletop ionization)

ionization devices or systems used to control static charges at a workstation

NOTE This type includes benchtop ionizers, overhead worksurface ionizers and laminar flow hood ionizers.

3.20

vertical laminar flow

non-turbulent airflow in a vertical direction

4 Safety requirements

In addition to the safety issues mentioned in this clause, there may be local, state, national

and international safety standards or regulations that affect the operation of ionizers. Users of

this standard test method should determine if such requirements will apply to their installation

of ionizers.

4.1 Personnel safety

4.1.1 The procedures and equipment described in this part of IEC 61340 may expose

personnel to hazardous electrical conditions. Users of this standard, therefore, are

responsible for selecting equipment that complies with applicable laws, regulatory codes and

61340-4-7 IEC:2010 – 9 –

both external and internal policy. Users are also cautioned that this standard cannot replace

or supersede any requirements for personnel safety.

Ground fault circuit interrupters (GFCI) and other safety protection should be considered

wherever personnel may come into contact with electrical sources.

Electrical hazard reduction practices should be exercised and proper grounding instructions

for the equipment must be followed.

4.2 Electrical

In the case of high-voltage ionizers with exposed emitters, the corona points or wires should

be peak current limited to applicable safety requirements for the installation.

4.3 Ozone

The OSHA limit, as defined by 29 CFR 1910.1000, shall not be exceeded. If ozone-sensitive

components are in the vicinity of an ionizer, the manufacturer should provide information

and/or evaluation suggestions for the situation.

4.4 Radioactive

The manufacturer is required to obtain a license from the Nuclear Regulatory Commission

(NRC) or the NRC agreement state in which the equipment is manufactured. The

manufacturer and user shall meet all requirements of 10 CFR 20 and any other applicable

government regulations.

4.5 X-ray

The manufacturer and user shall meet all requirements of 21 CFR 1020 and any other

applicable government regulations. Typically, state and local government agencies will require

the device to be registered at its use location. X-ray devices should be installed in such a way

that prevents accidental exposure to personnel. Typically this will include some type of

enclosure for the X-ray device and electrical interlocking to turn the X-ray device off when the

enclosure is opened.

4.6 Installation

Installation should conform to applicable electrical, mechanical and safety codes, as well as

individual facility standards. Some equipment, such as compressed gas guns and nozzles

may have to meet other requirements such as 29 CFR 1910.95 for noise exposure and

29 CFR 1910.242 for personnel safety with compressed gas devices. Installation techniques

should also be applicable to the particular environment in which the ionizer is to be installed

(e.g., cleanrooms).

5 Test equipment

5.1 The instrument recommended in this standard to make performance measurements on

air ionization equipment is the CPM (refer to Figure 1). The conductive plate shall be 15 cm

by 15 cm (6“ by 6“) with a minimum capacitance of 15 pF when mounted in the test fixture

without electrical hook-ups. The total capacitance of the test circuit, with plate, shall be

20 pF ± 2 pF (refer to Annex B). The instrument recommended by this standard test method

may also be used for the periodic verification of air ionizers (refer to ESD SP3.3).

5.2 There shall be no objects, grounded or otherwise, closer than dimension "A" of the

conductive plate except the supporting insulators or plate voltage contacts, as shown in

Figure 2 (refer to Annex B).

– 10 – 61340-4-7 IEC:2010

5.3 The isolated conductive plate, when charged to the desired test voltage, shall not

discharge more than 10 % of the test voltage within 5 min, in the absence of ionization.

5.4 The voltage on the plate shall be monitored in such a way that the system conforms to

5.1, 5.2 and 5.3. The response time of the monitoring device shall be sufficient to accurately

measure changing plate voltages.

5.5 The voltage source used to charge the plate should be current limited so as to meet

the requirements of 4.1.

6 Specific requirements for equipment categories

For the types of ionization equipment listed in 6.1, 6.2, 6.3 and 6.4, the following specific

requirements apply:

a) Discharge time test – The conductive plate of the test fixture shall be charged to an initial

test voltage and allowed to discharge to 10 % of the initial test voltage. The time required

shall be monitored and recorded for both polarities of initial charge. This time is referred to

as the discharge time (refer to 5.1 and Figure 1).

b) Offset voltage test – The conductive plate shall be momentarily grounded to remove any

residual charges and to verify zero of the monitoring device. The plate is then monitored

within the ionized environment, per the procedure described for each equipment category.

