IEC 60068-2-58:2004

(Main)Environmental testing - Part 2-58: Tests - Test Td: Test methods for solderability, resistance to dissolution of metallization and to soldering heat of surface mounting devices (SMD)

Environmental testing - Part 2-58: Tests - Test Td: Test methods for solderability, resistance to dissolution of metallization and to soldering heat of surface mounting devices (SMD)

This part of IEC 60068 outlines test Td, applicable to surface mounting devices (SMD), which are intended to mount on substrates. This standard provides the standard procedures for solder alloys containing lead (Pb) and for lead-free solder alloys. This standard provides standard procedures for determining the solderability and resistance of soldering heat to lead-free solder alloys. This standard provides standard procedures for determining the solderability, dissolution of metallization and resistance of soldering heat to solder alloys which are eutectic or near eutectic tin lead solders.

Essais d'environnement - Partie 2-58: Essais - Essai Td: Méthodes d'essai de la soudabilité, résistance de la métallisation à la dissolution et résistance à la chaleur de brasage des composants pour montage en surface (CMS)

La présente partie de la CEI 60068 décrit l'essai Td applicable aux composants pour montage en surface (CMS) qui sont destinés à être montés sur des substrats. La présente norme fournit les procédures normalisées pour les alliages de brasure contenant du plomb (Pb) et pour les alliages de brasure sans plomb. La présente norme fournit des procédures normalisées pour déterminer la brasabilité et la résistance à la chaleur de brasage des alliages de brasure sans plomb. La présente norme fournit des procédures normalisées pour déterminer la brasabilité, la dissolution de la métallisation et la résistance à la chaleur de brasage des alliages de brasure qui sont des brasures étain-plomb eutectiques ou quasi eutectiques.

General Information

- Status

- Published

- Publication Date

- 14-Jul-2004

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 3 - TC 91/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Mar-2015

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60068-2-58:2004 - Environmental testing, Part 2-58 (Test Td) - defines standard test methods for solderability, resistance to dissolution of metallization, and resistance to soldering heat for surface mounting devices (SMDs). The standard covers both lead-containing (Sn-Pb eutectic/near-eutectic) and lead‑free solder alloys, and specifies two primary methods: the solder bath (dipping) method and the reflow method. Its objective is to ensure SMD terminations meet solder joint requirements and can withstand process temperatures used in modern assembly.

Key topics and technical requirements

- Scope: Tests applicable to SMDs intended for mounting on substrates; includes procedures for leaded and lead‑free solders.

- Test methods:

- Solder bath method - applicable to SMDs for flow/dip soldering and, when appropriate, reflow-capable SMDs.

- Reflow method - applicable to SMDs for reflow soldering and for cases where dipping is inappropriate.

- Preconditioning: Specifies as‑received testing and options for accelerated ageing (referencing IEC 60068-2-20); special provisions for plastic‑encapsulated semiconductor SMDs per IEC 60749-20.

- Grouping of lead‑free processes: Clusters lead‑free alloys by typical process temperature ranges (examples include Sn‑Bi low-temp, Sn‑Ag‑Cu medium-high, etc.) to select appropriate test severities.

- Test parameters: Temperature profiles, dwell times, flux types, flux removal, recovery conditions and visual evaluation criteria (Annex A) are defined to determine wetting, metallization dissolution and heat resistance.

- Evaluation: Visual wetting criteria and final measurements guide pass/fail assessments; Annex C provides a quick overview of test conditions.

Applications and users

- Who uses it: component manufacturers, PCB assemblers, reliability/test laboratories, quality engineers, procurement/specification authors, and standards bodies.

- Practical uses:

- Qualifying SMD terminations for compatibility with specific soldering processes (reflow, wave/dip).

- Verifying suitability of SMDs for lead‑free transition and selecting appropriate solder alloys.

- Ensuring components meet solder joint requirements referenced in IEC 61191-2 and SMD specification rules in IEC 61760-1.

- Designing assembly process windows and failure analysis for solderability and solder‑heat damage.

Related standards

- IEC 60068-1 (general guidance)

- IEC 60068-2-20 (soldering tests)

- IEC 61191-2 (soldered assemblies requirements)

- IEC 61760-1 (SMD specification method)

- IEC 60749-20 (semiconductor SMD moisture/soldering heat)

- IEC 61190 series (solder and flux requirements)

Keywords: IEC 60068-2-58, solderability testing, SMD, lead-free solder, reflow profile, solder bath, resistance to soldering heat, dissolution of metallization.

Buy Documents

IEC 60068-2-58:2004 - Environmental testing - Part 2-58: Tests - Test Td: Test methods for solderability, resistance to dissolution of metallization and to soldering heat of surface mounting devices (SMD) Released:7/15/2004 Isbn:2831875382

IEC 60068-2-58:2004 - Environmental testing - Part 2-58: Tests - Test Td: Test methods for solderability, resistance to dissolution of metallization and to soldering heat of surface mounting devices (SMD) Released:7/15/2004 Isbn:283187842X

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-2-58:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-58: Tests - Test Td: Test methods for solderability, resistance to dissolution of metallization and to soldering heat of surface mounting devices (SMD)". This standard covers: This part of IEC 60068 outlines test Td, applicable to surface mounting devices (SMD), which are intended to mount on substrates. This standard provides the standard procedures for solder alloys containing lead (Pb) and for lead-free solder alloys. This standard provides standard procedures for determining the solderability and resistance of soldering heat to lead-free solder alloys. This standard provides standard procedures for determining the solderability, dissolution of metallization and resistance of soldering heat to solder alloys which are eutectic or near eutectic tin lead solders.

This part of IEC 60068 outlines test Td, applicable to surface mounting devices (SMD), which are intended to mount on substrates. This standard provides the standard procedures for solder alloys containing lead (Pb) and for lead-free solder alloys. This standard provides standard procedures for determining the solderability and resistance of soldering heat to lead-free solder alloys. This standard provides standard procedures for determining the solderability, dissolution of metallization and resistance of soldering heat to solder alloys which are eutectic or near eutectic tin lead solders.

