IEC 61189-2:2006

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2: Test methods for materials for interconnection structures

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2: Test methods for materials for interconnection structures

Provides a catalogue of test methods representing methodologies and procedures that can be applied to test materials used for manufacturing interconnection structures (printed boards) and assemblies.

General Information

- Status

- Published

- Publication Date

- 29-May-2006

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-May-2006

- Completion Date

- 31-Jan-2006

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61189-2:2006 is an International Electrotechnical Commission (IEC) standard that catalogs test methods for materials used in interconnection structures, including printed boards (PCBs), laminates and related assembly materials. Part 2 of the IEC 61189 series provides standardized methodologies and procedures to evaluate chemical, mechanical, electrical and environmental properties of materials used in manufacturing interconnection structures.

Key topics

The standard groups test methods into clearly defined categories and includes guidance on measurement quality and reporting:

- Preparation/conditioning (P) - sample conditioning and pre-tests.

- Visual (V) and Dimensional (D) - thickness, rectangularity, dimensional stability.

- Chemical (C) - resin content, gel time of prepregs, volatile content, total halogen content, flammability (vertical/horizontal/flex), UV blocking and corrosion/blistering checks.

- Mechanical (M) - peel and pull-off strength, bow/twist, flexural and rolling fatigue, resin flow, glass transition (DSC/TMA), time-to-delamination.

- Electrical (E) - surface/volume resistivity, dielectric breakdown, comparative tracking index (CTI), permittivity/dissipation, arc resistance, insulation resistance.

- Environmental (N) - water absorption, pressure cooker / accelerated ageing (as applicable).

- Miscellaneous (X) - additional dimensional and process-related checks.

The document also addresses accuracy, precision, resolution and uncertainty limits, provides Student’s t distribution guidance, and contains informative annexes with worked examples, conversion tables and laboratory pro forma forms.

Practical applications

IEC 61189-2 is used to:

- Verify raw material compliance during PCB laminate and prepreg qualification.

- Establish supplier quality control and incoming inspection criteria for PCB materials procurement.

- Support failure analysis and reliability testing for electronics manufacturing and assemblies.

- Define laboratory test procedures for independent test houses and R&D teams validating new materials or process changes.

- Provide test method references in product specifications and regulatory submissions where material performance must be demonstrated.

Typical users: PCB manufacturers, laminate/prepreg suppliers, electronics OEMs, contract manufacturers, independent test labs, materials engineers and quality managers.

Related standards

- Part of the IEC 61189 series (test methods for electrical materials and printed boards).

- Complements other PCB/assembly standards that specify performance or safety requirements (refer to IEC catalogue for cross-references).

By standardizing test procedures such as peel strength, glass transition (Tg by DSC/TMA), flammability and resistivity, IEC 61189-2:2006 helps ensure consistent, reproducible evaluation of materials critical to reliable interconnection structures and printed circuit board manufacturing.

Frequently Asked Questions

IEC 61189-2:2006 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 2: Test methods for materials for interconnection structures". This standard covers: Provides a catalogue of test methods representing methodologies and procedures that can be applied to test materials used for manufacturing interconnection structures (printed boards) and assemblies.

Provides a catalogue of test methods representing methodologies and procedures that can be applied to test materials used for manufacturing interconnection structures (printed boards) and assemblies.

IEC 61189-2:2006 is classified under the following ICS (International Classification for Standards) categories: 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-2:2006 has the following relationships with other standards: It is inter standard links to IEC 61189-2:1997, IEC 61189-2:1997/AMD1:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61189-2:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61189-2

Second edition

2006-05

Test methods for electrical materials, printed

boards and other interconnection structures

and assemblies –

Part 2:

Test methods for materials

for interconnection structures

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61189-2

Second edition

2006-05

Test methods for electrical materials, printed

boards and other interconnection structures

and assemblies –

Part 2:

Test methods for materials

for interconnection structures

IEC 2006 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale XF

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 61189-2 IEC:2006(E)