The resulting observed voltage is referred to as the offset voltage.

c) Locations – The discharge time and offset voltage should be measured for each test

location described in the test location figures (see Table 1).

d) Same conditions – Discharge time and offset voltage shall be measured under the same

conditions without any equipment adjustments. If ionizers from different categories are to

be compared, the same test voltages shall be used for all tests.

e) Peak offset voltage – In the case of pulsed ionizers, offset voltage should be measured

and reported in peak values using the test equipment described in 5.1.

f) Other parameters – Application specific parameters such as humidity, temperature, air

velocity, etc., should be recorded.

Table 1 – Test set-ups and test locations

Offset voltage

Equipment Figure Number of test Charged plate

measurement

category references locations initial voltage

time interval

Room ionization

Grids, AC 3 2 (1 to 5) min 1 000

Bars, pulsed and DC 3 2 (1 to 5) min 1 000

Single polarity emitter 4 3 (1 to 5) min 1 000

Dual DC Line 5 3 (1 to 5) min 1 000

Pulsed DC emitter 6 2 (1 to 5) min 1 000

Laminar flow hood

Vertical 7 and 8 8 (1 to 5) min 1 000

Horizontal 9 and 10 6 (1 to 5) min 1 000

Worksurface ionization

Benchtop 11 and 12 12 (1 to 5) min 1 000

Overhead 13 and 14 12 (1 to 5) min 1 000

Compressed gas ionization

Guns and nozzles 15 1 10 s to 1 min 1 000

61340-4-7 IEC:2010 – 11 –

6.1 Room ionization

6.1.1 The area around the charged plate monitor should be cleared for a horizontal distance

of 60“ in all directions. The ionization system should be operated for a minimum of 30 min to

stabilize conditions in the test area.

6.1.2 During the test, the test technician should be grounded and stand outside the 60“

cleared area.

6.1.3 Discharge time from a 1 000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.1.4 The air velocity at the test location should be recorded.

6.1.5 Measurements should be taken with the charged plate monitor at a distance of 60“

from the ionizer under test. Since installed ionizer heights may vary, a consistent

measurement height should be selected for the evaluation of different systems. This height

and the ionizer mounting height shall be recorded in the test results.

6.1.6 The minimum number of test locations is determined by the type of system. (See

Table 1 and refer to Figures 3 through 6.)

6.1.7 Discharge time as described in Clause 6, point a), should be measured at each test

location.

6.1.8 Offset voltage as described in Clause 6, points b) and e) should be determined at

each test location. Offset voltage shall be measured after a period of at least 1 mkin to allow

the reading to stabilize (5 min maximum).

6.2 Laminar flow hood ionization

6.2.1 The test should be performed on a surface that does not contain obstructions to

airflow. Unless otherwise specified, the test surface should be static dissipative or conductive

and properly grounded.

6.2.2 The test technician should be properly grounded.

6.2.3 Discharge time from a 1 000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.2.4 The air velocity at test location TP4, as shown in Figures 7 or 9, should be recorded.

6.2.5 For a vertical laminar flow hood, the test set-up is shown in Figures 7 and 8. Data

should be taken at test positions TP1 through TP8 as shown in Figure 7.

6.2.6 For a horizontal laminar flow hood, the test set-up is shown in Figures 9 and 10. Data

should be taken at test positions TP1 through TP6 as shown in Figure 9.

6.2.7 Discharge time as described in Clause 6, point a), should be measured at each test

location.

6.2.8 Offset voltage as described in Clause 6, points b) and e) should be determined at

each test location. Offset voltage shall be measured after a period of at least 1 min, or as

necessary to allow the reading to stabilize (5 min maximum).

– 12 – 61340-4-7 IEC:2010

6.3 Worksurface Ionization

6.3.1 The test should be performed on a surface that does not contain obstructions to

airflow. Unless otherwise specified the test surface should be static dissipative or conductive

and properly grounded.

6.3.2 The test technician should be properly grounded.

6.3.3 Discharge time from a 1 000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.3.4 The unit should be measured with the heater off, if so equipped. The unit should be

tested with any filters in place if so equipped. Measurements should be made at both

minimum and maximum airflows for units with variable airflow. The air velocity should be

measured and included in the test results. End users should test ionizers with the same

configuration of operating heaters and filters that they intend to use.

6.3.5 For benchtop units, the ionizer should be placed as shown in Figures 11 and 12.

Airflow should be directed at test location TP2 and measured at test locations TP2 and TP5.