IEC 60068-2-58:2004 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing; 31.190 - Electronic component assemblies. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-58:2004 has the following relationships with other standards: It is inter standard links to IEC 60068-2-58:1999, IEC 60068-2-58:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-2-58:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60068-2-58

Third edition

2004-07

Environmental testing –

Part 2-58:

Tests – Test Td:

Test methods for solderability, resistance to

dissolution of metallization and to soldering

heat of surface mounting devices (SMD)

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60068-2-58

Third edition

2004-07

Environmental testing –

Part 2-58:

Tests – Test Td:

Test methods for solderability, resistance to

dissolution of metallization and to soldering

heat of surface mounting devices (SMD)

© IEC 2004 ⎯ Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale T

International Electrotechnical Commission

ɆɟɠɞɭɧɚɪɨɞɧɚɹɗɥɟɤɬɪɨɬɟɯɧɢɱɟɫɤɚɹɄɨɦɢɫɫɢɹ

For price, see current catalogue

– 2 – 60068-2-58 © IEC:2004(E)

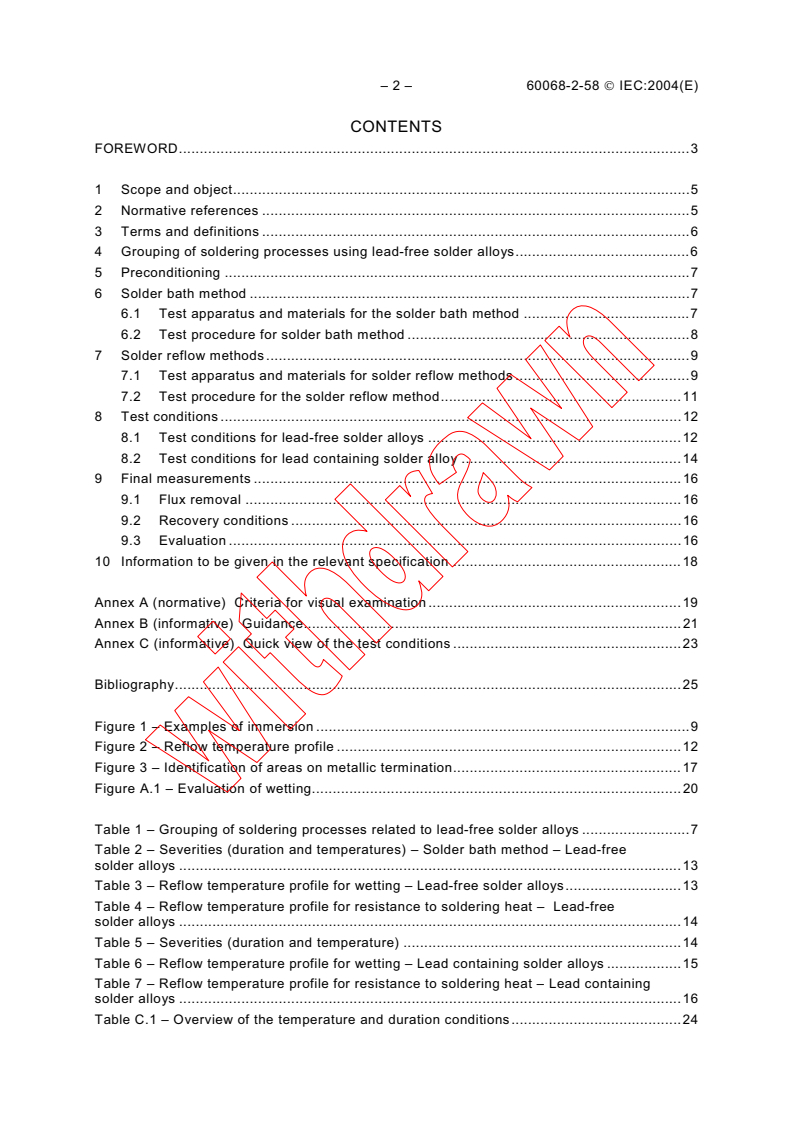

CONTENTS

FOREWORD.3

1 Scope and object.5

2 Normative references .5

3 Terms and definitions .6

4 Grouping of soldering processes using lead-free solder alloys.6

5 Preconditioning .7

6 Solder bath method .7

6.1 Test apparatus and materials for the solder bath method .7

6.2 Test procedure for solder bath method .8

7 Solder reflow methods .9

7.1 Test apparatus and materials for solder reflow methods .9

7.2 Test procedure for the solder reflow method.11

8 Test conditions .12

8.1 Test conditions for lead-free solder alloys .12

8.2 Test conditions for lead containing solder alloy .14

9 Final measurements .16

9.1 Flux removal .16

9.2 Recovery conditions .16

9.3 Evaluation .16

10 Information to be given in the relevant specification .18

Annex A (normative) Criteria for visual examination .19

Annex B (informative) Guidance.21

Annex C (informative) Quick view of the test conditions .23

Bibliography.25

Figure 1 – Examples of immersion .9

Figure 2 – Reflow temperature profile .12

Figure 3 – Identification of areas on metallic termination.17

Figure A.1 – Evaluation of wetting.20

Table 1 – Grouping of soldering processes related to lead-free solder alloys .7

Table 2 – Severities (duration and temperatures) – Solder bath method – Lead-free

solder alloys .13

Table 3 – Reflow temperature profile for wetting – Lead-free solder alloys.13

Table 4 – Reflow temperature profile for resistance to soldering heat – Lead-free

solder alloys .14

Table 5 – Severities (duration and temperature) .14

Table 6 – Reflow temperature profile for wetting – Lead containing solder alloys .15

Table 7 – Reflow temperature profile for resistance to soldering heat – Lead containing

solder alloys .16

Table C.1 – Overview of the temperature and duration conditions.24

60068-2-58 © IEC:2004(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-58: Tests – Test Td: Test methods for solderability,

resistance to dissolution of metallization and to

soldering heat of surface mounting devices (SMD)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-58 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This edition includes the following significant technical changes with respect to the previous

edition:

- expansion of the scope so that it includes lead-free solder alloy in addition to the existing

tin-lead eutectic or near eutectic solder alloy (the structure of the document has been

changed accordingly);

- addition of the definitions of "solderability" and "resistance to soldering heat" for SMDs;

- specification of the reflow temperature profiles for the resistance to soldering heat using

lead-free solder;

- addition of an Annex C enabling a quick overview of the test conditions.

– 4 – 60068-2-58 © IEC:2004(E)

The text of this standard is based on the following documents:

FDIS Report on voting

91/447/FDIS 91/459/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version may be issued at a later date.