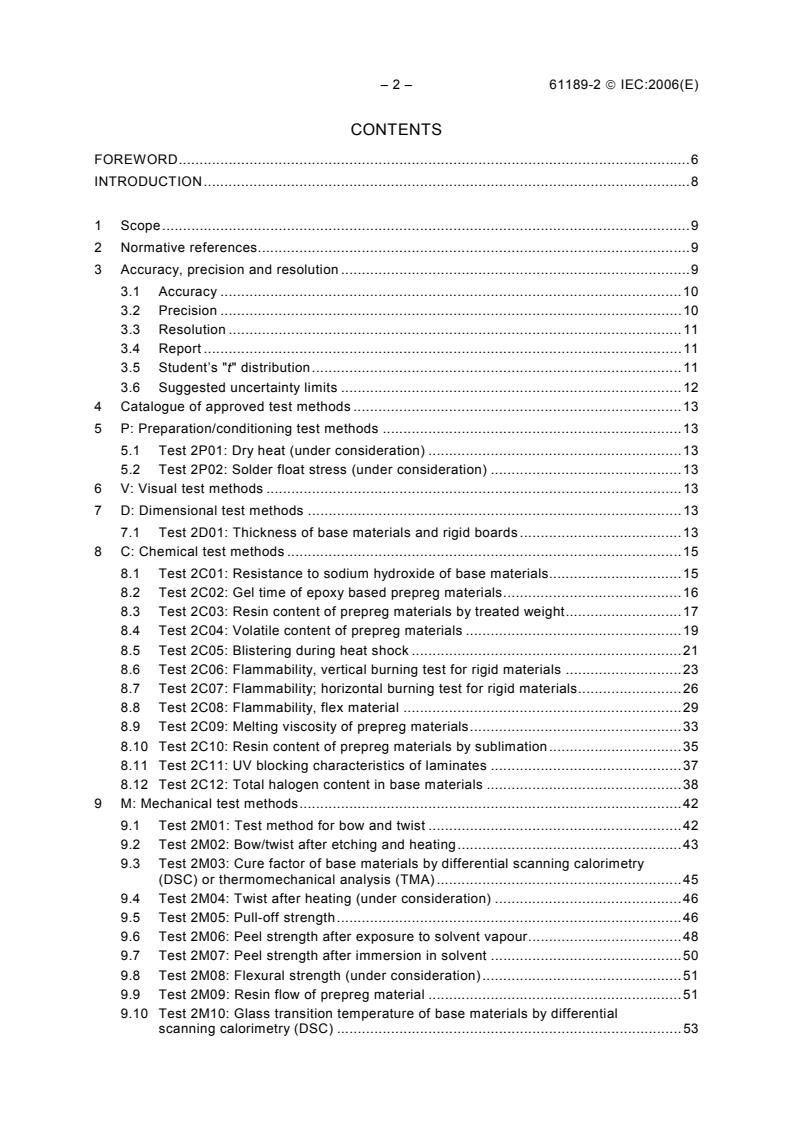

CONTENTS

FOREWORD.6

INTRODUCTION.8

1 Scope.9

2 Normative references.9

3 Accuracy, precision and resolution .9

3.1 Accuracy .10

3.2 Precision .10

3.3 Resolution .11

3.4 Report .11

3.5 Student’s "t" distribution.11

3.6 Suggested uncertainty limits .12

4 Catalogue of approved test methods .13

5 P: Preparation/conditioning test methods .13

5.1 Test 2P01: Dry heat (under consideration) .13

5.2 Test 2P02: Solder float stress (under consideration) .13

6 V: Visual test methods .13

7 D: Dimensional test methods .13

7.1 Test 2D01: Thickness of base materials and rigid boards .13

8 C: Chemical test methods .15

8.1 Test 2C01: Resistance to sodium hydroxide of base materials.15

8.2 Test 2C02: Gel time of epoxy based prepreg materials.16

8.3 Test 2C03: Resin content of prepreg materials by treated weight.17

8.4 Test 2C04: Volatile content of prepreg materials .19

8.5 Test 2C05: Blistering during heat shock .21

8.6 Test 2C06: Flammability, vertical burning test for rigid materials .23

8.7 Test 2C07: Flammability; horizontal burning test for rigid materials.26

8.8 Test 2C08: Flammability, flex material .29

8.9 Test 2C09: Melting viscosity of prepreg materials.33

8.10 Test 2C10: Resin content of prepreg materials by sublimation.35

8.11 Test 2C11: UV blocking characteristics of laminates .37

8.12 Test 2C12: Total halogen content in base materials .38

9 M: Mechanical test methods.42

9.1 Test 2M01: Test method for bow and twist .42

9.2 Test 2M02: Bow/twist after etching and heating.43

9.3 Test 2M03: Cure factor of base materials by differential scanning calorimetry

(DSC) or thermomechanical analysis (TMA) .45

9.4 Test 2M04: Twist after heating (under consideration) .46

9.5 Test 2M05: Pull-off strength.46

9.6 Test 2M06: Peel strength after exposure to solvent vapour.48

9.7 Test 2M07: Peel strength after immersion in solvent .50

9.8 Test 2M08: Flexural strength (under consideration).51

9.9 Test 2M09: Resin flow of prepreg material .51

9.10 Test 2M10: Glass transition temperature of base materials by differential

scanning calorimetry (DSC) .53

61189-2 IEC:2006(E) – 3 –

9.11 Test 2M11: Glass transition temperature of base materials by

thermomechanical analysis (TMA) .55

9.12 Test 2M12: Surface waviness .58

9.13 Test 2M13: Peel strength as received .59

9.14 Test 2M14: Peel strength after heat shock .60