The charged plate monitor shall face the ionizer. Measurements with the charged plate

monitor should be made at test locations TP1 through TP12 as shown in Figure 11.

6.3.6 For overhead units, the ionizer should be placed as shown in Figures 13 and 14.

Airflow should be measured at test locations TP5 and TP8. Measurements with the charged

plate monitor should be made at test locations TP1 through TP12 as shown in Figure 13.

6.3.7 Discharge time as described in Clause 6, point a), should be measured at each test

location.

6.3.8 Offset voltage as described in Clause 6, points b) and e) should be determined at

each test location. Offset voltage shall be measured after a period of at least 1 min, or as

necessary to allow the reading to stabilize (5 min maximum).

6.4 Compressed gas ionizers – Guns and nozzles

6.4.1 The test should be performed on a surface that does not contain obstructions to

airflow. Unless otherwise specified, the test surface should be static dissipative or conductive

and properly grounded.

6.4.2 The test technician should be properly grounded.

6.4.3 Discharge time from a 1 000 V initial voltage to a 100 V final voltage shall be

measured for both positive (+) and negative (-) polarities.

6.4.4 Unless otherwise specified, the input pressure should be 30 psig (pounds per square

inch gauge). End users should test compressed gas ionizers in the same configuration of

input pressure and distance that they intend to use.

6.4.5 The tests should be performed using the test set-up shown in Figure 15.

6.4.6 Discharge time as described in Clause 6, point a), should be measured at the test

location.

6.4.7 Offset voltage as described in Clause 6, points b) and e) should be determined at the

test location. Offset voltage shall be measured after a period of at least 10 s or as necessary

to allow the reading to stabilize (1 min maximum).

61340-4-7 IEC:2010 – 13 –

Probe

See NOTE

Switch

Conductive plate

Insulator

Grounded surface

Ground

High voltage

power supply-

current limited

Noncontacting

voltmeter or

electrometer

Discharge timer

IEC 2591/09

NOTE See Figure 2.

Figure 1 – Charged plate monitor (CPM) components

15 cm × 15 cm (6″ × 6″)

Conductive plate

Dimension A

Insulator

Grounded surface

Ground

IEC 2592/09

NOTE Grounded surface should be ≥ 15 cm (6“) square.

Figure 2 – Charged plate detail

– 14 – 61340-4-7 IEC:2010

(or)

Charged plate

DC bars AC grids

TP1

TP2

IEC 2593/09

NOTE 1 Example for AC grids (less than 100 % coverage) and pulsed or steady-state DC bars.

NOTE 2 TP1 is directly under grid or bar while TP2 is centered between grids or bars.

Figure 3 – Test locations for room ionization – AC grids and DC bar systems

Charged plate

Emitter

E

E

TP1

TP3

E

E

TP2

IEC 2594/09

NOTE Three measurement locations required.

Figure 4 – Test locations for room ionization – Single polarity emitter systems

61340-4-7 IEC:2010 – 15 –

Charged plate

Emitter

E E E

TP1 TP2

TP3

E E E

IEC 2595/09

NOTE Three measurement locations required.

Figure 5 – Test locations for room ionization – Dual DC line systems

Charged plate Emitter

E E

TP1

TP2

E

IEC 2596/09

NOTE Two measurement locations required.

Figure 6 – Test locations for room ionization – Pulsed DC emitter systems

– 16 – 61340-4-7 IEC:2010

15 cm 15 cm

(6″) (6″)

15 cm

Rear

(6″)

TP6 TP7

TP3

TP4 TP5

Center line

of test points

Charged plate

TP1

TP8

TP2

Front edge

Center line

of test points

IEC 2597/09

NOTE Eight measurement locations required.

Figure 7 – Test locations for vertical laminar flow hood – Top view

HEPA filter

Ionizing grid

(or)

Ionizing bar

Air flow

60 cm

(24″)

Charged plate

15 cm

(6″)

IEC 2598/09

Figure 8 – Vertical laminar flow hood – Side view

61340-4-7 IEC:2010 – 17 –

15 cm 15 cm

(6″) (6″)

Rear

HEPA filter

Ionizing bar or grid

Air flow

38 cm

(15″)

TP3 TP4 TP5

Charged plate

TP1 TP6 TP2

Front edge

Center line

of test points

IEC 2599/09

NOTE Six measurement locations required.