60068-2-58 © IEC:2004(E) – 5 –

ENVIRONMENTAL TESTING –

Part 2-58: Tests – Test Td: Test methods for solderability,

resistance to dissolution of metallization and to

soldering heat of surface mounting devices (SMD)

1 Scope and object

This part of IEC 60068 outlines test Td, applicable to surface mounting devices (SMD), which

are intended to mount on substrates. This standard provides the standard procedures for

solder alloys containing lead (Pb) and for lead-free solder alloys.

This standard provides standard procedures for determining the solderability and resistance

of soldering heat to lead-free solder alloys.

This standard provides standard procedures for determining the solderability, dissolution of

metallization (see B.3.3) and resistance of soldering heat to solder alloys which are eutectic

or near eutectic tin lead solders.

The procedures in this standard include the solder bath method and reflow method. The

solder bath method is applicable to the SMD designed for flow soldering and the SMD

designed for reflow soldering when the solder bath (dipping) method is appropriate.

The reflow method is applicable to the SMD designed for reflow soldering, to determine the

suitability of SMD for reflow soldering and when the solder bath (dipping) method is not

appropriate.

The objective of this standard is to ensure that component lead or termination solderability

meets the applicable solder joint requirements of IEC 61191-2 using each of the soldering

methods specified in IEC 61760-1. In addition, test methods are provided to ensure that the

component body can resist against the heat load to which it is exposed during soldering.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

IEC 60068-2-20:1979, Environmental testing – Part 2: Tests – Test T: Soldering

IEC 60194:1999, Printed board design, manufacture and assembly – Terms and definitions

IEC 60749-20:2002, Semiconductor devices – Mechanical and climatic test methods –

Part 20: Resistance of plastic-encapsulated SMDs to the combined effect of moisture and

soldering heat

IEC 61190-1-1:2002, Attachment materials for electronic assembly – Part 1-1: Requirements

for soldering fluxes for high-quality interconnections in electronic assembly

IEC 61190-1-2:2002, Attachment materials for electronic assembly – Part 1-2: Requirements

for solder pastes for high-quality interconnections in electronic assembly

– 6 – 60068-2-58 © IEC:2004(E)

IEC 61190-1-3:2002, Attachment materials for electronic assembly – Part 1-3: Requirements

for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic

soldering applications

IEC 61191-2:1998, Printed board assemblies – Part 2: Sectional specification – Requirements

for surface mount soldered assemblies

IEC 61249-2-7:2002, Materials for printed boards and other interconnecting structures –

Part 2-7: Reinforced base materials clad and unclad – Epoxide woven E-glass laminated

sheet of defined flammability (vertical burning test), copper-clad

IEC 61760-1:1998, Surface mounting technology – Part 1: Standard method for the

specification of surface mounting components (SMDs)

3 Terms and definitions

For the purposes of this document, the terms and definitions as defined in IEC 60068-1,

IEC 60068-2-20, IEC 60194, as well as the following apply.

3.1

solderability

ability of the termination or electrode of SMD to be wetted by solder at the temperature of the

termination or electrode which is assumed to be the lowest temperature in the soldering

process within solderable temperature of solder alloy

3.2

resistance to soldering heat

ability of SMD to withstand the highest temperature of the termination or electrode in

soldering process, within applicable temperature range of solder alloy

4 Grouping of soldering processes using lead-free solder alloys

The melting temperatures of lead-free solder alloys selected currently for industrial processes

are significantly different from those for Sn-Pb solder alloy. Moreover, the melting

temperatures of lead-free solder alloys are different from each other but can be clustered in

groups.

According to the ability of the SMD to withstand the typical temperature and dwell time

conditions that match the exposure to the processes using the selected lead-free alloys, the

following groups of soldering processes outlined in Table 1 are given as a a guideline for

selecting the severities for the wetting and resistance tests against the specified soldering

heat:

60068-2-58 © IEC:2004(E) – 7 –

Table 1 – Grouping of soldering processes related to lead-free solder alloys

Typical process temperature

Alloys

Group

(examples)

Flow soldering Reflow soldering

--------- 170 °C – 210 °C Sn-Bi

Low temperature

Sn-Zn-Bi

--------- 210 °C – 235 °C

Medium

Sn-Zn

temperature

3 Sn-Ag

Medium-high 245 °C – 255 °C 235 °C – 250 °C Sn-Ag-Cu

temperature

Sn-Ag-Bi

250 °C – 260 °C --------- Sn-Cu

High temperature

NOTE 1 Flow soldering applies to both wave soldering and dip soldering.

NOTE 2 Typical process temperatures for flow soldering are identical to the solder temperature. Typical process

temperatures for reflow soldering are the terminal and top surface temperature of the SMDs.

NOTE 3 In Group 2 reflow soldering under inert atmosphere (e.g. nitrogen) is required.

NOTE 4 The basic solder alloys listed in this table represent compositions that are currently preferred for lead-

free soldering processes. However, other solder alloys when matching with the specified group should not be

excluded.

5 Preconditioning

5.1 The specimen shall be tested in the “as-received“ condition unless otherwise specified

by the relevant specification. Care should be taken that no contamination, by contact with the

fingers or by other means, occurs.

5.2 When accelerated ageing is prescribed by the relevant specification, one of the methods

of 4.5 of IEC 60068-2-20 shall be used or, when appropriate, 4 h/155 °C dry heat shall be

used.

5.3 The preconditioning and resistance to soldering heat test of semiconductor SMDs in

plastic encapsulation shall be done conform the test procedure as described in IEC 60749-20.

6 Solder bath method

6.1 Test apparatus and materials for the solder bath method

6.1.1 Solder bath

The solder bath dimensions shall comply with the requirements of 4.6.1 of IEC 60068-2-20.

The material of the solder bath container shall be resistant to the liquid solder alloy.

6.1.2 Flux

The flux shall consist of 25 % by weight of colophony in 75 % by weight of

2-propanol (isopropanol) or ethyl alcohol (as specified in Appendix C of IEC 60068-2-20).

Preferably the flux activity should conform with the “Low (0)” level, corresponding to a halide

content of <0,01 wt % (Cl, Br, F) (see IEC 61190-1-1). When non-activated flux is

inappropriate, the above flux with the addition of diethylammonium chloride (analytical

reagent grade), up to an amount of 0,5 % chloride (expressed as free chlorine based on the

colophony content), may be used. Information concerning the used flux type shall be given in

the product detail specification.