9.15 Test 2M15: Peel strength after dry heat.63

9.16 Test 2M16: Peel strength after simulated plating .64

9.17 Test 2M17: Peel strength at high temperature .66

9.18 Test 2M18: Surface quality (under consideration).68

9.19 Test 2M19: Punching (under consideration) .68

9.20 Test 2M20: Flexural strength .68

9.21 Test 2M21: Rolling fatigue of flexible base materials .69

9.22 Test 2M22: Weight of foil after lamination .71

9.23 Test method 2M23: Rectangularity of cut panels .73

9.24 Test 2M24: Coefficient of thermal expansion (under consideration) .74

9.25 Test 2M25: Time to delamination by thermomechanical analysis (TMA).74

9.26 Test 2M26: Scaled flow test for prepreg materials .75

9.27 Test 2M27: The resin flow properties of coverlay films, bonding films and

adhesive cast films used in the fabrication of flexible printed boards .78

10 Electrical test methods.83

10.1 Test 2E01: Surface tracking, moisture condition (under consideration) .83

10.2 Test 10.2 2E02: Dielectric breakdown of base materials parallel to

laminations .83

10.3 Test 2E03: Surface resistance after damp heat, steady state .85

10.4 Test 2E04: Volume resistivity and surface resistivity.90

10.5 Test 2E05: Permittivity and dielectric dissipation (under consideration).94

10.6 Test 2E06: Volume and surface resistivity, 3 electrodes (under consideration).94

10.7 Test 2E07: Surface and volume resistivity, elevated temperature (under

consideration).94

10.8 Test 2E08: Surface corrosion.94

10.9 Test 2E09: Comparative tracking index (CTI) .96

10.10 Test 2E10: Permittivity and dissipation factor (under consideration). 100

10.11 Test 2E11: Electric strength (under consideration) . 100

10.12 Test 2E12: Resistance of foil (under consideration). 100

10.13 Test 2E13: Corrosion at edge (under consideration). 100

10.14 Test 2E14: Arc resistance. 100

10.15 Test 2E15: Dielectric break-down (under consideration) . 104

10.16 Test 2E16: Contact resistance of printed circuit keypad cont (under

consideration). 104

10.17 Test 2E17: Insulation resistance of printed board materials . 104

10.18 Test 2E18: Fungus resistance of printed board materials . 105

11 N: Environmental test methods . 109

11.1 Test 2N01: Pressure cooker test (under consideration) . 109

11.2 Test 2N02: Water absorption . 109

12 X: Miscellaneous test methods. 110

12.1 Test 2X02: Dimensional stability of thin laminates . 110

– 4 – 61189-2 IEC:2006(E)