Figure 9 – Test locations for horizontal laminar flow hood – Top view

38 cm

(15″)

HEPA filter

Charged plate

Ionizing grid

(or)

Air flow

Ionizing bar

15 cm

(6″)

IEC 2600/09

Figure 10 – Horizontal laminar flow hood – Side view

– 18 – 61340-4-7 IEC:2010

30 cm 30 cm 30 cm 30 cm

(12″) (12″) (12″) (12″)

TP1 TP4 TP7 TP10

30 cm

(12″)

Bench top

ionizer

TP2 TP5 TP8 TP11

Air flow

30 cm

(12″)

TP3 TP6 TP9 TP12

Charged plate

IEC 2601/09

NOTE Twelve measurement locations required.

Figure 11 – Test locations for benchtop ionizer – Top view

Charged plate

Bench top

ionizer

Air flow

15 cm

(6″)

IEC 2602/09

Figure 12 – Benchtop ionizer – Side view

61340-4-7 IEC:2010 – 19 –

Overhead ionizer centered

above test area

40 cm 40 cm 40 cm

(16″) (16″) (16″)

TP1 TP4 TP7 TP10

30 cm

(12″)

TP2

TP5 TP8 TP11

30 cm

(12″)

TP3 TP6

TP9 TP12

Charged plate

IEC 2603/09

NOTE Twelve measurement locations required.

Figure 13 – Test locations for overhead ionizer – Top view

Center line

of test points

60 cm

(24″)

Overhead ionizer

Air flow

45 cm

(18″)

Charged plate

15 cm

(6″)

IEC 2604/09

Figure 14 – Overhead ionizer – Side view

– 20 – 61340-4-7 IEC:2010

15 cm

(6″)

Compressed gas ionizer

Charged plate

(gun or nozzle)

Gas flow

15 cm

(6″)

IEC 2605/09

NOTE One measurement location required.

Figure 15 – Test locations for compressed gas ionizer (gun or nozzle) – Side view

61340-4-7 IEC:2010 – 21 –

Annex A

(informative)

Standard test method for the performance of ionizers

The field from static charges, located on insulators or isolated conductors, may be neutralized

by oppositely charged air ions depositing on the charged bodies.

A.1 Air Ions

Air ions are molecular clusters consisting of about ten molecules (often water) around a

(singly) charged oxygen or nitrogen molecule. Normally, relatively few ions are present in the

air. Typically, the number is less than 1 000 per cm . These "natural" ions are usually formed

by radiation from radioactive materials in the air, in the ground or in building materials.

For neutralization purposes, much higher ion concentrations are needed. Although

radioactivity may also be employed in such situations, the most common ion production

method is by collision between neutral molecules and electrons accelerated in an electric field

with field strengths exceeding 3 MV/m (at atmospheric pressure). This is generally referred to

as high voltage corona ionization.

A.2 Mobility and ion current

If an ion is exposed to an electric field E, it will move with an average drift velocity (v)

proportional to E, i.e.

v = kE (A.1)

where k = the mobility of the ion.

–4 2 –1 –1 2

Ordinary air ions have mobilities in the range of 1 to 2 × 10 m V s (meter per volt-

second).

If the air has a concentration n of positive ions with the mobility k, and charge e, an electric

field E will cause an electric current to flow in the direction of E with the density j.

j = enkE = λ E (A.2)

The constant λ (enk) is called the positive conductivity of the air (or more precisely, the polar

conductivity due to the positive ions). Negative ions will move in the opposite direction of the

field, but Equation (A.2) can still be used to calculate the current density from negative ions,

when e is taken as the numerical value of the ion charge. The current density from negative

ions will thus also be in the direction of the field.

A.3 Neutralization current

If a body completely surrounded by ionized air is given a charge q, an electric field is

established around the body and charges will flow toward it and away from it. The field will

vary from point to point, but is always proportional to the charge q. The current towards the

body is carried by the ions of polarity opposite to that of q, and is known as the neutralization

current. The neutralization current is proportional to the charge q and to the relevant opposite

conductivity of the surrounding air.

– 22 – 61340-4-7 IEC:2010

A.4 Neutralization rate

If the conductivity does not change, the relative rate of charge neutralization is constant and

the charge will decay exponentially with a time constant τ equal to the permittivity of the air e

o

divided by the conductivity λ.

τ = e /λ (A.3)

o

It should be noted that it is the conductivity, not the ion concentration itself, that determines

the neutralizing ability of the air. If the particle concentration of the air is increased, by smoke