– 8 – 60068-2-58 © IEC:2004(E)

6.1.3 Solder

6.1.3.1 Lead-free solder alloys

When testing solderability, the solder composition shall be as defined in Table 2. For the

resistance to soldering heat test, any alloys may be used, provided they are completely liquid

at the required temperature.

6.1.3.2 Solder alloys containing lead

The solder composition shall be either 60 % tin and 40 % lead according to Annex B of

IEC 60068-2-20 (Sn60Pb40A, according to IEC 61190-1-3) or 63 % tin and 37 % lead

(Sn63Pb37A, according to IEC 61190-1-3).

6.2 Test procedure for solder bath method

6.2.1 Specimens

A specimen shall not be used for more than one test.

6.2.2 Clamping

Unless otherwise specified in the relevant specification, the specimen shall be placed in a

stainless steel clip as shown in Figure 1. No part of the clip jaws shall make contact with the

areas to be examined. The specimen shall remain in the clip while being fluxed and dipped in

the solder.

6.2.3 Fluxing

Unless otherwise specified in the relevant specification, the specimen shall be completely

immersed in flux and withdrawn slowly. Any excess flux shall be removed by contact with

absorbent paper.

6.2.4 Solder immersion

When preheating is prescribed by the relevant specification, the specified duration and

temperature shall be applied immediately prior to the immersion of the specimen in the solder

bath.

The oxide film on the solder bath shall be skimmed off immediately before immersion.

The immersion and withdrawal speed shall be between 20 mm/s and 25 mm/s.

60068-2-58 © IEC:2004(E) – 9 –

View of surface to be examined

IEC 711/04

Figure 1 – Examples of immersion

6.2.5 Attitude

Two attitudes of immersion are standardized:

Attitude A: For most specimens, the areas to be examined shall be immersed not less than

2 mm below the solder meniscus (but not to a greater depth than necessary; see

Figure 1) with the seating plane vertical.

Attitude B: For certain specimens (see B.3.4), the specimen may be floated on the solder, but

only when testing resistance to soldering heat.

If the relevant specification does not mention the attitude, attitude A shall be adopted.

7 Solder reflow methods

7.1 Test apparatus and materials for solder reflow methods

7.1.1 Reflow equipment

As long as the test conditions are fulfilled, any reflow equipment may be used:

a) forced gas convection;

b) infrared;

c) vapour phase;

d) hot plate soldering; metallic plate (carrier), floating on a molten solder bath or an

electrically heated plate.

NOTE 1 Forced gas convection is preferred; including infrared assistance.

NOTE 2 Infrared reflow equipments are known to have variations of peak reflow temperature (PRT) of 30 °C or

more across the board in a PC board.

NOTE 3 In case of vapour phase soldering, a specific liquid is necessary for each test temperature.

NOTE 4 Hot plate soldering is a method which at times may have large PRT variations in the order of 40 °C.

– 10 – 60068-2-58 © IEC:2004(E)

7.1.2 Solder paste for solder reflow

7.1.2.1 Lead-free solder paste

Unless otherwise specified in the relevant specification, solder paste shall be as shown

below. For the resistance to soldering heat test, any alloys may be used, provided they are

completely liquid at the required temperature.

a) Solder paste for group 1:

– Alloy composition

The alloy composition to be used shall consist of 58 wt % of Bi (bismuth) and the

remainder of Sn (tin), Sn42Bi58. The solder alloy shall consist of 57 wt % to 58 wt % Bi

and the remainder of Sn may be used.

– Solder powder

Under consideration.

– Flux composition

Under consideration.

– Solder paste composition

Under consideration.

b) Solder paste for group 2:

– Alloy composition

Under consideration.

– Solder powder

Under consideration.

– Flux composition

Under consideration.

– Solder paste composition

Under consideration.

c) Solder paste for group 3:

– Alloy composition

The alloy composition to be used shall consist of 3,0 wt % Ag (silver), 0,5 wt % Cu

(copper) and the remainder of Sn (tin); Sn96.5Ag3.0Cu0.5 is preferred. The solder

alloys shall consist of 3,0 wt % to 4,0 wt % Ag, 0,5 wt % to 1,0 wt % Cu, and the

remainder of Sn may be used instead of Sn96.5Ag3.0Cu0.5.

– Solder powder

The powder size shall be symbol 3, specified in Table 2 of 4.3.2 of IEC 61190-1-2.

The shape of the solder powder shall be spherical.

– Flux composition

The flux to be used shall consist of 30 wt % polymerization rosin (softening point

approximately 95 °C), 30 wt % dibasic acid degeneration rosin (softening point

approximately 140 °C), 34,7 wt % diethylene glycol monobutyl ether, 0,8 wt % 1,3-

diphenylguanidine- HBr, 0,5 wt % adipic acid (chlorine content less than 0,1 %) and

4 wt % stiffening castor oil.

– Solder paste composition

The solder paste to be used shall consist of 88 wt % solder powder and 12 wt % flux.

The viscosity range shall be (180 ± 50) Pa·s.

60068-2-58 © IEC:2004(E) – 11 –

7.1.2.2 Lead containing solder paste

– Alloy composition

The solder composition shall be as specified in 6.1.3.2.

– Solder powder

Unless otherwise specified in the relevant specification, the particle size of the solder

paste shall be 20 µm to 45 µm.

– Flux composition

The composition of the flux shall be as specified in 6.1.2.

– Solder paste composition

The viscosity range and method of measurement shall be specified in the relevant

specification.

7.1.3 Test substrates

The test substrate shall consist of an unmetallized (no tracks or lands) piece of ceramic

(alumina 90 % to 98 %) for all reflow equipments or glass epoxy (see IEC 61249-2-7) except

for hot plate soldering.

Dimensional details and number of sample(s) to be tested shall be given in the relevant

specification.

7.2 Test procedure for the solder reflow method

7.2.1 Specimens

A specimen shall not be used for more than one test.

7.2.2 Application of solder paste

The solder paste shall be applied to the test substrate by screen or stencil printing,

dispensing or pin transfer.

The thickness of the solder deposit shall be between 100 µm and 250 µm and shall be

specified in the relevant specification.

The area (size) to be printed, and thus the amount of solder paste deposit, shall be specified

in the relevant specification. When solder paste is applied by dispensing or pin transfer, the

volume shall be adjusted so that a comparable solder volume can be achieved.

When the resistance to soldering heat of semiconductor SMDs is found to conform to

IEC 60749-20, then no solder paste shall be applied.