Annex A (informative) Worked examples . 114

Annex B (informative) Conversion table. 116

Annex C (informative) Laboratory pro forma (form) . 121

Annex D (informative) Laboratory pro forma . 122

Figure 1 – Thickness measuring points.14

Figure 2 – Position of specimens.20

Figure 3 – Fluidized sand bath.22

Figure 4 – Test fixture .28

Figure 5 – V method (Vertical flammability method) .32

Figure 6 – VTM method (vertical flammability method for recaltrant specimens).32

Figure 7 – Example of prepreg melting viscosity .35

Figure 8 – Position of specimens for resin content.36

Figure 9 – Absorption of combustion gas using a combustion flask set-up.40

Figure 10 – Composition of ion exchange chromatograph .40

Figure 11 – Specimen for peel strength measurement .49

Figure 12 – Differential scanning calorimetry .54

Figure 13 – Thermomechanical analysis (expansion mode) .57

Figure 14 – Test specimen pattern .70

Figure 15 – General arrangement of apparatus.70

Figure 16 – Scaled flow test specimen before lamination .77

Figure 17 – Scaled flow test specimen measurement points .77

Figure 18 – Test patterns for clearance filling test.79

Figure 19 – Punched test pattern for squeeze-out test .80

Figure 20 – Standard lay-up of materials in the press to prepare the test specimens for

referee tests .81

Figure 21 – Profiles of press conditions to prepare the test specimens for referee tests .82

Figure 22 – Measurement of volume resistance.89

Figure 23 – Measurement of surface resistance.89

Figure 25 – Electrode connections for measuring volume resistance.93

Figure 26 – Electrode connections for measuring surface resistance .93

Figure 27 – Ring and disk pattern.95

Figure 28 – Comb pattern.96

Figure 31 – Example of test apparatus .98

Figure 32 – Example of test circuit .98

Figure 33 – Arc-resistance test circuit. 101

Figure 34 – Tungsten steel rod electrode assembly . 102

Figure 35 – Test specimen for insulation resistance. 104

Figure 36 – Location of specimens on original sheet for dimensional stability test . 111

Figure 37 – Location of marks on specimen for dimensional stability. 112

61189-2 IEC:2006(E) – 5 –

Table 1 – Student’s "t" distribution.12

Table 2 – Example of analysing conditions for the ion exchange chromatography .41

Table 3 – Specimen dimensions .68

Table 4 – Number of plies per specimen as a function of glass thickness.76

Table 6 – Specimen dimension (cm).86

Table 7 – Test pattern dimensions.91

Table 8 – Arc resistance. 103

– 6 – 61189-2 IEC:2006(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 2: Test methods for materials for interconnection structures

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61189-2 has been prepared by IEC technical committee 91: Surface

mounting technology, in cooperation with technical committee 52: Printed circuits (now

disbanded), and technical committee 50: Environmental testing.

This second edition replaces the first edition, published in 1997, and its Amendment 1 (2000).

It constitutes a technical revision.

The document 91/564/FDIS, circulated to the National Committees as Amendment 2, led to the

publication of this new edition.

61189-2 IEC:2006(E) – 7 –

The text of this standard is based on the first edition, its amendment 1 and on the following

documents:

FDIS Report on voting

91/564/FDIS 91/572/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The significant technical changes with respect to the previous edition concern the addition of

several new tests in the following categories:

− C: Chemical test methods

− D: Dimensional test methods:

− E: Electrical test methods

− M: Mechanical test methods

− N: Environmental test methods

− X: Miscellaneous test methods

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This standard forms part of a series and should be used in conjunction with other parts in the

same series, all under the main title Test methods for electrical materials, interconnection

structures and assemblies:

Part 1: General test methods and methodology

Part 2: Test methods for materials for interconnection structures

Part 3: Test methods for interconnection structures (printed boards)

Part 4: Test methods for electronic components assembling characteristics

Part 5: Test methods for printed board assemblies

Part 6: Test methods for materials used in electronic assemblies

It should also be read in conjunction with IEC 60068: Environmental testing.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

___________

Under consideration.

– 8 – 61189-2 IEC:2006(E)

INTRODUCTION

IEC 61189 relates to test methods for printed boards and printed board assemblies, as well as

related materials or component robustness, irrespective of their method of manufacture.

The standard is divided into separate parts, covering information for the designer and the test

methodology engineer or technician. Each part has a specific focus; methods are grouped

according to their application and numbered sequentially as they are developed and released.