7.2.3 Placement of specimens

After printing, the terminations of the specimen shall be placed on the solder paste. The

placement procedure (for example depth of penetration) shall be prescribed in the relevant

specification.

7.2.4 Reflow temperature profile

7.2.4.1 Parameters for reflow temperature profile

As a minimum, the following parameters shown in Figure 2 shall be specified for reflow

temperature profile.

– 12 – 60068-2-58 © IEC:2004(E)

t

t

T

T

T

3 T

t

t

T

T

T

t

T

1 1

t

IEC 712/04 IEC 713/04

Figure 2b – “Angle” type

Figure 2a – “Hat” type

Key

T Minimum preheating temperature

T Maximum prehea

...

IEC 60068-2-58

Edition 3.0 2004-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 2-58: Tests – Test Td: Test methods for solderability, resistance to

dissolution of metallization and to soldering heat of surface mounting devices

(SMD)

Essais d’environnement –

Partie 2-58: Essais – Essai Td : Méthodes d’essai de la soudabilité, résistance de

la métallisation à la dissolution et résistance à la chaleur de brasage des

composants pour montage en surface (CMS)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60068-2-58

Edition 3.0 2004-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 2-58: Tests – Test Td: Test methods for solderability, resistance to

dissolution of metallization and to soldering heat of surface mounting devices

(SMD)

Essais d’environnement –

Partie 2-58: Essais – Essai Td : Méthodes d’essai de la soudabilité, résistance de

la métallisation à la dissolution et résistance à la chaleur de brasage des

composants pour montage en surface (CMS)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

U

CODE PRIX

ICS 19.040; 31.190 ISBN 2-8318-7842-X

– 2 – 60068-2-58 © CEI:2004

SOMMAIRE

AVANT-PROPOS.4

1 Domaine d'application et objet.8

2 Références normatives.8

3 Termes et définitions .10

4 Ensemble des procédés de brasage utilisant des alliages de brasure sans plomb .10

5 Préconditionnement.12

6 Méthode du bain de brasage .12

6.1 Appareillage d'essai et matériaux pour la méthode du bain de brasage .12

6.2 Procédure d'essai pour méthode de bain de brasage.14

7 Méthodes de refusion de soudure.16

7.1 Appareillage d'essai et matériaux pour les méthodes de refusion de soudure.16

7.2 Procédure d'essai pour la méthode de refusion de soudure .20

8 Conditions d'essais .22

8.1 Conditions d’essai pour les alliages de soudure de brasure sans plomb .22

8.2 Conditions d’essai pour les alliages de brasure contenant du plomb.26

9 Mesures finales .30

9.1 Nettoyage du flux .30

9.2 Conditions de reprise .30

9.3 Évaluation .32

10 Renseignements devant figurer dans la spécification applicable.34

Annexe A (normative) Critères pour examen visuel.38

Annexe B (informative) Guide .42

Annexe C (informative) Vue d'ensemble des conditions d’essais.48

Bibliographie.52

Figure 1 – Exemples d’immersion .16

Figure 2 – Profil de température de refusion .22

Figure 3 – Identification des zones sur les bornes métalliques .32

Figure A.1 – Évaluation du mouillage.40

Tableau 1 – Ensemble des procédés de brasage se rapportant aux alliages de brasure

sans plomb .12

Tableau 2 – Sévérités (durées et températures) – Méthode de bain de brasage –

Alliages de brasure sans plomb .24

Tableau 3 – Profil de température de refusion pour le mouillage – Alliages de brasure

sans plomb .24

Tableau 4 – Profil de température de refusion pour la résistance à la chaleur de

brasage – Alliages de brasure sans plomb.26

Tableau 5 – Sévérités (durée et température) .26

Tableau 6 – Profil de température de refusion pour le mouillage – Alliages de brasure

contenant du plomb .28

Tableau 7 – Profil de température de fusion pour la résistance à la chaleur de brasage

– Alliages de brasure contenant du plomb.30

Tableau C.1 – Aperçu des conditions de température et de durée.50

60068-2-58 © IEC:2004 – 3 –

CONTENTS

FOREWORD.5

1 Scope and object.9

2 Normative references .9

3 Terms and definitions .11

4 Grouping of soldering processes using lead-free solder alloys.11

5 Preconditioning .13

6 Solder bath method .13

6.1 Test apparatus and materials for the solder bath method .13

6.2 Test procedure for solder bath method .15

7 Solder reflow methods .17

7.1 Test apparatus and materials for solder reflow methods .17

7.2 Test procedure for the solder reflow method.21

8 Test conditions .23

8.1 Test conditions for lead-free solder alloys .23

8.2 Test conditions for lead containing solder alloy .27

9 Final measurements .31

9.1 Flux removal .31

9.2 Recovery conditions .31

9.3 Evaluation .33

10 Information to be given in the relevant specification .35

Annex A (normative) Criteria for visual examination .39

Annex B (informative) Guidance.43

Annex C (informative) Overview of test conditions .49

Bibliography.53

Figure 1 – Examples of immersion .17

Figure 2 – Reflow temperature profile .23

Figure 3 – Identification of areas on metallic termination.33

Figure A.1 – Evaluation of wetting.41

Table 1 – Grouping of soldering processes related to lead-free solder alloys .13

Table 2 – Severities (duration and temperatures) – Solder bath method – Lead-free

solder alloys .25

Table 3 – Reflow temperature profile for wetting – Lead-free solder alloys.25

Table 4 – Reflow temperature profile for resistance to soldering heat – Lead-free

solder alloys .27

Table 5 – Severities (duration and temperature) .27

Table 6 – Reflow temperature profile for wetting – Lead containing solder alloys .29

Table 7 – Reflow temperature profile for resistance to soldering heat – Lead containing

solder alloys .31

Table C.1 – Overview of the temperature and duration conditions.51

– 4 – 60068-2-58 © CEI:2004

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

___________

ESSAIS D’ENVIRONNEMENT –

Partie 2-58: Essais – Essai Td: Méthodes d’essai de la soudabilité,

résistance de la métallisation à la dissolution et résistance à la chaleur

de brasage des composants pour montage en surface (CMS)

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60068-2-58 a été établie par le comité d’études 91 de la CEI:

Techniques d'assemblage des composants électroniques.

La présente édition inclut les modifications techniques significatives suivantes par rapport à

l’édition précédente:

– extension du domaine d’application de manière à inclure l’alliage de brasure sans plomb

en plus de l’alliage de brasure étain-plomb eutectique ou quasi eutectique existant (la

structure du document a été modifiée en conséquence);

– ajout des définitions de «brasabilité» et de «résistance à la chaleur de brasage» pour les

CMS;

– spécification des profils de température de fusion pour la résistance à la chaleur de

brasage utilisant de la soudure sans plomb;

– ajout d’une Annexe C permettant un rapide aperçu des conditions d’essais.

60068-2-58 © IEC:2004 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-58: Tests – Test Td: Test methods for solderability,

resistance to dissolution of metallization and to

soldering heat of surface mounting devices (SMD)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-58 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This edition includes the following significant technical changes with respect to the previous

edition:

– expansion of the scope so that it includes lead-free solder alloy in addition to the existing

tin-lead eutectic or near eutectic solder alloy (the structure of the document has been

changed accordingly);

– addition of the definitions of "solderability" and "resistance to soldering heat" for SMDs;

– specification of the reflow temperature profiles for the resistance to soldering heat using

lead-free solder;

– addition of an Annex C enabling a quick overview of the test conditions.

– 6 – 60068-2-58 © CEI:2004

Cette version bilingue, publiée en 2005-02, correspond à la version anglaise.

Le texte anglais de cette norme est issu des documents 91/447/FDIS et 91/459/RVD.

Le rapport de vote 91/459/RVD donne toute information sur le vote ayant abouti à

l’approbation de cette norme.

La version française de cette norme n’a pas été soumise au vote.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous «http://webstore.iec.ch» dans les

données relatives à la publication recherchée. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60068-2-58 © IEC:2004 – 7 –

This bilingual version, published in 2005-02, corresponds to the English version.

The text of this standard is based on the following documents:

FDIS Report on voting

91/447/FDIS 91/459/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 8 – 60068-2-58 © CEI:2004

ESSAIS D’ENVIRONNEMENT –

Partie 2-58: Essais – Essai Td: Méthodes d’essai de la soudabilité,

résistance de la métallisation à la dissolution et résistance à la chaleur

de brasage des composants pour montage en surface (CMS)

1 Domaine d'application et objet

La présente partie de la CEI 60068 décrit l’essai Td applicable aux composants pour

montage en surface (CMS) qui sont destinés à être montés sur des substrats. La présente

norme fournit les procédures normalisées pour les alliages de brasure contenant du plomb

(Pb) et pour les alliages de brasure sans plomb.

La présente norme fournit des procédures normalisées pour déterminer la brasabilité et la

résistance à la chaleur de brasage des alliages de brasure sans plomb.

La présente norme fournit des procédures normalisées pour déterminer la brasabilité, la

dissolution de la métallisation (voir B.3.3) et la résistance à la chaleur de brasage des

alliages de brasure qui sont des brasures étain-plomb eutectiques ou quasi eutectiques.

Les procédures de la présente norme incluent la méthode du bain de brasage ainsi que la

méthode de soudure par refusion. La méthode du bain de brasage est applicable aux CMS

conçus pour le brasage à la vague et aux CMS conçus pour le brasage par fusion lorsque la

méthode du bain de brasage (immersion) est appropriée. La méthode de soudure par refusion

est applicable aux CMS conçus pour le brasage par fusion, pour déterminer l’adaptabilité des

CMS au procédé de brasage par fusion et lorsque la méthode du bain de brasage (immersion)

n’est pas appropriée.

Le but de la présente norme est de s’assurer que la sortie du composant ou la brasabilité de

ses extrémités est en mesure de satisfaire aux exigences applicables aux joints de soudures

de la CEI 61191-2 en utilisant chacune des méthodes de brasage spécifiées dans la

CEI 61760-1. En outre, les méthodes d’essai sont fournies pour s’assurer que le corps du

composant peut résister à la charge calorifique à laquelle il est exposé pendant le brasage.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60068-1:1988, Essais d'environnement – Partie 1: Généralités et guide

CEI 60068-2-20:1979, Essais d’environnement – Partie 2: Essais – Essai T: Soudure

CEI 60194:1999, Conception, fabrication et assemblage des cartes imprimées – Termes et

définitions (disponible en anglais seulement)

CEI 60749-20:2002, Dispositifs à semiconducteurs – Méthodes d’essais mécaniques et

climatiques – Partie 20: Résistance des CMS à boîtier plastique à l'effet combiné de

l'humidité et de la chaleur de soudage

60068-2-58 © IEC:2004 – 9 –

ENVIRONMENTAL TESTING –

Part 2-58: Tests – Test Td: Test methods for solderability,

resistance to dissolution of metallization and to

soldering heat of surface mounting devices (SMD)

1 Scope and object

This part of IEC 60068 outlines test Td, applicable to surface mounting devices (SMD), which

are intended to mount on substrates. This standard provides the standard procedures for

solder alloys containing lead (Pb) and for lead-free solder alloys.

This standard provides standard procedures for determining the solderability and resistance

of soldering heat to lead-free solder alloys.

This standard provides standard procedures for determining the solderability, dissolution of

metallization (see B.3.3) and resistance of soldering heat to solder alloys which are eutectic

or near eutectic tin lead solders.

The procedures in this standard include the solder bath method and reflow method. The

solder bath method is applicable to the SMD designed for flow soldering and the SMD

designed for reflow soldering when the solder bath (dipping) method is appropriate.

The reflow method is applicable to the SMD designed for reflow soldering, to determine the

suitability of SMD for reflow soldering and when the solder bath (dipping) method is not

appropriate.