In some instances test methods developed by other TCs (e.g. TC 50) have been reproduced

from existing IEC standards in order to provide the reader with a comprehensive set of test

methods. When this situation occurs, it will be noted on the specific test method; if the test

method is reproduced with minor revision, those paragraphs that are different are identified.

This part of IEC 61189 contains test methods for materials used to produce interconnection

structures (printed boards) and electronic assemblies. The methods are self-contained, with

sufficient detail and description so as to achieve uniformity and reproducibility in the

procedures and test methodologies.

The tests shown in this standard are grouped according to the following principles:

P: preparation/conditioning methods

V: visual test methods

D: dimensional test methods

C: chemical test methods

M: mechanical test methods

E: electrical test methods

N: environmental test methods

X: miscellaneous test methods

To facilitate reference to the tests, to retain consistency of presentation, and to provide for

future expansion, each test is identified by a number (assigned sequentially) added to the

prefix (group code) letter showing the group to which the test method belongs.

The test method numbers have no significance with respect to an eventual test sequence; that

responsibility rests with the relevant specification that calls for the method being performed.

The relevant specification, in most instances, also describes pass/fail criteria.

The letter and number combinations are for reference purposes, to be used by the relevant

specification. Thus "2D01" represents the first dimensional test method described in this

publication.

In short, for this example, 2 is the part of IEC standard (61189-2), D is the group of methods,

and 01 is the test number.

A list of all test methods included in this standard, as well as those under consideration is given

in Annex B. This annex will be reissued whenever new tests are introduced.

61189-2 IEC:2006(E) – 9 –

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 2: Test methods for materials for interconnection structures

1 Scope

This part of IEC 61189 provides a catalogue of test methods representing methodologies and

procedures that can be applied to test materials used for manufacturing interconnection

structures (printed boards) and assemblies.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

IEC 60068-2-2:1974, Environmental testing – Part 2: Tests – Tests B: Dry heat

IEC 60068-2-78:2001, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60093:1980, Methods of test for volume resistivity and surface resistivity of solid electrical

insulating materials

IEC 60243-1:1998, Electrical strength of insulating materials – Test methods: Tests at power

frequencies

IEC 61189-3:1997, Test methods for electrical materials, interconnection structures and

assemblies – Part 3: Test methods for interconnection structures (printed boards)

ISO 3274:1996, Geometrical Products Specifications (GPS) – Surface texture: Profile method –

Nominal characteristics of contact (stylus) instruments

ISO 9001:2000, Quality systems – Model for quality assurance in production, installation and

servicing

ANSI/UL-94:1993, Standard for tests for flammability of plastic materials for parts in devices

and appliances, Tests for

3 Accuracy, precision and resolution

Errors and uncertainties are inherent in all measurement processes. The information given

below enables valid estimates of the amount of error and uncertainty to be taken into account.

Test data serve a number of purposes which include:

– monitoring a process;

– enhancing confidence in quality conformance;

– arbitrating between customer and supplier.

– 10 – 61189-2 IEC:2006(E)

In any of these circumstances, it is essential that confidence can be placed upon the test data

in terms of:

– accuracy: calibration of the test instruments and/or system;

– precision: the repeatability and uncertainty of the measurement;

– resolution: the suitability of the instruments and/or system for the test.

3.1 Accuracy

The regime by which routine calibration of the test equipment is undertaken shall be clearly

stated in the quality documentation of the supplier or agency conducting the test, and shall

meet the requirements of ISO 9001:2000.

The calibration shall be conducted by an agency having accreditation to a national or

international measurement standard institute. There should be an uninterrupted chain of

calibration to a national or international standard.

Where calibration to a national or international standard is not possible, round robin techniques

may be used, and documented, to enhance confidence in measurement accuracy.

The calibration interval shall normally be one year. Equipment consistently found to be outside

acceptable limits of accuracy shall be subject to shortened calibration intervals. Equipment

consistently found to be well within acceptable limits may be subject to relaxed calibration

intervals.

A record of the calibration and maintenance history shall be maintained for each instrument.

These records should state the uncertainty of the calibration technique (in ± % deviation) in

order that uncertainties of measurement can be aggregated and determined.