The objective of this standard is to ensure that component lead or termination solderability

meets the applicable solder joint requirements of IEC 61191-2 using each of the soldering

methods specified in IEC 61760-1. In addition, test methods are provided to ensure that the

component body can resist against the heat load to which it is exposed during soldering.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

IEC 60068-2-20:1979, Environmental testing – Part 2: Tests – Test T: Soldering

IEC 60194:1999, Printed board design, manufacture and assembly – Terms and definitions

IEC 60749-20:2002, Semiconductor devices – Mechanical and climatic test methods –

Part 20: Resistance of plastic-encapsulated SMDs to the combined effect of moisture and

soldering heat

– 10 – 60068-2-58 © CEI:2004

CEI 61190-1-1:2002, Matériaux de fixation pour les assemblages électroniques – Partie 1-1:

Exigences relatives aux flux de brasage pour les interconnexions de haute qualité dans les

assemblages de composants électroniques

CEI 61190-1-2:2002, Matériaux de fixation pour les assemblages électroniques – Partie 1-2:

Exigences relatives aux crèmes de brasage pour les interconnexions de haute qualité dans

les assemblages de composants électroniques

CEI 61190-1-3:2002, Matériaux de fixation pour les assemblages électroniques – Partie 1-3:

Exigences relatives aux alliages à braser de catégorie électronique et brasures solides

fluxées et non fluxées pour les applications de brasage électronique

CEI 61191-2:1998, Ensembles de cartes imprimées – Partie 2: Spécification intermédiaire –

Exigences relatives à l'assemblage par brasage pour montage en surface

CEI 61249-2-7:2002, Matériaux pour circuits imprimés et autres structures d'interconnexion –

Partie 2-7: Matériaux de base renforcés, plaqués et non plaqués – Feuille stratifiée tissée de

verre E avec de la résine époxyde, d’inflammabilité définie, (essai de combustion verticale),

plaquée cuivre

CEI 61760-1:1998, Technique du montage en surface – Partie 1: Méthode de normalisation

pour la spécification des composants montés en surface (CMS)

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions définis dans la CEI 60068-1,

dans la CEI 60068-2-20 et dans la CEI 60194 (en anglais seulement), ainsi que les suivants

s’appliquent.

3.1

brasabilité

aptitude de la borne ou de l’électrode du CMS à être mouillée par la brasure à la température

de la borne ou de l’électrode qui est supposé être la température la plus basse du procédé de

brasage dans la plage de températures brasables de l’alliage de brasure

3.2

résistance à la chaleur de brasage

aptitude des CMS à résister à la température la plus importante de la borne ou de l’électrode

du procédé de brasage dans la gamme de températures applicable des alliages de brasure

4 Ensemble des procédés de brasage utilisant des alliages de brasure

sans plomb

Les températures de fusion des alliages de brasure sans plomb actuellement sélectionnées

pour les processus industriels sont significativement différentes de celles de l’alliage de

brasure Sn-Pb. De plus, les températures de fusion des alliages de brasure sans plomb sont

différentes les unes des autres, mais peuvent être regroupées.

Selon la capacité des CMS à résister aux conditions typiques de température et de temps de

maintien qui adapte l’exposition au processus utilisant les alliages sélectionnés sans plomb,

l’ensemble des procédés de brasage suivants indiqués dans le Tableau 1 sont donnés comme

références pour sélectionner la rigueur des essais de mouillage et de résistance à la chaleur

de brasage spécifiée:

60068-2-58 © IEC:2004 – 11 –

IEC 61190-1-1:2002, Attachment materials for electronic assembly – Part 1-1: Requirements

for soldering fluxes for high-quality interconnections in electronic assembly

IEC 61190-1-2:2002, Attachment materials for electronic assembly – Part 1-2: Requirements

for solder pastes for high-quality interconnections in electronic assembly

IEC 61190-1-3:2002, Attachment materials for electronic assembly – Part 1-3: Requirements

for electronic grade solder alloys and fluxed and non-fluxed solid solders for electronic

soldering applications

IEC 61191-2:1998, Printed board assemblies – Part 2: Sectional specification – Requirements

for surface mount soldered assemblies

IEC 61249-2-7:2002, Materials for printed boards and other interconnecting structures –

Part 2-7: Reinforced base materials clad and unclad – Epoxide woven E-glass laminated

sheet of defined flammability (vertical burning test), copper-clad

IEC 61760-1:1998, Surface mounting technology – Part 1: Standard method for the

specification of surface mounting components (SMDs)

3 Terms and definitions

For the purposes of this document, the terms and definitions as defined in IEC 60068-1,

IEC 60068-2-20, IEC 60194, as well as the following apply.

3.1

solderability

ability of the termination or electrode of SMD to be wetted by solder at the temperature of the

termination or electrode which is assumed to be the lowest temperature in the soldering

process within solderable temperature of solder alloy

3.2

resistance to soldering heat

ability of SMD to withstand the highest temperature of the termination or electrode in

soldering process, within applicable temperature range of solder alloy

4 Grouping of soldering processes using lead-free solder alloys

The melting temperatures of lead-free solder alloys selected currently for industrial processes

are significantly different from those for Sn-Pb solder alloy. Moreover, the melting

temperatures of lead-free solder alloys are different from each other but can be clustered in

groups.

According to the ability of the SMD to withstand the typical temperature and dwell time

conditions that match the exposure to the processes using the selected lead-free alloys, the

following groups of soldering processes outlined in Table 1 are given as a a guideline for

selecting the severities for the wetting and resistance tests against the specified soldering

heat:

– 12 – 60068-2-58 © CEI:2004

Tableau 1 – Ensemble des procédés de brasage se rapportant aux alliages de brasure

sans plomb

Températures typiques du processus

Alliages

Groupe

(Exemples)

Brasage à la vague Brasage par fusion

– 170 °C – 210 °C Sn-Bi

Basse température

2 Sn-Zn-Bi

– 210 °C – 235 °C

Température moyenne Sn-Zn

Sn-Ag

Moyenne – haute 245 °C – 255 °C 235 °C – 250 °C Sn-Ag-Cu

température Sn-Ag-Bi

250 °C – 260 °C – Sn-Cu

Température élevée

NOTE 1 Le brasage à la vague s’applique au brasage tendre à la vague et au brasage par immersion.

NOTE 2 Les températures typiques du processus pour le brasage à la vague sont identiques aux températures de la

brasure. Les températures typiques du brasage par fusion sont les températures de la surface supérieure et des bornes

des CMS.

NOTE 3 Dans le groupe 2, le brasage par fusion en atmosphère inerte (par exemple l’azote) est exigée.

NOTE 4 Les alliages de brasure de base énumérés dans ce tableau représentent des compositions qui sont

fréquemment choisies pour les procédés de brasage sans plomb. Cependant, il convient de ne pas exclure les autres

alliages de brasure lorsqu’ils s’accordent avec le groupe spécifié.

5 Préconditionnement

5.1 L’éprouvette doit être mise à l’essai dans les conditions «d’état de livraison» sauf

indication contraire dans la spécification applicable. Il convient de prendre des précautions

afin qu’aucune contamination ne se produise par un contact avec les doigts ou de toute autre

façon.

5.2 Lorsqu’un vieillissement accéléré est indiqué dans la spécification applicable, une des

méthodes de 4.5 de la CEI 60068-2-20 doit être utilisée ou s'il y a lieu, une chaleur sèche de

155 °C appliquée pendant 4h doit être utilisée.

5.3 Les essais de préconditionnement et de résistance à la chaleur de brasage des

semiconducteurs CMS à boîtier plastique doivent être réalisés conformément aux procédures

d’essais décrites dans la CEI 60749-20.

6 Méthode du bain de brasage

6.1 Appareillage d'essai et matériaux pour la méthode du bain de brasage

6.1.1 Bain de brasage

Les dimensions du bain de brasage doivent être conformes aux exigences de 4.6.1 de la

CEI 60068-2-20. Le matériau du bac de bain de brasage doit être résistant aux alliages de

brasure liquides.

6.1.2 Flux

Le flux doit être composé en masse de 25 % de colophane pour 75 % de 2-propanol

(isopropanol) ou d'alcool éthylique (éthanol) (comme spécifié dans l’Annexe C de la CEI 60068-

2-20). Il convient que l’activité du flux soit de préférence conforme avec le niveau “faible (0)”, ce

qui correspond à une teneur en halogénures <0,01 wt % (Cl, Br, F) (voir la CEI 61190-1-1).

Lorsqu’un flux inactif est inapproprié, le susdit flux avec le complément de chlorure de diéthyle

d’ammonium (catégorie analytique de réactif), jusqu'à une quantité de 0,5 % de chlorure (sous

forme de chlore non combiné sur la base de la teneur en colophane), peut être utilisé. Les

informations concernant le type de flux utilisé doivent être données dans la spécification

particulière de produit.

60068-2-58 © IEC:2004 – 13 –

Table 1 – Grouping of soldering processes related to lead-free solder alloys

Typical process temperature

Alloys

Group

(examples)

Flow soldering Reflow soldering

– 170 °C – 210 °C Sn-Bi

Low temperature

Sn-Zn-Bi

Medium – 210 °C – 235 °C

Sn-Zn

temperature

3 Sn-Ag

Medium-high 245 °C – 255 °C 235 °C – 250 °C Sn-Ag-Cu

temperature

Sn-Ag-Bi

250 °C – 260 °C – Sn-Cu

High temperature

NOTE 1 Flow soldering applies to both wave soldering and dip soldering.

NOTE 2 Typical process temperatures for flow soldering are identical to the solder temperature. Typical process

temperatures for reflow soldering are the terminal and top surface temperature of the SMDs.

NOTE 3 In Group 2 reflow soldering under inert atmosphere (e.g. nitrogen) is required.

NOTE 4 The basic solder alloys listed in this table represent compositions that are currently preferred for lead-

free soldering processes. However, other solder alloys when matching with the specified group should not be

excluded.

5 Preconditioning

5.1 The specimen shall be tested in the “as-received“ condition unless otherwise specified

by the relevant specification. Care should be taken that no contamination, by contact with the

fingers or by other means, occurs.

5.2 When accelerated ageing is prescribed by the relevant specification, one of the methods

of 4.5 of IEC 60068-2-20 shall be used or, when appropriate, 4 h/155 °C dry heat shall be

used.

5.3 The preconditioning and resistance to soldering heat test of semiconductor SMDs in

plastic encapsulation shall be done conform the test procedure as described in IEC 60749-20.

6 Solder bath method

6.1 Test apparatus and materials for the solder bath method

6.1.1 Solder bath

The solder bath dimensions shall comply with the requirements of 4.6.1 of IEC 60068-2-20.

The material of the solder bath container shall be resistant to the liquid solder alloy.

6.1.2 Flux

The flux shall consist of 25 % by weight of colophony in 75 % by weight of 2-propanol

(isopropanol) or ethyl alcohol (as specified in Appendix C of IEC 60068-2-20). Preferably the

flux activity should conform with the “Low (0)” level, corresponding to a halide content of

<0,01 wt % (Cl, Br, F) (see IEC 61190-1-1). When non-activated flux is inappropriate, the

above flux with the addition of diethylammonium chloride (analytical reagent grade), up to an

amount of 0,5 % chloride (expressed as free chlorine based on the colophony content), may

be used. Information concerning the used flux type shall be given in the product detail

specification.

– 14 – 60068-2-58 © CEI:2004

6.1.3 Brasure

6.1.3.1 Alliages de brasure sans plomb

Lors des essais de brasabilité, la composition de la brasure doit être comme définie dans le

Tableau 2. Pour les essais de résistance à la chaleur de brasage n’importe quel alliage peut

être utilisé du moment qu’il devient complètement liquide à la température exigée.

6.1.3.2 Alliages de brasure contenant du plomb

La composition de la brasure doit être soit de 60 % d’étain et de 40 % de plomb

conformément à l’Annexe B de la CEI 60068-2-20 (Sn60Pb40A, conformément à la

CEI 61190-1-3) ou soit de 63 % d’étain et de 37 % de plomb (Sn63Pb37A, conformément à la

CEI 61190-1-3).

6.2 Procédure d'essai pour méthode de bain de brasage

6.2.1 Éprouvettes

Une éprouvette ne doit pas être utilisée pour plus d’un essai.

6.2.2 Fixation

Sauf indication contraire dans la spécification applicable, l’éprouvette doit être déposée dans

une pince en acier inoxydable comme indiqué à la Figure 1. Aucune partie de la mâchoire de

la pince ne doit rentrer en contact avec les zones qui doivent être examinées. L’éprouvette

doit rester dans la pince lors du fluxage et de l'immersion dans la brasure.

6.2.3 Fluxage

Sauf indication contraire dans la spécification applicable, l’éprouvette doit être

complètement immergée dans le flux et retirée progressivement. Tout flux en excès doit être

enlevé par du papier absorbant.

6.2.4 Bain de brasure

Lorsque le préchauffage est prescrit par la spécification applicable, la température et la durée

spécifiée doivent être appliquée immédiatement avant l’immersion de l’éprouvette dans le

bain de brasage.

La couche d’oxyde sur le bain de brasage doit être ôtée du dessus du liquide immédiatement

avant l’immersion.

La vitesse d’immersion et d’extraction doit être comprise entre 20 mm/s et 25 mm/s.

60068-2-58 © IEC:2004 – 15 –

6.1.3 Solder

6.1.3.1 Lead-free solder allo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...