A procedure shall be implemented to resolve any situation where an instrument is found to be

outside calibration limits.

3.2 Precision

The uncertainty budget of any measurement technique is made up of both systematic and

random uncertainties. All estimates shall be based upon a single confidence level, the

minimum being 95 %.

Systematic uncertainties are usually the predominant contributor, and will include all

uncertainties not subject to random fluctuation. These include:

– calibration uncertainties;

– errors due to the use of an instrument under conditions which differ from those under which

it was calibrated;

– errors in the graduation of a scale of an analogue meter (scale shape error).

Random uncertainties result from numerous sources but can be deduced from repeated

measurement of a standard item. Therefore, it is not necessary to isolate the individual

contributions. These may include:

– random fluctuations such as those due to the variation of an influence parameter. Typically,

changes in atmospheric conditions reduce the repeatability of a measurement;

– uncertainty in discrimination, such as setting a pointer to a fiducial mark, or interpolating

between graduations on an analogue scale.

61189-2 IEC:2006(E) – 11 –

Aggregation of uncertainties: Geometric addition (root-sum-square) of uncertainties may be

used in most cases. Interpolation error is normally added separately and may be accepted as

being 20 % of the difference between the finest graduations of the scale of the instrument.

2 2

U = ± (U + U ) + U

t s r i

where

U is the total uncertainty

t

U is the systematic uncertainty

s

U is the random uncertainty

r

U is the interpolation error

i

Determination of random uncertainties: Random uncertainty can be determined by repeated

measurement of a parameter, and subsequent statistical manipulation of the measured data.

The technique assumes that the data exhibits a normal (Gaussian) distribution.

t ×σ

U =

r

n

where

U is random uncertainty

r

n is the sample size

t is the percentage point of the “t” distribution (from 3.5), statistical tables

σ is the standard deviation (σ )

n-1

3.3 Resolution

It is paramount that the test equipment used is capable of sufficient resolution. Measurement

systems used should be capable of resolving 10 % (or better) of the test limit tolerance.

It is accepted that some technologies will place a physical limitation upon resolution (e.g.

optical resolution)

3.4 Report

In addition to requirements detailed in the test specification, the report shall detail:

– the test method number and revision;

– the identity of the sample(s);

– the test instrumentation;

– the specified limit(s);

– an estimate of measurement uncertainty, and resultant working limit(s) for the test;

– the detailed test results;

– the test date, and operators’ signature.

3.5 Student’s "t" distribution

Table 1 gives values of the factor "t" for 95 % and 99 % confidence levels, as a function of the

number of measurements. It is sufficient to use 95 % limits, as in the case of the worked

examples shown in Annex A.

– 12 – 61189-2 IEC:2006(E)

Table 1 – Student’s "t" distribution

Sample t value t value Sample t value t value

size 95 % 99 % size 95 % 99 %

2 12,7 63,7 14 2,16 3,01

3 4,3 9,92 15 2,14 2,98

4 3,18 5,84 16 2,13 2,95

5 2,78 4,6 17 2,12 2,92

6 2,57 4,03 18 2,11 2,9

7 2,45 3,71 19 2,1 2,88

8 2,36 3,5 20 2,09 2,86

9 2,31 3,36 21 2,08 2,83

10 2,26 3,25 22 2,075 2,82

11 2,23 3,17 23 2,07 2,81

12 2,2 3,11 24 2,065 2,8

13 2,18 3,05 25 2,06 2,79

3.6 Suggested uncertainty limits

The following target uncertainties are suggested:

a) Voltage < 1 kV: ± 1,5 %

b) Voltage > 1 kV: ± 2,5 %

c) Current < 20 A: ± 1,5 %

d) Current > 20 A: ± 2,5 %

Resistance

e) Earth and continuity: ± 10 %

f) Insulation: ± 10 %

g) Frequency: ± 0,2 %

Time

± 1 s

h) Interval < 60 s:

i) Interval > 60 s: ± 2 %

j) Mass < 10 g: ± 0,5 %

k) Mass 10 g to 100 g: ± 1 %

l) Mass > 100 g: ± 2 %

m) Force: ± 2 %

n) Dimension < 25 mm: ± 0,5 %

o) Dimension > 25 mm: ± 0,1 mm

p) Temperature < 100 °C: ± 1,5 %

q) Temperature > 100 °C: ± 3,5 %

r) Humidity 30 to 75 % RH: ± 5 % RH

Plating thicknesses

s) Backscatter method: ± 10 %

t) Microsection: ± 2 µm

u) Ionic contamination: ± 10 %

61189-2 IEC:2006(E) – 13 –

4 Catalogue of approved test methods

This standard provides specific test methods in complete detail to permit implementation with

minimal cross-referencing to other specific procedures. The use of generic conditioning

exposures is accomplished in the methods by reference, for example IEC 61189-1 and

IEC 60068, and when applicable, is a mandatory part of the test method standard.

Each method has its own title, number and revision status to accommodate updating and

improving the methods as industry requirements change or demand new methodology. The

methods are organized in test method groups and individual tests.

5 P: Preparation/conditioning test methods

5.1 Test 2P01: Dry heat (under consideration)

5.2 Test 2P02: Solder float stress (under consideration)

6 V: Visual test methods

7 D: Dimensional test methods

7.1 Test 2D01: Thickness of base materials and rigid boards

7.1.1 Object

This test method covers the procedure for the determination of the thickness of base materials,

clad or unclad.

7.1.2 Test specimens

Standard sheet sizes of metal-clad or unclad base materials.

Standard panel sizes of metal-clad or unclad base materials.

7.1.3 Test apparatus and material

A suitable micrometer having a resolution of 0,01 mm or better shall be used.

7.1.4 Procedure

a) General conditions

– Test specimens shall be placed between the two faces of the micrometer, so that the

whole face of the pressure-foot will fall within the area of the material. The pressure-foot

shall be lowered gently, slowly and with great care onto the test specimen so that all

punching effect is avoided.

– No stress shall be imposed by hand on the instrument or the material when a reading is

being taken. The reading shall be taken as soon as the pointer has ceased to move. It

is necessary to take care in avoiding parallax errors and vibrations which may

significantly affect the results.

b) Method 1

– This procedure is intended for the thickness measurement of the sheets of metal-clad

or unclad base materials.

– The specimen shall be held vertically or horizontally.

– 14 – 61189-2 IEC:2006(E)

– Thickness to the nearest 0,01 mm at two points 25 mm or more inside each edge, at

eight points, and additionally at two points in the middle parts, so that a total of

10 points, shall be measured as shown in Figure 1.

– The measurement shall be made twice at each point and the mean value shall be

determined as the thickness of each point.

– For automatic thickness inspection, continuous measuring shall be performed in three

measuring tracks parallel to the longitudinal axis of the sheet, two at least 25 mm from

the longitudinal edges and the third near the midline.

25 min.

Measuring

points

25 min.

IEC 1890/99

Figure 1 – Thickness measuring points

c) Method 2

– This procedure is intended for the thickness measurement of panels of metal-clad or

unclad base materials. The thickness of the specimens held vertically or horizontally

shall be measured at the places which are agreed between the interested parties.

7.1.5 Report

The report shall include:

a) the test method number and revision;

b) the date of the test;

c) the identification of the material tested;

d) a statement certifying that the test was carried out for as-received metal-clad or unclad

base materials;

e) the thicknesses measured and the nominal thickness with its tolerance;

f) any deviation from this test method;

g) the name of the person conducting the test.

7.1.6 Additional information

The use of a micrometer with a damping device, or controlled rate of movement of the

pressure-foot, is advantageous.

61189-2 IEC:2006(E) – 15 –

8 C: Chemical test methods

8.1 Test 2C01: Resistance to sodium hydroxide of base materials

8.1.1 Object

The purpose of this test method is to provide a procedure for determining the alkaline

resistance of base materials by exposure to a sodium hydroxide solution.

8.1.2 Test specimens

a) Specimens shall be taken from the panel or sheet in such a way that they are at least

25 mm from the edge of the sheet.

b) Specimens shall be prepared from a sample of metal-clad base material from which the

metal has been completely removed by any appropriate method reflecting usual practice.

c) Specimen size is (50 ± 2) mm in both length and width, and shall be cut out using a fine

saw to give the edges a smooth finish.

d) A minimum of three specimens shall be used.

8.1.3 Test apparatus and materials

The following test apparatus and materials shall be used:

a) an appropriate alkaline-proof container which contains an analytical grade sodium

hydroxide solution maintained at a temperature of (40 ± 2) °C at a concentration by weight

of (3 ± 0,2) %. In order to ensure that the concentration remains within the tolerance, the

solution must be prepared daily. The number of specimens tested per litre of solution shall

not be more than 50;

b) a rack to hold specimens upright in the container. The design of the rack shall allow

maximum exposure of the specimen surfaces to the solution;

c) a clean dry gauze, cloth or paper to wipe off the water from the specimen surfaces;

d) a fine blade saw for the sample preparation.

8.1.4 Procedure

Place the specimens in the rack then in the sodium hydroxide solution for 3 min ± 20 s.

Take the rack out of the sodium hydroxide solution and quickly rinse the specimens under

running water for a minimum of 5 min.

Wipe the water from the specimen surfaces completely with a clean dry gauze, cloth or paper.

Immediately make a visual check for colour change, swelling, blistering and/or delamination.

8.1.5 Report

The report shall include:

a) the test number and revision index;

b) the testing date;

c) the identification of the material tested;

d) the changes in surface appearance, if any;

e) any deviation from this test method.

– 16 – 61189-2 IEC:2006(E)

8.1.6 Additional information

Sodium hydroxide is a powerful alkaline chemical. It shall be handled with care, avoiding eye

and skin contact by wearing protective glasses and chemically resistant gloves.

8.2 Test 2C02: Gel time of epoxy based prepreg materials

8.2.1 Object

The purpose of this test method is to provide a means for determining the gel time of epoxide

resin impregnated reinforcement cured to the B-stage used in the manufacturing of laminate

and printed boards.

8.2.2 Test specimens

A number of pieces approximately 100 mm square or another convenient size, in order to yield

approximately 1 g of dry resin, shall be cut from areas uniformly distributed across the width of

the sheet or roll, but excluding the area within 25 mm of each edge or selvage.

8.2.3 Test apparatus and material

The following test apparatus and materials shall be used:

a) heating plate capable of maintaining a temperature of (170 ± 0,5) °C;

b) timer, capable of determining time within ± 1 s;

c) wooden stick, pointed, approximately 3 mm in diameter;

d) a measure of capacity for 0,3 g to 0,4 g resin powder;

e) sieve, 50 mesh per inch.

8.2.4 Procedure

Detach the dry resin from the prepreg (B-stage) by folding or crushing. Remove any glass fibre

present by sieving alternatively, in the case of materials too soft to detach dry resin by crushing,

the resin required may be obtained by pressing the folded stack of material in contact with the

heating plate and squeezing out the melted resin.

Remove any glass fibre present by sieving.

Adjust the heating plate or equivalent to 170 °C and allow to stabilize at that temperature.

Using the measure of capacity a quantity of 0,3 g to 0,4 g resin powder shall be taken.

Pour the measured dry resin in the form of a small cone on one spot of the heating plate and

start the timer immediately. If the alternative method given above is used, the timer shall be

started at that moment when the folded stack is brought in contact with the heating plate.

Stir the resin, using a wooden stick approximately 3 mm in diameter, holding the stick as near

vertical as possible and mixing the centre as well as the edges of the melted resin. While

stirring, the diameter of the pool of melting resin shall not exceed 25 mm.

At the approach of the gel point the resin becomes tacky and forms strings when pulling the

stick out. The gel point is reached when it no longer forms strings when pulling the stick out,

and is no longer tacky but still elastic. At this point, the timer is stopped and the elapsed time

measured in seconds is taken as the gel time. When used as a reference, three separate

measurements shall be carried out and the average recorded as gel time.

61189-2 IEC:2006(E) – 17 –

8.2.5 Report

The report shall include:

a) the test method number and revision index;

b) the testing date;

c) the identification of the material tested;

d) the gel time in seconds (average);

e) any deviation from this test method.

8.2.6 Additional information

The determination of gel time may also be carried

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...